CIRCULAR ECONOMY 2.0: WHAT COMES NEXT? Circular Economy | Reusable Packaging | Resource Efficiency

CIRCULAR ECONOMY 2.0: WHAT COMES NEXT? Circular Economy | Reusable Packaging | Resource Efficiency

Dear readers,

How’s your year going?

The second edition of SPN brings you the latest on our brand-new event, Circular Economy week.

Our Circular Economy week, sponsored by Colpac and goplasticpallets.com, brings you the latest innovations and groundbreaking news from Duo, ProCarton and Rockwell Automation and many more. We have also got a roundtable event covering all things Circular Economy and our speakers include Jeremy Blake from Berry Global Inc, Dave Gudgeon from Reconomy and Gary Tee from TIPA. This week starts from 21st April and is not one to miss!

In this edition of the magazine, we also look at how LED printing; a new concept combining mercury lamps and to LED technology and how AI and IoT; new technologies which are having a big impact of the role of sustainability. We also look at statistics surrounding plastic packaging and how hybrid plastics are a potential solution to minimalizing plastic waste and becoming more eco-friendly.

I am very grateful for the companies who have provided us with articles and interview, and my co-writer Dominy Jones; thank you for making our magazine a success!

All the best and keep safe, Emily

linkedin.com/company/ sustainablepackaging-news/ youtube.com/ @sustainable packagingnews

spnews.com

Page 5

Is Industry 4.0 the Key to Sustainable Manufacturing? including

• FRESH FOCUS from ATS Tanner Banding Systems.

Page 12

Driving Sustainability in Printing: LED Curing, 3D Resins and Minimalist Packaging.

Page 16

From Policy to Practice: How the EU and UN are Leading Resource Efficiency. including

• FRESH FOCUS from SP Group.

• Interview with Sandrine DuquerroyDelesalle at Crown Holdings.

• Article provided by Food Packaging Forum.

• BUSINESS LIMELIGHT from Marchesini.

Page 29

Circular Packaging Revolution: Reimagining Reuse for a Greener Future. including

• CIRCULAR ECONOMY WEEK by SPN.

• Article provided by Flint Group.

• Interview with Lea Maguero at BioPaK.

• SPONSORED CONTENT from Colpac.

• SPONSORED CONTENT from goplasticpallets.com.

• Interview with Saxon Wright at Huskee.

Page 48

Reusable Packaging: Moving from Niche to Necessary by Dominy Jones. including

• Article by Emma-Jane Batey, Pont.

Page 52

Sustainable Solutions for Plastic Packaging and the Future of Circular Economy. including - Article provided by Flint Group.

Page 57

Why Corrugated Packaging is Stealing the Sustainability Spotlight by Dominy Jones. including - Article provided by Contact Originators.

Page 61 Can Fibre Bottles and Sustainable Carton Packaging Replace Plastic for Good?

It’s becoming more and more apparent that new technologies are having a big impact on the role of sustainability. Let’s take a further look into what is happening in today’s market. Emily Gambrill reports.

We’re now living in a world where technology like Artificial Intelligence (AI), the Internet of Things (IoT) and advanced data analytics is a concept understood by most people on the planet. In this article we’re going to see how advances in these areas are enabling optimized resource management, reduced waste, cleaner energy production and more sustainable urban development.

SPN has received news from TNA who have launched an immersive and interactive digital service to help food manufacturers visualise their plant floor, virtually replace systems and validate manufacturing plans and installations in a low-risk environment.

“Much of food manufacturing has readily adopted Industry 4.0 technologies due to the efficiency, productivity and repeatability benefits they offer,” explained Natasha Avelange, Global Extended Reality

Manager at TNA Solutions. “Building on this with XR allows the human element of food manufacturing to be enhanced, with creativity, productivity and problem solving brought together without barriers. This is the essence of Industry 5.0.”

“Food production is an area where there is a continuous drive towards higher output, greater efficiency and continuous uptime. That’s why it’s so important that equipment upgrades or introductions are well-planned and delivered as efficiently as possible. With tna intelliassist, we’ve innovated a way to significantly shorten project planning time, and improve accuracy, enabling teams to get integration right the first time.”

Commenting on the launch, Thiago Roriz, Chief Operating Officer at TNA Solutions said: “As a forward-

thinking company committed to innovation, we are proud to integrate Industry 5.0 technologies, particularly in VR, into our project management process. By harnessing the power of VR, we are not only enhancing operational efficiency but also empowering our teams to collaborate more effectively, train in immersive environments, and optimise production in real time. These advancements directly translate into a more responsive and agile approach to customer needs, allowing us to deliver tailored solutions faster and more effectively. This step marks a significant evolution in how we integrate cutting-edge technology with human-centred design, ensuring that it serves not only operational goals but also drives customer satisfaction. With Industry 5.0, we are ushering in a new era, one that balances advanced automation with the ingenuity of the human touch.”

“Building on this with XR allows the human element of food manufacturing to be enhanced, with creativity, productivity and problem solving brought together without barriers. This is the essence of Industry 5.0.”

For more information, please visit www.tnasolutions. com/campaign/tna-intelli-assist

We have also seen from Ishida that they have created a tray sealer which has been specifically developed for high-volume production lines. Its capabilities are immense and the product’s compact design saves in excess of 40% floor space whilst operating with 50% less power consumption.

Darren Chandler, General Manager for Protein Solutions

at Ishida Europe, said: “We are really excited to return to IFFA. We know meat processing and packaging is all about equipment that can keep production going 24/7 whilst meeting customer demand for high quality products. At IFFA, we will demonstrate that, whatever your production challenges, Ishida has the technology, the people and the experience to work out the best solution”.

“Automation and datadriven decision making is a key requirement from food manufacturers. With Sentinel 5.0, we can give operators smarter insights.”

Food safety is paramount for any food processing solution, especially for poultry processors. The presence of bone and other foreign bodies can lead to costly recalls and a loss of brand reputation. For these reasons, Ishida has developed the IX-PD-Poultry which is an integrated dual lane X-ray system that can inspect up to 400 chicken pieces per minute.

Darren explains: “The IX-PD-Poultry is our answer to one of the poultry industry’s most pressing concerns: bone detection in high-speed production lines. It utilises Photon-Counting Dual-Energy (PD) technology to produce ultra high-resolution images to detect wish, rib and fan bones and very small foreign bodies (such as steel wires).”

“The IX-PD-Poultry helps our customers to maintain or even enhance strict quality control procedures without compromising on throughput.”

In addition to the tray sealer, Ishida have designed the Sentinel 5.0 software. Using artificial intelligence (AI),

Sentinel 5.0 supports food manufacturers with optimising their production lines. It can analyse realtime data across both Ishida and non-Ishida equipment, providing instant performance insights along with identifying potential issues and recommendations for how to rectify them.

Darren adds: “Automation and data-driven decision making is a key requirement from food manufacturers. With Sentinel 5.0, we can give operators smarter insights. It also has an AI chatbot function, so operators can ask Sentinel 5.0 to troubleshoot issues and receive alerts to any deviations from normal machinery behaviour.”

