Editorial

Always Growing

In this new edition of Spraytec Global, we share with our family new product launches, research studies, reports, and life stories. It’s truly wonderful to grow alongside a team that’s all in, that maintains a positive outlook, and that is always striving for more—opening markets and expanding borders.

In this issue, Marcelo Carmona, the most renowned plant pathologist in Argentina, talks to us about the role of biostimulants when planning a crop season. “Phytostimulants and biostimulants are beginning to play a fundamental role. They are an alternative yet complementary tool to the traditional practices currently used in agriculture,” he affirms.

The “Identikit” section features Francisca Villa, a key member of our Argentine team. She states that something everyone should have is self-criticism… so true!

Lautaro Tesan, Sales Assistant at Spraytec, left his home country, Argentina, and relocated to Europe—specifically to Mechelen, a city of about 100,000 residents located between Brussels and Antwerp. His journey began back in 2019 when he started working at the company.

From Brazil, we share a very comprehensive and fascinating research study: “The efficiency of protection technologies in controlling soybean diseases at harvest.”

As part of an expansion plan that has already surpassed 45 million globally, we’ve inaugurated a new production plant in Roldán, Santa Fe, Argentina. From there, Fulltec OIL is produced and distributed to the rest of the world. All the details are in this edition.

Mariano Larrazabal takes us into the world of agronomists and artificial intelligence. “Today, value no longer lies only in ‘knowing the field,’ but in translating data from satellites, sensors, robots, or digital twins into decisions that improve profitability and sustainability,” he says.

For too many years, Argentine agriculture has operated in defensive mode. We’ve cut costs to the bone and prioritized protecting crops from adversity—but we’ve forgotten the most important thing: producing more. Our yields have stagnated, and this is costing us competitiveness compared to countries like Brazil and the United States. Guillermo Alonso explains why it’s essential to shift from Defensive to Offensive Agriculture.

And of course, as always, the Snapshots section—photos of this Spraytec family that I’m so proud to be a part of!

Until the next edition!

Editorial

Always growing

Francisca Villa

06 Interview with Marcelo Carmona

“Biostimulants should be considered as a complement, not as a substitute or an alternative”

By: Diego Peydro

10

First Person: Lautaro Tesan

Dreaming, planning, and making it happen

By: Juan Carlos Grasa

Identikit Launch Report Research Report Snapshots

General production: Horizonte A editions

From Defensive to Offensive Agriculture

By: Guillermo Alonso

Efficiencies of technologies in disease control in soybean crops

The New Agronomists: The Value of Translating Data

By: Mariano Larrazabal

Identikit

FRANCISCA

1. Position in the company:

Communications and Marketing.

2. Would you rather go back to the past, pause the present, or travel to the future?

The present is the most valuable thing we have; it’s the result of what we built in the past and the stage where, with every daily decision, we shape our future. Without a doubt, I would choose to pause the present to enjoy even more everything that surrounds me today.

3. How do you imagine your life in 10 years?

Being part of a big project.

4. The best reason to smile?

I don’t have one specific reason to smile. I believe it’s very important to practice it daily—for yourself and for others.

5. A life role model?

Can I pick two? Raquel Parodi and Rodolfo Villa.

6. If you were an animal, what would you be? A dog.

7. An Argentine pride? Pope Francis.

8. Which technological advancement surprised you the most?

Artificial Intelligence (AI) in general, and specifically ChatGPT. This tool keeps amazing me every day

9. If you could travel back in time, who would you like to meet?

My maternal great-grandparents. I met my great-grandmother, but I was very young. I’d like to spend time with them, hear their stories, and have my great-grandmother cook me strudel.

10. Something everyone should have?

Self-criticism.

11. Of all the places you’ve been, which one would you return to?

Capioví, Misiones—the most Christmas-themed town in the country. When I visited, it amazed me. It was during “Christmas in Capioví,” and the entire town was decorated with ornaments made from plastic bottles.

13. Tell me about Spraytec:

Spraytec is a school in motion. It’s a human group that, through its commitment, strength, and leadership of great mentors, achieves big things.

14. An event you can’t miss?

Expoagro. It’s a big event for checking in on our company’s growth

If you had to organize an expedition to a deserted island with Spraytec colleagues, who would you take knowing you’d face extreme situations?

If possible, I’d take everyone.

• To manage supplies: Flor Fernández.

• To carry the gear: Everyone, as we always do.

• To cook: Mariano Meineri.

• For fun times: Paula Garraza.

• To bring calm during tough moments: César Carriquiri.

• To coordinate the group: Flor and me.

• To ensure a safe return: Pablo Lafuente.

12. Who is Francisca Villa? I’m committed and demanding with myself. I get involved in what I do, but also with the people I do it with. I believe relationships make the difference. I’m not satisfied with what’s easy. I’m motivated by learning, creating, and supporting others.

FRANCISCA VILLA

INTERVIEW WITH MARCELO CARMONA

“Biostimulants should be considered as a complement, not as a substitute or an alternative.”

Renowned phytopathologist from the University of Buenos Aires, Dr. Marcelo Carmona, together with Spraytec, recently visited the United States and traveled over 9,000 km to witness in firsthand how the most productive farmers manage one of the main challenges: disease control.

By: Diego Peydro

Producers harvesting 20 tons of corn and 8 tons of soybeans manage plant health with great precision, combining early management, biotechnology, and the use of phytostimulants to deliver high-value crops.

In a context marked by climate change, intensifying diseases, resistant weeds, hardto-control pests, and the pressure to produce more sustainably, agriculture faces one of its greatest historical challenges. What is the strategic role of phytostimulants?

Today, farmers face an additional challenge: they must deal with completely different issues such as climate change, pests resistant to pesticides, and the need for more sustainable production that respects the environment.

In this context, phytostimu-

lants and biostimulants play a fundamental role. They are an alternative tool but complementary to the traditional practices currently used in agriculture.

How would you define the current role of phytostimulants in modern agriculture?

The term “biostimulant” is very broad because it includes molecules and microorganisms with different functions and mechanisms of action. Sometimes people try to simplify the concept, for example, by calling them “bio-inputs.” However, some biostimulants do not have a biological origin yet serve the same functions and should be considered biostimulants as well.

Thus, we can find biostimulants that enhance nutrition, others that have a protective effect—helping plants defend against abiotic stress—and also biostimulants that protect plants against biotic stress, especially damage from diseases or insects.

