Sustainability, Innovation, Regulation: The Focus at FACHPACK 2025

Driving the Circular Economy | Event Coverage | Machinery

Sustainability, Innovation, Regulation: The Focus at FACHPACK 2025

Driving the Circular Economy | Event Coverage | Machinery

Dear readers,

I’m delighted to share what’s brewing in the world of sustainable packaging. First up, FACHPACK, the long‑standing European trade fair in Nuremberg (23–25 September 2025), returns as a vibrant hub under the theme “Transition in Packaging” where innovation, EU regulation and sustainability converge.

In parallel, IMA Ilapak’s Fresh Focus shines through its OpenLab initiative, helping brands get ahead of the EU’s PPWR by testing recyclable, compostable materials.

Likewise, Ahlstrom is championing greener confectionery packaging with high‑performance, paper‑based options that slash environmental impact.

Meanwhile, Reuters Events’ Business Limelight: Sustainability Europe 2025 convenes over 500 leaders in London to ignite resilient, future‑fit business strategies.

And Archroma underscores the power of chemistry in sustainable packaging, driving progress from fibre to finished product through collaborative innovation.

As always, thank you to Dominy for co writing this magazine with me!

All the best and keep safe, Emily

linkedin.com/company/ sustainablepackaging-news/ youtube.com/ @sustainable packagingnews

spnews.com

Page 5

Innovative Machinery Driving a Sustainable Future

including IMA Ilapak FRESH FOCUS

Page 9

Driving the Circular Economy: Innovating for a Sustainable Future

including Archroma BUSINESS LIMELIGHT

Page 14

Can Sustainable Digital Printing Lead the Way to a Greener Future?

Page 17

FACHPACK event special

Page 19

Mono material Packaging Powers Shift to Sustainable Solutions

including Guala Pack FRESH FOCUS

PMMI ‑ BUSINESS LIMELIGHT

Page 26

K SHOW event special

Page 29

Driving Change: Big Steps in Reducing Carbon Footprint in Packaging

including article by Assan Aluminiyum

Page 34

Beyond Plastic: Exploring Sustainable Alternatives

including Ahlstrom FRESH FOCUS

Page 39

DRINKTEC event special

Page 42

Compostable Packaging: Innovation Meets Sustainability

including Reuters Events BUSINESS LIMELIGHT 25

How advanced automation and printing technologies are reducing waste and supporting a greener planet. Here at SPN, we have our own take on it! Emily Gambrill reports.

We live in an age where technology is advancing all day, every day. Here at SPN, we have had a lot of news coming in about how companies are using the advancements in technology to better the machinery they use to make their products.

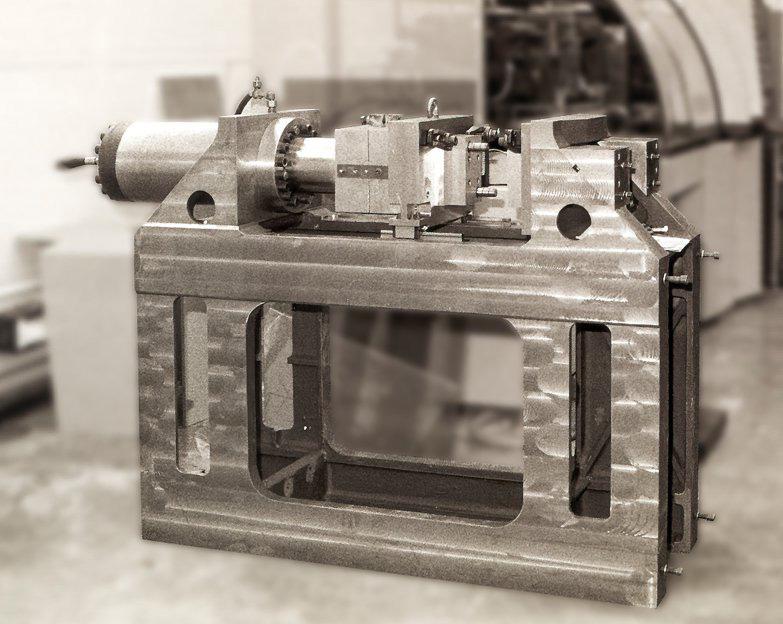

Haver & Boecker is redefining packing line automation with the launch of its innovative AMICUS® robotic solutions. The AMICUS® DEPAL Edition, a state of the art robotic depalletizer, and the AMICUS® PAL Edition, an intelligent robotic palletizer, work together to completely automate the journey from empty bags to neatly stacked pallets. Using advanced image recognition and a versatile end of arm tool, the DEPAL swiftly detects and handles unstrapped bag bundles of varying sizes, processing up to 6,000 bags per hour, while its compact design ensures easy integration even in space constrained facilities. At the other end of the line, the PAL takes filled bags, pails, canisters, or drums and stacks them with precision, adapting effortlessly to different pallet sizes and container types through its smart HMI interface. With options for slip sheets, film, and pallet magazines, it offers unparalleled flexibility. Designed to operate 24/7, the AMICUS robots

not only boost efficiency and uptime but also enhance workplace safety. As Haver & Boecker continues to push boundaries in end to end automation, the AMICUS family stands out as a “friendly” revolution in bulk material packaging.

“The advanced technology increases efficiency by precisely handling the bags, drums and other materials, leading to less downtime due to manual processes and required monitoring by employees.”

There’s no doubt in how the AMICUS robots are a key part of becoming more sustainable, they reduce materials waste with their precise handling, and the automation of this robot can streamline logistics and reduce the number of steps in the packing process can lead to a lower carbon footprint. On the other hand, as this is a 24/7 operated machine, while this is efficient, it still requires a lot of electricity. Installation and integration may involve additional infrastructure or modifications that carry their own environmental cost. To summarise these points, the AMICUS robots contribute to sustainability through efficiency, waste reduction and improved resource use, but their environmental benefit ultimately depends on factors like the energy source powering them and how their lifecycle is managed.

“Robots improve the efficiency of processes, provide more work capacity and create a stable, reliable and safe packing cycle.”

For more information on this, please visit www. haverboecker.com/en/product-solutions/machines/ amicus/

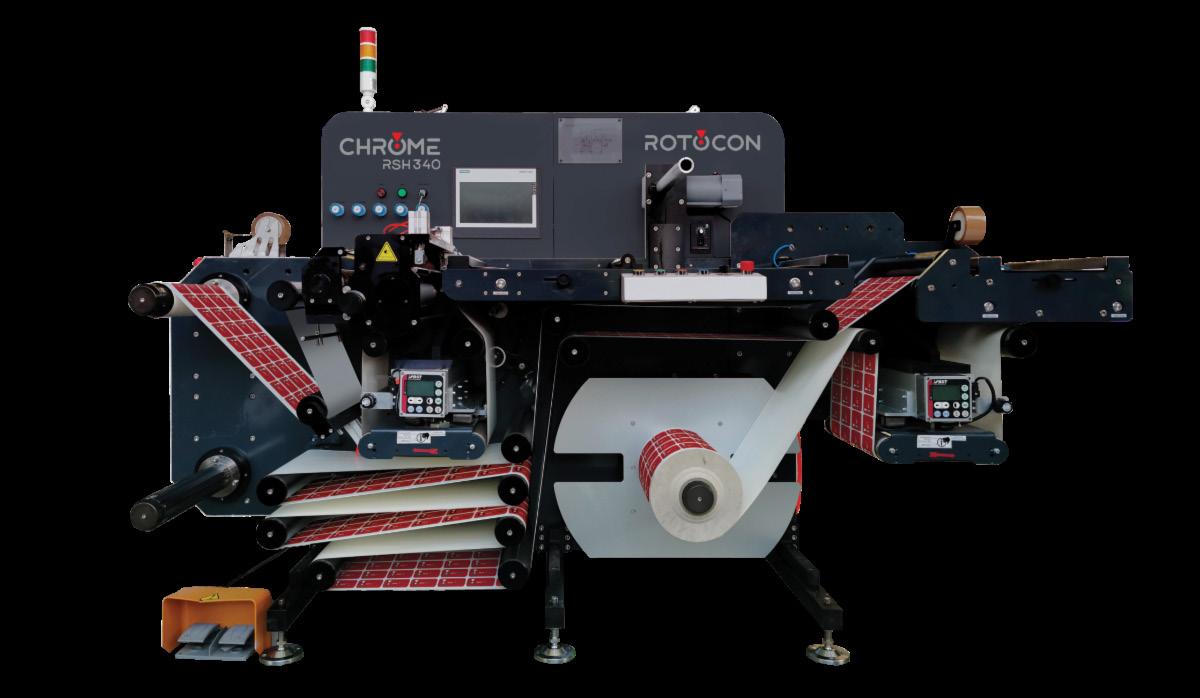

In addition, an Italian printing specialist, Stampa Sud S.r.l., is stepping up its production game with a major investment in cutting edge technology from ROTOCON, supplied through local agent NTG DIGITAL. The company has added two high performance machines to its lineup, the RFP 350 CHROME flexo press and the RSH 340 CHROME slitting inspection rewinder, significantly expanding its label production capabilities alongside its new Domino N610i 5C digital printing system. The RFP 350 impresses with a semi rotary die cutting station, dual rewinding, UV varnishing, cold foil/ lamination, and a versatile slitting unit equipped with six rotary blades delivering precision and efficiency at every stage. Complementing this, the RSH 340 brings advanced inspection and finishing features, including a 750mm unwinder, electronic web guide, splice table for quality control, BST TubeScan compatibility, and both manual and automatic slitting options with vacuum trim removal. Designed with a modular approach, both machines can be upgraded with additional components to meet evolving production needs. NTG DIGITAL’s Mauro Cellini highlights ROTOCON’s reputation for intuitive operation and consistent quality qualities that have made their technology a proven success in Italy. With this investment, Stampa Sud reinforces its commitment to efficiency, innovation, and delivering top tier service to its clients, cementing its position as a trusted partner in the competitive label printing industry.

