EDITORIAL Family

From Rosario to the world, we have conquered lands, producers, advisors, managers, and estate managers. Spraytec Global went from being a dream to becoming a reality. What we once projected as a corporate achievement is being reflected in the day-today operations of the company, not only in Argentina but worldwide.

When you are young, you have the ambition to grow, to win, to discover, to create, to expand; you think and dream it from the heart, knowing that you are capable of achieving it. But perhaps what you may not know is that it is impossible to do it alone. We all need the support of a group of people who dream and push the cart in the same direction, and thus, those people become the work family.

That is the most valuable thing we achieve in Spraytec: being a family, the Spraytec Global family, where no matter how far apart we are, each and every one of us is united by this passion, that of being SG. For this, thank you to each one of you for being part of it! Everything we have achieved would be impossible without you!

In this April edition, we will get to know Valladolid, Spain, where we are based. In addition, the identikit is to Lucas Gómez, Global Industrial Manager.

From Kazakhstan, we interviewed Adilzhan, an agricultural producer and Spraytec distributor. He shares details of the company in that part of the world, its beginnings, and the incorporation of Spraytec into the palette of offerings in the Kazakh market.

In Argentina, two new developments: on one hand, the Spraytec Business School began, a 9-month training project at no cost to the students, launched in the second half of March in Rosario; on the other hand, the new Spraytec Argentina production plant was inaugurated in the city of Roldán, Santa Fe. This project aimed to meet local and international demand. All the details are in these pages.

As for research, from Australia, we will read about weed control using Fulltec and Fulltec Max.

And as always, snapshots, reports, and news.

See you in the next edition!

Diego Parodi Presidente de Spraytec02

Editorial

Family

By: Diego Parodi

04

Identikit

Lucas Gómez

06

Research

Summer weed control (afghani melon) using Fulltec and Fulltec Max adjuvants in herbicide mixtures

By: Living Farm

12

Interview with Adilzhan

A kasajo in Argentina

By: Juan Carlos GrasaProducción General:

Horizonte A ediciones

16

Report

Cider: tradition, simplicity and timelessness

By: Lic. Nuala Szler

22

Territorial roots

Valladolid

24

Launching

Business School- Spraytec Argentina

26

Report

New plant in Argentina

30

Snapshots

LUCAS GÓMEZ

IDENTIKIT

1. What is your profession and position in the company?

Agronomist Engineer, Global Industrial Manager.

2. Did your experience at Expoagro provide you with tools for what you do today?

Yes, of course, Expoagro always leaves you with many good things, and undoubtedly human relationships are the most valuable tools.

3. How do you imagine your life in 10 years?

A difficult question for me, but I hope to be at home, working, and enjoying my family.

4. The best reason to smile?

Being alive, everything else comes after.

5. A life reference?

My parents, La chela, and El Kelo.

6. If you were an animal, what would you be?

I think a dog or a horse.

7. An Argentine pride?

Oh, undoubtedly many, but René Favaloro would be my favorite.

8. Of technological advances, which one surprised you the most?

Without a doubt, the Internet.

9. If you could time travel, who would you like to meet?

Steve Jobs!!!!

10. Something everyone should have?

A willingness to work.

11. Of the places you know, which one would you return to?

To Argentina, without a doubt, a unique and incomparable place.

12. Who is Lucas Gómez?

An honest, hardworking, and low-profile person.

If you had to organize an expedition to a deserted island with Spraytec colleagues, who would you take knowing

they would face extreme situations?

For managing supplies?

Lea Acosta, no doubt she can get water from rocks.

For carrying things?

Regardless of where I am, the industry team can assemble anything with a pair of pliers and a screwdriver, whether in Brazil, Argentina, or the USA.

For cooking?

Gabi Selbestrelli in Argentina and Thiago in Brazil, the best grillers or “churrasqueros” as they say in Brazil.

For bringing calm in difficult times?

Leo Torres, with his characteristic calmness.

For coordinating the group?

This one is tricky... but definitely it could be German Ricci.

For ensuring a good return?

Mariano Meineri, designated driver.

GÓMEZ

Identikit

CONTROL OF SUMMER WEEDS

USING FULLTEC AND FULLTEC MAX ADDITIVES TO HERBICIDE MIXTURES

Por: Living Farm

Abstract

A trial near Meckering, Western Australia, compared Fulltec and Fulltec Max with Uptake Spraying Oil as additives in the summer knockdown mixture of Roundup Ultra Max + 2,4-D Ester + Garlon Fallowmaster. The target species in this trial was

Afghan melon (Citrillus lanatus) at BBCH14 – BBCH16.

The herbicide mixture was applied at 3 rates (1.0x, 0.75x or 0.5x), with the 1.0x rate of Roundup Ultra Max (1000 mL/ ha) + 2,4-D Ester (600 mL/ha) + Garlon Fallowmaster (100 mL/ ha). Each herbicide mixture received an additive of Fulltec or Fulltec Max at 0.1 %v/v or 0.2 %v/v, with Uptake Spraying Oil

added at either 0.5 %v/v or 1.0 %v/v.