How was the U.S. technical tour organized with Spraytec professionals, and what was its main objective?

The main goal was to see how American farmers incorporate these new technologies. We saw producers who adopted these technologies quickly and closely monitored their impact.

Spraytec products have experienced significant growth throughout the U.S. because farmers there have a different mindset—they are constantly in the field, make their own decisions, rely on agronomic consultants, and when they adopt a technology, they monitor it closely. If it works and is beneficial, they adopt it quickly.

Which crops and characteristics of the American production system open the door for biostimulant use?

During the tour, we visited

There are biostimulants that are not of biological origin but that also perform the same functions and should be included under the concept of biostimulants.

crops such as corn, soybeans, peanuts, cotton, and rice. We saw a wide variety of crops in different states and also found disease problems very different from those in Argentina. For example, U.S. corn is currently suffering from a tar spot epidemic, a fungal disease that limits yields, which is not yet present in Argentina.

In soybeans, they face sudden death syndrome and late-season diseases like brown spot and cercospora, among others.

Biostimulants must be classified by origin and function and must demonstrate their efficiency through serious trials and measurable field results. Their true value lies in enhancing stress management and contributing to more sustainable agriculture.

Biostimulants should be seen as a complementary, not a substitute, alternative. They should

not replace successful traditional agronomic practices. Instead, they must demonstrate their additive and synergistic power. With different mechanisms of action, they provide plants with opportunities to resist both abiotic and biotic stresses, improve nutrition, and develop more vigorous plants better prepared to adapt to adversity.

Based on the main diseases affecting the American production system, how do biostimulants work synergistically with protective agrochemicals to achieve high yields?

Despite the huge potential of biostimulants, these products face major challenges ahead. The first is the need for scientific evidence on their mechanisms of action—knowing the correct dosage and timing of application is crucial.

The second challenge is managing expectations. Vendors,

producers, and the market often have very high expectations. It is necessary to manage these through educational demonstrations of the benefits and explain that biostimulants cannot be immediately compared to pesticides because their effects are usually more gradual, not instant. Therefore, patience is required to see the final benefits, and continued research is fundamental.

What competitive advantages can biostimulants offer in a highly technical market like the U.S.? Which types of biostimulants are of greatest interest to farmers?

American farmers are very interested in these complementary alternatives that work alongside traditional fungicides and fertilizers. They believe applications should not only be made at seeding or in-furrow but also as foliar sprays. In particular, they use biostimulants to manage

stress caused by herbicide applications.

Seed-applied biostimulants that improve germination, establishment, and seed pathogen control are also seen as companions that strengthen plants, helping them withstand herbicide toxicity. These two approaches are the most important and most widely adopted in the U.S. today.

Biostimulants act as natural defense inducers in plants, helping them face biotic stress more effectively with less reliance on chemicals. What protective effect do biostimulants have?

Biostimulants can protect against biotic stress in several ways. Directly, they can act like a fungicide that interferes with essential fungal metabolic processes. Indirectly, they can induce resistance or trigger plant defense mechanisms.

This means activating a complex, sophisticated immune-like system within the plant, equipping it with better tools to defend itself against biotic stress. In the case of fungicide-resistant pathogenic fungi, phosphite-based biostimulants,

such as Ultra Zinc Protector used as a seed treatment, can complement fungicides.

What message would you give to farmers who are not yet familiar with the physiological potential of these next-generation tools?

It is important for producers to recognize the benefits—these are alternative but complementary tools. Farmers should trust them, provided there is scientific evidence explaining their mechanisms of action, multifunctionality, and complexity. They should also understand that the effects cannot be immediately compared to those of synthetic chemical products.

How do production scale and business approach influence farmers’ adoption of these technologies? How does the American farmer differ from the Argentine farmer?

American farmers have certain advantages already solved—policy and economic conditions, access to irrigation, advanced machinery, and well-established fertilization practices.

In this context, adopting new technologies is easier and faster, as long as they see tangible benefits.

Marcelo Carmona presents a groundbreaking manual on biostimulant use backed by scientific evidence and concrete strategies for more sustainable agriculture

Biostimulants in agriculture are complex, diverse in origin, and often multifunctional. Sometimes it is even difficult to classify them succinctly, making it necessary to organize these concepts.

This led to the creation of a manual specifically on biostimulants, where the authors aimed to clarify classifications, functions, and mechanisms of action—with one guiding principle: scientific evidence.

We conducted a global review of scientific advances achieved with each biostimulant we studied—those aimed at nutrition, abiotic stress mitigation, and biotic stress management.

Thank you, Marcelo!

First person: Lautaro Tesan

Dreaming, Planning, and Making It Happen

By: Juan Carlos Grasa

- Director of Horizonte A

My Beginnings in the Company and My Dreams for the Future

I started working at Spraytec in 2019. Before joining the company, my dream was to be able to travel anywhere in the world to learn languages, experience new cultures, and live new adventures. At that time, I was 22 years old and wanted to go with my cousin, who was already living in New Zealand, to work picking kiwis. That’s when I started working at Spraytec’s packaging plant with the goal of saving money to make that trip at the end of the year.

Two months after joining the plant, Lucas Gómez called me into the office to tell me that a vacancy had opened up in the Rosario office. He mentioned they needed someone who

could speak English. Luckily, I had a strong foundation because my parents, Ana and Sergio, had enrolled me in English classes since I was 10 years old. Thanks to that, I accepted the job without hesitation.

That very same afternoon, I met Pablo Lafuente, and within two or three weeks, I was already working in the Rosario office with him and the entire administrative team at that time. Over time, and even throughout the pandemic, I worked hard and learned from everyone. My learning was multidisciplinary: in my commercial support role, I was in contact with salespeople, who were mostly agricultural engineers. At the same time, I worked alongside accountants and business ad-

ministrators who eventually became my friends. It was a great experience—not only did I learn a bit from each area, but I also enjoyed it immensely.

I had the opportunity to continue growing within the company, to be invited on trips, and to manage them. I was able to travel and see the world sooner than I had imagined. While Spraytec was growing in Argentina, I still carried within me the desire to have an international experience.

Where to Move Abroad?