For more information, please visit www.ishidaeurope. com/en

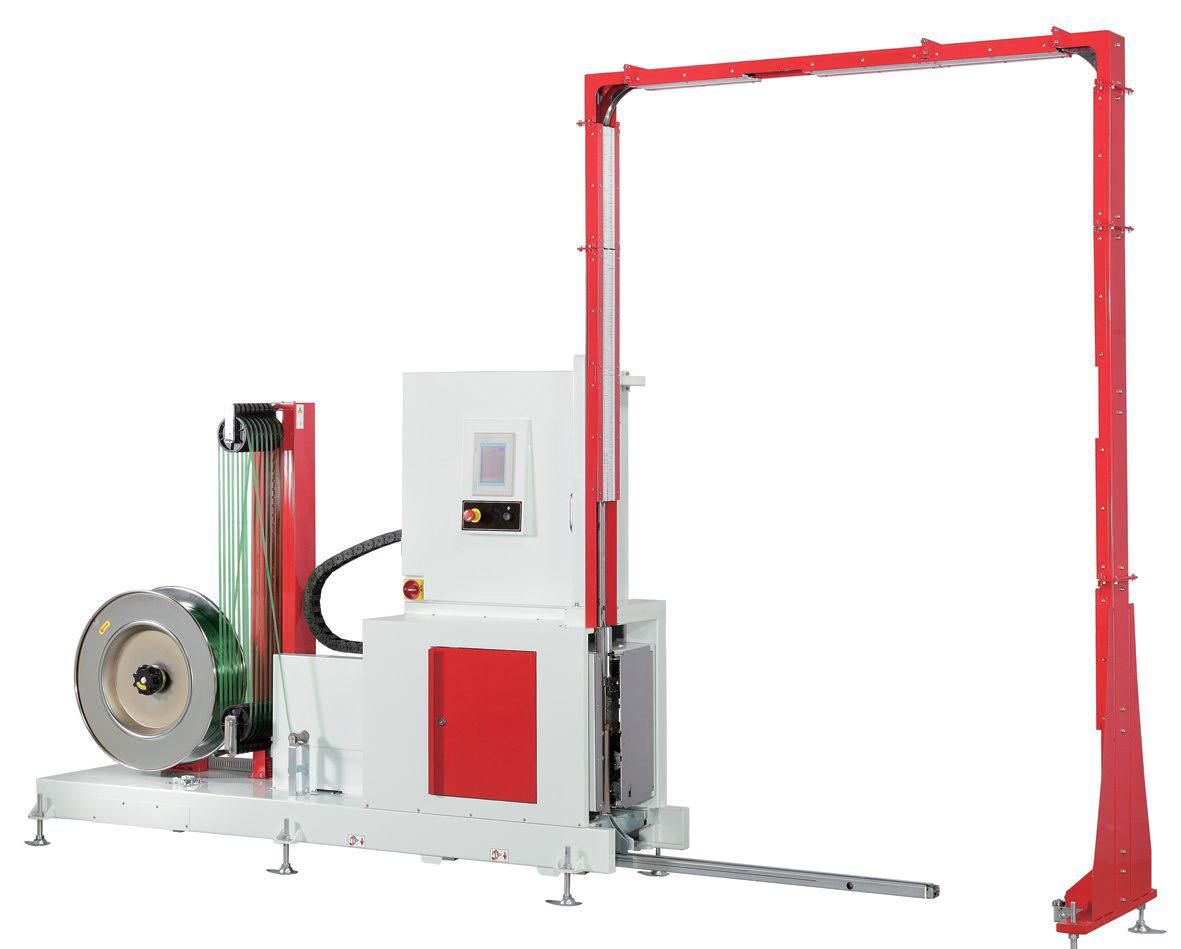

In our last edition of the magazine, we delved into the way we package our goods for transportation. We read interviews with Jim Hardisty at goplasticpallets. co.uk about how to minimize product damage for supply chain managers and Anke Thies at PapairWrap who wrote about how they create suitable alternative solutions to plastic packaging to protect products during transportation. Going on from there, we learn from PAC Strapping Products about how they have engineered a pallet strapping system which enhances pallet strapping efficiency for contract manufacturers across a range of applications.

The PSS733 series features a powerful 733 strapping head capable of applying over 720 pounds of tension, ensuring robust friction-welded joints with over 80% seal efficiency. Its modular arch system supports

The Siemens PLC control system provides intuitive operation through a touchpad interface, complete with onboard diagnostics to streamline maintenance and reduce downtime.

custom sizes, allowing for tailored solutions and shorter lead times. Compatible with both polyester and polypropylene strapping, the PSS733 accommodates various materials within the recommended working range, optimizing pallet security and lowering packaging costs.

Each model in the PSS733 series is built to address specific strapping requirements. Configurations include vertical including both side seal and top seal, and horizontal, with options like indexing heads for precise positioning and a lance system for strapping through pallet voids. The Siemens PLC control system provides intuitive operation through a touchpad interface, complete with onboard diagnostics to streamline maintenance and reduce downtime.

Durability and performance are central to the PSS733’s design. Engineered to integrate seamlessly into existing conveying systems, the PSS733 series ensures consistent, high-quality results across diverse production settings.

PAC Strapping’s commitment to quality is backed by industry-leading warranties, a comprehensive inventory of spare parts, and factory-trained technicians dedicated to supporting long-term performance.

For more information, please visit www.strapsolutions.com

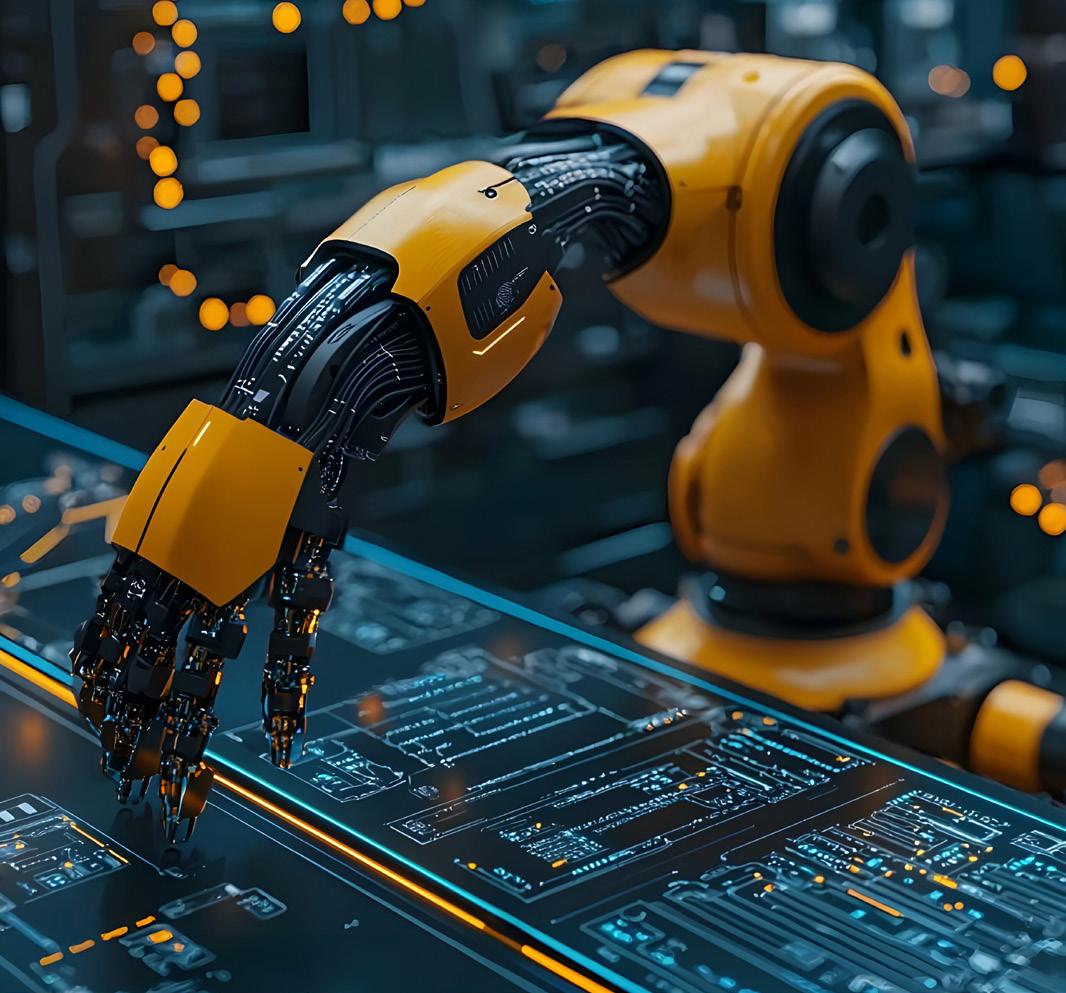

Finally, we look at the role of robotics in pharmaceutical manufacturing. It comes as a surprise to me that the pharmaceutical sector has long been considered slow to adopt new technologies, but it seems they are now catching up. Let’s read what Dr Laura Moody and Daniel Sturm have to say.

Robots have always captured our imaginations, whether it’s Wall-E cleaning up the Earth or the Terminator causing mayhem. But in the pharmaceutical industry,

robots are anything but science fiction. They are practical, precise, and efficient machines, designed for tasks that require absolute accuracy.

“Forget the images of robots you see in movies,”says Daniel Sturm. “The robots we use in pharmaceutical environments are specifically designed to improve productivity and consistency. We’re talking about machines that can take on highly specialized roles, enhancing the speed and safety of drug production.”

And what makes these robots unique? It all starts with the axes.

When discussing robotics, you’ll often hear about “four-axis” or “six-axis” robots, but what does that really mean? The term “axis” refers to the degree of freedom a robotic arm can move in. The axes determine the robot’s ability to move in different directions, with each additional axis adding more flexibility and range of movement. “You can think of a robot’s axes like a human’s limbs and joints,” Sturm says. “The more axes a robot has, the more tasks it can perform and the more complex its movements.”

In pharmaceutical manufacturing, this flexibility is key. Four-axis robots are commonly used for their ability to handle repetitive and straightforward tasks, while sixaxis robots offer more versatility for intricate jobs. These robots are integrated into everything from packaging lines to gloveless filling systems, where they help maintain cleanroom standards.

