6 minute read

Digitally connected supply chains & terminal automation

Sam Reid CEO of Dearman Systems, discusses how the digitalisation of terminals and the wider supply chain is impacting operations

TERMINAL AUTOMATION

Advertisement

software has evolved since its inception in the 1980s. Over the decades, the software has increasingly been used to streamline loading operations, simplify inventory management, enhance security, and automate reporting. Generally, bulk liquid storage operators know that it is worthwhile to automate their terminals, but the level of automation can vary drastically. Some companies choose to install state-of-the-art field instrumentation and connect everything together in an automation system. Others choose to maintain some manual reporting and operational processes. Automating a terminal drives cost savings for individual terminal operations, but what’s even more valuable is the ability to utilise data from the field to automate back office processes. Additionally, when you have terminal automation system data flowing up to the corporate level, you can enable the supply chain to access the information to create further cost savings and efficiencies.

THREE LEVELS OF AUTOMATION

There are three levels of modern terminal automation, each building on the capabilities of the previous: • Level 1: Terminal automation at the field or individual facility level • Level 2: Enterprise management (unified reporting and back office automation) • Level 3: A digitally connected supply chain

LEVEL 1: ACHIEVING TERMINAL AUTOMATION AT FIELD LEVEL

Terminal automation is achieved by connecting a central software system to flow computers, tank gauging systems, weigh scales, and secure access control systems, among other hardware devices and instruments. The typical technical architecture of a terminal automation system consists of a process control layer that interfaces to devices, a database, a web application for data management, and a human-machine interface (HMI) for real-time monitoring of tank levels and loading operations. Once connected, the terminal automation software receives data from the devices and aggregates the data into a central database. Additionally, in many scenarios, the terminal automation software can control these devices to implement loading sequences and restrict the process around loading and unloading product. Terminal automation software has many features and benefits: Authorisation and security – Integration with access control system ensures only authorised personnel are accessing your facility and loading only the products they are authorised to load. Pre-set loading sequences – Define exactly how product is loaded and unloaded at truck racks, weight scales, rail racks, and other loading positions.

Automated and accurate reporting

– With all transactions and third party entities in a single system, accurate reports can be sent on the necessary schedules. Simplified entity management – The terminal automation system keeps track of all products, suppliers, position holders, carriers, and other data making it easy to keep this information relevant and up-to-date. Visualisation – Visualise operations including rack activity, weigh scale activity, flow rates, tank level information, and any triggered alarms. Documentation – Automatic generation of custody transfer documents to ensure accuracy and compliance. With terminal automation, one size does not fit all. A profitable digital strategy requires a flexible terminal automation system that can map to a terminal’s unique processes across truck, rail, marine, and pipeline product movements. A robust software package will have many features out of the box, but will also need to be configured for specific business requirements (e.g. loading sequences, reporting, etc) and physical setup of a terminal (e.g. movement types, number of loading bays, etc). Sometimes a terminal may need custom modules in order to handle the operations and required reporting for the facility. For companies that store a wide variety of bulk liquids, a terminal automation

01

system that can be configured to handle all products and terminal types is a win in the effort of standardising and working with a single vendor. For example, if you process and store refined fuels and NGLs, you would ideally use the same software for both facilities to simplify system maintenance, customer support and ensure data from each terminal is compatible at the corporate level. Another key consideration when installing terminal automation software is that specific system’s ability to integrate with your existing field devices. Hardware is essential to implementing automation and must be factored into the total cost. A software package that can integrate with what you have already will save you money and time.

LEVEL 2: UNIFYING DATA AND BACK OFFICE AUTOMATION

With a terminal automation system in place at your facility, you will have all the local transaction and operational data in one place. The next step is to connect that data to a central data source for all your terminals. This can be accomplished through an enterprise-level terminal management software system that connects to all your terminals and aggregates the data. This allows for a single view into all of your operations and simplifies reporting across your terminals. Now, you can quickly report on cross-terminal activities by customers (or other important data fields) and unlock important insights without having to combine stale spreadsheets. An enterprise management system also enables you to centrally control administrative settings across your terminals, streamline contract enforcement and invoicing, and automatically push data into third party systems like ERPs. The key benefits of terminal automation at enterprise management level are: Unified reporting – See all your terminal data in one place to streamline reporting, simplify customer report distribution, and unlock insights.

Easier administration and terminal

management – Control administrative settings and details of all terminals from a single application. Automate business processes – Automate admin tasks such as contract enforcement and invoicing to improve accuracy and save time. Operational resiliency – If a server goes down at a terminal, you can install a new server and restore the data from the central system. ERP Integration – With a central, normalised database to draw on, third party integrations to important business systems are easily accomplished. But why stop at Level 2 of terminal automation? Next, let’s explore how to achieve modern terminal automation – a digitally connected supply chain.

