“Driving forward”

“Driving forward”

Dear Reader,

As the first quartile has past, we’re gearing up for the rest of this academic year. We look forward to more memories, more good moments, and, of course, more exams and projects.

In this edition of openME, we focus on the theme of driving forward, exploring the developments and transitions within our community and beyond. Change is constant, whether in technology, student life, or personal growth, and understanding this helps us navigate what lies ahead.

This issue covers a wide range of topics, including insights into SpaceX, student well-being at TU/e and the ME Student Day. You’ll also find articles about experiences from internships abroad, an interview with the new program director, and an insight into the names of the Associations beloved objects.

We hope this edition provides valuable perspectives as you continue your academic journey forward.

Wishing you an insightful and engaging reading experience.

With kind regards,

Rixt Hofman Editor-in-Chief

December 2024, volume 56, issue 1

The ‘openME’ is a publication by the study Association for Mechanical Engineering Simon Stevin of the Eindhoven University of Technology

Editor-in-Chief

Rixt Hofman

Design

Maartje Borst, Rik Lubbers, Roelof Mestriner, Joel Peeters, Lex Verberne

Layout

Jens van Bavel, Stefan Geerts, Ben Gortemaker, Rixt Hofman, Aditya Shekhar

Editorial committee

Stefan Geerts, Anastasia Ghlighvashvili, Ben Gortemaker, Rixt Hofman, Luuk Jentink, Aditya Shekhar

Illustrations and Pictures

Editorial committee, Photo committee, source stated otherwise

Printing office Drukkerij Snep

Circulation

800 pieces

Contact Eindhoven University of Technology

Traverse 0.34

Den Dolech 2 5612AZ Eindhoven

Post office box 513

E-mail: redactie@simonstevin.tue.nl

Homepage: simonstev.in

One and a half years ago, a pipe dream was created: let’s organize a symposium together with the other Mechanical Engineering Study Associations. On this day we can look back at this pipe dream becoming a reality. At the ME Student Day more than 450 students attended from all over the Netherlands, and it is one of the largest career activities organised by these Associations. 46

On October 13 at 7:25 a.m. local time, SpaceX successfully launched its 122-meter-tall Starship vehicle for the fifth time from its Starbase facility in South Texas. This mission marked a significant step forward for both Starship and spaceflight, as SpaceX attempted an innovative recovery approach for the rocket’s first-stage booster, known as Super

Roughly a year ago, Jens went to Australia. Now, he'll share his experiences of living and doing an internship Down Under! Doing an internship is part of the Master curriculum and while you can do it at the TU/e or a company in the Netherlands, he used it as an excuse to head to Australia from January until May.

Roughly a year ago, I boarded a plane to take me to the other side of the world: Australia. Now, I’ll share my experiences of living and doing an internship Down Under! Doing an internship is part of the Master curriculum and while you can do it at the TU/e or a company in the Netherlands, I used it as an excuse to head to Australia from January until May. Via a professor at the Power & Flow research group at the TU/e, I got in contact with a professor at the University of New South Wales (UNSW) in Sydney where I did my internship project on the direct injection of hydrogen in compression ignition engines.

Geographically speaking, Sydney is weird. Sydney consists of a lot of suburbs (over 650!) that are woven together in a single city. Most of these suburbs still have their own center where some small shops are located. Unlike most metropolitan cities, most of Sydney consists of low-rise buildings, with the Central Business District (CBD) being the only exception. By area, Sydney is massive: it’s 2.5 times the entire province of Noord-Brabant! Sydney is extremely diverse in culture, just walking around the city, you can clearly see that people from all over the world build Sydney, from the Vietnamese restaurants to the British pubs and the lively Chinatown. It’s often stated that Sydney is one of the most expensive places to live and this is true in some cases, like housing and gym memberships. Similar to Eindhoven, there is a housing shortage in Sydney, so for a room in a shared house, you can expect to pay the same price as in Eindhoven, only you have to pay this PER WEEK instead of every month.

Since housing is handled on a weekly basis, you can’t find a room more than two weeks in advance. So, I didn’t find a room before flying to Australia, which is kind of crazy when you think about it. Therefore, for the first week and a half, I lived in a hostel before I found a permanent place to stay. Also, if you like drinking, which most students do, you’re out of luck too as a crate of beer costs around $60 (~40 euros). The rest of your costs of living are quite similar to the Netherlands.

I lived in Kensington, which is one of the eastern suburbs, conveniently located next to the university. Public transport is really easy to use in Sydney, so taking the bus to the beach or the CBD is a piece of cake. When I didn’t feel like cooking, I’d get some takeaway and eat it on Coogee beach whilst the sun set. Usually there was a random guy playing the guitar, so it was the perfect chill spot.

Life in Australia is pretty laid back, even in a busy city like Sydney, there is a relaxed atmosphere. Everybody is friendly and always in for a chat. During weekends with nice weather (which it was most of the time), everybody flocks toward the beach to hang out, get a tan (or really sunburnt). I really noticed how “going to the beach” was an essential part to everybody’s life. I mean, with the quality of beaches right on your doorstep, I don’t blame them. The general attitude towards life is really chill, which we in the Netherlands could learn a thing or two from.

My internship

Now back to the whole reason I traveled to Sydney, my internship. Removing fossil fuels from the transportation sector is a big challenge that the world has to overcome. Industry and transportation are the biggest polluters of CO2. Electrification is seen as the best alternative for these sectors. However, for

Electric vehicles for long-haul transportation are not efficient since batteries are heavy and thus have a low specific energy density. Hydrogen is a known alternative fuel source, but whilst hydrogen powered internal combustion engines have been researched a lot over the past decades, this has mostly been studied in spark ignition (gasoline) engines. Compression

ignition engines work on using a different principle. Where in spark ignition engines the fuel is added to the cylinder, compressed, and then ignited by a spark plug, (direct injection) compression ignition engines work by first compressing the air in the cylinder, and then injecting the fuel at a later stage. Due to the high pressure and temperatures in the cylinder, the fuel auto-ignites. Since hydrogen has a auto-ignition temperature that is way lower than hydrocarbon fuels, it also auto-ignites in spark ignition engines, which is uncontrolled, therefore, undesired.

Since the properties of hydrogen are quite different than diesel, understanding how hydrogen behaves when it is injected in a high-temperature, high-pressure environment is crucial. Therefore, at UNSW, experimental research was done on the injection and ignition behavior of hydrogen in compression ignition (diesel) engines. These experiments showed that the injected hydrogen jet ignites around 30mm from the injector head after roughly 2ms. In order to better interpret these results, my job was to create a CFD model of these experiments. I used the CONVERGE software to create a numerical model, which I used to predict the ignition delay and the local equivalence ratio. I calculated that a local fuel-air equivalence ratio of 0.44 was ideal for auto-ignition, and this was confirmed by the numerical model. The model has a lot of detail, so a lot more future research can be done with this. The downside of this detail is that it took 2 full weeks to model 8ms on a dedicated server and the final results were around 150GB’s of data.

Exploring the rest of Australia

I didn’t spend all my time in Sydney, during the weekend I planned trips to hike in nature, go to a surf camp and I rented a campervan to drive from Adelaide to Melbourne along the Great Ocean Road. Before going to Australia, I thought I would’ve seen most of it by the time I was done with my internship. How naïve of me. After finishing my internship, I backpacked for a month along the east coast of Australia from Sydney to Cairns. This was of course the highlight of my time spent abroad. From the relaxed atmospheres in Byron Bay and Noosa, to the beautiful nature of the Whitsundays, Fraser Island and the Great Barrier Reef. I’ve never taken so many photos in my entire life! Sydney was a lot of fun, but leaving the busy city for a lot more quiet areas was just as breathtaking, but in just different ways.

It’s safe to say that one day I’ll go back down under (but maybe first graduate…). If you think about going to Australia (whether for your internship or just traveling), let me know and I’ll happily tell you about all the things I couldn’t write down here (spoiler alert: it’s a lot)!