In 2021, I started dating Dore—who is now my wife— and we often talked about the idea of having an experience abroad. At first, we thought of moving to Australia because Spraytec had a branch there. The company had been operating there for about three or four years and was growing,

“I was able to go out into the world sooner than I had imagined. While Spraytec was growing in Argentina, I still had that inner desire to have an experience abroad.”

so we believed there might be an opportunity.

After several months of discussing the idea internally and feeling more confident about going, we decided it was time to talk to Pablo and tell him about our interest. That same day, Pablo listened to what I had to say and told me that he had just returned from Australia. He explained that everything was running smoothly there and didn’t believe it was a significant opportunity to move there at that time.

He thought there was a bigger opportunity in Europe, where operations were just starting. There were already two employees, and they needed people willing to work and live in Belgium since the other team members were based in Spain.

I thought it was a great idea, discussed it with Dore, and she was also thrilled about the opportunity. We accepted the proposal almost immediately. That was in November 2023. From that moment, I became more actively involved in remote operations, working with the team in Spain. Months went by, and soon we had our first visit to Europe.

2024, a Turning Point

In June 2024, we traveled to Europe for the first time. During the first week, we participated in a trade fair—it was Spraytec’s first-ever presence at a fair in northern Europe, in the town of Lippstadt, Germany. After that, we explored and spent a week in the city where we wanted to live. We got to know Mechelen and confirmed it was a place where we wanted to settle.

We returned from that trip excited and with a return date set for October of that same year. However, we encountered some barriers and limitations regarding visas. There was a six-month waiting period, and we had other colleagues who also needed visas. The recommendation was not to apply for all visas simultaneously, which created a time constraint to get all the necessary paperwork.

So, we started looking into other options. One of them was obtaining Italian citizenship, which meant we would have to live in Italy for a few months. My family already had some relatives—mainly cousins—who had it, so I decided it was time to pursue my citizenship. I met with relatives, learned more about my origins, gathered the necessary documentation, and re-

quested missing records from my great-great-grandfather’s hometown in northern Italy.

Wedding

By September–October 2024, with the paperwork ready, we realized that being married would make it easier to stay in Europe. So, after four years of dating, we decided to get married! Initially, we thought of something simple—a civil registry ceremony and a small celebration—but as time passed, we realized we wanted something more beautiful, emotional, and with more people.

We ended up organizing a big party with 180 guests at an estate. It was one of the best nights of our lives—we had an amazing time celebrating our love and future with our loved ones. This was in December, the same month I graduated with a degree in International Business Management.

With my degree in hand and now married, it was time to say goodbye to family, friends, and colleagues in Rosario and pack our bags to head to Italy to get my citizenship done.

Italy

We arrived in late January 2025 and stayed at Franco’s house—our “Italian dad.” He was always attentive to our needs, sharing his customs, kindness, and way of living the Italian culture with us. We truly enjoyed our stay. We also traveled a bit to discover the country of our ancestors.

After four months, I finally obtained my citizenship. With Italy in our hearts, we were ready to move to Belgium. During those months in Italy, we worked remotely for Spraytec, preparing everything so that when the time came to settle in Belgium, we could start working as soon as possible.

Belgium

Today, we are living in Mechelen—a city of around 100,000 inhabitants in northern Belgium, between Brussels and Antwerp. It’s picturesque, organized, clean, safe, and full of activity, at least in summer— we’ll see about winter. Luckily, we have an Argentine community here, and in fact, through them, we discovered this city.

We found what we call our “Embassy,” a typical four-story European house. The ground

floor will serve as the office, and the upper three floors are our home, with rooms to host Spraytec visitors from around the world, as well as family and friends.

It’s a great challenge to have arrived in this country, which, despite its small size, has three official languages: French, Dutch, and German. English is essential for communication here, and a large part of the population speaks it very well.

Spraytec Family

With great responsibility, we’ve embraced this opportunity, working alongside Roberto and Bruno, members of the Spraytec Europe team, as we travel across northern Europe seeking to expand the remarkable work that has been done worldwide. In just a few weeks, we’ve had exciting and promising meetings with distributors and producers eager to learn more about us and our products.

This is an exciting and stimulating beginning professionally. With plans, dreams, and more goals ahead, I’m truly happy to live this experience alongside the Spraytec family.

LAUNCH

FULLTEC OIL

As part of an expansion plan that has already exceeded 45 million globally, Spraytec inaugurated its new production plant in Roldán, Santa Fe, Argentina. Located in the city’s Industrial Park, The plant is equipped with modern technology, automated systems, and can produce up to 5 million liters a year, placing it among the most advanced in the country for adjuvants and specialty agricultural products.

“For a company like Spraytec, which started in Latin America and now brings its products to the world, this is truly a great satisfaction. We’ve changed the way things are done—how to be more efficient, how to be more productive, and how to make agricultural production more economically profitable,” says Pablo Lafuente.

With more than 500 million hectares treated worldwide and market presence in key regions including Europe, the United States, Brazil, Russia, Ukraine, Australia, Turkey, and throughout the Americas, the company demonstrates strong adoption by producers and farmers globally.

Their flagship products— Fulltec, Fulltec Max, Optimix, Top Zinc, and Cubo—are wellknown, accepted, and widely used in the market. To these,

they are adding a new generation of products manufactured at their plant in Cambé, Paraná State, Brazil, including solid formulations such as Tractus Kit, Tractus Carbono, and Tractus Supera.

Global Manufacturing Facilities

Currently, Spraytec operates factories worldwide, including the Roldán plant in Rosario, Argentina; the Cambé plant in southern Brazil; and the Iowa plant in the United States. “As exclusive news, I can share that in six months, we’ll be inaugurating a new plant in Perth, Australia, on the Indian Ocean, to manufacture products for the Oceania region,” says Pablo.

Roldán Plant

This facility spans 3,600 m², plus office space bringing the total to 4,100 m². It includes several areas: raw material reception, a distribution center, two quality control laboratories, and another dedicated to Research and Development. There are packaging and production areas with four fully automated reactors for liquid production, each with a 7,000-liter capacity.

Additionally, there is a storage area for finished products before packaging. The plant has raw material tanks of 20,000 and 30,000 liters

used for automated production. Currently, three production lines enable them to produce 15,000 liters of product per shift.

Traceability

Every product delivered to the field carries a traceable batch number, allowing monitoring from Roldán to identify the raw materials used. From the box and cap to the components inside each bottle, everything is carefully controlled.

