Workbook Contents

Blackmore

Blackmore Studio Biofabricate Studio Biofabricate

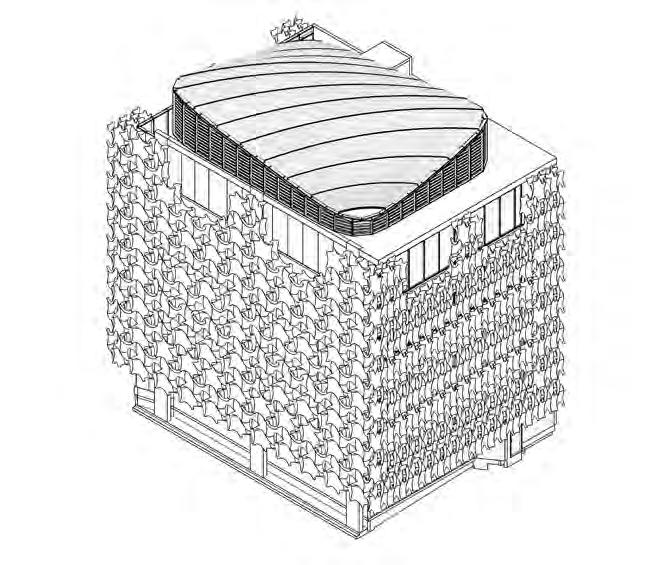

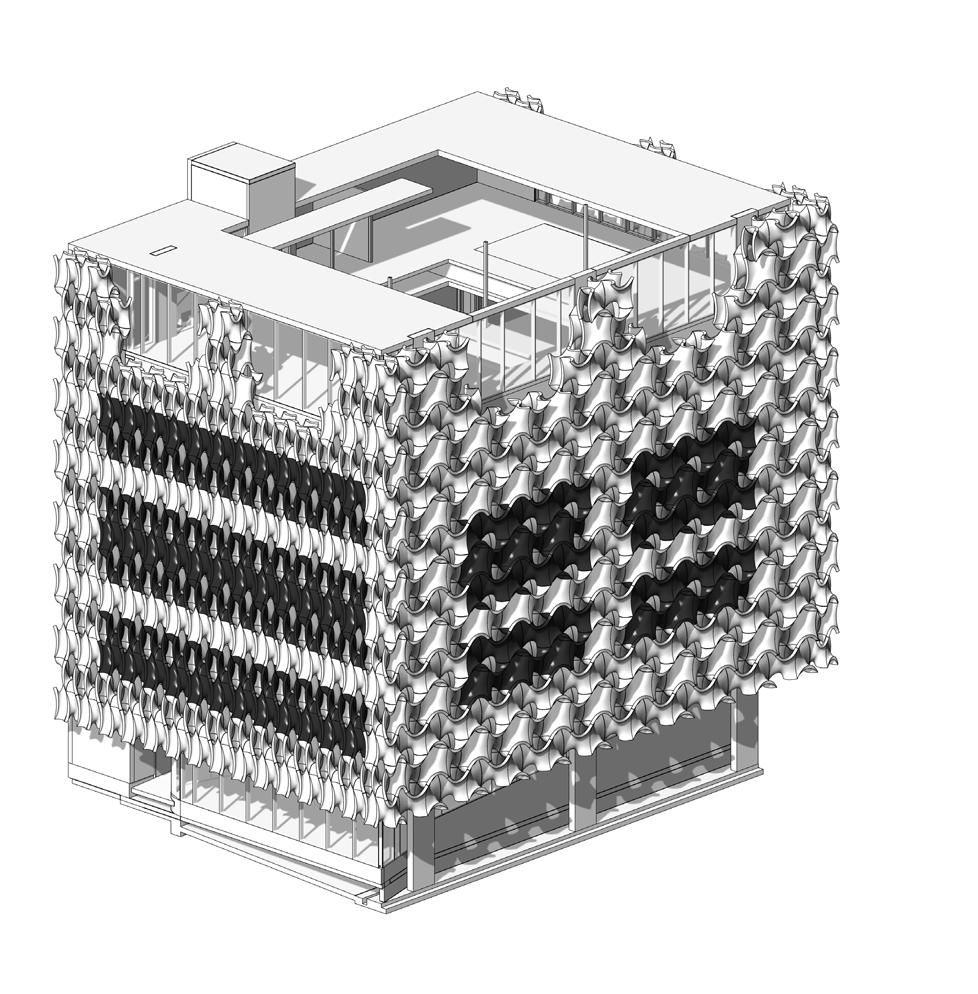

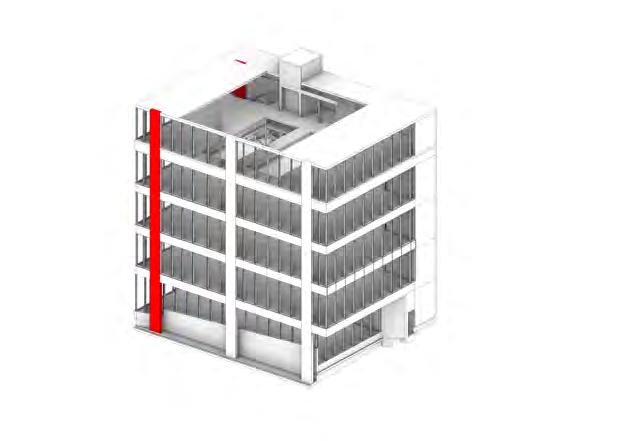

Pixel Building, Queensberry Street

North-Western View

housing

Building, Queensberry Street

North-Western View

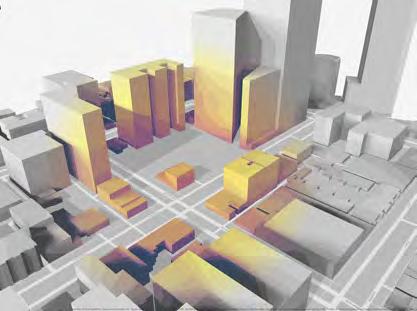

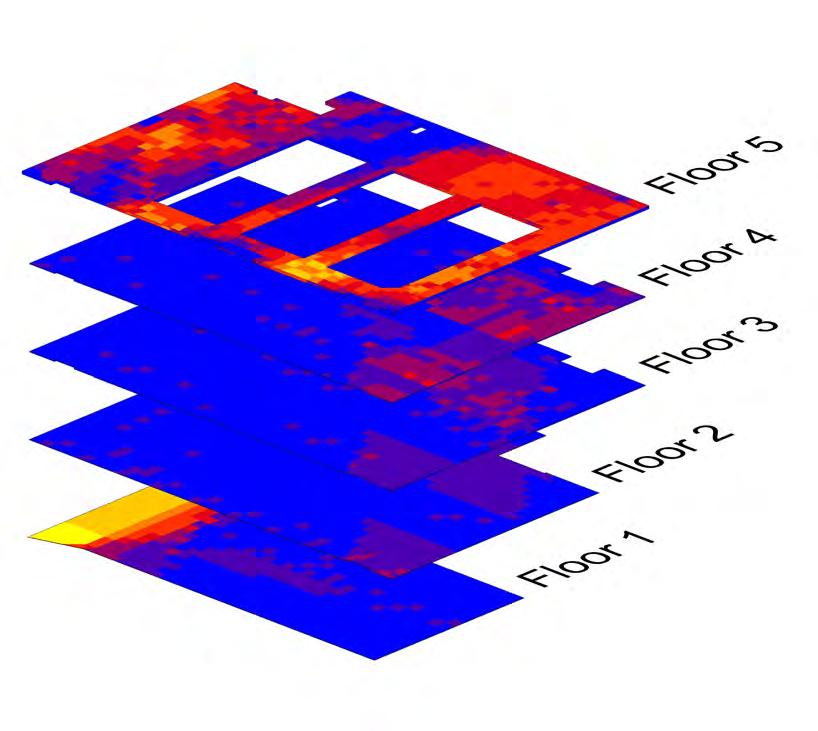

Analysis - Southern View to CBD

Pixel Building, Queensberry Street

QueensBerry

Bouverie

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Existing Garden Beds

Can we do something Architecturally with this?

Use it to our advantage? We think so.