“We have represented ROTOCON machines for many years, dating back to the introduction of their ECOLINE line initially through ROTOCONTROL in Europe. Their commitment to quality and intuitive operation has consistently proven successful in the Italian market.”

An interesting solution, the RFP 350 CHROME flexo press and the RSH 340 CHROME slitting inspection rewinder provide many sustainable benefits. These range from the machines being able to be upgraded rather than replaced to the potential for using sustainable materials such as eco friendly inks, laminations and substrates. However, some finishing processes, like UV curing and foiling, may rely on chemicals or materials that are harder to recycle. Also, the complex electronics and components in these machines can be challenging to recycle. Taking everything into consideration, the ROTOCON CHROME machines enhance efficiency and waste reduction, but their energy use, finishing processes and eventual disposal present environment

issues, which, when managed carefully, can be reduced significantly.

For more information, please visit www.rotocon.world/ chrome/

“Stampa Sud opted for the ROTOCON CHROME flexo press and finishing machine because both offer top-tier components in a modular design, allowing them to integrate additional modules later and expand their application reach.”

The advancements introduced by HAVER & BOECKER and Stampa Sud S.r.l. demonstrate how innovation in machinery can directly support the path towards a greener planet. Both companies have embraced technologies that improve efficiency, minimise waste, and make better use of resources. These benefits contribute significantly to sustainability by reducing the environmental impact of industrial processes.

While challenges remain, such as energy consumption and the recyclability of certain components, these can be addressed through careful management and the use of renewable energy sources. By continually innovating and optimising their operations, companies not only enhance productivity but also take meaningful steps towards lowering their carbon footprint.

Sustainable machinery is not just about improving performance; it is about shaping an industry that respects and protects the environment. With forward thinking solutions like the AMICUS robotic systems and the ROTOCON CHROME machines, the packaging and printing sectors are proving that efficiency and environmental responsibility can go hand in hand. Together, such innovations are paving the way towards a cleaner, more sustainable future for all.

With the publication of Regulation (EU) 2025/40 on February 11th, 2025 — the Packaging and Packaging Waste Regulation (PPWR) — a new chapter has begun for packaging management across the European Union. The regulation’s cornerstone is clear: packaging must be designed for recycling and be recyclable at scale.

Although the official guidelines defining recyclability and industrial recycling parameters will be released by the EU within 2028, companies of all sizes are already moving proactively to align with the regulation, which becomes mandatory in 2030. Many have turned to IMA — and specifically to OpenLab — to understand how to future proof their packaging lines.

OpenLab is IMA Group’s network of technological laboratories and testing areas, dedicated to the research of sustainable materials, packaging technologies, and production optimisation. It acts as a bridge between innovation and implementation, helping companies

identify the packaging solutions best suited to their objectives.

For producers in the food and personal care sectors, the transition to recyclable packaging means rethinking their entire supply chain. It implies major investments in new or upgraded packaging machinery, a reassessment of packaging materials, and careful analysis of how these changes affect product cost and performance.

In recent months, we’ve seen a strong increase in demand from both multinational corporations and SMEs to start collaborations with IMA OpenLab. The goal? To investigate how to switch from multilayer multi material plastic to mono material PP or PE films, or paper based films with a high cellulose content, while maintaining excellent packaging performance.

The challenge is simple yet critical: manufacturers cannot afford to shut down production lines for extended material testing, nor do they always have the in house expertise to assess new materials or optimise their wrapping lines accordingly.

This is precisely where IMA steps in. With almost 10 years of OpenLab experience and more than 6,000 films analysed and tested on our packaging machines, we offer tailored consultancy and hands on technical support to help companies move toward full PPWR compliance.

Our process begins with laboratory analysis of the customer’s “future ready” materials. These are then tested on IMA Ilapak flow wrapping machines in our dedicated test area. We conduct real time testing with expert technicians and machine testers who can adapt configurations and implement patented technical solutions.

At IMA OpenLab, we conduct mechanical, thermal, sealing strength, hermeticity, shelf life, visual, and comparative tests — covering all aspects that matter for recyclability, packaging performance, and consumer appeal.

A few real examples:

• For a leading snack producer, we developed a solution to package at 300 ppm using a 95% cellulose paper film — selected through multiple lab screenings — achieving strong sealing via hot seal. This even outperformed traditional cold seal plastic films.

• For a wet wipes manufacturer, we successfully implemented a technical solution to run recyclable mono material PE film at 140 ppm (260 mm cut length at 35 linear metres/min) with excellent gas tight sealing— delivering performance equal or superior to traditional solutions.

This is what we mean by a consultative, results driven approach. All solutions are tested and validated on real machines — with real outcomes — ensuring that our partners are not only compliant with future regulations but also maintain their performance and competitiveness.

Get in touch and test your recycle ready packaging with us. Work side by side with our experts and explore end to end solutions — backed by solid data and proven machine compatibility.

For more information, please visit www.ima.it/en/

Collaborative efforts in clean energy, education, and packaging innovation are playing a vital role in building a greener planet. By combining expertise across industries and academia, these initiatives drive the development of circular solutions that reduce waste, lower emissions, and promote sustainable growth. Let’s have a look!

From global brands investing in closed loop packaging systems to startups pioneering product as a service models, the business case for circularity is stronger than ever. Driving the circular economy means embedding circular principles into core business strategies by leveraging design, technology, and collaboration to stay ahead of the curve.

Clariant, a sustainability driven specialty chemical company, is advancing the transition to a circular economy by innovating in clean energy and green fuels. Its recent strategic cooperation agreement with Shanghai Boiler Works, a subsidiary of Shanghai Electric, aims to accelerate the development of sustainable energy solutions in China and globally.

The partnership builds on the success of Shanghai Electric’s pioneering biomass to green methanol plant in Taonan, Jilin Province, the first facility of its kind in China. Clariant played an integral role in this project by supplying its high performance MegaMax™ catalysts and offering technical support during the plant’s startup. The plant currently produces 50,000 tons of green methanol annually, with plans to expand to 200,000 tons of green methanol and 10,000 tons of sustainable aviation fuel (SAF) by 2027. The production of green methanol and SAF from biomass contributes to lowering carbon emissions, reducing reliance on fossil fuels, and creating renewable alternatives that support global climate goals. These fuels also align with circular economy principles by converting waste biomass into valuable products, closing resource loops, and enabling cleaner industrial processes.

However, biomass sourcing, if not carefully managed, can lead to land use issues, deforestation, or competition with food production. Large scale

production facilities require substantial energy and resources for construction and operation, which can offset some of the environmental benefits if not powered by renewables. Additionally, the technologies involved are still developing and can be costly, limiting their accessibility and widespread adoption in the near term.

Despite these challenges, the alliance between Clariant and Shanghai Electric demonstrates how collaboration and innovation can drive progress toward a more sustainable future. By combining catalyst expertise with advanced energy conversion technologies, the partnership reinforces Clariant’s position as a key enabler in helping industries transition away from fossil based inputs toward renewable, circular solutions.

For more information, please visit www.www.clariant. com/en/Corporate

Moving on, The PMMI Foundation, the charitable arm of PMMI, The Association for Packaging and Processing Technologies, has strengthened its commitment to education and sustainability by donating over $100,000 to the Michigan State University (MSU) School of Packaging through the PMMI U Skills Fund in 2025. This investment reinforces a long standing partnership aimed at developing the skilled workforce needed to drive innovation in the packaging and processing industry.