All treatments gave greater than 90% control of Afghan melon compared to the untreated control. Both Fulltec and Fulltec Max mixtures tended to show increased speed of burndown compared to Uptake Spraying Oil, however this increase was not always significant. Although no significant

WEEDS (AFGHAN MELON)

difference in control was observed between mixtures with Fulltec or Fulltec Max, the 0.2 %v/v additive rate consistently indicated higher control of Afghan melon compared the 0.1 %v/v additive rate.

Aims

1. Determine efficacy of Fulltec and Fulltec Max in herbicide mixtures for summer weed control.

Assessment Data Scoring Systems

Abbreviations used:

DAA Days After Application

BBCH Biologische Bundesanstalt, Bundessortenamt und CHemische Industrie growth stages

Percent Control:

A visual subjective percentage (%) score was given to each plot based on the percentage of weed control as compared to untreated control plots, where 0 = no observed control and 100 = total weed control.

Photographs

Photographs were taken of representative plants within each plot 14 and 21 days after application.

Example photographs of Afghan melons prior to application were also taken. See Appendix 1: Trial Photographs for full display.

Data Analysis

All data analysis in this report was conducted using ARM (Agriculture Research Manager). An analysis of variance was used to determine statistical significance using the least significant difference method at 95% confidence level. Where required, missing data was accounted for using Yates least square estimation.

Significance is represented by letters assigned to each mean. No letters are presented where significance was not detected at 95% confidence.

Data transformation was conducted where the ANOVA assumption of homogeneity of error terms was not met. Details of specific transformations are given in table footnotes. Means presented are back- transformed; l.s.d’s are not presented in these cases.

Discussion

The trial was conducted 15 km south of Meckering, Western Australia, to evaluate the influence of Fulltec and Fulltec Max on the effectiveness of summer weed control herbicide mixtures. The target species in this trial was Afghan melon (Citrillus lanatus) with the majority of plants in BBCH14 - BBCH16.

A typical summer weed control mixture of Roundup Ultramax (580 g a.i./L) + 2,4-D Ester (680 g a.i./L) + Garlon (755 g a.i./L) was applied to all plots, excluding the untreated control, at

Trial Design/Randomization

Experimental design

Site details

Experimental Application Details

Control

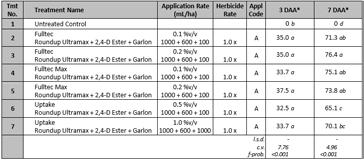

Table 1

Afghan melon control (%) at 3 and 7 DAA.

*Data presented as back-transformed means (square root of the arcsine).

Table 2

Afghan melon control (%) at 15 and 22 DAA.

*Data presented as back-transformed means (square root of the arcsine).

Table 3

Afghan melon control (%) at 3 and 7 DAA (1.0x rates only) compared to untreated control.

*Data presented as back-transformed means (square root of the arcsine).

Table 4

Afghan melon control (%) at 3 and 7 DAA (1.0x rates only) compared to untreated control.

*Data presented as back-transformed means (square root of the arcsine).

Table 5

Afghan melon control (%) at 3 and 7 DAA (0.75x rates only) compared to untreated control.

*Data presented as back-transformed means (square root of the arcsine).

Table 6

Afghan melon control (%) at 15 and 22 DAA (0.75x rates only) compared to untreated control.

*Data presented as back-transformed means (square root of the arcsine).

*Data presented as back-transformed means (square root of the arcsine).

*Data presented as back-transformed

rates of 1.0x, 0.75x and 0.5x. The 1.0x application rate was Roundup Ultramax (1000 mL/ ha) + 2,4-D Ester (600 mL/ha) + Garlon (100 mL/ha), and each mixture received an adjuvant of Fulltec, Fulltec Max or Oil of Spray Uptake at one of two rates. Afghan melons germinated after receiving 30 mm of rain from February 26 to 29, followed by 12 mm of rain 9 days before treatment application.

All treatments gave more than 90% final control of Afghan melon compared to the untreated control. As expected, a significant reduction in con-

trol was recorded in response to decreased application rates of the Roundup + 2,4-D Ester + Garlon mixtures. Overall, all 1.0x and 0.75x rates gave near 100% final control of Afghan melon at 22 DAA, compared to approximately 95% control in response to the 0.5x rates (Table 1, Table 2 ).

Although not always significant, the 1.0x and 0.75x herbicide mixtures with Fulltec and Fulltec Max additives tended to show greater 7 DAA removal compared to Uptake Spray Oil (Table 1). Analysis of variance performed on subsets of appli-

All treatments provided greater than 90% control of Afghan melon compared to the untreated control.

cation rates (e.g., treatment 2 - treatment 7) compared to the untreated control, showed a significant increase in the control 7 DAA in response to both Fulltec (0.1%v/v) as to Fulltec Max (0.1%v/v) compared to Uptake Spray Oil (0.5%v/v) (Table 3). No significant difference was observed in the final control, suggesting a higher removal rate in response to both Fulltec and Fulltec Max.

