“Evolutionary”

OCTOBER 7TH

JAARBEURS, UTRECHT

10:00-17:00

• Lectures • Cases

• Workshops

• Company market

“Evolutionary”

OCTOBER 7TH

JAARBEURS, UTRECHT

10:00-17:00

• Lectures • Cases

• Workshops

• Company market

Dear Reader,

As the summer holiday draws near, we’re gearing up for the nal push of this academic year. Each exam, project, and assignment carries more weight, shaping the memories of this academic year.

With the new academic year on the horizon, changes are abound. Whether you’re charting a new course of study or transitioning into professional life, change is inevitable. In this edition of openME, we explore the upcoming transformations within Eindhoven, the TU/e, and Mechanical Engineering. But before we look forward, let’s take a moment to understand the past, diving into the rich history of student life in Eindhoven.

Within these pages, you’ll nd insights into the new master track in Mechanical Engineering, Robotics, a glimpse into the history of the Multiped Robot CBL, updates on construction projects on campus, and intriguing projects by student teams in Eindhoven. Furthermore, you can read about internships abroad, Bachelor nal projects and even a Master esis.

May this edition provide you with valuable insights as you navigate the evolving landscape of our eld.

Wishing you an enlightening and forward-looking reading experience as we evolve together.

With kind regards,

Stefan Geerts

Editor-in-Chief

June 2024, volume 55, issue 3

The ‘openME’ is a publication by the study Association for Mechanical Engineering Simon Stevin of the Eindhoven University of Technology

Editor-in-Chief

Stefan Geerts

Design

Maartje Borst, Rik Lubbers, Roelof Mestriner, Joel Peeters, Lex Verberne

Layout

Jasper Bekkers. Stefan Geerts, Ben Gortemaker, Aryan Bakermans, Daniel Kleinjan

Editorial committee

Aryan Bakermans, Jasper Bekkers. Stefan Geerts, Anastasia Ghlighvashvili, Imke Goofers, Ben Gortemaker, Daniël Kleinjan, Aditya Shekhar, Tom Slangen

