INTERVIEW SETTELS SAVENIJE

BUDGET CUTS AT THE TU/E

ILLUMINATION OF WATCHES

INTERVIEW SETTELS SAVENIJE

BUDGET CUTS AT THE TU/E

ILLUMINATION OF WATCHES

Dear Reader,

Now that we are at the ending of the acadamic year, it is time for one more openME. We are happy to look back on another acadamic year with a lor of stories, lectures, studying, and memories

In this issue, we explore a variety of topics, including two internships, some information about the University council and the Department council. And some more information about the brand new department instagram.

Beyond education-focused content, we also have more topics, such as an article about a GPS works or the hubble space telescope.

In this edition we also look back on some activities like the Brascursion and the first edition PartEE with ME. If you do not know what to do this summer you can also read the summer guide for fun things to do in Eindhoven

So there are a lot of different topics and I wich you a lot of fun reading all the articles!

With kind regards,

Rixt Hofman Editor-in-Chief

March 2025, volume 56, issue 2

The ‘openME’ is a publication by the study Association for Mechanical Engineering Simon Stevin of the Eindhoven University of Technology

Editor-in-Chief

Rixt Hofman

Design

Maartje Borst, Rik Lubbers, Roelof Mestriner, Joel Peeters, Lex Verberne

Layout

Jens van Bavel, Stefan Geerts, Ben Gortemaker, Rixt Hofman, Vera Riemersma, Luca Prundus

Editorial committee

Max Dumoulin, Stefan Geerts, Anastasia Ghlighvashvili, Ben Gortemaker, Rixt Hofman, Luuk Jentink, Luca Prundus, Vera Riemersma, Carlijn Roggen, Aditya Shekhar

Illustrations and Pictures

Editorial committee, Photo committee, source stated otherwise

Printing office Drukkerij Snep

Circulation

600 pieces

Contact Eindhoven University of Technology Gemini-North -1.830

Den Dolech 2 5612AZ Eindhoven Post office box 513

E-mail: redactie@simonstevin.tue.nl

Homepage: simonstev.in

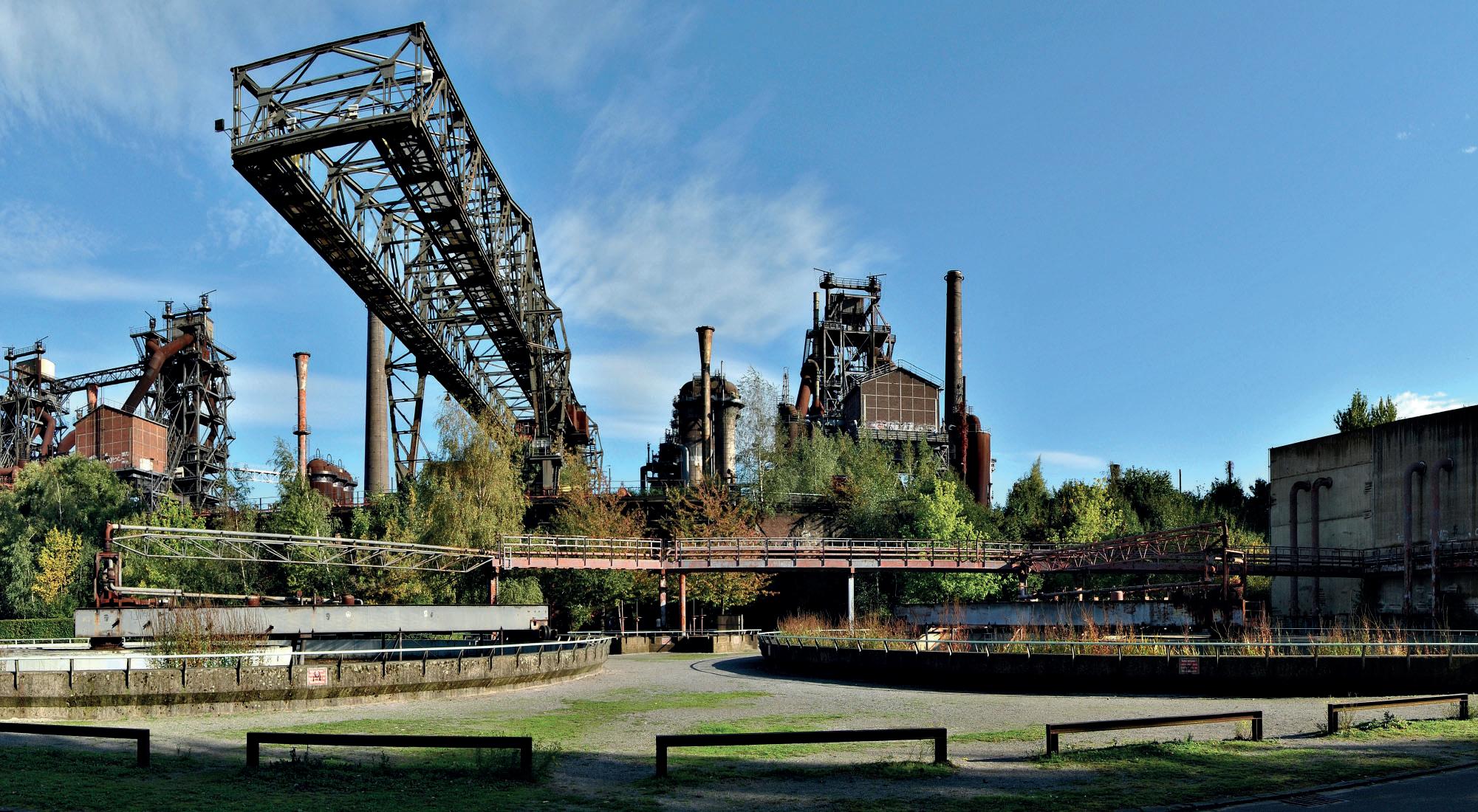

Settels Savenije group of companies is based at Strijp-T, Eindhoven. Founded in 1987 by John Settels and Jan van Amelsvoort, the company has grown into a leading provider of advanced engineering solutions. With a strong focus on technical excellence. We were invited to visit Settles Savenije’s inspiring work environment and have a talk with John Settels himself.

A beautiful piece of

on the wrist of a human being; a

Watches come in a wide variety of

es, colors and

but they have one thing in common, telling the time. One more fascinating thing they have is that their the

On the 7th of February, 2025, the most dazzling gala took place at the Ketelhuis on Strijp-S. This year, the theme of the gala was the Roaring 20s, an era known for its

and extravagant

On September 14, 2023, the president of the TU/e released a message describing that there must be a new future governance for the TU/e. The reason for this is that the TU/e needs a better and effective organisation to be able to deal with the growth of the university. This growth is mainly because of the internationalisation of the Brainport region, to keep up with the TU/e’s ambition in research and education, and to be able to satisfy the Beethoven project. Now, on the 30th of October 2024, this resulted into the advise to, amongst two other things, cut back from 9 departments to 4.

BY

Why do we need it?

Because of the growth of the TU/e itself and the pressure from the Brainport region, with the Beethoven project as the key driver, the university felt that the current organisation is not the best. It was felt among the members of the Executive Board and the deans that the current governance and organisational structure had several challenges that are currently blocking the effectiveness, with the large number of departments as one of them. For this rather important problem, a working group was established named the Future Governance TU/e. The working group has met with several leaders of four universities (TU Delft, KU Leuven, Technical University of Denmark, and University College London) to discuss the governance structure on their university. The structure the TU/e has is a rather unique structure: almost every study has its own department. The problem with this structure is that there is a significant difference in the working methods between various departments, which creates university-wide confusion about who is actually responsible for what. The large number of stakeholders, resulting from the many departments, also has a delaying effect on decision-making and implementation. So the new system would just make things go faster and more efficient.

The working groups has advised three things. The first being to change the top-level governance structure to three preparatory councils to be able to improve the decision making process, which I won’t bother you with. The second one is to narrow down to four service departments to improve the services and responsibilities. The last and most important change for us is the four department plan to better balance size and improve the strategic alignment.