The adjuvant rate of 0.2%v/v of both Fulltec and Fulltec Max consistently contributed to greater control of Afghan melon compared to 0.1%v/v, however, this difference was not always significant. These trends were most evident at 7 DAA and 15 DAA during the most rapid clearance period. Additionally, a significant difference was observed between the application rates of Fulltec and Fulltec Max in the 0.5x 15 DAA herbicide mixture (Table 8), suggesting higher herbicide uptake at 0.2%v/v compared to 0.1%. v/v.

Overall, both Fulltec and Fulltec Max contributed to equivalent

or increased removal of Afghan melon in this trial compared to Uptake Spray Oil. This suggests that both adjuvants are a viable alternative to existing spray adjuvants for use in summer spraying of Afghan melons in Western Australia.

Conclusions

In this essay:

• All treatments provided greater than 90% control of Afghan melon compared to the untreated control.

• Although not always significant, Fulltec and Fulltec Max consistently showed a higher removal rate compared to the industry standard adjuvant, Uptake Spray Oil.

• Fulltec and Fulltec Max (0.2%v/v) consistently showed greater control of Afghan melon compared to the lower application rate of 0.1%v/v.

There was no significant difference between Fulltec or Fulltec Max at 22 DAA.

A Kazakh in Argentina

Juan Carlos Grasa Director of HorizonteAYou are a great representative of Spraytec in Kazakhstan. Tell us a little about your farmer profile and that of your company.

The company ABN Tecnologías was founded in 2014, with ABN representing agricultural business, science, and technology. We distribute agricultural technologies in Kazakhstan, including well-known brands like Great Plains from the United States, products from various Argentine companies, as well as fertilizers and biological products. Our key business partner is Spraytec.

How was the first contact with Spraytec’s products in Kazakhstan and specifically in your field?

Due to our productive traditions, climatic conditions, and the characteristics of our

We interviewed Adilzhan, an agricultural producer and distributor for Spraytec. He shares with us details about the company in that part of the world, their beginnings, and Spraytec’s incorporation into the range of offerings in the Kazakh market. Producing sustainably with the best technology is possible in many places around the world.

work organization, we were unable to carry out field production processes on time, but thanks to Spraytec and its products, we have been able to solve this issue. The interesting thing is that we had been using effective adjuvants from Spain, and my father, who is the main agronomist of our business, was quite satisfied with them. However, after using FULLTEC, we stopped using the Spanish products and opted for Spraytec’s.

What was the reason for the change?

With the competitor’s product from Spain, we had to double

the recommended dosage to get the performance expectations of agrochemicals. In contrast, the effect received after applying FULLTEC at the recommended dosage was much better.

Knowing that your father is the primary technologist of the company, which is a family-run business with family-owned fields, considering the challenges crops face in Kazakhstan, how do Spraytec products contribute to effective agronomy practices?

When I first saw this prod-

“I am very impressed with this nation”

uct, I couldn’t believe it! It seemed like it was made just for our fields. It helps us use less water per hectare during applications, which boosts productivity. This is super important in Kazakhstan because we have huge areas to cover, and time is limited for application.

Productivity is very important to us. Furthermore, with the help of FULLTEC, by achieving greater effectiveness, we were able to reduce pesticide doses to the minimum recommended and be more efficient.

What’s the dynamic like concerning the available water for crops there in Kazakhstan?

There is very little water in Kazakhstan, and strong winds make it even harder to manage. Spraytec, especially FULLTEC, is unique because it works well even in windy conditions, keeping the droplets from evaporating and reaching the plants. It is a lifesaver for us, especially with the rising temperatures every year.

Being stress-relieving, anti-evaporative, pH corrector, and water conditioner, results very beneficial for our conditions.

Considering that your father is a recognized professional in the scientific activity of Kazakhstan and the first client they had to convince - the most difficult one - Could you tell us a nice story?

Of course! When I told him that I wanted to buy a

product, which was

fective and solved almost

problems at the same

and was also very

he didn’t believe

him we could sell it, but

use it in the family company, because we already

a product from Spain

worked well.

I convinced him to try

he chose the most

ing conditions for FULLTEC, using it in the sorghum

Sorghum is a plant

stressed very quickly

agricultural conditions,

ing it the ideal candidate

test this stress-relief

If it is a good penetrant and helps herbicides in their effectiveness, we will apply it where the Sorghum is most affected by weeds. And if you really think it prevents evaporation, we will reduce the amount of spray to apply by half. That’s how we tested it.

And how does the story end?

Then my father asked me who Javier was and told me to bring him here because there was no stress in the Sorghum and all the weeds were under control. We also minimized the amount of herbicides. And when Javier came to my house, my father gave him a big hug because he couldn’t believe what we had done in the field with his favorite crop. He showed him the worst conditions, and FULLTEC worked! That’s how he immediately adopted it.