LEVEL 3: UNIFIED, REAL-TIME DATA LEADS TO A CONNECTED SUPPLY CHAIN

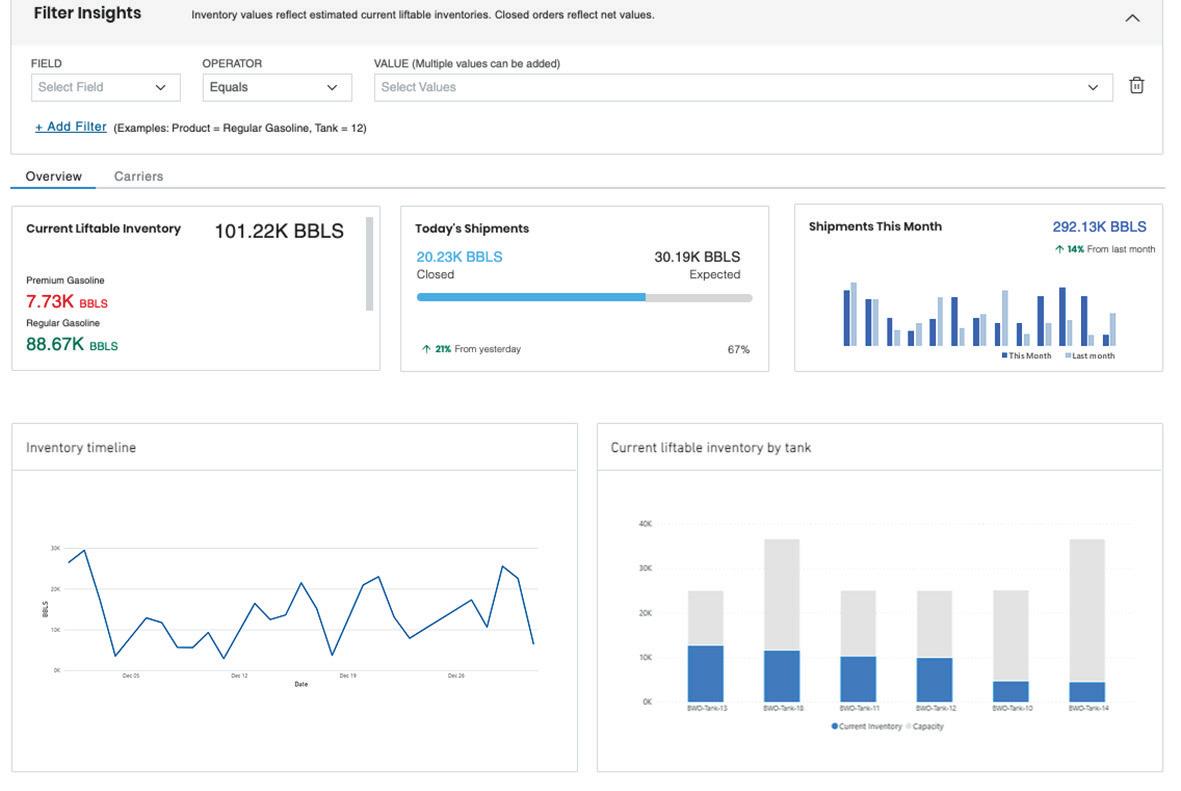

Once you have terminal automation in place at the field level and the corporate level, you can connect the supply chain in a single web application. Whether you have one terminal or 50, connecting the third parties that interact with your terminal can lead to serious cost savings and more efficient administrative operations. With today’s cloud-based web technologies, you can enable the supply chain to securely interact with administrative data needed for moving bulk liquid products — from carriers and railroads to position holders and their customers. Furthermore, inventory information can be readily available, allowing customers to place orders for product pickup. These will have be preauthorised by the web application before flowing down to the terminal automation system for additional load authorisation at the scheduled time of product pick up. Using the web application, customers can view completed orders across all terminals and associated BOLs in a selfservice manner. Connecting the bulk liquids supply chain (terminal operator, position holder, buyers, sellers, carriers) in a single application unlocks:

Self-service terminal administration

and reporting – Companies can view and edit their administrative information and access completed order information. Real-time inventory information – Expose available inventory information to relevant parties.

Streamlined order management

– Allow your customers to schedule and track their own orders through a structured workflow. Rapid issue resolution – When the entire supply chain has access to the data that’s relevant to them, it’s easier to get on the same page and solve problems. Transparency and accountability – Carrier performance at a terminal is easily tracked and reported on.

Better allocations and credit

management – One intuitive application for managing all contractual arrangements along the supply chain.

MODERN TERMINAL AUTOMATION IS HERE

The benefits are too meaningful to pass up. You’ve invested in the flow computers and field instrumentation, a terminal automation system and enterpriselevel data aggregation. Now it’s time to fully leverage those investments by connecting your supply chain and further automating the reporting, administration, and communication that occurs to move products.

02

For more information:

www.dearmansystems.com +1 520 298 1677

01 Level 1 streamlines loading operations, simplifies inventory management, enhances security, and automates reporting 02 Levels 2 and 3 organise data to unlock insights and help the entire supply chain make better, more profitable decisions