As of now, the university has nine departments, which were installed to meet the needs of the regional industry. However, the current system creates an unbalance in terms of size. As yet, the largest department in terms of staff, which is Industrial Engineering and Innovation Sciences, is more than ten times the size of the smallest department, which is CE&C Chemical Engineering. This results in unequal representation in the decision-making process. For example, departments with fewer students may not recognise that other departments offer courses for hundreds of students, or vice versa. Decisions regarding education that are easy to implement in smaller classes can have a significant impact on larger courses, or the other way around.

In the 2000s, most universities in the Netherlands clustered their departments into large science and engineering departments. However, the TU/e didn’t. This was done to meet the specialised need for nearby industries. Now, with the ever-growing demand on impact of research from the Brainport, the forming of four departments needs to happen. The exact implementation of the plan is not sure yet and the names of the departments can also still change, since this whole plan is still an advise. But the working group has come up with a possible clustering (between brackets is the number of staff ).

FBS: Faculty of Basic Sciences (194)

• CE&C Chemistry and Materials (27)

• Applied Physics (63)

• Biomedical Engineering (44)

• Mathematics (60)

FAE: Faculty of Applied Engineering (181)

• Computer Sciences (71)

• Electrical Engineering (110)

FMT: Faculty of Manufacturing Technologies (137)

• CE&C Chemical Engineering (11)

• Mechanical Engineering (88)

• BE Engineering (41)

FDI: Faculty of Design and Innovation (179)

• IE&IS (122)

• Industrial Design (38)

• BE Design (19)

And what about the four service departments? Is this somethings important for me as a student? To be honest, not really. But it sure is worth to take a look at and it gives you a great insight. For example, when introducing digital testing in a course, multiple bodies need to be involved: General Affairs for policy, ESA for scheduling, planning, and logistics, the department for course organization, and IT for software support. While each service does its best to provide support, none of the bodies oversees the entire process, and no one is responsible for managing the full chain of activities. It’s like having a Study Association without a Board to oversee the full picture. Quite weird right?

To tackle this, a shift in governance and decision-making is necessary. In the past, services were organised in a decentralised manner, with each department having its own finance person, IT specialist, and so on. Over time, services were more and more centralised to improve efficiency, with only operational support staff remaining in the departments. This works great for a rather small university and it was beneficial for procedures that could be easily handled by the smaller departments. Ironically, this approach has in the end led to more customised solutions and higher costs. Now, the gap between central services and departments needs to be narrowed again. This means that the new organisational structure will require a balance between centralised and decentralised services, with a greater emphasis on decentralisation and more experts working directly within the departments. Here, one could say: “it used to be better in the old days.”

I won’t bother you with further details of who will work with whom, but it comes down to four different services departments, with each service department having a full-time director overseeing the process.

• Education Services: This service department is responsible for supporting the entire student journey, starting from the initial contact with TU/e, through enrolment in an educational program, and continuing throughout the education process until graduation or departure from TU/e. So most important for you as a student.

• Research and Valorisation Services: This service de partment is responsible for supporting the entire research process, from the initial idea and securing funding to executing the research, developing proof-of-concept, and, when applicable, commercialising the results.

• General Services: This service department is responsible for supporting university-wide processes and activities, such as compliance, accounting, and IT.

• Real Estate and Facilities: This service department is responsible for ensuring a safe and clean environment at TU/e. Its main tasks include maintaining the buildings and facilities.

The full implementation of the Future Governance plan is still a long way off. First, a so called Governance Process Organisation has to be set up. This organisation needs to make sure that the changes are actually implemented which first requires a thorough research on the consequences of the implementation of the ideas. Then, the restructure will begin slowly and from bottom-up. Finally, the change will be fully made once there is enough groundwork and support from everyone, and will be easier once the new top-level governance functions efficiently and is fully trusted. So, while it’s definitely on the horizon, it’s more of a marathon than a sprint: progress will come, just not overnight!

Forging, the ancient craft of shaping metal with heat and hammer, has been a cornerstone of human progress for thousands of years. What began with simple fire pits evolved into an art form that fueled technological advancements, shaped societies, and left an undeniable mark on human history. This is the story of forging with its origins, growth, and enduring legacy.

WRITTEN BY THOMAS POPPE

The story of forging begins in the Bronze Age, around 4000 BCE, when humans first learned to manipulate metals like copper and tin. Early blacksmiths discovered that heating these metals allowed them to be hammered into tools, weapons, and ornaments. These primitive forges, simple fires fueled by wood or charcoal, laid the foundation for one of humanity’s greatest crafts.

The bronze tools and weapons revolutionized daily life, while these creations symbolized power and spirituality. Metalworking was often viewed as a sacred art, with smiths revered as keepers of divine knowledge.

In Greek mythology, forging was elevated to a divine art under the watchful eye of Hephaestus, the god of fire, metalworking, and craftsmanship. Born to Zeus and Hera, Hephaestus was cast out of Olympus due to his deformity but found solace in his forge.

From his volcanic workshops, Hephaestus created magnificent artifacts, including Achilles’ impenetrable armor, the shield of Hercules, and even the thrones of the gods themselves. Despite his physical imperfections, Hephaestus symbolized the transformative power of forging, taking raw materials and shaping them into objects of unparalleled beauty and strength.

The myths of Hephaestus inspired blacksmiths throughout history. His story reminds us that forging is not only about strength but also about creativity and perseverance .

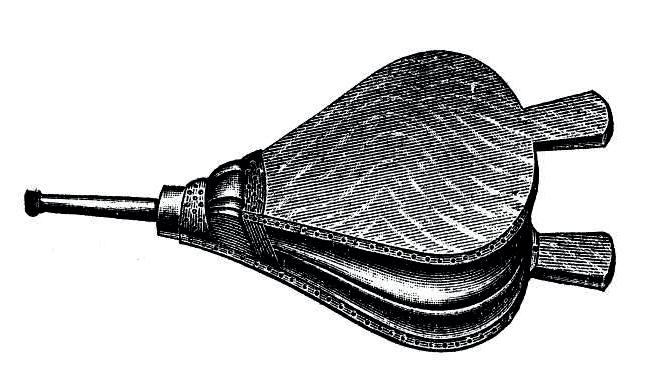

The advent of the Iron Age, around 1200 BCE, marked a turning point. Iron was more abundant and durable than bronze, but working it required higher temperatures. With the invention of bellows (see fig: bellow) to intensify heat, blacksmiths began forging iron tools, transforming agriculture, construction, and warfare.

Iron plows boosted farming efficiency, while forged swords and shields changed the dynamics of battle, empowering empires like the Romans. Smiths became central figures in society, and in myths like those of the Norse and Celts, they were celebrated as creators of magical and indestructible artifacts.

By the medieval period, forging had become a highly specialized and respected craft. Blacksmiths played an integral role in every village, crafting essential items such as horseshoes, nails, and plowshares. Their forges were hubs of activity, where the rhythmic clang of hammers echoed daily life.

Guilds began to regulate the trade, ensuring quality and passing down knowledge. Armorers focused on creating chainmail and plate armor for knights, while other smiths forged decorative yet functional iron gates, hinges, and tools. Forging wasn’t just practical, it became an art form, with high leveled designs reflecting the blacksmith’s skill and creativity.

The Industrial Revolution in the 18th and 19th centuries transformed forging forever. Steam-powered hammers and mechanical presses allowed for mass production, replacing much of the manual labor while increasing the scale and precision of forged products.

Steel emerged as the material of choice, combining strength and flexibility. Forging became critical to the expansion of railroads, shipbuilding, and industrial machinery. Axles, wheels, and anchors, all forged with precision, helped power the era of industrialization. Despite mechanization, skilled smiths remained indispensable, overseeing the operation of massive machines and ensuring quality.

Today, forging is a blend of ancient craftsmanship and modern innovation. Advanced machinery allows for the creation of complex, high-precision components used in industries like aerospace, automotive, and medicine.

Nowadays like mechanical engineers we see two main topics, precision forging and sustainability

Precision Forging: Computer-aided designs enable unparalleled accuracy, producing everything from turbine blades to surgical implants.

Sustainability: New techniques and materials are making forging more environmentally friendly, aligning this ancient craft with modern values.

