Dear readers,

It’s hard to believe we’re already halfway through 2025. This time of year naturally invites us to reflect — not just on what’s behind us, but on the opportunities ahead. In the packaging industry, change is constant, and it’s accelerating. That momentum is driving exciting innovation.

Colpac explores how to navigate change in today’s fast-moving industry. Their latest article encourages businesses to embrace disruption from evolving consumer expectations to regulatory shifts and the growing push for circularity. With a focus on collaboration, adaptability, and smart design, Colpac positions itself as a partner in progress.

Meanwhile, Ahlstrom has launched LamiBak™ Flex, a new flexible packaging material designed for sustainability without compromising functionality. It’s a promising solution for brands aiming to meet both environmental and performance standards.

These two articles, along with the others, is the core for what will be an exciting read. A huge thank you to the businesses who’ve contributed their insights, and to my co-writer Dominy, your hard work never goes unnoticed. All the best and keep safe,

All the best and keep safe,

linkedin.com/company/ sustainablepackaging-news/ youtube.com/ @sustainable packagingnews

spnews.com

Page 5

Global Push for Sustainable Packaging Through Recyclability.

including - Article by UPM Raflatac.

- Interview with Karin Von Kienlin at L.E.K Consulting.

Page 13

How are Leading FMCG Brands Turning Sustainability Into Strategy.

including - BUSINESS LIMELIGHT by Ahlstrom.

- Article by Tetra Pak.

Page 20

Bioplastics in Sustainable Packaging: Promise or Problem.

Page 22

Slimming Down Packaging Without Silmming Down Perfromance.

Page 25

The Rise of Paper: How Global Shifts are Transforming Packaging Sustainability.

including - FRESH FOCUS by Colpac.

- Interview with Paul Krochak at Graphic Packaging International.

Page 33

From Petrochemical ro Plant-Based Adhesives for a Net-Zero Future.

including - Article by Power Adhesives.

Page 38

Rethinking Film Recyclability: Challenges and Progress in Flexible Packaging.

including - Article by kp films.

Page 42

Rethinking Waste for a Sustainable Future. 16 28

Recyclability is no longer just a buzzword—it’s a global priority shaping the future of packaging. As businesses and governments confront mounting environmental pressures, the stark contrast between plastic and paper recycling rates becomes impossible to ignore. But beyond the statistics, real progress is being made through innovation, investment, and bold sustainability commitments. SPN reports.

There are many interesting global statistics where recyclability is concerned. When it comes to plastic, the results for plastic recyclability are far from perfect. For example, as of 2024, the global plastic recycling rate remains below 10% and between 1950 and 2015, only 9% of all plastic waste was recycled.

However, we look at the other ‘P’ word and can see that paper recyclability has come a long way. For example, the global paper recycling rate was approximately 59.9% in 2021 and in 2022, the EU achieved a staggering 83.2% recycling rate for paper and cardboard packaging, resulting in the highest rate among all packaging materials.

As we all know, the difference between plastic and paper packaging recyclability is due to several factors, but material complexity and the total cost of recycling plastic are major factors as to why the plastic recyclability rates are far from where we want them to be.

All references made above have come from www. thesustainableagency.com using ChatGPT.

Even though the statistics for plastic packaging recyclability are low, goplasticpallets.com have celebrated a huge achievement which, in the future, will change those statistics for the better.

The UK’s leading provider of sustainable plastic pallets and boxes have said that they have recycled 2,000 tones of plastic in 6 years. 2,000 tones of plastic can also be illustrated in different ways:

• Stacked vertically, these pallets would form a tower twice as high as Mount Everest.

• Laid flat, the pallets would cover a surface area of 160,000 square metres, the equivalent to 22 Wembley football pitches, two entire O2 Arenas, or seven times the base area of Rome’s iconic Colosseum.

• Placed end-to-end, the pallets would stretch precisely 100 miles - the exact distance from London to Birmingham, and over seven times longer than Manhattan.

“We aren’t finished yet. We have calculated that we’re halfway to filling Central Park – so that’s something to strive for in the coming years!”

Goplasticpallets.com set an original target in 2019 of recycling 1,500 tonnes of plastic by the end of 2025. As we can see, not only have they surpassed that goal two years early, but they have also set a new and ambitious

target to recycle 5,000 tonnes by the end of the decade. This is an incredible achievement, and I have no doubt that goplasticpallets.com will again smash their new target!

“We continue to help businesses across several industries - including retail, construction, manufacturing, food production, automotive and waste management – to green their supply chains. Not only are 93% of the products we supply made from 100% recycled materials, but we also guarantee full responsibility for recycling the plastic pallets and boxes we provide - along with those from other suppliers.”

For more information on goplasticpallets.com’s recycling services or to explore the company’s sustainable logistics solutions, please contact sales@goplasticpallets.com or call the team on 01323 744057.

“As sustainability expectations rise, businesses need packaging that protects their products while reducing environmental impact,” says Remy Eecke, Senior Value Chain and Sustainability Manager at Mondi Containerboard. “Our containerboard papers are 100% recyclable and made from 100% sustainably sourced raw materials, giving brands the edge they need in a competitive, ecoconscious marketplace.”

Looking at paper packaging recyclability, Mondi have told SPN that their ProVantage containerboard paper grades range ensures that businesses can meet the growing demand for sustainable packaging without compromising on performance. From fully recycled to 100% fresh fibre, the containerboard paper can be used for the foundation for corrugated packaging and are also well-suited for applications like honeycomb structures and fibre drums.

Mondi are continually investing in technology to provide

reliable solutions. As one of few companies who have been at the forefront of papermaking innovation for over 100 years, their investment has been used to advance the paper machine at the Ružomberok mill in Slovakia, which launched the ProVantage SmartKraft White paper grade in 2021. This Kraft Top White grade combines fresh and recycled fibres which offer strength and printability for brands who are looking to make an impact. Mondi have said that once fully ramped up, the machine at Mondi Duino will produce 420,000 tonnes of high-quality recycled containerboard annually.

For more information on this, please visit www. mondigroup.com.

Now, when people think of recyclability they immediately go to plastic and paper, due this being the main form of packaging for our goods. However, it’s important to highlight the impact that glass and metal have on the overall result of recyclable materials. According to The Sustainable Agency, approximately 74.5% of all aluminium ever produced is still in use today, which I’m sure you’ll agree, showcases its high recyclability. Also, recycling rates for metals exceed 73% in regions like Europe, which compared to plastic packaging, is a huge difference. Flip this to glass packaging recycling methods and as a global rate, only about 21% of glass is recycled around the world. However, contrary to this statement, the EU had a 75.6%

recycling rate for glass packaging in 2021.

References made in the previous paragraph have come from www.thesustainableagency.com and www. greyparrot.ai using ChatGPT.

Wheaton have told SPN that their new ‘The Surprise Line’, which consists of three new packages, are suitable for different segments within their packaging. The versatility of this new glass bottle makes them not only ideal for the skin care, hair care and perfumery markets, but also easy to separate the components for recycling.

“Each bottle we develop translates this search for excellence, without giving up sustainability,”

Wheaton’s continuous commitment to sustainability is echoed in their investment into processes and materials that promote a cleaner and more efficient production cycle. They go on to say that since 2023, 100% of all electricity consumes in the São Bernardo Campo industrial park comes from a certified renewable water source, resulting in the company’s zero scope 2 emissions.

‘The Ecoglass Line’ reinforces this commitment with bottles developed to maximise the sustainable benefits of glass in the circular economy. This bottle has been highlighted for its reuse by being manufactured with 20% less glassy mass than conventional models, resulting in lower energy consumption and an approximate 15% reduction in CO2 emissions.

