TECH: WOMEN IN ME

EDUCATION: BACHELOR

COLLEGE 2.0

ASSOCIATION: INTRO RECAP

TECH: WOMEN IN ME

EDUCATION: BACHELOR

COLLEGE 2.0

ASSOCIATION: INTRO RECAP

The first quartile has passed, and we are amid the second quartile. We are just getting used to a life without lockdowns, but just as these troubles eased, new challenges arise. From global issues & conflicts to the housing problems we deal with here locally, things never seem to get back to normal. But one thing that is back is the release of the openME. Whilst you have been studying, teaching or doing other important work to improve the world around you, we as the editorial committee have been very busy making the first edition of the 54th volume of the openME.

I want to thank the committee and all the people that wrote articles for this edition. Thanks to them we have an edition packed full of interesting articles to read.

In this edition, we take a look at various scales of things: from the smallest highest precision engineering to the largest structures known. Furthermore taking this scale into historic account, what once was a large leap can these days be a small uneventful step. Next to that, we also take a look at some smaller and larger objects of the Association, and of course, the usual articles about education are also still present.

I wish you a lot of reading pleasure! With Kind regards.

December 2022, volume 54, issue 1

The ‘openME’ is a publication by the study Association for Mechanical Engineering Simon Stevin of the Eindhoven University of Technology

Editor-in-Chief

Ben Gortemaker

Design

Maartje Borst, Rik Lubbers, Roelof Mestriner, Joel Peeters, Lex Verberne

Layout Jankatiri Boon, Ruben Bravo Veldhuijzen, Mart de Bruijn, Veerle Bus, Imke Goofers, Ben Gortemaker, Daniël Kleinjan, Ryan Leal, Kim van Loon, Remco Martin Lizandara, Martijn Zoer.

Editorial committee

Ruben Bravo Veldhuijzen, Mart de Bruijn, Veerle Bus, Imke Goofers, Ben Gortemaker, Daniël Kleinjan, Ryan Leal, Kim van Loon, Remco Martin Lizandara, Martijn Zoer.

Illustrations and Pictures

Editorial committee, Photo committee, source stated otherwise

Printing office

Drukkerij Snep

Circulation

1000 pieces

Contact Eindhoven University of Technology

Traverse 0.34

Den Dolech 2

5612AZ Eindhoven

Post office box 513

E-mail: redactie@ simonstevin.tue.nl

Homepage: simonstev.in

In the academic year 2022-2023 the bachelor college 2.0 will start, were the redesign of the bachelor college will be implemented. 46

Gemini south is getting rebuild and the facilities had to be moved, which was not an easy feat. But the

WRITTEN BY FREEK JANSEN

WRITTEN BY FREEK JANSEN

A year and a half back, it became clear I would be able to finish all master courses, leaving only the internship and the master graduation project to wrap up my study. Given the COVID situation, I immediately signed up for the option to swap these two parts of my program, as I intended to do the internship in a country abroad. So here I am now, in Sweden, for the final three months of my master, doing an internship at the University of Lund!

Let’s start at the beginning. The bachelor introduction week in Eindhoven. For many an unforgettable week where you meet the university and its people for the first time. For me it was already the fifth time as a parent. The program is the same as always. Five days of partying, then about a week of recovering, right? Wrong! My ambitious self has planned my departure on the Friday evening of the introduction week, a choice that I have come to highly question during my preparations for leaving that very same day. After successfully finishing ‘DoorhaalVrijdag’ of the introduction week, my bus arrived in Kopenhagen on Saturday morning, where my mother was waiting for

me. For a week, we did some travel in Sweden together. I went as far as the large city Gothenburg, another great destination for students in Sweden. Through various places land inwards, I eventually made my way back to the final destination, Lund, after which I sent my mother back home again. Although during the first 6 weeks I actually found myself a home just outside of Lund in a nearby small town. About all my sightings in Sweden and my travels I will tell you about later, let’s first start with which I will be busy most of my time here, the internship!

After my graduation project focused on numerical iron combustion, I am now keeping myself busy with something different, although also similar in certain aspects. To improve the safety of primarily electric vehicles, but also smaller devices such as smartphones or other household electronics, it is important to study the effects of ‘thermal runaway’ in a lithium-ion battery cell. One might remember the catastrophes of the Samsung Galaxy note 7, which could explode or set aflame due to a malfunctioning battery. Additionally there have been various cases of electric vehicles that were ignited by a failing battery system, either by mechanical failure as a result of a crash, or, fortunately less often, at random. When a battery cell gets damaged, the internal components can react with one another together with short-circuiting, which in the worst case results in exothermic reaction heat. Given that an electric vehicle consists of hundreds of battery cells, a single cell failure could quickly spread through the entire pack, similar to the domino-effect. Given that a single fully charged battery cell could already release plenty of heat for a small fire, the entire back bursting into flames will be catastrophic for the car and the safety of the passengers. Studying the effects of thermal runaway can help to mitigate the spread of heat through the battery pack, containing the malfunctioning cells, without compromising the performance too much. My project is mainly focused at the modelling of such a cell, in order to study the runaway to neighboring cells.

So how to approach this phenomenon numerically?

Ultimately, it would be beneficial to model a 3D battery cell that undergoes the thermal runaway process, after which flames burst out in every direction, heating the cells nearby. Additionally, heat transport through conduction and convection should be included as well. One can imagine however that modelling the process in 3D can be quite expensive in terms of computation power. To be able to model a three dimensional battery with chemical reactions happening within can be quite extensive already. The accurate modelling of flame propagation after a cell bursts not only adds to the complexity, but might be very ineffective due to its random, explosive nature. Every simulation is unlike the previous. One can argue that given these difficulties, it can be more interesting to start small, with a rather simplified MATLAB (Simulink) model. We first consider a cylindrical battery with a diameter of 18 millimeters and a height of 65mm, often going by the name “18650”. This is slightly larger than an AA battery. The equation in simple terms can be written as

here Q’heat is the heat generated by the battery, mb the battery mass, cp the specific heat, hc the convective heat transfer coefficient, Ac the convective heat transfer area, Ta the ambient temperature, Tb the battery temperature, k the conductive heat transfer coefficient and dx the thickness of the conductive material. Finally Tb2 here would refer to the adjacent battery. The battery temperature is considered homogeneous, which is an acceptable assumption, given the dimensions of the battery. By defining the conduction properties of the battery insides, the Biot number (< 0.01) is used to verify this assumption. The modelling now requires a kinematic aspect that defines the release of heat during the thermal runaway process. This is slightly different from other combustion simulations, that are often based on kinematic mechanisms that describe the reactions between the various molecules present. For batteries it is not that straightforward, and the reaction heat is directly taken from experimental data. By measuring the temperature over time during the actual ignition of a battery cell, one can determine the rate of temperature change over time. This rise in temperature can give an indication on the heat released, as the battery mass and specific heat are known quantities. This experimental data can then be used in the numerical model to give an expression for Q’heat, parameterized by the battery temperature.

In the figure 1 a graph is shown for a single battery cell. This cell is heated up by a constant heating power of 20W, resulting in a nearly linear increase in temperature. At a temperature of about 500 degrees Kelvin, you can see the

thermal runaway process kicks in and the temperature exponentially increases in a short amount of time. Then at around 900 degrees, the burning process is finished and the cell continues to cool down due to convective and conductive heat transfer with its surroundings. Now lets increase the cells, to include the heat transport in between multiple cells going into thermal runaway. The roster below represents a total of 16 cells. At t = 0, the green encircled cells are heated. Through interaction with adjacent cells, the heat is transported and the domino effect kicks in in all directions. A true fire hazard has suddenly presented itself! Although I am burning batteries

during the week, most weekends I tend to burn some calories. Lund is located in the very south of Sweden, just 20 km north of Malmö. In fact, within 45 minutes you can already be in Copenhagen. Lund houses a large university, which results in over 40% of the entire population here being students (!). The center is nice, small and cozy with plenty of opportunities to relax after a week of studying. But of course, Sweden itself is all but small and cozy.

Travelling to Gothenburg felt like a journey from Eindhoven to Groningen, but at that point I have only just left the very southern tip of Sweden. Gothenburg itself is a very large city (2nd biggest city in Sweden after Stockholm), with an interesting bunch of small islands just off the coast. The contrast with the much smaller Lund is huge, but nevertheless the center was perfect for a fika (coffee + cookie). Malmö was much more comparable to the larger cities in the Netherland, with

some interesting architecture. The Mechanical Engineers with some ambition in Build Environment might be especially interested in this twisted tower. With a trip planned for the southern part of Sweden, to Copenhagen and to Stockholm in November, I intend to keep myself busy! Not to mention the widely stretched national parks that can be found all around Sweden. With an average population density of about fourty times smaller than in the Netherlands, untouched forests and large open fields can be found everywhere. But the exotic pieces of nature are not limited to the national parks. When arriving at my place in Lund, I can still speak Dutch to a fellow parrot! Although to be honest, I think neither of us can understand each other.

