From algae-based nutrition to aluminium recycling and advanced machinery, the beverage packaging industry unites innovation, circularity and digital transformation to build a more sustainable global drinks ecosystem. Emily Gambrill reports.

The beverage packaging industry is undergoing a remarkable transformation, driven by innovation, sustainability, and collaboration. From pioneering algae-based protein drinks to nationwide aluminium recycling initiatives and advanced packaging machinery showcased at drinktec 2025, the sector is proving its ability to adapt and evolve. As global demand for beverages continues to rise, so too does the responsibility to reduce environmental impact, enhance circularity, and embrace digitalisation. The following highlights showcase how industry leaders are redefining what’s possible in sustainable beverage packagingcreating smarter, greener solutions that meet the needs of both today’s consumers and tomorrow’s planet.

A new global partnership between SIG and Nutrition from Water (NXW) is redefining the future of beverage packaging and sustainable nutrition. By combining algae-based protein beverages with SIG’s advanced aseptic packaging, the collaboration aims to deliver nutrient-rich, shelf-stable products to underserved communities, addressing both malnutrition and environmental impact.

With the global population expected to reach 10 billion by 2050, sustainable food and beverage solutions are essential. The initiative, born at MISTA – a global food innovation platform in San Francisco – brings together biotechnology and packaging innovation to promote accessible, healthy diets while reducing reliance on resource-intensive ingredients and cold-chain logistics. Smart Packaging for Nutritional Impact NXW’s Marine Whey™ range, derived from microalgae,

offers a high-quality, digestible protein alternative to traditional sources. When paired with SIG’s aseptic carton and pouch systems, these products can be distributed without refrigeration or preservatives, significantly lowering the carbon footprint of beverage distribution. The result is a new category of proteinenriched drinks that blend nutrition, safety, and sustainability.

Both companies emphasise collaboration as key to transformation. By integrating advanced bioprocessing with responsible packaging design, SIG and NXW are not only closing the nutrition gap but also contributing to a more circular, resource-efficient beverage packaging ecosystem - one that truly supports global wellbeing and environmental resilience.

As sustainability becomes an increasingly important factor in packaging choices, consumers are playing a growing role in shaping the future of the industry. The demand for environmentally friendly alternatives has never been stronger, with shoppers driving the shift away from plastic and towards renewable, low carbon materials.

This shift is particularly evident in the home and personal care sector, where retailers and global brands are swapping plastic bottles for fibre-based cartons in products ranging from laundry detergent to liquid soap. Now, new lifecycle data is providing the evidence to support what consumer preferences have already signalled.

A Landmark Life Cycle Assessment commissioned by Elopak and conducted by sustainability consultancy Anthesis has provided data on the environmental performance of refill packaging options. The study compared Elopak’s D-PAK™ cartons with LDPE pouches for laundry detergent in the EU market, revealing substantial advantages for the fibre-based alternative.

The results demonstrate that cartons deliver significantly lower global warming impact compared to plastic pouches, with larger format packs showing even greater benefits. Notably, D-PAK™ cartons maintained their environmental advantage even when LDPE pouches are made with 50% and 100% recycled material.

Resource scarcity impact tells a similar story, with the carton solution substantially outperforming pouches across different pack sizes. Perhaps most significantly for brands looking to address plastic reduction targets, D-PAK™ cartons contain a fraction of the plastic found in LDPE pouches or polypropylene bottles, representing a meaningful step towards reducing plastic dependency.

“This LCA demonstrates that by choosing fibre-based cartons, home and personal care brands can offer shoppers similar sustainability advantages as Elopak customers in the food and beverage sector,” said Emilie Olderskog, Senior Director for Sustainability at Elopak. “This gives consumers a more environmentally responsible option right across the supermarket aisles.”

“Now, new lifecycle data is providing the evidence to support what consumer preferences have already signalled.”

Since relaunching the D-PAK™ carton in 2021, Elopak has partnered with major retailers and brands including Sainsbury’s, smol, Omo and Paperdent across applications ranging from laundry detergent and fabric softener to mouthwash and wiper fluid. The packaging can function both as primary packaging and as a refill solution, offering flexibility for different business models.

Consumer research supports this momentum. Recent studies across UK and German markets found that many shoppers would purchase household products like fabric softener, detergent and floor cleaner in carton refills. These figures reflect broader consumer priorities, with the overwhelming majority of respondents considering plastic reduction important when choosing refill options.

The findings arrive as Elopak pursues its ‘Repackaging tomorrow’ strategy, launched in September 2024, which positions plastic replacement as a core pillar of growth. The company is expanding fibre-based packaging into new markets and product segments, capitalising on regulatory pressure and shifting consumer preferences. As plastic reduction targets tighten and consumer

expectations evolve, the data demonstrates that fibre-based alternatives offer measurable environmental advantages alongside the functional performance brands require. For home and personal care manufacturers evaluating refill strategies, the evidence now extends beyond consumer preference to include quantified lifecycle impacts across multiple environmental indicators.

For more information on this, please visit www.elopak.com

“This

LCA demonstrates that by choosing fibre-based cartons, home and personal care brands can offer shoppers similar sustainability advantages as Elopak customers in the food and beverage sector. This gives consumers a more environmentally responsible option right across the supermarket aisles.”

Emilie Olderskog, Senior Director for Sustainability at Elopak.

Elevate your food presentation to showcase your sharing menu

Interchangeable ranges

Recyclable

See product details Simple construction

One team, one offer, shared expertise.

From cardboard Octabins to metal coatings and reusable plastic systems, leading packaging companies are proving that recycling and reuse can work hand in hand to build a stronger, more sustainable future. Article by

The packaging industry is entering a new era where recycling and reuse are no longer competing ideals but complementary forces driving meaningful change. From stronger, smarter cardboard designs to reusable plastic systems and future-proof metal coatings, innovators across the sector are proving that circular thinking can deliver both performance and sustainability.

Octabins: The Smart Choice for Strong, Sustainable Bulk Packaging

As sustainability moves from aspiration to expectation, the packaging industry is rethinking how strength, efficiency and circularity can coexist. One innovation gaining attention is the cardboard Octabin, a heavyduty and fully recyclable alternative to traditional bulk containers.

Constructed from renewable corrugated board, Octabins combine impressive load capacity of up to 1,000 kilograms with a significantly lower environmental impact. Their octagonal design provides strength and stability while reducing the use of excess material. Flatpacked for delivery and easy to assemble, they also cut transport emissions and storage requirements before use.

In trials, businesses switching to Octabins have reported an 80 per cent reduction in labour hours and more than £11,000 in combined savings through improved stacking efficiency and faster handling. Optional moistureresistant liners offer additional protection for sensitive goods such as powders and grains, helping to reduce product loss and waste.

With EPR 2025 approaching and consumer demand for environmentally responsible packaging continuing to grow, Octabins present a practical route towards circular supply chains. By uniting performance with sustainability, they are helping manufacturers and logistics operators move from single-use systems to durable, low-impact alternatives.