From the bronze tools of ancient farmers to the steel skyscrapers of modern cities, forging has shaped the world as we know it. The forge, whether fueled by charcoal or electricity, remains a symbol of resilience, creativity, and mastery. Through the centuries, the blacksmith’s hammer has not only forged metal but also the story of human innovation. The flames of the forge continue to burn, linking us to a shared history of fire, strength, and determination.

After taking ‘only’ 5.5 years to finish my bachelor’s, I decided it was time to speed things up with my master’s. I completed my first year on schedule, leaving just the internship and master’s thesis. Initially, I considered going abroad for the experience, but when I came across an offer I couldn’t refuse, all those plans flew out the window. The internship was in Geleen, Limburg, and focused on ballistic testing of polymer fiber-based armor. As soon as I heard the word ballistics, I was hooked.

WRITTEN BY FERENC STERKENS Master Student Processing and Performance

My day would start at 6:30 AM with a shower and getting ready. By 7:30 AM, I’d be in my car, setting off from Eindhoven with some relaxing music. The 50-minute drive included a 10-minute stop at a gas station for coffee, a quick chat with the staff or other travelers, and—more often than not—a panini. (I probably ate more paninis in three months than I have in my entire life.)

By 8:30 AM, I’d arrive at work and start the day with tasks like data analysis, reviewing high-speed camera footage, or writing reports. Around lunchtime, I’d take a break to eat and chat with colleagues. At around 4–5 PM, I’d hit the gym before heading home. The schedule was intense, but the experience was well worth it. And thankfully, I didn’t have to wear any of the vests during ballistic tests!

Internship

My research focused on UHMWPE (Ultra-High-MolecularWeight Polyethylene) or HMPE (High-Modulus Polyethylene) fiber. This material is insanely strong and lightweight—about 15 times stronger than steel by specific strength—and has the highest impact resistance of any thermoplastic.

UHMWPE fibers are used in a variety of applications. When turned into ropes, they create ultra-strong yet lightweight lines

for sailing, parasailing, and even aerospace projects—like the 30 km-long space tether used in the Young Engineers’ Satellite 2. When made into fabric, UHMWPE is used in ultra-light camping gear, including tents, backpacks, and even bear-proof food bags.

My research focused on Dyneema® laminates, which are commonly used in body armor and ballistic vests. These laminates are created by layering fiber yarns in one direction, pressing them onto an adhesive, cutting them into squares, and then stacking them at 90° angles with additional adhesive layers. Each yarn contains 780 fi laments, and the final laminate is about 10–12 fi laments thick.

To evaluate the material’s impact resistance, we fired projectiles at a fixed distance and measured their speed before and after impact. High-speed cameras captured the impact, while microscope imaging helped analyze fiber behavior. By calculating the dissipated energy, we could determine how effectively the material absorbed the impact.

The goal of my research was to study how a steel cylinder impacts pressed Dyneema® panels (HB) and unpressed packs (SB). By analyzing high-speed footage, velocity data, and penetration depth, we compared the results to theory and simulations, gaining valuable insight into how Dyneema® composites absorb energy.

Although people love to joke about Limburg, it’s not all that different from where I’m from—except for the funny accents and some more hills, of course! But what was interesting were the research results and high-speed footage we gathered.

Below is a graph showing data from different soft ballistic panels. The Y-axis represents the dissipated energy per ply, while the X-axis shows impact velocity. The dotted lines represent the normalized kinetic energy of the projectile—physically, no data

points can go above these lines because that would mean more energy was dissipated than the projectile had in the first place (which is obviously impossible!).

The targets with more plys were actually more effective in stopping projectiles! Even when looking at normalized energy, therefore performance scales with more than increased the material amount!

Soft vs. Hard Ballistics – Which Works Better?

One of the most surprising discoveries was that soft ballistics are more effective at stopping projectiles than hard ballistics. This seemed counterintuitive at first, but after analyzing the highspeed footage, it made sense.

High-Speed Footage Breakdown

• HB Material (Hard Ballistics) – Below, you can see the 16-ply HB material at a velocity of about 450 m/s. On the left, the projectile is just before impact; on the right, it’s five frames later.

• SB Material (Soft Ballistics) – The same test was done with SB material. The left image shows the moment just before impact, while the right shows the projectile five frames later.

The key difference? The backface deformation in soft ballistics is much greater, meaning the material absorbed significantly more energy. This explains why soft ballistics dissipate impact energy more effectively than hard ballistics.

Conclusion

This research gave me a deep understanding of ballistic impact resistance and how UHMWPE composites behave under extreme conditions. If you’re curious to learn more, check out my full internship paper: “Characterization of Impact Ballistics: UHMWPE Fiber Composite”.

Thanks for reading—I hope at least some of this information penetrated your brain!

Last summer the Olympic games in Paris were in full swing and our very own Bas Jansdam was on the scene to report on the race against cheating in the Olympic games.

In Olympia, in the year 776 BCE, the first ever Olympic games took place in honour of the greatest chariot racer of the time, Pelops, who beat Oinomaos in a great race for what would now be called the Peloponnesus. A wonderful story of how those with immense talent and dedication can claim victory against any odds. At least, it would be if Pelops had not cheated and created an unfair advantage. Not only did he advantage himself by having immortal horses and a flying chariot, he also took the opportunity to have the chariot of his opponent sabotaged, which ended in Oinomaos’ death when the axle came loose. 1

While this was largely celebrated at the time, these tactics would be considered unfair and unsportsmanlike at later events, which is why the Olympics have tried to make the games as fair as possible ever since.

When we think of ways to keep sports fair these days we often envision camera technologies like Hawkeye™, but in the days of the Greeks these solutions were decidedly more low-tech. Besides, tennis wasn’t even invented yet and these first games in Olympia had only one event: the stade. 2

The stade was a massive event in Olympia, where up to 40.000 people could be seated on the banks beside the track 3 and where up to 40 competitors lined up to take home the olive crown and eternal fame.

WRITTEN BY BAS JANSDAM

There were however some problems that the Greeks had with the organisation of the stade: How do you make sure that everyone starts at the same time, and how do you prevent false starts? Both good questions with no easy answers. In fact, they seemed to have no answer at all. Cheating was rampant during the stade. Which makes you wonder what they did to stop this cheating, and how it is prevented today.

The modern 100m dash looks the most like the races in ancient Greece, so we will use that as our modern day equivalent. A quick recap on the 100m dash. We have a start line and an endline, with a distance between them of approximately 100 meters. Everyone lines up at the start, waits for the signal and tries to get over the endline as quickly as possible. Getting there quicker than the competition is of course easier if you don’t wait for the signal and leave before everyone else. This is considered cheating.

To make sure nobody cheats by leaving before they get the signal, the starting blocks are fitted with strain gauges which are used to measure the force of the athlete’s foot on the block. When there is no longer a force applied, that means the foot has left the block and if this happens before the signal has gone off you have made a false start and are immediately disqualified.4

The problem with this solution is that the starting signal is given using a starting pistol, and in a field where the difference between winning and losing often comes down to milliseconds the time it takes for sound to travel from the sideline to the furthest competitor is not insignificant.

To make sure everyone hears the pistol at the same time the starting blocks are fitted with speakers, which sound when the starting pistol is engaged.

These solutions do not quite work for the Greeks as they had not yet invented the starting block, which makes mounting strain gauges and speakers impossible. So in the first few hundred years of the games these problems were solved by having a lot of officials to look for false starts. Around the third century BCE however, a new invention was introduced, which is still in use at modern Olympic events: the starting gate.

Starting gates are used these days mostly in the winter Olympics as timing systems. When a skier sets off, they pass and trigger a gate, starting a timer. This ensures that all times are started at the same point. The ancient Olympics used a very similar system, the hysplex. (reference: Valavanis, 1999) (figure by Veronika Miketa).

The hysplex at Olympia consisted of a vertical bar with a horizontal bar on top of it that could pivot. This bar was held horizontally by a rope that was connected to the short overhang of the bar. All the ropes were led to the referee, who was located at a central point behind the runners. At the start of the race, the referee would let go of the ropes, causing the bars to fall down, allowing the Olympian to start running.

This way everyone got the signal at the same time and false starts were made impossible, making all running competitions finally fair after only a few hundred cheating filled games. (Footnote: except for the occasional tripping of opponents and the one time take over and fortification of the stadium by the Pisans and the Akkadians.)