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

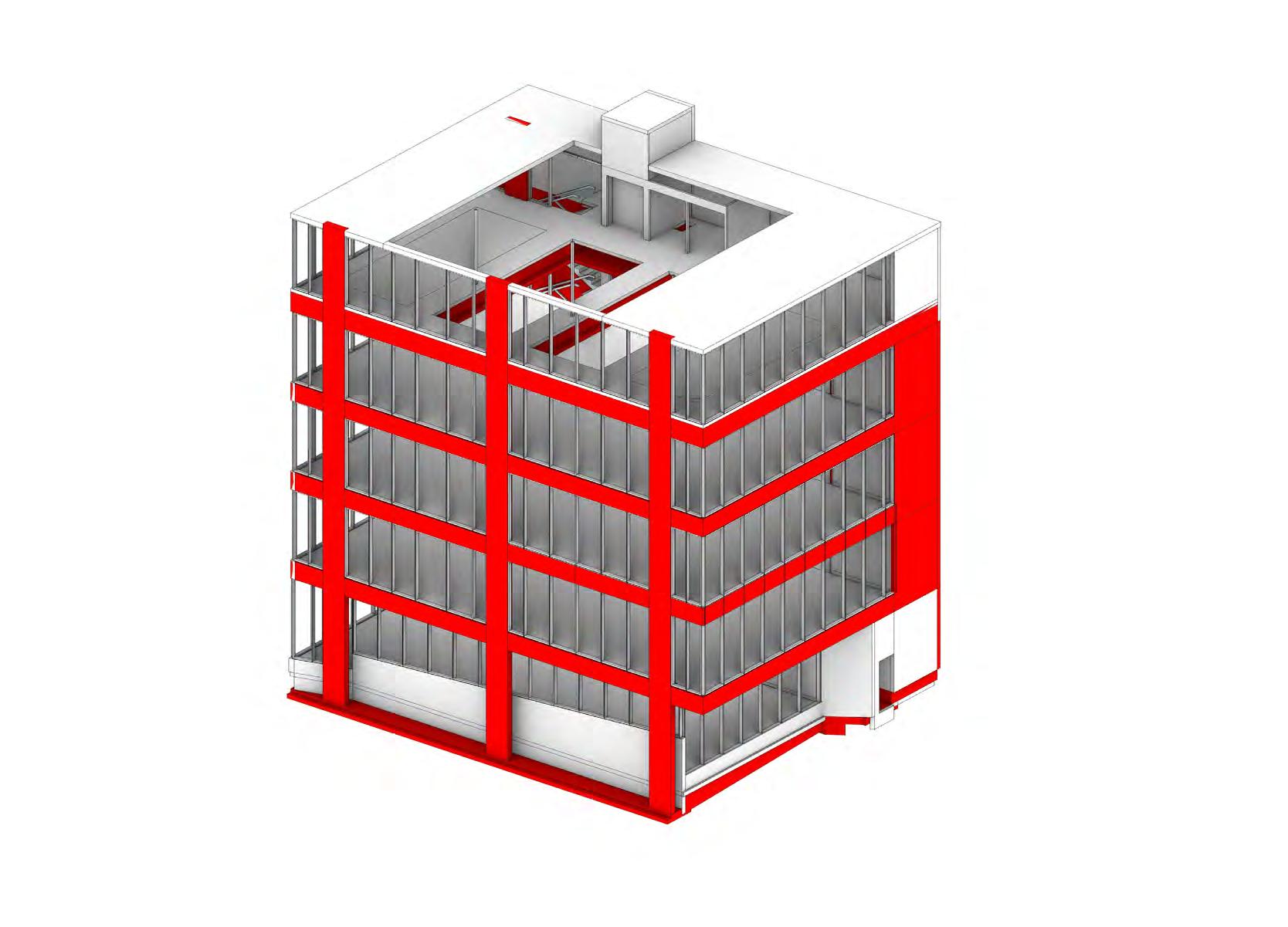

Structure, Queensberry Street

Produced By Lachlan Blackmore

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

https://1drv.ms/i/c/9f953f796408abae/EfBbJE4L4HZBgZRs9IhrkoUBh1wwiNe0clRuUGgZZrkCfQ?e=uTbG50

Research

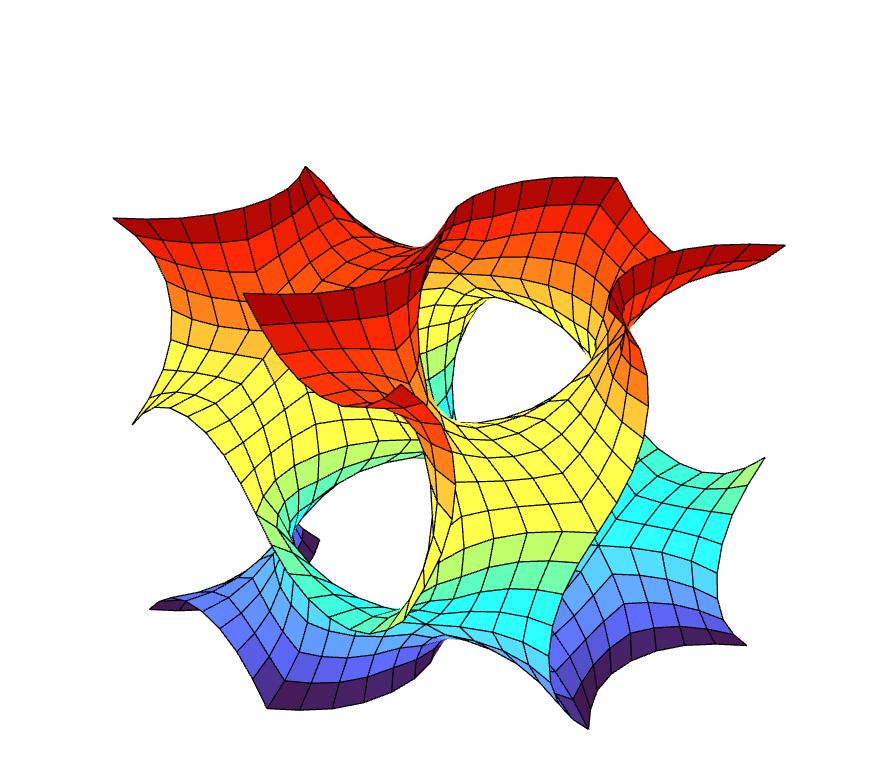

Minimal

https://1drv.ms/i/c/9f953f796408abae/EQysk6-8fUNKlfojfpGv1mIBOnADuCh0AnvuBtwp8mc-fw?e=DPSurW

Blackmore

Blackmore Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Produced By Lachlan Blackmore