Illustrations and Pictures

Editorial committee, Photo committee, source stated otherwise

Printing o ce

Drukkerij Snep

Circulation

800 pieces

Contact

Eindhoven University of Technology

Traverse 0.34

Den Dolech 2 5612AZ Eindhoven

Post office box 513

E-mail: redactie@simonstevin.tue.nl

Homepage: simonstev.in

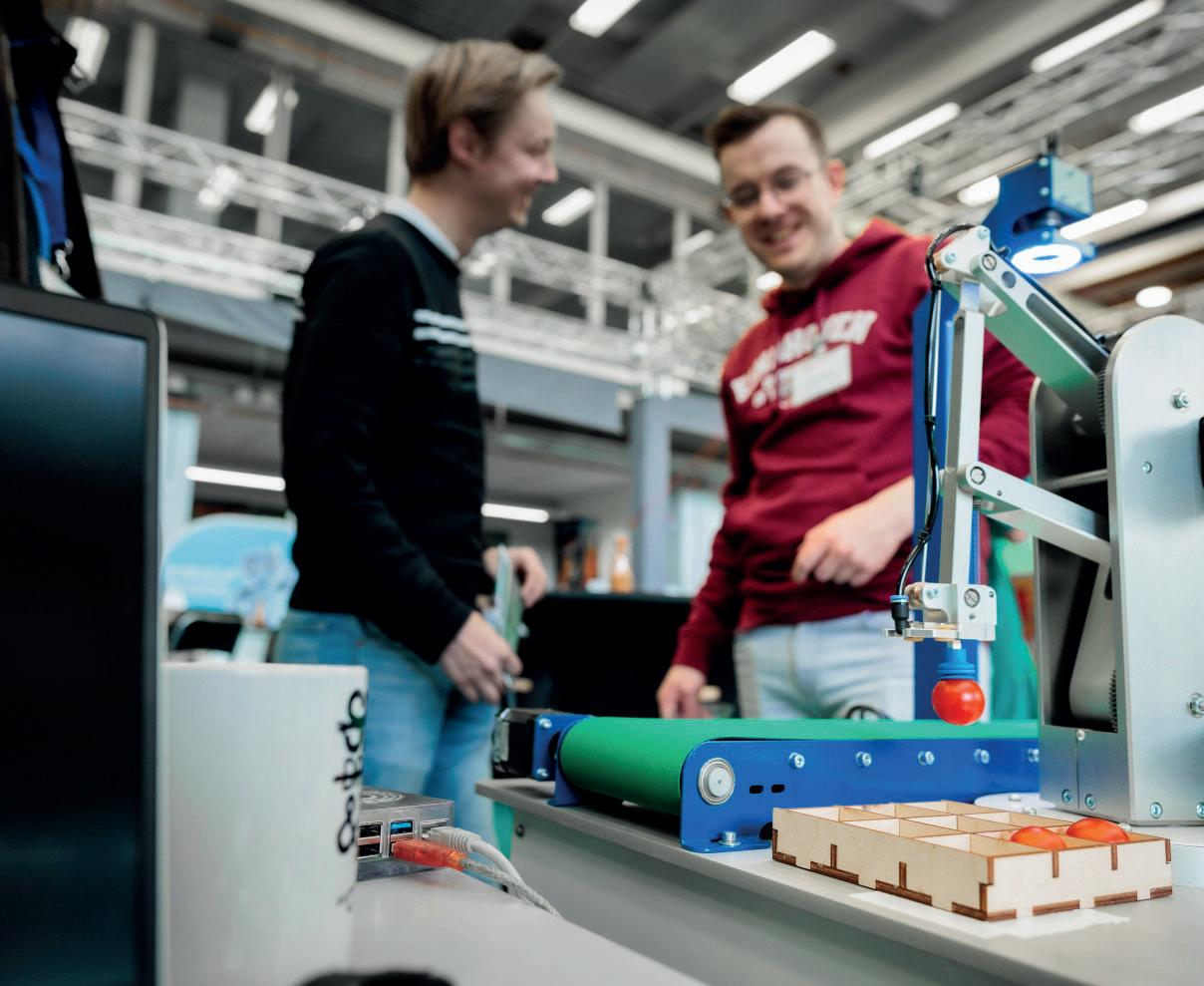

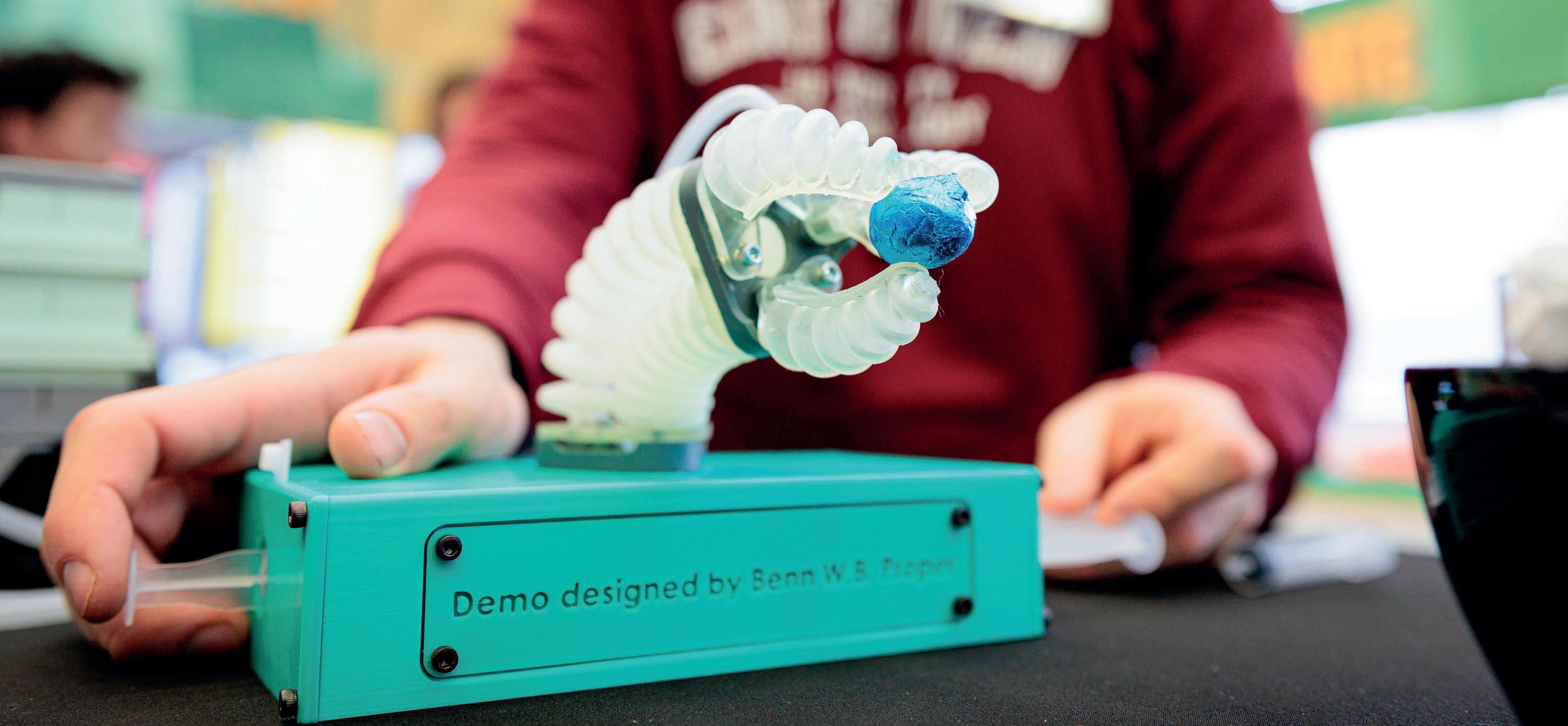

The Mechanical Engineering Department at TU Eindhoven is excited to announce the launch of a new Master’s track in Robotics. This development is a signi cant milestone, building on 35 years of expertise in robotics education under di erent guises, and now establishing a dedicated and clearly de ned program. René van de Molengraft, chair of the Robotics Division, shared insights into this new track and what it brings to the table for both Dutch and international students.

WRITTEN BY STEFAN GEERTS

Integrating CST and D&C into Robotics

Historically, students interested in robotics at TU/e would nd their niche through courses in Control Systems Technology (CST) and Dynamics and Control (D&C). These courses laid a robust foundation, o ering internships and projects that steered students towards robotics, albeit under a di erent banner. Van de Molengraft explains, “By clearly labelling our program as ‘Robotics,’ we hope to attract more students speci cally interested in this eld. The new track encompasses courses on mobile robots, haptics, and soft robots, integrating the control courses from CST which form the backbone of this study.”

The program aims to expand further in the coming years, incorporating more robotics-speci c courses on cutting-edge topics like Arti cial Intelligence (AI). This focused curriculum ensures that students are well-equipped to meet the industry’s evolving demands.