While starting before your competitors is an obvious case, cheating has proved to be a notoriously difficult concept to define. A commonsense understanding of cheating as the ‘intentional violation of the rules to gain a competitive advantage’ is riddled with difficulties (reference: Russell, 2017). For example, if cheating is necessarily a type of rule violation, what of the violation of conventions and other norms not captured by the formal rules? What if these violations are not intentional? And even if there was cheating, can this be excused? The case of cyclist Lance Armstrong has provided a focal point for some of this debate (reference: Moore, 2017). Is cheating wrong if one’s competitors (or at least a significant proportion of one’s competitors) are also cheating? I’m just happy I don’t have to answer these questions.

It is also worth noting the related discussion of ‘gamesmanship’. This is a term used to denote conduct that falls short of cheating (as it does not violate the formal rules) but is morally dubious nonetheless and are often called unsportsmanlike behaviour. Such acts might include the intimidation of one’s opponent, the manipulation of officials, or the intentional disruption of an opponent’s preparations (e.g. coughing just as they are about to putt). And while such conduct is not formally proscribed, it speaks to a question that every athlete must ponder: what should I be prepared to do to win?

Because the competitions are so close, and the rewards so large, many people seek advantages anywhere. Most famously the Russian version of the NOC-NSF had set up a program for systematic doping for their athletes. In this program Russian athletes across all disciplines were encouraged to take EPO and steroids to improve their performance, while the Russian sports governing bodies would protect these athletes. Following the discovery of these practises by WADA (world anti-doping agency) Russia was banned from participating in all major international events for four years.

The reason these drugs were taken are simple, they improve performance. EPO encourages the production of red blood cells, making the athletes able to perform better for longer, while anabolic steroids are a modified version of testosterone that is even better at preventing muscle breakdown, allowing for more muscle buildup and more strength in the athlete.

While both of these substances are found in some form in the human body, the increased amounts offer unfair performance benefits. This is clearly cheating, because external methods are used, but it is undeniable that these chemicals appear in the human body naturally and that some people have higher levels than others. Which brings us to a very difficult question: can being naturally gifted be considered cheating?

Men have one huge advantage over women when it comes to sports: their testosterone levels. Because having more testosterone in your blood allows for more muscle growth, men will have an easier time getting stronger than women, which is considered an unfair advantage in many disciplines. Because of this there is a separation of gender in most sports, so that women who are immensely talented and dedicated have a chance to win in a battle with their peers. This is no different than having weight classes in boxing or age groups in football. We want to see people with talent and dedication have a fighting chance against their peers. Which is why, in 2018, World Athletics (formerly the International Association of Athletics Federations) decided to ban Caster Semenya from all short distance female track events.

Caster Semenya is a south-African woman who dominated track events through the late 2000’s and 2010’s. She is an amazing runner that naturally produces a lot of testosterone. She truly dominated. So much so, that after desperate cries for intervention from her peers World Athletics banned her from the track. If the most talented and dedicated athletes in the world are without a chance of winning we can not speak of fairness, they argued, and to keep the competition fair they instituted a limit to the amount of testosterone a woman could have in competitions were elevated levels were too large an advantage. As a result Semenya was forced to pivot to the 5000m race, where she failed to qualify for the Olympics.

Keeping the games fair is a hard job. Deciding on what is an unfair advantage is a job that is sure to lead to unhappy people whatever you decide. Are the Nike Vaporfly™ shoes cheating? (footnote: It was decided they were banned until the competition was able to catch up as to not disadvantage athletes sponsored by other brands.) Is using high altitude tents unfair? (footnote: Despite the advantage they give by increasing red blood cell production it is allowed, as all competitors can do it without risk to health and the same advantage can be achieved by living at high altitude.) And can you be too good to compete with your peers? All difficult decisions, but the result of these decisions is a competition where those who have impeccable talent and true dedication can show the world they can go faster, higher, and stronger than anyone else.

In February 2005, three former PayPal employees—Chad Hurley, Steve Chen, and Jawed Karim—launched a website that would forever change how people consume and share video content. What began as a simple platform for sharing home videos quickly grew into a global powerhouse of entertainment, education, and professional development. Now, 20 years later, YouTube is more than just a social media platform—it has become an indispensable resource for industries like mechanical engineering, where professionals and enthusiasts alike turn to it for learning, innovation, and collaboration.

When Me at the Zoo, the first-ever YouTube video, was uploaded in April 2005, the platform was still a novel experiment in online video sharing. In its early years, YouTube was primarily a hub for personal videos, viral clips, and home recordings. However, as the site gained traction, universities and educators saw an opportunity to share knowledge on a global scale.

During this period, MIT OpenCourseWare and other academic initiatives began uploading engineering lectures, allowing students worldwide to access high-level mechanical engineering content for free. Though valuable, these videos were often lengthy and lacked the visual engagement that would later define the platform’s most successful educational content.

By 2006, Google acquired YouTube for $1.65 billion, a move that signaled the platform’s immense potential. The introduction of the YouTube Partner Program in 2007 incentivized creators to produce high-quality content, and soon, early engineering educators began experimenting with new formats to explain complex mechanical concepts in a more accessible way.

WRITTEN BY STEFAN GEERTS

As YouTube matured, it became clear that visual storytelling and engaging explanations were key to making engineering accessible. This era saw the rise of dedicated creators who transformed the way mechanical engineering was taught online.

Derek Muller, the mind behind Veritasium, was among the first to revolutionize science and engineering education on YouTube. His research-backed, interactive approach to explaining physics and mechanical principles made even the most abstract concepts feel tangible. Through high-speed cameras, realworld experiments, and hands-on demonstrations, Veritasium introduced millions to the deeper mechanics behind everyday phenomena.

During the same period, Tom Scott emerged as a master of exploring engineering marvels and scientific oddities. Rather than filming in a traditional studio, he took viewers to fascinating locations—from unique bridges to underground tunnels— explaining the hidden mechanics behind infrastructure and design in a clear and engaging manner. His ability to make complex systems understandable helped popularize engineering among broader audiences.

As educational content gained popularity, hands-on engineering channels also began to take off. This set the stage for a new wave of creators who focused not just on explaining engineering but also on building and demonstrating it.

By the mid-2010s, YouTube’s engineering content was no longer limited to explanations—it was becoming a showcase for realworld builds and hands-on mechanical applications. This shift led to the rise of creators who blurred the line between engineering education and entertainment.

One of the most unconventional yet influential figures in this space was Colin Furze. A former plumber turned inventor, Furze pushed engineering to its extremes, creating jet-powered bicycles, homemade hoverbikes, and retractable superhero claws. His over-the-top projects weren’t just about spectacle— they showcased the fundamentals of mechanical design, fabrication, and problem-solving in action. His work inspired a new generation of young engineers by proving that engineering could be exciting, creative, and sometimes even a little bit reckless.

At the same time, Mark Rober, a former NASA engineer, introduced a more refined, methodical approach to engineering entertainment. His viral projects—ranging from the world’s largest NERF gun to highly sophisticated squirrel-proof obstacle courses—demonstrated engineering principles in ways that were not only educational but also deeply engaging. By carefully explaining his design process and iterating through multiple prototypes, Rober highlighted the importance of trial and error in engineering.

As YouTube entered its second decade, its role in engineering education solidified. High-resolution 3D animations, in-depth CAD tutorials, and virtual prototyping made it easier than ever for students and professionals to learn complex mechanical engineering concepts.

Channels like Practical Engineering and Real Engineering set new standards for technical education on the platform, diving deep into infrastructure mechanics, engineering failures, and design principles. Their well-researched, visually engaging content turned YouTube into a legitimate alternative to traditional engineering education, complementing textbooks and classroom lectures with real-world examples.

By now, YouTube had become an essential tool for professional development. Many engineers relied on it for software training, finite element analysis guidance, and staying up-to-date with emerging industry trends. Companies and universities increasingly recognized YouTube as a valuable educational platform, integrating its content into formal training programs.

Engineering collaborations also became more common. Creators frequently worked together to tackle ambitious projects, merging expertise from different disciplines. This collaborative culture further reinforced YouTube’s role as a knowledge-sharing platform, helping engineers and enthusiasts alike learn from some of the brightest minds in the field.