Looking ahead, the future of robotics in pharmaceutical manufacturing looks bright. As companies continue to invest in automation, the potential for robots to take on even more roles—both inside and outside the machine— is vast. From transferring materials in cleanrooms to operating complex machinery, robots are poised to play an even bigger role in pharma’s future.

Coupled with AI, robotics promises transformative advancements, driving highly adaptive and efficient production processes through predictive analytics and intelligent automation. These technologies are set to revolutionize drug manufacturing by enhancing quality control, streamlining workflows, and enabling groundbreaking innovations such as gloveless isolators and fully integrated digital twins. However, the integration of AI introduces both opportunities and

challenges.

Robotics are not just the future of pharmaceutical manufacturing—they are the present. With companies like Syntegon leading the way, robots are helping to revolutionize the industry by improving efficiency, safety, and flexibility. As the sector continues to navigate regulatory landscapes and technological advancements, one thing is clear: the future of pharma is automated, and robots are here to stay.

For more information, please visit www.syntegon.com

What these articles have in common is that technology is increasing productivity, enhancing quality control and reducing power consumption. We must understand that even though careful application is crucial to diffuse the potential negative impacts, such as increased electronic waste and

energy consumption from new technologies, Fourth Industrial Revolution (4IR or Industry 4.0) can be a powerful tool for driving a more sustainable future.

The European Union’s new Packaging and Packaging Waste Regulation (PPWR), which came into force in February 2025, aims to transform packaging practices across the EU. Its objectives include reducing the use of primary raw materials, ensuring all packaging is recyclable by 2030, incorporating recycled plastics safely, and achieving climate neutrality in the packaging sector by 2050.

Key provisions of the PPWR include setting minimum recycled content requirements for plastic packaging, mandating that all packaging be recyclable, and introducing stringent design for recycling criteria. The regulation also imposes obligations on producers to minimize packaging volume and weight, and to ensure packaging is reusable or recyclable.

The PPWR’s comprehensive approach is expected to significantly impact businesses involved in packaging. Companies operating in the EU need to assess their packaging strategies to ensure compliance with the new regulations and to contribute to the EU’s sustainability objectives.

Banding is a highly sustainable packaging solution due to its minimal material usage and flexibility. Unlike traditional packaging methods like plastic wrapping, banding uses only a small band to secure products together, label them and reduces so the amount of packaging waste generated. And at the same time it has the same advantages as traditional packaging methods:

- Branding with banding on the shelf.

- Integrated printer.

- Company logo’s, sell-by dates or retail prices can be

printed directly just-in-time during the banding process.

- No additional adhesives needed.

- Less waste.

Banding materials are often recyclable and easy to remove, encouraging proper disposal or recycling. Because it can accommodate a variety of product shapes and sizes, it minimizes the need for excessive packaging, making it an eco-friendly alternative to more resource-heavy options.

ATS offers banding machines with ultrasonic and heat seal technology with material-saving, efficient bundling of all kinds of products for logistical purposes, as well as ecological, promotional and customer-friendly sales packaging. Recyclable paper banding replaces shrink films, plastic bags and other conventional plastic packaging when packing fruit and vegetables, convenience food, pharmaceutical and cosmetic products or printed matter of all kinds. Banding is used in e-commerce to bundle ordered products for right-size packaging systems, to seal shipping packages or serves as tamper-evidence for returns handling.

In banding, a 15 to 100 mm wide band of paper or film is placed around one or more products by a banding machine and sealed with ultrasound or heat. The length of the band is determined either by the resistance of the product or by an adjustable fixed length. The force with which the band surrounds the product is infinitely adjustable.

TruePaper is an environmentally friendly, ultrasonic and heat-sealable paper band. It consists of optionally at least 95% pure or more than 50% recycled fibers, can be recycled in the normal paper cycle and is suitable for direct contact with food. TruePaper contains a waterbased bonding agent that can be sealed with ultrasonic and heatseal technology. Basically, any paper with the new bonding agent can become TruePaper which means high flexibility and security in the supply chain.

The main drivers behind the development of TruePaper were the sustainability strategies and goals of ATS’ customers, the legal bans on single-use plastic in a growing number of countries as well as the increasingly important implementation of the circular economy.

The new and exclusive post-consumer recycled (PCR)

banding film: FTN PCR35 is an environmentally friendly, high strength banding film with a minimum of 35% postconsumer recycled (PCR) content that can be sealed using ultrasonic and heat-sealing technologies.

This environmentally friendly banding film promotes the circular economy by using recycled materials and reducing the need for virgin plastics. FTN PCR35 is manufactured from high quality polypropylene (PP) and contains a minimum of 35% post-consumer recycled polypropylene. The film contains no harmful plasticizers and is easily recycled. And with FTN PCR35, our customers can save money: The EU plastic tax aims to reduce plastic waste and promote recycled materials. FTN PCR35 with PCR content supports this goal and reduces taxes.

For more information on this article or to get in touch with ATS Tanner Banding Systems, please visit www.atstanner.com/en/banding

What does an LED curing system, 3D printing, FSC certified paper and a future in minimalistic design all have in common? A group of companies who have sustainability at the forefront when it comes to printing solutions. SPN has their say on this!

Sustainable printing solutions have been around for over two decades now which, in the grand scheme of things, is not a long time. We look back at the early 2000’s and think it was not that long ago and that it was only yesterday we were celebrating the millennium. Fast forward 25 year and we start to think otherwise. Sustainable solution started gaining traction at the beginning of the millennium with a significant focus on using recycled paper and environmentally friendly inks. However, we all know that the practice of using recycled materials existed long before this.

LED UV printing is a fairly new concept; it has combined

the process of using mercury lamps to LED technology to create a process which is more sustainable. SPN has heard from Aztec Label, who are working with Fujifilm to use the LeXtreme LED curing system.

“The LuXtreme LED curing system has proven to be a game changer. The installation was handled with ease and the system is remarkably efficient. The operators appreciate the simplicity of the controls, and the LED response time is perfect. As soon as we’re ready to print, we can dry our inks almost instantaneously, with no delays.”

“One of the primary motivations for transitioning to LED technology was the significant energy savings. “Through rigorous testing, we demonstrated a remarkable 63% reduction in power consumption compared to traditional UV systems. With energy prices soaring, this shift not only makes financial sense but also aligns with our continued commitment to sustainability,” Colin explained.

“The transition has not only allowed us to maintain energy costs comparable to a decade ago, despite tripling production, but it also enhances operational efficiency. The longevity and low maintenance needs of LED systems are expected to reduce costs and downtime significantly, moving away from the costly and time-consuming routine of annual lamp changes. Looking ahead, we are excited about the future and confident that Fujifilm will play a pivotal role in our journey,” concluded Colin.

For more information, please visit www.fujifilmprint.eu/ label-packaging-sector/

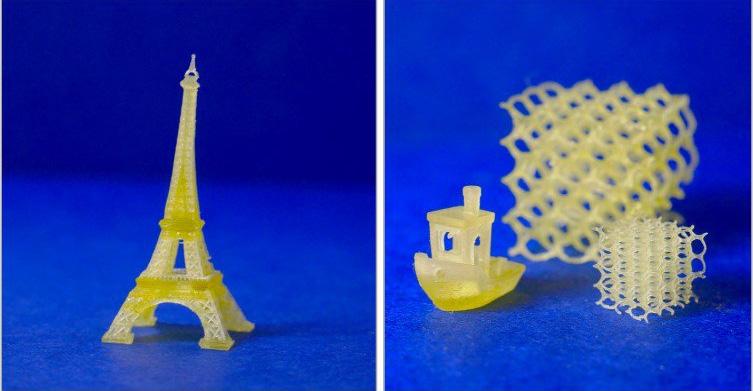

Another form of sustainable printing solutions, as you may know, is 3D printing. There is continuing research and SPN hears from University of Birmingham (UoB) who have designed a new type of photocurable resin that offers to key benefits over existing 3D resins. Current 3D printing usually relies on epoxies or acrylics, which mostly come from petrochemical feedstock. This new resin is made from lipoic acid. This is a naturally occurring fatty acid molecule that is 100% bio-sourced and commonly sold as a dietary supplement. The UoB article says:

Additionally, the recyclability of conventional resins is still limited, because they rely on irreversible bonds created when the resin cures (hardens), and this poses challenges when the material needs to be recycled.

In contrast, the resin designed by the Birmingham team can be printed, then broken back down to its constituent parts, recycled and reprinted, with the addition of just a small amount of photoinitiator to maintain the material’s curable properties, meaning 3D printed products can be recycled in an almost fully closed-loop system.

The new resin is compatible with light-initiated printing techniques such as DLP, SLA or by direct ink write, or InkJet printing, and provides high fidelity, with resolution down to 0.05mm.