An unmanned aerial vehicle (UAV), more commonly known as a drone, is an aircraft without any humans on board. Drones are one of the most fun toys for people interested in technology. There are so many different drones but the most well-known drones are the ones used for races and the ones that are used for filming. But drones are also used for many more purposes. The 2 types of commonly used Drones are human controlled and autonomous flight drones. The range of drones is wide from the biggest weighing 8000 kilograms to small drones. But what are the smallest drones in circulation?

The earliest ideas of unmanned aerial vehicles were presented in 1940. It was presented as a combat drone to fight in the Second World War. It was considered a massive advantage to bomb the Germans while not endangering any allied soldiers. In 1971 the first modern drone was made by a model airplane hobbyist, he drew up plans and DARPA ( Defence Advanced Research Projects Agency) built two prototypes. These prototypes were powered by a modified lawn-mower engine and could carry a 13 kg load for two hours. The first time drones were used in war was in 1973. Israel used unarmed target drones to spur Egypt into firing its anti-aircraft missiles. Before deploying their own pilots. The mission was an astounding success with no injuries to any of the Israeli pilots.

After this successful mission drones were used in every war since. The first full-on UAV war was the first Persian Gulf War. According to the Department of Navy of The USA: “At least one UAV was airborne during Desert Storm”. The development of drones was from surveillance and diversion to combat. Drones were fitted with weaponry and in 2001 the first kill was reported by a UAV, in Kandahar. In recent years the USA has increased its drone strikes as part of the War on Terror. In 2015 it was reported that at least 6.000 people were killed by drone strikes.

Since 2012 drones are commercially available, and after that, the market has rapidly grown. The market has an approximate value of 10 billion dollars. Commercially available drones are mostly used for photographing and videoing difficult-toreach places or getting shots that normally were only possible by having a high budget. Companies like Amazon are trying to have drones deliver their packages. And companies like Esso are using drones to search for leaks in their setups, to increase the safety of the powerplants where they are working. Commercially available drones are used in Ukraine to help them defend their country. Drones are bought for approximately € 2000 and a small explosive is placed underneath it. Then they search for a Russian tank that cost approximately 5 million and is dismantled by such a simple solution.

In Warfare and espionage, it is extremely helpful if your drone is not detected by the enemy. A smaller drone could be the answer. All drones previously discussed are rather large, but there is a UAV that is extremely small: the Black Hornet. It is the smallest Military drone in use. It weighs less than 33 grams, it has a removable mission data SD card and upgraded graphic control systems. The rotor diameter is 123 mm and the total length of the drone is 168 mm. This drone has a range of an impressive two kilometres and has a maximum flight speed of 21 km/h. It has an endurance of 25 minutes of flight time before it needs to recharge. This drone can automatically return to your location and is also able to be controlled remotely. It is one of, if not the best drone that is available for espionage. But it is limited to going even smaller due to the rotors and motors that have to be in the drone. So can we go even smaller?

The wingspan drones are still not the smallest flying humanmade structures. Microfliers could be the smallest we can realistically go. Microfliers are small microchips, the size of a grain of sand, that can fly. This is not done by engines. Instead, they catch the wind and spin like a helicopter through the air. These kinds of Microfliers are based on the maple tree seeds that slowly glide through the air. By replicating the maple tree seeds the microchips will be able to monitor air quality and the spreading of viruses. If that ever becomes a problem again.

With a mass of only 80 mg and a wingspan of only 3 cm, we went even smaller with the Flapping wing robot of Harvard. The flapping speed of the wings is a maximum of 12Hz. This drone can flap its wings independently. The wings are currently powered by a laser and it takes less power to fly this bee than it would take to light a single LED bulb. This means it is not yet market-ready. A new power source is needed to make this kind of drone workable. Inventions such as solid-state batteries and graphic capacitors could be the answer needed to make these micro drones in the future. But more innovation is required.

It is speculated that wingspan drones are the future of drone production. They are more easily usable than the microfliers in less controlled areas. The biggest problem they still have is the batteries to get them working on that scale.

In the 1960s the CIA came up with a weird idea. They wanted to use a cat to spy on the Soviet embassies. A microphone was implanted in the cat’s ear canal, a small radio transmitter at the base of its skull, and a thin wire in its fur. The idea was, that cats go where they want and it is not suspicious if a cat wanders in some random rooms. Project Acoustic Kitty was born and $20 million later the plan was set up. The biggest problem they could not control was where the cat went. $20 million down the drain, but what if we can control cats, dogs, or even smaller animals?

Researchers at Rice University have shown how they can hack the brains of fruit flies to make them remote-controlled. Within a second of a given command to its brain, the action was performed. The flies were genetically engineered by giving them some heat-sensitive ion channels in some of their neurons. When the heat was sensed it would activate the neurons that caused the fly to spread its wings. The flies were kept in a small cage, when a magnetic field was turned on the ion channels would activate and a remote-controlled fly became a reality.

Being able to remote control small animals would give a whole new dimension on the uses of drones. The question that arises is whether remotely controlling a fly is the same as making a drone. Where is the line to call something a drone? To be honest, I don’t know how far we can go, but one thing I do know is that in times of war the weirdest ideas are tried to get a technological leg up on the enemy. This time it is a fly or a cat, however, trying to remote control animals won’t be the last time it is tried in history.