As YouTube enters its third decade, its influence on mechanical engineering is expected to grow even further. Emerging technologies such as artificial intelligence, augmented reality, and virtual reality could enable more interactive and immersive learning experiences.

Furthermore, as more universities, research institutions, and industry leaders recognize the power of YouTube, we may see greater integration between traditional engineering education and digital content. The ability to access high-quality, up-todate engineering knowledge at any time will continue to shape the next generation of engineers, making learning more flexible and globally accessible.

At 20 years old, YouTube has gone far beyond its original purpose of video sharing. It has become a global classroom, a professional development tool, and a critical component of the engineering community. As mechanical engineers continue to innovate and push boundaries, YouTube will undoubtedly remain a key platform for learning, sharing, and inspiring the next generation of problem-solvers and creators.

One of the oldest properties of the Association, Den Dis had seen better days. While some instability was inherent in its design, it had deteriorated to the point where it was no longer acceptable and needed attention. In this article, I’ll take you through the process of repairing Den Dis and highlight its unique (some might say cursed) features.

WRITTEN BY BEN GORTEMAKER

Around a year ago, the top of Den Dis became loose, rendering it impossible to lift. This is an issue if you’re trying to clean De Weeghconst. To investigate, the top had to be removed. This brought the first challenge: was the glue or beer that had seeped into the top holding it together? The top of Den Dis had a large split, causing beer to leak into the MDF plate below. The MDF material, unfortunately, proved suboptimal—absorbing moisture and weakening over time. Additionally, screws were pulling out of the MDF, loosening the connection. A quick fix with rings reattached the plate, but a more permanent solution was necessary.

Further complicating the issue, the screws in both the top and bottom of the plate were improperly positioned, causing them to bend under pressure. The unique design of Den Dis, resembling a spring nest, caused the screws to undergo excessive stress with any applied force.

Moreover, moving Den Dis, especially during rehousing and drink constitution, revealed that the large top made it cumbersome. The new design prioritizes making the top easier to remove and handle.

To strengthen Den Dis, we’ll replace the existing screws with M8 threaded bolts and inserts. These will better distribute the bending loads from the rods connecting the top to the base. The metal-to-metal connection is more durable and less likely to strip compared to wood, offering a stronger and longer-lasting solution. Assembly and disassembly will also be easier, as metalto-metal connections endure more wear than wood.

Next, the single MDF plate will be replaced with two multiplex plates. One will attach to the top of Den Dis, and the other will connect to the legs. M8 threaded connections between the two plates will allow for secure, durable disassembly and reassembly. Finally, the split in the top will be closed as much as possible, and any remaining gap will be filled with epoxy to restore the structure.

At this stage, attention turned to the rods of Den Dis, all of which had to be removed to install threaded inserts. The original connection to the base was weak, allowing the rods to be easily pulled off. Unfortunately, this also left behind screws that had been secured from the bottom of Den Dis, protruding upwards from the base. Since these screws couldn’t be removed from the top, they had to be unscrewed from below.

However, this task was easier said than done. Accessing these screws required a complete disassembly of the base, a process made even more challenging by several stripped threads. The only silver lining was that some screws had rusted so severely that they crumbled apart, simplifying their removal.

During the disassembly, a surprise awaited. The 50th Board of our Association had left a message from their repair efforts, likely dating back 18 years. But there was no time to dwell on this discovery, as the next layer of MDF awaited. Unlike other parts of the table, this MDF had been glued down rather than receiving the traditional De Weeghconst treatment, which allows parts to naturally settle together. Fortunately, the MDF was still in relatively good condition and reluctantly has been reused. Once it was removed, the screws securing the rods were finally accessible and could be taken out.

The first step was to remove the deteriorating MDF plate and replace it with a new multiplex plate. The gap, likely caused by wood expansion, had become a collection point for the remnants of spilt drinks. These drinks that had missed their desired location had seeped in, forming a hardened, black, crystal-like structure that made closing the gap significantly more difficult. Before any further work could continue, this stubborn residue had to be carefully removed.

Once the junk was cleared, efforts turned to closing the gap itself. This required patience, several failed attempts, and the use of straps to pull the tabletop back into place as much as possible. After achieving the best possible smallest gap, the multiplex plate was attached to keep it in place. To prevent future damage, the gap was filled with epoxy. This step was crucial in ensuring that no further liquid could seep into the table, avoiding the same destructive process that had weakened it in the first place.

Interestingly, the old MDF plate, now completely useless for structural support, still had one last role to play, Serving, as a template for marking the attachment points of the table legs. Once it had fulfilled this final duty, it was retired to a place where it would never be seen again.

With that hurdle cleared, the threaded inserts could now be installed in the base. However, positioning them precisely was tricky. As some inserts ended up slightly off-centre due to pre-existing holes left by the original screws. This misalignment required extra effort when reattaching the rods. A note for any future repairers: If Den Dis ever needs another restoration, consider removing the inserts, filling the holes with epoxy, and then reinstalling the inserts to ensure perfect alignment.

After a long process of installing the rods, it was finally time for reassembly. The connection plate was secured with countersunk hex bolts, and the top of Den Dis was reattached to the base using the same type of bolts. The new plates featured a keyed design, making it easier to align the top and bottom correctly.

Now, Den Dis is as structurally sound as possible. A fresh coat of stain and lacquer will restore its original appearance, bringing it back to pristine condition.

But one question remains: How long will this ancient piece of Association property endure?

Time will tell, but for now, Den Dis has been given a new lease on life, standing as a testament to the dedication of those who have worked to preserve it over the years.

AI models have been popping up around every major social media site over the last few years. While there have been attempts to respond to the ever-evolving landscape of artificial intelligence, DeepSeek has emerged as a groundbreaking yet highly controversial development. As an advanced AI model developed by a Chinese research team, DeepSeek has demonstrated remarkable capabilities in language processing, coding, and multimodal tasks. However, its release has raised some debates regarding data security, and the future of AI dominance.

WRITTEN BY ANASTASIA GHLIGHVASHVILI

DeepSeek has been able to match the performance of the reigning titan of the AI space, OpenAI. One of its key strengths is its ability to operate in multiple languages, including Mandarin and English, with high accuracy. This multilingual capability makes it a powerful tool, with earning potential even beyond the English-centric models dominating the market.

But why is DeepSeek so special? Its because of its reduced cost. While both OpenAI and DeepSeek are able to perform the tasks of text generation, problem-solving and programming, DeepSeek matches OpenAI’s performance at 95% less cost (Buntz, 2025). OpenAI’s operational scale highlights the significant financial gap between proprietary and open AI systems. As reported by Business Insider, the company incurred daily infrastructure costs of 700,000 in 2023, with annual expenses for training and inference expected to approach 7 billion in 2024. Training its GPT-3 model in 2020 cost 4.6 million, while its upcoming GPT 5 model reportedly demands 500 million every six months for training, according to The Wall Street Journal. In contrast, DeepSeek’s RL training budget for R1 was reportedly $12 million, putting into question if such heavy investments into AI models is really worth it.

DeepSeek’s success challenges the notion that substantial budgets and high-end chips are essential for AI advancements, raising questions about the future demand for high-performance hardware. The revelation of DeepSeek’s lower operational costs unsettled financial markets on January 27, triggering a broad sell-off in the tech sector. The Nasdaq dropped over 3%, impacting chip manufacturers and data centers globally (Ng, 2025). Nvidia, previously the most valuable company by market capitalization, saw its stock plummet 17% on Monday before beginning to recover the following day. Its market value declined from $3.5 trillion to $2.9 trillion, pushing it down to third place behind Apple and Microsoft, according to Forbes.

Venture capital investments in AI startups may also shift in response to DeepSeek’s capabilities. If investors perceive Chinese AI models as superior or more cost-effective, funding for Western AI firms may decrease, altering the financial landscape of AI development. Currently, DeepSeek is a privately held company and is not publicly traded, meaning investors cannot purchase shares on major stock exchanges.

Beyond economic impacts, another concern surrounding DeepSeek is data security. Critics argue that AI models developed in China may pose a risk to sensitive data, particularly if the technology is used outside its domestic market. Given the ongoing tensions between China and Western nations over cybersecurity, some governments and companies have expressed hesitation in integrating DeepSeek into their systems.