“Participating in LuxePack is always a valuable opportunity for us to show how innovation and sustainability can go together. Our commitment goes beyond design, we seek to develop packaging that tells stories, arouses emotions and elevates the consumer experience with brands”

For more information on this, please visit www.wheaton.com.br

Trivium Packaging have told shared their 2024 Sustainability Report with us. As a global supplier of infinitely recyclable metal packaging solutions, it has highlighted significant strides in environmental performance, circular innovation and community impact. As only 7.2% of the world’s materials are currently being cycled into the economy, Trivium are committed to playing its part in advancing sustainable practices and redefining how materials are used and reused. Their main key achievements are:

• Reduction in Greenhouse Gas Emissions: Trivium achieved a 2% reduction in Scope 1 and 2 greenhouse gas (GHG) emissions in 2024, keeping the company on track to meet its Science-Based Targets initiative (SBTi)validated goal of a 42% reduction by 2030 (from a 2020 baseline).

• Advancing Circular Solutions: With metal packaging solutions uniquely positioned to support circularity, Trivium continued to innovate by increasing recycled content and lightweighting products. In 2024, 47% of Trivium’s total revenue came from eco designed products, moving them closer to their target of 50% by 2030.

• Recognition for Innovation: Trivium’s teams

received 12 awards from industry associations across business segments in 2024, underscoring the company’s technical and sustainable innovation leadership. Among these recognitions are the retention of the Platinum rating by EcoVadis for the fourth year in a row, a spot on CDP’s A List for Climate, and multiple product awards in the categories of sustainability and design across a variety of awards, including Pac Global and the Can of the Year Awards.

• Adopting Higher Standards: Trivium remains in scope for its Corporate Sustainability Reporting Directive (CRSD) target by January 1, 2027, despite the EU’s decision to delay the implementation of large companies.

“In 2024, we continued to reduce our carbon footprint while empowering our teams to innovate for a circular economy. We are proud of our progress but remain focused on the work ahead as we strive toward netzero emissions by 2050. Together with our partners and communities, we are shaping a future where sustainability is at the heart of every decision.”

For more information on this, please visit www.triviumpackaging.com

“At Trivium Packaging, sustainability is not just an operational goal. It’s a foundational mindset that drives our business transformation”

As the global spotlight intensifies on sustainable packaging, it’s clear that recyclability remains a crucial benchmark for measuring environmental responsibility. While the statistics for plastic recyclability remain discouraging—with global rates still below 10%— initiatives like Goplasticpallets.com’s pallet recycling milestone show that with ambition and innovation, even the toughest materials can be part of a circular future. In contrast, the paper industry, with leaders like Mondi, demonstrates how decades of investment and technological advancement can yield high recycling rates and versatile packaging solutions. Beyond plastic and paper, metals and glass are proving that high recyclability is possible, especially when companies like Trivium and Wheaton embed circular thinking at the core of product design and energy use.

What is evident across all packaging types is that progress stems not just from recyclability alone, but from collaboration, infrastructure, and a commitment to designing for the entire lifecycle. As more businesses adopt eco-driven goals and transparent reporting, the packaging industry is steadily reshaping itself—one recyclable innovation at a time.

When it comes to rigid plastic packaging solutions, customers – particularly within the HPC and food categories – are prioritising packaging that combines strong shelf appeal with improved sustainability credentials. Here, Suvi Rasa, Sustainability Manager at UPM, discusses label solutions that are compatible with recycling processes.

To enhance recyclability, particularly in bottle-to-bottle recycling processes for PET packaging and HDPE and PP rigid packaging, it’s essential to consider the choice of label face material and adhesive. This is why we have focused on developing recycling compatible labels for HDPE and PP. For PET packaging we also have a range of wash-off, Institut cyclos-HTP approved options which enable clean separation during the recycling process. This helps to support a closed-loop system where PET packaging can be more effectively recovered and reused, rather than downcycled or lost to landfill. This process reduces waste, increases the supply of high-quality recycled raw materials, and lessens the demand for virgin plastic.

To help advance the recycling of rigid plastic packaging, we launched our innovative New Wave paper label material - the first RecyClass certified paper label material to obtain a Letter of Compatibility for

use on rigid high-density polyethylene (HDPE) and polypropylene (PP) containers. The test results confirm compatibility even for natural and white material streams.

The label material is designed to provide functionality for the full life cycle of products, primarily home and personal care (HPC) products such as soap bottles or washing detergent containers. It supports the purity of recycled materials by washing off cleanly without fibre loss at just 40°C using plain water with no chemicals required. This not only preserves material integrity but also provides packaging producers with greater flexibility to use label materials derived from renewable sources.

Also designed to support circularity is our Carbon Action portfolio. When compared to standard plastic label materials, this range enables Scope 3 emission reductions for printers and brand owners, with impact quantified by an externally validated LCA calculation process.

The portfolio includes Carbon Action PP UCO – an ISCC PLUS certified bio-circular face film made with 30% renewable content on a mass-balance basis. Developed to leverage the value of refined renewable waste material – used cooking oil (UCO) – it offers a more sustainable alternative to fossil-based polypropylene films, while maintaining high performance and quality. The Carbon Action PP UCO white is certified by Institut cyclos-HTP to be recycling compatible in the PET recycling stream, when paired with our RW307 & RW704 wash-off adhesives.

As regulations tighten and consumer expectations rise, demand is growing for label materials that support closed-loop recycling and reduce environmental impact, without compromising on performance or appearance. Thanks to these innovative solutions we are helping producers attain their circularity and climate targets More information can be found here: https://www. upmraflatac.com/ebook/packaging-recyclability-guide/

From cost to compliance—why recyclability is now a brand’s bottom-line issue. At SPN we hear from Karin von Kienlin, Senior Partner at L.E.K. Consulting.

Can you explain the main objectives of the UK’s new Extended Producer Responsibility (EPR) scheme and how it shifts financial responsibility?

The Extended Producer Responsibility sets out to address two key aims: developing a circular economy and improving recyclability. In moving the financial burden to the packaging manufacturers, the scheme hopes to encourage sustainable packaging design because the more recyclable your packaging is, the less you pay in fees.

The immediate reaction from the industry has been concern around the cost of implementing the scheme, given the need to account for and track the lifecycle of your packaging. Estimates suggest that it will add between 10-30% to operations costs, although our assessment is that 30% is on the high side.

How are businesses reacting to the implementation of PackUK, and what are the key challenges they face under the “polluter pays” principle?

There are certainly some businesses that see this as a competitive advantage, particularly larger supermarkets that see an opportunity to leverage their own-brand products and the control they have over packaging design. The size and scale they have in the market means that they can drive more circularity to their benefit, and this is something we have seen under similar schemes in markets like Germany too. Smaller brand owners have been less enthusiastic because the extra administration cost has a proportionately larger impact on their cost base. However, it is important that regulation creates a level playing field that encourages change and innovations in the market should help to offset this in the medium-term.

“Estimates suggest that it will add between 10-30% to operations costs, although our assessment is that 30% is on the high side.”

L.E.K. Consulting’s study suggests that 42% of packaging spend is currently allocated to sustainable solutions, rising to 59% by 2028. What factors are driving this increase?

For a while, consumers were driving the uptake of sustainable packaging by pressuring brands, but this has fallen away as cost concerns have overtaken the willingness to pay more for sustainable products. Today, the factors pushing brands to use sustainable packaging are much more compliance and operationally focused, as well as commercially focused in light of nonconsumer stakeholder pressures. Clearly, businesses want to minimise the fees that they pay under schemes, such as the EPR, so there is a cost driver there. There are also technological developments which have lowered the barrier of adoption. For example, monomaterial multilayer packaging is more recyclable than the multi-material multilayer solutions used previously. Operational efficiency to long-term cost is also a key driver, as businesses look at how sustainable solutions

can aid profitability and create a competitive advantage in the market.

How are businesses balancing the pressure to reduce costs with the need to achieve their sustainability goals in the current economic climate?

There are instances in which sustainability and cost reduction go hand in hand, and this is where brands are really focused at the moment. One obvious solution is to use less material, by lightweighting or downgauging, and there is also a big focus on procurement and production to improve reporting across the supply chain.