What is the most difficult

“I think that our level of adoption has to improve a lot so that we get closer to the level of Argentine producers”

thing about customers and the market in Kazakhstan?

I think what we offer in the Kazakh market is something that many do not understand. Some accept it as a pH corrector; others accept it as a penetrant; others accept it as an adjuvant. They are not

“Spraytec is key to our business”

used to a product with so much technology combined.

Speaking now about this trip to Argentina, specifically your visit to Expoagro, what impression do you have of this country regarding agricultural technology?

I think that Expoagro is one of the best exhibitions I have visited worldwide. Regarding technology, I think our level of adoption needs to improve significantly for us to approach the level of Argentine producers – we should study more in depth the technologies used here in Argentina.

Have you had the opportunity to visit Argentine producers in the field?

Yes, there is a major trend here regarding the promotion of no-till farming, with institutions such as INTA, AAPRESID, etc. We have visited INTA and Jorge Romagnoli, a producer who belongs to AAPRESID. It is great to see farmers who have been practicing technology for decades, unlike in Kazakhstan, where it’s only been for years. We knew that Argentina is one of the leaders in agricultural technologies, but when I arrived here - not just me, but the entire delegation - we were very impressed. In the agricultural lands under irrigation in Kazakhstan,

we have 2 to 3 times lower yields than here, but thanks to the technologies here, they achieve this without irrigation.

Do you think that science and research in Argentina are much more advanced than in Kazakhstan?

Kazakhstan has a lot to learn. They pioneered no-till farming because we visited INTA, we visited Jorge Romagnoli from AAPRESID on his farm. The delegation was very surprised by everything they saw and by the advances in productivity and sustainability.

Although it’s not your first time in Argentina, it was your first time at Expoagro. What impression do you take away from our country?

It’s a prosperous nation that always seeks to evolve, to adopt available technology, and to create it if necessary to contribute to solving different problems that arise in the day-to-day of agriculture. They are pioneers in No-Till farming, and that is something the whole world is adopting. Expoagro is clear evidence that Argentine agriculture is a great engine of work, passion, and knowledge. I am very impressed with this nation.

Thank you, Adilzhan!

Cider: tradition, simplicity, and timelessness

By: Lic. Nuala SzlerThe history of cider is as long as it is fascinating. Although its origin is not entirely certain, ancient records account for its early forms of production and consumption. In those early instances, its production was associated with the particular consumption of each producer. It was only in the 18th century that it began to be industrially produced and, from that moment on, commercialized and even used as a commodity for exchange.

Since when do we toast with cider?

Historians point out that cider originated in the civilizations of Ancient Egypt and Classical Greece. In fact, “cider” comes from the word sicra, which is a Latin translation of the Greek word sikera. However, although research tells us that Hebrews, Egyptians, and Greeks were already familiar this drink, it seems that the Arabs were the ones who developed advanced agricultural systems, cultivated all

kinds of apples, and worked to make cider production processes increasingly efficient.

In the Iberian Peninsula, some references from Pliny the Elder about apples suggest that cider already existed in the region of Asturias before the Roman invasion. The Asturian region was one of the first to put its touch on the drink, leaving for posterity a more acidic and bubbly cider.

In France, more specifically in the region of Normandy, cider has also been produced for centuries. There are also records from the United Kingdom, where regions like Somerset, Herefordshire, and Devon produced this beverage under the name of cider. Nowadays, this fermented beverage enjoys great tradition in different regions of Europe such as Spain, Portugal, France, Italy, Germany, and the United Kingdom.

Indeed, this journey shows us that it was the Spaniards and Italians who, inheriting the Roman tradition, exported it centuries later to Latin

America. England, on the other hand, brought cider to the United States, thus tracing a process of convergence and global commercialization. However, a curious and not insignificant fact is that the manufacturing method has not changed much.

Cider: manufacturing and variety

Cider is a beverage obtained from the alcoholic fermentation of fresh apple juice. In certain cases, juices from other fruits, such as pear, are also added. The manufacturing process, as mentioned, embodies history, tradition, and simplicity.

To obtain cider, high-quality and flavorful apples are first selected, based on their maturity and sugar concentration. Then, they are washed to remove excess dust and dirt, and subsequently, the apples are crushed. This results in a juicy pulp that is then carefully pressed to avoid oxidation. The juice obtained may then be treated with very low doses of sulfites and enzymes to

help achieve a clear product. Finally, it is left to rest.

Approximately two days later, racking is performed, stimulating the onset of alcoholic fermentation. After six days of fermentation by yeast, malolactic fermentation begins, where bacteria transform malic acid into lactic acid, giving the product more smoothness. During these processes, temperature must be controlled and maintained between 14° and 15°C.

Also, once again, it is necessary to inspect the density of the must and the tank fillings to prevent oxidation. Then, new rackings are performed (as many as the manufacturer considers appropriate for their product), and the liquid is separated from any solid residues that may still exist through filtration. Finally, carbon dioxide is added, either naturally or artificially, thus obtaining the delicious apple cider.