For more information on this, please visit www. smurfitkappa.com/uk or www.spnews.com/cardboard-octabins/

“With

62% of UK consumers saying they ‘often or always’ choose sustainable options (The Roundup) and nearly a third valuing responsible supply chains (Deloitte), the importance of sustainable packaging can’t be ignored.”

AkzoNobel Packaging Coatings recently hosted an industry webinar bringing together leading voices from across the metal packaging value chain. The session explored how brand owners, canmakers and coatings suppliers can collaborate to build compliant, resilient and sustainable supply chains in response to the fastevolving EU Packaging and Packaging Waste Regulation (PPWR).

Hosted by Tessa Slagter, Sustainable Innovation Manager at AkzoNobel Industrial Coatings, the event featured contributions from Hans van Bochove of The Heineken Company, who discussed how the brand is aligning its packaging strategy with consumer expectations and upcoming regulatory demands. Diane Watson of Rud Pedersen Public Affairs outlined key policy developments to watch, including chemical regulation reforms, the Circular Economy Act, and updates to food contact material legislation.

Representing AkzoNobel, Chris Bradford, Market Director for Coil & Packaging Coatings, highlighted the need for future-proofed coatings technologies that anticipate regulatory shifts, particularly around bisphenols. He emphasised that cross-industry collaboration is vital to ensure compliance, prevent costly reformulations and maintain sustainable progress.

For more information on this, please visit www. packagingcoatings.akzonobel.com/en or www.spnews.com/future-of-metal-packaging/

“The session underscored the need for closer collaboration between regulators, brand owners, manufacturers, and coatings suppliers. The complexity and speed of regulatory change means that no part of the value chain can afford to work in isolation. Our goal with this webinar was to foster dialogue, share insight, and help prepare the industry for the future –Shaping Change Together.”

As the debate around recycling versus reuse continues to shape the future of sustainable packaging, Amcor has demonstrated that the two can go hand in hand. The company has been awarded the RECOUP Award for Best Plastic Product – Development for Recyclability and Reuse for its innovative range of reusable cups and lids.

Developed with sustainability at the forefront, the range combines durability, reusability and recyclability without compromising quality or brand appeal. Manufactured from mono-material polypropylene (PP), the cups are dishwasher-safe, stackable and long-lasting, designed for repeated use. At the end of their lifespan, the PP material remains fully recyclable in dedicated recycling streams where the infrastructure exists.

Amcor’s range offers multiple cup sizes for hot and cold beverages, with heat-insulating ribs to ensure comfort and stability. Each cup can also be customised using

In-Mould Labelling, while optional embedded RFID chips or QR codes enable efficient deposit return, tracking and refill systems, helping to build scalable reuse models for foodservice and events.

Accepting the award, Uwe Zinnert, Sales Director Reusables at Amcor, said: “There has been increasing demand for alternatives to single-use packaging. RECOUP’s recognition highlights the true potential of our reusable solutions.” Amcor’s innovation shows how design for reuse and recyclability can coexist, setting a strong example for a circular packaging economy.

For more information, please visit packagingsolutions. amcor.com/en/productsearch?q=reusables or www. spnews.com/amcor-reusable-solution/

“In

the foodservice industry – particularly the events and takeaway sectors –there has

been increasing demand for alternative solutions to single-use packaging,”

said Uwe Zinnert, sales director reusables of Amcor.

“We’re delighted that our range has been recognised by RECOUP, an organisation that understands the nuances of reusable packaging. Their recognition is a powerful statement about the benefits of our solution.”

As global regulations tighten and consumer expectations for sustainability rise, the packaging industry is embracing a more circular mindset, one that values durability, recoverability, and long-term performance. Whether through Amcor’s reusable and recyclable cups, AkzoNobel’s future-proof coatings, or Octabins’ strong, space-saving cardboard design, these innovations share a common purpose: reducing waste while maintaining efficiency and quality. The line between recycling and reuse is becoming less about competition and more about collaboration. Together, these forward-thinking solutions illustrate that circularity is not a single path but a connected system driving the next generation of sustainable packaging.

The International Moulded Fibre Association (IMFA) will host one of the most renowned global gatherings in sustainable packaging: the 28th Annual IMFA Conference, taking place 14–16 April 2026 at Torre Melina Gran Meliá in Barcelona, Spain.

This marks a landmark moment for IMFA and the moulded fibre industry as IMFA’s flagship event returns to Europe, reflecting both the rapid growth of moulded fibre packaging across the continent and the region’s central role in shaping a more circular, sustainable packaging future.

As the moulded fibre industry expands rapidly across Europe, Asia, and the Americas, the 2026 IMFA Conference will convene a truly international audience to shape the next chapter in sustainable packaging.

Around the world, regulators, brands, and consumers are accelerating the shift to renewable, recyclable, and compostable packaging. At the centre of this transformation is moulded fibre, combining material

innovation with real-world circularity. Scaling these solutions requires collaboration across disciplines and borders.

IMFA provides that platform. As the only global trade association dedicated exclusively to moulded fibre, IMFA promotes knowledge sharing and partnerships among manufacturers, material suppliers, equipment innovators, and designers to advance an industry that’s rapidly moving from niche to mainstream.

The 28th Annual Conference will bring together nearly 200 international participants for three days of focused sessions, technical presentations, panel discussions, and networking opportunities. Highlights include:

Global Perspectives – Engage with international leaders shaping sustainability frameworks and market direction.

Technical Deep Dives – Explore feedstock developments, coatings, tooling, automation, and recyclability.

Networking & Collaboration – Share insights and ideas through roundtables, receptions, and dedicated networking sessions.

Plant Tours – Step inside leading moulded fibre production facilities to see innovation in action.

For European businesses, this is an exceptional opportunity to engage directly with global moulded fibre leaders without crossing the Atlantic.

Why join IMFA?

While the conference welcomes all participants, IMFA membership provides year-round value: access to regulatory updates, technical resources, and a community of peers driving the industry forward. For companies in Europe seeking to expand in moulded fibre or explore sustainable alternatives, membership offers an unparalleled platform to connect, learn, and lead. Join us in shaping the future

“IMFA provides that platform. As the only global trade association dedicated exclusively to moulded fibre, IMFA promotes knowledge sharing and partnerships among manufacturers, material suppliers, equipment innovators, and designers to advance an industry that’s rapidly moving from niche to mainstream.”

“As the moulded fibre industry expands rapidly across Europe, Asia, and the Americas, the 2026 IMFA Conference will convene a truly international audience to shape the next chapter in sustainable packaging.”

Whether you are a packaging producer, brand owner, machinery supplier, or sustainability consultant, Barcelona is where the conversation will happen in 2026.

Registration is now open. Join global colleagues and industry leaders in Barcelona as we share the future of moulded fibre packaging.

Learn more at www.imfa.org/28th-annual-conference

From luxury wooden caps to recyclable sliders and tethered beverage closures, leading brands are redefining packaging performance and circularity through innovation in sustainable closure systems. Let’s see what SPN has to say!