They have shown the resin can complete two ‘recycles’, and anticipate further recycling is possible, meaning the material could be used in sustainable packaging, industries that do rapid prototyping, optical and electronic devices, construction and architecture, or fashion and jewellery.

For more information, please visit www.birmingham. ac.uk/university)

When the Forest Stewardship Council (FSC) was founded in 1993, it was built on the concerns of over-forestation, specifically when it comes to paper and the products derived from it. At the time, it marked the start of the certification process for sustainably managed forests and here at SPN we have news from Nissha and Tetra Pak, who have developed an aseptic carton for milk with a paper-based barrier using FSC certified paper.

“We are extremely proud of this achievement. Our joint effort to develop this solution supports the journey of increasing paper content and reducing carbon emissions in aseptic beverage cartons. Our paper-based solution offers barrier properties that help the package to deliver comparable shelf life and food protection as traditional aseptic cartons for liquid dairy products, such as milk”

says Giorgio Bosso, CEO, NMS.

The portfolio offered by NMS includes paper-based solutions that are classified as recyclable, renewable and mono-material ones. The company uses paper from FSC® (FSC-C109768) - certified forests and other controlled sources. These solutions can deliver the required level of protection from oxygen and light, for example through the application of different coatings. And paper is a material that comes from renewable sources which, when responsibly sourced, can grow back and absorb CO2 from the atmosphere as they do so. Moreover, our products decrease dependence on nonrenewable resources compared to the barrier layer used in traditional aseptic cartons.

“The Tetra Brik® Aseptic 200 Slim Leaf carton with a paper-based barrier ... demonstrates how the paper-based barrier can pave the way towards tomorrow’s low carbon circular economy for packaging.”

Commenting on the paper-based solution offered to Tetra Pak, Marco Marchetti, Vice President of Packaging Materials and Sales Distribution Systems, Tetra Pak, says “Tetra Pak has always believed in the power of paper, and now we’re taking that even further. Building on the high share of paper in our cartons today, the paperbased barrier pushes the paper content in our cartons to approximately 80% and, when combined with plantbased polymers, increases the total renewable content of a carton to 90% – cutting the carbon footprint by one-third (33%)1. The Tetra Brik® Aseptic 200 Slim Leaf carton with a paper-based barrier, which we launched with a leading dairy producer in Portugal in November 2023, demonstrates how the paper-based barrier can pave the way towards tomorrow’s low carbon circular economy for packaging.”

Further benefits of the paper-based barrier are also expected downstream, where cartons with a higher fibre yield are likely to become more attractive to paper mills. In this context, the paper-based barrier represents an opportunity for recycling infrastructures and their efficiency, since it changes the material structure of the carton package from three to just two main materialspaper and polymers.

For more information, please visit www. nisshametallizing.com

Most of us have heard of the concept ‘less is more’. When it comes to sustainable printing solutions, it’s definitely the way forward. Minimalistic designs

“However, as consumers become more conscious of their purchasing decisions, minimalist packaging has emerged as a valuable resource to enhance and amplify a brand’s sustainability initiatives.”

emphasize using fewer materials, reduces waste, energy consumption and the overall carbon footprint. It also means that we can reduce the need to store excess inventory and all leading to working with the space we do have in a more sustainable and efficient way.

Danny Smith, Global Product and Technology Director at SML Group explains to SPN that consumers are beginning to move on from unsustainable fast fashion trends. These practices involve the rapid design, production, and distribution of clothing items, getting new styles to customers at a record pace. However, for all of the output fast fashion generates, it is also responsible for a considerable amount of waste. Fast fashion consumers are quick to throw items away, whilst production also involves the excessive use of

non-renewable energy sources and energy-intensive processes. While these practices still exist, consumers are starting to think differently about how they purchase their items.

Championing a straightforward design, minimalist packaging emerged in response to non-environmentally friendly practices and a change in consumer preferences toward sustainability. This shift in attitude forced brands to rethink how they package their products and adopt alternative solutions. Minimalist packaging offers retailers the opportunity to improve sustainable value by offering a greener alternative, aligning with ecofriendly consumer values.

Using eco-friendly materials in minimalist packaging can also significantly reduce waste and a brand owner’s carbon footprint. Recycled yarn or non-solvent-based inks have minimal environmental impact, improving a retailer’s sustainability initiatives. This appeals to a growing base of customers, where 80% of consumers say they are willing to pay more for sustainably produced or sourced goods, according to PwC.

The appeal of minimalist packaging lies in its design. However, as consumers become more conscious of their purchasing decisions, minimalist packaging has emerged as a valuable resource to enhance and amplify a brand’s

sustainability initiatives. By prioritizing simplicity and brand identity, retailers can reduce their environmental impact and create stronger connections with customers. As this trend continues to gain traction, brands will be at the forefront of a sustainable future for all.

For more information, please visit www.sml.com

Collectively, these innovations represent a forward-thinking approach to sustainable printing solutions, emphasizing energy efficiency, renewable materials, and circular economy practices. As the industry continues to evolve, these pioneering technologies are poised to play a crucial role in achieving environmental sustainability and operational excellence, paving the way for a greener future in printing and packaging.

From reusable packaging projects to cutting-edge recycling advancements, SPN explores how industries and governments worldwide are tackling environmental challenges and revolutionizing sustainability practices.

Resource efficiency focuses on maximising the use of resources while minimising waste and environmental impact. Ultimately, it’s aiming for sustainable practice and optimal resource utilisation. The key principles to this are reduce, reuse, recycle and substitute. All these key principles clearly state that by minimising resource consumption, finding innovative ways to use resources multiple times, processing used materials into new products and using recycled or alternative materials instead of virgin materials, is a fundamental way of contributing to a more sustainable world.

There are many international initiatives which relate specifically to resource efficiency, mainly from the UN and the EU. The UN Environment Programme (UNEP) is aiming to support countries in improving resource efficiency and reducing environmental impacts as well as working on policies related to sustainable consumption and production (SCP). Also, they have a 10-Year Framework of Programmes on Sustainable Consumption and Production (10YFP) which outlines a global commitment under SDG12 (Responsible Consumption and Production) whilst also encouraging sustainable lifestyles, procurement and food systems. Another initiative that is happening is the International Resource Panel (IRP) which was established by UNEP to provide scientific assessments on resource use and environmental impacts. It published reports on material flows, resource efficiency and circular economy.

The EU initiatives differ slightly to that of the UN but

ultimately have the same goals. The EU Circular Economy Action Plan (CEAP) aims to transition the EU towards a circular economy with policies on waste reduction, eco-design and sustainable production. In addition, the EU Eco-Management and Audit Scheme (EMAS) is a voluntary environmental management system helping businesses improve their resource efficiency and sustainability. Both these schemes have one major thing in common, promoting resource efficiency by supporting sustainability goals, encouraging business and industry participation and contributing to the circular economy. However, there is another initiative which must be mentioned and that is the Horizon Europe program (2021-2027). This research program is funding projects related to sustainable materials, circular economy and resource efficiency. An example of this research program is AIMPLAS, who in 2022, participated in a Horizon Europe project on reusable packaging. The BUDDIE-PACK project aims at implementing a systemic approach for the largescale deployment of reusable plastic packaging (RPP) based on a multidisciplinary approach combining social, technological and economic innovations.

The project will contribute to cut down the production of single-use plastic packaging, reduce water and energy consumption, and avoid the release of microplastics into the oceans.

AIMPLAS, the Plastics Technology Centre, participates in new European research on reusable plastic packaging

The project BUDDIE-PACK, funded by the Horizon Europe programme, was launched on 21 and 22 September in Oyonnax (France) and is coordinated by the Industrial Technical Centre for Plastics and Composites (IPC).

This circular economy project is aiming at implementing a systemic approach for the large-scale deployment of reusable plastic packaging (RPP) based on a multidisciplinary approach combining social, technological and economic innovations. The project will take advantage of behavioural innovation to promote consumers’ acceptance of RPP by analysing drivers and analysing consumers’ psychology of reuse.

Sound synergies with technological innovations will be developed to manufacture packaging, fulfilling the demanding requirements of RPP based on innovative designs and recyclable materials. The project will focus on innovative cleaning solutions to guarantee the safety of consumers against the possible contamination and ageing of RPP during their repeated use, and the durability of their functional properties to avoid food spoilage. BUDDIE-PACK will dramatically cut down the production of single-use plastic packaging, reduce water and energy consumption, and avoid the release of microplastics into the oceans.

Viable economic models will ensure the sustainability of the proposed solutions thanks to the profitability of stakeholders throughout the value chain, including solutions based on social & solidarity economy models.