Establishing a new Master track is a considerable endeavour. Van de Molengraft, who has spent the majority of his career with CST, re ects on the journey. “In 2005, we started participating

in robotics competitions, and since then, interest and projects in robotics have surged. Over time, smaller robotics groups formed within D&C and CST. Last year, we began exploring the potential of creating a separate section dedicated to robotics. With approximately 50-70 individuals involved, it was crucial to make this development public.”

What sets the Robotics track apart from CST and D&C is its focus on enabling robots to navigate and operate within variable and less controlled environments. Van de Molengraft emphasizes, “The goal is to teach robots to handle the world’s variations, a signi cant challenge compared to controlled environments like ASML’s wafer machines. The emphasis is not on metric precision but on robustness and autonomy—getting robots to execute tasks independently.”

Robotics is inherently interdisciplinary, requiring knowledge of software, low-level motor control, and sensor data interpretation. It’s about system integration, addressing challenges in diverse sectors such as healthcare, warehousing, and agriculture.

For prospective students, the path to the Robotics Master begins in the Bachelor’s program. Courses like Signals and Systems, Dynamics and Control of Mechanical Systems, and an

introductory robotics course in the second year’s fourth quarter lay the groundwork. These courses cover essential topics such as actuation, decision-making, AI, and robot perception. Van de Molengraft highlights, “In the Master’s program, students deepen and broaden their knowledge based on a solid foundation in systems and control. Although it is a separate section, it operates within the Dynamics and Control division (DSD).”