One and a half years ago, a pipe dream was created: let’s organize a symposium together with the other Mechanical Engineering Study Associations. On this day we can look back at this pipe dream becoming a reality. At the ME Student Day more than 450 students attended from all over the Netherlands, and it is one of the largest career activities organised by these Associations. In this article we want to reflect on this day, and what it took to organise it.

It all started on the 24th of January 2023 when the three mechanical engineering study associations met together in De Horst, Enschede. They came together at the WETD meeting, a meeting where the three mechanical engineering associations of the technical universities come together and share their knowledge and experiences.

It was at this meeting, that the Commissioner of External Affairs of the 66th Board of W.S.V. Simon Stevin laid the first bricks of what was to become a bigger project, with more uncertainties and risks that had been taken before.

It being a project larger than one could reasonably manage within a single Board year, it first started with discussions with the successors and the tobe committee if they wanted to continue with this ambitious project. This was also the point where one of the three Associations withdrew from the project.

At the start of the 67th Board year and the hectic first weeks that come with the academic year, the work got started. Starting with long

discussions about the locations, name and brand identity that we wanted to have, and of course the thousands of dollar question is this a feasible idea?

But, after the committee officially got appointed by the GMM on the 20th of December 2023, the raking or rather the leaf-blowing by the external affairs of the committee gave the feeling that it might become a reality.

On the 22nd of April 2024, it was time to present the budget, which was presented with confidence, as the minimal budget was already realized at this moment due to the efforts of the committee. The question at this point was how successful of an event can we make it.

While we felt relief from successfully pitching this event to companies, the stress of selling it to students quickly followed. Making sure that hundreds of students give up their day to visit our career event in Utrecht is easier said than done. A fact that kept most of the committee members awake at night.

After many sleepless nights, and arriving very early in the morning, it was finally time. All the nerves of the committee soon settled, as it quickly became clear that we were well prepared. The hard work paid off, and it resulted in an amazing day that companies and students enjoyed. We could not have asked for more.

If you ever want to have the opportunity to organize this amazing event yourself, feel free to contact the Board!

What exactly do you do as the Program Coordinator?

I’m still discovering some aspects of the role, but as the title suggests, it involves coordinating various events, such as academic lunches, celebrations, and curriculum updates. This includes discussing and deciding with the team and the program director on potential curriculum adjustments. I also coordinate the P&PD training and handle day-to-day tasks, like assisting the department with resources or updating the study guide. It’s a very diverse role with both large coordination tasks and smaller, detail-oriented responsibilities. Overall, it’s a team effort focused on keeping everything running smoothly.

What did you study?

I completed a Bachelor’s in Biology in Utrecht and quickly developed an interest in education, which led me to an Educational Minor. Afterward, I completed a Master’s in Science Education and Communication (Teacher Track) in Utrecht, earning my certification as a first-degree biology teacher.

How did you end up at the University of Technology of Eindhoven?

I initially taught in a high school, but it wasn’t the right fit for me. After that, I saw a vacancy for a junior lecturer, which involved teaching, mentoring first- and second-year students, and coordinating biology-related courses. This was on the VU Amsterdam, and while this role was temporary, it confirmed my interest in higher education. At that time, I lived in Eindhoven (I was born in Afghanistan but grew up in Eindhoven). With the flexibility of remote work during COVID, I could explore other roles and found myself drawn to academic advising. My main criteria were a position in Brabant, with potential for a permanent contract, and at the university level. That led me to apply for a Master’s Student Advisor position in Mechanical Engineering at TU/e. Later, when Rob left his position, I was approached about taking on the Program Coordinator role, which felt like a natural next step.

What are your goals as the program coordinator?

My goals are to continuously improve and develop the educational program and to make a positive impact in these areas. Personally, I aim to do my job well, find enjoyment in it, and deliver highquality work.

What are some of the challenges you encounter in your daily work?

My predecessor, Rob, handled many smaller tasks directly, sometimes shifting the focus away from a purely coordinating role. I aim to focus more on coordination, but it’s an adjustment for everyone, and it takes time. As a program coordinator, I’m at the center of a wide network, which often leads to additional tasks coming my way. One of my goals is to establish clear boundaries around which tasks are within my scope.

How would you describe the culture of the department?

Our team, ESA, is friendly and supportive. We look out for each other and help each other when needed. We also have team-building activities, like visiting museums, such as a recent trip to muZIEum, which highlights the experience of people with vision impairments. We focus on inclusivity and have a large, dynamic team where everyone’s responsibilities are clear. Every Thursday at 10:00, we have an informal coffee break to chat and connect, which helps maintain a close and welcoming atmosphere.

What are your hobbies?

I love traveling, reading, especially crime and detective novels, and walking. I also enjoy spending time with family and friends and I like being creative too, especially with henna design as you can see on the picture on this page.

Do you have any advice for students?

Based on my experience as an academic advisor, I think it’s essential to find a healthy balance between studying and personal life. You need downtime to recharge and enjoy activities that give you energy. Remember, studying isn’t just about sitting down with your books: it starts from the very first lecture. Most importantly, keep enjoying the program and everything it offers alongside your studies.

Where can people find you?

You can find me in Traverse 3.32, or you can me reach me by email me.program.coordinator. me@tue.nl

W

RITTEN B Y JENS VAN BAVE L

A life without the use of a Global Positioning System (’GPS’) is in the current society almost unimaginable. There is one in every car, every phone, and in many more electronic devices to help the user find his/her current location, job or home. But how did the great voyagers navigate around the globe during the 17th century? A new innovative idea came from a Flemish Simon Stevin, who made important observations on the deviation of a compass which could possibly be used to find a harbor.

Before diving into the method Simon Stevin described to find a harbor, a little bit of background information of the time Simon Stevin was living in. Stevin was born in 1548 in Brugge and lived until 1620, which was at the beginning of the ‘golden age’ of the Netherlands. At that time trading and sailing was rising in the Dutch Republic and eventually led to the biggest trading and sailing company of the 17th and 18th century, the VOC. This company was responsible for trading in Asia and was only founded in 1602.

In the 16th century, most ships sailed the safest routes due to the lack of a proper positioning system. One of the reliable methods used at that time, that did not require sailing next to land all the time, was measuring the latitude1. This method required to calculate the latitude. The method consisted of looking at the height of the sun or pole star and having an accurate clock. The position of the sun at the horizon shifts as the latitude changes, if this position shift was measured accurately, the latitude of a ship could be known. When a ship reached the desired

latitude of its destination it only had to sail true east or true west to reach its destination. However, this method had 2 major downsides. The first downside is that in the 16th and 17th century no clock functioned properly after a long time at sea. The second downside is that after reaching the correct latitude there was no way to tell for sure if the targeted harbor was east or west.

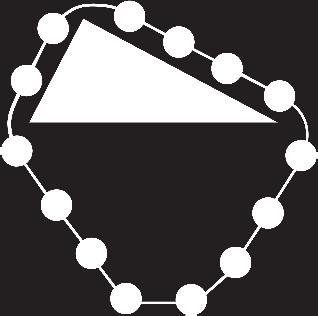

De Havenvinding

In his book ‘De Havenvinding’, Stevin describes how a compass has a deviation related to true north. He also describes how this deviation is not the same everywhere, it looks like it is dependent on the place on earth. He believes that with the use of these deviations a sailor can find a harbor. He does that by dividing the earth into sections. Each section he then subdivides into eastern deviation and western deviation. With each section having first increasing and later decreasing deviations compared to true north. The start position which he calls the centrum, is the Flemish island Korvo (Currently known as Azores). This starting position can be compared to the current start position Greenwich. A fraction of the measurements notated in ‘De Havenvinding’ can be seen below. In which the last column shows the longitude of the locations.

Figure 2: The deviation compared to true north (Ofleting), the latitude (breede), and the longitude (langde) of some places on earth by Simon Stevin (p.167 of ‘Eertclootschrift’).