WRITTEN BY PATRICK ANDERSON

WRITTEN BY PATRICK ANDERSON

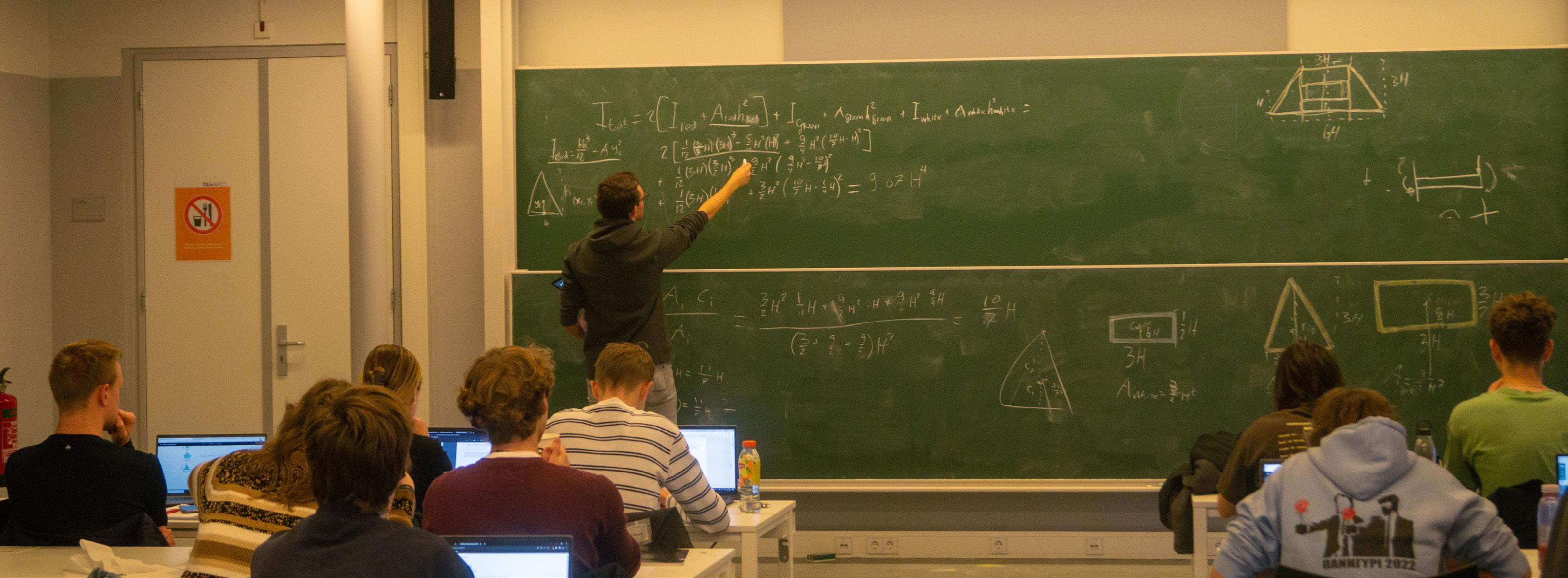

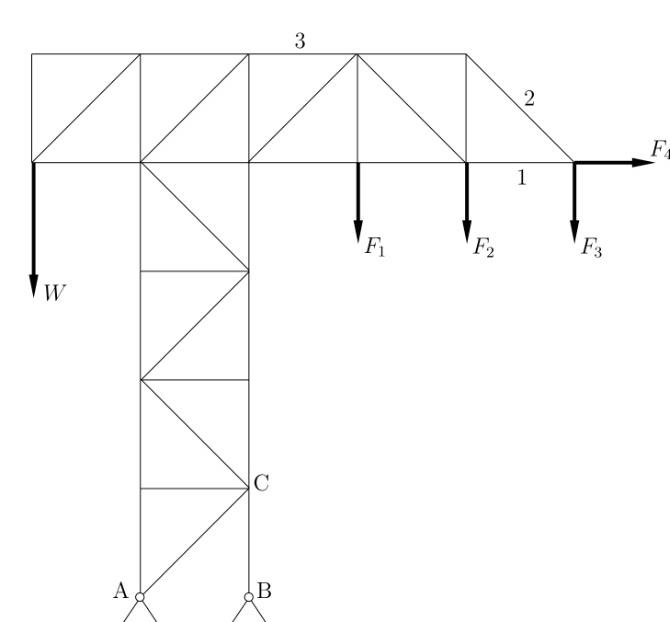

The new academic year has just started and as the new Dean of the Department of Mechanical Engineering, it is my great pleasure to introduce myself. I guess most of you were or are enrolled in our BSc program and know me from the first-year course Introduction Mechanical Engineering and Truss Structures. For a long time I have been teaching this course and I really love the style of interaction in teaching you make possible. Here I try to combine different styles of teaching using slides, live demo’s for example with the pallet jack, lawn blower or tensile testing equipment combined with theory worked out on the board. And it is simply a lot of fun. Both ways I hope. As a Dean I have to reduce several teaching activities, but not Introduction ME. For me this is the perfect way to get in touch with all students!

Quite some firework at the start of the academic year. During the opening, where ASML CEO Peter Wennink gave a lecture, it became clear how much growth of our university is asked for by the companies in the Brainport area. Some companies plan to double or quadruple in the next seven to ten years. Close to 80% of all employees in those companies are trained in Brabant and Brainport is asking the University to scale and grow as well. Our Executive Board is working on a strategy to enable such a growth while not sacrificing excellence in research and education.

The Department of Mechanical Engineering is in great shape. Our researchers are international well known and we have strong educational programs in the BSc and MSc. Historically we have strong ties with the industry and we are exploring options to hire hybrid teachers as one of the options to enable growth, in particular for our MSc programs. We are at the crossroad coming out of a period of isolation and online teaching due to COVID into an exciting path of growth, interaction and many on-campus activities. Social safety and providing a diverse and inverse working environment clearly must be safeguarded for every student and employee of our department during the journey.

As a teacher and researcher I have always embraced an open-door mentality and as a Dean I plan to continue this. So, if you have anything you would like to share, criticise, or have suggestions or even compliments, please do so and drop by!

Last year, I did my bachelor end project within the Power and Flow research group under the supervision of Nijso Beishuizen. The project was focused on creating a Python script that could locally and adaptively refine a mesh from the SU2 software the group uses for their Computational Fluid Dynamics analyses.

WRITTEN BY FEMKE VAN DEN ELZENSU2 is open-source software developed in 2013 to provide a free alternative for the existing, often expensive, CFD (Computational Fluid Dynamics) analysis tools. It is mainly based on C++ and has been extended over the years with Python codes. It is predominantly used for internal and external flows, heat transfer and combustion, and for instance, the air circulation around aeroplanes or liquid pipe flows. SU2 is a finite volume solver designed to perform Partial Differential Equation analyses and solve PDE-constrained optimization problems with CFD. However, it is extensible to treat arbitrary sets of governing equations such as potential flow, elasticity, electrodynamics, chemically-reacting flows, and many others.

aspect ratio and the face-orthogonality the optimal value would be 1. Because the mesh quality has a significant influence on the quality of the final results, each new mesh was analyzed on those three criteria.

To determine the most optimal refinement method, a simple mesh consisting out of 13 cells with all an optimal mesh quality was created, both for a square and a triangular mesh. In each

One of the required input files for the CFD simulations is a mesh file. Such a mesh is preferably uniform and structured, because structured meshes are often of high quality, leading to better convergence and lower errors. Often, meshes are unstructured because they are easier to create for complex geometries. The local cell size determines the discretization error, and in simulations, the choice of cell size is determined by a tradeoff between computational time and accuracy. Choosing a very small cell size will result in an accurate analysis, however, it will have a large computation time. Choosing a very large cell size leads to a mesh with fewer cells and a smaller computational time, however, it will have a greater error. A solution for this can be local mesh refinement. When applying local mesh refinement on a coarse mesh, only the cells that have the largest impact on the solution and/or lead to the largest reduction of the error, are refined. Thereby keeping the computation time low while increasing the accuracy of the analysis. This project focusses on creating an adaptive mesh refinement algorithm implemented in Python that will perform a local mesh refinement based on the solution data exported from SU2.

A mesh needs to be of sufficient quality for it to give accurate results. In the case of a 2D mesh, this quality can be analyzed using the aspect ratio, skewness and face orthogonality. The aspect ratio, is the ratio between the longest and shortest edge. If the difference in edge length becomes too large, the model will become less accurate and hence the edges must be as close to an equal length as possible. The skewness can be described as the difference between the actual angle and the most optimal angle. For a triangle this would be 60 degrees and for a square this would be 90 degrees. For a cell, the least optimal skewness will be taken as the skewness of that particular cell. Next to this, the face orthogonality is determined. Now, the angle offset between the perpendicular vector to the edge, the blue vector, and the vector form the center of the cell to the middle of the edge, the red vector, is determined. A remark has to be made here. For the skewness, the optimal ratio would be 0 and for the

small mesh, the middle cell was refined according to one of the previously determined methods. There was one problem to deal with. The SU2 software cannot handle hanging nodes. Hanging nodes are points on an edge of a cell that are not the corner points of that cell. Hence, some of the neighboring cells of this middle cell had to be refined as well. From the mesh quality analysis it became clear that option c for the triangular and option b for the square mesh would be the most optimal. These results were verified using a second mesh with non-optimal cells dimensions.

Based upon the results of the two separated meshes, the final refinement algorithm was made. It is divided into six steps through which I am going to guide you. As a first step, the cell that has to be refined needs to be determined, in this example the three pink cells. Then the algorithm will start by refining the quadrangular cell with the refinement method previously determined. Then the neighbouring cells of the triangular cells will be determined. If a particular cell is neighbour to two pink cells, the cell will be added to the list of to be refined cells. This is done to prevent any error for when later removing the hanging nodes. If such a cell exists in the mesh, the algorithm will start again at step 2 until there is no overlap in neighbouring cells anymore. Then the algorithm will move on to step 5 where it will refine the pink cell. And then finally the hanging nodes will be removed accordingly.

This whole algorithm has been converted into code and to make it as user friendly as possible, an user interface has been made.

To show and validate the working of the code, a demonstration will be done on a Tesla valve flow simulation. A Tesla valve, or valvular conduit, is an invention created by Nikola Tesla in 1920. It is essentially a tube that is designed in such a way that the flow in one direction experiences significantly less resistance than flow in the opposite direction. This is due to the implemented loops.

For the analysis, only a single segment of the Tesla valve was simulated. The mesh was created with 5 different grid sizes, varying from 12121 cells up to 99572 cells. Next to that, two locally refined meshes were made using the algorithm. These results were analyzed. No clear conclusions could be drawn from it. This could be the result of various different factors such as the mesh quality, the location of the measurement, or the refinement criteria. Because of the time limitations of the project, no solution could be found in time.

However, to still show the working of the algorithm, a close up was taken. There could be seen that the algorithm indeed does refine the cells it was assigned to refine. Thereby validating the working of the code.

WRITTEN BY BEN GORTEMAKER

WRITTEN BY BEN GORTEMAKER

We as an Association own many things, some of them quite new and shiny, and a lot of them have a lot of history. For those who don’t already know this rich history, we will tell you a bit more about it. But most importantly, in this column we will answer the question of what the eigenfrequency is of these wonderful objects.

In this edition of the openME we will take a look at three of our most priced possessions from small to large. Starting with the lounge table in the center of the lounge chairs and couch. This table has been given to us by the forty-fourth Board of W.S.V. Simon Stevin. Making it more than twenty-two years old, which is older than many of the current editors.