For food products, striking this balance is harder due to hygiene requirements. Meat and fish, for example, need to be packaged in virgin material or in especially approved rPET. About two thirds of rPET in Europe is approved for food contact based on strict regulatory requirements and approval processes. In the UK rPET substrate for food application also needs to be approved by the Food Standards Agency (FSA). The recycling process must either ensure a closedloop system with no contamination or demonstrate, through scientific tests, that contamination is reduced to safe levels, with strict conditions and monitoring requirements outlined by the FSA. This particularly poses issues for non PET plastics (where the multitude of different materials in post consumer waste creates high barriers to recycling). Recycling companies can struggle to make the business case work for the level of processing required to create food grade recycled materials. Other consumer products like beauty and detergents do not have these same requirements, so it has been easier for brand owners in these categories to use recycled content.

What strategies are brands adopting to address the shortages of sustainable packaging materials, and how do you foresee these challenges evolving?

Material innovation and redesigning packaging to reduce the amount of material used are the primary actions being taken by packaging converters to mitigate the shortage in sustainable packaging materials because this is where they can have the quickest impact. Supply chain diversification is another strategy that is being pursued to reduce dependency on any one supplier and improve carbon scores by shortening delivery routes.

There are some packaging converters that have invested in their own recycling capabilities, but this is still nascent across the industry. Interest in owned recycling facilities has grown due to price differentials in materials like recycled PET, which have always been

more expensive than virgin material, and concern about the amount of high-quality recycled material available on the market. Connected to this, we are seeing consumer engagement schemes that encourage the return of packaging so that it can be recycled, but the effectiveness of these today is limited by the softness of the market and price pressure from retailers.

Do you think the PackUK initiative sets a benchmark for other countries, and how might it influence global packaging and waste management policies?

The UK’s PackUK scheme shows that there is continued momentum behind the move to a global circular packaging industry, following in the footsteps of schemes such as those in Germany and Canada. Whether it sets a benchmark for other markets is yet to be seen, given that its success is predicated on the enforcement of the fees and penalties and the extent to which it forces everyone across the packaging value chain to adopt more sustainable practices and choices. However, it is clearly a positive that it sets a level playing field that provides security for investments in infrastructure and new materials which will create change over time.

“The UK’s PackUK scheme shows that there is continued momentum behind the move to a global circular packaging industry, following in the footsteps of schemes such as those in Germany and Canada.”

Can you highlight any unexpected trends or insights from L.E.K. Consulting’s Packaging Sustainability study that businesses should be aware of?

One thing that was clear in the difference between respondents in the US and Europe was the importance of sustainability when choosing packaging materials: for the US this was still the most important consideration whilst in Europe it had fallen to 6th place. Quite simply, this is down to pragmatism in goal setting and cost considerations. In the US, we see that brand owners are confident in their ability to pass on the higher costs to consumers from recycled materials or absorb it. In Europe, the economic mood is much darker and enthusiasm for sustainability has declined with cost being cited as the primary issue.

Interview conducted by SPN for L.E.K Consulting. For more information on L.E.K Consulting, please visit www.lek.com

As sustainability becomes a defining priority in the FMCG sector, leading brands are stepping up with innovative strategies that tackle plastic waste, carbon emissions, and circularity head-on. From refillable packaging to renewable energy in manufacturing, companies are rethinking how everyday products are made and delivered. Emily Gambrill reports.

Sustainability in FMCG refers to the practice of producing, distributing and selling everyday consumer products in a way which minimises environmental impact, supports social responsibility and ensures long-term economic viability. With companies such as Unilever, Nestle and Procter & Gamble (P&G) committed to achieving a more sustainable footprint, we look at how this is being done.

Unilever, a British multi-national consumer goods company, is aiming to halve its environmental footprint by 2023. To achieve this, they have pioneered a refillable and reusable packaging system through brands such as Dove and Persil. The company has reduced its virgin plastic use by more than 100,000 tonnes since 2018 and continues to invest in circular packaging models. Nestlé, one of the world’s largest food and beverage companies, is striving to achieving net zero emissions by 2050. One of its notable innovations is its transition to paper-based, recyclable packaging for major confectionary brands like KitKat and Smarties.

P&G, a consumer good corporation known for owning a vast portfolio of iconic brands in areas like personal care, home care, beauty and baby care, has set a target to make 100% of its packaging recyclable or reusable by 2030. It introduced shampoo bottles made from ocean-bound plastic for its Head & Shoulders brand, demonstrating a scalable solution to marine plastic pollution.

Here at SPN, we recently heard from scientists at the Woods Hole Oceanographic Institution (WHOI) about a breakthrough study showing that cellulose diacetate (CDA)-based foams made with Eastman Aventa™ compostable materials degrade by up to 70% within just 36 weeks in marine environments. This finding is a game changer for sustainability in the Fast-Moving Consumer Goods (FMCG) sector, where packaging waste remains a leading source of ocean plastic pollution.

The study, published by ACS Publications, highlights how Eastman Aventa™—a biodegradable, compostable material made from renewable wood pulp—is being developed as a sustainable alternative to polystyrene in food packaging, one of the FMCG industry’s biggest plastic users. This directly tackles a critical challenge: reducing dependence on non-biodegradable materials that persist in the environment.

“Foaming biodegradable bioplastics like Aventa offer a promising strategy to reduce the environmental impact of frequently mismanaged consumer plastics, particularly in food packaging applications. These materials not only degrade rapidly in the ocean but also support circularity and material efficiency.”

Importantly, the research also embraces a systemslevel view of circularity, evaluating everything from raw material sourcing to end-of-life compostability. It demonstrates how using renewable feedstocks and efficient material design can create packaging that aligns with circular economy principles.

And the economic case is just as compelling: replacing polystyrene with Aventa in food trays could save society more than $1 billion annually in costs linked to plastic pollution. This reinforces a key message for the FMCG industry—eco-innovation isn’t just good for the planet; it makes business sense too.

“Traditional plastic foams face challenges in end-of-life management, often unintentionally ending up as plastic pollution in the environment”

For more information, read the full article in the October 2024 issue of ACS Sustainable Chemistry & Engineering or visit www.eastman.com/aventa

Another major sustainability milestone in the FMCG sector comes from Ardagh Glass Packaging–Europe (AGP-Europe), part of the Ardagh Group, which has successfully completed a groundbreaking industrial fuel-switching trial at its Knottingley facility in the UK. In a bold step toward decarbonising packaging production, the company replaced traditional natural gas with bioderived fuels in its glass furnace—cutting an impressive 242 tonnes of CO₂ emissions in just one week (1).

Glass packaging plays a vital role across FMCG categories, including food, beverages, and cosmetics. This £6 million trial, supported by the UK Government’s Net Zero Innovation Portfolio, proves that it’s possible to dramatically reduce carbon emissions without compromising product quality or production efficiency—a critical concern for FMCG brands. What makes this breakthrough especially impactful is its scale: more than 4.1 million glass containers were produced during the trial, demonstrating that alternative fuels can support commercial-level manufacturing. It’s a significant leap toward cleaner industrial processes and aligns directly with FMCG companies’ net-zero supply chain ambitions.

By showing that sustainability and performance can go together, this initiative sets a powerful precedent for what’s possible in large-volume FMCG operations.

(1) Compared to carbon emissions from the same furnace using 100% natural gas / www.www.ardaghgroup.com

Henkel, a global powerhouse in adhesives and coatings, has teamed up with Synthomer, a leading innovator in specialty polymers, to launch a strategic partnership aimed at cutting carbon emissions in Henkel’s TECHNOMELT® hot melt adhesive range. Targeting key FMCG markets across Europe, India, the Middle East, and Africa, this collaboration marks a major step forward in making packaging adhesives more sustainable—without compromising performance.

Hot melt adhesives like TECHNOMELT® are essential to FMCG packaging, used in everything from cartons and labels to bottle seals and personal care wraps. While often overlooked, adhesives play a big role in the overall environmental footprint of consumer goods—and making them greener can significantly shift the dial on packaging sustainability.

“As industry leaders in the adhesives market, we share the responsibility to drive meaningful change. By partnering with suppliers like Synthomer who are equally committed to transparency, innovation, and verifiable climate action, we’re not just reducing emissions, we’re redefining what leadership looks like in our industry.”

At the heart of this initiative is Henkel’s focus on tackling Scope 3 emissions, which often make up the bulk of an FMCG company’s carbon footprint. By integrating CLIMA-branded polymers from Synthomer— produced using renewable electricity and optimized manufacturing processes—Henkel is achieving meaningful cradle-to-gate carbon reductions in its adhesive products.