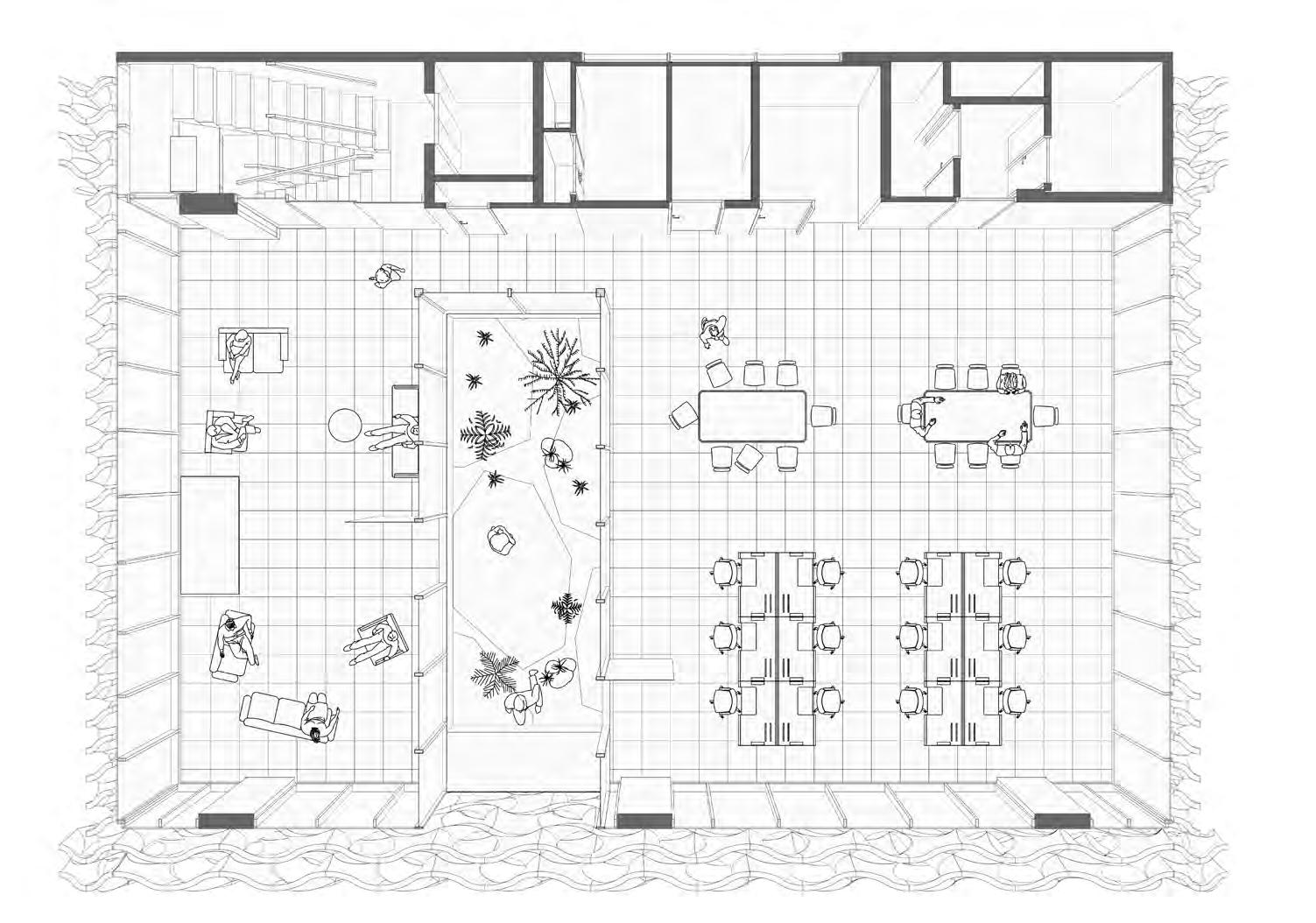

Pixel liminal Pixel Building Renovation Pixel Building

Technology developments

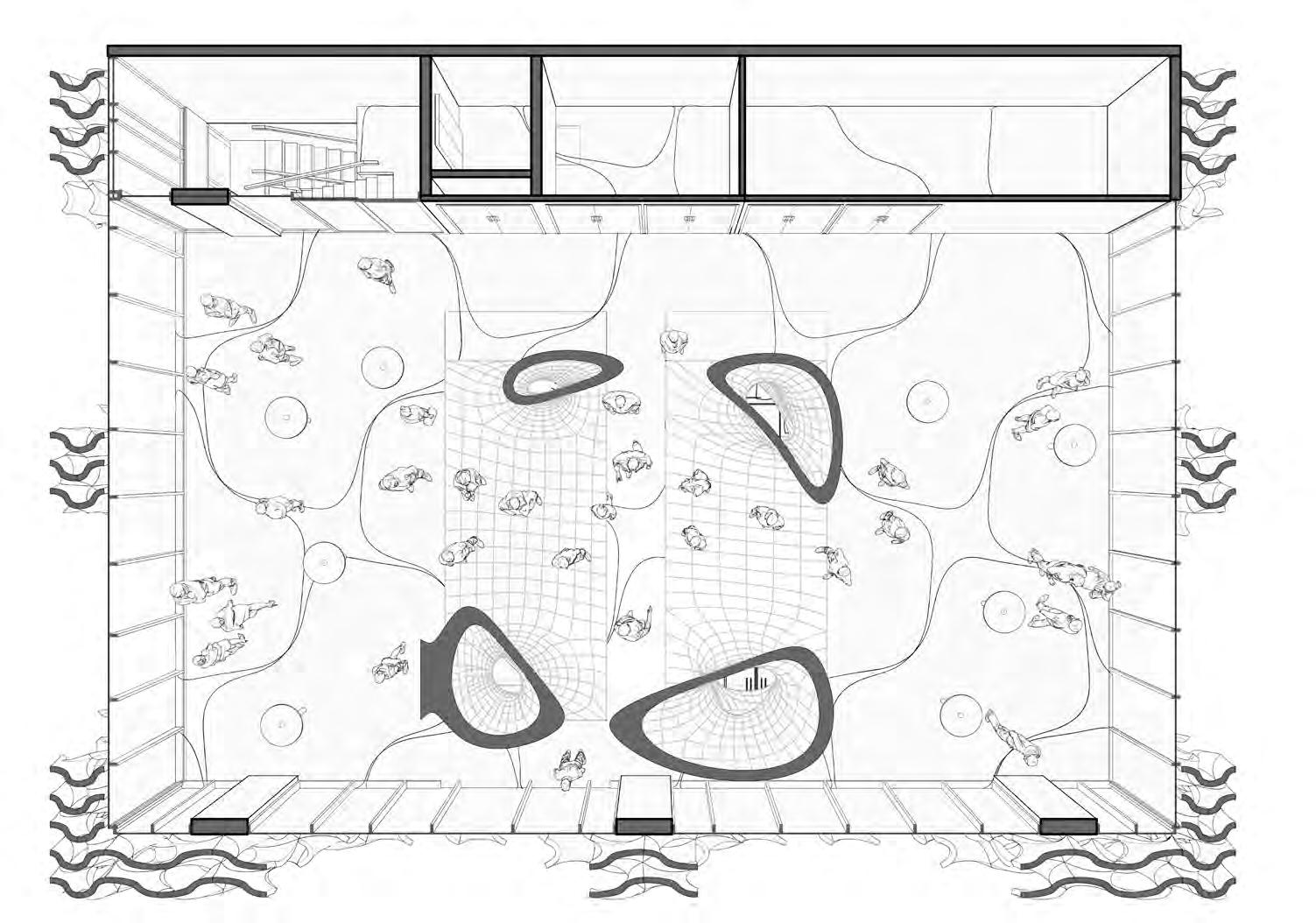