This project brings together 19 partners from 6 different countries and will take place over a period of three and a half years with a budget of nearly 7 million euros. The project consortium is made up of IPC, Trivéo, ACTIA, CTCPA, LNE, Technological University of the Shannon, AIMPLAS, Searious Business BV, Vytal Global GMBH, Eternity Systems, Uzaje, Betelgeux, Plasmion GMBH, Knauf Industries Gestion, Auzo Lagun S. Coop, Dawn Meats Group, Plasticos Vicent, Echo Brand Design and the University of Sheffield.

For more information, please visit www.aimplas.net

“Recycling EPS transport packaging is not just feasible; it is already advancing on a global scale,”

Going back to our note about the UNEP, the Global EPS Sustainability Alliance (GESA) report has confirmed that 72 countries engaged in varying level of recycling EPS Transport Packaging in 2023, with many of them achieving recycling rates above 30%. The data summary was announced ahead of the UNEP INC-5 negotiations, which took place at the end of November 2024, where UN Member States will continue to negotiate policy considerations to address global plastic pollution.

Of the 72 countries engaged in EPS sustainability efforts, 54% have reported their respective recycling rates. A significant portion achieved rates exceeding 30%, including the regions of North America and Europe, and countries like Brazil and South Africa. Notably, it also includes smaller island states and developing nations like the Dominican Republic and Guatemala, underscoring the global feasibility of EPS recycling. Several Asian countries reported even higher rates, with China at 46%, Japan 68%, Korea 88%, and Taiwan 83%. The compiled data was verified through multiple sources, including government agencies, third-party EPS industry reports, and EPS recycling machinery suppliers.

The United Nations Environment Programme (UNEP) has recognized expanded polystyrene (EPS) as one of only six materials recycled at scale and in practice, underscoring its role in the global push for circularity.

“Recycling EPS transport packaging is not just feasible; it is already advancing on a global scale,” said Betsy Bowers, Executive Director of the Global EPS Sustainability Alliance and the North American EPS Industry Alliance (EPS-IA). “This reaffirms UNEP’s acknowledgment of EPS recycling and demonstrates the industry’s continued efforts and success in spearheading initiatives that contribute to a more circular economy.”

To support ongoing progress in EPS recycling, GESA is developing a uniform data repository that will help standardize reporting and encourage greater transparency. By providing a centralized and reliable source of data, this initiative will foster more accurate benchmarks and help drive continuous growth in EPS recycling globally.

EPS maintains an essential role in key industries including packaging, construction, transportation, manufacturing, and automotive, among others. Applications such as packaging for the safe and effective transportation of food and vital medicines and vaccines, protective gear to prevent injury, refrigeration components, insulation for housing, and car seats are all made using EPS.

“By providing a centralized and reliable source of data, this initiative will foster more accurate benchmarks and help drive continuous growth in EPS recycling globally.”

EPS recycling supports some of the world’s leading brands and manufacturers across these industries.

Companies like Canon, General Motors, Hewlett Packard, Hyundai Motors, L’Oréal, and Toyota Motors rely on EPS for packaging, safety, and insulation propertiesspotlighting its critical role in global supply chains and economies.

“As global leaders discuss considerations like production capping, chemicals of concern and problematic plastics, it’s key they also consider the vital role of essential materials like EPS transport packaging, and the viability of proposed alternatives,” added Bowers. “Materials like paper, which itself contains styrene, are not always a one-size-fits-all panacea for environmental challenges to improve circularity. Ultimately, the success of the plastics pollution treaty depends on embracing practical, scalable solutions that foster real, long-term progress.”

References made link to:

• https://globaleps.org/, https://www.unep.org/incplastic-pollution/session-5

• https://www.prweb.com/releases/eps-transportpackaging-now-recognized-as-recyclablein-practice-and-at-scale-in-united-nationsenvironment-programme-plastic-pollution-science-report-302122891.html

• https://www.epsindustry.org/

The global push for resource efficiency and circular economy practices is gaining momentum, with significant efforts from both the UN and the EU. The various initiatives discussed - ranging from the UNEP’s 10-Year Framework of Programmes (10YFP) to the EU’s Circular Economy Action Plan (CEAP) - demonstrate a collective commitment to sustainability, waste reduction, and responsible resource management.

Projects like Horizon Europe’s BUDDIE-PACK highlight the importance of innovative approaches in achieving large-scale implementation of reusable packaging systems. These efforts aim to reduce dependency on single-use plastics, minimize environmental impact and foster economic viability in the transition towards sustainability. The role of behavioural, technological, and economic innovations in driving circular economy solutions is crucial in ensuring long-term success.

Additionally, the progress in expanded polystyrene (EPS) recycling reflects a growing awareness and commitment among nations and industries. With recycling rates improving across regions, particularly in Asia, and significant endorsements from the UNEP, EPS is proving to be a viable material in the global effort to improve waste management and sustainability. The establishment of standardized data repositories and

transparent reporting systems will further strengthen these initiatives, ensuring greater accountability and effectiveness.

As global discussions continue around policies such as the plastics pollution treaty, stakeholders must embrace practical and scalable solutions that contribute to a sustainable future. The combination of policy frameworks, research initiatives, industry participation, and consumer behavioural shifts will be essential in making circular economy principles a global reality. Through collaboration and continued innovation, the goal of optimizing resource efficiency while minimizing environmental harm is becoming increasingly attainable.

What began in 1985 as Plastienvase S.A. has grown into a trailblazer in flexible packaging—SPG. Over the past four decades, the company has transformed challenges into opportunities, continuously evolving through cutting-edge technology, sustainability-first solutions, and an unyielding commitment to quality. As SPG celebrates its 40th anniversary in 2025, it stands not only as a symbol of industry excellence but as a forward-thinking partner ready to shape the future of packaging.

In 2025, SPG proudly celebrates its 40th anniversary, marking four decades of excellence in the flexible packaging industry. Established in 1985 as Plastienvase S.A., SPG has consistently evolved, embracing innovation and sustainability to meet the dynamic needs of its customers. This milestone reflects the dedication of SPG’s team and the trust of its clients, suppliers, and strategic partners. Throughout its journey, SPG has led the shift towards more sustainable packaging, emphasizing eco-design and recyclable materials.

The year 2024 was particularly significant for SPG, characterized by substantial growth, innovation, and expansion. The latest incorporations of the company to enhance its production capabilities, are:

• New 9-Unit Rotogravure Printer: Installed at the Villarrubia plant, this high-performance printer is now operational, significantly boosting printing efficiency and quality.

• High-Speed Pet Food Bag Forming Machine: With automatic adjustments, this machine increases production speed and precision in the pet food packaging sector.

• New Slitting Machine: This addition streamlines the slitting process, further improving production efficiency. As part of its continued commitment to innovation, SPG has also expanded its product portfolio with the launch of Cold Seal technology. This solution is specially designed for heat-sensitive products and high-speed packaging lines, enabling secure sealing without the need for heat application. It is particularly well-suited to sectors such as chocolates, energy bars, and ice creams, offering a safe, efficient alternative to traditional heatsealing methods.

“SPG

has anticipated these changes by developing a range of sustainable and recyclable solutions tailored to flexible packaging applications, and stands ready to guide its clients through this transition.”

Sustainability remains a cornerstone of SPG’s strategic vision. In 2024, the company made important strides in developing environmentally responsible solutions. One of the most notable achievements was the recognition of RB ECO, SPG’s recyclable material, which received certification from the CYCLOS-HTP Institute. This certification affirms the company’s efforts in creating eco-friendly packaging that meets strict environmental standards.

SPG is also proactively preparing for the European Packaging Regulation (PPWR). This regulation is set to drive major change across the industry, with key objectives including:

• Ensuring all packaging is reusable or recyclable by 2030.

• Reducing packaging waste through optimized design.

• Increasing the use of recycled content.

• Limiting the use of hazardous substances.

SPG has anticipated these changes by developing a range of sustainable and recyclable solutions tailored to flexible packaging applications, and stands ready to guide its clients through this transition.

In parallel with its technological and environmental progress, SPG has also focused on strengthening its strategic partnerships. In 2024, the company consolidated its alliance with Rotor Print, following the acquisition of a majority stake. This move enhances SPG’s capabilities, extends its market reach, and reinforces its position as a key player in the flexible packaging sector.

As SPG reflects on its 40-year journey, the company remains steadfast in its dedication to innovation, sustainability, and excellence. With a focus on adapting to regulatory changes, embracing technological advancements, and fostering strategic partnerships, SPG is well-positioned to navigate the evolving landscape of the packaging industry, continuing to deliver value to its customers and stakeholders.

For more information on this article, please visit www.www.spg-pack.com/en/

Inside Crown Holdings’ 2030 plan: cutting emissions, boosting recycling, driving circularity, and taking global responsibility for a sustainable future.