The establishment of the Robotics track not only consolidates existing expertise but also enhances research capabilities and industry collaboration. “We’ve always engaged in research with industry contacts. With a larger, dedicated group, we can better unite our strengths and achieve significant advantages,” says Van de Molengraft. This synergy is already fostering improved collaboration and promises to expand further, aligning with the rising importance of robotics over the next two decades.

Graduates of the Robotics Master have a promising career outlook. Alumni have founded companies like Smart Robotics and Avalar, while many have joined startups and established rms in the region. Van de Molengraft notes, “We aim to create an ecosystem for the robotics sector in Eindhoven, leveraging the region’s hightech talent and the legacy of companies like Philips.”

The Robotics lab, located in the Impulse building, is a dynamic environment where numerous projects and experiments come to life. “An ideal lab for robotics is exible, allowing recon guration for various experiments. We envision transforming the lab into a space where virtual worlds can be created for robots to interact with, much like the lm sets of ‘The Mandalorian,’” says Van de Molengraft.

In this lab, robots learn to perceive their surroundings, build and maintain world models, and perform tasks autonomously. The integration of AI enables robots to learn and correct mistakes, bridging the gap between theoretical knowledge and practical application.

The introduction of the Robotics Master track at TU/e marks an exciting development for the Mechanical Engineering Department. With its clear focus, comprehensive curriculum, and strong industry ties, the program is set to attract a new generation of students eager to explore and advance the eld of robotics. Whether you’re a Dutch or international student, this new opportunity at TU/e is one to consider for a cutting-edge education in robotics.

A walk down memory lane from a pump to a robot on a track that is growing more di cult each year. The history of the Q3 CBL project: Multiped robot

WRITTEN BY ELLE VAN HOUT

As some of you might know Multiped robot hasn’t been a project in our curriculum for a very long time. A few years ago our students were still building a pump. The students had to go through the 7 design phases just like now in order to develop, realize, and test a linear peristaltic pump. The peristaltic pump had to be operated by Arduino-controlled servo motors, the main coding had to be done in Matlab. Just like now, there was a competition. But for this project, the goal was to see who could pump the water the highest.

The rst year of Multiped robot

When implementing CBL’s instead of DBL’s into the curriculum, the course changed to multiped robot. The students still had to go through the seven design phases and work in groups. The biggest di erence was of course the

change in what had to be built but also the set up of the course. This was the rst time the students got more freedom and only had one group meeting per week. The other meeting was a planned building session in ProtoZone where the groups got together to assemble, test and improve their robot.

As the name of the project suggests, the goal of the course was to build a robot that moved using more than one leg. Students were free to choose the amount of legs themselves but they were limited to a number of servo motors. Another issue there was, the more servo motors you use, the more movement your robot had, but this also meant your robot got signi cantly heavier. In total, the students had 2.5 months to design, print, assemble and test their robot using Arduino, servo motors, acrylic glass and 3D printed material.

However, the main challenge in the rst year turned out to be the track the robot had to walk. The track contained one 180-degree turn and di erent surfaces ranging from fake grass to pebbles. Even though the challenge seemed quite straightforward many di erent designs were made and quite some robots were unable to nish the track successfully. As an incentive to make the robot as e cient and fast as possible, students got half a grade higher on their nal report if they were their robot could complete the track the fastest.

According to the responsible professor, Ye Wang, the course exceeded his expectations and according to him, students could see early on in their studies what mechanical engineering entails since it is so very broad. Students were really enthusiastic about the course as well. The students liked the practical work instead of only theory and they never thought they would be programming their own robot.

After the great success of the rst year, the course was gladly kept within the curriculum. Even though the rst year not all robots were able to nish the track, the track got more di cult the next year. The second year the robots had to be able to nish a track with a small hill, a 180-degree turn, and walk straight with holes in the track. The same materials were used and since the apparent success of CBL’s the setup of only one group meeting and one building session was kept. Even though the project was more di cult in the second year the students liked the project a lot. The students seemed to like the course and the professor so much that Ye Wang even won the Best Teacher Award for our department this year.