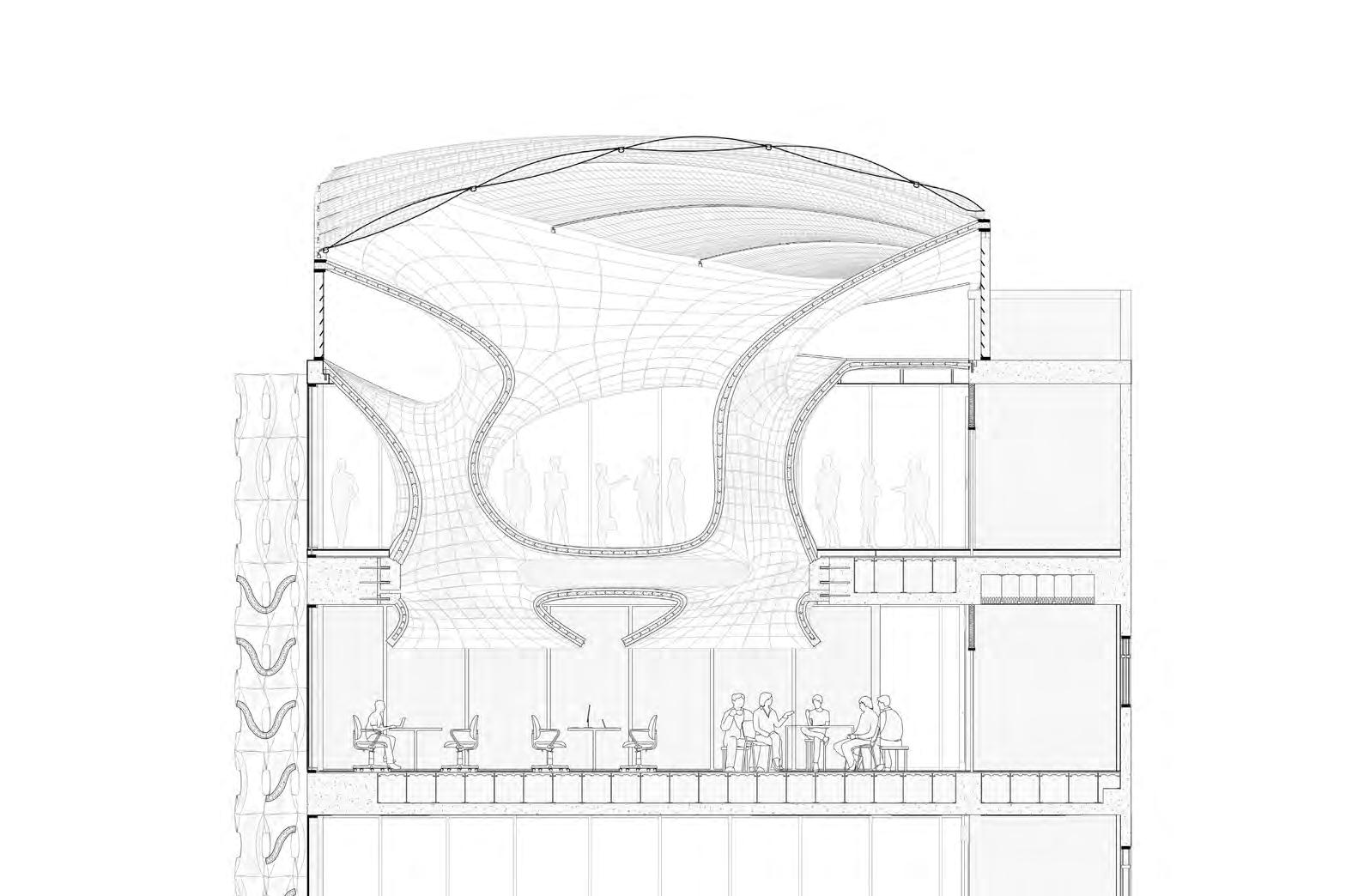

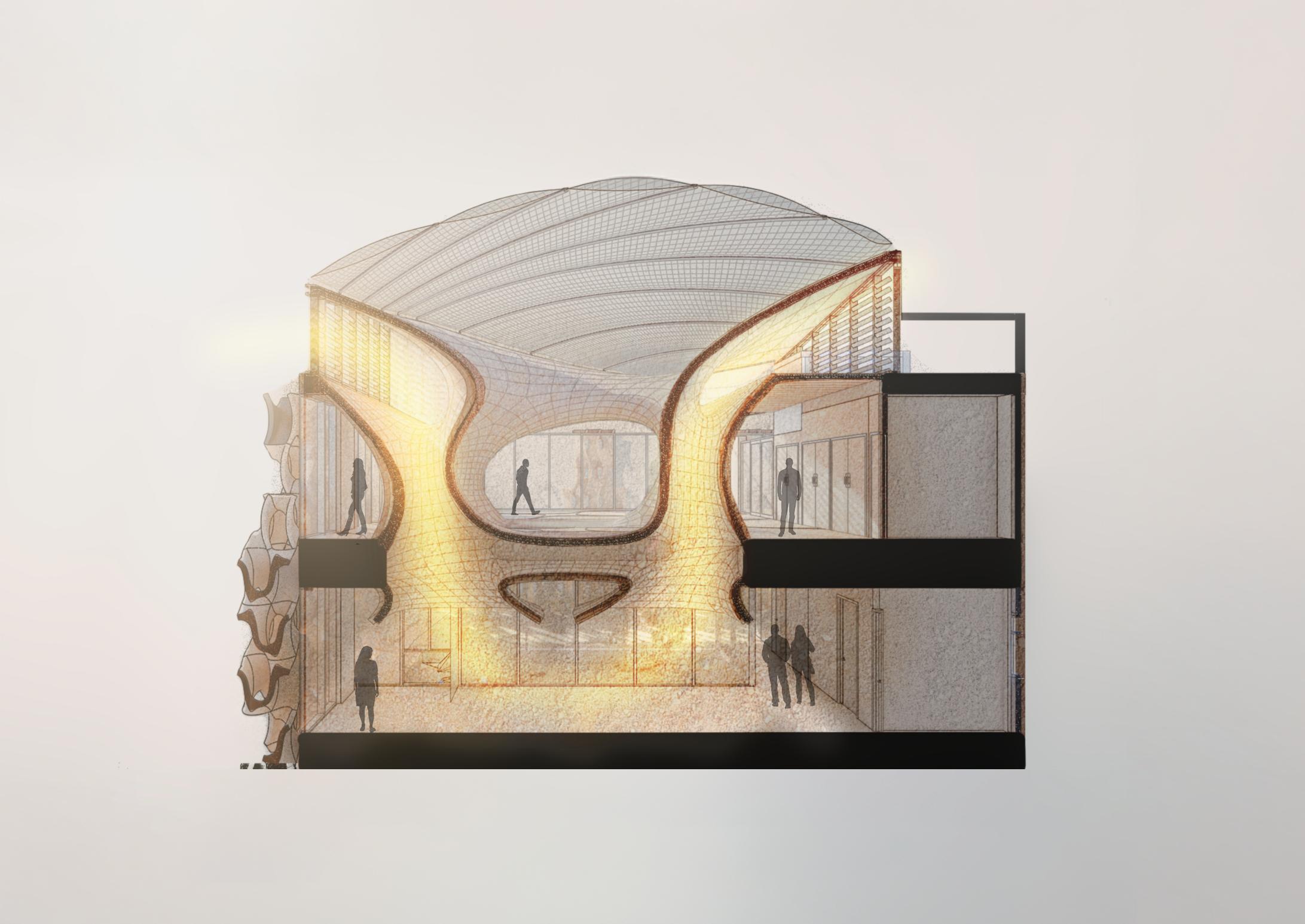

Pixel Building What did we do for the new level?