Today, to obtain each variety of cider, a selection of different apple varieties is made, each contributing its characteristic flavor. Thus, for example, natural cider is obtained, another type of this beverage that, like wines, is

consumed without carbonation. But sparkling ciders are also available, whose carbonation process can be artificial, through an industrial system, or natural, through the same bottle fermentation. The latter, however, involves a more complex and costly production method.

The particularity of natural cider is that it retains its organoleptic properties intact for a short period of time and, in that sense, must be consumed quickly. It is an unstabilized product, which degrades easily due to, primarily, a loss of carbon dioxide formed during the initial fermentation. In fact, it was this particularity that, in the mid19th century, led producers to create sparkling or champagne cider, to which carbon dioxide was added.

We see some of the main varieties of cider:

- Traditional natural cider: in this case, maximum care is taken to make the production process as sustainable as possible, from the cultivation of the apple tree to its bottling, to obtain a high-quality product. No sugars or any type of carbonation are added. This type of cider usually has a minimum alcohol content of 5% and when served, it requires pouring from a height.

- Sparkling natural cider or champagne cider: as the name suggests, this type of cider is characterized by being more effervescent than artisanal natural cider. Like the previous case, it falls under the category of natural ciders and is distinguished by its high quality. Its alcohol content is usually slightly

higher, around 5.5%, since its carbon dioxide is a product of the fermentation process.

- Table cider or new expression: This is one of the most well-known varieties of cider, obtained from select groups of apples. Table cider undergoes filtration and stabilization processes to offer a more homogeneous flavor. It is distinguished from other varieties by not requiring pouring from a height.

- Flavored cider: This is the variety of cider commonly commercialized, encompassing those ciders that result from a fermentation process of natural apple must and, unlike natural cider, usually contains added sugars and a variety of different flavors. Its alcohol content is approximately 4%.

- Sweet cider: This variety is possibly the origin of cider as such, and from which the remaining varieties later emerged. Sweet cider is simple to make, does not undergo any fermentation process, and its only treatment consists of squeezing the apple immediately after harvesting. This achieves the intense flavor of the apple and its typical sweetness.

- Ice cider: This is one of the lesser-known varieties, but one of the most exquisite. It originates in Canada, where low temperatures facilitate the alcoholic fermentation of frozen and pressed apples, and also allow for the concentration of sugars. In this case, the alcohol content is significantly higher.

- Non-alcoholic cider: This is called “cider for children.” It is sparkling natural cider that

retains the traditional flavor but does not include alcohol.

- Organic cider: In this case, cider is obtained through a sustainable and responsible production process. Each stage, from apple harvesting to bottling, is carried out under rigorous control to avoid any harmful environmental footprint.

The boom of craft cider

Craft cider has become the ideal alternative for those who enjoy a refreshing, fizzy, not-too-sweet beverage made from fruits. In recent times, if one thing has become clear, it’s that cider is no longer just consumed during the holiday season (Christmas and New Year’s). Any occasion can be well accompanied by this amber-colored drink. Even more so when, no matter how small, there is a reason to celebrate and toast.

The craft cider production is a growing market in Argentina and around the world, driven by the common desire of small and medium-sized producers to create a product

that people can find and enjoy at any time of the year, on any occasion. In other words, by the desire to make this beverage a popular option in everyday life, to revalue its consumption, and why not? Make it a protagonist.

It is also a commitment to traditional cider: cider made from natural juice of organic apples (without pesticides and chemicals), instead of an artificial alternative, free from flavorings, colorings, and excessive sugars. The craft cider making process takes around 45 days: first, the apples are selected, washed, and crushed. Then, as they are, they are placed in a press to extract the must, and it is decanted to separate solids from liquids. From there, it goes to the fermentation process, where tannins, pH, and sweetness are analyzed and yeast is added. It is left to rest in containers, usually stainless steel, and finally, it is bottled, sealed, and packaged for sale.

Cheers!

Cider is synonymous with gathering and ritual, celebra-

tion and gratitude, promises and hopes for the future. In Asturias, for example, it is served by pouring it from a height (pouring it into the glass after raising the bottle above the head to activate the carbonation) and it is consumed in a quick, long sip. Then, the remainder must be poured onto the ground, as a symbolic gesture of returning to the earth a part of what it has provided us.

But, not only in Argentina and Spain is this beverage wrapped in symbolism. France and England are also major cider-producing and consuming countries. French cider, in fact, stands out for being a sweeter and fizzier cider made from apples and pears. As mentioned, the taste for cider in Latin America arrives and expands, primarily through the influence of Spanish and Italian immigrants during the early decades of the 20th century. With this, its special reserve for the main festivities of the year and the ritual of toasting was also sealed.

Today, from the most artisanal cider variety to the most innovative variety (like the new cider in a can!), this beverage continues to demonstrate how, even on the most important occasions, the simplest recipes are the most delicious and special. During these festivities, cider may possibly not be missing from the table. Tradition still reigns, even in the present times where consumption changes rapidly.