Sustainability is reshaping the world of caps and closures, driving innovation that blends performance, responsibility and design. From luxury fragrances to everyday beverages and flexible packaging, brands are redefining how products are sealed, protected and experienced. The latest developments reveal a future where sustainability and sophistication work seamlessly together.

Guerlain’s iconic Habit Rouge fragrance marks its 60th anniversary with a limited-edition release, Habit Rouge Spirit, featuring a sustainable twist in its packaging. At the heart of this celebration lies an innovation in caps and closures – a beautifully engineered wooden cap developed by Quadpack. The monomaterial design, made from FSC®-certified ash, exemplifies how luxury and sustainability can coexist in modern packaging.

Quadpack’s Woodacity® Hidden cap represents a breakthrough in sustainable closure technology. This premium wooden cap integrates a patented click system

that replicates the functionality of plastic closures, while being entirely crafted from responsibly sourced wood. Its seamless two-part construction is bonded using a biodegradable, water-based adhesive, ensuring both durability and minimal environmental impact.

For Guerlain, a long-standing Quadpack partner, the use of wood is part of a broader eco-innovation strategy aimed at reducing virgin plastics and incorporating renewable materials. Produced at Quadpack’s lowemission facility in Catalonia, the ash cap is finished in a deep red varnish, echoing the fragrance’s rich, woody notes. The result is a cap that elevates both form and function, reinforcing the role of sustainable closures in luxury packaging design.

For more information on this. please visit www. quadpack.com and www.spnews.com/luxury-wood-cap/

“Guerlain’s Habit Rouge, the first amber fragrance for men, is celebrating its 60th anniversary. The iconic creation is inspired by the equestrian world so dear to its creator, Jacques Guerlain. To mark the occasion, this legendary fragrance has been reinvented with a limited edition: Habit Rouge Spirit. It is adorned with a beautiful wooden cap – a monomaterial closure made of FSC®-certified ash, crafted and decorated by beauty packaging provider and manufacturer Quadpack.”

Amcor, a global leader in responsible packaging solutions, showcased its latest range of caps, closures and reusable cups for the beverage industry at Drinktec 2025 in Munich. The company’s exhibit featured innovations designed for waters, juices, soft drinks and dairy products, including advanced flat caps, sports closures, and solutions for returnable glass and PET bottles. These developments highlighted Amcor’s ongoing commitment to enhancing circularity, performance and sustainability in beverage packaging.

A key highlight was Amcor’s tethered closures, engineered for cold fill and aseptic applications such as still and functional drinks. Fully compliant with EU regulations for bottles up to three litres, these closures include a tamper-evident band that remains attached after opening, helping to reduce litter and promote recycling. Amcor’s lightweight designs and improved recyclability supported brands in meeting their sustainability goals, aligning perfectly with Drinktec’s focus on circularity and resource efficiency.

Amcor also presented its innovative sports closures and reusable polypropylene cups. The ergonomic flip-top sports closures ensured hygiene and comfort, while the

mono-material cups proved both durable and elegant. Dishwasher safe, lightweight and stackable, they offered practicality alongside visual appeal. At end of life, the PP cups remained fully recyclable - reinforcing Amcor’s holistic approach to sustainable caps and closures.

For more information on this, please visit www.amcor. com and www.spnews.com/amcor-brings-caps/

“Cups and closures are a critical component of beverage packaging, both for practical performance and enhancing user experience,” said Sarah de la Mare.

“The innovations we’re bringing to Drinktec reflect our commitment to combining functionality and sustainability.”

“Good packaging not only does its job protecting the product, but also helps a brand stand out,” said Sarah de la Mare, product line director, closures for Amcor. “At Drinktec, we’ll show how more sustainable materials and smart design can work together to create packaging that appeals to consumers while meeting regulatory challenges.”

Presto Products Company’s Fresh-Lock® brand, a leader in reclosable flexible packaging technology, recently unveiled two major innovations that redefine slider functionality. The Fresh-Lock® Ergo Ultra slider enhances consumer accessibility with its contoured, easy-grip design, while the Child-Guard® Edge slider system introduces child-resistant technology for smallformat pouches. Together, they mark an important step forward for sustainable and user-friendly caps and closures in flexible packaging.

The Fresh-Lock® Ergo Ultra slider was engineered to combine comfort and performance. Crafted entirely from polyethylene, both the slider and track are recyclable, supporting mono-material pouch designs and qualifying for the How2Recycle Store Drop-Off program. Its reduced-scale design minimises material use while maintaining durability, offering a sleek, low-profile closure that balances sustainability with an improved tactile experience.

Addressing a key gap in the market, the Child-Guard® Edge system was developed specifically for narrow pouches, providing the same secure, child-resistant functionality previously limited to larger packs. With a smaller slider and track, it enables brands to design compact, reclosable pouches without compromising safety or convenience. By expanding the possibilities of flexible packaging, Fresh-Lock® continues to demonstrate how sustainable closures can meet both regulatory demands and consumer needs.

For more information, please visit www.fresh-lock.com/ and www.spnews.com/fresh-lock-closures/

“The Fresh-Lock team is dedicated to driving innovation and advancing sustainability across the flexible packaging industry. No matter the market, if you have a product that needs reclosable packaging, we want to give you closure options that perform. That’s why we’re excited to bring Ergo Ultra and Child-Guard® Edge to select pouch converters and the broader marketplace”

Across every segment of the packaging industry, caps and closures are evolving beyond function to embody sustainability, precision, and brand identity. Whether through Quadpack’s elegantly engineered wooden cap for Guerlain, Amcor’s circular-ready beverage closures, or Fresh-Lock®’s recyclable and child-resistant sliders, each innovation demonstrates how thoughtful design can support both environmental goals and consumer experience. As material science, regulation, and creativity converge, the industry continues to move towards closures that protect, perform and preserveproving that the smallest component of packaging can make one of the biggest impacts on sustainability.

Container lightweighting has become an increasingly important part of the sustainable packaging toolbox. Here Peter Tindale, International Sales Director at Selig Group at Selig Group, a global leader in container sealing and venting technology, looks at the relationship between lightingweighting and induction heat sealing and how, thanks to a new liner, industrial producers can reduce material usage and save even more money too.

Induction heat sealing and lightweighting – the perfect match

Lightweighting sounds good in practice, as who doesn’t want to reduce material and freight costs, meet lower GHG goals and save money? However, thinner packaging can lead to performance issues and increased spoilage levels. And this is where induction heat sealing comes into its own.

Induction heat sealing technology has long been part of the packaging mix for producers looking to deliver tamper-evidence, container security and shelf-life optimisation. However, thanks to the hermetic seal created when an induction heat seal liner is used, the container and closure can both be made structurally lighter, without compromising the item’s integrity or leak performance.

“However, thinner packaging can lead to performance issues and increased spoilage levels. And this is

where induction heat sealing comes into its own.”