What sets this partnership apart is its commitment to transparency and credibility. Emission reductions are measured according to ISO 14067 standards, and verified by TÜV SÜD, ensuring data integrity for brands and retailers. With today’s consumers more eco-conscious than ever, such rigorous accountability strengthens brand trust and supports growing demand for sustainably sourced products.

Ultimately, this partnership shows how smart collaboration across the value chain can accelerate the

FMCG sector’s path to net zero. It’s a clear signal that industry transformation is possible—through shared innovation, measurable action, and a firm commitment to sustainability at every level.

“We are proud to support Henkel and their customers with novel adhesive solutions based on a significantly reduced carbon footprint. Our capability is based on our broad portfolio of high performing adhesive ingredients, a global production and development network paired with a relentless passion for innovation and sustainability. We continue to engage with partners to create sustainable value chains and reduce carbon emissions on our planet”

For more information on this, please visit www.henkel.com and www.synthomer.com

As the FMCG sector continues to evolve, it’s clear that sustainability is no longer an optional addon—it’s a core business imperative. From refillable packaging models by global giants like Unilever, to cutting-edge compostable materials like Eastman Aventa™, companies are pushing the boundaries of what’s possible in environmentally responsible design. Innovations like Ardagh’s biofuel-powered glass production and Henkel’s low-carbon adhesives show that deep collaboration, material innovation, and smart energy choices are all key levers in reducing emissions and closing the loop on waste.

Whether it’s through biodegradable packaging, circular manufacturing systems, or Scope 3 carbon reductions, these examples highlight a clear trend: sustainability in FMCG is advancing fast—and with measurable impact. As regulatory pressure increases and consumer expectations grow, brands that invest in scalable, transparent, and innovative solutions will not only meet compliance requirements—they’ll lead the market.

In short, the future of FMCG is not just faster and more convenient. It’s smarter, cleaner, and deeply sustainable.

Ahlstrom, a global frontrunner in sustainable fiberbased solutions, has expanded its well-regarded LamiBak™ portfolio with the launch of LamiBak™ Flex — a new base paper specifically engineered for flexible food packaging. This addition marks a strategic development for converters and brand owners looking to move away from plastic- and foil-based substrates without compromising on performance, regulatory compliance, or consumer appeal.

The global shift toward more circular packaging systems has intensified pressure on the food packaging industry to deliver materials that support both environmental targets and functional requirements. Ahlstrom’s LamiBak™ Flex addresses this dual challenge by offering a high-performance paper-based solution that enables sustainability from sourcing through end-of-life,

while maintaining the versatility required for complex packaging applications such as pouches, sachets, and flow wraps.

LamiBak™ Flex builds on Ahlstrom’s deep-rooted commitment to environmental responsibility. The base paper is made from 100% responsibly sourced wood pulp, holding either FSC® or PEFC™ certifications, which guarantees that raw materials are derived from sustainably managed forests.

This product complies with paper recyclability standards in Europe under EN 13430 and CEPI protocols, and it is designed to be compatible with U.S. recycling standards and has specifically passed Part 1 of Western Michigan’s

repulpability test method. Additionally, it meets the criteria for industrial compostability in several regions, offering further flexibility in waste management strategies.

A key feature that sets LamiBak™ Flex apart is its PFAS-free composition. As regulatory bodies across the globe move to restrict the use of the so-called “forever chemicals” (PFAS), Ahlstrom’s proactive formulation helps converters stay ahead of compliance demands

By integrating recyclability, renewable sourcing, and chemical safety, LamiBak™ Flex enables packaging producers to support a more sustainable value chain while maintaining the material integrity needed for food-contact applications.

While its environmental attributes are significant, LamiBak™ Flex is equally defined by its highperformance profile. Engineered for flexibility, the base paper serves as a conversion-friendly platform suitable for further processing techniques, including extrusion, coating, and metallization. This adaptability allows packaging converters to tailor the final barrier properties according to the product requirements.

One of the paper’s notable performance features is its ability to reduce the need for excess primer or barrier coatings. This not only streamlines the converting

process, saving time and cost, but also has the potential to improve recyclability and lower the material footprint — further supporting the product’s overall sustainability credentials.

With its tailored made paper-based structure, LamiBak™ Flex offers excellent mechanical strength and runnability, ensuring smooth performance on packaging lines and consistent results across various packaging formats.

Ahlstrom’s launch of LamiBak™ Flex reinforces its role as a proactive innovator in the sustainable packaging space. By delivering a paper solution that balances functional, environmental, and economic priorities, the company supports brand owners and converters in achieving both regulatory readiness and consumer trust.

As global expectations continue to shift toward transparency, safety, and environmental stewardship, LamiBak™ Flex presents a timely and forward-thinking solution. It helps bridge the gap between performancedriven design and planet-positive action — a critical intersection for the future of packaging.

To learn more about LamiBak™ Flex and explore Ahlstrom’s broader range of sustainable packaging materials, visit https://www.ahlstrom.com/products/ lamibak-base-paper/

By Kinga Sieradzon, Vice President Sustainability Operations, Tetra Pak

As global food systems evolve to meet rising demand, packaging plays a critical role. Aseptic cartons keep perishable food, such as milk, juice, and plant-based beverages safe during transport and storage for up to a year, without the need for preservatives or energy-intensive refrigeration. The extended shelf life reduces food waste and supports access to safe, nutritious food, particularly in regions where cold chain infrastructure is limited.

Tetra Pak cartons are also made primarily from paperboard sourced from FSC™ certified forests and other controlled sources, which is renewable as it replenishes over time. This high share of renewable

materials has been shown in Life Cycle Assessments to mean that aseptic cartons have a lower climate-impact versus single-use packaging made primarily from fossil fuel-based materials in the dairy and juice categories. This means cartons are a vital part of transforming our food systems. But we are facing the reality that these systems still use substantial resources, and it is our responsibility as industry-leaders to support the transition to a circular economy. We are working continuously, alongside the recycling value chain and governments across the globe, to make this happen. Our cartons are designed to industry-standard recycling guidelines, optimised for recyclability when they complete their journey. To support this, we invest €100 million annually to further enhance the environmental profile of our carton packages, including simplifying material structures and increasing fibre content with circularity in mind. One example of this is the paperbased barrier. Cartons can be recycled where collection, sorting and recycling infrastructure exists at scale. But the picture is very fragmented across the globe, and more needs to be done through collective action, transformational innovation and bold investments before we reach a circular economy.

Some countries are leading the way. Belgium, where 70% of beverage cartons are collected for recycling, offers a strong example of what’s possible through coordinated national systems and public engagement. Elsewhere, the picture is more fragmented. Innovation in recycling infrastructure is a critical component to changing this, so we are investing more than €40 million per year to develop the collection and recycling value chain through collaborations and new technologies. A recent success is the new recycling plant in the Netherlands, a collaboration between Tetra Pak and Yellow Dreams, which has the potential to process the entire volume of polyAl from beverage cartons recycled across the Netherlands and Belgium, as well as some volumes from Germany.

Next, we must ensure that the materials resulting from recycling processes holds commercial value. For the fibre portion of our cartons, this is already well established, with paper fibres commonly repurposed into products such as cardboard boxes, paper bags, tablecloths, napkins and toilet paper. However, to make circularity work at scale, we need to go further.

The remaining portion of the carton, known as polyAl (a combination of polymers and aluminium), can already be turned into plastic pellets and used to manufacture durable goods, such as floor panels and outdoor furniture. The challenge lies in scaling this process in a commercially viable way.

We have made significant progress in this area. For example, we recently launched a new transport crate with Schoeller Allibert made from up to 50% polyAl from used beverage cartons, with the rest made up of raw materials from other recycled streams. The crates are undergoing rigorous quality and durability tests and, once validated, will gradually replace over 50,000 crates at our global spare parts distribution centre in Sweden.

Another area with significant potential is cargo pallets, which are used extensively across supply chains. The Noè pallet, developed in Italy through a collaboration between Tetra Pak, CPR System and Lucart, is made entirely from recycled polyAl. These pallets are themselves recyclable, offering a closed-loop solution.