The AI’s ability to process vast amounts of information has also raised alarms about potential surveillance applications. Some fear that DeepSeek could be leveraged for state-sponsored monitoring or information control, further intensifying concerns about privacy. Australia has banned DeepSeek on government devices and systems, saying it poses a national security risk, while Italy blocked DeepSeek’s app on 30 January and ordered the company to stop processing the personal information of its citizens over data protection concerns.

Despite the controversy, DeepSeek remains a technological marvel with significant potential applications. Its capabilities could revolutionize multiple industries. However, addressing security concerns and ensuring ethical AI deployment will be crucial to its acceptance in global markets. As the AI landscape continues to evolve, and the Silicon Valley tech giants feel mounting pressure, the world will be watching closely to see how DeepSeek shapes the future of artificial intelligence.

A key hub for innovation and technology, Settels Savenije group of companies is based at Strijp-T, Eindhoven. Founded in 1987 by John Settels and Jan van Amelsvoort, the company has grown into a leading provider of advanced solutions, with a strong focus on technical excellence. We were invited to visit Settles Savenije’s inspiring work environment and have a talk with John Settels himself.

John Settels was born in Son en Breugel. Having completed his secondary education in Eindhoven, in 1980 he began studying industrial engineering and management science at the city’s Technical University, specializing in industrial psychology. Upon graduating in 1986, John worked for a small high tech engineering and manufacturing company in Veldhoven, which employed between 60 and 70 people.

When this company went bankrupt in September 1987, John and his colleague Jan van Amelsvoort were prompted to start a business of their own. Jan, who had been head of development at their former company, approached John with a proposition: “Let’s hire four mechanical engineers. I’ll handle the projects, and I need you to deal with everything else.”

Thus, their company was launched on September 1, 1987. Jan focused on the technical side whilst John took on all other responsibilities, from financial administration to insurances.

A year later, John had everything fine so fine-tuned that he was able to complete the work needed to run the business in one day a week, so he suggested the rest of his time be spent on management consultancy and company restructuring. This he did for 10 years.

By 1999 the engineering company had expanded to 25 employees. The staff expected Jan to be the manager, but he didn’t like the role and preferred to focus on technology and do engineering projects. Therefore he called John and told him he wanted him full time in the engineering company, as the manager.

John asked Jan if he was really sure about this, because they only had mechanical engineers in the firm, and they didnt take him seriously, because the technicians said his degree wasn’t a real profession. However Jan was totally convinced that John was the perfect man for the job. And John took on the role.

By 2001, the company had grown to 35 employees, but due to a challenging period in the high tech industry, they had to let go of 10 people in 2004. That same year, they moved their operations from Waalre to Eindhoven, and in 2006 Jan retired.

At that point, John had doubts about whether to continue with the company, because there was so little business available. However, instead of closing, he started sending his employees out to customers. His employees didn’t like this because it felt as if they were in a temporary work agency, not a real engineering firm.

John started to create a world that really worked for talented technical people. His philosophy was simple: if he could build a great workplace for engineers, and an open and transparant working culture which would inspire talented people, they would want to work for him, and the customers would follow.

Today, customers come to Settels Savenije because of their employees. John believes that nowadays 90% of their business is granted to them because the customers have confidence in the Settels teams; that they can achieve what the customers are looking for.

After a few years, projects started to come back to the company. In 2010, John was approached for a project at a machine factory, and the engineers returned with big smiles, inspired by the high level of craftsmanship. This experience led to an investment in that factory, and Settels Savenije developed a combination of three uniquely inspiring connected environments, namely Research and Development, Advanced Systems and Precision Parts.

build a great workplace for engineers, then talented people want to work for you and customers will follow

In 2011, John first visited a building that would eventually become the company’s new home. The building, previously used to purify water, consisted of large concrete compartments, tubes, and pump systems. Despite skepticism from others, John was able to see the potential in the structure and in its technical aspects. The building, 60% of which is underground, captured his imagination. And while many thought he was crazy for considering it, he was convinced it was the right place.

By 2014, John decided to move into the building. After working with an architect, they signed a deal with the building’s owner in

2015. Finally, in February 2017, the company officially moved into its new installations, marking a significant milestone in John’s vision for the company. The move not only reflected the company’s growth but also changed how they were perceived by others in the industry.

Since moving, the company has grown remarkably. The number of employees has increased from 50 in 2017 to 170 in 2024, with a turnover of 30 million euros. John’s dedication to fostering the right environment for his team has played a crucial role in this success.

John believes that creating the right environment for engineers is much easier in a small company. As the company grows, maintaining its core philosophy requires a different level of attention and effort. Preserving this philosophy is essential to John, since it is the foundation of the company’s success.

One of the key questions John asks himself is: How big should the company become? He firmly believes that if the company grows too large, it could compromise the culture that makes it so unique.

Currently, with a staff of 170, John estimates that the ideal maximum size is around 250 employees, a scale where it’s still possible to know everyone personally. This is important because one of the most important parts of the company’s success is its unique culture and how everyone works together. John is convinced that exceeding 250 employees could weaken the powerful company culture.

When broaching the type of environment that best suits technical professionals, John is very clear: a workplace with minimal politics, transparency and open communication.

For John, it is crucial that employees feel comfortable providing strong feedback to their colleagues when something isn’t done well. However, this feedback should always be given constructively, to inspire and to motivate people to improve.

On April 1, 1989, John was driving his car with Jos Berben sitting beside him. They were on their way to the first day of a new project, where they had to restructure a company. As they approached the company, John asked Jos what their plan was. Jos replied that he had no idea, but he was confident it was going to work.

Jos then shared a piece of advice that John took to heart and wants to pass on to all mechanical engieering students, which is: there is no such thing as a silly question. Even if you feel you probably should have known the answer, always ask anything you want, no matter how basic it may seem. Silly answers however, do exist. Especially when you are young, you should never hesitate to ask questions.

We express our thanks to John Settels for telling us about his experiences at Settels Savenije.

We hope that, as a reader, you’ve gained a better understanding of Settels Savenije and its founding story.

If you want to know more about Settels Savenije or to keep up to date with their news or job vacancies, make sure to visit www.sttls.nl

At the TU/e, students are educated to become excelling engineers in research or industry. The vision is to teach students how to become experts in their field of work, as well as broadly developed in order to work in interdisciplinary teams. The TU/e forms a diverse and international community, and also her education should teach students how to become inclusive leaders, being aware of cultural differences and diverse needs of students. Within ME, we go a step further to ensure that everybody feels welcome at the TU/e. The P&PD line we have should prepare bachelor’s students to become the next generation of leaders in their field of expertise

In April 2024, the first Social Safety training took place in the form of a theatre play for the freshmen as the start of the Social Safety P&PD line at ME and the TU/e. After this, three other trainings will be given for this generation student. These will be given as part of the courses Sustainable Fuels (2024, Y2Q2), Multidisciplinary CBL (2024, Y2Q4) and Computational mechanics (2025, Y3Q1). However, for the students after this generation, the trainings start earlier in the year to educate students early on the importance of social safety.

What are the trainings, and why are these important?

As stated above, the first part of the P&PD line, you will follow an interactive theatre session on social safety, discrimination, and transgressive behaviour. This theatre session will be held by Time Out Café. The goal of this interactive theatre session is to open the dialogue on social safety, to open your eyes on where discrimination and transgressive behaviour takes place and in what way we can search for the boundaries between what is okay, and what is not. And to stress that this happens in higher education. This training is part of the CBL Launching mechanism (Y1 Q2).

In collaboration with Stichting GELIJKSPEL, you will follow a workshop on social safety and transgressive behaviour. This workshop is a continuation on the theatre play Safe Space. You will learn how to check boundaries and state boundaries in their student life. Also, the role of bystander will be discussed. A focus point in the workshop is the ‘rules of the game’ when it comes to safe and enjoyable ways of sexual interaction. Student life

plays a large role in exploring sexuality, especially with students from all different backgrounds. By educating you on this matter, the TU/e helps facilitate a socially safe interaction within your student community and therefore keep the university a space where you can develop, academically and personally. This training will be given in Q4 of Y1 as a part of the CBL Energy storage and transport.