In the table, there is not a lot of data from a lot of places especially not around the world. This has a few reasons. First of all Stevin was dependent on others for this data, for example Plancius, but he was also dependent on captains for their data. However, captains at that time did not want to hand over their data, and even sometimes faked the data if they had to hand over some data. Next to that the first time a Dutch fleed sailed around the world was only in 1598. Of the nine ships which started only one of the ships returned in 1601, meaning that data on the deviation of the compass could not yet be known when Stevin published his book ’De Havenvinding’ in 1598.

Maritinal navigation suggested by Stevin

In this era, captains used curved compass needles for short trips to counteract the deviation of truth north. But Prince Maurits wanted to have a systematic approach to the problem. In ‘De Havenvinding’ a method is described for finding a harbor. For

this method, the deviation of the compass needle compared to true north has to be determined. Next, the deviation of true north of the designated harbor needs to be found within the table, such as shown in Figure 2. A ship should sail such that the difference between them becomes smaller until it is eventually the same, at which the destination should have been reached.

But how does one calculate the deviation of the compass compared to true north, in ‘De Havenvinding’ the method of calculating this deviation is discussed. The measurement is done around the time the sun or polestar is at its highest position. At that time it is known where the true north is, due to the position of the sun or polestar. When true north is known, the deviation of the compass can be measured with the compas.

Shortly after publishing ‘De Havenvinding’ there was already criticism about the method, by Aelbert Hendricksz. He published in 1600 a book a bout the art of marine, and how to improve it. He states in his writing that the writer of ‘De Havenvinding’ is incompetent. Currently, it is also known that the measurements of Stevin were inaccurate. In the table in Figure 2, the found longitude is not accurate. The difference with the actual result is rather big. For example, the difference in angle between Corvo (currently called the Azoren) and Amsterdam was according to Stevin 39 30⁄60° while in reality, it is 36 30⁄60°. The difference is even bigger for other locations, like the house at Nova Zembla. It was found to be 23° more east than in the results of Stevin. On the contrary, the results regarding the latitude of the places only have an error of around a quarter of a degree.

Even though the nice ideas of Stevin to guide at sea with the variation of a compass, it was only after 1700 that it could be used for positioning at sea. At that time Edmond Hally did a lot of measurements and made a map of the Atlantic Ocean of the magnetic declination.

Next to the problem of finding the correct longitude, the problem of having an accurate way of measuring the latitude of a ship at sea was only solved in 1765. At that time John Harrison won a price of 20.000 pounds, due to developing a clock which only had a deviation of mere seconds every month, even if it was at sea.

So overall it can be concluded that the findings of Simon Stevin might not have been accurate, but have contributed to the development of navigating at sea to harbors.

Every great adventure begins with a reliable vehicle, but what makes them truly memorable are the stories and names that come with them. Over the years, our Association has owned several rolling treasures, each with a name as unique as their journeys. These aren’t just names picked out of thin air; they re flect a slice of our history, our creativity, and the occasional after-drink fooling around. Let us introduce you to Jean-Pierre, Walter, Chrisje, and Patricia.

WRITTEN BY ILIAS VAN DEN HEUVEL

As some of you might know, the Association owns a cargo bike. This cargo bike is a prominent object within the Association but has unfortunately not been driven for a long time now. The cargo bike we are talking about is of course Jean-Pierre, or JP for short. JP is a cargo bike with a really large container. The bike is powered by a Zundapp engine, and the bike itself is built by the 51st Board. JP was primarily used to buy groceries at the Sligro, as this bike was bought long before our first Association van, Walter. Because of this, JP is made such that it can fit through the bicycle gates at the Sligro. JP used to be even longer than that it is now, but some members fell over a bit too often due to the difficult steering. The bike was gifted during the first GMM of the 52nd Board and was first called ’Jan-Piet’. This name was, however, not up to the new trends and to give the name somewhat ’cachet’, the name was finally changed to ’Jean-Pierre’. About three years ago, Jean-Pierre broke down and after numerous attempts to repair it, the effort was put to a halt. Jean-Pierre does still exist and every GMM where a quarterly financial statement is presented, a picture of the Commissioner of External Affairs cleaning JP is shown.

In openME 54.2, the Land Yachting Committee shared an update on the transformation of their old trailer into a multi-purpose unit for both transporting and storing land yachts. Two years on, the Committee can proudly say they are still very happy with this upgrade. The trailer has proven to be a significant time-saver. Till a few weeks ago, the trailer was always called ‘the trailer’, ‘de aanhanger’, or ‘de zeilwagenwagen’, but an official name was still missing. During one of the meetings of the committee a list of possible names was made. The last entry in the list was ‘Even aan Chris vragen’ (‘Ask Chris’). Chris is a former committee member who did a lot for the Land Yachting committee and the committee wanted his opinion on the name. A meeting later it was decided that instead of asking Chris, we call the trailer ‘Even aan Chris vragen’, or ‘Chrisje’ for short. With this, a new rule was introduced for the committee: if you call Chrisje a trailer, you get punished.

Walter wasn’t just a bus; he was an icon. Purchased during the 59th Board year, Walter was named after the legendary chauffeur from Tijlcars, who drove us across the BeNeLux for countless unforgettable trips. The name was the fruit of a creative brainstorm during a drink on March 24th 2016. Walter served us faithfully, carrying us to all kinds of events with style and reliability (although Walter’s reliability was questionable in later years). Eventually, even legends must retire; after years of loyal service, Walter’s final trip for the Association was made in the 67th Board year. But his name—and memories—live on.

When it was time to replace Walter, creativity once again took the wheel. Enter Patricia, the red beauty named after the Chairman of the 67th Board. After a few glasses of alcohol, he’d transform into a different version of himself: Patricia. The name was chosen in a poll, beating other contenders like Heinz, Kachoow (a nod to the bus’s red color), Rob and Thea. We hope Patricia will bring us just as many stories as Walter once did and that she’ll stay with us for many adventures to come.

Studying at the TU/e can be hard sometimes, since the engineering courses are one of the hardest courses in the Netherlands. This can bring stress, anxiety or restlessness. Or being a woman studying here in a male-dominant University can make you feel unease. Don’t worry, the University cares for you, and there are a lot of places to go to! So don’t sit too long with your questions or discomforts, and ask for help.

WRITTEN BY LUCAS HASELHOFF

When strolling around campus, you might have noticed the Wellbeing Webs hanging on the glass walls of the overpasses between the buildings on the University. These webs give you an insight of all the help available at the TU/e. All of this help is nicely categorised to make it easy for you to know where to go to. But what if your problem doesn’t fit nicely in a box, or what if your problem is too complex for the web, or perhaps you are puzzled by the possibilities of help. No need to worry, the University got you!

Since the beginning of this academic year, the TU/e has launched the Integrity and Social Safety Desk. But what does this desk mean for you? This helpdesk is the central point for your questions, issues and suggestions about integrity and social safety within the University. So how does it work? A confidential advisor will listen to you and you can talk about your question, issue or suggestion. The confidential advisor will always plan a meeting together with you to discus what’s on your mind. Of course, all information you share is kept confidential.

But how to contact them? Easy! You can email them on safe@tue.nl or call them on 040-247 8430. The Desk is available on Monday to Friday between 09:00 and 17:00. When you contact them outside these office hours, they will get back to you typically within 24 hours on working days.

Sometimes, the University can be overwhelming: a big campus, lots of people, tons of teachers and staff. This can all feel quite unsettling. Every so often, you may want to talk to a student who can help you further and knows the University well. For this, the CPS is here for you!

As the name suggests, the CPS are fellow students who can support you with your questions, and all if this will stay confidential. They are trained to help you figure out what the best next steps are and who to contact for support. Whether you just want to chat, want help in contacting a professional, or would like some help with understanding what you can do. They are here for you! They will listen and support you in taking the necessary next steps.