Technology also has an important role to play in scaling circular solutions. Connected packaging can improve transparency and accessibility by helping consumers understand how and where to recycle. Further down the recycling chain, Aldi is using artificial intelligence to track and verify the recycling of flexible plastics. Not only does this build public trust that such material is being recycled; it provides the wider industry with information about what is possible using this feedstock.

The failure to reach an agreement at last year’s global treaty negotiations on plastic pollution in Busan highlighted just how challenging it is to achieve consensus on circularity. The ongoing negotiations indicate a mutual wish to make progress. We must persist. In the end, our greatest challenge is also our greatest opportunity: expanding access to safe, nutritious food while keeping valuable materials in use, creating greater value for society and the planet.

References: www.un.org/en/global-issues/population In 2021, the Alliance for Beverage Cartons and the Environment (ACE) released a third party reviewed study. The study concludes that beverage carton packages have a lower carbon footprint than glass, plastic or metal packages.

www.acrplus.org/media/origin/images/technicalreports/2024_ACR_DRS_Belgian_case.pdf

Article provided by Tetra Pak. For more information on this, please visit www.www.tetrapak.com/en-gb

by Dominy Jones

As the packaging industry races to meet sustainability targets, bioplastics are often positioned as a promising alternative to conventional plastics. Derived from renewable sources such as corn starch, sugarcane, or even seaweed, bioplastics are gaining ground across sectors—from food and beverage to cosmetics. But as with any emerging solution, the reality is more nuanced than the marketing might suggest.

First, it’s worth clarifying that “bioplastic” is an umbrella term. It can refer to bio-based plastics (made from renewable resources), biodegradable plastics (which break down under certain conditions), or both. This ambiguity can create confusion both in supply chains and in consumer messaging. Not all bioplastics are compostable, and not all compostable plastics break down in home compost bins. Some require industrial facilities, which are not widely available—particularly in the UK.

“But as with any emerging solution, the reality is more nuanced than the marketing might suggest.”

John

challenges – none of them mutually exclusive.”

For many of the bio offers on the market, despite significant investor support, they are still very much work in progress. Despite claims from some quarters, there is no one biobased material solution. The target end products are complex and new biobased products must meet functional and regulatory requirements. There’s a very real risk that if the industry continues to operate in silos, development will remain painfully slow. Collaboration between industry partners will be key to success.

“The bioplastics industry faces servral different challenges - none of them mutuall exclusive”

For packaging professionals, the key lies in context. Bioplastics may offer lower carbon footprints than fossil-derived plastics, particularly when produced using waste feedstocks or under controlled farming systems. PLA (polylactic acid), for example, is popular for food containers and has a significantly lower CO₂ impact than PET. However, when it ends up in the wrong waste stream—such as conventional plastic recycling—it can cause contamination and disrupt established processes.

There are also growing concerns about land use and competition with food crops. As demand for bio-based materials rises, the industry must ensure it doesn’t replicate the sustainability pitfalls of other global supply chains. Transparency in sourcing and life cycle analysis is crucial.

That said, bioplastics do have a role to play—particularly in applications where reuse or recycling is challenging. Think flexible films for perishable goods, or items that are likely to be contaminated with food waste. In such cases, compostable options can support more circular systems, especially when aligned with organics recycling.

The COM4PHA project is committed to developing new formulations of bioplastics based on the PHAs group to promote new lines of product development based on these biodegradable materials. In particular, the project is working on formulations based on the PHBV copolymer for applications in the packaging and agriculture sector, using innovative processing technologies for this type of polymer. These technologies include hollow-body blown extrusion for bottles and the application of the copolymer as a coating on paper substrates and agricultural mulch films.

“There are also growing concerns about land use and competition with food crops. As demand for biobased materials rises, the industry must ensure it doesn’t replicate the sustainability pitfalls of other global supply chains. Transparency in sourcing and life cycle analysis is crucial.”

Looking ahead, innovation is promising. Secondgeneration bioplastics using agricultural residues, algae, or even captured CO₂ are emerging, with the potential to sidestep some of the issues linked to first-gen materials.

Eating fish and chips by the sea with a fork made of seaweed could one day be imaginable, as seaweed

plastic is one alternative for harmful plastics discussed in the “Bioplastics 2025-2035: Technology, Market, Players, and Forecasts” report. IDTechEx’s research draws attention to materials used to create biodegradable plastics that can be broken down by microorganisms in soil and used to create feedstock for new bioplastics, bringing sustainability to both the start and finish of the bioplastic life cycle.

Notpla, a leading innovator in sustainable packaging and winner of The Earthshot Prize in 2022, announced the successful completion of a £20 million fundraising round (over US$25 million), doubling its initial target despite challenging economic conditions. The Series A+ raise marks a significant step forward in Notpla’s mission to offer an alternative, natural solution for single-use plastics. With their sustainable, seaweedbased alternatives, Notpla expect to replace over 100 million single-use plastics per year.

“With their sustainable seaweedbased alternatives, Notpla expect to replace over 100 million single-use plastics per year.”

Ultimately, bioplastics aren’t a silver bullet—but they can be a useful part of a broader, systemsbased approach to sustainable packaging. For brands and suppliers, the focus should be on matching materials to end-of-life infrastructure, clear labelling, and investing in education and collection systems. Only then can bioplastics genuinely help close the loop.

As downgauging gains traction across industries, companies are finding smart ways to cut packaging weight without compromising recyclability or protection. From food to industrial sectors, innovative materials and regulatory drivers like the EU’s PPWR are reshaping packaging strategies—proving that sustainability and performance can go hand in hand. By Emily Gambrill.

As we all know, downgauging is a common and effective strategy in sustainable packaging. It’s screaming out to us that this is one of the best ways of becoming more sustainable.

Due to its involvement of reducing material to create the packaging, most often by making it thinner or lighter, it can have detrimental effects to the packaging itself. Don’t get me wrong, downgauging offers not only environmental benefits, but economic benefits too. However, the challenges that are presented from this are something to consider. Material performance is a first, in terms of over-downgauging, it is important to know that this can compromise product protection, which in turn increases the risk of damage and spoilage. The next big thing, Recyclability. Thinner materials can be harder to recycle, especially if they involve complex multilayer composites.

At SPN we have been made aware of how companies are successfully downgauging on packaging without having to affect the way their packaging can be recycled.

Quorn, the food company specifically known for producing vegetarian and vegan food, has told us that they are taking steps towards shared environmental responsibility. Their article explains that the removal of printed carton sleeves is the substantial reduction in packaging materials. As cardboard sleeves require resources including raw materials, energy and water to produce and recycle, Quorn have shifted to a more efficient packaging solution. They go on to say that they are decreasing its usage and excess carton board where possible leading to a reduction in materials wastage at the consumer end and an overall reduced carbon footprint.

Quorn’s statistics show, that by shifting to this streamlined and minimalistic approach, it ‘reduces packaging weight by approximately 20% per SKU, and in combination with a redesigned Escalope tray (further lowering plastic usage) the initiative has resulted in an estimated annual saving of 87,000kg CO2 (based on 2024 figures).’ This is the equivalent of discarding approximately 424,000 road miles in carbon emissions.

For more information, please visit www.quorn.co.uk

‘On February 11, 2025, the long-awaited EU Packaging and Packaging Waste Regulation (PPWR) entered into force, outlining key dates and targets to reduce packaging waste, enhance recyclability and boost circularity across the EU economy’ says Gabriel Magdaleno, Strategic Product Management & Marketing Director at Masterpress.

While many of the of the key deadline and targets outlined in the regulation may still meet further debates, the document provides long-awaited regulatory stability that companies like Masterpress have needed to confidently shape sustainable growth strategies. One of those targets requires all packaging on the EU market to be recyclable in an economically viable way by 2030. It offers long-awaited regulatory stability, not only to Masterpress, but to all businesses and it helps them plan and invest in sustainable solutions. Any regulation that intends to reduce packaging waste, enhance recyclability and promote circularity is fundamental to becoming more sustainable.