How does the Twentyby30™ programme aim to address climate change, and what specific targets have been set for reducing environmental impact by 2030?

Crown’s Twentyby30™ programme was built in 2020 to address the pressing sustainability issues plaguing our world. It encompasses five pillars of action – Climate Action, Resource Efficiency, Optimum Circularity, Working Together, and Never Compromise – where Crown can make the most notable impact, including operational improvements in energy, material use efficiency, recycling, responsible sourcing, and food safety.

Within our Climate Action pillar, we have set goals to reduce our Scope 1 and Scope 2 greenhouse gas (GHG) emissions, targeting a 50 per cent combined reduction in absolute Scope 1 (fuel) and Scope 2 (electricity) emissions by 2030. We also aim to reduce absolute GHG emissions from our supply chain (Scope 3) by 16 per cent in the same timeframe.

We are proud of the progress we have made to reduce our emissions. As of December 31, 2023, we are 33 per cent toward our Scope 1 and Scope 2 emissions goal and we have exceeded our Scope 3 goal.

What role does circularity play in the Twentyby30™ programme, and how does metal packaging contribute to the principles of a Circular Economy?

Circularity is at the core of our business and our Twentyby30™ programme, with metal’s inherent recyclability supporting our Circular Economy goals and progress. Aluminium cans can be infinitely recycled without loss of properties, making it one of the most circular materials on the market. Additionally, the

process of making a can from recycled aluminium takes only 5 per cent of the energy compared to the same process with virgin aluminium, emphasising the importance of recycling’s impact on the Circular Economy model. With these facts in mind, we have constructed our sustainability programme around the ways Crown can build upon the benefits of a substrate critical to our business to make a difference in climate progress.

“As of December 31, 2023, we are 33 per cent toward our Scope 1 and Scope 2 emissions goal and we have exceeded our Scope 3 goal.”

How does the company plan to achieve its goal of sending zero waste to landfill, and what are the key steps outlined for waste reduction?

We are committed to increasing material recycling and reuse within our processes, improving our understanding of where and how waste is generated across our global operations. Enhancing our waste reduction culture is critical, ensuring our global team members understand the best practices for decreasing excess materials and how we can work with our suppliers and partners to increase waste reuse. We are constantly validating and verifying disposal practices data to ensure waste is being disposed of properly and to identify opportunities for maximising circularity.

For example, two of our beverage can plants in Turkey recently received a Zero Waste certification from the Turkish government for implementing measures to reduce hazardous waste by 80 per cent, decrease greenhouse gas emission rates through energy-saving activities, and reduce waste deposited in landfills by 95 per cent. The certification is part of Turkey’s Zero Waste Policy, an action plan initiated in 2017 with the primary goals of separating waste and increasing recycling rates.

What is lightweighting in the context of this sustainability initiative, and how will making cans lighter impact resource efficiency and product performance?

Lightweighting references our commitment to reducing packaging material use through the size of our aluminium cans while maintaining the quality, efficacy, and safety of the products. We have set a goal to reduce the weight of our standard 330ml beverage can by 10 per cent, with our progress as of December 31, 2023, currently at 6.44 per cent. Less material leads to less waste, therefore decreasing the resources we need to rely on for our processes and products.

“We have set a goal to reduce the weight of our standard 330ml beverage can by 10%”

How does the company plan to collaborate with industry partners to meet or exceed the recycling rate goals for aluminium beverage cans in different regions by 2030?

In Europe, the updated Packaging and Packaging Waste Regulation requires all packaging on the EU market to be recyclable in an economically viable way by 2030, emphasising the need for closer collaboration across the supply chain to advocate for improved recycling infrastructure and policies, investment in global recycling systems, and educational campaigns for conscious consumption and disposal. To support this, we work with key European associations such as Metal Packaging Europe (MPE), CanMakersUK, Alupro, and the newly formed Global Beverage Circularity Alliance. The Alliance has launched a global advocacy plan this year to boost the recycling rate of aluminium beverage cans worldwide.

It will take all members of the aluminium supply chain to improve the global recycling infrastructure. No one company or organisation can singlehandedly achieve these goals – we all play a critical, collective role in actioning progress.

What actions are being taken to ensure that the recycled content in metal cans and plastic strapping is increased, and why is this important for circularity?

In addition to the partnership mentioned previously, we have also co-hosted the Global Aluminium Can Sustainability Summit for two years, providing an opportunity to engage in important conversations

with members of the aluminium supply chain. Key discussions include industry decarbonisation, increasing consumer education on recycling rates, improving access to recycling, and working toward common parameters for recycled content in beverage cans. By using these types of platforms to connect with our industry peers, we can work together toward global circularity goals.

While advocating for stronger recycling systems and increased recycling rates are critical initiatives, it is equally important we seek opportunities for using more recycled content in our products. For example, our Transit Packaging Division has engineered a new plastic strap that contains 30 per cent post-consumer recycled material. The new strap features a 9 per cent lower carbon footprint than similar products made with virgin materials, addressing the demand for more sustainable solutions in Europe while maintaining performance standards for customers.

Why is water stewardship a critical part of the sustainability strategy, and what specific measures are being implemented to reduce water usage and replenish water in high scarcity areas?

Fresh water is one of the Earth’s most precious and threatened resources. According to the World Wildlife Fund, only 3 per cent of the world’s water is fresh water, over 1.1 billion people lack access to water, and 2.7 billion find water scarce for at least one month of the year. Water is also a critical component of our manufacturing processes, and we recognise our responsibility as a global manufacturer to protect water sources and replenish water where possible, particularly in high-scarcity areas.

We have initiated three major water replenishment projects in Brazil, Greece, and Mexico, focusing on improving water treatment, conservation, and replenishment to support the surrounding communities. For example, in collaboration with the Global Water Partnership–Mediterranean, our project near the Korinthos, Greece facility recirculates 26,498 cubic meters of filter backwash water annually, helping to preserve the local water basin and balance the facility’s consumption.

“Fresh water is one of the Earth’s most precious and threatened resources. According to the World Wildlife Fund, only 3% of the world’s water is fresh water...”

How does the company align its sustainability efforts with the United Nations’ Sustainable Development Goals (SDGs), and which SDGs are most relevant to the Twentyby30™ programme?

Our Twentyby30™ goals address 12 of the 17 UN SDGs so that our actions can contribute to a greater collective impact. By achieving our goals, we will help solve a large set of societal challenges ranging from climate change to water scarcity and natural resources depletion.

What strategies are in place to improve wastewater compliance, and how will the company ensure that its operations do not negatively impact local water quality?

Crown currently maintains a 100 per cent track record of meeting local wastewater standards for our facilities. Our teams regularly seek innovative ways to not only dispose of wastewater safely but also determine methods for the treatment and reuse of wastewater for production processes. For example, one of our U.S. plants safely and effectively filtered wastewater for coolant system reuse, preserving an estimated 7 per cent of water withdrawn annually. The goals across our Twentyby30™ programme strategically go hand-in-hand – in this case, wastewater compliance efforts decreasing overall water use.

How do the sustainability initiatives in locations such as Da Nang, Vietnam; Guadalajara, Mexico; and Dahej, India, reflect the company’s broader goals for resource efficiency and climate action?

Our plants in these three cities are just a few of examples of the work we are implementing globally. With the right framework, dedicated team members, and communities and partners who are committed to change, it is proven that we can successfully manage natural resources and have a positive impact on our climate. Our Best Practices programme is an annual recognition of innovative sustainability work accomplished by our teams across the globe, aiming to elevate the impactful work being done at Crown and serve as an inspiration for others. In many cases, we have implemented the operational efficiencies uncovered by one team in multiple other facilities, emphasising the importance of collective impact.

In years to come, we expect to recognise even more facilities for the innovative, important work they are doing to preserve our world’s resources and reduce the impact on our communities.

Interview conducted by SPN for Crown Holdings. For more information on Crown Holdings, please visit www.crowncork.com.

The free Understanding Packaging (UP) Scorecard tool allows anyone to compare the environmental and human health impacts of their foodware and food packaging choices

The first fully complete version of the Understanding Packaging (UP) Scorecard is now available for use after four years of beta testing, user feedback, and iteration. Built by the Single-Use Material Decelerator, a collaboration of food service leaders, non-governmental organizations, and technical experts, this free, science-based online tool helps users comprehensively assess and compare foodware and food packaging for their impacts on human and environmental health to support informed decisionmaking.

The UP Scorecard applies standardized life cycle assessment methods and novel scoring approaches to measure the impacts of foodware and food packaging from production to disposal across six key metrics: plastic pollution, chemicals of concern, recoverability, climate impact, sustainable sourcing, and water use. These metrics are compiled into an aggregate score that makes it easy to compare the sustainability of foodware and food packaging products.