To measure the eigenfrequency of the lounge table we will excite with varying frequencies and look at which frequency the response is the highest. The excitation will be done in two directions transverse and longitudinal directions as can be seen in the figure bellow. We will ignore the other directions as those are too rigid to measure with our current’s methods. On top of that we will take a look at the different locations and compare if there is a difference in which location you excite the lounge table at. The results from this experiment are as following:

WRITTEN BY BEN GORTEMAKER

WRITTEN BY BEN GORTEMAKER

In this day and age, every engineer has a powerful computer in hand reach at all times. If it isn’t your TI84, laptop, Casio, or another cheap knock-off calculator, you likely still have your phone in your pocket to do some quick calculations. The luxury of having extremely fast, portable, and cheap calculators in your pocket is a luxury that has only existed in the past 50 years. What did engineers use back in the day, where there were no electric calculators to do their computations. Did engineers carry an abacus around all the time? Or have an expensive mechanical calculator? Or did they do everything in their head? You likely have never heard about it, but the calculator of an engineer back then was a slide ruler.

With its oddly shaped scale and moving parts a slide ruler is no good for measuring things like a normal ruler, luckily it is not designed to measure things, but then the question still stands: how can a slide ruler be used as a calculator? If you have paid attention to your calculus course you might remember how logarithms, and their special properties work. Logarithms have the unique property that if you sum two logarithms it is equivalent to multiplying the terms inside together and subtracting two logarithms is equivalent to division. Now back to the slide ruler, if you look a bit closer you might notice the fact that the scale is logarithmic, which as we now know can be used to exploit the additive property of logarithms to perform multiplications.

Now we know the basic functionality we can use it to do some multiplication and divisions. The first step is to put the 1 that is on the sliding part, also called the slider, on the number you want to multiply. Then go over to the number on the slider you want to multiply the first number by and read the value on the ruler and then you

have done your multiplication. To do division you do the above in reverse, you start by placing the number on the slider you want to divide by on the number you want to divide and then read of the value that is at 1.

Not only can the slide ruler be used for multiplication and division but also for computing ratios, squares, cubes, roots, trigonometry, powers and many other functions, really the only thing the slide ruler is not good for is addition and subtraction. This makes the slide ruler a very versatile and useful mathematical tool (at least in the time before electronic calculators), truly the only limitation was the size of your ruler and how accurate and sharp your eyesight was. Even though the slide ruler sounds like an ancient and low-tech tool it was actually the tool that was used by the NASA engineers for the Apollo missions, and even the astronauts on the moon landing had slide rulers with them. Making the slide ruler one of the most important mathematical tools in our history.

The origin of the slide ruler starts with the “Gunter’s Line” which was a single logarithmic scale that could be used to do multiplication. The “Gunter’s Line” was created around 1620 by the English theologian, mathematician, and professor of astronomy Edmund Gunter and within a couple of years the Englishman William Oughtred improved on his design by having the two logarithmic scales you could slide beside each other making it the first thing that could be recognized as the slide ruler we know today.

After its conception in the 17th century, many other variations were made for specific applications, but the technology did not spread very far from the borders of England. In 1859 the French artillery lieutenant Amédée Mannheim improved the slide ruler making it easier to use and more accurate. After that, the slide ruler really gained popularity at the end

of the 19th century when the engineering profession became more and more relevant. And this popularity stayed, up until the 1970s when pocketable electronic calculators started becoming commonplace the slide ruler was the tool of an engineer.

In conclusion, if you ever find yourself in a situation where you have to do some calculations and the only thing you have nearby is a slide ruler you now know what to do. Or if you are in the attic rummaging through your grandparents’ stuff you might understand how one of those weird old things actually works. Or if you ever find yourself on an exam and the battery of your calculator runs out you can use a slide ruler as a backup or you just use it to confuse your fellow students and teachers.

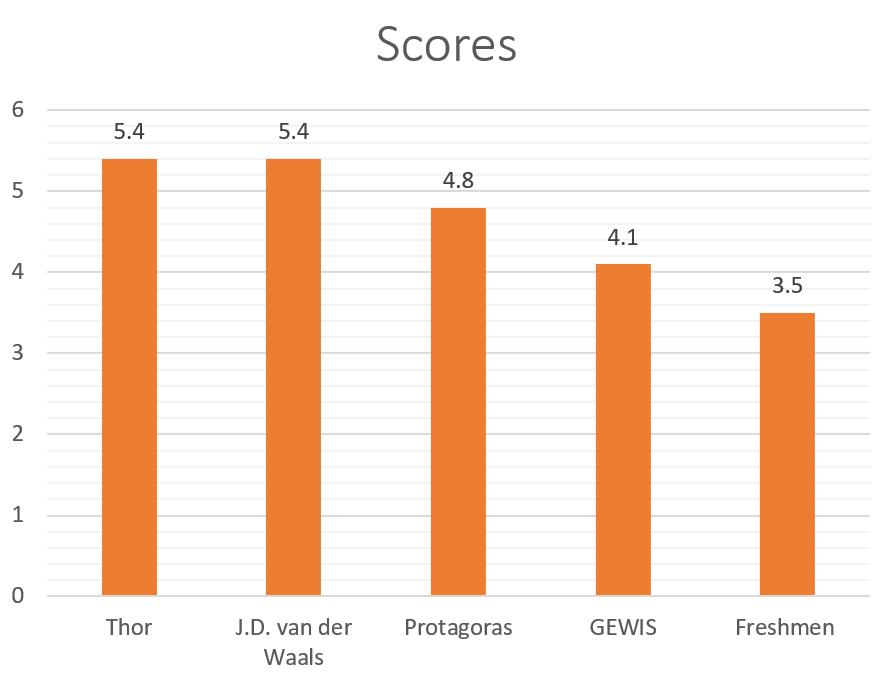

A week full of partying, exploring and meeting new friends. That was the introduction week of 2022. Some of you call this week “fantastic”, others call it “the time of their lives”. But only one word can truly encapsulate this amazing week. This word is of course “ImMEnse” , the motto of the IntroCie 2022, the committee which organized this year’s Introduction week. For them, the introduction week was not only partying, but also a lot of organizing and hard work. Behind every intro activity, there were months of preparations. In this article, we will take you behind the scenes of every day of the Introduction week.

The day started at 7:30 in the morning. We all gathered in De Weeghconst, and we were very excited for the Introduction week. We went through the schedule quickly, while eating our delicious breakfasts and then it was time for the preparations. The introduction week had begun.

IntroCie was responsible for giving the kiddo’s a good first impression of Mechanical Engineering and Simon Stevin. We started with gathering and registering the kiddos and introparents in Atlas. Here, the introweek started with a presentation from the faculty and from Simon Stevin. After we all sang ‘Het Simonlied’ together, the kiddos were divided into groups and were handed over to their responsible introparents. We made sure that every kiddo received some gadgets and an intro shirt.

Of course, the engineering skills of the kiddos had to be put to the test before they could become a true freshman. So, it was time for the business case. Employees from Sioux came to give the intro-kiddos an awesome presentation, followed by a challenge to build a ballista from scraps. It was great to see the motivation and ingenuity of some groups. Although other groups were definitely better at decorating the ballista...

Afterwards, it was time for dinner and the day ended with an amazing party. All in all, a great start of the Introduction week!

Tuesday

Now, during the academic year, a normal Tuesday (probably) doesn’t consist of waking up hungover, pursued by happily throwing a bucket of water over your intro parents, taking a thrilling ride on the lustrumstunt and finishing the day with a barbecue and an epic party. This glorious sequence of events is commonplace during the introduction week. All these events were organized by our IntroCie. This meant we had a lot of work to do in terms of preparation and execution to realize this day.

The day started off with a university tour in combination with the testing of the ballista’s. Our committee had spent a good amount of time building a ballista testing construction. We designed a not previously used construction using a toilet flushing mechanism. Intro parents were forced to sit within the construction with a water filled bucket with a flushing mechanism right above their heads. When their introkiddos accurately shot at the target, the flushing mechanism was automatically activated and the parents would receive a lovely morning shower.

While some committee members were present during the ballista testing, others were already setting up the so called ‘green strip market’. To represent Simon Stevin, we had made a small chilling lounge decorated with a land yacht, sand and a swimming pool. As a bonus, we used the lustrumstunt as an interactive activity. During the market there was a short period of time for the IntroCie to take a break and eat lunch. We immediately had to go back to work however, as 500kg of loose sand had to be moved afterwards. A reasonable job, if you are aiming for a tremendous amount of back pain.

Giving up was not an option though. We still had to set up a barbecue and an entire party with performances of DJDuckers and the world famous band: MAVO. This took a lot of work and we are incredibly thankful to the volunteers who helped us this day. After the barbeque was cleared away and the party was in full swing, IntroCie got to enjoy this awesome party and we got to look back on a successful day of hard work.

After two days of hard work, IntroCie got to relax a bit on Wednesday. The day started at 10:00 with a nice breakfast after which we started cleaning up the left-over stuff from yesterday.

In the afternoon, IntroCie disassembled the ballista’s and the testing construction. This is one of the moments where we would all shared a blissful feeling of accomplishment. We knew that we had done a good job the last two days and disassembling the construction marked the end of a big part of our project. No better way to end this day then with a good party together.