Every Study Association has their own CPS. Within Mechanical Engineering, we have two Confidential Peer Supporters.

Raya Giezenaar is a Master student from Mechanical Engineering and is member of Student Association SSRE.

Noor de Klerk is a Bachelor student from Mechanical Engineering and is active member of the Study association Simon Stevin and member of Sport Association Thêta.

Both are willing to listen to you while going for a nice walk or over a cup of coffee or tea. Don’t hesitate to email Raya on r.w.n.giezenaar@student.tue.nl or Noor on n.d.klerk@student. tue.nl!

The Mechanical Engineering department at the TU/e is committed to creating an inclusive and welcoming environment that values diversity and promotes equity. The department strives to create a community where everyone feels safe, respected, and valued.

The Wellbeing Signal Group (WSG) at ME is there for you for a more inclusive and fair campus environment starting at the department level. You can contact the WSG when experiencing any type of unsafety, diversity issues, or uneasiness about a situation or someone. They will listen to you and, and reach out to the right person to take actions regarding your signal. All of this is done confidentially.

PhD representative

• Toos van Gool: c.e.a.g.v.gool@tue.nl

Master student representative

• Claudia Hanegraaf: c.j.w.a.hanegraaf@student.tue.nl

Master student representative

• Elise van Lieshout: e.m.v.lieshout@student.tue.nl

Bachelor student representative

• Lucas Haselhoff: l.f.p.haselhoff@student.tue.nl

Bachelor student representative

• Raghad Benothman: r.a.o.benothman@student.tue.nl

WSG in general

• WSG: WellbeingSG-ME@tue.nl

Within your studies, you can also face all sorts of problems. This could be personal problems, study-related problems, or you just want to know what the possibilities are within your studies. For these type of questions, you can contact the Academic Advisors.

The Academic Advisors can help you with anything impacting your study progress. Their goal is to ensure you stay on track and make the most of your life at the TU/e, offering guidance and resources to help you overcome obstacles and succeed academically. Most issues they can offer help with, but if not, they can refer you to the right person.

Even if you have questions about making the right choice about specific subject combinations, the difficulty level of the study material, and your educational program. The Academic Advisors can also help you with applying for exemptions and arranging the entrance exam.

Don’t sit too long with uncertainties or questions about your study, but contact the study advisors of your degree!

• Bachelor: me.academic.advisor.bsc@tue.n

• (Pre-)Master: me.academic.advisor.msc@tue.n

• Master SC, AT, SET: academic.advisor.AT.SC.SET@tue.nl

What ended up as a new landyacht started o ff as a simple idea: Can we make a landyacht that fi ts in just about any car? Until now, we have always called upon Chrisje to transport our beloved wind-powered sand racers, but an old friend of mine and me wanted to change this up a bit. As I have personally been a part of the Land Yachting committee for quite a few years now, and had wanted to build my own landyacht for a little while, I would love to take you through the process in which we made this new yacht. We based our design on the ideas of the Land Yachting Committee, but with easier transport , and private use (outside of Land Yachting activities organized by Simon Stevin) as a requirement. What started o ff as a seemingly simple task, turned out to be a beautiful project with lots of unexpected stops along the way.

As our Association already has a wide range of existing landyacht designs, creating a completely new landyacht design from scratch did not seem like a good start. Instead, we decided to modify the design of the landyacht that most closely met our requirements, which are Bobbie and Buizerd. Both of these can already be taken apart into a few pieces, which are relatively easy to transport. The masts consists of a set of aluminum pipes and the rear axles can also be taken out entirely. This means only the body is relatively large for transport. Buizerd’s body is made as a wooden coffin, and Bobbie’s body is a thin steel frame, with a mostly flat seat. So clearly, using Bobbie as our preliminary design would work well. Luckily, the design of Bobbie is nicely documented, so using existing measurements will be a breeze. Breaking Bobbie’s body up into a few pieces should allow it to fit in the trunk of a car. Therefore, if we made the seat detachable using some safety pins, as well as the front wheel fork, the body should be easily transportable.

Next to this, landyacht sails are quite expensive. Just the sail alone would go over the budget we would like to spend for the entire build. We quickly realized that windsurf equipment can be found for a much smaller price, especially second-hand. This does require some modifications to the existing designs, but should be very reasonable. Ideally, the new landyacht would be compatible with the existing small landyachts, so the mast foot dimensions of those were be copied.

With these preparations made, and next to nothing extra drawn out or written down, we decided to start “Beun”-ing this project. For those who do not (yet) know what the Dutch term “Beun” entails, it is probably best defined to: “Improvising, or working on a project in an informal, unconventional matter”.

With the plan somewhat envisioned, the building could begin. As a classic case of ‘Niet Gebeunt is Altijd Mis’ (If you never beun, you will always miss), not much more though was put in before ordering materials and getting to work. The most crucial dimensions were simply measured of Bobbie, and the rest was made with educated guesses. To further save on costs, the body was made of mild steel instead of the usual stainless. This mild steel was then painted with a weather and rust protective black paint, which actually gave the vehicle a classy black and aluminum look, with bright red wheel rims and red and yellow accented sail.

This initial build went quite well. Everything went together on the first attempt, and after just a few days of manual labor, a full landyacht was created. The most difficult part was adapting the existing plans to accommodate the windsurfing sail. In the end, an adapter piece was created, that can fit into the existing mast foot, and to which the mast-extender and carbon mast of the windsurf sail can be connected to.

The obvious next step is to throw some caution to the wind, and take the freshly built landyacht for its very first test drive. Therefore, it was taken on a Land Yachting Weekend to IJmuiden, where we had some setup-issues. Turns out, the initial idea of using the entire mast-extender was a bad idea, as the bottom of the extender wasn’t strong enough to carry the sail. The soft sidewind on the sail made the mast snap of the landyacht before its first drive. Luckily, we were able to use Bobbie’s mast and sail as a temporary replacement, to figure out what else was wrong with our creation. It turned out that there was a lot of play on the steering mechanism, making it very difficult to keep under control. On top of this, a footplate is missing, so if your foot slips of the steering plate, it could get stuck below the landyacht. These were clearly some things to improve on.

The play in the steering mechanism, as well as the front wheel, was almost completely eliminated during a following BEESD (Beun Eet en Stap Dag), a full day in which the Land Yachting Committee will work on the yachts, have dinner and go out. A new adapter for the mast was also made, now being a full steel pipe instead of having some weaker plastic parts in it. On the next few weekends, the yacht was brought and minor adjustments were made. Nonetheless, the overall build was seen as a success.

During the last Land Yachting Midweek, a new problem came up. The wind was much stronger than it had been during any of the earlier drives, now reaching close to 6-7 Beaufort, where 4-5 was the previous record. With this much wind, combined with a sail that is quite large, the mast adapter snapped again. Luckily, there was no damage to any other parts. With a replacement adapter made, from a much thicker steel pipe, this issue was quickly resolved. For safety reasons, a smaller sail was also bought. Luckily, this is a simple replacement, as we can keep using our existing mast and boom. A big upside to using standard non-modified windsurfing equipment for them.

After all these fixes, improvements, and some upgrades, a beast of a landyacht was brought to life. We managed to make a yacht which feels like Bobbie, drives like Buizerd, but has a much faster acceleration than either of them. This is in part because of the windsurfing sail instead of a custom landyacht sail, but also because the yacht is significantly lighter. With the color palette in mind, and the deadly rush of adrenaline you experience when controlling him, we have decided to name this new yacht ‘de Vampier’, which translates to vampire.

Nonetheless, I would not say that there is no more room for improvement. Quite the opposite, there are still some things that can be improved. As a typical Beun project, the Vampier is a perfect example of one of the ever living rules of the Land Yachting committee: Every time something breaks, it shall be replaced with a new mechanism, that is an improvement over the previous. This way, all the landyachts will keep evolving and improving. For this reason, we will keep driving, working on, and most importantly ‘beun’ing our entire fleet for years to come.