This year the track was changed again. This year the students had to build a robot that would be able to climb a ladder. Students had to use laser-cut wood before they were allowed to use plastic. The ladder caused even more di erent designs than previous years, but also more DNFs than previous years. Students spent more time this year building as well, the wood sometimes came bent due to the heat of the laser, and somehow ordered pieces disappeared. The height of the ladder also didn’t help due to some unexpected falls and less sturdy robots than expected. The big change in track design also led to some more ‘interesting’ designs like a robot that used a grappling hook to pull itself up or a robot that jumped as high as possible, if this was still classi ed as a multiped robot is up for debate.

Whether the course will be more di cult again next year is not yet known, but the students hope that the track will be more doable for the new students. What we do know is that the course itself is not going anywhere. The course is still there in Bachelor College 2.0 and students, even though the di culty, are still positive and like the practical work.

Good luck to all students still having to follow the course, we hope you have as much fun as we had designing your very own robot.

WRITTEN BY NICKY VERHEIJEN

Japan. Located in the Far East, you nd the country of the rising sun. This cultural diamond of Asia would become my home for a few months. From September until January, I would live and work in Tokyo, doing my internship at Keio University. In this article I will tell you about my experience in living in a metropolitan like Tokyo, how I experienced the Japanese culture, and more about Japan.

Before I share how I experienced Tokyo, it might be good to know what daily life looks like for most Japanese people (or how I perceived life is like). As an average Japanese citizen, you wake up, get dressed, take the commute to work (or school), work until your boss goes home, commute back, sleep, and start over. As the greater Tokyo area is more than half of The Netherlands, it is not uncommon to commute for more than an hour to work. For everyone who has ever seen a video of people pushing other people in overfull trains, this is true, it happens. Why? I am still unsure, because most of the time, the next train arrives 5 minutes later. So luckily, I managed to avoid this situation.

For me, my days looked quite similar, except I clearly stated my boundaries and did not work overtime, even though other students were. At the end of my internship, my professor even applauded me for my work-life balance, stating she hoped her students learned something from me. I am very happy I had such an open-minded professor.

Wondering when Japanese people have time to cook and eat in this busy schedule? They don’t, cook I mean. Near every station, you can nd many restaurants for a quick, time-e cient meal. Eating alone is quite normal. A barrier, we know from the good old corona times, is placed between all individuals enjoying their quiet meal. If you do not feel like having company at all, you can always pick one of the many great microwave dishes, and when I say great, I mean it, because these dishes are truly delicious.

Tokyo is a big and I mean BIG city. Each district is its own mini-city, with its own unique atmosphere. If you ever want to go to Tokyo for holidays, I would highly recommend you to stay in di erent areas throughout the week. Go to the Str p-S of Tokyo, Daikan-yama. The always lively Shibuya, with the famous Shibuya crossing. Feel the “Zuid-as” atmosphere in part of Ginza. Wherever you go, you nd new spots to discover and more people.

About the people. Japanese people might be the politest people I have ever met but do not mistake their politeness for kindness. Yes, they are friendly and will help you, and guide you if needed. However, I preserved them as more individualistic, not selfcentred nor self-focused, just individualistic. Happy on their own and not keen to start a conversation or make new friends, at least not with foreigners. Of course, you have the language barrier, most Japanese struggle with speaking English, some not

Source: Getty

because they do not have the skills, but because they are afraid to make mistakes. But even without the language barrier, it can be di cult to connect. Historically, unity is a big part of the culture, so if you are not Japanese (or do not look like one), you stand out, and not necessarily in a good way. For me this led to being very self-aware in public, I felt observed, and sometimes judged. After a while, I got used to the feeling. Later I realized, this might not be unique to Japan, and it made me gain respect for foreigners (or people who look di erent) in The Netherlands, or anywhere in the world for that matter.