For a lot of people the Thursday was the most eventful day (or, rather, night) of the Introduction week. This is, of course, due to it being the famous doorhaaldonderdag, where everyone tries to make it through the night without sleeping.

Our day started with helping E.W.D. Hephaestus arrange the ‘hangover breakfast’. Bacon, eggs and a nice glass of orange juice at 10 o’ clock meant people had time to take a nice breather from the partying the day before and get some energy for the long night ahead of them. During the breakfast, a large belly sliding course was created with the help of a winch and copious amounts of liquid soap.

After everyone had eaten, it was time for the main event of that morning: putting Mart (chairman of the 65th boar d) in a pillory and throwing a ridiculous amount of eggs at him. This tradition was of course kept hidden from the first-years until it was time to do it. Afterwards the committee did help clean up the Flux-field somewhat so that other people could set up their workshops.

In the afternoon all the kiddos could do workshops of their choosing, and after helping clean up the BBQs, the IntroCie enjoyed some nice naps and Disney films in De Weeghconst, until it was time for Eindhoven by Night, the bar crawl the Central Introduction Committee put out. This marked the true start of doorhaaldonderdag. Not everyone remembers the entire evening, and not everyone managed to complete it, but there was no one who didn’t have a good time that night.

Friday, the very last day of the intro. The day started early for some of us (well, the previous day had not ended yet due to doorhaaldonderdag). Around 09:00 we helped MAVO move their instruments to the main stage. After some hard work, it was time to chill. We once again gathered in De Weeghconst, which had become our second home by now. Some introkiddo’s and parents joined us. Now it was time for “entertainment De Weeghconst!” We had karaoke, watched movies and did both at once.

After catching up on some sleep and a delicious breakfast, it was time for the very last party of the week: All TU/ egether. The highlight was, of course, MAVO. Jens came up with a genius idea. The guitarists name, Van der Vleuten, sounds a lot like Van der Feuten. So, we all wrote a letter on our stomach and back and while they were performing, we all lifted our shirts to spell out Van der Feuten.

After the party, it was time to face the harsh truth, the Introduction week was over. We laughed together, cried together, were mad together and had fun together. All in all, an amazing week which we are very proud of. We hope that all introkiddo’s and parents had as much fun as we did and we are already looking forward to next year, when there is a new committee ready to take over.

WRITTEN BY RYAN LEAL

WRITTEN BY RYAN LEAL

One of TU/e’s interesting student teams is Team Polar. It was originally an Honours Academy team with six people in its first year. Over the timespan of three years, the team has grown to 28 people and is open to everyone that is willing and enthusiastic. They are a completely part-time student team, where it is expected to take ten to fifteen hours per week.

Team Polar’s mission started with Wilco van Rooijen, a Dutch mountain climber who has climbed the tallest mountains on every continent. He even climbed K2 without oxygen and almost died on that mountain, losing many of his toes. He came to our university with a small toy car with a solar panel and he said, “I want that, but in Antarctica.” And with that, the goal was to create an autonomous rover for researchers to collect data in Antarctica.

The research done right now in Antarctica is powered by kerosene-filled trucks. Each Artic fuel truck carries 7,918 gallons of fuel, and typically it is in these vehicles that expeditions for research take place. Fuel also powers the labs where all research collected on these expeditions are sent. A whole research facility may get shipments totalling to over 500,000 gallons of fuel during a threemonth warm period in Antarctica. In the remaining nine months, when traveling is too difficult, those gallons will have to be rationed for survival.

This calls for sustainability: the first pillar in Team Polar’s mission. Sustainable energy is energy that meets the needs of the present without compromising the needs of future generations. At Team Polar, they envision a research vehicle free of the limitations of humans, which with human-present vehicles requires extra need of environmental control systems, and storage of human commodities like food, beverages, and sleeping arrangements. Creating a sustainable vehicle can help reduce the amount of fuel used on these expeditions, and even make the range for research expeditions — in practice — infinite. Additionally, using sustainable resources that do not emit CO 2 emissions will reduce harm to not affect the environment with which they are studying. The way they approach this pillar is by considering solar-powered battery cells.

The second pillar to Team Polar’s mission is autonomy Driving in Antarctica is quite dangerous, as it cannot be easily known whether the ground you are driving along

is stable. There can be layers of fresh snow that appear normal but beneath could lie deep cracks in the ice called crevasses. These can be especially unlucky, as getting a wheel stuck in a few meters deep crevasse can put a halt for some time on research collection. In even worse cases, these crevasses can be hundreds of meters deep, resulting in a loss of the whole vehicle and fatality of any researchers inside. Therefore, Team Polar’s rover is designed to detect these crevasses using GPR (Ground Penetrating Radar). These sensors can look into the ground and detect the previously mentioned small crevasses, and these sensors along with training a neural network on some already obtained crevasse data, can help the rover to redirect course under suspicion of possible danger.

The third and last pillar is affordability. In undertaking engineering, there are always designs that will be the most efficient, but presumably be the most expensive as well. For example, NASA uses gallium arsenate solar cells, as they are the most efficient today. However, if they were used in Team Polar’s rover these cells would account for 95 percent of its cost because it is so expensive. To tackle this, Team Polar is designing within the bounds of cost constraints; looking at the numbers so that it can be made as efficient as possible while also being generally affordable to manufacture and use.

One current challenge they have is maximizing the efficiency of their batteries. Batteries suffer under lower temperatures because there is a reduced capacity from lower kinetics and in the battery’s chemical reaction and increased internal resistance from the battery. Around sub -20 degrees Celsius, lithium-ion batteries cannot be reliably used anymore.

To combat this, a heating system for these batteries are explored, or the use of other energy storage system alternatives all together. Examples of these are special types of batteries with a solid-state and liquified gasstate electrolyte that preserve reaction kinetics better at these lower operating temperatures. However, presently they are very expensive and not very commercialized. The Team Polar rover now uses lithium-ion phosphate for the battery.

Team Polar has finished their first prototype’s complete exterior design and showcased it during the Dutch Design Week at the TU/e. They are almost complete in its interior and technical parts as well, planning to finish it in mid-November. By the end of November, they desire to perform initial tests on their rover so that in January of 2023 it can be taken to Norway for further testing.

Laurenz Edelmann is an Applied Physics Master’s student in his third year. In his first year of his Master, he joined Team Polar through the Honors Academy. He has been there since the beginning. He is currently the manager of Team Polar.

The MATLAB genius, the planner and the silent one, we all know them: a DBL group consists of different people with a lot of different personalities. These seven types of DBL people will be very recognizable for you as a Mechanical Engineer!

After the introduction round in the very first meeting of every DBL, you and your new teammates start discussing what the actual assignment for the DBL is. Most of the times, everyone is a bit confused: although it seems that a lot needs to happen during this DBL, you have no idea where to start and what the new SSAs need to be. Luckily, the RPC list and the planning are always a sure thing in these uncertain times. The small tasklover immediately jumps up when the SSA division takes place: this is his time to shine.

For loops, if statements and creating plots of everything, nothing and everything in between: the MATLAB genius will make it work. A DBL without a MATLAB genius is as biking with a flat tire: it makes life harder. What you would write in ten lines of code, this genius puts in one line. With a few clicks and changes, he easily improves the mistakes that were made by other team members as well. To every MATLAB genius out there, what would we be without you?

‘Actions speak louder than words’ and ‘quality over quantity’ are the mottos of the silent in the DBL group. He maybe does not say as much as the other team members during the meeting, but when he does,

it is always well thought through. Not only his quality comments contribute, his SSAs are of great importance as well. When the silent starts to feel comfortable in the group, he lives up and starts to speak words as well: with a lot of enthusiasm he tells about his own work and asks questions to others about theirs. It is at that moment that everyone starts to see it: this is a great team member.

‘Why do they schedule a meeting on Friday morning?’ is a question the partyanimal asks himself every Friday morning. After having a great evening in the Peppers, which was so fun that – of course – a nice afterparty had to be visited as well, the hangover is real at 08:45 in the morning. Although the partyanimal feels a little like he can start to puke anytime soon, he gets himself together and goes to the meeting. Comforting himself with the thought:’ I have done this before, I can do it again’, he drags himself through the meeting.

The project information document is the favorite file of the planner in the group. At the start of the project he has already marked every important deadline and put them in his agenda. Handing in a deadline too late? That an absolute no go. Completely trusted by the group on what the requirements of the assignment are and whether these are reached with the progress made: the planner makes sure everything is handed in on time.

For some, words speak louder than actions. During the meeting, the sneaky is making more comments than anyone else –quantity over quality. But as much comments as he makes during the meeting, so little work puts he into his SSA. For some reason, the sneaky exactly knows the bare minimum he needs to do in order to pass the course, often even with a good grade. We have to give it to him: it is an art.