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

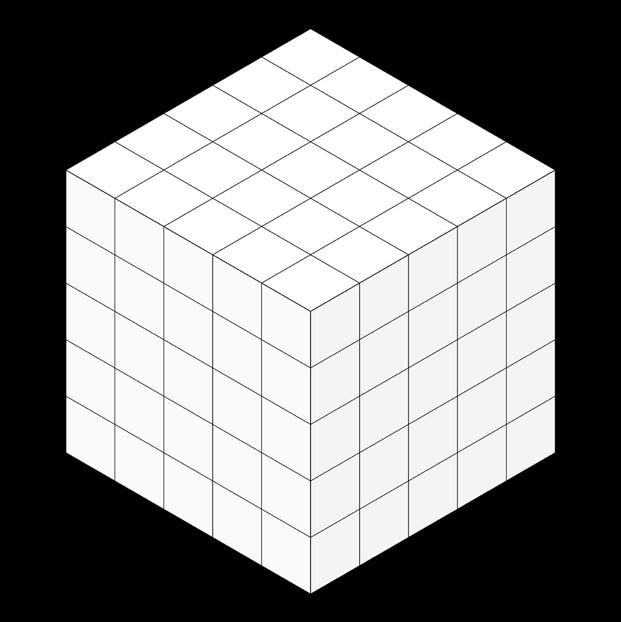

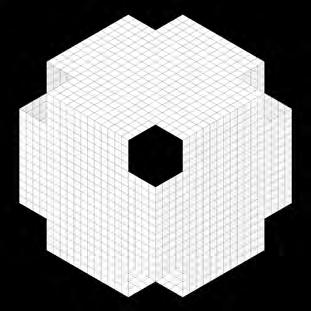

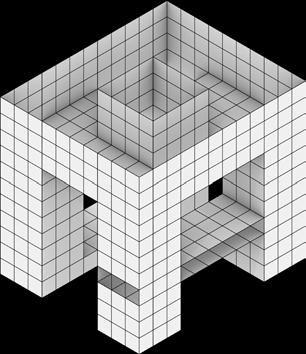

Axonometric Diagram

Others By Lachlan Blackmore

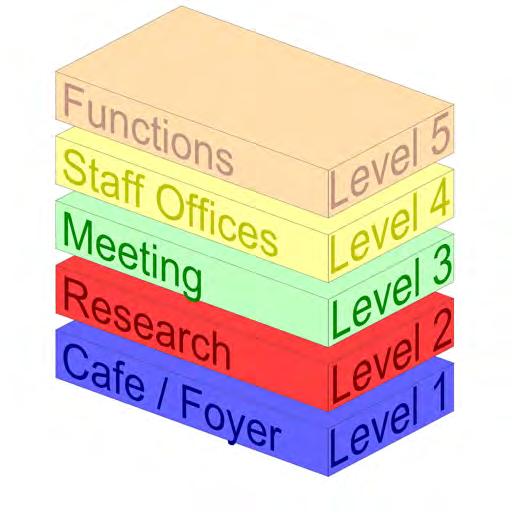

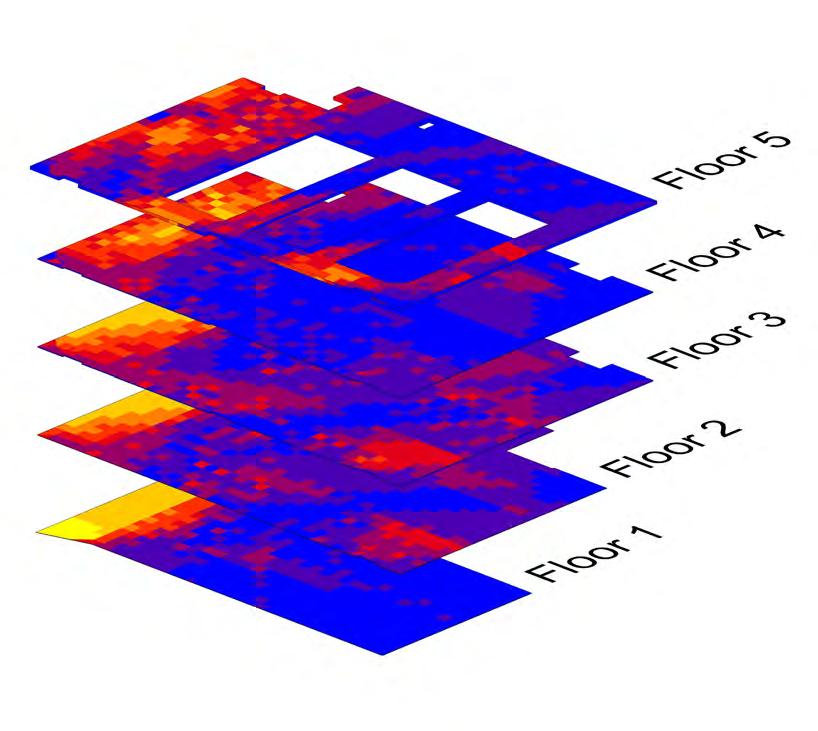

Program diagram

Joshua Muldeary

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

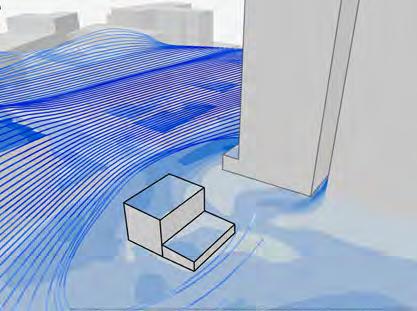

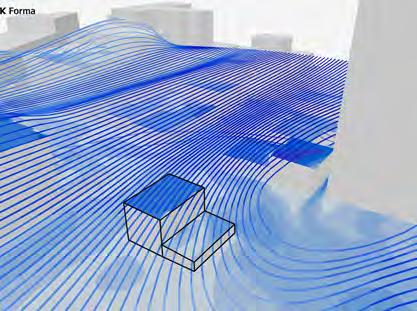

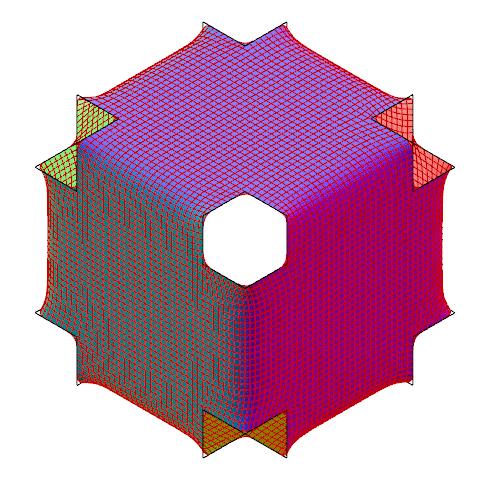

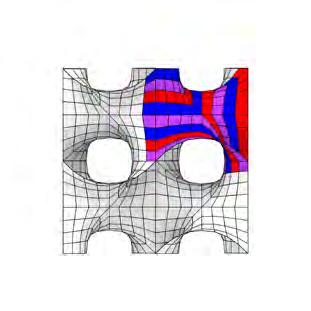

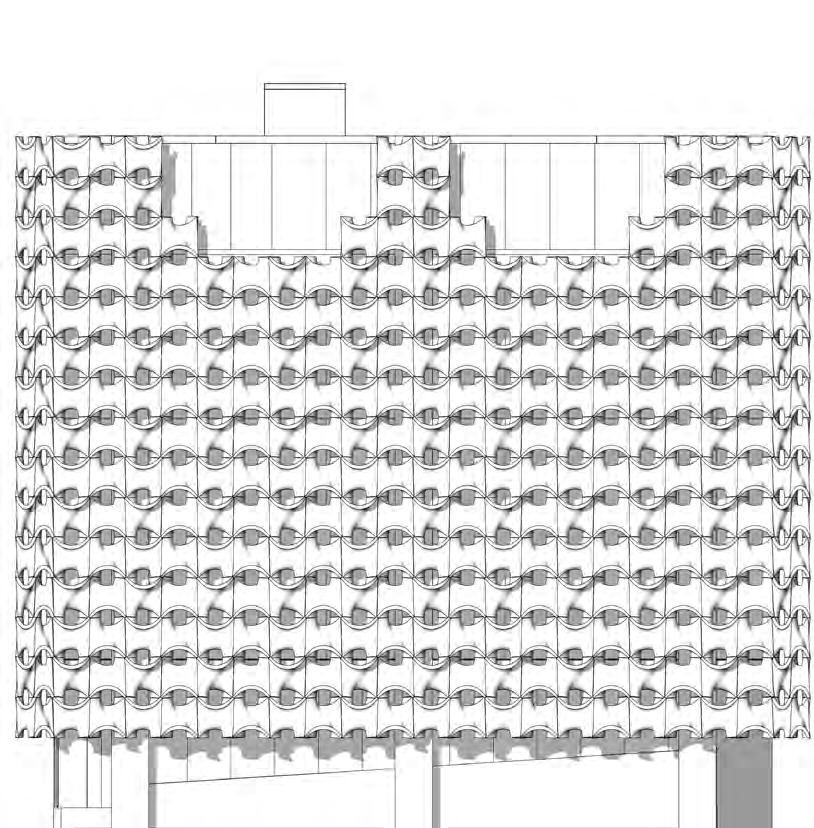

Facade Technology developments

Pixel Building

Facade Environmental Response

Pixel Building

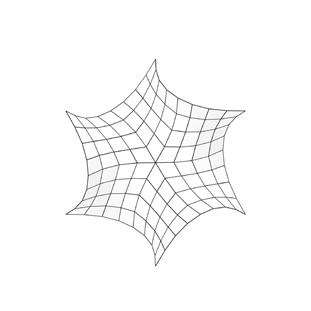

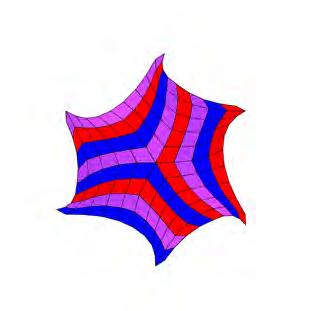

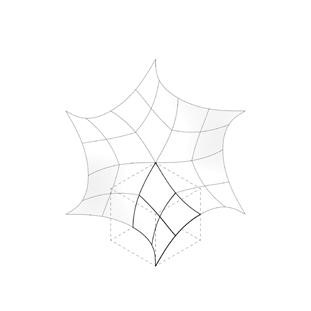

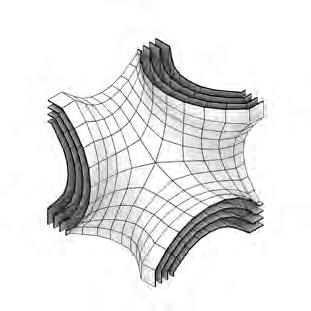