Fulltec Oil

This new product will be manufactured exclusively in Argentina and distributed worldwide. Plans are underway to build an additional 2,000 m² warehouse to store more raw materials and finished products within the Distribution Center.

Fulltec Oil combines the best of both worlds—the best properties of adjuvants and oils—with a completely innovative EW (emulsion in water) formulation.

“There’s no other product in the world with this formulation, and we’re truly proud that our R&D department, led by Lucas Gómez, achieved this major technical breakthrough,” says Pablo Lafuente.

The product is a microemulsion straight from the plant, capable of simultaneously correcting water quality, reducing foam, and delivering all the benefits of oil.

This truly represents a new generation of products. Fulltec Oil contains 40% oil and 60% formulation—double the formulation of the leading silicone-based oil on the market—offering numerous

advantages for precise agricultural applications.

Economic Impact

Spraytec’s products deliver a very high economic return—more than 6 to 1. For every dollar invested, customers can expect at least $6 in benefits. This is a key factor valued by our clients and one of our greatest strengths.

The arrival of Fulltec Oil and the solid products from the Brazilian plant is expected to spark a small yet significant revolution in the Argentine market.

Spraytec promotes regenerative agriculture based on technologies that improve input efficiency, enhance soil biology, and foster more sustainable long-term production systems.

From Defensive to Offensive Agriculture:

The Change Argentina Needs

For too many years, Argentine agriculture has operated in a defensive mode. We’ve been laser-focused on cutting costs and protecting crops against threats, but we’ve forgotten the most important thing: producing more. Our yields have been flat for years, costing us competitiveness against countries like Brazil or the United States.

By: ING. Guillermo Alonso

Stagnant Yields, Depleted Soils

In Argentina, while our competitors keep boosting productivity—and in Brazil’s case, even expanding planted areas—we’ve seen no growth in yields or acreage for years. The reasons are many and well known: inconsistent policies, heavy taxes, lack of investment, and more. But we must also face our own agronomic shortcomings with self-criticism.

Our main goal must be to increase yields and reach the attainable potential in each region.

We can keep blaming anti-production policies, high taxes, climate issues (but after so many years, we know La Niña isn’t the only culprit), or genetics (it’s clear by now that’s not the main cause either). The real lagging fac-

tors are nutrition and crop management.

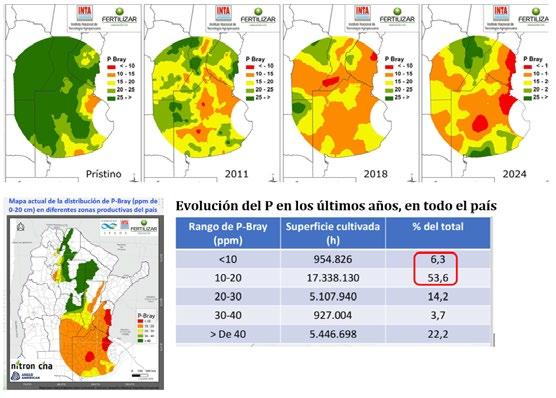

One of the most serious problems is the lack of nutrient replenishment—macro, meso, and micronutrients alike. In most Argentine soils, phosphorus levels are critically low; nitrogen and sulfur have shown severe deficiencies for decades; potassium is now an issue in the east of the country; and organic matter (OM) is declining at an alarming rate, dragging down all the soil’s physical properties with it.

Micronutrients like zinc, boron, magnesium, and calcium are also becoming increasingly deficient. Data presented by Engineer H. Sáenz Rosas at the last FERTILIZAR Symposium was eye-opening. We know what’s missing, yet we do little about it. Only 15% of fields are tested, and less than 20% of those tests even include micronutrient analysis.

Cultural and Technical Shifts

Fifteen years ago, in the core farming region, early corn was planted at densities over 85,000 plants per hectare. Today, it’s uncommon to see fields even reach 70,000. Wheat and barley yields that once required growth regulators are now rare and generally only achieved under irrigation.

We rent fields expecting 20 quintals of soy but manage them as if they were 10. Fertilizer rates are calculated on spreadsheets instead of real needs. Post-emergence field interventions are minimal. With corn, aside from a starter nitrogen application at planting, nitrogen topdressings at V4/V8 stages are rare. In soybeans, there’s an average of just 2.5 applications during the entire cycle, mostly defensive, not nutritional. The situation with wheat and sunflowers is even worse.

There’s no proactive, balanced nutrition strategy, no physiological stimulation. We only react to weed escapes, pests, or sudden disease outbreaks.

Learning from Our Neighbors

The case of the corn leafhopper is telling. Brazil has dealt with it for years, managing it with 3–4 planned applications that combine insecticides and beneficial fungi like Beauveria. In reproductive stages, they also apply fungicides and insecticides but supplement each spray with potassium, magnesium, boron, or whatever’s needed. Sure, it’s a different economy, a different reality—but it shows what’s possible.

And when it comes to seeds, we should be learning from them as well. The whole

world understands that yield starts with the seed. Today, a progressive farmer in Paraná, Brazil, may apply 8–10 active ingredients in a professional seed treatment: nematicides, fungicides, insecticides, micronutrients, coatings, biostimulants, polymers. Biologicals (Rhizobium, Azospirillum, Bacillus, etc.) are applied separately, in-furrow, ensuring they’re not mixed with chemicals—a practice that has improved results.

Meanwhile, in Argentina, we still treat seeds in the same way that we did 20 years ago.

Where to Start

Change must begin with the seed and continue through vegetative and reproductive stages. We need more applications with nutritional

purposes, not just defensive ones. We should integrate cover crops, diversify rotations, adopt site-specific agriculture, and improve soil structure.

We must better understand root systems—the hidden half of crop performance. The rhizosphere is where life begins; root health and development largely determine whether the crop above will succeed or fail.

We need to embrace phytostimulation—working on metabolic, enzymatic, and hormonal pathways that help mitigate biotic and abiotic stresses throughout the crop cycle. We must also focus on carbon recovery and practices that rebuild organic matter. No-till alone is no longer enough.

Technologies like drones can

Evolution of P deficiency in Argentine soils, source Fertilizar

Marked Boron Deficiency in Corn

be key allies, enabling targeted applications in later crop stages, when grain filling and quality improvements matter most

Carbon is the Future

Looking ahead, carbon will become the centerpiece of agronomy: capturing it, retaining it, and integrating it

into soils will be essential to maintaining productivity and soil health. It’s a precious resource that must be revalued—it’s the thermometer of soil vitality.