A lot of different solutions were thought of during the project and a lot of steps were taken. Luckily, the final report writer exactly knows how to summarize everything together. From re-writing pieces of other team members to checking spelling and grammar: the final report writer makes sure that the final report meets all requirements and that the important messages are conveyed.

A DBL group is special. It is beautiful to see that a set of people with so many different characteristics can still form one group. Which DBL team member are you?

Sometimes, it can be quite hard to come up with original feedback. Can you get a bingo in your next DBL?

1. You were a bit silent this meeting, but you were minute taker, so that is understandable.

2. The board looks nice.

3. You had good input during the meeting.

4. You asked critical questions during the meeting.

5. Reread your SSA one time before you hand it in.

6. Your SSA was of good quality.

7. As a chair you can conclude things a bit sooner.

8. You were a bit silent this meeting.

9. You were minute taker, but you still had good input.

10. As a chair try to facilitate the meeting more.

11. You were very active during this meeting.

12. You could be more active during the meeting.

13. Do not be afraid to pick the more challenging SSAs.

14. Good that you ask for clarification when you do not understand something.

15. You are well prepared with your notes.

16. You are also active outside of the meeting.

17. Nice that you implement the feedback that was given to you.

18. It was nice to work together with you on the SSA.

19. Your SSA was a bit short.

20. Try to be on time next meeting.

21. Prepare questions and write them down in advance so that you can ask them during the meeting.

22. Nice agenda.

23. Your SSA had a nice structure.

24. Good presentation.

WRITTEN BY FABIAN BOOTS

WRITTEN BY FABIAN BOOTS

“Records are meant to be broken” is a saying everyone is probably familiar with. On the 8th of October, a 26-year-old record was broken. In 1996, Chris Boardman cycled 56.375 km in 1 hour. Filippo Ganna beat him by adding 417 meters to the record, accumulating 56.792 km. These 417 meters might not sound spectacular at all. However, the initial record was set using a time trial position which was banned straight after. Ganna has now beaten it using the latest technologies and aerodynamic advances, which is where it becomes interesting for us as Mechanical Engineers!

Normal road bikes have decreased a lot in weight. As the courses are much less predictable, accelerations are very frequent and elevation plays a big role, weight becomes very important. The lightest bikes that can be created, weigh just over 4 kilograms. In a world where every gram matters this makes an insane difference! However, the UCI (Union Cycliste Internationale) has instated a minimum weight requirement of 6.8 kilograms, as otherwise, the weight of bikes would become too light, compromising safety. In climbing races, the road to success is the wattage per kilogram which a rider can put out over several hours. Dragging an extra useless 2.2 kg of weight over many cols in the Alps or Pyrenees results in a much higher kilo joule expenditure, creating more fatigue in the later moments of day races and stages of stage races. This difference would neutralize any climber on the tour!

For time trial bikes, however, weight is not as relevant. In the hour record of Filippo Ganna, weight is almost negligible as both bikes have been designed for pure speed on a flat area. That makes stiffness much more important because all the energy which is put into the pedals needs to be converted to forward motion. In 1996, the bike was already made from carbon, which made it a very futuristic-looking bike. The standard frame material of superbikes used in that time of the Tour de France consisted of titanium, steel and aluminium. Next to that, the bikes were made from hollow tubes welded at the corners. Carbon, however, opens a whole new range of shapes and techniques. This allowed frames to be engineered which provide much more stiffness, especially in a lateral direction. It is not only important when accelerating, but also when holding speed. Which in turn is critical in the hour record! 26 years later carbon has become the standard and almost the only option used in superbikes.

The new Pinarello Bolide F HR 3D is pioneered using a new technique which does not use carbon, but scalmalloy. A material which is made from scandium, aluminium and magnesium. It originates from the aerospace industry and is specifically designed for 3D printing. With 3D printing, even more, specific shapes can be created. It can also be used to reinforce critical points to make the structures even stiffer. Lastly, it can keep the material usage to a minimum, to decrease the weight as much as possible.

Even though climbing on a bike is a lot of fun and can get you to the most amazing and beautiful places, some riders think riding criteriums is even better. A criterium, or crit, is a bike race consisting of several laps around a closed circuit. Riding these short and hard courses with anywhere around 50 people, with speeds in the range of 45 km/h, creates an insane amount of adrenaline. In these races, aerodynamics is key, just as with the hour record.

Both bikes have been engineered with one purpose in mind, which is to go as fast as possible for as many laps through the velodrome. Next to that, they have been tailor-made for the person riding the bike. The shape used in 1996 is probably more aerodynamic than the one used in 2022. However according to the UCI a bike nowadays needs a bottom tube. Therefore, Pinarello has created a bike which allows Ganna and the bike to have an as small as possible frontal area and CdA (coefficient of aerodynamic drag), mainly by placing the rider in the most optimal position. This means that the hands are placed close together in front of the face, where the head is in line with the back and the shoulders are shrugged in.

The cyclist on a bike can contribute as much as 80 percent to the aerodynamic drag. This aerodynamic drag is in turn around 90 percent of the overall drag, which makes it the most important factor to influence. To decrease the drag as much as possible, the illegal superman position was created. This decreases aerodynamic drag drastically in comparison to the current legal aero position utilized by Ganna, called the praying mantis position. To overcome this difference, an insanely talented cyclist is required and apparently 26 years of technological developments.

When looking at the CdA once again, the rider is most important. Tests have shown that skin is slow and fabric can be made which is much more aerodynamic. When comparing both attempts, it is clear that Ganna is wearing more fabric than Chris Boardman. Specifically on the arms and legs, which in turn are critical areas. Firstly, the arms and hands are the first parts that touch the air. Next to that, the legs are continuously spinning at high speeds creating much more turbulence compared to the upper body. Lastly, the teardrop shape is the most aerodynamic. The arms and legs, however, resemble a cylindrical shape, which has extensively been proven to be ineffective.

To compensate for the ineffective arms and legs, fabrics are made which keep the air attached to parts where it needs to be attached, and also the opposite if required. On the arms, shoulders and legs rougher fabrics are typically better than smooth fabrics. It follows the same logic as the texture on golf balls. The structure of the fabric adds turbulence to the surface airflow, which is called ‘boundary layer turbulation’. For an athlete to be fast in cross-winds and benefit from a good sailing effect, what they are wearing needs to have a turbulent boundary layer.

When talking about aerodynamics, one of the final areas which cannot be ignored is the wheels. Just like the legs these are spinning at high speeds and creating turbulence. To decrease this as much as possible, disc wheels are used. Spokes in a wheel once again create a big amount of turbulence. Next to that, if air flows over the middle of the wheel, the rim disturbs the airflow after which it unifies again to hit the front fork and then gets disturbed again by the second part of the wheel. If a disc wheel is utilized, it can flow over the surface and will not be disturbed as much. This decreases the CdA value. There are also disadvantages to discuss. They impede steering capability on open roads, thus it is not recommended to utilize two disc wheels anywhere with crosswinds. However, on a velodrome where the hour record is being held, there are no relevant cross winds, so disc wheels are the best option.

Thus far we have concluded that bikes have been made stiffer, more aerodynamic and lighter. The final part to address is the remainder of the resistance, which stems from rolling resistance and drive train resistance. Tyres of course create most of the rolling resistance. For the tyres, the choice was made to go for the Continental Grand Prix 5000 TT TdF. They are 17 seconds faster over 40 kilometres than the already very good tires the Continental Grand Prix 5000 S TR, due to being 35 grams lighter and having more optimal thread thickness. It is hard to compare these to normal tires, but they generate approximately 7.6 watts of resistance, which is nothing in comparison to already very fast normal race tires.

Finally, for the drive train, the choice was made to go for the most aerodynamic and low-friction options possible. On the front, it had a 64-tooth chainring from Wattshop, which was paired with a 14-tooth in the back. They were connected by an Izui KAI chain. This setup is once again specifically tailored to Ganna. As a finishing touch, to decrease the friction even more, a special low-friction coating from the British company Muc-Off was applied.

Another area also influencing the CdA are the helmets utilized. Both Boardman and Ganna have helmets shaped to guide the air from head to back. By keeping the gap between the back and helmet as small as possible the least amount of disturbance is created on the top, which decreases drag. In both cases, this has already been done very effectively, which can be seen in the pictures.

All in all, it can be concluded that the best technology has been used to improve the record. It can be assumed that the weight does not matter between both attempts. Next to that Boardman had a more aerodynamic position and Ganna had the better technology. Given these points, the conclusion might actually be that technology and aerodynamics did not make the difference, but talent of Ganna did. Many people have tried before with all the new technologies and only Ganna succeeded!

WRITTEN BY BEN GORTEMAKER

WRITTEN BY BEN GORTEMAKER

We as an Association own many things, some of them quite new and shiny, and a lot of them have a lot of history. For those who don’t already know this rich, history we will tell you a bit more about it. But most importantly, in this column we will answer the question of what the eigenfrequency is of these wonderful objects.