The MSU School of Packaging, the first program of its kind in the United States, is a cornerstone of packaging education and a founding member of PMMI’s Education Partner Program. It actively collaborates with the industry through initiatives like PACK EXPO events, ensuring students are exposed to cutting edge technologies and real world challenges. According to Laura Bix, Ph.D., interim director and professor at the School of Packaging, the support from PMMI provides tangible benefits by meeting diverse needs and connecting students with industry expertise. By funding education, the PMMI Foundation is helping to cultivate a new generation of packaging professionals equipped with the knowledge to design more sustainable packaging solutions, optimize processing

systems, and reduce environmental impacts. The partnership also encourages collaboration between academia and industry, fostering innovations that can lead to reduced waste, lower carbon footprints, and more circular packaging systems.

While education is a vital driver of change, it does not directly address the immediate environmental footprint of the packaging industry, which continues to face challenges with plastic waste, recyclability, and resource use. There is also a risk that without strict alignment to sustainability goals, funds could be channelled into technologies that prioritize efficiency or cost over environmental responsibility.

Despite these potential drawbacks, the PMMI Foundation’s investment plays a crucial role in shaping the future of the packaging industry. By empowering MSU with resources, technology, and industry connections, this partnership strengthens the pipeline of innovators who will be instrumental in advancing sustainable packaging and creating a more circular economy.

For more information, please visit www.pmmi.org/ foundation

“The MSU School of Packaging appreciates our partnership with PMMI. The incredible breadth of member companies not only provides a direct link to partners with practical knowledge and expertise regarding processes and machinery, PMMI’s generous matching program, and its flexibility in use, has enabled us to meet varied and many needs as they arise,”

The efforts highlighted by Clariant and the PMMI Foundation show how sustainability driven innovation can pave the way towards a greener future. By investing in renewable fuels, clean energy technologies, and education, these organisations are addressing some of the most pressing environmental challenges while supporting economic growth.

Clariant’s advancements in green methanol and sustainable aviation fuel demonstrate the power of technology to reduce carbon emissions and turn waste into valuable resources, aligning closely with the principles of a circular economy. Meanwhile, the PMMI Foundation’s support for the next generation of packaging professionals ensures that future innovations

will continue to focus on reducing environmental impact and promoting circular practices across the industry.

Although challenges remain, including the need for responsible biomass sourcing and the management of plastic waste, these initiatives illustrate that progress is possible when businesses, academia, and technology leaders collaborate. Such actions not only reduce environmental harm but also inspire systemic change.

By embracing sustainable solutions and fostering innovation, we can collectively move closer to a circular economy that benefits both industry and the planet, creating lasting value for generations to come.

by Lisa Clark, VP Marketing & Sustainability – Archroma Packaging Technologies

We’re hearing variations of this question from brand owners and converters worldwide:

“How can we produce packaging that protects the health and safety of people while protecting the environment and enabling a circular economy.”

It’s a big ask and, of course, there is no quick fix, magic solution that will address all this overnight. BUT, at Archroma Packaging Technologies, we have made it our mission to create chemistries that enable packaging to do just that. We believe that progress will always happen faster when there is close collaboration across the packaging supply chain.

While these collaborations continue to take shape

– from raw materials suppliers, manufacturers and designers, to regulators, research institutions and consumers, we are continually collaborating directly with customers and tailoring solutions that overcome their specific packaging application challenges, right now.

It all starts with chemistry.

Though it’s often the unsung hero, chemistry is central to answering the above question. Why? Because it’s chemistry that keeps packaging strong, safe, and functional while also ensuring it is easier to recycle. It’s chemistry that can give paper fibres a second, third, even twenty fifth life before they start to break down. And it’s chemistry that enables the replacement of harmful substances with safer, high performance alternatives, and move to water based adhesives, coatings and colorants that lower emissions and waste.

Collaboration is key when it comes to producing packaging that protects both people and the environment. When brands and converters set out to design safer and more sustainable packaging, a critical first step is engaging directly with chemistry providers. Asking questions such as ‘what chemistries can replace the ones we rely on today? Do they offer PFAS free or bio based alternatives?’ helps the industry move away from incumbent materials that may no longer align with consumer expectations or evolving regulations.

Equally important is taking a holistic view of the package rather than treating each component in isolation. Every layer – from board strength to barrier coatings, colorants, adhesives and finishing – plays a role in both performance and end of life outcomes. Considering sustainability at the outset of design, instead of as a

late stage check enables choices that balance protection, recyclability and circularity. For example, lightweighting with stronger fibres, designing with renewable or compostable inputs and ensuring coatings are repulpable all contribute to packages that are functional, compliant and better aligned with circular economy goals.

Of course, no two customers’ starting points are the same, and the challenges they face differ greatly. For customers in flexible packaging, this might be moving away from solvent based systems, designing products that are easier to recycle, or rethinking how packaging will be handled at the end of its life. For others, it might be about producing tapes and labels that stick where they should, release when they need to, and still fit into a circular system.

Customers worldwide are also working in very different

conditions and, importantly, packaging needs to adapt with local water and fibre sources, machinery types, as well as relevant local regulations.

With operations on every continent and over a century of experience in cellulose chemistry, we understand the variables that can affect packaging performance and environmental impact from one region to another.

Ultimately, our role as experts in chemistry for packaging is part problem solver, part navigator. It’s our mission to use our deep heritage and expertise, global resources and adaptive solutions to help customers produce packaging that is strong enough to do its job while helping both people and the planet to thrive.

To learn more about Archroma Packaging Technologies visit: www.archroma.com/packaging-technologies

Digital printing is rapidly transforming the industry by offering solutions that not only enhance efficiency but also minimise environmental impact. Through innovations that reduce waste, lower energy consumption, and eliminate the need for excess materials, companies are proving that sustainability and productivity can work together. SPN has its say!

From reducing waste through on demand production to minimizing the need for excess inventory and harmful chemicals, digital printing is redefining how businesses approach both efficiency and environmental responsibility. ‘Over 60% of converters plan to invest in digital printing within the next 24 months, driven by its ability to support print on demand workflows that significantly cut waste, lower consumables use, and reduce carbon emissions across the supply chain’; an interesting statistic taken from our website, it’s detailing that a large proportion of the industry is moving towards digital printing not just for efficiency, but also because it supports environmentally responsible practices.

SPN has learnt from Mondi that it’s actively advancing the use of digital printing to make packaging more efficient and environmentally responsible. Following its acquisition of Schumacher Packaging’s Western European operations, the company has expanded its portfolio with a high performance digital printing solution. This technology allows customised, high volume packaging to be produced more quickly and sustainably.

A prime example of this is Mondi’s collaboration with KOMSA, a leading German distributor of digital infrastructure. KOMSA dispatches an impressive 35,000

parcels every day, a scale that makes efficiency crucial for maintaining next day delivery. By adopting Mondi’s solution, KOMSA has replaced traditional label dispensers with direct digital printing of barcodes onto corrugated packaging. These barcodes are now precisely printed on all four sides, reducing errors, cutting costs and significantly shortening lead times.

The environmental benefits are notable. The use of water based, food compliant inks support safer and cleaner production. Eliminating the need for labels and printing plates not only reduces material consumption but also lowers waste levels, while the flexibility of the technology enables seasonal campaigns, regional designs and individual QR codes to be produced in a single run with minimal environmental impact. Harald Josef Ollinger, Vice President Marketing and Communications at KOMSA, praised the partnership, highlighting both technological and sustainability gains.

“The collaboration with Mondi is a real benefit for us – technologically, economically and strategically. We are not only making our logistics processes more efficient, but also more sustainable.”

Harald Josef Ollinger, VP Marketing and Communications at KOMSA

Mondi’s innovation demonstrates a clear commitment to promoting sustainable practices in digital printing. Their technology reduces waste, improves efficiency and enhances customisation, meeting both operational and environmental goals. The fact that a high volume operator like KOMSA has successfully integrated this solution showcases its effectiveness on a large scale. However, while the technology reduces waste and avoids labels, the overall environmental impact will also depend on factors such as energy sources and end of life packaging practices.

By providing high performance solutions that blend efficiency with environmental responsibility, they are setting an example for the industry. The successful collaboration with KOMSA highlights how their technology can deliver measurable benefits at scale, reinforcing Mondi’s position as a leader in driving sustainable innovation in the printing and packaging sector.

For more information, please visit www.mondigroup.com

Let’s take a look at Domino Printing Sciences, a global leader in variable data and digital printing technologies. Domino is preparing to showcase its latest innovations at Labelexpo Europe 2025 in Barcelona. Central to its presentation is the launch of the Domino N410 LED label press, a compact and versatile solution designed to help converters transition into digital printing while maintaining low operational costs and delivering clear environmental benefits.