Cheers!

TERRITORIAL ROOTS

VALLADOLID

Located in the heart of Spain, Valladolid emerges as a treasure that enchants both visitors and locals alike. With a rich and diverse history, this city has witnessed countless events that have left an indelible mark on its landscape and its people.

History

The origins of Valladolid date back to the pre-Roman era when it was inhabited by Celtic and Vetton peoples. However, its true peak period came during the Middle Ages when it became an important commercial and cultural enclave of the Kingdom of Castile. For centuries, Valladolid was the seat of the Spanish court and the birthplace of many kings and queens, including Isabella the Catholic and Philip II.

The 16th century was especially significant for the city as it witnessed the splendor of the Spanish Renaissance. Majestic architecture, such as the Casa de Cervantes and the University of Valladolid, attest to this golden age. However, Valladolid also endured periods of decline, such as during the War of the Spanish Succession and the War of Independence, where the city was the scene of battles and suffering.

In more recent times, Valladolid has experienced a cultural and economic revitalization, becoming an industrial and service center. However, its

rich history remains palpable in every corner of the city, attracting tourists eager to explore its fascinating monuments and museums.

Cuisine

Valladolid cuisine is a celebration of authentic flavors and culinary traditions of the region. Local cuisine is characterized by its simplicity and focus on fresh, quality ingredients. Among the most emblematic dishes are:

Roast Suckling Lamb: Considered one of the most exquisite delicacies of the region, roast suckling lamb is prepared with suckling lamb, slowly roasted in a wood-fired oven until it reaches a tender texture and incomparable flavor.

Castilian Soup: Comforting and delicious, Castilian soup is a traditional soup made with bread, garlic, paprika, and eggs, perfect for the cold winters of the Spanish plateau.

Villalón Cheese: Cheese lovers must try Villalón cheese, a semi-cured cheese made with sheep’s milk and with a

unique and distinctive flavor.

Culture

Valladolid is a hub of cultural activity, with a wide range of events and festivals that attract artists and spectators from around the world. The International Festival of Theater and Street Arts, known as TAC, is one of the city’s most prominent events on the cultural calendar, transforming its streets and squares into improvised stages for theater, dance, and music.

Additionally, Valladolid boasts a vibrant artistic and musical scene, with numerous museums, galleries, and concert halls offering a fascinating glimpse into local and global creativity. The National Museum of Sculpture, located in the former College of San Gregorio, houses an impressive collection of Renaissance and Baroque sculptures, while the Miguel Delibes Cultural Center is the perfect venue to enjoy classical and contemporary music concerts.

Concha Velasco. Spanish actress born on November 29, 1939, in Valladolid, Spain. She has had an extensive and successful career in film, theater, and television. Known for her versatility as an actress, she has played a wide range of roles from comedy to drama. Velasco has received numerous awards and accolades

throughout her career for her talent and contribution to the entertainment industry in Spain. She is an iconic figure in the Spanish entertainment industry.

José Zorrilla. Renowned poet and playwright of the 19th century, especially known for his work “Don Juan Tenorio”. His contributions to Spanish theater have made him an emblematic figure both in Valladolid and throughout Spain.

As a noteworthy fact, in the city of Valladolid, Miguel de Cervantes obtained royal privilege to print the first part of Don Quixote of La Mancha.

Agriculture and Agribusiness

The fertility of its soil, combined with a favorable climate, has turned the city into a hub for agriculture and agribusiness on the Iberian Peninsula. From vineyards to cereal fields, the agricultural diversity of the region has been key to its economic and social development.

The Land of Vineyards

Its vineyards produce some of the most recognized wines nationally and internationally. The Ribera del Duero Designation of Origin covers much of the province, known for its high-quality red wines. Iconic wineries such as Vega Sicilia, Protos, and Emilio Moro have elevated the name of Valladolid to the top of the wine world.

They are not only a source of renowned wine but also of employment and tourism. The culture of wine tourism has flourished in the region, attracting wine enthusiasts and experts from around the world. Additionally, the wine industry provides employment to thousands of people in cultivation, harvesting, production, and wine-related tourism, thus contributing to the economic and social fabric of the region.

Wheat Cultivation

Wheat is one of the main crops in this area. Farmers grow various varieties of wheat, which are used both for the production of staple foods and for the manufacturing of processed products. The quality of wheat produced in the province is recognized both nationally and internationally.

Barley Production

Barley is primarily used in livestock feed production, but it is also used in the brewing of beer and other food products. The high-quality barley cultivated in the province is appreciated for its flavor and nutritional properties.

Oats and Corn

Oats are mainly used as livestock feed, while corn is used for both human and animal consumption. These crops complement the agricultural diversity of the province and contribute to its sustainability.