The next object we will take a look at is Den Dis. Den Dis is one of the oldest objects in De Weeghconst, as it has been given as a gift by the fortieth Board when De Weeghconst first opened in 1997. Den Dis has been there from the beginning of the Thursday drinks and still to this day accompanies us during the Thursday drinks.

1 24 3

The eigenfrequency will be measured in a similar fashion as the Lounge Table. Exciting it with varying frequencies and in the longitudinal and transverse directions. And of course we will also take a look at if the location of the excitation has an influence on the measured eigenfrequency.

The results from this experiment are as following:

With its wingspan of 88.4 meters, a length of 84 meters and a production cost of around 3 billion dollars, the Antonov 225 ‘Mriya’ is (or was sadly) the largest operating airplane in the world. The Mriya, which means ‘dream’ in Ukrainian, was designed by the Ukrainian Antonov Design Bureau in the 80s as a military plane with the purpose of transporting the Soviet version of the Space Shuttle for the USSR.

This gigantic plane is powered by six large turbofan engines, each with the capacity to produce almost 230 kilonewtons of thrust. To keep all these engines running, 342,000 liters of fuel can be carried along a flight. All of this fuel is distributed evenly across both wings (to keep the center of gravity around the same spot). Moreover, the An-225 has a special landing gear system to carry the 285,000 kilogram weight of the plane. It consists of 32 wheels, of which 4 are in the nose gear (located in front) and the other 28 are aligned in pairs of two, left and right of the fuselage.

Let’s start with a basic lesson on how airplanes are able to fly. The simple answer: due to a pressure difference between the lower and upper part of an airplane’s wing. Because of this, an orthogonal force is created with respect to the fluid’s (which is the air) motion. This force is referred to as the lift force. In the second year of our bachelor, during the course ‘Heat and Flow ’, this concept is explained by means of Bernoulli’s principle

WRITTEN BY DANIËL KLEINJANThanks to the rounded top of an airplane’s wing, air needs to travel a greater distance compared to the air beneath the wing. This results in the speed on top of the wing being higher than beneath. As can be seen in Bernoulli’s principle, when the speed increases, the pressure must drop since energy is conserved at all times. Under the wing, the exact opposite happens: the speed is slower and thus the pressure increases. Due to this pressure difference, the airplane is pushed up.

In order for this to work, the speed of the air to flow around the wings is required to be high enough to generate enough lift force. For the An-225, six turbo fan engines are used. Additionally, this plane needs at least 3,000 meters of runway to be able to reach the required speed for a successful take off.

During the time of the cold war between the USA and the USSR, both space programs were in a fierce competition. When the USA started operating with their space shuttles, the USSR developed the Buran (the Soviet version of the Space Shuttle).

The goal of both spacecraft was transportation of payloads to space at a lower cost since a Space Shuttle has the ability to go to space as well as return to earth and land like a regular aircraft.

At the time, the USA was using the Boeing 747 to transport their own space shuttles, thus the USSR also needed a plane to perform the same tasks with their Buran. Therefore, the ministry of Aviation of the USSR asked the Antonov Bureau to design an aircraft that would be capable to transport such cargo. Throughout this period, the Antonov Bureau was working on the design of the An-124, a plane that had the goal of transporting cargo. Initially, the design team thought the An-124 could be a potential candidate to fulfil the type of missions for the Buran program. However, when the engineers from the Buran Space Program concluded that the Buran would be much heavier than originally planned, it was decided that the An-124 was not suitable anymore.

Later in 1983, a proposal from the Antonov Bureau was drafted to use some of the elements of the An-124 to create a larger plane, that did have the capabilities that were requested by the Buran Space Program. Some of these changes were structural changes to increase the strength of the plane. Furthermore, the width of the wing was increased to be able to fit an extra turbofan engine on each side. In addition, the tail was changed. This was done due to the fact that when a Buran would be transported, its engines would be in the direction of the vertical stabilizer, according to the design of the An-124. Consequently, the tail was changed into a twin tail, consisting of two vertical stabilizers on both ends and horizontal stabilizers in the middle. After three and a half years, the development was finished and on November 30 1988, the plane rolled out of the hangar in Kiev. After ground tests, the plane took off and flew for the first time on December 20, 1988. Its first mission was on May 3 1989, when the Mriya carried the Buran for testing.

In the course of the next years, the An-225 fulfilled its purposes and was used for commercial flights to transport other cargo. However, after spending no more than 671 hours in the air, the An-225 was (temporarily) placed in storage, not long after the collapse of the Soviet Union and the discontinuation of the Buran Space Program. During this time, the real profitability of the plane was doubted and therefore the plane was stored.

Then, a couple of years later and after restoration work, a new task was found for the plane, namely commercial cargo transport. In May 2001, the ‘second’ official take off took place. The plane was used to transport the largest single cargo in aviation history, according to the Guinness Book of Records. It even flew to Eindhoven in 2005 and 2008, with many people watching this giant land on our air basis.

Sadly, during the war in Ukraine, Antonov’s largest airplane was destroyed in a Russian attack on the Antonov Airport, near the Ukrainian Capital, Kiev. People went to the site to see the destroyed airplane filled with bullet holes and surrounded by destroyed tanks. The entire front section of the fuselage (including the cockpit) was destroyed, as well as parts of the right wing. The last commercial mission of the An-225 was in February 2022 with the objective to collect around 90 tons of COVID-19 tests and fly them from China to Denmark. Its final flight was back to Antonov Airport, where it was scheduled for maintenance. When the threat of the Russian invasion began to rise, the An-225 was prepared to depart from Ukraine, on advice of NATO. Unfortunately, on the day the plane was supposed to evacuate, the Russian invasion was launched with the Antonov Airport as one of its targets, which lead to the destruction of the plane. The rumor goes that Antonov Airlines, who were operating the An-225, were already aware of the danger but took steps to evacuate the plane too late.

Now the largest commercial airplane in the world has been destroyed, the question about whether the original plane is intact enough to be revised arises. Based on video research, the plane looks to be in too bad shape to be revised. However, experts from the from Antonov have not yet investigated the plane, resulting in the official status to remain unknown. On May 20th, the Ukrainian president Zelensky announced the attention to build a new Mriya in honor of the pilots who have died in the war. Furthermore, manufacturer Antonov has started a fundraiser to acquire money to be able to manufacture a new plane. To sum up, we will need to wait and see whether the giant of the sky will ever return to its full glory.

Els de Vaan-Bruinsma receiving her Bachelor diploma at the TU/e

Women in engineering have come a long way from where they began, however it is still not as normal to be a woman studying mechanical engineering as it would to be a man. In the 1960s, the famous ‘draw a scientist’-research was done. 5000 grade school children were asked to draw a scientist and only 28 of those drew a woman, of which all the 28 were drawn by girls. Luckily times have changed and by a recent study in 2018 it showed that more than half of the girls drew female scientist when asked to draw a scientist. This study shows that woman are scaling up within the industry.

Years back, the first ever female to receive a bachelors diploma in Mechanical Engineering was Stanny Koopman, in the year 1921 at the TU Delft. It took a good 45 years for the first woman to receive her bachelor diploma at the TU/e, for a study she did from start to finish in Eindhoven. Her name was Els de Vaan-Bruinsma and she received on 18 may of 1966 her diploma in chemical engineering. She received her diploma twice, because the

first one only contained male pronouns. After an excuse letter by the university she did receive a correctly formulated diploma. She was not the first woman studying at the university, as Henny van der Leeden started electrical engineering in 1957. She was the daughter of physics professor, and later to become rector magnificus P. van der Leeden. On her first day, the rector magnificus spoke to her and her year: ‘Mejuffrouw en mijne

heren’, which is translated to ‘miss and gentlemen’. Her apperaence was quite special this day and she even got to shook queen Juliana’s hand. This day she was the example for the many women who followed after her studying at the TU/e. However, she did not finish her bachelor, as she started programming the PACE-computer (a big analog calculator) in 1960.

After the first woman had made their way into the male dominated world, the university itself started realizing that becoming more diverse was important. Plus, statistics showed that women who studied at the TU/e were performing better than male students at their study, as they had on average more credits each year. More than enough reasons for the TU/e to start actively recruiting new female students. The rates of women at the university were around 10-15% for quite some time, where some studies reflected more the gender distribution of society (like biomedical engineering and industrial engineering) and others not at all. Some nation wide campaigns were already running, but in the 1985 special information activities were organized for the first time. Those activities were a huge success, as more than 700 woman showed up. As a follow up to this, an exclusive pre-intro was organized for all new female students. They were able to get to know each other and to study. However, in September of 1987 the first criticisms arose about this, as the new women did not want such a special treatment. In the 1990s this emphasis stops and 1995 would be the last year that a special information event for women is organized.