The N410 LED press is expected to attract significant attention due to its sustainability credentials. LED technology inherently uses less energy compared to traditional curing systems, resulting in reduced environmental impact and lower energy bills for converters. Additionally, the press offers flexibility and waste reduction, enabling converters to produce high quality, customised labels without unnecessary overruns. This capability aligns well with the industry’s shift towards sustainable practices.

Domino will also demonstrate its N730i Integration Module, a modular solution designed for hybrid printing and finishing. When combined with the Grafotronic DCL2, the module creates an efficient, future proof system capable of high speed, high resolution printing. Operating at speeds of up to 90 metres per minute with 1200 dpi quality, the system not only improves output but also reduces waste through precise production runs. This is further enhanced by the official release of Domino’s Sunrise DFE upgrade, which employs artificial intelligence and machine learning to increase job processing speeds and maximise press efficiency.

“LED

presses are versatile

increasing

and

enjoy

popularity because of their environmental benefits, helping converters save on energy costs and reducing waste,” explains Russell Weller, Head of Digital Products, Domino. “The N410 offers excellent value for converters looking to unlock new growth opportunities with a versatile digital solution, future-proofing their investment with LED inks, supported by Domino’s world-class service and global support network.”

By integrating LED technology, modular hybrid systems, and AI driven software, Domino is helping converters achieve better energy efficiency, reduce waste, and expand their printing capabilities. The focus on environmental benefits, combined with solutions that lower operational costs, positions Domino as an innovator promoting sustainable practices across the industry. However, smaller converters may find the investment in advanced systems daunting, despite the long term savings. Furthermore, the full environmental impact of these technologies will depend on the energy sources used during operation and the end of life management of printed materials.

Domino Printing Sciences is making significant strides in promoting sustainable digital printing practices. Through its new LED label press, advanced hybrid modules, and AI enhanced software, the company is delivering solutions that improve efficiency while addressing environmental concerns.

For more information, please visit www.domino-printing. com/en/home.aspx

The developments from Mondi and Domino Printing Sciences show how innovation in digital printing is creating real progress towards a more sustainable future. By adopting solutions that use less energy, cut waste, and reduce reliance on harmful materials, both companies are helping the industry to move away from outdated practices that harm the environment. Their technologies allow businesses to meet operational needs while also lowering their environmental footprint, proving that sustainability and efficiency can go hand in hand.

As more converters invest in these solutions, the collective impact on reducing emissions and conserving resources will grow. While challenges such as energy sourcing and end of life packaging remain, the proactive steps taken by companies like Mondi and Domino demonstrate a clear path forward. These advancements not only support the industry but also contribute to the wider goal of creating a greener planet, showing that sustainable digital printing can be a powerful driver of positive change.

From 23 to 25 September 2025, the packaging industry will converge on Nuremberg, Germany, for FACHPACK 2025, Europe’s leading trade fair for packaging, technology, and processes. Held at the NürnbergMesse exhibition centre, the event welcomes professionals from food and beverages, pharmaceuticals and cosmetics, luxury goods, non food sectors, and beyond. Running from 09:00 to 18:00 on the first two days, and closing at 17:00 on 25 September, FACHPACK offers a concentrated three day experience of innovation and exchange.

Under the guiding theme “Transition in Packaging”, the show places a spotlight on sustainability, circular economy, and evolving EU regulations like the forthcoming Packaging & Packaging Waste Regulation (PPWR). Exhibitors and forums will explore how digitalisation, regulatory shifts and material innovation are reshaping packaging landscapes.

• Mondi, a global leader in sustainable paper and packaging, will take centre stage at the fair, showcasing everything from kraft and corrugated solutions to barrier papers and flexible packaging – all designed for regulatory compliance and enhanced resource efficiency.

• Baumer hhs is set to premiere its Xmelt fusion melter at FACHPACK, a hot melt adhesive dispenser capable of 14 kg/hour output with just 1.6 kW energy use. Alongside, its PXH 1000 electric applicator and new metal core hot melt hoses underline the firm’s commitment to precision and resource care.

• Henkel Adhesive Technologies will shine a light on adhesive solutions with a significantly lower carbon footprint. Its “Packaging RecycLab” enables realistic testing for recycling compatibility, especially given the demands of the PPWR.

Gather insights from a wide range of leading brands:

• delfort will feature custom made barrier papers for food applications – from ice cream and chocolate to muesli – across formats like stand up pouches, flow wraps, and transparent paper variants. They will also host a joint presentation with research partner delsci on paper packaging innovations on 23 September, 14:00–16:00 in the “Alternative Packaging Solutions” Pavilion in Hall 3, booth 3 368.

• Sappi Europe brings its portfolio of recyclable high barrier papers—Guard Pro OHS, Guard Pro OMH, Guard Duo and more—for confectionery and food applications under the theme “Future Proof Paper Packaging”, showcasing their commitment to mono material design and sustainability at booth 306 in Hall 4A.

• Metsä Board will showcase lightweight folding boxboards and white kraft liners designed to reduce carbon footprint. As part of their €60 million Simpele mill investment, they aim to reach 98% fossil free energy by late 2025. Visitors can learn how board selection impacts packaging performance and Scope 3 emissions.

‘delfort at Fachpack: Custom-Made Barrier Papers’ ‘PackSynergy at Fachpack 2025: Innovation, sustainability and strong partnerships all at one booth.’

Additionally, PackSynergy Group, a network of mid market packaging wholesalers, will present automation systems under brands like Sealed Air (AUTOBAG® systems) and Emba Protec (TrayTec®, Buzz’n’Pack®), along with PayPerPallet smart pallet wrapping solutions in Hall A4, Stand 326.

Attendees can also explore FuturePack, a startup summit held on 22 September, the day before the trade fair opens. This platform brings startups, investors, and corporates together for pitch sessions, panels, and networking— capping with live votes and prize based access to FACHPACK’s InnovationBox Forum.

Whether you’re seeking material innovation, regulatory insight, or cutting edge machinery, FACHPACK 2025 delivers a forward thinking perspective on packaging’s next chapter.

Mono material packaging is revolutionising the industry by making recycling simpler and reducing plastic waste. With innovations that improve material recovery, cut virgin plastic use and maintain high performance, companies are proving that sustainability and functionality can go hand in hand. SPN shares the latest developments!

Mono material packaging, made almost entirely from a single material such as polyethylene (PE) or polypropylene (PP), is increasingly being heralded as a pivotal solution for improving recyclability, reducing contamination in sorting streams, and advancing circular economy goals. It isn’t just theoretical: according to one market source, in 2023 around 23 billion pounds of multi layer plastic packaging film were in use globally, most of which cannot practically be delaminated and recycled at scale. Redesigning these into mono material formats means boosting sortability and producing higher quality recyclate.

Origin Materials and Royal Hordijk Packaging have entered into a strategic partnership to accelerate the mass production of polyethylene terephthalate (PET) bottle caps. This initiative focuses on using a single material to simplify recycling and reduce environmental impact. Hordijk, with over a century of expertise in packaging innovation and operations across 25 countries, is providing its PET extrusion technology to produce high quality sheets. These sheets will feed into Origin’s CapFormer lines in Europe, which are expected to manufacture billions of PET caps, including tethered designs that prevent littering and enhance recycling potential.

This collaboration is a strong move towards a circular economy. The use of PET as a mono material simplifies recycling streams and enhances the quality of recycled products. The lightweight nature of the caps contributes to reducing plastic consumption, while tethered designs improve recycling rates. Targeting a market worth over 65 billion dollars demonstrates the scale and ambition behind the project. The partnership also merges technological expertise and global reach, suggesting a high potential for widespread

impact. However, the environmental benefits of mono material caps rely heavily on the existence of effective recycling infrastructure, which is inconsistent across regions. Without comprehensive recycling systems and regulatory support, much of the material could still end up as waste.

Origin Materials and Hordijk are making significant progress in promoting mono material packaging. Their collaboration demonstrates how using a single polymer such as PET can greatly improve recyclability, enhance material recovery, and reduce contamination in recycling streams. The production of billions of lightweight, tethered PET caps showcases how mono material solutions can maintain product performance while reducing environmental impact. Through this partnership, the two companies are setting a strong example of how innovation in packaging design can deliver tangible sustainability benefits on a global scale.