Taking an example from the UK dairy sector, over the past decade or so a 37% reduction in plastic has been achieved in every plastic milk bottle, thanks to the use of induction heat sealing. It isn’t only in the FMCG sector either. Companies such as Castrol have garnered press attention in the industrial sector, with significant plastic reduction thanks to the combination of container redesign and induction heat sealing.

To help more and more industrial producers make the most of the benefits of lightweighting, Selig has announced the launch of its new Safe-GardTM Industrial liner. This multi-layer barrier liner has been optimised for use in industrial applications, and offers producers a cost-effective, hermetic seal to PE containers.

Safe-GardTM Industrial has been designed to seal both aggressive and non-aggressive contents in agricultural, institutional, cleaning, pet and motor care applications and more. It features a robust material in the liner that provides an increased tolerance to higher temperature storage, compared to the original Safe-GardTM liner. The two piece pulp backed heat induction foil innerseal creates a weld seal with PE containers, and enables high performance and protection for even the most challenging contents.

The liner is a non-food compliant version of Selig’s industry leading Safe-GardTM two-piece liner. It enables producers to access all of the benefits of the original liner, including leak prevention, tamper-evidence, on-liner branding, shelf-life extension and packaging lightweighting, but all at a lower price point. Similar to Safe-GardTM, the liner materials are easy to use and can be glued into the cap or inserted behind the retention feature, without any changes to existing cap designs.

By adding this Safe-GardTM Industrial liner to the range, Selig Group offers industrial and chemical users a more cost-effective sealing and lightweighting solution that still delivers required levels of performance. Industrial producers now have even more ways to achieve peace of mind regarding container integrity, security and consumer convenience at a very competitive price point.

“Safe-GardTM Industrial has been designed to seal both aggressive and non-aggressive contents in agricultural, institutional, cleaning, pet and motor care applications and more. It features a robust material in the liner that provides an increased tolerance to higher temperature storage, compared to the original SafeGardTM liner. “

For more information on the Safe-GardTM Industrial visit www.seliggroup.com

From advanced recycling systems in Europe to marine-safe polymers and mono-material pouches, innovation is reshaping how packaging supports a circular economy. Emily

The packaging industry is undergoing a major transformation as recycled materials, innovative polymers, and circular design principles redefine sustainability. From advanced recycling systems in Europe to marine-safe packaging and mono-material pouches, brands and manufacturers are working together to reduce waste, enhance recyclability, and build a more sustainable packaging future.

The packaging industry’s journey towards circularity continues to accelerate, with recycled materials now at

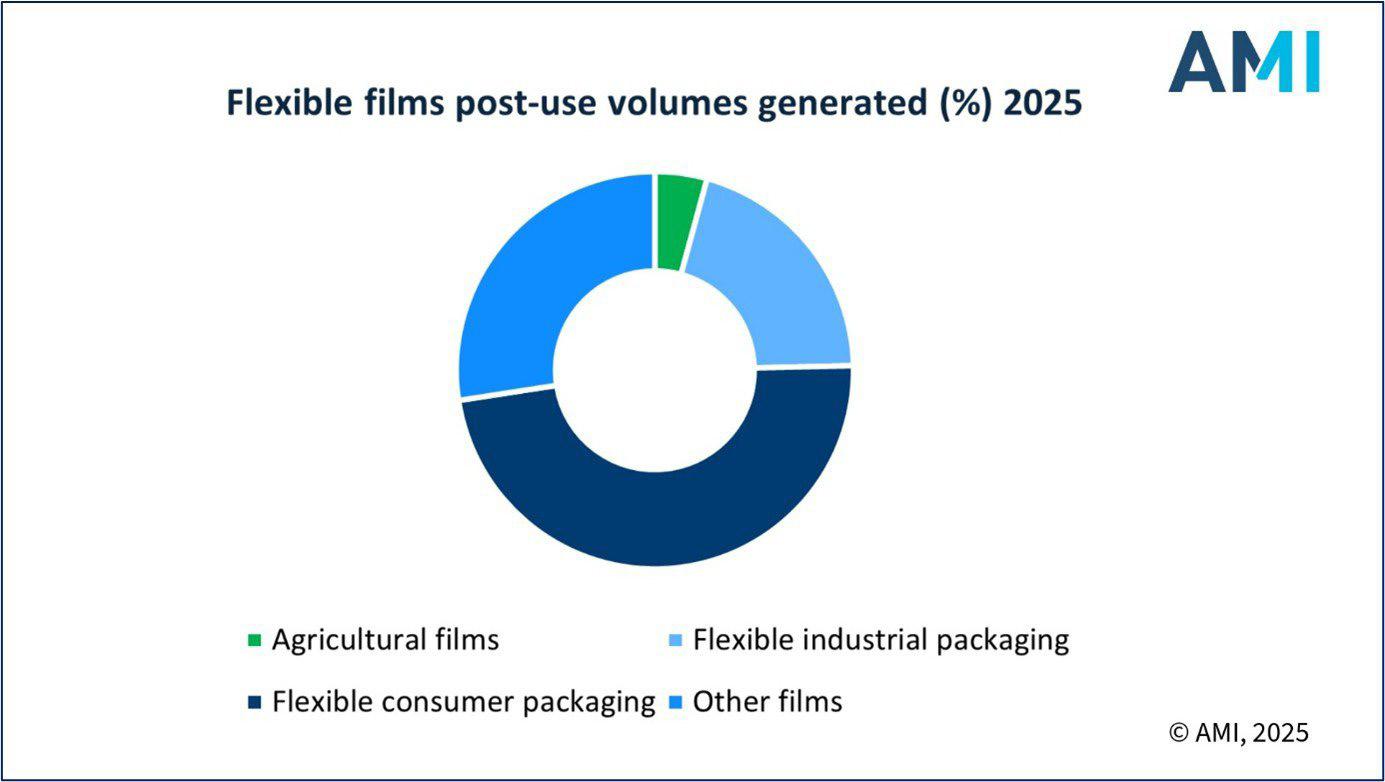

the forefront of sustainability strategies. AMI’s latest research highlights that around 14.2 million tonnes of post-use flexible films were generated across the EU27+3 in 2025. The majority stem from flexible consumer and industrial packaging, positioning these segments as key drivers of circular packaging innovation and regulation under the Packaging and Packaging Waste Regulation (PPWR).

Despite marked progress in design for recycling and advances in material processing, insufficient collection

and sorting infrastructure remains a major barrier. The European recycling landscape continues to face operational strain, with capacity losses driven by rising costs, cheap virgin plastics, and imports from low-cost regions. Uncertainty surrounding PPWR targets and opt-out clauses further hampers investment in recycling infrastructure. Without a strong push in funding and collaboration over the next five years, the EU’s 55% recycling target for flexible packaging by 2030 may remain out of reach.