Technological Innovation

Agriculture in Valladolid is not limited only to vineyards; the province is also a leader in the adoption of advanced agricultural technologies. Precision agriculture, which uses geographic information systems (GIS), remote sensing, drones, and state-of-the-art agricultural machinery, has revolutionized the way land is cultivated in Valladolid.

Valladolid farmers have embraced these technologies to optimize the use of resources such as water and fertilizers, thus increasing efficiency and reducing the environmental impact of agriculture. Additionally, the digitization and automation of agricultural processes have improved the productivity and profitability of farms, keeping Valladolid at the forefront of modern agriculture.

The Agri-Food Sector and Export

The province is known for its high-quality cereals, legumes, fruits, and vegetables, which find their way to European markets and beyond. The agri-food industry is not limited only to primary production; it also encompasses the processing and marketing of agricultural products. Local companies are engaged in food processing, canning, dairy, charcuterie, and gourmet products, adding value to raw materials and generating employment in the agri-food value chain.

With a rich and diverse history, this city has witnessed countless events that have left an indelible mark on its landscape and its people.

In summary, agriculture and agribusiness are fundamental pillars of the economy and identity of Valladolid. From the vineyards that adorn its landscapes to the technological innovation that drives its production, the province continues to cultivate the wealth of Castilian land, ensuring a prosperous future for generations to come.

Places of Interest

Plaza Mayor

Condenses history, commerce, and hosts the statue of the city’s founder.

Campo Grande

It is the largest urban park in the city. Its origin dates back to the late 18th century when it was called Campo de la Verdad.

Academia de Caballería

The Cavalry Academy of Valladolid arrived in 1852 from Alcalá de Henares.

Pasaje Gutiérrez

It is the only commercial passage in Valladolid and one of the few built in Spain. It is a must-visit in the city.

Playa de las Moreras

Valladolid boasts an excellent river beach bathed by the waters of the Pisuerga. The beach in Valladolid has showers, bathrooms, parking, and a bar.

San Pablo

The Church of San Pablo in Valladolid was founded by María de Molina in 1286 and reformed in the 15th and 17th centuries. The best Gothic church in Valladolid.

Cathedral of Valladolid

It was designed by Juan de Herrera in the 16th century, although it remains unfinished.

Museum of Sculpture

It is located in the College of San Gregorio, next to San Pablo. It is the most important in Spain in its field.

The city enjoys a vibrant cultural life thanks to its status as a university city, as well as events such as the Seminci, the International Film Week, an essential date on the Spanish film calendar, or the International Festival of Theater and Street Arts.

Another event that marks the life of Valladolid and arouses the fervor of its inhabitants is Holy Week. Declared an International Tourist Interest, its processions represent a true parade of sacred art pieces.

BUSINESS SCHOOL Spraytec Argentina

The Project

Spraytec Business School is a tuition-free 9-month training program, which was launched in the second half of March in Rosario, Argentina. It is led by professionals from the University of Buenos Aires (UBA) and Teplipz & Asociados, with involvement from the internal team and distributors of the firm.

It has a workload of two non-synchronous weekly hours, a bi-weekly synchronous online meeting, and a quarterly face-to-face meeting with the participation of experts in each topic in a virtual format.

Objectives

Those who participate in the Business School will be able to:

• Develop their technical and commercial knowledge and skills to be more efficient.

• Train in the development of soft skills that contribute to improving their performance.

• Improve service quality, customer relations, and identification with Spraytec.

• Promote efficiency and competitiveness.

• Foster loyalty in the value chain.

• Facilitate personal transformation and improve quality of life.

• Certify their professional qualification.

Methodology and Workload:

• Weekly asynchronous content (starting from the 1st half of May)

• Zoom meetings every 15 days

• First in-person event of 2 ½ days (July)

SCHOOL

• Weekly asynchronous content (starting from the 1st half of May)

• Zoom meetings every 15 days

• First in-person event of 2 ½ days (October)

• Closing in-person event.

Tentative Schedule

- Weekly asynchronous content (starting from the 1st half of May)

- Zoom meetings every 15 days

- First in-person event of 2 ½ days (July)

- Weekly asynchronous content (starting from the 1st half of May)

- Zoom meetings every 15 days

- First in-person event of 2 ½ days (October)

- Closing in-person event.

Asynchronous Multimodal Methodology

• Short interactive online content

• Podcasts

• Short videos

• Online games

• Practical activities

• Self-assessments

Synchronous Multimodal Methodology

• Interactive Zoom workshops with a duration of 90 minutes.

In-person Meetings:

• Three intensive seminars per year.

• Experiential and practical activities.

• Participation of artists as “masters of ceremonies” and leading content experts for each topic.

• The dynamics will incorporate asynchronous content and experiences, designed pedagogically to create immersive experiences that

engage both the mind and body.

Academic Structure

Academic Directory: Spraytec. University of Buenos Aires. Teplitz & Associates

Purpose

With the creation of the SPRAYTEC BUSINESS SCHOOL, the company gains its following benefits:

• Cultivating its talents to achieve retention and career plans.