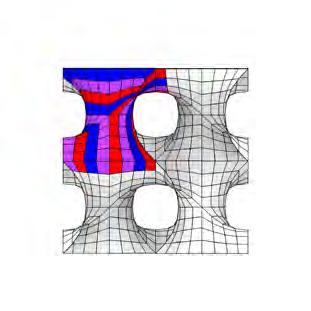

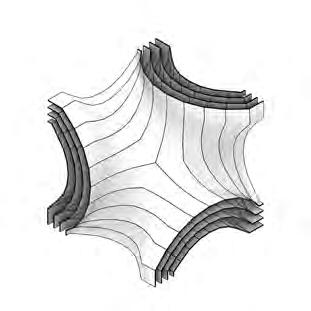

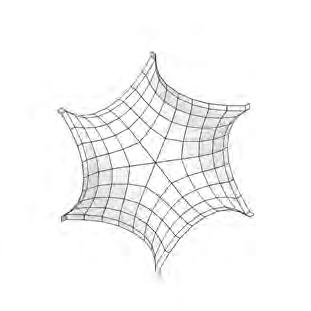

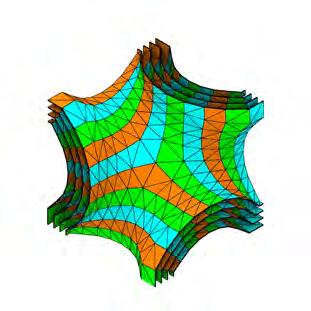

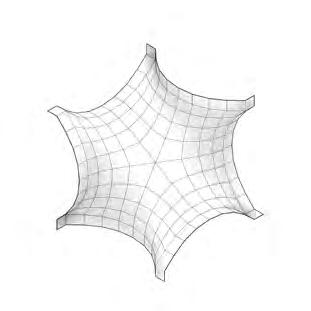

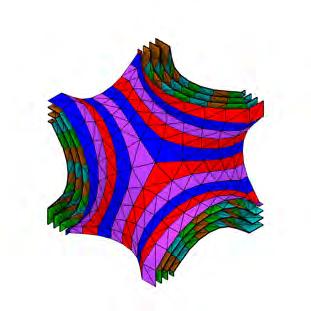

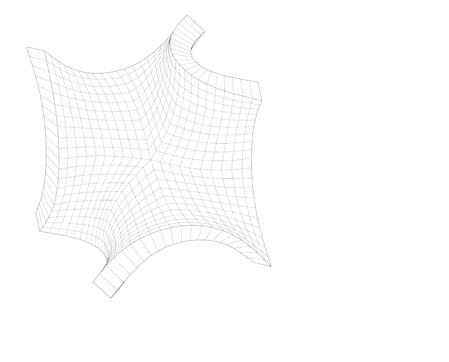

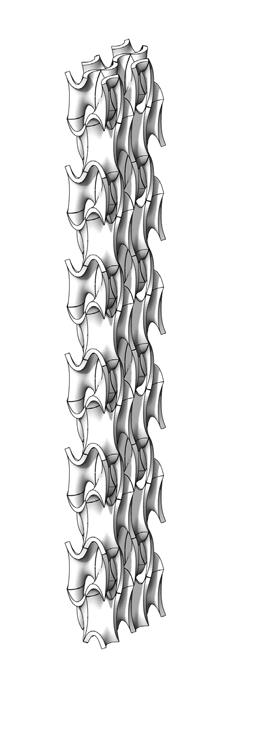

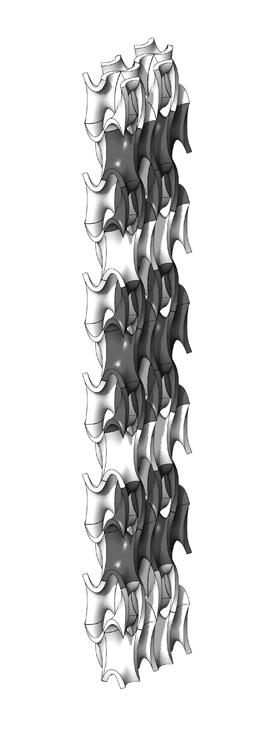

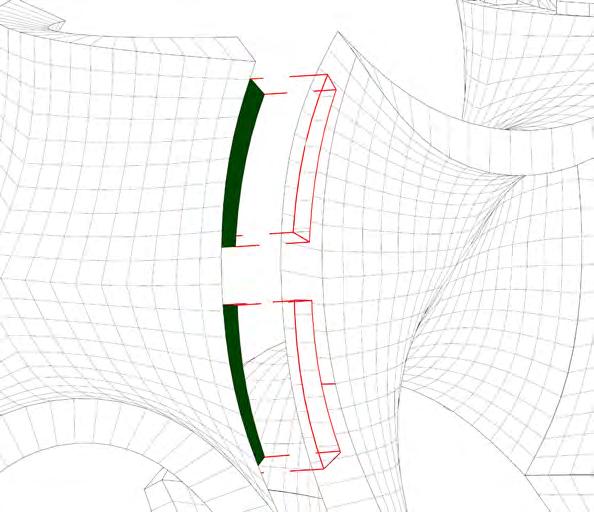

Gyroid with selective cutouts

Modelling by lachlan Blackmore

Design & Diagrams by Joshua Muldeary

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Facade

Response

Facade

Gyroid with selective cutouts

Modelling by lachlan Blackmore

Design & Diagrams by Joshua Muldeary

Lachlan Blackmore

Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore

Produced

Blackmore

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Studio Biofabricate

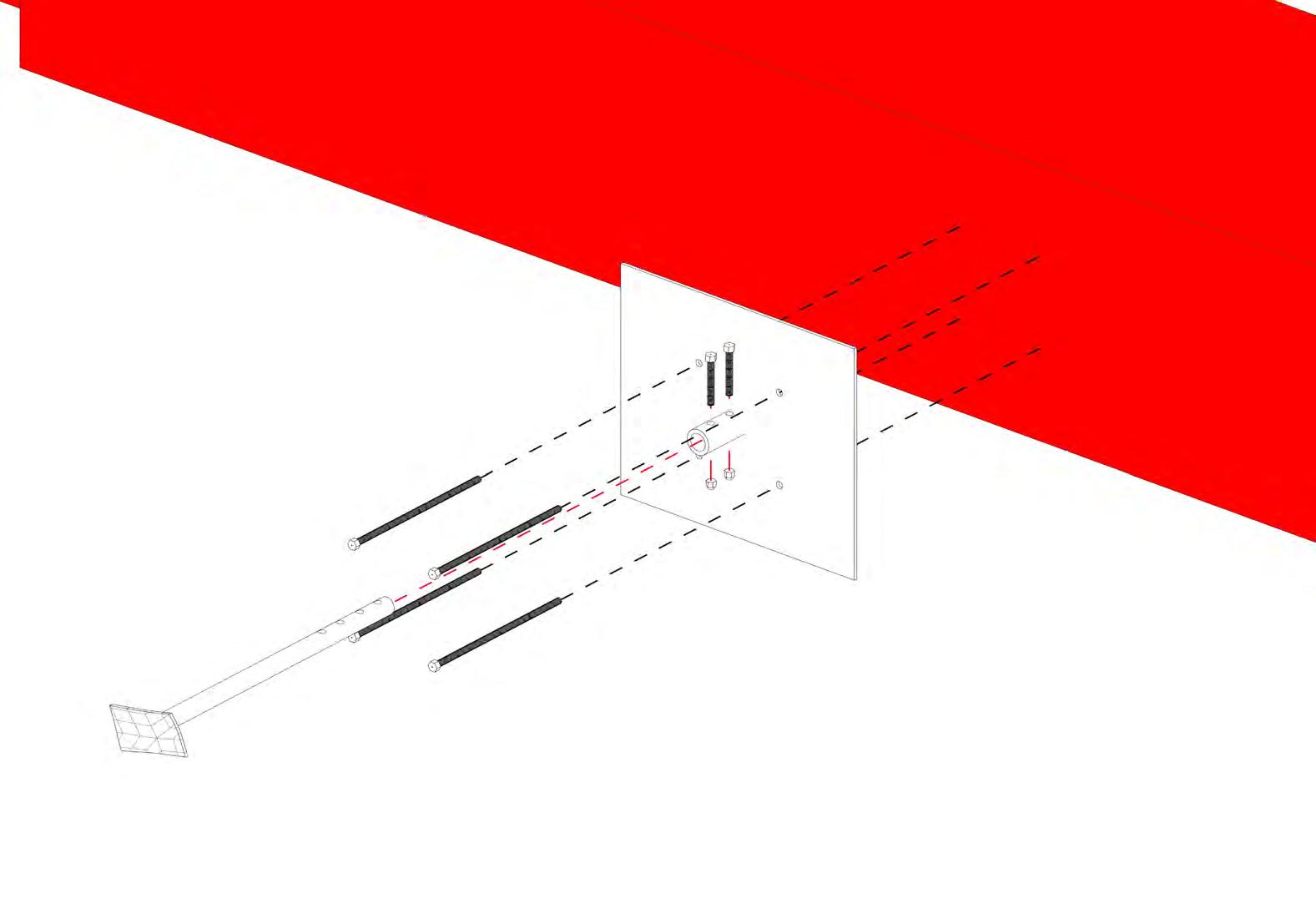