“At Masterpress, we recognize the complexity of shifting this mindset but believe our projects, like the thinnest polyolefin shrink sleeve, can encourage the industry to shift from competition to collaboration. Moreover, we stand ready today to pursue partnerships that address key challenges, such as standardization in reusable packaging systems, to ensure that our industry can package a greener tomorrow.”

Critically, the PPWR is viewed not only as a legislative mandate but as a catalyst for industry-wide collaboration and standardisation, which are seen as essential for overcoming challenges such as fragmented reuse systems and inefficient recycling infrastructures. Companies like Masterpress are leveraging the regulation to drive innovation, such as downgauging materials and adopting recyclable label technologies, while also highlighting the need for further regulatory clarity, infrastructure investment, and support for scaling sustainable packaging solutions.

Although the PPWR currently lacks detailed

implementation guidelines and standardisation requirements, it represents a foundational step toward a more circular economy.

For more information on this, please visit www. masterpress.com

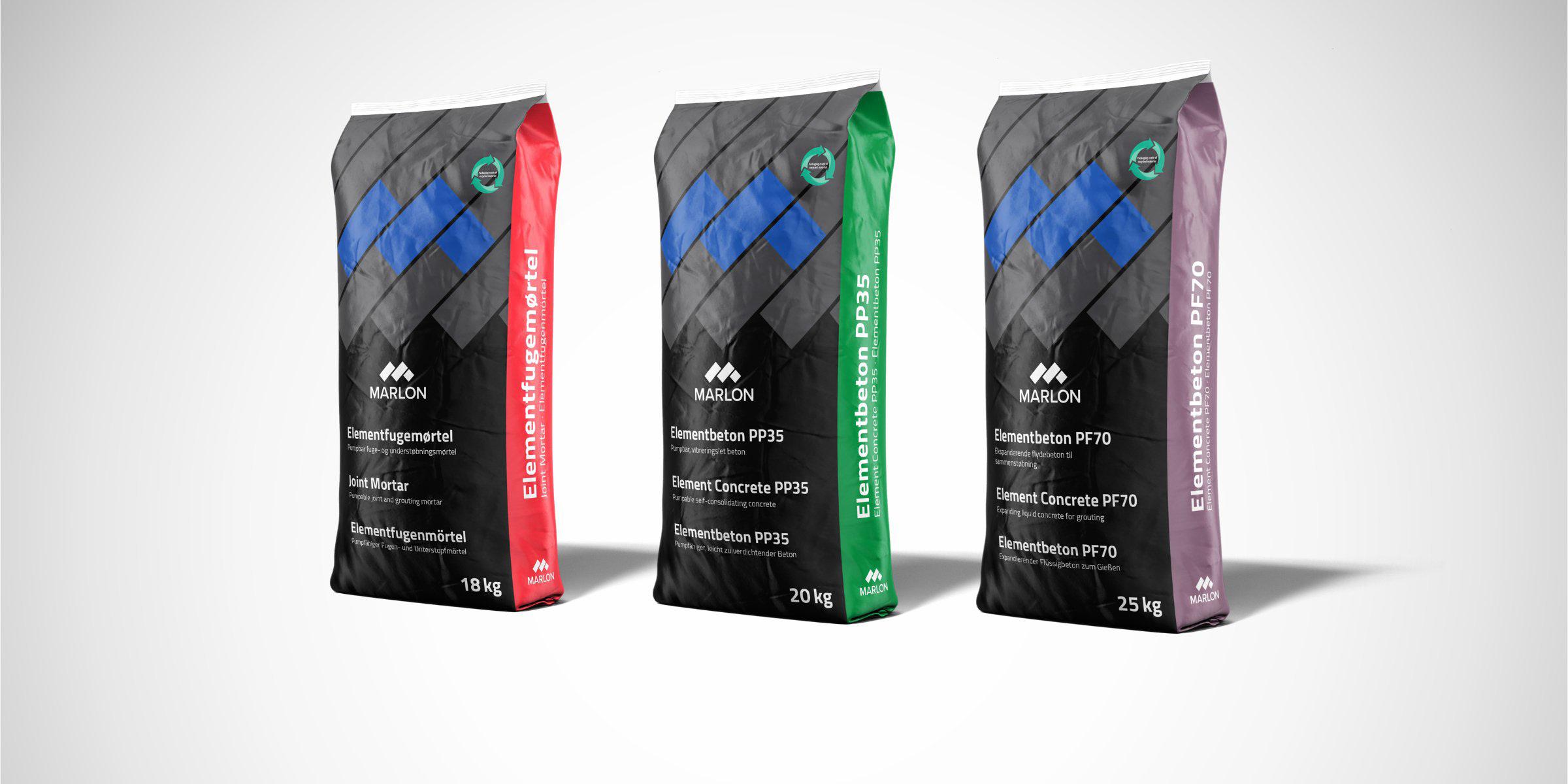

Here at SPN, we have heard from Berry Global, on how they incorporate 30% PCR content into its NoDiVent dry packaging solution. The article further explores how they’re partnership with Marlon has been able to switch from NoDiVent bags made from 100% virgin plastic to a version containing 30% post-consumer recycled (PCR) plastic. Alongside this, the film has also been successfully downgauged by 7% while maintaining its strength characteristics. These reductions are part of ongoing initiatives between Berry and Marlon that will eventually see the inclusion of greater levels of recyclate and further downgauging for which successful trials have already been conducted. Increasing the use of circular polymers is one example of Berry’s commitment to sustainability, which also includes improved recyclability and reducing the carbon footprint of its products as well as utilising renewable resources and refill and reuse systems.

“Berry and Marlon share an ongoing commitment to sustainability in all areas of our operations”

These initiatives are not one-off measures; they are part of a broader, ongoing effort aimed at increasing the use of circular polymers, enhancing recyclability, and further reducing carbon emissions. With successful trials already paving the way for even greater levels of recycled content and additional downgauging, both companies are setting new benchmarks in industrial packaging innovation.

This commitment not only drives cost efficiencies and performance improvements but also aligns closely with the industry’s broader sustainability goals. The continued evolution of these initiatives demonstrates that strategic partnerships and a focus on innovation can help create a more sustainable future.

“Nevertheless, specialist products such as ours also need the best packaging in terms of protection and convenience to ensure the highest quality and user experience for our customers. Through our partnership with Berry and thanks to the company’s technical know-how, we have been able to ensure that both requirements have been achieved with no compromise”

I know I said at the beginning that over-downgauging can compromise on product protection, however we can clearly see here that companies are already overcoming this hurdle. Downgauging has emerged as a critical strategy in the shift toward more sustainable packaging, offering a practical means of reducing material use, energy consumption, and carbon emissions without compromising performance or product protection.

As demonstrated by industry leaders across sectors, downgauging supports both environmental goals and operational efficiency.

Food brands like Quorn are leading by example, removing unnecessary packaging components such as carton sleeves and adopting lightweight alternatives that still meet branding and functionality needs. Their efforts have led to significant reductions in packaging weight and carbon emissions. At the same time, regulatory frameworks such as the EU’s Packaging and Packaging Waste Regulation (PPWR) are pushing companies to rethink packaging design and recyclability. In response, firms like Masterpress are combining downgauging with recyclable mono-material solutions to meet the regulation’s ambitious targets.

In more technical applications, the partnership between Berry Global and Marlon shows how downgauging can succeed even in demanding industrial settings. Their thinner NorDiVent film, made with 30% post-consumer recycled content, offers durability and circularity benefits.

Together, these examples illustrate how downgauging is not just a sustainability tactic, but a forward-looking design principle that will continue to shape the future of packaging. It enables progress across sectors while aligning with circular economy goals and evolving regulatory standards.

For more information on this, please visit www. berryglobal.com/en

With regulations tightening, consumer pressure mounting, and environmental urgency escalating, paper is stepping into the spotlight - not just as a recyclable material, but as a dynamic platform for innovation, circular design, and responsible manufacturing, helping industries meet sustainability goals while reshaping the future of global packaging. By Emily Gambrill.