Conclusion

Argentina has the knowledge, genetics, and potential. But if we keep working

with a defensive mindset, we’ll only fall further behind. The future demands an offensive agriculture—smart, strategic, and determined to produce more, better, and sustainably.

Yield and sustainability go hand in hand; it’s time to think about them together and rise to the challenge.

“Yield and sustainability go hand in hand; it’s time to think about them together.”

Efficiency of technologies for disease control in soybean

Crops during the 2021/2022 harvest

OBJECTIVE

To evaluate the agronomic efficiency of different technologies for managing and controlling major diseases in soybean crops during the 2021/2022 harvest.

GEOGRAPHIC AND CLIMATIC INFORMATION

Geographic coordinates:

• Latitude: 18°16’05.80”S

• Longitude: 7°50’50.77”W

• Altitude: 745 m

As shown in Figure 1, between November 2021 and February 2022, rainfall was high, exceeding 200 mm per month—higher than in previous years. Rainfall decreased in March, but since the crop was near the end of its cycle, there was no impact on the trial. Average temperatures

remained consistent throughout the cycle and were similar to previous years.

MATERIALS AND METHODS

The study was conducted at the Cerrado Experimental Station in Ouvidor (GO) during the 2021/2022 harvest, using a randomized block design with 4 replications and experimental units consisting of 8 rows, each 6 meters long. The variety used was CZ 37B43 IPRO, with a planting density of 300,000 seeds/ha (15 seeds/m). Treatments tested are shown in Table 1.

Work began on November 9, 2021, and germination occurred on November 16, 2021. 120 kg ha-1 of KCl (60% K2O) was applied broadcast during pre-planting, and 120 kg ha-1 of MAP (11% N, 52% P2O5) was distributed in the planting row. A foliar application schedule for micronutrients was followed to meet crop demand. Weed and pest

management was carried out with a focus on high yields and following common management practices for the region.

The evaluations included disease incidence and severity (Annex I), defoliation percentage (Annex II), phytotoxicity and productivity in kg ha-1 and sacks ha-1, and thousand grain weight (TGM).

For contrast, the collected data were statistically analyzed using Tukey’s test at the 5% level using SASM-Agri (System for the Analysis and Separation of Means in Agricultural Experiments) software Version 8.2.

RESULTS AND DISCUSSIONS

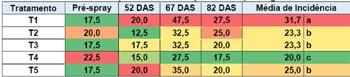

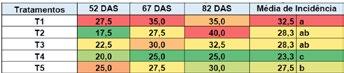

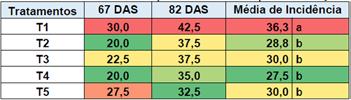

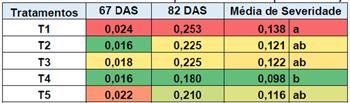

Regarding Septoria, the incidence and severity data follow the same trend. In the pre-spray, the data were homogeneous as early as 52 days after planting (DAP), and a statistical difference

In this trial, it was observed that the use of Ultrazeb fungicides turned out to be the best alternative.

Figure 1. Precipitation, relative humidity, and temperature from October to March in the trial “Efficiency of Technologies for Disease Control in Soybean Crops during the 2021/2022 Harvest,” conducted by Cerrado Pesquisa e Soluções Agronômicas.

Table 1. Discrimination of the treatments implemented in the trial Efficiency of technologies for protection in the control of diseases in soybean crops in the 2021/2022 harvest conducted by Cerrado Pesquisa e Soluções Agronômicas:

Oil/adjuvants were added according to label instructions. DAS = Days After Sowing.

was observed between treatments. The control treatment had the highest incidence and severity values. This demonstrates the importance of application during the vegetative phase of the crop.

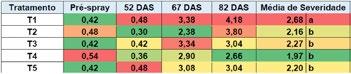

Cercosporiosis is a very common disease in the region, which has caused severe productivity losses in soybean crops. In this trial, we can observe that, in the evaluations of the lower and middle thirds, treatment 4 stands out from the others, with the low-

est incidence rates. In terms of severity, this treatment proved to be an important alternative, as it presented the lowest rates.

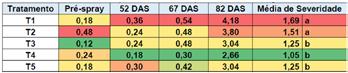

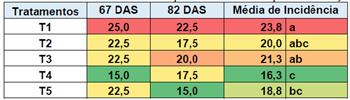

In the mid-third evaluations, we observed the importance of using protectant fungicides in managing this disease. At the 52 and 67 DAS evaluations, management without protectant fungicides had proven effective, but at the 82 DAS evaluations, the incidence and severity of Cercospora increased considerably.

This behavior is common in this disease when management allows for fungal infection, which remains latent and shows its symptoms toward the end of the crop cycle. In contrast, in management with protectants, symptoms remained stable at the end of the crop cycle, conferring a lower average incidence and severity. We also observed that, in the case of Cercorpora, the combination of fungicides Ultrazeb and Unizeb Gold (treatment 5) did not confer greater plant

Table 2. Evaluation of the incidence of Septoria (Septoria glycines) in the lower part, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% probability of error level and presented a CV of 11.03%.

Table 4. Evaluation of the incidence of Cercospora (Cercospora spp.) in the lower part, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% error probability level and had a CV of 4.69%. DAS = days after sowing.

Table 6. Evaluation of the incidence of Cercospora (Cercospora spp.) in the middle third, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% probability of error level and had a CV of 6.35%. DAS = days after sowing.

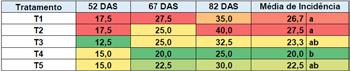

Table 8. Evaluation of the incidence of Ring Spot (Corynespora cassiicola) in the lower part, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% probability of error level and had a CV of 7.1%. DAS = days after sowing.

Table 3. Evaluation of the severity of Septoria (Septoria glycines) at the bottom, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% probability of error level and had a CV of 12.01%. DAS = days after sowing.

Table 5. Evaluation of the severity of Cercospora (Cercospora spp.) at the bottom, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% probability of error level and had a CV of 5.84%. DAS = days after sowing.

Table 7. Evaluation of the severity of Cercospora (Cercospora spp.) in the middle third, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test with a 5% probability of error level and had a CV of 8.14%. DAS = days after sowing.