“Past years have seen significant progress in both design for recycling initiatives and technological advancements in the processing of post-use flexible film material streams.“

Encouragingly, recycling rates for flexible consumer packaging are projected to climb significantly, supported by both mechanical and emerging chemical recycling technologies. As shown in recent data, total recycling rates are steadily increasing, reflecting industry commitment to scaling solutions. With innovation in design, technology, and material recovery, recycled materials are reshaping packaging’s future—turning sustainability from aspiration into actionable progress.

For more information on this, please visit www. amiplastics.com/market-intelligence/market-report/ recycling-of-flexible-films-in-europe-2025 and www. spnews.com/flexible-films-in-europe/

Navico Group uses marine-safe Hydropol bags as part of its commitment to sustainability and protecting the natural environment.

Navico Group, a global leader in integrated systems across marine and recreational industries, is pioneering the use of Aquapak’s Hydropol bags to reduce packaging waste and support a circular economy. The collaboration reflects the growing shift within the packaging sector towards sustainable, recycled, and recyclable materials that maintain performance while safeguarding the environment.

Developed by Aquapak, Hydropol is a watersoluble, biodegradable polymer designed to replace conventional flexible plastics. It can be processed on existing machinery to create strong, anti-static films and

bags that dissolve harmlessly in water, breaking down without releasing microplastics. Crucially, Hydropol is compatible with existing recycling systems and contributes to improved recycling efficiency - qualities that make it a vital innovation in the transition to more sustainable packaging.

“It

can be used as an alternative to conventional plastic as it provides the same functionality and performance but without harming the environment.”

Navico Group’s adoption of Hydropol demonstrates a tangible commitment to reducing the environmental footprint of its marine electronics packaging. By replacing traditional polybags made from LDPE, which are often incinerated or landfilled, the company is promoting materials that leave no trace in the natural environment. This initiative mirrors a wider industry trend, with brands such as Finisterre and NBrown Group also adopting Hydropol solutions. As Aquapak CEO Mark Lapping highlights, the material delivers high performance without harming marine life - a key step in advancing truly sustainable packaging solutions.

For more information, please visit www. aquapakpolymers.com and www.spnews.com/navicogroup/

Siegwerk, Borouge, and TPN Food Packaging Launch Fully Recyclable Mono-material Packaging Solution

In a powerful step towards sustainable packaging, Siegwerk, Borouge, and TPN Food Packaging have unveiled a fully recyclable, mono-material barrier stand-up pouch designed to meet the growing demand for circular packaging solutions. This collaborative innovation showcases how recycled materials and de-inking technologies are transforming packaging performance and recyclability across global markets.

The new stand-up pouch features a full polyethylene (PE) triplex laminate structure using Borouge’s Borstar® FB5600 and Anteo™ PE sealant film, achieving high stiffness, seal integrity, and printability—all while remaining fully recyclable. Siegwerk’s CIRKIT OXYBAR BC1582 coating delivers an effective oxygen barrier, while its CIRKIT CLEARPRIME de-inking coating enables clean delamination, producing high-quality recycled PE feedstock for next-life applications. This monomaterial construction provides the same functionality as traditional multi-material laminates but without compromising circularity.

“This collaboration brings together material science, ink innovation, and manufacturing excellence to deliver a mono-material solution that is fully recyclable and de-inkable. It supports our customers in creating packaging that is not only high-performing but also designed for a circular economy.”

As highlighted by Siegwerk and Borouge, this project demonstrates the power of cross-industry collaboration in scaling sustainable packaging. TPN’s production expertise and high-speed rotogravure printing ensure both technical excellence and commercial viability. With an oxygen transmission rate comparable to metallised PET, the pouch delivers strong barrier performance while being fully de-inkable and recyclable. Designed for products such as nuts and pet food, this innovation exemplifies how the integration of recycled materials, material science, and ink technology can accelerate the packaging industry’s transition towards a circular economy.

For more information, please visit www.siegwerk.com and www.spnews.com/siegwerk-borouge/

Across Europe and beyond, the packaging industry is redefining its relationship with materials, performance, and sustainability. The adoption of recycled and recyclable materials, whether through improved film recycling systems, marine-safe Hydropol bags, or fully recyclable mono-material pouches, demonstrates clear progress towards circularity. Yet, to truly close the loop, sustained investment, regulatory clarity, and industry-wide collaboration remain essential. As these innovations scale, they showcase the transformative potential of recycled materials to preserve product functionality while protecting the planet, proving that circular packaging is no longer a distant goal but an achievable reality driven by ingenuity and shared purpose.

When the European Union’s Packaging and Packaging Waste Regulation (PPWR) comes into force, recyclability will no longer be a “nice-to-have” but a market entry ticket. From 2030, only packaging that meets clearly defined criteria may be placed on the EU market. For brand owners, retailers, converters and manufacturers, the countdown has begun.

Interzero - Europe’s leading circular-economy specialist - now offers a shortcut to compliance: “Fit for Recycling”. The new service delivers a quick, specification-based assessment of your packaging, backed by laboratory data and expressed in an easy-to-read recyclability report. In short: you learn exactly where you stand today and how to reach tomorrow’s targets—before the regulation reaches you.

By working with the technical specification of a packaging item, Interzero’s experts can identify critical materials and design elements long before production runs or listings with retailers begin. Targeted lab analyses at the company’s Competence Center for Recycled Plastics provide the missing data - resulting in a solid, decision-ready PPWR grade in just a few weeks.

Three steps to certainty

1. Send your sample, specification sheet and the onepage checklist.

2. Interzero engineers compare the spec against PPWR criteria, run essential lab tests and log every parameter.

3. You receive a concise report with a PPWR recyclability grade (A–CThe business case removing a metallic barrier layer, switching to a single polymer family, tweaking the label adhesive - small design changes can push a pack from a “C” to an “A”. That difference will soon decide access to supermarket shelves, lower EPR fees and, ultimately, consumer preference. “With “Fit for

Recycling”, companies gain a clear roadmap instead of trial-and-error,” says Jonathan Scheck, Packaging Engineer at Interzero. “Our clients value the fact that we combine desk analysis with real lab data. It’s fast, reliable and practice-oriented.”

• FMCG brands preparing 2025/26 launches.

• Private-label retailers auditing supplier compliance.

• Packaging converters seeking a competitive edge.

• Exporters entering the EU market.

Stay ahead of regulation - get “Fit for Recycling” today.

About Interzero:

Interzero is one of the leading service providers in the field of closing product, material and logistics loops as well as an innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions”, the company supports over 80,000 customers throughout Europe in the responsible handling of recyclable materials, thus helping them to improve their own sustainability performance and conserve primary resources. With

about 2,000 employees, the company achieves a turnover of nearly one billion euros. According to Fraunhofer UMSICHT, Interzero’s recycling activities could save 1.2 million tonnes of greenhouse gases compared to primary production and 11.1 million tonnes of primary raw materials in 2023 alone. As a pioneer in the circular economy, Interzero is winner of the German Sustainability Award as well as the related special award in the “Resources” transformation field for 2024. For further information, please visit www.interzero.com.