For more information, please visit www.originmaterials. com and www.hordijk.nl/en

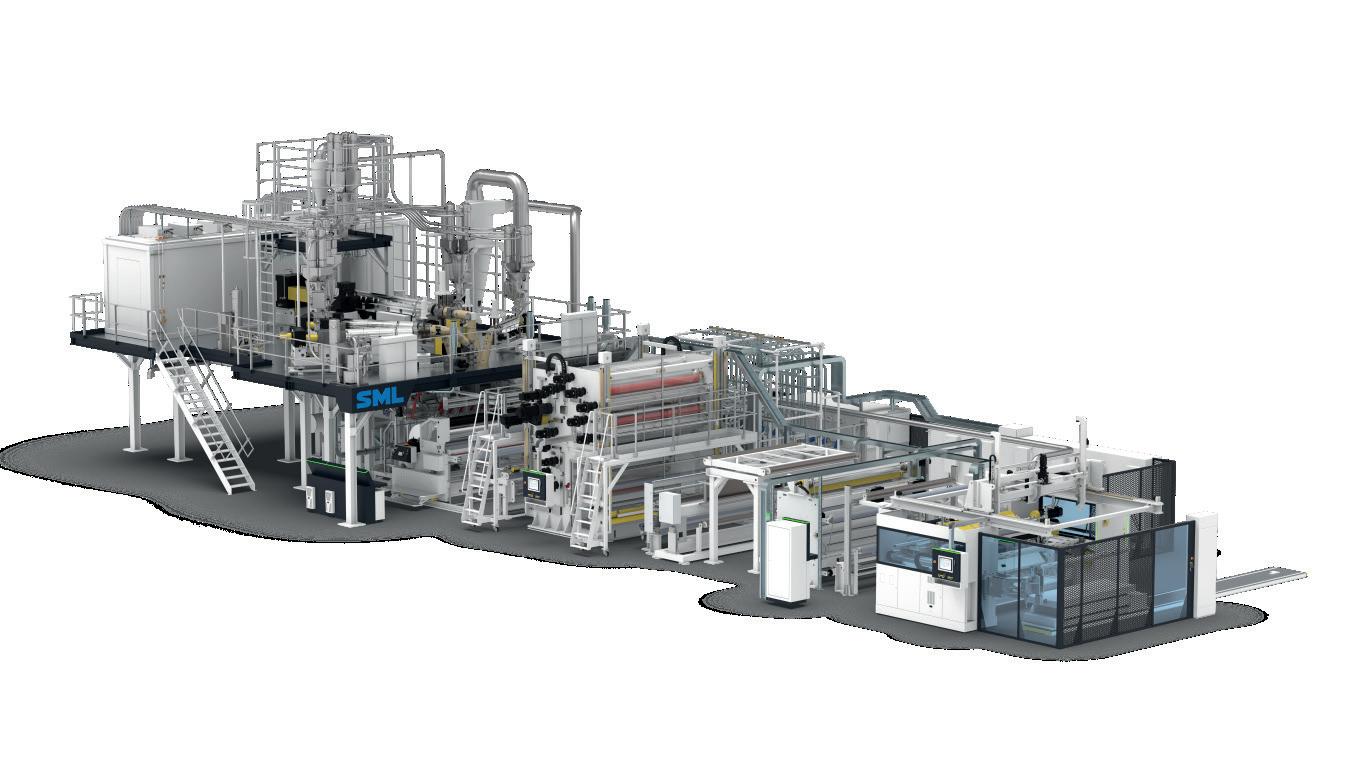

Brückner at K 2025

▪ Greenline concept for saving energy and raw materials

▪ 12m lines: Increased productivity and efficiency

▪ Solutions for recyclate use

▪ Heat recovery unit reducing operating costs

Innovia Films, a leader in materials science, is actively promoting sustainable mono material packaging through its newly launched range of polypropylene (PP) film solutions. These products, compliant with the Packaging and Packaging Waste Regulation (PPWR), are designed to replace multi material structures with fully recyclable mono material alternatives. At the Fachpack trade fair, Innovia presented several innovations including high barrier films, PET replacement films and recyclable lidding films, all aimed at enabling brands to design packaging that aligns with recyclability standards and supports circularity.

A key highlight is the Encore portfolio, which integrates recycled content from post consumer sources, chemically recycled food grade options and plastics recovered from ocean waste. The company also unveiled Propafilm CHS and CHT films, produced using advanced LISIM technology, offering enhanced printability, thermal stability and conversion efficiency. Additionally, ultra high barrier metallised films deliver oxygen and moisture vapour barrier levels as low as 0.1 g/ m²·24hrs, maintaining product protection while ensuring recyclability.

Innovia Films is addressing several sustainability challenges through its portfolio. By replacing traditional PET, foil and multi layer laminates with mono material polypropylene, the company enables packaging that is easier to recycle without sacrificing performance. Their solutions also reduce virgin plastic usage and offer high print quality, meeting industry demands for both sustainability and functionality. The inclusion of recycled content from ocean plastics adds significant environmental value by tackling plastic waste at its source. However, the success of these solutions depends heavily on the availability of recycling infrastructure capable of efficiently processing polypropylene. Without widespread collection and recycling systems, the environmental benefits may not be fully realised. Innovia Films is making considerable progress in redefining the packaging landscape with its innovative mono material polypropylene solutions. By focusing on recyclable designs that maintain high performance, the company is setting new standards in sustainable packaging. Their commitment to materials that enhance printability while reducing environmental impact demonstrates how mono material innovations can support both brand requirements and broader environmental goals. Through these efforts, Innovia Films is successfully positioning itself as a leader in promoting sustainable practices within the packaging industry.

For more information, visit www.innoviafilms.com/

• Wide application range and flexibility in film production

• Good flatness for printing applications

• Safe and easy-to-service design

The developments by Origin Materials, Royal Hordijk Packaging and Innovia Films clearly demonstrate how mono material packaging is reshaping the industry. By replacing complex multi layer structures with single polymer solutions such as PET and PP, these companies are directly addressing recyclability challenges and improving the quality of recovered materials. Their products reduce contamination in recycling streams, lower virgin plastic consumption and maintain high performance standards.

The production of billions of lightweight, tethered PET caps and the introduction of recyclable polypropylene films with exceptional barrier properties show that mono material packaging can meet both functional and

environmental requirements.

These innovations also illustrate how the industry can respond to regulatory pressures while creating packaging solutions that are easier to recycle and better for the environment.

Overall, the commitment of these companies to advancing mono material technologies highlights the significant benefits this approach brings to the packaging industry. By prioritising recyclability and material efficiency, they are setting new benchmarks for sustainable packaging and leading the way towards a cleaner, more resource efficient future.

As the packaging industry responds to growing environmental concerns, monomaterial packaging is gaining prominence as a key enabler of circular economy principles. At Gualapack, a global leader in flexible packaging solutions, the transition toward recyclable monomaterial structures is a central pillar of sustainable innovation.

Flexible packaging has long played an essential role in protecting products, particularly in food, pharmaceutical, and personal care sectors. But packaging must do more than protect—it must also minimize its environmental footprint. Gualapack has embraced this dual mandate by investing heavily in eco design and innovation. The company’s R&D efforts focus on developing high performance solutions that can be collected, sorted, and recycled more easily than conventional multi material structures.

A prime example is Pouch5®, Gualapack’s flagship monomaterial pouch. Made entirely of polypropylene (PP), Pouch5® replaces layers of PET, aluminium, and polyamide with custom engineered PP films. The result is a fully recyclable, high barrier solution that reduces carbon emissions and meets growing regulatory demands.

Pouch5® has passed rigorous recyclability testing by third party bodies including Interseroh, Recyclass, and HTP Cyclos. According to internal Life Cycle Assessment (LCA) studies presented in Gualapack’s 2024 report, the pouch delivers up to 39% lower CO₂ emissions across its lifecycle compared to traditional multi material solutions. Even in a non recycled scenario, the monomaterial pouch achieves a 25% emissions reduction—proof that recyclability and lower environmental impact can go hand in hand. The company is also expanding the Pouch5® concept with monomaterial PE versions designed for cold and

hot fill applications, undergoing validation for future market deployment.

Recognizing that true circularity requires more than just recyclable films, Gualapack redesigned its spouts and caps to match the sustainability profile of its monomaterial pouches. New tethered caps comply with the EU Single Use Plastics Directive, ensuring components remain attached during use to reduce litter and improve collection rates.

In the personal care segment, InnowebMONO™ extends Gualapack’s monomaterial strategy to tubes. This polypropylene based laminate is compatible with rigid PP recycling streams, enabling more circularity even in the cosmetics industry.

Moreover, most of Gualapack’s standard laminates today are available in fully PP or PE formats, broadening the recyclable options across diverse markets—from baby food and dairy to pet care and cleaning products.

Despite these innovations, global recycling infrastructure still lags. Lightweight flexible packaging, while efficient in material use, is often not prioritized in collection and sorting systems due to its low volume to value ratio. Gualapack addresses this challenge through active participation in cross industry initiatives like CEFLEX, which aims to align packaging design with evolving infrastructure capabilities.

The company also explores polyolefin blends and PE/ PP combinations where full monomaterial formats are not feasible, ensuring incremental sustainability gains without compromising performance.