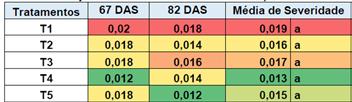

Table 9. Evaluation of the severity of Ring Spot (Corynespora cassiicola) at the bottom, carried out in the trial Efficiency of Protection Technologies in Disease Control in Soybean Crops in the 2021/2022 Harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% probability of error level and had a CV of 11.3%. DAS = days after sowing.

Table 10. Evaluation of the incidence of Ring Spot (Corynespora cassiicola) in the middle third, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test with a 5% probability of error level and had a CV of 9.58%. DAS = Days after sowing.

Table 12. Evaluation of the incidence of mildew (Peronospora manshurica) in the lower part, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test with a 5% probability of error level and had a CV of 4.49%. DAS = days after sowing.

Table 14. Evaluation of the incidence of mildew (Peronospora manshurica) in the middle third, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test with a 5% probability of error level and had a CV of 8.54%. DAS = Days after sowing.

Table 16. Evaluation of the incidence and severity of Asian rust (Phakopsora pachyrhizi) in the lower and middle third, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns do not differ statistically from each other according to the Tukey test with a 5% probability of error. DAS = days after sowing.

Table 11. Evaluation of the severity of Ring Spot (Corynespora cassiicola) in the middle third, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test with a 5% probability of error level and had a CV of 13.06%. DAS = days after sowing.

Table 13. Evaluation of the severity of mildew (Peronospora manshurica) at the bottom, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test with a 5% probability of error level and had a CV of 9.39%. DAS = days after sowing.

Table 15. Evaluation of the severity of mildew (Peronospora manshurica) in the middle third, carried out in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest, carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns did not differ statistically from each other according to the Tukey test at a 5% probability of error level and had a CV of 20.8%. DAS = days after sowing.

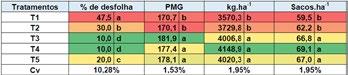

Table 17. Evaluation of defoliation in R6, thousand grain weight (PMG) and productivity (kg ha-1 and sacks ha-1) in the trial Efficiency of technologies for protection in disease control in soybean crops in the 2021/2022 harvest carried out by Cerrado Pesquisa e Soluções Agronômicas.

Means followed by the same lowercase letter in the columns do not differ statistically from each other according to the Tukey test with a 5% probability of error level.

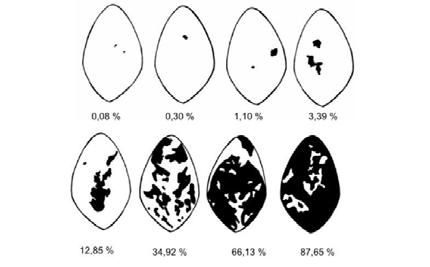

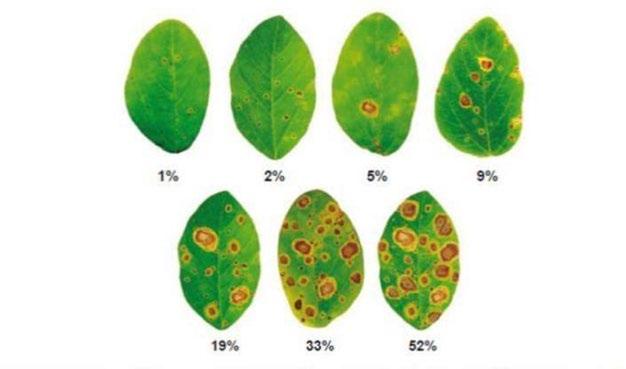

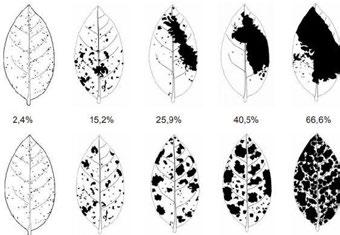

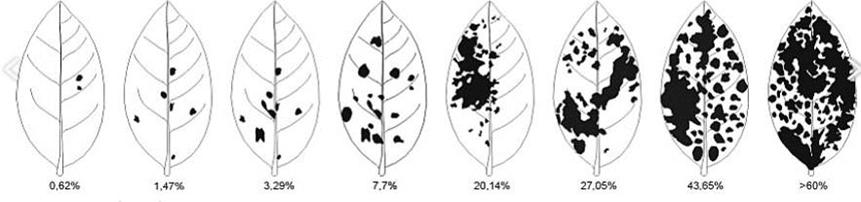

Image1. Diagrammatic scale for assessing the severity of downy mildew in soybeans caused by Peronospora manshurica. (Kowata et al. 2008).

Image 2. Diagrammatic scale for assessing the severity of ring spot in soybean caused by (Corynespora cassiicola). (Soares et al. 2009).

Image 3. Diagrammatic scale for assessing the severity of CFD in soybean caused by (Cercospora kikuchii and Septoria glycines). (Martins et al. 2004).

health than the use of the fungicide combined with only one of these protectants.

Ring spot is another major blotch in soybean crops, and this year it caused significant damage in our region. The importance of using protectant fungicides is even more evident for this disease, as, in both the lower and middle thirds, the management without protectants showed similar results to the control. On the other hand, treatments with protectants were once again more effective, with T4 standing out above the others, while the combination of Ultrazeb and Unizeb Gold fungicides showed no improvement in crop health.

The incidence of downy mildew (Peronospora manshurica) was observed only at 67 DAYS, and we see that the use of fungicides improved crop health. And since the first symptoms appeared near the end of the cycle, the protectant fungicides were not as exposed to the disease. With this, we can only say that a positive difference was noted in the treatments that used protectant fungicides. However, further studies are needed in this regard.

Finally, we have Asian rust, the main disease of soybean crops, which has already caused significant losses in our region. Currently, in areas with early-season crops planted at the beginning of the planting window, rust symptoms have only been observed at the end of the crop cycle, which often does not cause any loss in productivity.

This trial was no different, with the first symptoms observed at 82 DAYS, and treatment 4 was the most effective.

Regarding defoliation, PMG, and productivity, we again see the importance of protectant fungicides. Protectant treatments showed the lowest defoliation and the highest PMG and productivity values, standing out from the others and presenting a statistical difference. Among the protectant treatments, we see that treatment 4 was the most efficient.