Iknow that we touched base on paper packaging in the feature focused on ‘Recyclability’, but I think that this needs a whole feature on its own. As we all know, paper packaging is one of the most sustainable methods; it’s a renewable resource, biodegradable, recyclable, has a lower carbon footprint and it supports circular economy. However, with these comes the risk of deforestation, manufacturing processes can be resource-heavy and are generally less durable than the alternatives (one of many being plastic).

In the last magazine edition, we spoke about the EU and UK having set regulations surrounding sustainable packaging. Following on from that, India and China have set bans on certain plastic packaging which is pushing industries to adopt paper-based solutions (a huge step to becoming more sustainable as India and China collectively contribute roughly 63% of global packaging material exports) and Canada have banned certain single-use plastics and are using paper as a key alternative.

With paper packaging at the forefront of a greener planet, SPN has heard from James Cropper, who are a leader in advanced materials and paper packaging, specifically pioneering circular economy solutions in the beaty and cosmetics sector. By investing in R&D, James Cropper is advancing its Rydal Packaging collection by incorporating used jeans, coffee cups and postconsumer and post-industrial waste into fully recyclable paper. Through running their CupCucling® programme, they’ve diverted 58 million coffee cups from landfill and produced 696 tonnes of cup fibre, which is enough for around 1.74 million perfume boxes. Collaborating with leading entities in stamping foils and embossing tools,

they are producing high-end, sustainable packaging that dispels myths about luxury and sustainability being incompatible. Their campaign, ‘Sometimes it is Black and White’, has been launched to encourage brands to adopt sustainable practices without compromising aesthetics or quality, w key are which beauty and cosmetics brands want to follow vigorously.

For more on this, please visit www.jamescropper.com

“By offering 100% upcycled fibre products, we innovate with sustainability front of mind. The circular economy is the future of sustainable business.”

Moving on, Sappi have sent us news on how they, and their partners, are actively promoting paper and print as sustainable, valuable and modern communication tools through education, awareness campaigns and industry initiatives across France, Italy and Germany. The article explains how Sappi and Groupement des métiers de l’Impression et de la Communication (GMI) are working together to launch a nationwide campaign to promote the value of paper and print. In this launch, its main demographic is the general public, specifically the younger generation who are unfamiliar with print. The campaign has 4 key visuals which are addressing common myths:

• Paper causes deforestation.

• Paper isn’t recyclable.

• Paper is outdated or misunderstood.

In Italy, the OrigAMA La Carta Initiative is an educational campaign reaching over 1,000 students in 15 schools and universities. The initiative entails students to design creative campaigns promoting paper’s environmental benefits. This has produced impressive results, with over 400 students participating in the competition, and the winning campaign that was implemented across multiple channels including metro posters, newsstand displays and social media.

“In a world facing urgent environmental challenges, the paper industry stands as a model of transformation”

In Germany, the WE.LOVE.PRINT. initiative aims to strengthen the print industry and integrate it into omnichannel communication. The initiative educates society about the values of print and sustainability while providing training opportunities in the graphic arts industry. Sappi contributes by funding the partnership annually and by providing premium papers for WE.LOVE. PRINT magazines and promotional materials. The platform invites print enthusiasts from the entire spectrum of the industry to participate. Communication about the range of print services naturally also addresses society. After all, print is not an industry topic, but an integral part of social life. Sappi actively promotes this integrative approach via its newsletters and social media channels. This support helps to ensure that printed communication remains relevant, innovative and responsible in modern marketing strategies.

From this, we have learnt that Sappi VP Flavio Froehli have highlighted the industry’s transformation in reducing carbon emissions, leading in circular economy practices and educating the next generation about sustainable communication. It also shows that Sappi have clear aims to strengthen the future of paper as a renewable, sustainable medium, set new standards in eco-conscious manufacturing and innovate in production methods and circular economy models.

For more information, please visit www.sappi.com

News regarding a major development has come in through Mondi; they have successfully started up a state-of-the-art paper machine as it Štětí mill (Czech Republic) which began in December 2024. Early production runs show excellent results in paper strength, runnability and consistent quality. This new machine enables Mondi to meet the rising demand for paper-based flexible packaging while strengthening the group’s vertically integrated Paper Bags business. They go on to say that it also supports the optimisation of production efficiency across the Group’s entire kraft paper portfolio.

Mondi is committed to ensure a reliable supply of kraft paper to support customers in their transition to paperbased solutions. The paper machine strengthens the company’s position as a leader in sustainable packaging, offering a full range of kraft paper products from high strength to high porosity grades, for various applications such as construction and industrial bags.

The start-up marks an important milestone in Mondi’s

journey towards making all packaging solutions reusable, recyclable, or compostable, as part of its Mondi Action Plan 2030 sustainability commitments, and is testament to the company’s expertise and long-term vision for a truly circular economy.

“We are delighted to have started production on this paper machine. The project team did a fantastic job and ensured it was installed on time and in budget. The quality of the paper is exceptional, and we are impressed with how quickly we have been able to deliver paper that meets our customers’ expectations.”

For more information, please visit www.mondigroup.com

As we’ve seen across these features, paper packaging and print are undergoing a renaissance; driven by innovation, regulation, and a rising demand for sustainable alternatives. From James Cropper’s closed-loop packaging innovations in

the cosmetics industry to Sappi’s continent-wide educational initiatives and Mondi’s industrial-scale commitment to circularity, the message is clear: paper is no longer just a material; it’s a movement.

Together, these initiatives point to a future where paper is not only a sustainable choice but a smart, scalable, and highly adaptable solution. Whether it’s in premium cosmetics, printed media, or industrial applications, paper is proving its worth as a modern material capable of supporting a greener planet. The momentum is building - and if the pace of innovation continues, paper packaging could soon become one of the defining pillars of sustainable development in the global packaging landscape.

With increasingly complex global supply chains, the packaging industry is dealing with challenges around supply and distribution networks, product quality, and new legislative obligations.

Food producers, foodservice providers, and retailers are looking for packaging companies that can support them in solving these challenges, through working more locally and developing solutions that support packaging circularity. Colpac is a full-service packaging partner that actively drives all parts of the packaging process, from conception to delivery, and beyond.

Recent changes are making global distribution networks more difficult to manage and we are seeing the industry struggle to get materials and finished packaging to where it needs to be. This demonstrates the need for flexible supplier networks and the benefits of local packaging production.

Colpac has an agile manufacturing facility in the UK, which is highly adaptable to suit demand. The team also has an established supplier base to support the requirement for a variety of materials to meet customer requirements. This helps Colpac to provide regular supply to many UK customers that look to reduce risk by choosing packaging that is produced locally.

Food safety and quality are at the forefront of our customers’ businesses, and the packaging that their food is presented in should showcase this. With many of its core stock lines manufactured in the UK, the Colpac team can closely manage production processes and meet quality standards. This is reflected in the company’s BRCGS audit grade of AA+, the highest possible grade, which includes unannounced audits and meeting non-conformance requirements. This demonstrates Colpac’s commitment to audit ready safety standards and assures customers that products

are manufactured in a safe environment.

In addition to having control over product quality and providing real-time updates to customers on production progress, Colpac also supports industry development. Frances Dickman, Head of Compliance, was recently part of the BRCGS Technical Working Group, set up to develop the BRCGS Global Standard Packaging Materials Issue 7, which was launched in October 2024.

Colpac team members with BRCGS AA+ certificate, in the company’s factory in Bedfordshire, UK.

Packaging reforms are bringing significant impacts to stakeholders throughout the supply chain. Colpac can guide you through legislative topics such as Packaging Extended Producer Responsibility (pEPR) and Simpler Recycling reforms.

The company is providing two-way support for industry and customers in implementing pEPR, with Talia Goldman, Colpac’s ESG Director, being part of the pEPR Scheme Administrator (now PackUK) interim steering group. By working with Colpac, customers gain access to a wealth of expertise across packaging legislation and the implementation of circular solutions.

Legislative changes are driving the need for materials that are more easily recycled and that reduce packaging weight in support of reduced pEPR fees.

Colpac’s design team constantly evaluates existing and new products to review materials, to lightweight and reduce plastic, improve closures for filling efficiency, and create new packaging formats to meet customer needs.