The shift to monomaterial packaging is part of a broader commitment: as of 2024, 24.3% of Gualapack’s global sales come from sustainable products—up 11% from the previous year. The company expects this share to rise sharply as eco conscious consumers and legislative frameworks push brands toward recyclable, lightweight, and lower impact packaging.

Gualapack’s sustainability strategy spans multiple fronts—including reuse, recycled content, compostability, and bio based solutions—but monomaterial structures remain foundational in its drive to reduce carbon intensity and align with the EU Packaging and Packaging Waste Regulation (PPWR) effective from 2026.

As climate related disasters intensify, consumer packaged goods (CPG) companies are under pressure to reduce their environmental impact and support a circular economy. This is driving investments in setting ESG (environmental, social, and governance) goals, eliminating single use plastics, choosing recyclable and renewable materials, and promoting reuse and compostable packaging.

Digital tools play a pivotal role in achieving sustainability goals. AI helps design lightweight packaging, 3D printing cuts waste in prototyping, and smart packaging using Quick Response codes or radio frequency identification tags educates consumers on proper disposal. Blockchain ensures traceability, giving consumers confidence in sustainable sourcing and processes.

Consumers want to know how brands are advancing on sustainability. Transparent reporting of packaging materials, energy usage, and partnerships fosters trust

and aligns with consumer values.

Many CPG firms now integrate ESG into their operations and reap benefits like lower waste, higher productivity, and better profits, according to Sustainability and Technology – the Future of Packaging and Processing, a report published by PMMI, The Association for Packaging and Processing Technologies. Strategies include switching to sustainable packaging formats, renewable energy use, and designing with end of life disposal in mind. New disclosure rules from the U.S. Securities and Exchange Commission and more rigorous Scope 3 emissions regulations in California and the EU are pushing companies to track and report climate data throughout their supply chains.

Partnerships with suppliers and retailers help develop innovative, sustainable packaging while ensuring compliance with evolving standards. At the same time, brands are investing in consumer education on recycling and proper disposal through detailed labeling.

Renewable materials derived from plant based sources are being viewed in an increasingly favorable light because they lessen dependence on fossil fuels, and some are biodegradable and/or compostable. According to the Packaging Compass report, produced by PMMI and AMERIPEN, compostable packaging is expected to be one of the fastest growing formats.

CPG firms are cutting plastic use, specifying biodegradable films, recyclable plastics with post consumer content, and paperboard alternatives. Lightweighting and better design reduce overall material use. Reusable packaging models are also gaining traction, particularly in the personal care and wine sectors.

The Healthcare Plastics Recycling Council is exploring circularity through advanced recycling, while Finland’s Reusify project is researching new reuse systems across industries. Small adjustments can yield big results: One study found that raising cold chain temps from 0 to 5°F could save energy and reduce emissions, without compromising food quality.

Sustainability in packaging is no longer optional — it’s a brand imperative. The industry is taking vital steps toward a greener future through transparency, collaboration, and innovation. Sustainability will be a leading topic at PACK EXPO Las Vegas (Sept. 29–Oct. 1, 2025; Las Vegas Convention Center). The 30th year of the show features 2,300 exhibitors and expects 35,000

attendees from 40+ vertical markets.

Attendees will experience demonstrations of breakthrough packaging, processing, and sustainability solutions in action across the show floor and in pavilions devoted to Containers and Materials, Logistics, Processing, Healthcare Packaging, Confectionery, and Reusable Packaging. In addition, PACK EXPO Las Vegas offers more than 100 educational sessions on seven show floor stages, including Sustainability Central (presented by Packaging World and sponsored by Dow), Innovation Stage, Industry Speaks, and the Reusable Packaging Learning Center (sponsored by the Reusable Packaging Association). New this year, the PACK EXPO Sustainability Tour, produced by PMMI Media Group, will provide a curated experience designed for CPG brand owners actively seeking sustainable solutions. Additional resources include the PACK EXPO Sustainability Solutions Finder, an online search tool with unique filters to help you curate a list of vetted exhibitors showcasing sustainable products or solutions that suit your needs. These exhibitors are also identifiable by the PACK EXPO Green logo within the exhibitor directory listing and on placards onsite. Don’t miss this opportunity to stay ahead in the industry. Register now to connect with industry leaders, discover state of the art innovations, and gain a competitive edge. Visit packexpolasvegas.com to learn more and register. Registration is $30 through Sept. 5, after which the price increases to $130.

The countdown is on for K 2025, the world’s leading trade fair for the plastics and rubber industry. Taking place from 8 to 15 October 2025 at Messe Düsseldorf in Düsseldorf, Germany, the event is set to once again raise the bar for innovation, sustainability, and industry collaboration. With more than 3,200 exhibitors from over 60 countries and tens of thousands of professional visitors expected, K 2025 promises to be an unmissable event for anyone shaping the future of materials and production.

This year’s edition will focus on three key drivers transforming the industry, circular economy, digitalisation, and climate protection, providing insights into how cutting edge materials and processes are revolutionising plastics.

Plastics Shape the Future: The special show of the same name will highlight breakthrough developments in sustainable plastics, energy efficient processes, and innovations that close the loop on material use. Digital Manufacturing: From smart robotics to connected injection molding systems, exhibitors will showcase how digital tools enhance efficiency, traceability, and product quality.

Green Materials & Climate Solutions: Expect to see a wave of new bio based polymers, recyclable thermoplastics, and low carbon production technologies that align with global climate goals.

Among the thousands of global players attending, several exhibitors have already revealed exciting previews of what’s to come:

FEDDEM (Hall 15, Stand A42) will debut its FED 18 MTS laboratory extruder at K 2025. Featuring a modular design, optional side feed and vacuum degassing, it delivers flexibility, stability, and reproducibility for R&D, pilot production, and quality assurance. Visitors can experience its capabilities firsthand in Düsseldorf. Dow (Generation Transformation Pavilion, near Hall 4) will present a broad range of materials, mono PE, biocircular, circular, and PCR polymers, demonstrating their role in driving packaging, mobility, and

ENGEL (Hall 15, Stand B42 and C58) will demonstrate a highly automated production cell for fuel cell components, featuring a vertical injection molding machine with 1500 kN clamping force. The system uses a two cavity mold and integrated rotary table to overmold gas diffusion layers in liquid silicone rubber with precision and efficiency, supporting advancements in hydrogen mobility technologies.

Colines (Hall 16, Stand A39) is set to debut its 9 layer POLYBLOWN® blown film extrusion line, running live during the show. Visitors can also see the latest ALLrollEX® cast stretch film line, equipped with AI based MASTERMIND® control, coreless reel technology, and edge reinforcing systems—delivering high performance films with up to 30% PCR content.

BOBST (go to https://go.bobst.com/ to register) will host a series of exclusive events throughout the show, unveiling innovations for the flexible packaging sector. Their latest technologies aim to enhance productivity, recyclability, and resource efficiency, reinforcing BOBST’s commitment to advancing circularity and sustainable production.

With 18 exhibition halls, a packed programme of presentations, and a wealth of innovations shaping the future of plastics, K 2025 is set to reaffirm its status as the industry’s ultimate meeting point. For professionals looking to stay ahead of market trends and technological advancements, Düsseldorf in October is the place to be.

For more informationand to register for the event, please visit www.k-online.com

BOBST set to unveil new solutions to power performance at series of exclusive events during K 2025

‘Dow inspires next-generation innovation at K 2025’

Sustainable packaging is reshaping the industry by delivering solutions that cut emissions while maintaining performance. Through innovations that reduce plastic use, lower resource demand, and support circular practices, companies are showing that environmental responsibility and growth can go hand in hand. SPN shares its insights!

Over the past decade, the packaging industry has made meaningful strides in reducing its carbon footprint, and Sustainable Packaging News provides compelling evidence of this progress. According to a sustainable development report featured on our website, the carbon footprint associated with food packaging (including meat, fish, and cheese) has fallen by approximately 43.9% since 2005, a significant drop over about two decades, which implies a substantial reduction in the last ten years alone.

Sandland Packaging, one of the United Kingdom’s leading cardboard packaging manufacturers, has successfully retained its Carbon Neutral certification for the fourth consecutive year. This achievement ensures that any packaging purchased from them carries no carbon footprint, a strong testament to their environmental commitment. They are also targeting Net Zero by 2040, which is a decade ahead of the legal requirement. This proactive stance places Sandland among the frontrunners in the packaging industry’s sustainability efforts.

“We are delighted to continue to support Sandland Packaging on their journey to Net Zero and look forward to mobilising their supply chain to join them on elevating sustainability and carbon emission reduction aligned to Sandland Packaging’s Net Zero target”.