WRITTEN BY BEN GORTEMAKER

Despite monumental strides in robotics, achieving the agility and adaptability of animals remains elusive. Machines like those developed by Boston Dynamics amaze us with their ability to walk, run, and jump, but their performance in dynamic environments pales in comparison to that of living creatures. Animals, shaped by millions of years of evolution, exhibit unparalleled abilities to navigate complex terrains, respond instantaneously to stimuli, and conserve energy efficiently. Robots, in contrast, excel in controlled environments but struggle with unpredictability. While individual robotic components often surpass their biological counterparts in power or precision, the seamless integration seen in nature continues to evade engineers.

At first glance, robotic systems seem poised to outperform biological ones. Modern actuators, for example, can deliver immense power, and sensors can detect minute environmental changes with incredible precision. Yet, when these systems are combined, they fail to replicate the fluidity and efficiency seen in animals. In this article, we will break down where this comes from.

At the core of this disparity lies the extraordinary coordination within biological systems. Animals integrate their physical structures—such as muscles, tendons, and bones—with a sophisticated nervous system to perform tasks with remarkable fluidity. This interplay allows them to adapt to environmental changes in real time, optimize energy usage, and maintain stability under challenging conditions. For instance, a cheetah sprinting at top speed can instantaneously adjust its stride to avoid obstacles, a feat achieved through a tightly coupled feedback loop between its many sensory and motor systems. Robots, on the other hand, lack this level of cohesion. Their smaller amount of sensors, actuators, and processors often operate as discrete units, leading to slower reactions and less efficient movements.

One area where the gap between animals and robots is most apparent is energy efficiency. Nature’s designs are marvels of conservation. Consider tendons, which act as biological springs. When an animal runs, its tendons store elastic energy during each step and release it to propel the next movement, significantly reducing the energy cost. This efficiency allows creatures like gazelles to sustain high speeds over long distances without quickly depleting their energy reserves. Robots, in contrast, rely on motors and batteries that lack

comparable mechanisms. Even the most advanced robots, burdened by heavy power sources, consume significantly more energy than animals to achieve similar tasks. While researchers are exploring alternative energy systems like hydrogen fuel cells and capacitors, mimicking the effortless energy recycling found in nature remains a formidable challenge.

Sensory systems further underscore the gap between robots and animals. Biological organisms process sensory input with astonishing speed and precision. A bird, for example, can instantly adjust its wings to navigate turbulent air currents, and a cat’s whiskers provide critical tactile feedback for moving through narrow spaces. The speed and amount of integration of sensory and motor responses allow animals to thrive in unpredictable environments. Robots, despite their advanced sensors capable of detecting minute environmental changes, struggle with processing and responding to this data in realtime. The latency between sensing and action often renders

robots inefficient or ineffective in dynamic settings. Advances in artificial intelligence, particularly machine learning, have improved robots’ ability to interpret sensory data, but these systems still lack the intuition and fluidity of biological control systems.

The durability and adaptability of animals further highlight the limitations of current robotics. Biological systems are not only robust but also self-healing. When injured, animals can often recover and continue functioning, a capability that extends their lifespan and utility. Robots, however, are far less forgiving. A damaged joint or sensor might render a machine inoperative until repaired or replaced, which often requires human intervention. The development of self-healing materials, inspired by biological tissues, represents a promising avenue in robotics. However, these materials are still in their infancy and far from being implemented in practical systems.

In recent years, bio-inspired design has emerged as a promising approach to bridging the gap between animals and robots. Engineers are no longer merely attempting to replicate specific animal functions but are studying the underlying principles that enable those functions. Soft robotics, for instance, uses flexible materials like hydrogels and elastomers to mimic the elasticity and adaptability of biological tissues. Unlike rigid robots, soft robots can deform and adapt to their environment, allowing for more natural and efficient movement. Researchers have even developed robotic legs that emulate the spring-like behavior of tendons, significantly enhancing energy efficiency and agility.

Control systems are another area where nature offers valuable lessons. Traditional robotic systems rely on preprogrammed instructions or reactive algorithms that are illsuited for complex and unpredictable environments. Advances in artificial intelligence, particularly deep reinforcement learning, are enabling robots to learn and adapt in ways that more closely resemble biological evolution. By simulating the trial-and-error processes seen in nature, these systems allow robots to optimize their movements over time. For example, robots trained using reinforcement learning can develop locomotion strategies that are both efficient and adaptable, enabling them to navigate unfamiliar terrains with greater competence.

The practical applications of robots with animal-like capabilities are vast and transformative. In disaster response, agile robots could navigate rubble and debris to assist in searchand-rescue missions, reaching areas inaccessible to wheeled or tracked vehicles. Their ability to adapt to uneven terrain and tight spaces could save countless lives in the aftermath of earthquakes, landslides, and other natural disasters. In logistics, robots with running capabilities could revolutionize last-mile delivery, overcoming obstacles like stairs and narrow hallways in urban environments designed for humans. These

robots could ensure faster and more reliable deliveries, particularly in densely populated areas.

Exploration represents another exciting frontier. Robots that mimic the movement patterns of animals could traverse challenging terrains, from dense forests to rocky mountain slopes. In space exploration, such robots could play a critical role in missions to Mars or other celestial bodies, where conditions are unpredictable and traditional machines may falter. Their ability to adapt to unfamiliar environments would make them invaluable tools for scientific discovery. In healthcare, bio-inspired designs are transforming prosthetics and exoskeletons, offering greater mobility and comfort to individuals with disabilities. These devices, modeled after the natural movements of limbs, provide users with enhanced functionality and a better quality of life.

The question is not whether robots will catch up but when— and the answer lies in how well we can learn from the greatest engineer of all: nature. Every day inovovations are made in robotics that bring us closer to machines that can truly rival the capabilities of living creatures.

Since May 3rd, 2024, our Association has acquired a beautiful new vehicle. Since May 3rd, 2024, our Association has acquired a beautiful new vehicle: Patricia. A replacement for the well-known Association van ‘Walter’. This Tornado Red Volkswagen Transporter Kombi Trendline has become the new workhorse of the Association, transporting goods, people and even landyachts all around Europe!

WRITTEN BY STEFAN GEERTS

The search for a new van started at the end of 2023. At this point, it was clear that the previous van (Walter), was not going to survive for much longer. A financial plan for buying a new van was made well before already. However, since Walter was still operational, it was never implemented. When the search started, with the help of the it quickly became clear that the budget requirements were set a long time ago. With the upcoming environmental restrictions in and around Eindhoven and the strict demands for the trailer and number of seats, only a small number of vans were fit for our perfect van.

A big discussion in the search for a van was the difference between a manual or automatic transmission. When driving with a trailer, a manual transmission could be better for control and driving around the beach. However, an automatic transmission would make for more comfortable driving for longer distances.

Furthermore, the height of the van was a point of concern. Walter had an extended height that made it more fit when loading large amounts of luggage. However, it also meant that it did not fit in regular parking garages which are essential for international trips.

The red colour has a great story. The van was previously owned and used by the fire department. Even though it was stripped before being decommissioned, you can still find some remaining details inside and outside. For example, the dashboard is still equipped with the buttons for sirens or light signals, as well as the hole in the roof for the lightbar. These buttons can be used in the future for controlling suitable interior lighting.

The new van has several improvements over the old van. For a start, the speedometer works all the time instead of sometimes. Furthermore, the odometer tracks all kilometres again which greatly simplifies the tracking of driven kilometres for driving contracts. The van has a built-in Bluetooth connection to directly stream media from your phone and all doors open reliably.

As mentioned before, it is lower which makes the van fit in all types of parking garages and low passes. And I didn’t even mention the smooth DSG transmission and the cruise control that works with a usable button.

As with the previous van, we hope Patricia will live a long and happy life in service of the Association. With its short time in the hands of the ME-ers from our Association, it is still mostly stock.