The team has worked with several customers to replace plastic laminates with direct food contact inks, to eliminate unnecessary plastic and increase pack recyclability. In doing so, Colpac significantly reduced customers’ projected pEPR unit costs, all whilst maintaining the look and feel of the packaging to suit consumer preferences.

Colpac is thoroughly embedded in industry, as part of trade associations and technical working groups, driving collaboration and clarity in support of positive change. As a co-founder of the Alliance for Fibre-Based Packaging, which aims to unify the voice of the fibre supply chain, the company regularly advocates for customers within the packaging economy.

Active participation in these key groups enables its team and customers to access the latest guidelines in context with discussions from industry wide forums and demonstrates Colpac as a trusted voice at the heart of industry.

The culmination of Colpac’s experience positions the company as a full-service packaging partner to support you in overcoming industry challenges and developing your next packaging solution.

“Colpac is a full-service packaging partner that actively drives all parts of the packaging process, from conception to delivery, and beyond.”

Colpac worked with Pret A Manger to bring direct food contact ink technology to their platter bases, to eliminate added plastic.

Beyond the Box: Driving Circular Economy Innovation in Fibre-Based Packaging. Paul Krochak of Graphic Packaging International shares how smarter design and value chain collaboration are cutting carbon and eliminating plastic.

Graphic Packaging is recognised as a global leader in paperboard packaging. What are your current priorities when it comes to sustainable innovation across your product lines?

Our priority is to create consumer packaging solutions that make a positive impact by being more circular, more functional, or more convenient than traditional alternatives. Our innovation and manufacturing teams are focused on advancing both our packaging and processes through a Design for Environment (DfE) approach.

More circular means we are prioritising the use of renewable, recycled and responsibly sourced raw materials. We design our packs to be recyclable or compostable at end-of-life and continually refine our manufacturing processes to make better use of renewable energy, reduce waste, and build circular economy principles into every aspect of production.

In combination, these efforts help keep the carbon footprint of our packaging as low as possible. Compliance with food safety and regulatory standards is embedded from the start.

“Compliance with food safety and regulatory standards is embedded from the start.”

More functional means packaging that performs better across the value chain. In addition to designing our packaging and automation solutions for optimal operational efficiency, we assess packaging functionality with assessments such as shelf-life trials, storage performance in terms of stackability and sealability, containment, integrity testing and more. This ensures that the design provides optimal protection to minimise product damage and loss during transport and storage from the production facility to the consumers’ hands.

More convenient means recognising that the widespread adoption of packaging hinges on consumer acceptance. We conduct trials to understand packaging convenience in terms of real-world use, such as dispensing of goods, ease of carrying, ergonomics, re-sealability, and hygiene. Practical consumer tests help us evaluate preferences and the acceptance of different features and materials.

Your packaging solutions span critical sectors like food, healthcare, and pharmaceuticals. How do you balance regulatory demands, functionality, and sustainability in these highly sensitive industries?

We balance these demands by considering circularity, functionality, convenience, and regulatory compliance in our innovation process. It’s not about compromising, but rather about finding the “sweet spot” where properties are optimised. Our DfE methodology enables us to weigh things like material choice, functional requirements, and compliance pressures simultaneously, so we design solutions that work across the full spectrum of needs.

Can you tell us more about any recent developments or initiatives that reflect Graphic Packaging’s commitment to circular economy principles?

The circular economy is one which decouples value generation from resource depletion to make the economy more resilient, operating within planetary boundaries with a balanced use of resources and avoiding side effects on nature’s ecosystem. Circular economy principles are core to our innovation process and are reflected in all recent innovations. The ProducePack™ Punnet tray, for instance, is designed to be recyclable and can be plastic-free to support compliance with the Single–Use Plastics Directive (SUPD). This aligns with the circular economy principle of eliminating waste and pollution A cradle-to-gate LCA has demonstrated a significant reduction in carbon footprint versus a virgin PET tray, thereby supporting the value chain in reducing their CO2 emissions and its irreversible effect on climate change. As it’s paperboard, it’s made primarily with renewable materials and has a recycling rate of more than three times that of the plastic tray (Eurostat, PETcore), helping to keep materials in circulation for longer. What’s more, independent testing conducted by Washington State University showed cherry tomatoes had a longer shelf life in the ProducePack Punnet than in a plastic tray in both refrigerated and ambient conditions. Preventing food waste is particularly important, as it often leads to a much higher environmental burden than the packaging itself.

“As it’s paperboard, it’s made primarily with renewable materials and has a recycling rate of more than three times that of the plastic tray (Eurostat, PETcore), helping to keep materials in circulation for longer”

Another key area of focus for our customers is lightweighting - reducing material use across packaging formats while still meeting strength and performance requirements. Reducing material use means fewer resources are needed to achieve a given level of functionality. But it also means less material needs to be transported, processed, and managed at end-of-life, leading to environmental benefits across the entire value chain. Beverage multipacks are a great example of this in action. For example, we’ve developed intelligent paperboard clip-style cartons for larger PET bottle multipacks that have allowed customers to move from formats with more paperboard, such as fully enclosed cartons.

Folding cartons have seen renewed interest due to recyclability. How is Graphic Packaging leveraging fibrebased materials to replace less sustainable substrates?

We’re focused on developing advanced paperboard solutions that can replace plastic even in sensitive and demanding applications. Boardio™ paperboard canisters, for example, bring advanced barrier technologies to products like baby formula, nutrient powders and coffee, offering equivalent shelf-life protection and enhanced consumer convenience. Our CleanClose™ child-proof laundry tab pack, developed initially for Unilever’s Persil laundry tabs, eliminates the need for plastic tubs, while HoldRite™ paperboard cups replace microwaveable plastic cups for shelf-stable applications such as instant noodles with a recyclable, structurally robust paperboard alternative.

“We’re focused on developing advanced paperboard solutions that can replace plastic even in sensitive and demanding applications.”

Each of these paperboard examples showcases advanced barrier solutions and intelligent structural design. We’re also exploring biopolymer and bioplastic barriers that can match the performance of fossil-based materials, but that come from renewable feedstocks, with a lower carbon footprint and meet recyclability (or compostability) requirements at end-of-life.

What role does lifecycle analysis play in your material selection and product design processes?

Lifecycle analysis is one of the methodologies we use to measure circularity performance. Carbon footprint is an important metric to many customers, especially those aligned with science-based decarbonisation targets or net-zero commitments.

We continuously aim to improve our DfE methodology using a range of tools from simple models that provide screening-level material circularity indicators and carbon footprint values to more sophisticated models and life cycle assessment. These tools help us understand the impact of different design choices on circularity and to inform the innovation process. A plan for broader LCA deployment is underway to support the design and development of products that deliver quantifiably lower environmental impact than traditional alternatives.

“A plan for broader LCA deployment is underway to support the design and development of products that deliver quantifiably lower environmental impact than traditional alternatives.”

How is Graphic Packaging collaborating across the supply chain—from raw material sourcing to retail—to advance sustainability goals?

We can, and do, everything possible within our operations to advance packaging sustainability. But meaningful, scalable progress depends on effective collaboration. In our experience, the most significant and lasting sustainability impacts often result not from isolated efforts, but from coordinated action across organisations.

We’re active participants in initiatives like 4evergreen, Compostability by Design Platform, Preserve, BioSupPack, and the Alliance for Fibre-Based Packaging. These partnerships bring together expertise from across the value chain to tackle shared challengesfrom innovating barrier materials to improving fibre recovery infrastructure. It’s this kind of collaboration that enables real systems-level change and accelerates progress far beyond what any single organisation could achieve alone. These partnerships focus on everything from barrier material innovation to fibre recycling infrastructure.

What are some of the key metrics or KPIs you use to evaluate sustainability success across your global operations?

On the product side, we track factors such as Design for Recyclability, renewable and recycled content percentages, carbon footprint, and the Ellen MacArthur Foundation’s Material Circularity Indicator. At the organisational level, we’re guided by our Science Based Targets initiative (SBTi) commitments and our ‘Better by 2030’ goals, which inform everything from greenhouse gas emission reduction and circularity to employee engagement, safety and wellbeing.