Once ground rules on social safety and interaction within student life are set, the focus will be on educating how to collaborate in an inclusive way. In this training session, inclusive and intercultural collaboration will be on the agenda. You will learn about cultural differences and personal differences in ways of communication, different cultural values and social preferences. Moreover, the training will pay attention to what intercultural and diverse groups can also bring to a group in terms of quality of the end product. The training will be part of Sustainable Fuels in Q2 of the second year.

In the last part of the P&PD line on social safety and Inclusive collaboration & leadership, inclusive leadership in general will be tackled. A recap will be held for what diversity means for the quality of the end product for the project. Moreover, you will learn how to become inclusive leaders. This means the workshop educates you on how to create an inclusive environment for working with others. How you can adapt to diverse needs, and how to get the most value out of each other. You will learn the importance of taking time, setting up a team and speaking out about each other’s expectations for a project. Moreover, the workshop will also pay attention to inclusive collaboration with non-peers (supervisors or other stakeholders). This final training will be given during Computational mechanics in Q1 of your third bachelor year.

With this P&PD line, Mechanical Engineering is a pioneer in the Netherlands in ensuring the wellbeing of students. This all to get the best out of your education to make sure that you excel in your career.

Have you every watched those car-pimping shows like Wheeler Dealers or Top Gear, and wished you could a fford to do something similar. Well, the Land Yachting Committee has great news for you. You can upgrade just about everything on your car without spending a dime! All you need is a sledgehammer, crowbar, and some beun in your blood. Welcome to the ultimate guide on how to pimp your ride, for absolutely free!

Lost your car keys, or fear ever losing them in the future? Simply remove the ignition cylinder, and hotwire the wires to a button on the custom dashboard. This way, you will never need your keys to start your car again! If you do this to someone else’s car, it is definitely considered theft, but doing it to your own is just innovation in our eyes.

Always wanted to be able to look up at the stars while driving at night? How about some nice sunshine on your head? Paying for a sunroof is not a small investment, so making it DIY is much cheaper. First, determine the size of the sunroof you want, and mark it on the roof of the car. This can best be done by scratching the markings in with the crowbar, as the markings will not be visible in the end anyway. Next, take your sledgehammer and hit the markings all the way around. This will weaken the material the perfect amount, so now you can chisel away at it with the crowbar. Pro tip: leave a bit of material on one side that works as a hinge, so you can always close the roof again when the rain comes.

Have you ever looked at your dashboard and thought: “Why are there so many buttons? I don’t even know what half of these do!” There is an easy way to simplify this. Simply take your sledgehammer, and hit every button that you do not understand or need anymore. This way, only the bare required will remain. Make sure you disconnect or remove the airbags before you do this, because otherwise you might get an unexpected surprise.

Getting bored with the simple and plain paintjob on your car? Let your imagination go wild. Take your crowbar and carve in whatever drawings, sketches, or other patterns you feel like. The more scratches, the more personalized and impressive the car will become. If you really feel like it, you can always take the sledgehammer and customize the shape of the panels as well!

Want that lifted-truck look but don’t want to spend money on an actual lift kit? Just take a sledgehammer and start whacking the wheel wells until the suspension gives up. Instant clearance upgrade! Beware: results may vary, usually in favour of catastrophic failure.

Why waste money on expensive subwoofers when you can create your own unique sound experience? Smash the exhaust pipe for a custom bass-heavy growl, or rip out the muffler entirely for a thrilling high-volume effect.

We at the ZWC are clearly fans of feeling some wind through your hair when driving. Having this in your car would also help keep your head cool, and feel much more powerful on the road. The procedure is simple, take a crowbar and chisel away at the edges of the windshield. After the edges are taken care of, simple peel away the entire windshield. For a real wind tunnel effect, it is best to also remove the rear windshield.

Ever been jealous of those Jeep drivers rolling around with no doors? Here’s your chance! Simply wedge a crowbar near the hinges and pry away until you achieve that open-air experience. Bonus points if you remove just one door for a bold asymmetrical look.

Ever noticed how clean racecars and high-performance vehicles minimize distractions? Eliminate pesky reflections and distortions by removing all windows! Not only will your view be perfectly unobstructed, but you’ll also enjoy a totally open driving experience—whether you like it or not.

Side mirrors only show you where you’ve been—not where you’re going. Remove them entirely for a sleek, futuristic design. Who needs to check blind spots when you can just rely on vibes?

Fuel economy is important, and excess weight is your enemy! Rip out anything unnecessary—passenger seats, panels, carpets, even the dashboard—to maximize mpg. Just remember: the lighter your car, the faster it disappears in strong winds.

After following these simple, budget-friendly car modification tips, you’ll be left with a truly one-of-a-kind vehicle. So, grab your sledgehammer, summon your inner artist, and get to work. And if you ever doubt your skills, just take a look at what the ZWC managed in 1 hour, with these exact tools.

Cherenkov radiation is a fascinating physical phenomenon that manifests as a blue glow when electrically charged particles move faster than the speed of light in a specific medium. This effect, named after the 1958 Physics Nobel Prize laureate Pavel Cherenkov, was first experimentally demonstrated and explained by Cherenkov himself.

According to Einstein’s theory of relativity, nothing can surpass the speed of light in a vacuum, which is approximately 299,792 kilometers per second . However, in different mediums like water, glass, or certain gases, light slows down significantly. For instance, in water, light travels at about 75% of its speed in a vacuum. Meanwhile, other particles, such as electrons, may maintain higher velocities than the sloweddown light, resulting in the emission of Cherenkov radiation.

This process is analogous to a sonic boom, which occurs when an object moves faster than the speed of sound in air. Similarly, Cherenkov radiation represents a “shock wave” of visible light produced when charged particles exceed the speed of light in a given medium.

When a high-speed charged particle moves through a medium like water, it disturbs the surrounding atoms, disrupting their energy balance. These atoms then release energy in the form of photons (light particles) as they return to equilibrium. The light emitted is predominantly in the blue, violet, and ultraviolet portions of the electromagnetic spectrum due to the high energy levels involved.

The color of visible light is determined by the wavelength and frequency of its photons. High-energy photons have short wavelengths and high frequencies, which correspond to blue and violet light. Although some Cherenkov radiation extends into the ultraviolet range, which is invisible to the human eye, specialized instruments can detect and measure this radiation.

One of the most common and well-known sources of Cherenkov radiation is the cooling water that surrounds the fuel in nuclear reactors. During nuclear reactions, high-energy charged particles are produced, and when they travel through water at speeds greater than the speed of light in that medium, the characteristic blue glow emerges.

t: Will the roads of tomorrow still be enjoyable?

“To fight climate change in this ever-changing world, it is a necessity to keep innovating towards a more sustainable future.” This may sound like the beginning of a USE Engineering Design presentation, but it’s also a reality our generation has to deal with. If it is up to the European Union, we must take the lead on multiple fronts regarding this mission, but what does this mean for the survival of iconic vehicles on the road?

WRITTEN BY JOEY VAN PETERSEN

Many mechanical engineers have an unconditional love for everything that contains a combustion engine. The expensive car your dad bought during his midlife crisis, an old two-stroke moped your granddad gave you as a present, or even a hard-tostart standalone single-cylinder, they all have their own charm, character and feeling. Even though they are loved by many, their survival has been under pressure for a long time.

As a contribution to global climate initiatives, the EU introduced its first European Emission Standard (EURO 1) in the early 1990s, containing the first vehicle emission regulations on the continent. It was implemented to mitigate the effects of deteriorating air quality on public health. The first standard had a lasting impact on vehicle design. Emission limits for carbon monoxide, hydrocarbons and nitrogen oxides, directly led to the widespread use of unleaded gasoline, which we still use today. Additionally, this standard mandated the use of a three-way catalytic converter in the exhaust system of passenger cars for the first time. Every four to five years, the standard was revised with lower emission limits, the required adoption of new technologies and or newer testing methods. The equivalent standard for two-wheeled vehicles was later introduced in 1999.

Engineers are always challenged to innovate, especially when tightened regulations come into effect. This often leads to a game of cat-and-mouse being played between regulators and designers. The design goal of a vehicle is almost never the same as the goal of the regulations, but focusses more on creating an affordable and well-performing system. Volkswagen’s Dieselgate is perhaps the most wellknown example of such a difference.