However, new lights to boost the atmosphere and a sound kit for the back of the van can be bought in the future. It has already proven itself in multiple landyachting weekends. 140 PK

7 gears DSG automatic transmission 172 km/h 1876 kg 9 pers.

Electric and hybrid vehicle Electric and vehicle powertrain design ( powertrain (4AUBAUB1010)

19%

5 ECTS 5 ECTS

6.4

15%

Structure and Structure properties of materials properties of materials (4 M MAA0000)

5 ECTS 5 ECTS

6.8

8%

75.7 (out of 140)

Feedback:

• The students liked the freedom of the project.

• The description of assignment could be clearer for the students.

• The students would have liked to see more study material.

Improvements by the teacher:

• The teacher is going to look into how to connect the project better to the written exam.

89.6 (out of 140)

Feedback:

• The amount of practical examples during the lectures was liked by the students.

• Students would have liked to see more extensive exam solutions.

• The students do think that the lectures were too fast paced.

Improvements by the teacher:

• The teacher will reconsider the availability of previous exams and their answers.

Note that all the response rates are insufficient. This means that too little students filled in the course survey. In case the response is too low, the representativeness of the results should be questioned. So please fill in these Course Surveys! This is a easy way of improving the quality of education.

*1 = % of student who filled in the survey

*2 = Average grade for the course given by students

*3 = Average spent time on the course in hours

Advanced discretization techniques (4 E EMM6060)

5 ECTS 5 ECTS

9.0

95.2 (out of 140)

Feedback:

• The students liked the interaction with the teachers.

• The oral examination was not representative.

• The course content was to the liking of the students.

Improvements by the teacher:

• The timeslots for the CBL and selfstudy sessions are swapped.

• Continue to develop the CBL assignments to improve their alignment with the study material.

Best Teacher Score Best Score

Hydraulic turbomachines turbomachines (4BM10)

5 ECTS 5 ECTS

7.0

89.8 (out of 140)

Feedback:

• The topic in general is very interesting, according to the students.

• The students comment that the handwritten slides are hard to read.

• More practice exams would be helpful for the students.

IImprovements by the teacher:

• The teacher intents to type out the slides for next year.

Assistant professor: Stein Stoter Advanced discretization techniques

9.8

Hi there! I am Ruth, and I am currently part of the Board of Stichting Wervingsdagen Technische Universiteit Eindhoven. For the people who are not familiar with us, Wervingsdagen is an annual series of career-focused events held right here at the TU Eindhoven. Our mission? Helping students connect with di fferent companies , sharpening their professional skills, and preparing them for life after the university. Let me give you a quick overview of what we do!

First up, the Skill Sessions. Each year, we organize workshops where professionals help us work on essential skills, this year 56 in total. The workshops differ from technical training to soft skills like pitching or negotiation. This year’s theme is Career Under Construction, emphasizing that building a career is about steady, step-by-step progress. Whether you’re in your first year or wrapping up your master’s, Skill Sessions offer something for everyone.

Then there is the Career Expo. Auditorium and Atlas are packed with booths from top companies, all here to meet students like us. Taking place over two days in March, this year on the 11th and 12th March. This is our biggest event of the year, with companies like ASML, Philips and TNO. This is the ultimate opportunity to explore different industries, have a chat with recruiters, or find out what companies are looking for.

After our Career Expo, we wrap things up with the Interviewing Days. Here you can have one-on-one interviews with companies you are interested in. It’s where networking can turn into real internships or job offers! The Interviewing Days help make the leap from university to the professional world feel easier, giving students a real taste of what’s next.

We do not only focus on career fairs and workshops. At Wervingsdagen, we also believe in having a good time! Sometimes, you’ll see us sponsoring a party or sports event. We are here to support student life in every way we can.

Being on the board has been an incredible experience so far. While organizing these events you gain experience in event planning, collaborating with professionals, and working in a team. Each event has its own challenges, but that only makes it more rewarding. It is great to see everything come together and create events that are beneficial for students.

So, whether you are a first-year discovering all your options or about to graduate, Wervingsdagen has something for everyone.

WRITTEN BY JANKATIRI BOON MONTOYA

“Qua Patet Orbis”. That is how the Latin motto of “Het Korps Mariniers” reads, which was established on December 10, 1665. This roughly translates to “As far as the world reaches”, indicating the vast area of operations that the Marine Corps encompasses. Given that this corps is one of the oldest ones in the world, it can be expected that it brings its own rich history and traditions. Interestingly, this section comprising amphibious combatants of the Dutch defense is not its own service branch, since it is officially part of the Dutch Marine.

The journey to Chatham

During the 17th century, also known as the golden age in Dutch history, tension was building between the British Empire and the Republic of the Seven United Netherlands, which led to the 2nd Anglo-Dutch wars. The main reason was that the Dutch Republic was growing into a global economic and political superpower, mainly due to the international influence of the “Vereenigde Oostindische Compagnie”1, or VOC.

The peace talks between both parties were severely delayed by King Charles II, which angered the “Raadpensionaris”2 Johan de Witt. It was found out that the British were forced to reduce the size of their fleet, due to economic reasons. For its decommission and sale, the fleet was stationed in Chatham. This intel prompted Johan to authorize a military operation to sabotage the fleet in order to gain a negotiation advantage and to force peace.

To lead this mission to success, a regiment of infantry would be appointed to the Dutch Marine, on the initiative of Johan de Witt and Michiel de Ruyter. This would be the creation of the Dutch Marine Corps. Before the regiment entered the river Thames, the officers on board the boat “De Zeven Provinciën” advised against the plan. The mission continued under the guidance of Cornelis de Witt (brother of Johan).

A chain was hung over the river to block entry of the ships, but this protection was no challenge for the Dutch. In the end, the marines entered Chatham, under the leadership of Willem Joseph van Ghent3, and destroyed the British fleet and even captured the British flagship the HMS “Royal Charles”! This crippled the British navy, resulting in a glorious victory for the Dutch leading to peace. The Dutch Marine Corps would be part of the history books now.

In modern days, the marines have had a worldwide impact for different purposes. Not only during World War 2, but also afterward. A notable event in 1970 was called “Het schoonvegen van de Dam”, where a delegation of marines and sailors took it upon themselves to remove the Dam square of hippies who had stationed themselves on the Amsterdam war memorial monument. Since this was not a command, but an action of their own initiative, the corps received mixed commentary from the public. Partly due to this, the survival of the corps as a whole would be in danger. As a result, a new division would be added which would have arctic specializations. And with that, the “Whiskey Compagnie”, was founded in 1972 and the continuation of the Marine Corps was guaranteed.

The Marines have served during a multitude of humanitarian missions globally, also under the UN. In these missions, the key mission is peacekeeping, conflict resolution, and humanitarian assistance. These missions aim to stabilize regions affected by conflict, support peaceful transitions, protect civilians, and provide essential services in the aftermath of crises. Some countries where such missions took place were:

• Cambodia (UNTAC, ‘92-’93)

• Yugoslavia (UNPROFOR, ‘92-‘95)

• Haiti (UNMIH, ‘93-‘96)

• Eritrea (UNMEE, ‘00-‘08)

• Mali (MINUSMA, ‘13-‘23)

• And many more…

The reason why the Dutch Marine Corps is often sent first is because they can be deployed anywhere in the world within 48 hours. They can quickly drop small units somewhere that can operate for the first few weeks without assistance. After that, the duties of the Marines can be relieved by forces from the army, airforce, or navy.