“Foodware and food packaging fulfill important functions,” said Etienne Cabane, Engagement Director at the Food Packaging Forum, which hosts the UP Scorecard. “They offer convenience to customers, allow for transportation, protect food from spoiling, and support communications and marketing. However, they also have significant human and environmental health impacts. The UP Scorecard helps users assess the complex landscape of foodware and food packaging options using a science-based approach to encourage

more sustainable choices.”

“The UP Scorecard enables sustainable packaging decision-making by providing science-based, easy to understand scores across key categories,” said Sevrine Bethy, Head of Responsible Sourcing with Sodexo North America. “This allows users to prioritize action areas such as climate, health, or recoverability, understand trade-offs across categories, or consider the overall impact of packaging choices. Sodexo is pleased to support the tool’s development and enable operators to navigate the complexities of packaging to make the best choices possible for our clients.”

Unlike other life cycle assessment tools, the UP Scorecard takes into account chemicals of concern within foodware and food packaging materials. This metric has been improved in the new version of the UP Scorecard and now uses peer-reviewed data from the Food Packaging Forum that considers thousands of chemicals with known health hazards and evidence for consumer exposure or migration from food contact materials into food. With this information, the UP Scorecard uniquely helps the food service industry stay ahead of legislation while providing valuable

knowledge for other stakeholders. Other additions in the latest version include new materials, containers, geographic regions, and an interactive user guide as well as the ability to compare entire portfolios of products to each other. More information on all the new features and updates can be found in the UP Scorecard’s change log or the complete methodology.

Article provided by Food Packaging Forum. For more information, please www.foodpackagingforum.org.

Products are shown in order of their summary score (scale from 1 to 100). A higher score means better performance. All scores represent the provision of one functional unit. For coffee Cups this is 1 liter of container volume. Empty Circles with a dotted outline represent scores that had to be approximated due to the limited availability of underlying data.

Driving packaging innovation through recyclable materials, smart design, and circular economy solutions—Marchesini Group leads the charge in sustainable pharma and cosmetics packaging. Let’s see what they have to say.

Marchesini Group, a leading company in the design and production of automatic lines and machines for pharmaceuticals and cosmetics packaging, has become a conscious and active player in the field of sustainability in the packaging supply chain. In recent years, a dedicated cross-functional team has been created, primarily focused on analysing new types of packaging materials and, subsequently, on testing their machinability in synergy with suppliers. This led to the creation of a network of collaborations with producers of new mono-material and recyclable packaging films, which has fostered mutual discussions aimed at improving the workability characteristics of materials and the performance of the machines handling them.

The project also involved various divisions of the Group with the goal of creating synergies and developing a standardised working method that considers both the different needs of each machine and their integration in

the production lines. The results of all these activities have led to the creation of an internal database that brings together all the know-how derived from the case studies conducted. This database is now a benchmark to help customers identify and implement the most suitable solution for their product’s needs.

The backdrop to this project is the new EU Regulation 2025/40 of 19/12/2024, which will supersede Directive 94/62/EC, with the aim of providing a harmonised and certain framework for the industry’s operations. This regulation, which came into force in February 2025 and will be applicable from August 12, 2026, establishes environmental sustainability requirements for the entire lifecycle of packaging. In particular, it introduces numerous objectives for the recyclability of packaging and its recycled content, while recognising the priority of safety, quality, and protection of human health, with some exemptions for the pharmaceutical sector.

Marchesini Group produces machines and lines able to package products with different types of materials, including paper, recyclable and recycled mono-material plastics, and aluminium. One of the latest innovations from the Group is a machine designed to carton vials in paper trays: this solution is presented together with a new paper tray design, researched and developed entirely by the Group itself, which generates savings of about fifty percent in terms of paper and about fifty percent in terms of glue.

Moreover, the new paper tray is thinner, providing space savings of thirty percent when products are combined inside the case, with clear benefits during shipment in terms of shipping volumes and relative CO2 emissions. The Group, which has been developing paper tray solutions for over ten years as a valid, safe alternative to thermoformed plastic, has created this new prototype with the aim of guaranteeing even more responsible use of packaging material, while further reducing production costs and avoiding waste.

A further innovation is the introduction of technologies in the packaging processes aimed at gradually replacing PVC and introduce mono-material packaging solutions made with recyclable materials in the thermoforming of blisters and trays.

Over more than two years of experimentation and collaboration with some of the main packaging manufacturers, Marchesini Group technicians have

worked to create blisters and trays that can be easily disposed of through normal recycling channels. In particular R-PET, PET with up to 100% recycled content, has allowed the creation of mono-material packaging that is perfectly suited to the purpose. For primary packaging, there are also recyclable monomaterial packaging solutions in PP and HDPE. For products requiring a higher barrier, on the other hand, there is also a new generation of aluminium products with more than 70% aluminium content and which are PVC-free.

The solutions also include a line comprising a Schmucker 12-lane stick packaging machine, a stick inspection system and innovative printing systems. This line is designed to process PP-based packaging materials (with and without PE) such as 100% recyclable mono-material plastics like OPP or BOPP with a metallised intermediate layer. Due to its suitability for food contact, this material is a valid polyolefin-based substitute for the traditional PET/ALU material for production of high-barrier flexible packaging. The sustainability of packaging materials is just one of the many frontiers in which Marchesini Group is investing in order to comply with the paradigms of the circular economy: it is also engaged in other activities such as the business of Rinova, the company created to give new life to pre-owned original Marchesini lines and machines. Indeed, its remanufacturing process allows the Group to offer customers a more advantageous solution in both economic and environmental terms, with the same level of quality and reliability.

For more information on this article, please visit www. marchesini.com/en

What does Reuseabox’s model for reusing cardboard boxes, Berry Global’s development of durable and recyclable packaging options and research conducted by City to Sea about consumer thoughts on single-use plastics have in common? Let’s take a look! Emily Gambrill reports.

Where do we start with Circular Economy (CE) and its role in promoting sustainability when it comes to packaging. It is to be said; Circular Economy is considered to be one of the most popular and prominent approaches to sustainability. It gains significant traction among governments, businesses and environmentalists as a potential solution to address environmental issues. We may now know it, but CE is everywhere; it’s on the adverts we see on billboards whilst we’re busy rushing around, it’s on a TV advert which its key point is that they are creating a product which can be recycled instead of put to landfill and it’s all over the SPN website, because we love to talk about it!

“By

putting people and the planet first, we now work with thousands of businesses each year, helping them reuse cardboard boxes and cut their Scope 3 emissions”

Founded in 2015 by Jack Good, Reuseabox is transforming the packaging industry by helping businesses reuse cardboard boxes, reducing waste, cutting carbon emissions, and lowering packaging costs. The company’s innovative impact model has already saved millions of trees and enabled thousands of businesses to adopt more sustainable supply chains.

Jack Good, Founder of Reuseabox, said “It’s fantastic to be recognised in the first-ever Green Growth Awards. We’ve built Reuseabox on the belief that businesses can be both profitable and purpose-driven. By putting people and the planet first, we now work with thousands of businesses each year, helping them reuse cardboard boxes and cut their Scope 3 emissions.”

Michelle Ovens CBE, Founder of Small Business Britain, said “The Green Growth Awards recognise the outstanding small businesses that are not only leading the way in sustainability but are also using it to fuel innovation and growth. These businesses are proving that greener practices not only benefit the planet but also create real business success, whether through cost savings, waste reduction, or deeper customer engagement. Their passion and commitment are making a real impact on their communities and the economy.”

The nation’s 5.5m small businesses are estimated to represent half of the UK’s business emissions, and the Green Growth Awards has been launched as part of Small Business Britain’s ongoing partnership with BT to empower UK small businesses to better understand their environmental impact and embrace more sustainable practices and growth opportunities.

Chris Sims, Chief Commercial Officer, UK Business, at BT, said “The Green Growth Awards shine a spotlight on the small businesses that are not only driving sustainability but also setting the standard for innovation and growth. It’s truly inspiring to see how these businesses are leveraging sustainable practices to achieve real business success and create positive change in their communities. We’re really proud to support this initiative”.

For more information, please visit www.reuseabox.co.uk

Highlights on the stand include Berry’s new range of reusable cups; lightweighted food containers, including those with recycled plastic and enhanced recyclability; and Berry’s high-quality CleanStream® recycled plastic for contact sensitive applications.

Berry Global’s new range of reusable cups meets increasing demand for alternative solutions to singleuse packaging. Ideal for both on-site and takeaway requirements, they combine reusability with a premium quality feel and high-impact branding opportunities. They are dishwasher safe, lightweight but exceptionally durable, and can be recycled when they finally reach their end of life, where appropriate recycling facilities exist.