Since implementing changes to processes, procurement, and corporate mindsets, the company has reduced its operational control emissions (scope 1 and scope 2) to only 7.86 percent of its total carbon footprint. This is a remarkable achievement that demonstrates effective management of emissions directly under their control. However, the majority of their emissions, a striking 87.32 percent, come from their supply chain (scope 3 category 1 – purchased goods and services). Tackling this area remains their greatest challenge.

The company’s retention of its Carbon Neutral certification for four consecutive years is an outstanding achievement. Their early commitment to Net Zero by 2040 illustrates leadership and innovation in sustainability. By measuring all 15 categories of scope 3 emissions in addition to scope 1 and scope 2, they

demonstrate a level of transparency and thoroughness that is ahead of many competitors. Furthermore, their approach to aligning supply chain practices with their own Net Zero targets reflects forward thinking strategy, showing they are not only managing internal emissions but also influencing the wider ecosystem. However, Sandland Packaging faces significant hurdles in achieving their Net Zero ambitions. The overwhelming 87.32 percent of their emissions arising from the supply chain presents a complex challenge. Mobilizing and aligning suppliers to match Sandland’s sustainability goals will require extensive effort, collaboration, and potentially increased costs.

“We are delighted to continue to support Sandland Packaging on their journey to Net Zero and look forwward to mobilsing their supply chain...”

Overall, Sandland Packaging is doing an excellent job in its mission to reduce its carbon footprint. Their proactive measures, consistent achievement of Carbon Neutral certification, and ambitious Net Zero target place them at the forefront of sustainability within the packaging industry. While the scale of their supply chain emissions presents a significant obstacle, their commitment to tackling this issue head on, coupled with industry support, strongly suggests they are on track to make a lasting impact in reducing carbon emissions.

For more information, please visit www. sandlandpackaging.co.uk/sandland-packaging-retainscarbon-neutral-certification-for-the-4th-year-runningand-welcomes-the-move-from-pas2060-to-iso14068-1/

Elopak has recently published findings from a Life Cycle Assessment (LCA) study comparing its D PAK cartons to LDPE pouches for household product refills. The results show that the D PAK cartons have a significantly lower environmental impact than pouches across several key measures, including global warming potential, carbon dioxide emissions, resource scarcity, and plastic usage.

The study, conducted by Anthesis, found that using a D PAK carton as refill packaging results in a 24 per cent lower impact on global warming than a 1 litre pouch, rising to 28 per cent for a 1.8 litre pouch. Even when LDPE pouches are manufactured with 50 per cent or 100 per cent recycled content, cartons still maintain a measurable advantage. Furthermore, cartons have a 33 per cent lower impact on resource scarcity for 1 litre refills, increasing to 38 per cent for larger packs. The plastic saving is even more pronounced, with D PAK cartons using 44 per cent less plastic than LDPE pouches, containing only 9 grams compared to 20.1 grams in a pouch and 76.7 grams in a polypropylene bottle.

“We are delighted to be able to share these findings, which show that Elopak cartons are a significantly more sustainable packaging solution for laundry detergent than common refill alternatives like pouches.”

The results strongly reinforce Elopak’s reputation as an innovator in sustainable packaging. By delivering a solution that uses less plastic, reduces greenhouse gas emissions, and lowers resource depletion, the company demonstrates leadership in environmental responsibility. The findings align with consumer sentiment, as research shows that most shoppers in the United Kingdom and Germany prefer more sustainable packaging options, with 64 per cent stating they would buy fabric softener in a carton and over 60 per cent willing to purchase detergent or floor cleaner in similar formats. Elopak’s strategy, ‘Repackaging tomorrow’, capitalises on this growing demand and positions the company to expand its fibre based solutions into new markets. However, while the cartons significantly reduce plastic, they still contain some plastic components, which may be criticised by those advocating for fully plastic free packaging.

Elopak is making impressive progress in reducing its carbon footprint and helping brands move away from plastic dependency. Their D PAK cartons show

Where there is water, there is life. We use the power of water for renewable energy to build a more sustainable future.

substantial advantages over LDPE pouches and plastic bottles, with strong reductions in emissions, resource use, and plastic content. Although challenges remain in terms of supply chain adoption and market expansion, Elopak’s commitment to innovation and consumer engagement demonstrates that they are on the right path.

For more information, please visit www.elopak.com

Sandland Packaging and Elopak are making significant progress in reducing carbon emissions and driving sustainability in the packaging industry. Sandland’s early Net Zero target for 2040, combined with four consecutive years of Carbon Neutral certification, highlights its leadership. While supply chain emissions remain a challenge, the company’s transparency and proactive approach suggest it is well positioned to meet its goals. Elopak is similarly advancing with its D PAK cartons, which cut emissions, resource use, and plastic content compared to LDPE pouches. Supported by strong consumer interest, their fibre based solutions show clear environmental benefits, despite the hurdles of partial plastic use and market adoption. Together, Sandland Packaging and Elopak are leading the charge in transforming the packaging sector. Their initiatives not only cut carbon emissions but also promote a circular economy by encouraging sustainable practices across supply chains and consumer markets. By pushing boundaries, embracing innovation, and committing to ambitious environmental goals, both companies are helping to shape a future where packaging is not only functional but also a force for environmental good.

As one of Europe’s largest aluminium foil producers and a trusted supplier to the packaging sector, Assan Alüminyum understands that sustainability must be more than just a commitment — it must be an operational standard. With climate conscious consumers and stricter regulations shaping the future of many industrial sectors, the company is actively reducing its carbon footprint through a comprehensive and forward thinking Decarbonization Roadmap.

At the heart of this transformation lies clean energy. The company produces renewable energy at its hydroelectric and solar plants and fully offsets its market based Scope 2 emissions through International Renewable Energy Certificates (IRECs). This ensures that its low carbon aluminium products are aligned with evolving market expectations for climate responsible packaging solutions.

“Our investment in renewable energy is not just an environmental or an economic choice, it’s a strategic one. We are one of the few flat rolled aluminium manufacturers with inhouse renewable energy power plants, allowing us to reduce our overall carbon footprint.”

The Decarbonization Roadmap 2050 outlines clear milestones: reducing carbon intensity to 7 tCO₂e/t by 2030, then further lowering it to 3 tCO₂e/t by 2035, with the goal of achieving net zero emissions by 2050. Assan Alüminyum supports these targets through data driven execution and technological investments.

While the packaging industry is increasingly exploring new, innovative solutions, aluminium remains a vital material thanks to its unique sustainability attributes, including impermeability, lightweight strength, durability

and infinite recyclability. In particular, aluminium foil plays a key role in extending shelf life by providing an effective barrier against light, oxygen, moisture and contaminants. This not only protects product quality and flavor but also contributes meaningfully to reducing food waste, a major global environmental challenge.

Assan Alüminyum also works closely with its suppliers through its parent company, the Kibar Group’s K STAR Supplier Sustainability Program, encouraging improved ESG performance across the value chain. This collaborative approach reinforces the company’s broader responsibility toward sustainable sourcing and production.

Assan Alüminyum’s environmental leadership is independently recognized. The company holds the Aluminium Stewardship Initiative (ASI) Performance Standard certification, affirming that its operations meet internationally recognized ESG criteria for the aluminium value chain. It also achieved a “B” rating from the CDP Climate Change Program, placing it above industry averages in climate transparency and risk management. Whether reducing emissions, supporting biodiversity, or mitigating climate risks, Assan Alüminyum continues to lead by example.

Article courtesy of Assan Alüminyum

by Dominy Jones

As environmental pressure mounts and regulations tighten, industries are increasingly turning away from single use plastics toward sustainable alternatives. From compostable foils to fibre based boards, innovations led by Sulapac, Scanfill, and EBB Board are redefining what packaging can be—without compromising functionality.

In June 2025, Scanfill, a materials specialist firm, unveiled its Degrafoil Flow 1.7 in collaboration with Sulapac, positioning it as a next generation plastic foil replacement suitable for thermoforming applications across Europe. Made from Sulapac Flow 1.7 wood composite, this material combines functional strength, smooth surface finish, and compostability—all while cutting carbon footprint relative to conventional plastics like PET.

Juho Luukkanen, Sales Director of Sulapac commented: “Sulapac always aims to make sustainability an easy choice, together with Scanfill we can accelerate towards that goal.”

Degrafoil products are produced in southern Sweden and meet food contact regulatory standards, with early commercial rollouts already underway.

A recent report featured solutions from EBB Board addressing plastic substitutions in food delivery and service packaging. Their innovations, FiloPack and FiloServe, are PFAS‑free, food‑grade paperboards with coatings that resist grease, oil, and water—making them ideal for bakery cartons and takeaway trays.

FiloServe is tailored for bakery and frozen foods, while FiloPack delivers performance for oily or greasy products. Both materials are recyclable and industrially compostable, printable for branding, and fully compatible with existing board fabrication lines.