“The new service delivers a quick, specification-based assessment of your packaging, backed by laboratory data and expressed in an easy-to-read recyclability report. In short: you learn exactly where you stand today and how to reach tomorrow’s targets—before the regulation reaches you.”

From carbon calculators to plastic free materials and efficient pack formats, the latest developments in flexible packaging are driving measurable sustainability gains across industries. Emily Gambrill shares her views.

Sustainability in packaging is no longer optional; it is an expectation. Across industries, brands are rethinking materials, processes and performance to reduce environmental impact while maintaining quality. From carbon transparency to plastic free innovation and smarter packaging design, flexible packaging is leading the shift toward a cleaner, more circular future.

As sustainability becomes a defining measure of business integrity, the environmental footprint of flexible packaging is under greater scrutiny. Lightweight, adaptable and resource efficient, flexible packaging offers clear benefits, but its true environmental cost can be difficult to quantify. Industry leaders are now introducing data driven tools to improve transparency and help brands make informed material choices that genuinely support their sustainability goals.

While many companies track their overall carbon footprint, the specific impact of packaging materials often goes overlooked. Flexible packaging, made from multilayer films or composites, can vary widely in production emissions depending on resin type, thickness and recyclability. Carbon comparison tools are helping brands identify where reductions can be made, whether through switching substrates, light weighting or using recycled content.

Terms such as ‘recyclable’ or ‘biodegradable’ are often used across flexible packaging, but they can obscure more complex realities. True environmental performance depends on factors such as end-oflife processing, energy use during manufacture and recycling infrastructure. Measuring carbon emissions at each stage of a pack’s life cycle helps companies separate marketing claims from measurable impact. Driving Meaningful Change Across the Supply Chain The rapid rise of e commerce, food delivery and healthcare logistics has driven demand for flexible formats. This makes carbon accountability more urgent than ever. Tools that quantify packaging emissions empower businesses to design for circularity, align with sustainability pledges and demonstrate genuine progress towards net zero. The future of flexible packaging is versatile and verifiably sustainable.

For more information on this, please visit www.hydropac. co.uk/ or www.spnews.com/gel-ice-packs/

“We simply believe in giving businesses the facts so they can choose solutions that genuinely reflect their environmental commitments - not just what sounds good in a press release.”

Zero Plastic. Zero Waste. Endless Possibilities.

Today marks a significant milestone for sustainable packaging as SmartSolve introduces PureNil 0, a 100% bio based, plastic free, paper based pouching material designed to meet growing demand for zero waste flexible packaging. The first product in the new PureNil Series, it allows brands to move beyond recyclability and take meaningful steps towards advanced sustainability goals.

PureNil 0 is crafted entirely from renewable resources, eliminating synthetic polymers and petroleum-based inputs. Unlike many so-called eco-friendly options that still contain some plastic, it is fully biodegradable and genuinely plastic free. For decades, flexible packaging has relied on multilayer plastic laminates that are difficult to recycle. PureNil 0 removes that compromise, offering brands a credible, fossil fuel independent alternative that aligns with genuine environmental commitments.

Maintaining SmartSolve’s signature water dispersible performance, PureNil 0 dissolves safely in water systems without releasing microplastics. It can be flushed, composted or recycled with paper, creating a unique end of life experience that empowers consumers and reduces waste.

PureNil 0 runs efficiently on standard form, fill and seal machinery and is printable even for small dose applications, supporting household, personal care, agricultural and food products. Certified for direct food contact under ISO and FSSC 22000 standards, it offers a scalable, commercially available alternative that is both high performing and sustainable.

By pairing innovation with accountability, SmartSolve’s PureNil 0 represents a genuine breakthrough. It proves that flexible packaging can be functional, safe and completely free from plastic - ushering in a new era where packaging no longer becomes waste but part of a circular future.

For more information, please visit www.SmartSolve.com or www.spnews.com/smartsolve-launches-purenil/

“Brands now have a viable, scalable, and commercially available alternative that’s fully bio-based, plastic-free, and water-soluble. This is the kind of innovation that will help our partners lead, versus just keep up, in the sustainable packaging movement.”

Why use two bags when one will do? This simple question captures the essence of innovation in the packaging sector, where smarter, more efficient solutions can cut waste, save time and reduce environmental impact. That’s exactly what Cortec distributor Lake Engineering Solutions achieved for a major aerospace company by replacing a two-bag system with a single, high performance protective pack.

The client required rigorous protection for precision machined metal parts used in aircraft construction. Both corrosion prevention and cushioning were essential during transport. Initially, this meant double bagging with a corrosion inhibiting film and a separate bubble wrap. By switching to a single Cortec Cor Pak VpCI 126 Bubble Bag, which combines both cushioning and Vapour phase Corrosion Inhibitor protection, the company simplified its process while maintaining the same high-performance standards.

This tailored solution eliminated an entire packaging step, saving time and improving consistency without compromising quality. The single bag design provided dual functionality, ensuring components arrived ready for assembly and meeting strict aerospace specifications.

Beyond the immediate efficiency gains, the manufacturer also implemented a tracking system using date codes and colour indicators to ensure quality control and traceability. The principle extends beyond aerospace: any sector using flexible packaging for sensitive goods can adopt similar multi-functional materials to reduce waste, streamline operations and enhance overall sustainability.

Across every corner of the packaging industry, innovation is redefining what sustainable design looks like. Whether it’s quantifying the carbon footprint of materials, replacing plastic with bio-based alternatives, or simplifying packaging processes to cut waste, the message is clear: flexibility and sustainability must go hand in hand. Brands now have access to data, materials and systems that enable real progress rather than promises. The future of flexible packaging lies in practical, verifiable solutions that protect products, preserve resources and support a truly circular economy - proof that smarter packaging can be both high performing and genuinely sustainable.

For more information, please visit www.cortecvci.com or www.spnews.com/doing-the-math/

We all use them—stick packs and sachets for on-the-go drink mixes, electrolytes, and protein powders. These single-serve packages are a CPG staple—but most still end up in landfills.

Traditional high-barrier flexible packaging often combines aluminum foil and petroleum-based plastics to protect freshness. While effective, this mix creates a barrier to sustainability—non-recyclable, noncompostable, and persistent in our environment for decades.

TIPA Compostable Packaging has changed the game with its Ultra High Barrier Metallized Laminate (T.LAM 428). Instead of aluminum foil, TIPA uses a metallized coating that offers outstanding barrier performance— while remaining 100% home compostable.

This innovative 3-ply laminate shields against moisture, oxygen, UV light, gases, aromas, oils, and greases— ensuring extended shelf life and product freshness. Made from renewable materials, it delivers high sealing strength, excellent printability, and anti-static properties. Packaging that performs and disappears responsibly.

Ideal for protein powders, drink mixes, condiment sachets, salad dressings, confectionery, nuts, seeds, dried fruits, and herbs, TIPA’s laminate works seamlessly with HFFS, VFFS, and pouch machines. It’s a practical, drop-in solution for brands seeking sustainability without compromise.