Being female when studying mechanical engineering is still not normal and is only 10% of the people doing the study. That is why years back, woman found it important to stick together and get to know each other better. This is when the Woman Committee was set up at the study association Simon Stevin. They organize several activities throughout the year, with the first one always being a delicious lunch. The whole committee show off their baking skills and make homemade goodies for new female ME student who would likes to join. This year, a special speed date edition was planned, to get to know even more fellow students.

Some female ME students took it a step further than just doing a few activities a year together. They formed a sorority called Venilia which was founded on the 28th of February in 2018. They have four main goals, which are giving a place to females studying mechanical engineering and connecting everybody from all different ages. They make connections with other students within and outside Eindhoven, through integration drinks and they prepare themselves for the business life, that will be mostly male dominated. This is all done with a lot of fun and laughter, Venilia even has their own drink, which is homemade limoncello with a touch of vanilla. While there is a lot of opportunity for females studying engineering nowadays, there are always people trying to involve even more women in engineering in the future. Associations like woman in STEM and SWE (Society of Women Engineers) connect people on a more global scale. Some individuals, for example Debbie Sterling, try to make an impact themselves. Sterling found that most building or engineering children’s toys were targeted towards boys and she wanted to change that. So she designed a toy helping young girls improving their analytical skills, which was well received.

Women in (mechanical) engineering have come a long way since 1921. It has definitely not been easy for some, but they all made it easier for the women following them up and that is something to be grateful for. In the end, being the minority gives you quite some privileges that you can take advantage of. So hopefully the rise of woman in technology can continue and end up being a normality.

WRITTEN BY RUBEN BRAVO VELDHUIJZEN

WRITTEN BY RUBEN BRAVO VELDHUIJZEN

Since the mechanical engineering department moved buildings to Traverse last year, The workspace at the basement of Gemini also needed a new home. Undeniably reallocating all the before available facilities was not an easy feat. But the newly finished ProtoZone on the second floor in Traverse, and under supervision of Michiel van Gorp is ready to give everyone new opportunities.

During a welcoming guide around the space we spoke to Michiel van Gorp and his assistant Bert Friedl to hear what ProtoZone is all about and what their vision is for the future.

If you take a look at the ME major curriculum, Design and Challenge Based learning goals are at the forefront of each student’s academical progression. Van Gorp took on the assignment to rearrange the newly acquired workspace and bring in all the tools students would need throughout their studies. Unsurprisingly, as soon as you enter it is obvious that workbenches are protagonists. Sturdy tables arranged in files along the length of the room, waiting for the next group of students working on a new crane, pump or robot.

When we asked van Gorp how students should see ProtoZone, he points out the lack of chairs and emphasizes that a workspace is there to build stuff. Performing tests or doing computer work should be done at appropriate places elsewhere. Luckily right outside in the hallway an array of office tables are a great place to work on simulations or CAD design without compromising your laptop fans to the possible saw and metal dust.

Answering to our curiosity about the equipment that was moved or left behind, van Gorp told us that with every rearrangement some things are bound to be lost or repurposed. As such the 3D printers that originally had their place at Gemini in the measurement room Sel, were now part of ProtoZone. On the flip side some heavy equipment had to be sold, that was either not being used or very antiquated. Nonetheless ProtoZone has plenty of cool tools now always accessible at one place.

As mechanical engineers it is only natural to crave working on your own projects in your spare time. And it this mindset should be encouraged more often if you ask Michiel van Gorp. For this reason he decided that giving students the chance to ask for help and use tools from the workspace adds valuable experience to their development as an engineer. ‘What is the use of a new tool if you use it once and leave it sitting your

shiny toolbox’ he said, referring to all the knowledge students gather throughout their bachelor’s but seemingly leave unused as they move onto new challenges.

To grant the students interested in this kind of activities the options work at ProtoZone once in a while. Van Gorp has approached the Association to introduce a subscription portal to the simonstev.in web site where ME students can request joining one of the work evenings. Depending on how much demand there is and how much the academic schedule can allow these evening would be planned in some recurring fashion.

In the meantime while this is setup, emailing van Gorp is for questions and appointments is the way to go.

Now that ProtoZone has opened to its intended capacity, it will stay this way for the foreseeable future. But of course will it have to evolve according to the needs of the department and the future goals of growing the ME major. With expectations of growing the student count to around double the current throughput in upcoming years.

Exposing students to different manufacturing methods is an important part to stimulate their practical intuition. Although there are no plans on the table to expand the current facilities, it is always in the back of the mind of the department’s organization. On the one hand what will be the needs of DBL courses still in development but also what useful skills outside the academic scope can be taught to future students. Manufacturing machinery have seen leaps of modernization in the last decades and having a basic understanding of their functioning is undeniably worthwhile. So, although purchasing machines that are expensive and difficult to handle are not a current priority. It is certainly the department’s ambition to offer the most complete education to their students with innovative practices and a safe working environment in mind.

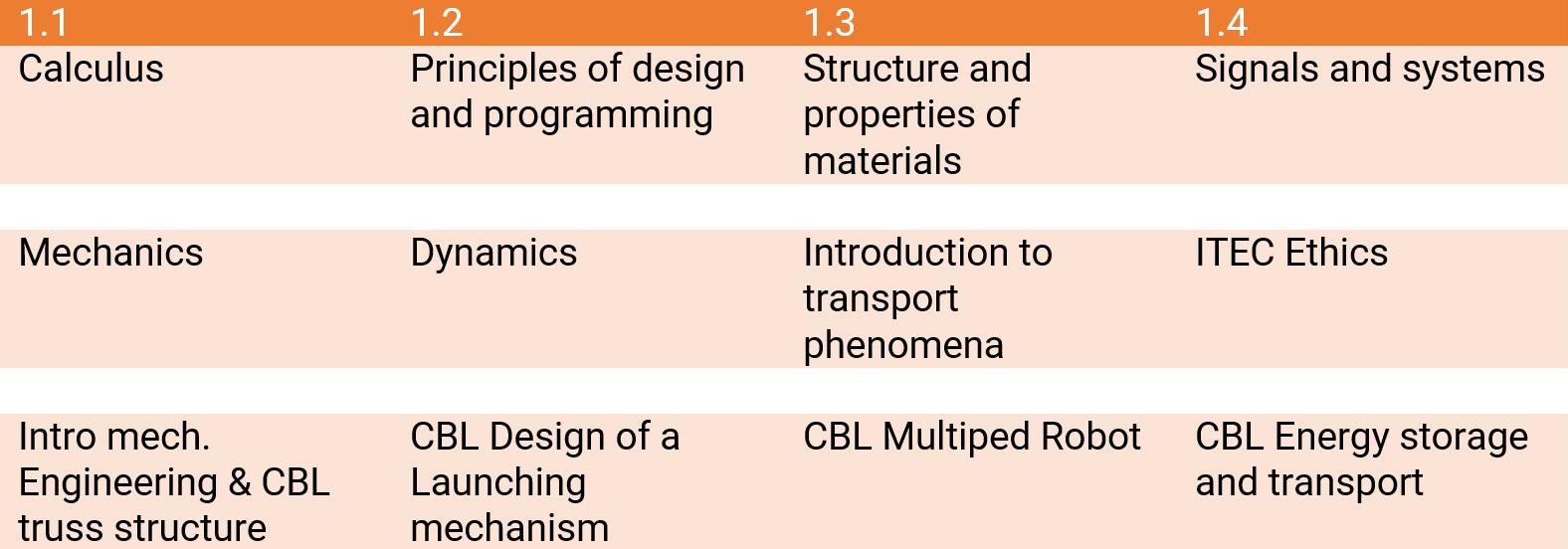

In the academic year 2022-2023, the Bachelor College 2.0 will start. This is a redesign of the current bachelor college in which some big changes are implemented. These changes mainly focus on the cancellation of the basic courses, which are the courses followed by all departments at the same time, as well as the introduction of challenge based learning courses. Next to this, the USE learning trajectories will be redeveloped and changed into two courses about the impact of technology, such as the ethical aspects.

* At this moment, October 2022, the new curriculum looks like this. However, some small changes can still be made over the years.

One of the big changes is the cancelation of the core courses. In the previous curriculum, the courses Calculus, Applied Natural Sciences, Data Analytics, USE Basic and Engineering design were taught. In the new curriculum only calculus stays. The other courses are implemented in different courses, only the information needed within a specific department is now implemented in the courses. For our curriculum this can be seen in the new courses named Principles of design and programming and Statistics & Probability. Next to this, the USE Basic course will be partly transformed into the ITEC Ethics course.

The cancelation of these core courses makes room for an extra major course in the first year. This means that Signals and systems is now placed in the fourth quartile of the first year while it used to be in the first quartile of the second year.