The wide choice of containers available for food and non-food use include initiatives such as lightweighting, the incorporation of recycled plastic, and the inclusion of robust plastic handles, which provides a monomaterial pack solution for easier recycling.

Isabelle Rival, Area Sales & Key Account Manager, France, Berry CPI Food, Beverage, and Specialities had this to say “We continue to work with our customers in the drive towards a circular, net zero economy. At CFIA Rennes, we will demonstrate ways in which we can achieve this while still devising solutions that meet

other essential requirements for food packaging. As well as safety, these include functionality, consumer convenience, aesthetics, and branding.”

Following on from Berry Global’s new range of reusable cup, they have introduced a versatile, multipurpose sip lid to accompany the reusable cup. This sip lid complements the reusable cup and meets market demand for high-performing alternatives to single use plastics.

Part of Berry’s B Circular Range of standard packaging solutions designed for circularity, the new lid has been developed to enhance the functionality of the cups for both hot and cold drinks and is engineered for flexibility. It is produced to the Ø89 standard market dimension, making it compatible with all Berry hot and cold cups. The lid is leak-proof with a liquid tight fit, ensuring secure transportation, and allows users to enjoy hot or cold beverages with or without a straw.

Crafted from widely recyclable polypropylene (PP), the lid is both stackable and dishwasher-safe. It also offers the option for logo embossing with a matte versus shiny surface contrast, providing a stylish and practical solution. Like the cups, the sip lid is designed for repeated use and reclosure, supporting a circular economy.

The lid is available in a variety of standard colours, all approved for reusable products. For black lids, Berry offers a Near-Infrared (NIR) detectable black colourant, enabling efficient sorting of black cups and packaging for recycling in countries with the appropriate recycling infrastructure.

For more information, please visit www.berryglobal.com/ en/

“The Global Reuse Summit 2025 brings together people from around the world to hold critical conversations to unlock the new reuse economy. The market is ready, the opportunity is significant, and the time is now The market is ready, the opportunity is significant, and the time is now.”

SPN has been informed that research released by environmental charity City to Sea revealed the public overwhelmingly agree that reusable packaging must replace single-use packaging to tackle single-use waste. I know what you’re thinking: this shouldn’t come as a shock, but businesses are facing increasing costs to become more sustainable.

This comes as 69 per cent believe the government should set legally binding targets for reusable and refillable packaging to drive change. Whilst recycling has been touted as a solution to the plastic waste crisis, only nine per cent of plastic has ever been successfully recycled, leaving the rest to be dumped in landfills, incinerated or left in the environment[1]. Alternative solutions have been on the rise, including reusable,

refillable and returnable packaging that can be returned to shops after use to be cleaned and reused.

The majority of shoppers (64 per cent) across the country agree that reusable, refillable and returnable packaging systems are more effective at reducing waste than recycling. Supermarkets in the UK have been implementing reusable packaging schemes with positive engagement from consumers. Meanwhile online retailers, including Ocado and Abel & Cole, have recently expanded their pre-filled returnable packaging schemes to more products. With the urgent need to tackle single-use plastic pollution at scale, 77 per cent want to see all retailers offer reusable, refillable, and returnable packaging long-term, instead of short-term pilot schemes.

Jane Martin, CEO of City to Sea, said “It’s easy to forget that single-use plastic only took over our supermarket shelves in the 60s and 70s, and the decision to use plastic for most of our products was a choice. Half a century later and we understand the damage that single-use plastic causes people and planet. It’s time for retailers to step up and commit to more sustainable packaging systems. Consumers want it, the environment needs it, our economy requires sustainable growth and high street regeneration. Imagine a world of refilling and returning, rather than dumping and burning. The Global Reuse Summit 2025 brings together people from around the world to hold critical conversations to unlock the new reuse economy. The market is ready, the opportunity is significant, and the time is now.”

Will Ghali CEO of Ecosurety said “Over the past few years there has been a welcome increase in alternative

packaging systems, presenting opportunities for innovative solutions to the single-use packaging crisis. We have steered retailers and packaged consumer goods brands in the right direction to make sure their reusable packaging systems are safe for consumers whilst protecting the environment, but more retailers and brands need to feel confident making this transition. The Global Reuse Summit is an opportunity to share insights and ideas and discuss data-driven insights that prove reusable packaging can succeed for all retailers and packaged consumer goods brands worldwide.”

[1] OECE (2022) - www.oecd.org/en/publications/globalplastics-outlook_de747aef-en.html

For more information on the Global Reuse Summit visit: www.refill.org.uk/the-global-reuse-summit

It seems (putting it lightly there, I know!) that there are a lot of companies creating products which are contributing to a Circular Economy and the results from City to Sea show that the consumer in the UK is agreeing that using reusable, refillable and returnable packaging is better than recycling. It’s not just the consumer and the businesses that are seeing a growth trend in CE, but also we have heard from Reusabox, a small business based in the UK, that they have been recognised in the Green-Growth awards.

As the world races to meet ambitious sustainability targets, the circular economy has emerged as a fundamental pillar in reshaping how we consume, produce, and manage resources. It’s not just a trend— it’s a necessary transformation. Shifting from a linear “take, make, dispose” model to one that is regenerative by design is key to minimizing waste, conserving resources, and cutting carbon emissions. Sustainable Packaging News is proud to announce its dedicated Circular Economy Week, a thought-provoking series that brings together industry leaders, innovators, and changemakers to explore how packaging is playing a pivotal role in this global effort.

At the heart of this initiative are insightful thought leadership articles from some of the most influential voices in sustainable packaging. Winfried Muehling, Director of Marketing & Communications at Pro Carton, shares his perspectives on how fibre-based packaging

is advancing circular solutions. Zoe Brimelow, Brand Director at DUO, offers a deep dive into how brands can redesign packaging systems to align with circular principles—rethinking materials, supply chains, and endof-life strategies. These articles, and many more from prominent experts, set the tone for a week filled with insight, action, and inspiration.

Adding further depth, exclusive interviews provide a front-row seat to the strategies being implemented across the packaging value chain. Talia Goldman, ESG Director at Colpac, unpacks how sustainability is embedded in product development and corporate culture. Dan Starnes, Sales Director at goplasticpallets. com, discusses the growing role of reusable transport packaging and how plastic can still be part of a responsible circular model when handled correctly. These interviews offer actionable perspectives from professionals actively working to make circularity a reality.

One of the highlights of Circular Economy Week is an exclusive roundtable event, bringing together leading voices from across the sector to tackle the most pressing challenges and opportunities in circular packaging. The panel includes Gary Tee, VP Global Converting at TIPA Compostable Packaging, Dave Gudgeon, Head of External Affairs at Reconomy, and Jeremy Blake, Director of Circular Economy at Berry Global Inc.

In addition to written content, engaging video features will enrich the week’s offering. These include a spotlight on Rockwell Automation, which demonstrates how intelligent automation is enabling more efficient, sustainable manufacturing. Also featured is Silvia

D’Alessio, Food and Packaging Ecosystem Expert at Politecnico di Milano, who offers an academic perspective on the transition to circularity and how education and innovation go hand in hand in shaping the future of packaging.

Sustainable Packaging News’ Circular Economy Week isn’t just another editorial series—it’s a call to action. It brings together some of the brightest minds in the field to foster a deeper understanding of the circular economy and inspire meaningful change. As the urgency to act becomes more pressing, initiatives like this are essential to keeping sustainability at the forefront of the packaging industry—and beyond.

The packaging industry is working hard to achieve a circular loop and its current approach to circularity risks overlooking a crucial reality: creating recyclable packaging isn’t enough if the components used to produce it compromise the recycling process itself. While substrate selection dominates industry discussions, the critical role of inks and coatings in enabling or hindering effective recycling demands equal attention from packaging professionals seeking to achieve meaningful and lasting circularity.

A prime example lies in plastic recycling, where traditional inks can contaminate the recycling process.

During caustic washing for example, ink bleeding can compromise recyclate quality, often forcing valuable materials into lower-grade applications outside the packaging industry. This ‘downcycling’ breaks the industry’s desired goal of circularity. For packaging designated for food contact applications, this is particularly problematic; once materials are downcycled, they typically cannot return to food-grade packaging applications, removing valuable materials from the packaging loop entirely.

However, technological advances from companies like Flint Group are making a real difference.

New ink formulations are specifically designed to either cleanly separate during recycling or remain firmly bonded to materials designated for alternative recovery streams. For instance, in narrow web applications, deinking primers and specialised coatings now enable PET labels to be processed alongside PET bottles, significantly increasing high-quality rPET yields. These innovations can help recover up to 99% of substrate material in a form suitable for reuse in packaging applications, compared to traditional processes where label contamination might render significant portions of the material unsuitable for high-grade recycling.