To highlight a mission, we can take a closer look at UNTAC in Cambodia. Starting in the early 60’s, a communist military dissident group later named the Khmer Rouge staged a coup d’etat. Its infamous leader, Pol Pot, unleashed a reign of terror with a final death toll of between 1.5 and 2 million people. This genocide was caused by social engineering policies, a failed collective agricultural reform, and insistence on self-sufficiency when that was not possible. Eventually, Cambodia was invaded by Vietnam and the Khmer Rouge was driven out. A civil war continued for a while but eventually led to a cease-fire. The UN then deployed after which the UN began conducting two peacekeeping missions: UNAMIC and UNTAC. UNAMIC’s main tasks were to monitor the cease-fire and mine vital areas. UNTAC was to oversee the return of refugees, disarm the armed groups, and organize free elections. In the end, both missions were successful.

The reasons why these conflicts happen where UN missions are deemed necessary can be very complex. What is absolute is that the affected suffer tragic losses, but it is a warming thought to know that there are always people who are ready to aid those in need.

Once a marine, always a marine.

Since the Dutch Marine Corps is over 350 years old, it is sure to have some traditions within its organization. For example, when a marine crosses the equator by boat for the first time, he has to take part in the Neptune ritual. Parallel to student culture, this also served as hazing. These trials used to be quite rough in character, but today they have been somewhat curtailed.

The influence of the VOC is also hard to miss at the Marines Corps. Where Malaysian and Indonesian words (pendek, spatoes, tempo dulu) have become part of their vocabulary, a marine also has a deep love for their weekly “blauwe hap”, or Indonesian cuisine. The motto, as mentioned in the introduction, is the anthem for every marine.

But also three other keywords are very important. The three Corps values are Verbondenheid (Connection), Kracht (Power), and Toewijding (Commitment). These Corps values do not stand alone but are interconnected and reinforce each other. They emerge during education, training, and deployment. These three Corps values, with their underlying traits, together generate the pride that every Marine feels to be part of the Marine Corps. Because: “Eens marinier, is altijd marinier”. QPO.

1. The Dutch East India Company, abbreviated in Dutch as VOC, which had a monopoly on the asian spice trade.

2. In the historical context this basically translates to Prime Minster.

3. He would become the first commander of the Marine Corps and the Marine training barracks in Rotterdam would be named after him.

Boon being carried by his class into the waterpit done as a sign of respect and gratitude for leading the class.

WRITTEN BY BEN GORTEMAKER

To give their last goodbye, the members leaving the Extraordinary Activities Committee (BACo) decided to draft BACo in a special manner: straight from the tap!

This faster and more efficient way of giving our members our favorite mixed drink, was so popular the keg was empty within 90 minutes. Due to this popularity we would like to share with you the way the keg of BACo was made. Thus, if you ever find yourself in a situation where you are in need of a keg filled with anything, you now know how!

1. Obtain an empty keg

The first thing we need is an empty keg to fill. This might prove to be difficult because most kegs you can buy come filled. This means that in some way you need to empty the content of this keg, you can do this any way you desire.

2. Depressurize the keg

After the keg is emptied, it is likely still pressurized with CO2. Grab a coupling and place the end of the beer tube in the drain, attach the coupling and let the rest of the contents of the keg run out.

3. Setup

To empty and fill the keg with our desired liquid, we first need to remove the one-way valve that is placed within the coupling of the keg. After this, we can attach the pump, one that can either blow or suck air, to the gas input of the keg. Then by placing the beer tube in the drain or a liquid, we can fill the keg by sucking the air out of it. Vice versa the keg can be emptied by pumping air into it.

4. Cleaning the keg

Before the keg is filled with BACo it first needs to be cleaned, such that the taste of the previous beer does not contaminate the taste of BACo. To do this we first fill the keg with water by placing the beer line in the sink filled with water and sucking

it in. Then shake it around such that the inside is cleaned, and then push the water out again. Repeat until there is no taste of beer left in the water.

5. Fill the keg with C02

The next step before filling the keg with BACo is filling it with CO2. This step is we did not originally take, but recommend to do, because it will result in a less flat BACo. By attaching the coupling back to the original draft setup, the keg can be completely filled with CO2, such that when the keg is pressured, CO2 can saturate the liquid, this results fizzy nature of beer and soda.

6. Fill the keg

Then it is finally time to fill the keg. We go back to the setup with the pump, and place the beer line in a pitcher. The pitcher is continuously filled with the ingredients of BACO whilst it is sucked into the keg using the pump. After it is filled attach it again to the drafting setup to pressurize the keg one last time, such that it will be fizzy when it is time to consume the keg.

7. The last step of course is to enjoy the BACo you drafted. With the efficiency it can be made using a keg, it best to enjoy it together with everyone!

In Kirlian photography, the object to be photographed is placed on a photographic plate or film that’s connected to a highvoltage source. When voltage is applied, an electric field is generated around the object, ionizing the air around it and creating a visible discharge. This discharge appears as a colorful, often ghostly glow surrounding the object on the photographic plate.

The colors and shapes of the glow depend on various factors, such as:

• Moisture levels: Objects with higher moisture content, like living plants or human hands, create brighter and more complex auras due to better conductivity.

• Pressure and Temperature: Environmental conditions can change the appearance of the discharge.

• Material Properties: Different conductive properties of materials will affect the way the corona discharge forms around them.

It is named after Soviet scientist Semyon Kirlian, who, in 1939, accidentally discovered that if an object on a photographic plate is connected to a high-voltage source, an image is produced on the photographic plate.

WRITTEN BY ANASTASIA GHLIGHVASHVILI

While Artificial Intelligence has only recently entered the Zeitgeist, its existence dates back to the early 1900s. For the past century, many writers, filmmakers, and creatives have incorporated the idea of AI in their works. As early as 1818, Mary Shelley depicted a scientist who creates a sentient being from assembled body parts in her novel, Frankenstein (Hel P, 2022). Frankenstein is a pillar in the horror genre and emphasises the view of the general public in regards to artificial machines with human characteristics. Further down the line, Stanley Kubrick’s “2001: A Space Odyssey”, inspired by Arthur C. Clarke’s 1951 short story “The Sentinel”, depicts a human-like computer messing with the lives of the characters. This depiction was far more positive but still imbedded the viewer with the overwhelming sense that the power of the rogue AI was beyond the scope of their understanding. More modern interpretations of AI in media have been closer to what we have come to associate it with, such as in films like Jonze’s “Her” (2013) and Spielberg’s “AI: Artificial Intelligence” (2001).

AI’s presence in pop culture has skyrocketed in the past few years with exponential developments in technology allowing the everyday person unabridged access to AI machines such as ChatGPT, and with many apps incorporating new AI features. With many trends created on the basis of AI templates generating images and texts, the use of artificial intelligence has never been higher. Additionally, with AI’s growing influence on academia, with many students using it as assistance for their homework, essays, or coding assignments, AI is more prevalent than ever before. But with this casual use of AI comes a budding concern: what is artificial intelligence doing to our planet?

AI’s biggest sin is its carbon footprint. Most large-scale AI deployments are housed in data centres which house electronics such as 2 kg computers that require 800 kg of raw materials per computer to produce. Since 2012, the amount of computing power required to train cutting-edge AI models has doubled every 3.4 months, with the ICT industry expected to reach 14% of global emissions by 2040. The training of AI models produces upwards of 600,000 pounds of CO2. It is expected that the energy consumption of AI could match the energy consumption of countries such as Belgium and Ireland by 2026. Additionally, the microchips that power AI need rare earth elements, which are often mined in environmentally destructive ways (UN Environment Programme, 2024). The EU plans to account for 20% of global chip production by 2030, increasing the sector’s environmental impact by 400-500%. While transportation and end use account for some of that jump, most of the emissions linked to the lifecycle of electronic products come from the manufacturing phase (Newton & Newton, 2024).

Data centres also lead to the production of electronic waste in the form of mercury and lead. This can contaminate the soil and water of the surrounding area and endanger the ecosystem. By

2050, the World Economic Forum (WEF) projects that the total amount of waste generated will have surpassed 120 million metric tonnes (Kanungo, 2023).