Software in the onboard computers recognized when an emission test was being conducted and temporarily optimized the catalytic conversion by mixing more urea in the exhaust gases than during regular usage. This significantly reduced nitrogen oxide emissions, allowing Volkswagen to obtain the EURO 5 certification without developing expensive technologies or requiring the user to refill urea regularly. To prevent manufacturers from circumventing regulations in a similar manner again, the ‘Real Driving Emissions’ test was introduced with EURO 6. This test uses mobile equipment to measure emissions during normal driving conditions, which must stay under specific limits, in addition to the traditional roller bench tests.

This scandal revolved around everyday diesel cars, but creatively working around the rules is simply part of our nature as engineers, even if such approaches might backfire. For example, some motorcycle designers were unable to meet the EURO V standards, introduced in 2020, without compromising too much on sound and performance. Like a CBL group tackling a vaguely defined assignment, they came up with a clever solution. By using thin coating layers, non-heat-resistant materials and rapidly wearing filters, they developed catalytic systems that passed the emission tests, but afterwards wore out much faster than usual. Once the catalytic converter wears down, back pressure reduces, allowing for a bigger power output at high RPMs, greatly benefitting sport motorcycles in particular. Like a startled professor, still revising the project assignment well into the quartile, the EU also responded to this development trend. In this case, several years later, EURO V+ was introduced. While the limits remained the same, the tests now have to be conducted after 35,000 kilometres as well. In addition, sensors monitoring the catalytic converter’s performance became mandatory. If a significant loss in performance, compared to the initial level, was detected, the check engine light would be activated. This made it nearly impossible to design a system that only performed adequately under normal use for a limited period. Even after thousands of kilometres of intensive use, the standards must still be met.

The European regulations, along with those of the Environmental Protection Agency in the United States, have been world leaders in enforcing a cleaner transport sector, and with great success. According to the E.P.A. new vehicles are up to 99% cleaner compared to 1970. Dozens of countries worldwide also adopt the European and/or American standards, or older versions thereof, as their own. This means that nearly all manufacturers globally must comply with these standards. It is undoubtedly good for the environment, but every story has two sides. Over the years our roads have bid farewell to countless iconic cars, motorcycles and mopeds. Both the Mazda RX-7 and its successor, the RX8, were discontinued as a result of EURO 2 and EURO 5, respectively, after which the unique rotary engine would never return in passenger cars. The disappearance of the Nissan Silvia

and Mitsubishi Evo further marks the end of the ‘The Fast and the Furious: Tokyo Drift’ era. In the motorcycle world, Yamaha also had to yield to Euro V regulations, ceasing production of the popular YZF-R6, while the YZF-R1 will no longer have a European variant due to EURO V+. Even two-stroke motorcycles and mopeds have long ceased to be produced for public roads due to these standards. Now only old ones are still out there, destined to gradually disappear from the streets entirely.

The future of exhilarating internal combustion engines does not look all too bright. For bigger car producers, it is often still viable to develop technologies like ‘EcoBoost’ or ‘BlueTEC’ to obtain their certifications, but to be honest, these cars are far from truly exciting. In contrast the lower production volumes and specific market demands of sport-oriented vehicles cannot be combined with the emission certifications in an affordable manner. Notably, the rising popularity of electric alternatives further reduces the available funds for new fuel and exhaust technology. And to make matters even worse, the Euro 7 standard, set to take effect in 2026, introduces limits on emissions from tire and brake wear. These new requirements will be specifically challenging for sporty vehicles, as these components endure more stress compared to those on regular vehicles. While it cannot be definitely stated that emission standards are the sole reason for halting production of many models, they are often a decisive factor for our beloved, nostalgic and iconic vehicles. With ambitious climate goals ahead, it is highly likely that this trend will continue in the near future. For enthusiasts, this may sound a bit disheartening, but fortunately, we are in the right place for a glimmer of hope! Mechanical engineers stand at the forefront of realizing the innovations needed to meet these climate goals, without sacrificing our passion on the roads. Whether you’re designing a more efficient exhaust system, modelling a wear-resistant brake disc or optimizing the controller in an ECU, every research group within our faculty can contribute to preserving enjoyable vehicles. Enthusiastic engineers are the key to keeping iconic cars, motorcycles and mopeds alive. By doing so, we might even save the internal combustion engine as a whole.

Almost everyone has one; a smartphone. Just take your phone out of your pocket, purse or jacket and the screen will light up and tell you the time. But there is another way of time telling, which is done by a beautiful piece of craftsmanship on the wrist of a human being; a watch. Watches come in a wide variety of sizes, colors and shapes, but they have one thing in common, telling the time. One more fascinating thing they have is that they have the ability to in a magical way ‘glow in the dark’. But why does humanity even need watches that glow?

WRITTEN BY MAX DUMOULIN

Maybe first introduce the importance of watch illumination, as this might not seem so obvious at first. For an every day user is enhances the readability in low light. For example at a movie theatre or driving at night, no external light source is needed to tell the time.

Lume is also essential for divers. They rely on it to check for example dive times underwater where the natural sun light is limited. A famous diving watch is the Rolex Deepsea Challenger, which can you up to a sea depth of 11000 meter . And for an watch admirer the glow of a watch is just aesthetically pleasing. This all made me wonder, how do watches glow in the dark? And what is the history behind this phenomenon?

Between 1910 and 1920, watch and clock companies employed women to paint dials and hands with luminous radium paint mixed with zinc sulfide. This cutting-edge technology, which became widespread around the time of the First World War

(1914-1918), allowed timepieces to glow in the dark. The potential of radium had a lot of pros, it was self-illuminating, bright and long lasting glow. It did enhance the readability of watches in the dark, which was particularly useful for military usage at that time. An extraordinary example of a watch that radium illumination is the highly collectable Rolex GMT Master 6542.

This watch had an original Bakelite bezel and is therefore considered quite rare. Despite the major pros, the danger of radium was initially underestimated, leading to devastating health consequences for workers. The workers who did this work are the socalled the Radium Girls. These women, who painted watch and clock dials with radium-laced paint, unknowingly ingested the toxic substance through a practice called “lip-pointing,” in which they shaped their brushes with their lips. Over time, they developed severe health issues, including necrosis of the jaw, bone fractures, anemia, and cancer. After more than 40 years, radium was banned in 1968 and replaced with safer alternatives. In the year 2020 a movie was made, which told the captivating story about these Radium Girls.

Promethium

In the same time promethium was used, which is also radioactive, but less then Radium. The major downside of the Promethium was that the lifespan was only 2.62 years, making it not a feasible option for the production of watches.

In the 1960 Tritium H-3 was used. This is a radioactive isotope of hydrogen with a respectable half-life of 12.3 years. The radioactivity of tritium was also way less then that of radium and promethium. The other major disadvantage of tritium was that it had a tendency to diffuse, seeping through the case and coming into contact with the wearer’s skin. Many watch brands, including Rolex, utilized tritium-based paints until they were banned in 1998 .

Since the banning of radioactive the most commonly used way of the ‘lighting’ of a watch is by the use of photoluminescent pigments. The biggest constraint between the different areas is the fact that the radioactive watches have the capability to glow without the need of a charge by a light source. While the LumiNova and Super LumiNova works more like a battery, It works by absorbing light or UV and the stored energy releases visible light, which causes it to ‘glow in the dark’.

LumiNova

LumiNova was invented 1993 in Japan, by Nemoto & Co, this type of luminance quickly became the standard for watches and is still mostly used today. LumiNova is, like has been said before, not a radioactive luminescent. It absorbs the energy and then emits it afterwards. LumiNova is based on strontium aluminate, an aluminate compound. This new material had to be combined with a chemical element called europium to glow.

The new LumiNova is about ten times brighter traditional luminescence and comes in variations of bright blue and bright green. The green hue glows the brightest, while the blue hue lasts the longest. Like a rechargeable battery, it must absorb light to glow in the dark, so the luminescent is not permanent. The brightness of the glow depends on factor like the intensity and the length of the light exposure. The glow gradually fades after 3-5 hours even under the most ideal conditions.