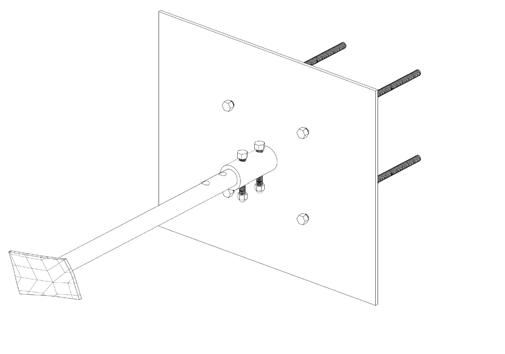

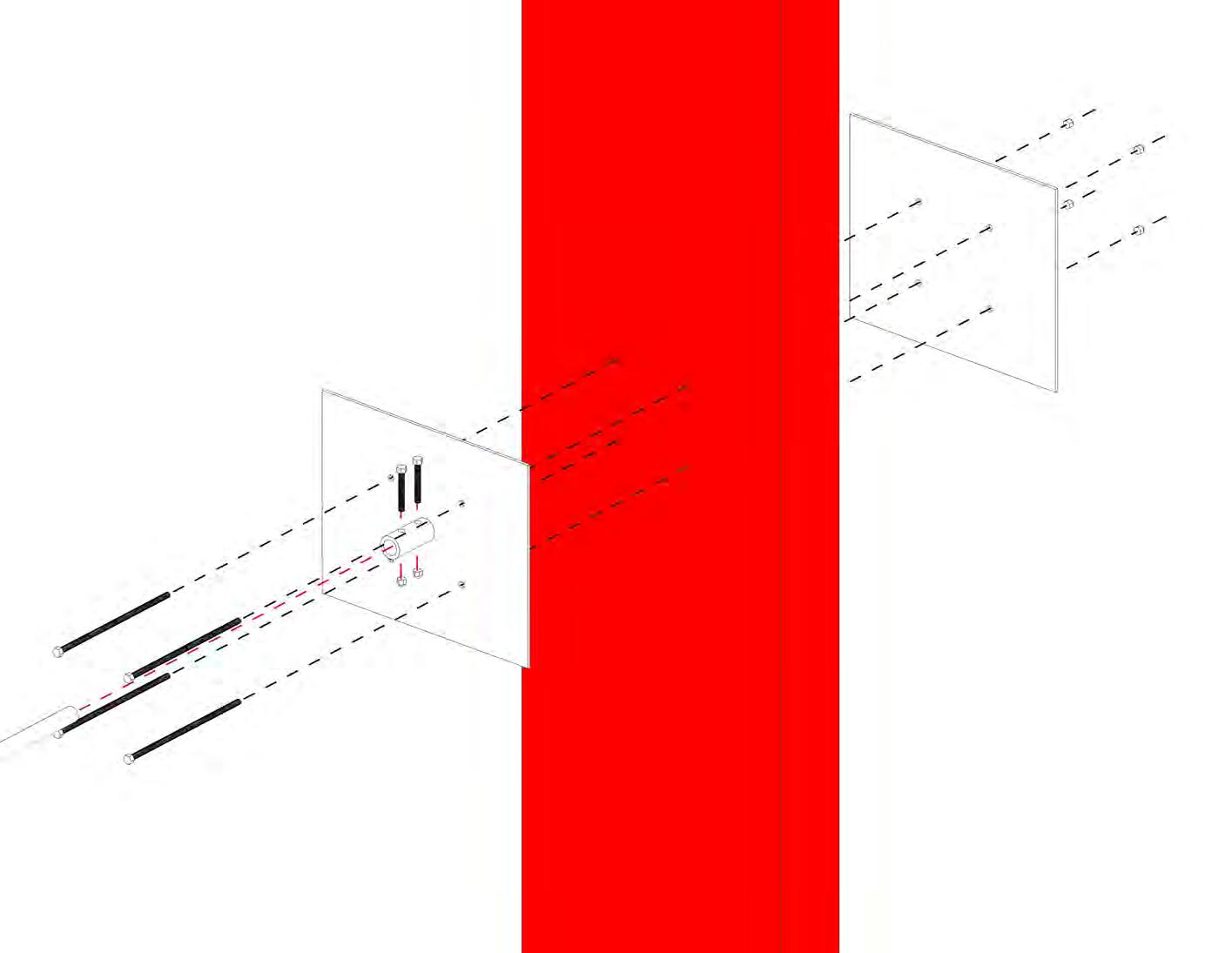

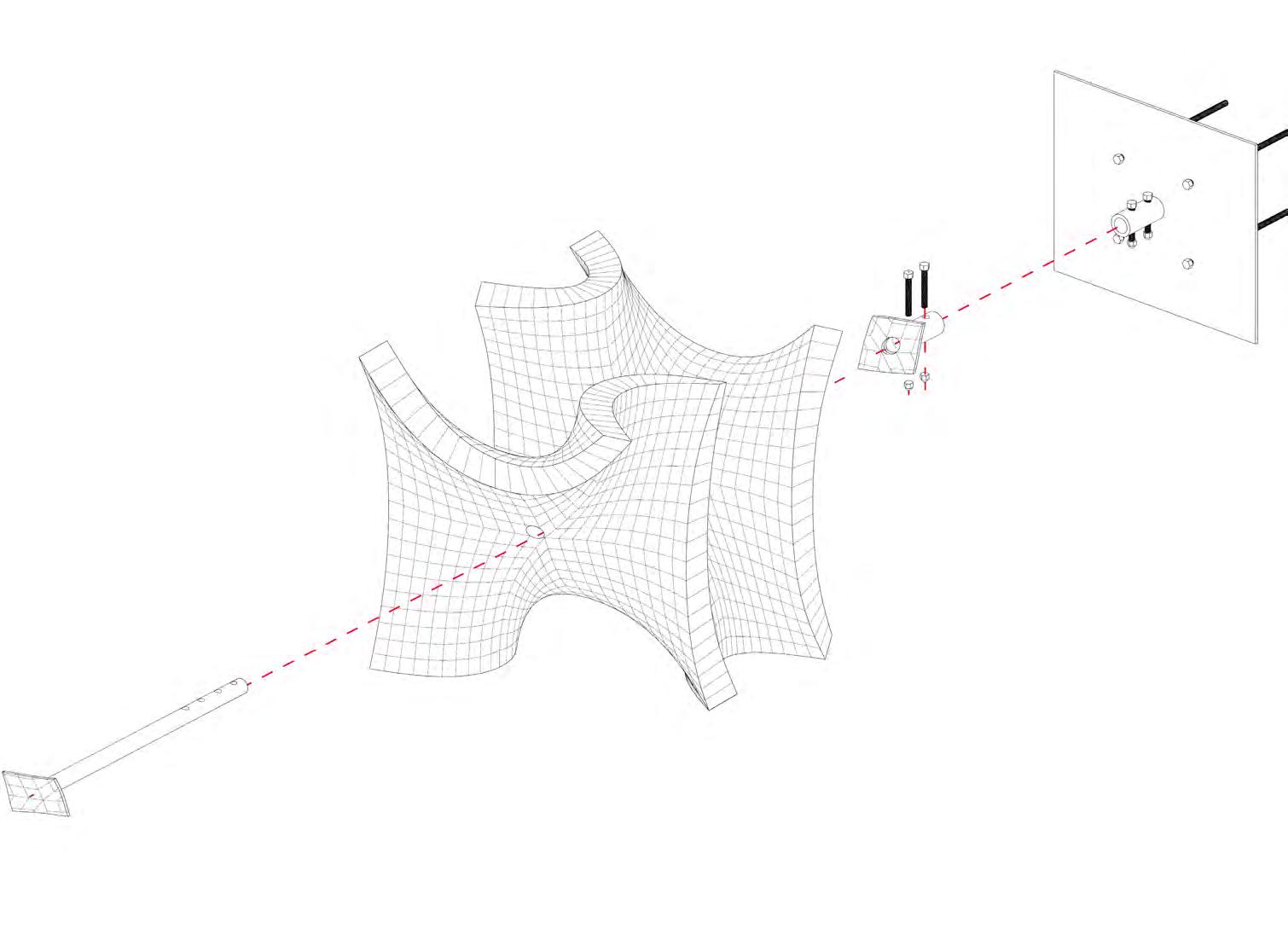

Details

Slab Mounting Plate & Bracket Arm

Flat plate base with bracket arm mount

Produced By Joshua Muldeary

Produced By Joshua Muldeary

Produced By Joshua Muldeary

Produced By Joshua Muldeary

Lachlan Blackmore

Biofabricate

Mortice and tennon connection points

Mortice and tennon connection points

Gyroid Module

Produced By Joshua Muldeary

Produced By Lachlan Blackmore

Lachlan Blackmore Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

Lachlan Blackmore Lachlan Blackmore

Studio Biofabricate

Studio Biofabricate

Produced By Lachlan Blackmore

Produced By Lachlan Blackmore

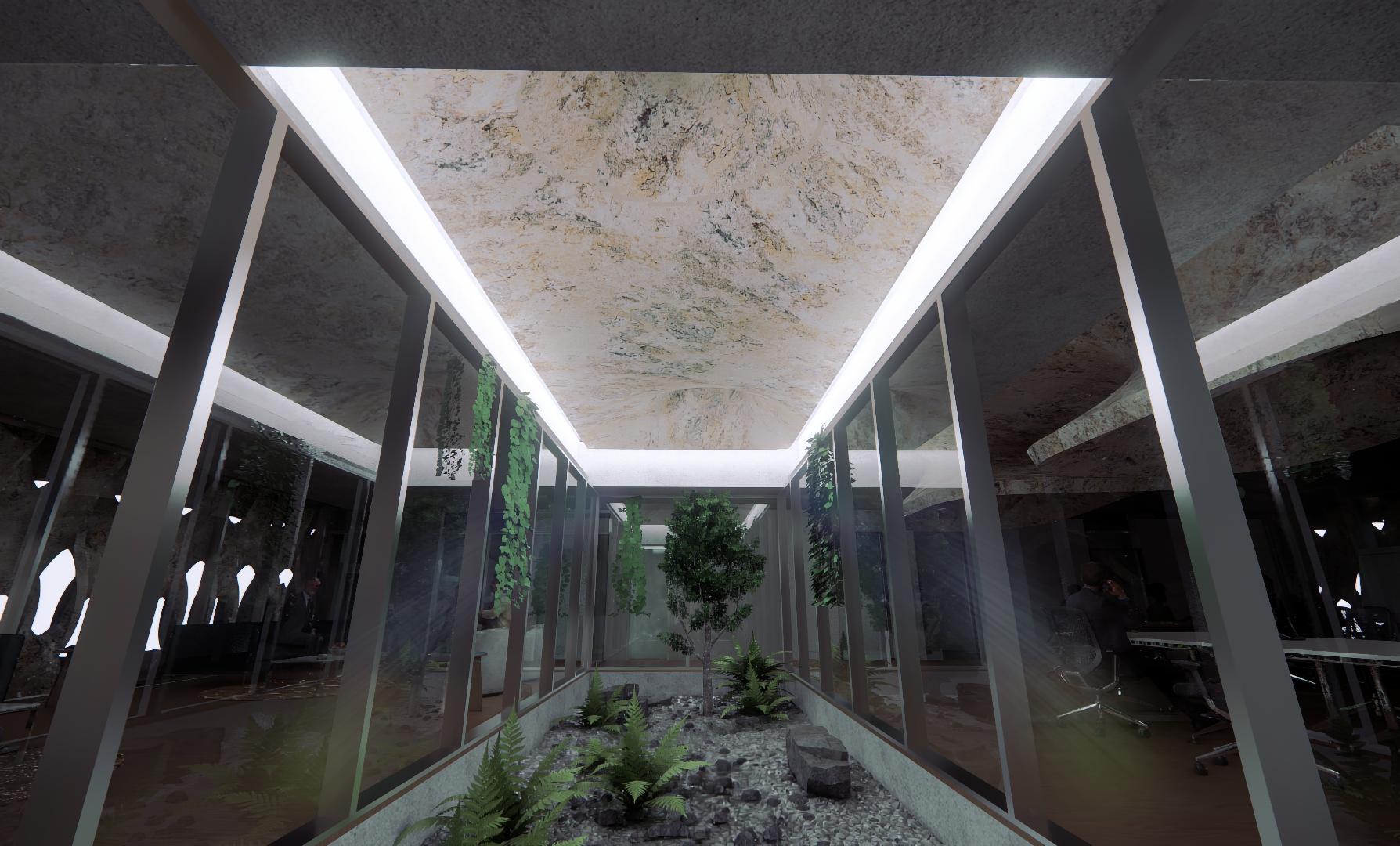

Renders

A Reflection on Biofabricate 2025

Technology developments

This semester has been both challenging and engaging.