Another major concern for the budding environmental apocalypse is AI’s water consumption. Water is used in AI development for onsite cooling and offsite electricity generation. AI servers’ consume massive amounts of energy, which leads to the generation of heat, which then must be dissipated in the outside environment. To accomplish this, most data centres use cooling towers which require water to be evaporated to produce cold water. This means that in order to keep the desired temperature and avoid overheating of the chip, copious amounts of clean water is wasted (Ren, 2023). To put AI’s use of water into perspective, asking ChatGPT-3 10 to 50 questions consumes 500 millilitres of fresh water. Additionally, AI chip manufacturing requires about 2,200 gallons of water. Training the AI model also requires water evaporation.

Another key aspect of AI’s environmental impact is its uneven distribution of consequences for different regions. In 2022, Google operated its data centre in Finland on 97% carbonfree energy. Comparatively, for its data centres in Asia, that number drops to 4–18%. Similarly, the water consumption is much heavier for regions with already existing water-stress like Arizona or Chile. This increases the grid congestion, leading to increased prices for electricity for locals.

However, with all this being said, AI has the power to reduce humanity’s impact on the environment. AI helps smart grids adapt to real-time changes in electrical supply and demand to prevent wasted power. Similarly, factories can use AI-enabled HVAC solutions to sustain production while using as little energy as possible. This can lead to a reduction in greenhouse gas emission by 4% in the next 5 years (Newton & Newton, 2024). In the same vein, AI can reduce household CO2 emissions by 40% with the integration of smart homes. Other potential benefits for utilising AI as a planet-saving tool include efficient ways to make digital tech, efficient flight routines for major airlines, reduce transport waste and so on. For example, UNEP uses AI to detect when oil and gas installations vent methane.

Currently, legislation is being implemented to reduce AI’s impact on the environment. This includes establishing procedures to measure the impact of AI, companies disclosing their personal environmental impact, tech companies increasing the efficiency of their AI models, and the implementation of green data centres. The latter entails chipmakers transitioning from the use of fossil fuels to green energy. Patterson’s analysis predicts that AI’s carbon footprint will soon plateau and then begin to shrink (Berreby, 2024). However, it is up to the government, the legislators, businesses, and everyday people to ensure that AI’s abilities to reduce negative environmental impact are being utilised and implemented.

On the last summery September day of the year 2016, a very familiar vehicle to us was tested. Most likely one of the few vehicles that even gets to have its own name. You guessed it, this time our very own Walter was put to the test. Maybe not the fastest car, but certainly a fine addition to our Association.

LoesvandenBeuken&LinusKlaassen

The Association van has four key aspects on which it must perform well. These were the areas we tested: exterior, interior, driving experience, and loading capacity.

Exterior and Interior

Walter looks solid both on the outside and the inside. The bus is clearly in good condition and is neatly decorated with stickers. However, even before departure, we were made aware of a small occasional defect with the driverside window. Other than that, everything seemed in order.

At first glance, a few things immediately caught our attention. For example, the gear stick is extremely long. And no, not just a little long: we estimate its length to be somewhere between twoand-a-half and three-and-a-half meters. Additionally, we noticed that all the seats, except for the driver’s seat, are not adjustable.

The air conditioning seemed almost essential in these summery temperatures. However, there was a significant difference between the various air conditioning settings. While setting 2 wasn’t cool enough, setting 3 provided an overly cold breeze. Opening the window turned out to be a better alternative.

SpecificationsWalter

Motor1998cc4-cylinderDiesel

Power92kW(125pk)

Drivefrontwheel Topspeed160-170km/h

Consumption13.2km/liter

Newprice±€40.000

Seats9

Well, time for a test drive. We were both immediately impressed by the excellent road visibility you get from the club vehicle. Even through the rearview mirror, you can keep an unexpectedly good eye on the traffic behind you—assuming, of course, that the cargo space is clear.

We decided to head toward ASML to take a nice photo of this gem sponsored by them. The clutch feels quite heavy, as does shifting gears itself. After shifting, we occasionally doubted whether Walter was in the correct gear, though in 100 percent of cases, he turned out to be.

With 92 kW of power, Walter accelerates surprisingly strongly. Using an improvised measurement, we recorded an acceleration from 0 to 50 kilometers per hour in 3 seconds. Unfortunately, the Dutch roads didn’t allow us to measure up to 100 kilometers per hour.

The bus drives smoothly at speeds up to 120 kilometers per hour, and at this speed, there is no noticeable trouble with gusts of wind or noise inside the vehicle. Whether Walter, like many vans, is sensitive to crosswinds couldn’t be tested due to the pleasant late-summer weather.

When we arrived at ASML, we were both a little taken aback. While the TU/e campus is practically flooded with ASML logos on every notebook, poster, or mug, they were surprisingly scarce at their own complex. We continued our journey to the High Tech Campus.

Walter offers seating for no fewer than 9 people. Additionally, the van already has a fairly large cargo area. This space can be expanded to approximately 1.4 by 1.4 by 3 meters if the rear 6 seats are removed. Since the amount of beer and golf balls Walter can transport is crucial for the final evaluation, we attempted to estimate these capacities.

If the van is completely empty, except for the front seats, the total volume is 7,440 liters. This equals 248 beer crates, each containing 24 bottles. With a single load, Walter can therefore provide nearly 6,000 people with a beer!

The calculations for golf balls are a bit more complex. Here, we refreshed our knowledge from the course Structure and Properties of Materials. To estimate the volume taken up by golf balls, we assume they form a lattice with the highest possible Atomic Packing Factor (0.76). Based on this assumption, Walter’s loadable space can fit a staggering 138,997 golf balls.

Walter is a highly practical addition to our Association and also drives very smoothly. It can transport both a large number of people and a significant amount of cargo.

After five years of research, the restoration of De Nachtwacht has begun. Conservators at the Rijksmuseum are carefully removing the aged varnish from Rembrandt’s masterpiece to preserve it for future generations. This delicate work is conducted with microscopic precision in a specially designed glass chamber, allowing visitors to watch the process live. The whole process is called operation nachtwacht and this article will give you the insights of this operation.

WRITTEN BY RIXT HOFMAN

Over the past five years, a large team of conservators, restorers and scientists have studied The Nachtwacht using the most advanced techniques, from digital imaging to scientific and material-technical research and from computer science to artificial intelligence. This has led to several breakthroughs in knowledge about and the state of the painting, and the artist’s work process.

Launched in July 2019, Operatie Nachtwacht is an unprecedented, multi-phase restoration e ffort. What sets it apart is not just its scale but also its transparency: the entire process is conducted in full view of the public. A specially designed glass chamber in the Rijksmuseum’s Gallery of Honour allows visitors to witness the intricate work being performed, fostering a deeper connection between the audience and this iconic masterpiece. Taco Dibbits, General Director of the Rijksmuseum, emphasized this openness, stating, “We want to show the world how we care for our greatest treasure. This is about protecting our past for future generations.”

Before restoration began, The Nachtwacht was temporarily removed from its original position, providing a rare opportunity to study the painting’s canvas support. Though often overlooked, the canvas is the foundation of any artwork, and its stability is crucial for long-term preservation. Using shearography, an optical technique that detects delamination

between layers, professionals judged the condition of the original and lining canvases. Small samples of wax resin and fibers were also tested to determine their strength. Preliminary findings suggest the lining is in good condition, but ongoing research ensures that any potential issues are addressed.

The term wear and tear describes one of the aspects that determine the current condition of The Nachtwacht. Wear and tear means that original paint has disappeared, literally worn off, sometimes even down to the canvas threads. The cause of this was often the incorrect application of (unsuitable) restoration materials during the many treatments that the painting has undergone in the past.

CocqJan van der Heede

Dark areas of paint are often extra sensitive to overly aggressive restoration materials, which is why they are generally more worn than lighter areas of paint. In The Nachtwacht, Banninck Cocq’s black costume is a clear example of this. In many places, the paint is worn down to the brown primer underneath, which makes the modelling of the fabric di fficult to read.