As seen in Chart 1, this year we had high rainfall volumes

during the growing months, with an even distribution of rainfall, and no Indian summer season during this trial. It is common knowledge that mancozeb-based products, such as Unizeb Gold, have reduced efficacy in years like this because these products lack systemic action and are washed off the leaves. Despite this, the use of mancozeb was more effective than not using it, with positive responses in terms of health and productivity.

On the other hand, the combination of Ultrazeb and Unizeb Gold fungicides was no more effective than the use of fungicides in combination with

only one of these protectants. Therefore, further studies on the relationship between these products are required.

CONCLUSION

It was observed that the use of fungicides is essential for soybean cultivation, and that the use of protective fungicides is essential for better plant health. Furthermore, this combination, in addition to health benefits, also provides productivity benefits.

In this trial, it was observed that the use of Ultrazeb fungicides was the best alternative.

Image 4. Diagrammatic scale for assessing the severity of Asian soybean rust caused by (Phakopsora pachyrhizi). (Canteri and Godoy, 2003).

Image 5. Diagrammatic scale to assess the severity of powdery mildew in soybeans caused by (Microsphaera diffusa). (Canteri and Godoy, 2003).

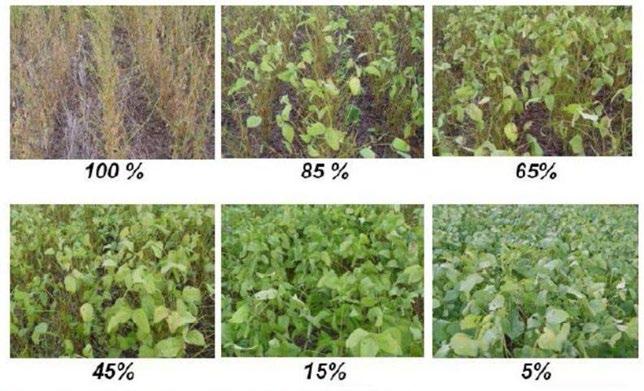

Image 6. Diagrammatic scale to evaluate soybean defoliation in R6. (Canteri et al. 2010).

The New Agronomists: The Value of Translating Data

The emergence of Artificial Intelligence (AI) and digital technologies has expanded the scope of action for agronomists. Today, the value lies not only in “knowing the field” but also in translating data from satellites, sensors, robots, or digital twins into decisions that improve profitability and sustainability.

Ing. Agr. Mariano Larrazabal.

Consultant in Digital Transformation and AgTech for the Agrifood Sector

The 21st-century agronomist is a translator between the soil and the algorithm. An integrator of traditional knowledge with computational intelligence. A leader capable of guiding producers through a process of constant innovation.

These professionals will be essential for bridging technical and agricultural knowledge with digital tools, leading the transformation toward more efficient and sustainable farming.

Below is a descriptive map with real examples of roles currently in demand by agrifood companies, research centers, and startups across Europe and the Americas.

Here are the profiles already sought after by global AgTech companies—what they actually do, real examples, and job offers published in 2025:

1. Agricultural Data Scientist

Role: Converts massive volumes of satellite imagery, IoT monitoring, and field logs into algorithms that predict yields, detect anomalies, optimize inputs, and model irrigation scenarios.

Skills: Python, R, geospatial libraries, machine learning, spatial statistics, big-data cloud platforms, plus the “agronomic interpretation” of data.

Market: Job portals list salaries from $50,000 to $120,000 annually, depending on experience and location.

2. Agricultural Computer Vision Engineer

Role: Designs and trains neural networks to recognize pests, weeds, or water stress from drone and tractor-mounted cameras.

Demand: Growing due to European precision agriculture projects and specific job

“The real value lies in mastering the four skills that turn data into profitable decisions for the field.”

postings like “Crop Computer Vision Engineer” on LinkedIn Jobs.

3. Digital Twin Engineer for Farms

Role: Integrates sensors, GIS, and 3D models to create virtual replicas of plots or greenhouses. Essential for simulating “what if” scenarios for irrigation or crop varieties before making field changes.

Example: Iowa State’s AI Institute for Resilient Agriculture updates digital twins of millet and corn with 80–90 million 3D points weekly to test hundreds of management scenarios.

4. Rural IoT Manager

Role: Manages networks of sensors (humidity, nutrients, weather) and connectivity gateways in low-coverage areas. Requires knowledge of LoRa/5G protocols, device maintenance in harsh environments, and cybersecurity.

Salary Trend: Companies like Semios or Amazon AWS offer over $180,000/year for “IoT Agriculture Manager” roles in North America, highlighting growing global demand.

5. Agronomic-AI Analyst

Role: A bridge profile that interprets dashboards from data scientists, translates insights into crop plans, and validates them in the field. Requires understanding predictive models, agronomic calendars, and farm economics.

Value: Translates complex metrics into operational lan-

guage and measures the economic return of each recommendation. (Emerging role; no specific listings yet but supported by previous profile demands.)

6. Blockchain & Food Traceability Specialist

Role: Designs “digital passports” tracking each lot from planting to retail shelves, complying with BRCGS, IFS standards, and retailers’ ESG requirements. Manages smart contracts and food safety regulations.

Market: The agro-blockchain market is growing at a 41.9% CAGR, expected to rise from $509M (2025) to $8.4B (2033), driving demand for specialists in smart contracts and food regulations.

7. Climate-IA Technician / Climate-Risk Analyst

Role: Combines weather models, generative AI, and historical data to anticipate climate impacts at field or supply chain level (water, heatwaves, frost).

Reference Platform: ClimateLens™ provides 1 km resolution forecasts and manages alerts in over 1,000 locations; jobs prioritize agronomists skilled in machine learning and climate statistics.

8. Agricultural AI Governance & Ethics Manager

Role: Regulatory-driven role: The EU AI Act (effective August 2024) requires model inventories, risk classifications, and thorough documenta-

tion. Agribusiness SMEs need professionals to lead audits, transparency efforts, and internal training.

9. Field Robotics Automation Engineer

Role: Integrates computer vision, LiDAR, and autonomous navigation into harvesters, sprayers, or nut tree shakers.

Demand Indicator: Bonsai Robotics raised $15M in January 2025 to scale autonomous machines that halve labor in almond and pistachio farms.