The “TripAdvisor of Sustainable Packaging” is Here! At Packaged Sustainable, we’re connecting brands with innovators like TIPA who prove sustainability and performance can go hand in hand.

TIPA’s Ultra High Barrier Metallized Laminate is redefining what’s possible—protecting both your

product and the planet.

Ready to explore? Visit TIPA’s page on PackagedSustainable.com to discover more compostable solutions.

Are you a sustainable packaging supplier? Sign up for a free Supplier Page and get your solutions discovered by CPG brands worldwide!

From seafood boxes to advanced polymers, leading industry players are transforming postconsumer waste into high-quality packaging materials through innovative circular feedstock technologies.

The packaging industry is entering a new era of sustainability driven by circular feedstocks. By transforming plastic waste into valuable raw materials, companies are closing the loop on resource use. Recent advances across Europe show how innovation and collaboration are reshaping packaging into a truly circular and low-impact system.

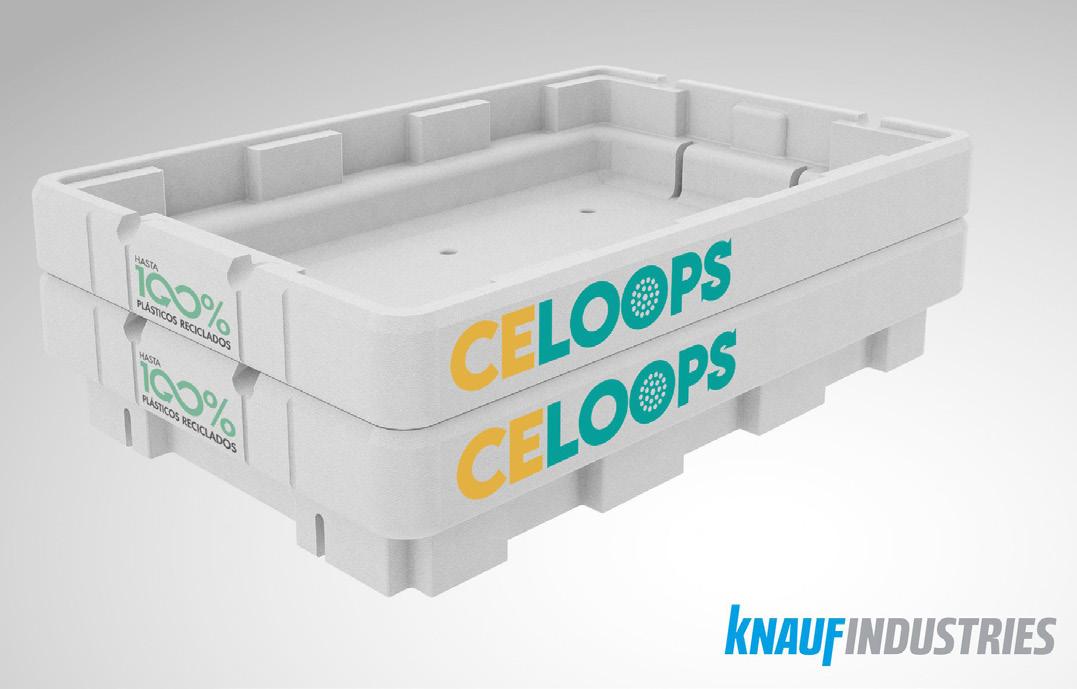

Pescafácil starts transporting fish and seafood in Knauf Industries’ CELOOPS® boxes produced with Ccycled® EPS from BASF

Seafood supplier Pescafácil is embracing circular feedstock innovation by adopting fish boxes made from Knauf Industries’ CELOOPS® material, produced using BASF’s Styropor® Ccycled® expandable polystyrene (EPS). Instead of relying on fossil-based resources, this process replaces virgin feedstock with pyrolysis oil derived from post-consumer plastic waste. The result is a material identical in performance to conventional EPS but with a significantly lower environmental footprint, exemplifying how circular feedstocks can help decouple packaging production from finite resources.

EPS remains a leading choice for temperature-sensitive packaging thanks to its thermal insulation, durability, and lightweight properties. With CELOOPS®, these benefits are retained while integrating recycled content via the mass balance approach. This ensures consistent food safety and product protection, crucial for coldchain applications such as seafood transport, without compromising on sustainability standards.

The collaboration between BASF, Knauf Industries, and Pescafácil highlights how chemical recycling technologies can transform plastic waste into valuable circular feedstocks. Such innovations align with emerging regulations, including the EU’s Plastic Packaging Waste Regulation, by demonstrating that high-performance, food-safe packaging can also support a fully circular economy. CELOOPS® fish boxes, 100% recyclable at end of life, represent a tangible step towards closing the loop in packaging materials.

For more information on this, please visit www.pescafacil.com, www.knauf-industries.es, www.basf.com or www.spnews.com/pescafacil-starts/

“CELOOPS® offers the same high standards of hygiene and food contact quality, but also conserves fossil resources and contributes to the circular economy”

MOL Group Turns Plastic Waste into High Value Products with First Circular Feedstock Test at its MOL Petrochemicals Site in Tiszaújváros

MOL Group has reached a key milestone in its SHAPE TOMORROW strategy by completing its first ISCC PLUScertified production run using circular feedstock at its MOL Petrochemicals site in Tiszaújváros, Hungary. The pilot project demonstrates the company’s ability to convert post-consumer plastic waste into high-quality polyethylene (PE) and polypropylene (PP), showcasing how waste materials can be reintroduced into the value chain as valuable raw inputs.

During the pilot, circular feedstock derived from postconsumer waste was processed in MOL’s steam cracker to produce circular-based monomers and polymers. Using the mass balance approach, MOL ensures that circular inputs are accurately tracked and accounted for throughout production, maintaining transparency and integrity within certified processes. This achievement

follows ISCC PLUS certification for MOL Petrochemicals in Tiszaújváros and Slovnaft in Bratislava, reinforcing the group’s commitment to verifiable circular operations.

Central to MOL Group’s SHAPE TOMORROW strategy is maximising synergies between petrochemicals and waste management. With plans to utilise up to 1.5 million tonnes of circular feedstock by 2030, the company is building a robust platform for sustainable material recovery through recycling acquisitions, municipal waste concessions, and partnerships in chemical recycling. These efforts place MOL Group at the forefront of the transition towards circular feedstock in the European packaging and plastics sector.

For more information, please visit www. spnews.com/ mol-group-turns/

“It

is a significant step towards sustainable petrochemicals and strengthens our position as a leading circular economy player in Central and Eastern Europe.”

INEOS Styrolution Marks Milestone with First Commercial Delivery of Recycled Styrene Monomer from Indaver

INEOS Styrolution has taken a major step towards circular feedstock integration with the arrival of the first truckloads of recycled styrene monomer (SM) at its Antwerp site. Supplied by Indaver’s new depolymerisation facility - Europe’s first dedicated polystyrene recycling plant, inaugurated in September 2025 - this milestone marks the first commercial-scale delivery of recycled SM in Europe. The close proximity of both facilities in Antwerp keeps logistics short and emissions low, strengthening the circular supply chain for styrenics.