• Improve the quality and productivity of its internal team, distributors, and producers.

Certificate

Upon finishing the course, those who pass will receive a certificate endorsed by the Faculty of Agronomy of the University of Buenos Aires.

A New Plant in Argentina

Spraytec Argentina’s new production plant is located in the city of Roldán, Santa Fe. This project aimed to meet both local and international demand, manufacturing all our products with the highest technology and subject to strict quality routines. Additionally, and no less important, all our employees can thrive in a model and functional plant according to their daily tasks. Currently, our plant has 15 direct collaborators in the operations area, allowing us to deliver products that meet the highest demands of the international agricultural sector. The company is certified under ISO 9001-2015 standard in the implementation and maintenance of a quality management system for the production and commercialization of phytostimulant products. In its new 11,000 m2 site, we can find the following sectors:

Production

Production capacity will increase by 450%, taking our current capacity of 1.3 million liters per year to over 5.5 million liters. To achieve this capacity and make it the most technologically advanced plant in the company, investment was made in the construction of a stainless steel platform which includes:

• 4 reactors supported on load cells with a capacity to produce batches of 7000 liters and withstand temperatures of up to 90°C.

• 2 heated chambers to keep inputs with high viscosity and consistency in liquid phase.

• 4 external tanks of 20000 liters and 2 of 30000 liters.

• 7 Raw Material Silos, along with the external tanks and deposits in the heated chambers, allow us to carry out the corresponding dosages to the reactors using our piping and individual pumps.

In its new 11,000 m2 property we can find the following sectors:

These chemical product dosages (our inputs are all traceable through a management system) inside the reactor are commanded through an industrial PLC (Programmable Logic Controller), which already has the formulations loaded in encrypted form, allowing it to control all loading pumps and each of the pneumatic actuators of the ball valves, ensuring that the manufacturing process is carried out, respecting weights, times, and mixing speeds.

• 8 silos of 8500 liters of finished product. Once the batch is finished in the reactor, quality controls are carried out as established, and then it is placed in the aforementioned silos with their respective agitators, awaiting the demand from the packaging sector.

• Overhead crane with a 5-ton double rail trolley. It allows us to bring solid inputs closer to the reactors and, at the same time, facilitate

the removal of tanks or silos in case of any unforeseen circumstances.

Packaging

With over 200 m2, the new packaging room features 2 semi-automatic and 1 automatic packaging machines, all of which are multi-format, allowing us to package all our rigid container presen-

“In these days, when I see how the new Spraytec production plant in Argentina is very close to starting to operate at its full capacity, I can say that I feel satisfied and completely grateful for the opportunity, trust, and freedom that Lucas Gómez has given me from the beginning to continue and closely follow this great project that was initially dreamed of with Mariano Maineri. It is gratifying and impossible not to get involved and consider the company as my own when working under these conditions.

All my feelings can be measured by the feedback and positive responses I receive from the entire team, once again highlighting the great human value that the company has and of which I am truly proud to be a part. I emphasize this, as well as the determination and heart that the entire team puts into it daily to maintain that sense of family that I perceived from the first day I joined, and that continues to this day, regardless of the exponential growth that has transformed us into a great company.”

tations. This set of packaging machines has more than enough capacity to meet the liters produced in the production sector, with the latest automatic packaging machine acquired featuring 3 nozzles with flow meters, achieving a speed of 10 packages/minute in our future 5-liter presentation, totaling 3000 liters/hour

(21000 liters/shift).

Applied Research and Development Laboratory

It consists of a fully equipped shared workspace where tests and determinations corresponding to the company’s new research projects can be carried out. Additionally, all determinations related to the products currently

on the market can be conducted.

Quality Control Laboratory

The new quality control laboratory is located on the mezzanine of the production facility, an ideal location for quality personnel to work alongside production sectors. It is equipped with everything necessary to perform analyses of raw materials and finished products before their release.

Control and Monitoring Room for Production Process

The purpose of the control room is to ensure that all electronic equipment is housed in a conditioned room. Additionally, with pro-

cess automation, the operator can make decisions and set the production process, if necessary, through monitoring and variable collection.

Meeting Room for the Production Sector

This purely productive space, used daily, is utilized among other things for internal planning, informing, and training within the sector.

Customs for Release of Finished Product

This sector was created so that when our finished product pallets leave the packaging room, they are retained in the sector until the quality control performs the corresponding visual checks, before entering the distribution center.

Raw Material Storage

The raw material storage capacity is 510 positions in the production warehouse. In addition to the positions, it is important to note that in the tank area, we have the capacity to store 140,000 liters of bulk liquid inputs. This not only allows us to automate the supply of some inputs to the reactors but also increases the raw material storage capacity.

Distribution Center

The storage capacity of our distribution center is 2,394 positions between selective and drive-in racks. The total storage capacity of our new Spraytec plant in Argentina is 2,940 positions.

Spraytec

SNAPSHOTS

The technology that is sweeping the world Spraytec®, more than 300 million hectares treated.