Other paper based innovations include Viscose’s self shrinking fibre collars, which biodegrade within four months in soils or home compost, and Ecopack’s grass fibre “TerraMoulds” baking trays, which are oven safe and compostable, with significantly lower energy and water footprints compared to plastics.

Stepping beyond fiber based materials, European packaging provider Modepack has introduced a revolutionary option: Lignin Mailing Bags, launched in June 2025. Crafted from a blend of post consumer recycled plastic (LDPE) and Renol®, a thermoplastic derived from lignin (a wood processing byproduct), these mailers offer a sustainable spin on e commerce packaging.

According to Jure Širić, Managing Director at Modepack: “This is more than just another eco friendly mailer, it’s a transformative step towards a greener future.” The new bags reduce CO₂ emissions by 60–70% compared to traditional recycled plastic mailers, while remaining moisture resistant, tear proof, and compatible with existing recycling systems.

These latest innovations exemplify a broader shift in materials choices:

• Functional equivalency: Scanfill/Sulapac’s material matches plastic’s durability and processing ease, while FiloPack boards handle moisture and grease effectively. Modepack’s mailers combine performance with low impact design.

• Industrial compostability: Both offerings meet industrial end of life standards, making real world disposal feasible.

• Scalability: They integrate with existing production infrastructure—whether thermoforming lines or board converters—reducing barriers to adoption.

• Consumer alignment: Recent surveys show that nearly 90% of consumers prefer cartonboard based packaging over plastic when given a choice, boosting demand for such solutions.

Analysts note that fibre based packaging continues its growth trajectory. Renewed consumer interest and legislation phasing out certain single use plastics have accelerated uptake of materials like cartonboard, paper based foils, and moulded fibres.

While bioplastics remain appealing, industrial compostability ensures the intended benefits are realised. Fibre and wood based materials offer clear transparency on recyclability and renewable sourcing— advantages that are resonating with conscientious brands and consumers alike.

The path to scalable, high performance alternatives lies not just in innovation, but also in infrastructure support, accurate labelling, and cross sector collaboration. Sulapac/Scanfill, EBB Board, and Modepack are leading this shift—showing that what was once experimental can now become essential in the journey toward a truly circular economy.

However, broader progress hinges on consumer education, optimised end of life infrastructure, and seamless supply chain integration. Brands willing to pioneer these materials today—not as symbolic gestures, but as operational cornerstones—stand to lead in an authentically circular future.

The confectionery sector is enjoying robust growth—but with a twist. As demand for more sustainable products and packaging increases, consumers are pushing for more than just indulgence. They expect transparency, health-conscious options, and above all, sustainable packaging. For confectionery brands, this means navigating a complex landscape—still predominantly reliant on plastic materials—while adapting to evolving consumer tastes, stricter regulations link to recyclability and limitation of single use plastic.

Ahlstrom, a leader in fiber-based materials, is at the forefront of this transformation. We offer high-performance, sustainable solutions that meet the technical and regulatory needs of today’s and tomorrow confectionery market. The ambition is to help brands reduce the environmental impact of their packaging through paper-based alternatives.

From chocolate and gum to bars and hard candies, confectionery is flourishing globally. In North America, the snack market is forecasted to grow from $215 billion in 2024 to $275 billion in 2029. Europe follows closely, with growth from $155 billion to $190 billion over the same period. Rapid innovation is underway, especially in Europe, which accounts for nearly half of all new global confectionery launches.

Consumer trends are driving this momentum. Healthier treats, plant based formulations, and functional confectionery (like prebiotic packed or low sugar candies) are reshaping product development. Equally important is the packaging: consumers are increasingly seeking recyclable, compostable, and plastic free formats. Here lies a powerful opportunity for fiber based solutions. Sustainable packaging innovations should maintain product quality and shelf life, without driving up costs.

As the EU’s Packaging & Packaging Waste Regulation (PPWR) and other global regulations accelerate the push toward circular packaging, fiber based solutions are becoming not just desirable—but essential. Made from renewable resources and recyclable through established systems, paper is a strategic packaging choice for

confectionery brands looking to future proof their products.

Ahlstrom’s packaging papers answer this call by delivering technical performance without compromising sustainability. Designed to meet the demands of various confectionery applications—from recyclable twist wraps for hard candies to recyclable flow wraps for bars— Ahlstrom papers offer a viable alternative to plastic based packaging.

Ahlstrom’s comprehensive portfolio addresses the entire spectrum of confectionery packaging needs. For high speed wrapping, Rocalonde™ delivers excellent twistability and high gloss, ensuring both efficient machinability and strong shelf appeal. Its recyclability makes it a preferred choice for many leading brands. Its recyclability credentials make it a leading choice for many brands on the market.

We’ve also developed GreaseGuard™ Liner—a high performance, PFAS free paper designed for direct food contact. Optimized for microflute structures, it’s ideal for applications such as cookie packaging, chocolate box cushion pads, corrugated sleeves for biscuits, and pastry trays.

When transparency is essential—especially for certain confectionery products—Cristal™ transparent paper offers clear visibility and a clean aesthetic without the need for plastic films. It’s ideal for window style bags and candies where product visibility drives appeal. For flexible packaging formats like sachets, pouches,

or flow packs, our advanced base paper LamiBak™ Flex provides superior mechanical properties, enhanced surface smoothness, and compatibility with high barrier coatings. Moreover, LamiBak™ Flex is certified recyclable according to regional guidelines in both North America and Europe, and compliant with EU and U.S. food contact regulations for primary packaging

At Ahlstrom, we drive packaging innovation through close collaboration with brands, converters, and value chain partners. From GreaseGuard™ to Cristal™ and LamiBak™ Flex, our fiber based solutions deliver performance, food compliance, and sustainability— enabling confectionery brands to lead with purpose. As consumers continue to sweeten their cravings with values driven choices, Ahlstrom is ready to wrap the future of confectionery—beautifully, sustainably, and smartly.

For more information, please visit www.ahlstrom. com/products/food-packaging-baking-and-cookingsolutions/food-packaging-papers/Confectionarybaked-goods-papers/

The countdown is on for drinktec 2025, the world’s leading trade fair for the beverage and liquid food industry. Taking place from 15 to 19 September 2025 at the Trade Fair Centre Messe München in Munich, Germany, the event promises to once again set the benchmark for innovation and industry collaboration.

This year’s edition will shine a spotlight on sustainability, digitalisation, and health trends—three areas driving transformation in the beverage industry.

• Circularity & Resource Management: Expect to see cutting edge solutions for recyclable mono material packaging, residue free labelling, and resource efficient production systems—paving the way towards a fully circular economy.

• Data2Value: Industry leaders will demonstrate how artificial intelligence, data analytics, and smart sensors are revolutionising production lines, optimising efficiency, and enabling data driven decisions.

• Lifestyle & Health: Responding to the growing demand for wellness focused products, exhibitors will present the latest developments in plant based drinks, functional beverages, and health oriented formulations.

The Liquidrome: Innovation at the Heart of the Show

A highlight of the event is the Liquidrome, located

in Hall C4. This interactive hub will feature keynote presentations, expert panel discussions, and live startup showcases. Visitors can also experience the Health Bar and explore the “Science Wall”, where research meets real world applications—creating a dynamic platform for knowledge exchange.

Among the many global players attending, several exhibitors are already making headlines with their latest innovations:

• PakTech (Hall C2, Stand C2 150) will showcase its fully recycled HDPE multipack handles and the CCA 120/180 automatic can carrier applicator, boosting circularity in beverage packaging.

• Aptar Closures (Hall C6, Stand C6 342) is set to unveil next generation sports closures, including NexTE, Rocket, and Balance—tamper evident, recyclable, and compliant with upcoming EU packaging regulations.

• KHS Group (Hall B4) will demonstrate holistic line solutions, including the InnoPET FreshSafe QuadBlock system for blow fill labelling PET bottles, alongside digital tools such as Innoline and KHS ConnectApp.

• Domino Printing Sciences (Booth A5 101) introduces advanced laser and fibre laser coding systems, including an all in one Beverage Empty Can Coding System that supports sustainability and traceability.

• LEIBINGER will highlight its robust CIJ printers with 2D code marking and innovative keg inks that withstand challenging environments while enabling residue free cleaning during reuse cycles.

• CCL will present its latest sustainable labelling solutions, such as EcoShear® labels for glass, EcoFloat® sleeves, and mono material pouches—designed to enhance recycling and circularity.

With 11 exhibition halls, an extensive programme of presentations, and a wealth of new product launches, drinktec 2025 is set to reaffirm its status as the ultimate meeting place for the global beverage industry. For professionals seeking to stay ahead of market trends and technological advancements, Munich in September is the place to be.

KHS AT DRINKTEC 2025 15–19 SEPTEMBER