Depolymerisation technology enables polystyrene waste to be broken down into its original building block, styrene monomer, which can then be used to produce virgin-quality polystyrene and other styrenics. This recycled feedstock maintains the same purity and performance as fossil-based alternatives, even meeting stringent food-contact and medical-grade standards. It joins INEOS Styrolution’s sustainable portfolio, which also includes mechanically recycled and bio-attributed materials, offering customers greater flexibility in reducing their environmental impact.

By turning post-consumer waste into new highquality material, depolymerisation showcases the unique recyclability of polystyrene and the efficiency of circular feedstocks. The process avoids multiple resource-intensive steps and lowers greenhouse gas emissions compared to conventional production. Through innovation and partnerships such as this, INEOS Styrolution and Indaver are demonstrating that circularity and performance can coexist - keeping valuable materials in use and advancing the circular packaging economy.

For more information, please visit www.ineos.com/ styrolution or www.spnews.com/ineos-styrolutionmilestone/

Across Europe, companies like Pescafácil, MOL Group, and INEOS Styrolution are proving that circular feedstocks can combine performance, safety, and sustainability in modern packaging. Whether through chemical recycling, mass balance certification, or depolymerisation, these initiatives show how waste can be reintroduced into the value chain as a valuable raw material. By reducing reliance on fossil resources and ensuring recyclability at end of life, circular feedstocks are accelerating the transition towards a more resilient, low-carbon packaging industry - one where innovation, collaboration, and closed-loop thinking redefine how materials are made, used, and reused.

Consumer demand and government regulations are urgently driving brands to explore sustainable packaging. Brands need an easy way to see what sustainable packaging solutions exist and which apply to their products. Sustainable packaging suppliers are looking for new marketing channels to cut through the noise and reach buyers who are actively seeking sustainable solutions.

Enter PackagedSustainable.com – the “TripAdvisor for Sustainable Packaging” – that connects brands with trusted sustainable packaging suppliers and their products.

CPG Brands: Whether you’re searching for compostable, PCR, or other sustainable solutions, you’ll find hundreds of options in minutes, not months. The sustainable options are out there and our mission is to make it easy for you to discover them.

Suppliers: You’ve invested time, resources and capital in creating innovative sustainable packaging solutions, but when you go to market, you’re fighting through millions of social media posts that make your message almost impossible to see.

No more convincing buyers that sustainable packaging is important — on Packaged Sustainable, that’s a given and this gives you direct access to your target audience. In the packaging industry, one new client — if they are the right client — can change your business forever. Connect with them on Packaged Sustainable!

Featured Supplier Spotlight: TIPA® Compostable Packaging

Want home compostable packaging? TIPA® is launching several new home compostable packaging solutions which can be found on their Supplier Page on Packaged Sustainable.

TIPA® is a developer and producer of fully compostable flexible packaging solutions that break down into compost just like organic material. Inspired by nature’s perfect packaging, TIPA® created breakthrough packaging that undergoes the same biodegradation process as organic waste, just like an orange peel. TIPA® compostable packaging, designed to work on existing machinery, allows for a future where plastic will no longer linger in landfills for hundreds of years, but will biodegrade within months under compost conditions. TIPA® solutions are built to fit existing machinery and chain of supply systems and operate on a global scale with compostable polymer technology that is applicable worldwide.

CPG Brands: Search sustainable packaging suppliers and their solutions at www.packagedsustainable.com

Suppliers: Get discovered by brands actively seeking sustainable packaging solutions. Sign up free: www. packagedsustainable.com/supplier-signup

The sustainable packaging you want probably exists. The platform to find it is now here.

by Dominy Jones

In the booming world of online retail, e-commerce packaging has evolved far beyond the simple box or padded mailer. With consumers and regulators increasingly demanding both convenience and sustainability, brands are under pressure to deliver packaging that protects the product, enables an efficient fulfilment process, and leaves as small an environmental footprint as possible. A growing number of companies are stepping up with innovative solutions that meet these demands.

One key trend is the shift from single-use plastics and excess packaging toward recyclable, reusable or biobased materials. For instance, the packaging company Mondi recently introduced a broad e-commerce packaging portfolio designed to eliminate plastic, optimise fulfilment space, and reduce waste. Their “paper-based eCommerce solution” range is designed to be fully recyclable and to handle the rigours of shipping.

“By using our FunctionalBarrier Paper, easy2cool can work towards its targets of using resources efficiently to deliver the protection of temperature-sensitive goods anytime, anywhere”

“Our eRange innovations are designed to be the next step in sustainable eCommerce packaging. We want to demonstrate that cost-effective packaging can deliver on quality and tick all the sustainability boxes.”

Jason Jeffery, Group Business Development

In one collaboration with easy2cool, Mondi helped replace a mono-PE (polyethylene) layer used in insulated mailers with a recyclable paper barrier—so frozen or chilled items can be shipped using paperbased liners rather than traditional plastic-heavy solutions.

Another example is the UK firm Reedbut Group which launched a dedicated “eRange” of sustainable e-commerce packaging. Their offering includes tapefree boxes, adjustable packaging for different sizes, and plastic-free designs — all created to give online retailers a more Earth-friendly way to fulfil orders.

Similarly, packaging distributor Antalis Packaging introduced a new range of bespoke e-commerce boxes made from FSC®-certified materials, 100% recyclable, tape-free and designed to enhance the unboxing experience while lifting sustainability credentials.

Yet another forward-looking example: the start-up Kvatt (in partnership with lifestyle brand TOAST) is piloting reusable mailing bags, allowing customers to opt into a returnable bag system instead of one-time-use packaging. Each bag is designed to be used up to ten times, tracked via software, cleaned, and eventually upcycled—reflecting a true circular-economy mindset.

The benefits of these kinds of innovations are manifold. They reduce raw material use, lower both waste and carbon emissions, and align with growing regulatory and consumer expectation for sustainable practices. For e-commerce brands, packaging is no longer just about protecting a product in transit — it’s a brand experience, a sustainability statement, and a logistics challenge all in one. Companies that embrace smarter packaging (right-sized boxes, reusable systems, recyclable materials) are more likely to win loyalty and mitigate environmental risk.

In summary, the e-commerce packaging landscape is being reshaped by sustainability. From Mondi’s recyclable mailers to Reedbut’s plastic-free boxes, Antalis’s bespoke eco-range, and Kvatt’s reusable

bags, there are real solutions available today. As online commerce continues to scale, packaging will increasingly be the nexus where experience, logistics and environmental stewardship intersect.

Where there is water, there is life. We use the power of water for renewable energy to build a more sustainable future.

D-PAK™ cartons are considerably better liked than alternative solutions. In fact, 97% of consumers prefer D-PAK™ cartons as a refill solution over alternative packaging.

But above all, they’re recognized as best-in-use versus other packaging formats. They’re seen as:

- Modern

- Innovative

- High quality