Pixel Building

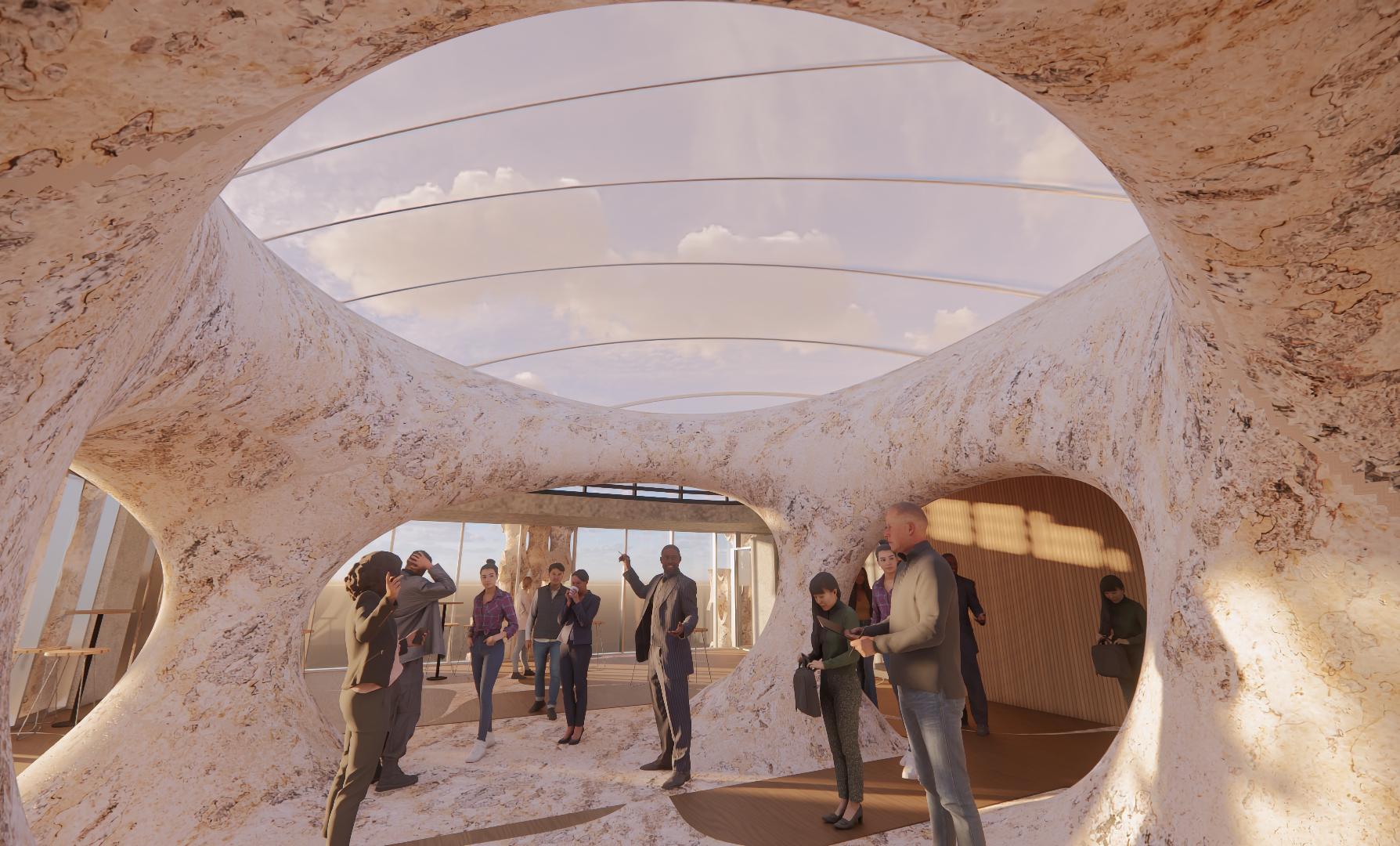

Beginning with the research of the Pixel Building, re-modelling and in turn understanding its structure was a valuable experience. Being able to access the building here in Melbourne and view it under renovation meant that could see and grasp it better. It was especially helpful having the architects from Studio 505 (BLP) there to meet with us. Iterating over rooftop canopy designs and trying to address structure, views, and the planned nearby buildings was a fun and realistic challenge.

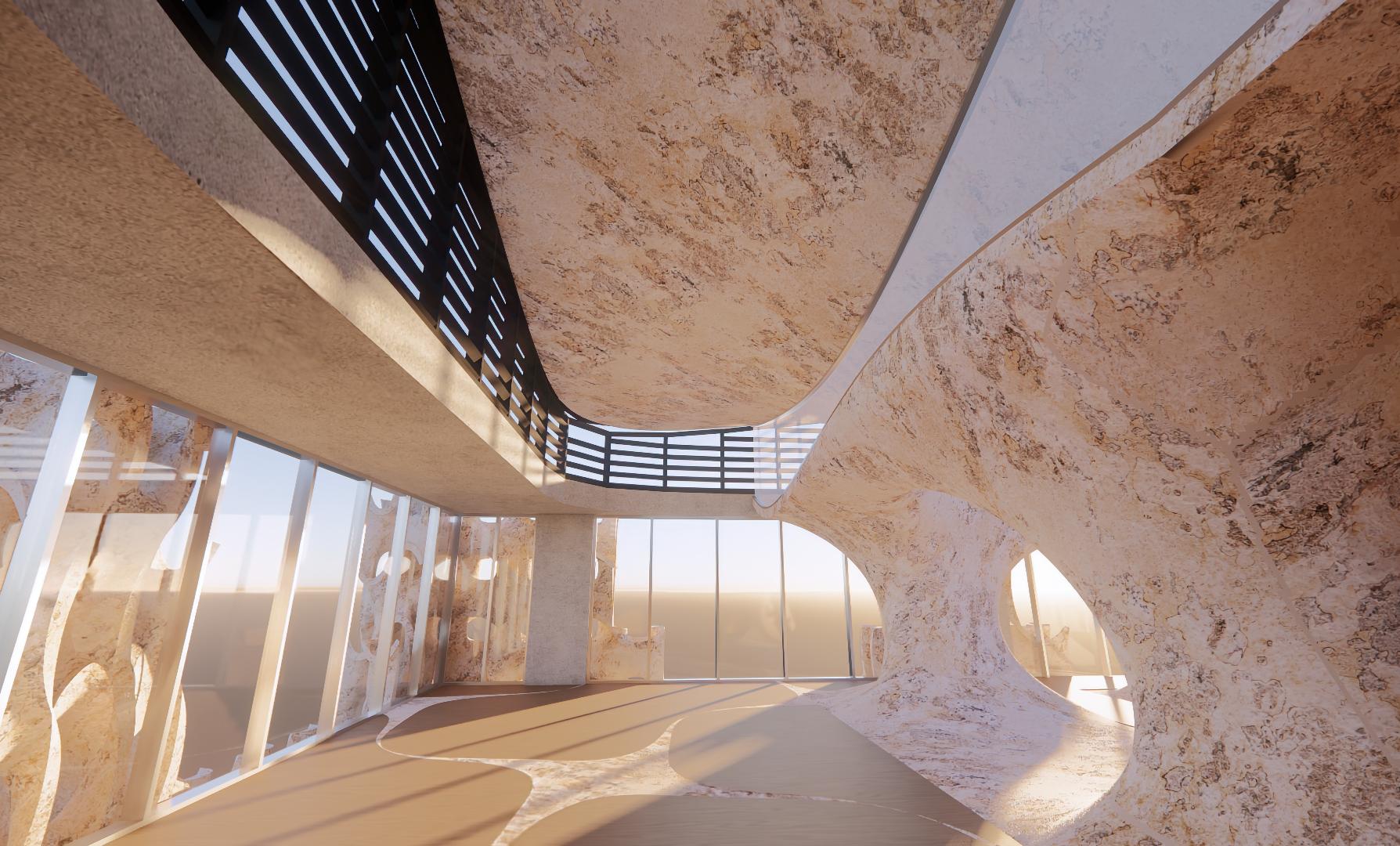

The mid-semester review was eerily quiet, other than some praise for the project’s realistic sense. saw this as a sign to get a lot more ambitious. The design at this stage wasn’t good, and took inspiration from international examples like ETH Zurich’s ‘HiLo’ in Dübendorf to push what mycelium could be used for in building. This led to the question: “Can mycelium be used as a sustainable formwork to cast concrete in?” The rest of the studio was aimed at understanding the geometry and digital design needed to fabricate a prototype concrete-mycelium model, while still offering an enticing renovation for the Pixel Building.

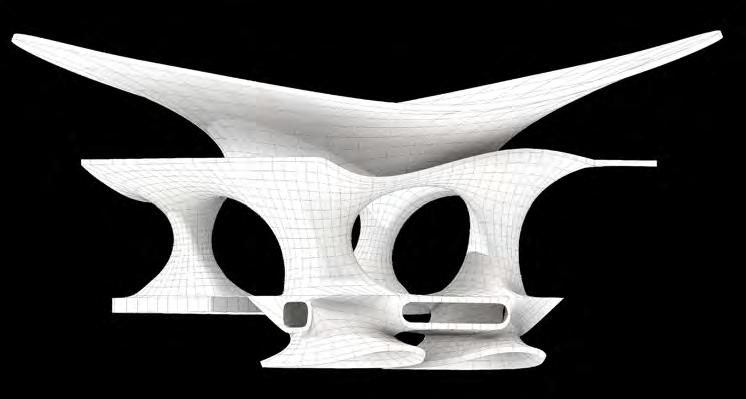

The building’s new form was based on a simple set of key drivers: existing structure, ventilation, light, and program, with the goal being to do so in one bespoke piece. To achieve this,

investigated minimal surfaces as they are highly configurable and adaptable. Interestingly, due to their geometry, they easily blur the lines between inside, outside, floor, wall, and ceiling.

With this in mind, demolished the existing garden beds (which were really just gaps between beams in the slab) to create openings between floors.

This would be the beginning of the new form, giving it somewhere to grow from and connect to the building. This form would open up on the fourth floor to connect with the outdoors, and the roof itself became the centrepiece of the fifth floor.

While iterating this form, my groupmate worked on the façade. Some of the feedback given to our class was that Swinburne students don’t tend to integrate their work with one another.

We were told that in a real practice, everyone is delegated their own tasks, but they are incredibly collaborative in their thinking and goals (in a good studio, at least). Here believe we could have made improvements. While we both investigated a shared technology, don’t believe we borrowed from and pushed one another enough. This is a good lesson going forward.

While maybe geometrically or digitally impressive, the work we showed missed the mark in some very important aspects.

We were not clear enough in establishing what we were doing and why (“Can mycelium be used as a sustainable formwork to cast concrete in?”).

We could have clarified this narrative more strongly through our prototyping.

We didn’t explain how and why we used minimal surfaces properly – we just plainly got this wrong by stating it was structural (to an engineer – not good).

We didn’t show precedents of these minimal surfaces to provide context and show that we hadn’t just made it up.

We didn’t indicate even a rough understanding of the forces at play in a structure like this.

We needed further research into this kind of concrete panel construction, as well as the basics of the type of concrete used for this application.

We were questioned all together why we even chose to go down this path, which is a pretty good indicator that the message had definitely not made it through.

If had to present this again in 6 weeks to a new group of people, would change a number of things.

I would: Keep the analysis.

Shift the focus of the prototyping from just making the object to showing how it works.

Work much harder on justifying the design in a few ways:

Show precedents that support the need and

possibility of this technology.

Back the design up by detailing it further with consideration to the material.

Show more research into understanding the geometry we were working with.

Keep the rest of the design, but work harder to reiterate the narrative.

Lastly, one of my goals for this semester was to gear this project towards digital fabrication and the sorts of architectural firms that specialise in it. wanted to demonstrate how could take an awkward and difficult shape, break it down, and produce a model cleanly, all while nodding towards an architectural and aesthetic understanding. While the outcome missed a number of key things, do believe achieved my goal to an extent and have given myself the foundation to push this where it needs to go (in my own spare time).