10. Digital Agronomist / Precision Agriculture Specialist

Role: Combines drone, IoT sensor, and predictive model data to design irrigation, fertilization, and management prescriptions.

Example: Nitrogen dosage adjustment plot by plot in a vineyard using NDVI maps and recommendation algorithms.

Jobs: Multiple Digital Agronomist postings in the U.S. and Europe with salaries ranging $37,000–$240,000/year (ZipRecruiter).

11. Remote Sensing & Geospatial Agronomist

Role: Processes satellite/LiDAR imagery and produces spatial analyses for agricultural insurers, banks, or large farms.

Example: Early detection of soybean wilting with Sentinel-2 and automated field alerts.

Jobs: Geospatial Analyst (remote) – New Light Technologies.

12. IoT Smart-Farming Solutions Architect

Role: Designs sensor networks, gateways, and cloud platforms that feed agronomic recommendation algorithms.

Example: Soil moisture monitoring system at 5 cm and 30 cm depths with app alerts for citrus farms in Valencia.

Jobs: Customer Success Lead at Orchard Robotics (San Francisco, hybrid).

13. Field Robotics Engineer / Robot Implementation Specialist

Role: Calibrates and supports adoption of autonomous weeding, spraying, or harvesting robots.

Example: Deploying SwarmFarm platforms for wheat in

Queensland, cutting tractor hours by 60%.

Jobs: Field Engineer – Agricultural Robotics Internship 2025 at Climatebase; SwarmFarm Robotics expansion creating dozens of technical roles.

14. Digital-Twin & Crop Simulation Specialist

Role: Builds digital twins of crops or greenhouses replicating real-time physiological and environmental variables.

Example: Simulating water stress in tomatoes within a digital twin to optimize ventilation and irrigation.

Jobs: Doctoral projects and technical positions at AI & Cyber Futures Institute (Australia) and U.S. universities.

15. Carbon & Sustainability Data Analyst

Role: Models emissions, car-

bon sequestration, and generates reports for credit programs or ESG compliance.

Example: Ex-ante CO₂-eq calculation for a 4,000-ha regenerative soybean project in Paraguay.

Jobs: Data Analyst/Environmental Scientist at Regrow Ag (remote); GHG Quantification Specialist at Terra Global Capital.

16. AI Product Manager –AgTech

Role: Oversees AI product lifecycles (from discovery with farmers to delivery with dev and data science teams).

Example: Launching a hybrid maize recommendation model based on microclimates.

Jobs: 40+ AgTech Product Manager roles in the U.S. with salaries $89,000–$149,000/ year (Glassdoor).

17. Plant Phenotyping AI Analyst

Role: Captures hyperspectral or 3D images and trains AI to quantify traits like biomass or leaf area.

Example: Classifying heat stress in experimental wheat using computer vision models.

Jobs: Postdoctoral researcher in plant phenomics (ETH Zurich, Univ. of Sydney) and phenomics technician roles in the U.S.

18. AgTech Adoption / Customer Success Lead

Role: Bridges technology developers and farmers; provides training, measures ROI, and ensures service renewal.

Example: Implementing vision-camera systems for apple counting in Washington State.

Jobs: Customer Success

Lead – Orchard Robotics (hybrid).

Far from becoming obsolete, the agronomist is transform-

ing into a field data architect:

• Dataset curator: Ensures accuracy and representativeness of samples.

• Tech translator: Explains to farmers why an algorithm recommends 12% less nitrogen.

• Workflow designer: Integrates robots with human labor.

• ESG manager: Uses AI and digital twins to quantify CO₂ and water usage for auditors.

AI frees up agronomists’ time to focus on strategic decisions and high-value margins (new crops, diversification, carbon markets).

Agronomist 4.0 in the AI Era

Today, having “AI” on your business card isn’t enough— the true value lies in mastering the four competencies that turn data into profitable farm decisions:

1. Data literacy: Beyond Excel—cleaning, merging, and

contextualizing agronomic, climatic, and economic data to detect patterns previously unnoticed.

2. Platform management: From agricultural CRMs that centralize field histories to APIs for digital twins simulating the next season, agronomists must orchestrate diverse tools into a unified, actionable view.

3. Interdisciplinary work: Success requires speaking the language of developers, business analysts, and European regulators; coordinating field trials, validating models, and integrating compliance without stalling innovation.

4. Continuous learning: With algorithms evolving monthly, competitive advantage comes from rapid learning— from generative AI simplifying CAP processes to new sensor architectures expanding crop coverage.

Agronomists will be key not just in the field, but in designing future technologies. Their role will be decisive in ensur-

ing AI is not only efficient but also fair, sustainable, and adapted to real-world farming needs.

Collectively, these skills make agronomists the link that translates data science into effective, sustainable agricultural practices.

Key Competencies Adding Value:

• Data Science & Python: Data cleaning, AutoML, visualization.

• Geomatics: QGIS, Google Earth Engine, index interpretation.

• IoT Connectivity: LoRa/ NB-IoT protocols, edge computing.

• Robotics & Mechatronics: ROS, actuator control, LiDAR.

• Sustainability & ESG: GHG Protocol methodologies, ISO 14064.

• Soft skills: Data storytelling, multidisciplinary leadership, change management.

Final Thoughts

Artificial Intelligence has stopped being a promise and has become the driving force redefining agricultural production. When adopted wisely, it simultaneously boosts productivity, sustainability, and profitability—ensuring the sector not only survives new challenges but thrives.

Rather than replacing agronomists, AI expands their role. The professional capable of connecting crop physiology with algorithmic models will stand out in a context demanding “more production with fewer resources.”

Hybrid profiles—Agricultural Data Scientist, Computer Vision Engineer, Digital Agronomist—become the bridge that translates technological

complexity into tangible, onfield decisions.

Agronomy has always balanced soil, plants, climate, and market forces. Today, we add a fifth pillar: data. Used correctly, data reveals invisible patterns and enables precise risk anticipation, essential for managing ever-narrower margins.

As an AgTech consultant, I see this evolution as a unique opportunity: to honor our agronomic roots while bringing field science into the digital age—without losing sight of our fundamental mission: feeding the world fairly and sustainably.

Those who embrace these new career paths will not be abandoning their vocation but projecting it into the future.

Spraytec

SNAPSHOTS

The technology that is sweeping the world Spraytec®, more than 300 million hectares treated.