Alright, enough philosophy, back to technology. During my internship, I was part of the Multiphysics Materials Computation Research Group within the Department of Mechanical Engineering. In my research, I tried to make a simulation to analyze the crack initiation and propagation in a composite. For this simulation, I used the phase- eld crack model nite element method, where mostly skills from the course Computational Mechanics.

After my internship, I travelled to di erent places and cities in Japan. I did not come close to visiting all the beautiful spots Japan has to o er, but I did get the chance to see plenty. Big cities like Kyoto, Osaka, Hiroshima, and Fukuoka all have their own unique avour, and depending on what you like you might feel more at home. My personal favourite might be Kyoto, because of the cultural richness. However, if it is temples, you are looking for, you can nd them at every corner in Japan, and you might even get temple-tired after a while. Hopefully, this article gives you a good inside of my time in Japan and does not read too much like a travel blog. I could write many more pages about Japan, and its unique culture. By living and travelling in Japan for almost half a year, I discovered how fascinating and majestic the country is, but I was also ready to leave when the time came.

WRITTEN BY ANASTASIA GHLIGHVASHVILI

Television often entertains, but certain shows captivate and inspire mechanical engineers by showcasing real-world engineering feats. “Extreme Engineering” explores ambitious architectural projects, “Top Gear” blends car reviews with engineering insights, and “MythBusters” tests myths through innovative experiments. This article highlights how these programs bring mechanical engineering principles to life, making them both educational and exciting.

In April of 2003 the rst episode of Extreme Engineering, titled Tokyo’s Sky City, aired on the Discovery Channel. The episode unveils the awe-inspiring story behind the construction of one of the world’s most ambitious architectural marvels. Set against the backdrop of Japan’s bustling capital, the episode delves into the innovative techniques and groundbreaking technologies employed to realize this sky-high vision, explaining how Japan plans to build Sky City, the tallest structure on earth. The towering, vertical city will house more than 100,000 people. Sky City would be home to the world’s very rst homesteaders in the sky. But how exactly could Sky City be built? Would it be safe? Would Sky City be the metropolis of the future or a death trap in the sky? These are the questions the episode sets out to answer. The main goal of Sky City was to make the residents so comfortable that they could live from cradle to grave without ever setting foot on Earth. However, building a city within a city comes with a long list of challenges.

Tokyo’s loose sandy soil may not be rm enough to support a structure of this magnitude. Sky City, weighing 6 million tons due to the combined weight of every man woman, and child in Japan, would be the heaviest structure ever built in Asia. A further escalation of the risk that comes with building such a structure on the unstable soil that was once the bottom of an ocean, causing Sky City to sit on sandy sediment, is the single most horrifying disaster looming over Tokyo, Earthquakes.

While Tokyo’s worst earthquakes wreak havoc, even moderate earthquakes bring buildings down. To account for this, engineers at the Taco Knocker Research Institute are looking for ways to safeguard such an enormous building. The conducted experiment included a 150-ton g-force simulator deep

underground which produces the load of enormous buildings on di erent types of soil. It will simulate the total weight of a 20-story o ce tower built on packs and as the centrifuge accelerates, it can produce 200 times the force of gravity. In this experiment, a simulated earthquake forced the model to move 1/16 of an inch. This is invisible to the naked eye but the same test suggests that a six million-ton building could shift a whopping 100 feet, which is enough to possibly destabilize the human structure and bring it crashing down.

The rest of the episode delves deep into the solutions to the problems facing the construction of Sky City. Ultimately, the episode concludes with the triumphant unveiling of the Tokyo

Sky City, a testament to human ingenuity and perseverance. Rising majestically against the city skyline, this architectural masterpiece stands as a symbol of Japan’s commitment to pushing the boundaries of possibility in the realm of extreme engineering.

The highest-rated episode of extreme engineering aired in July 2011, titled Building Mumbai’s modern airport. The episode follows a similar format to its pilot, even though it aired 8 years and 8 seasons later. Extreme Engineering delves deep into some of the world’s most interesting buildings, monuments, and engineering marvels. It is a show concerned with exploring some of the key aspects of being an engineer, taking on huge projects, and the obligations and duties taken on by engineers.

Top Gear, a British motoring magazine and television show was resurrected by Jeremy Clarkson and Andy Wilman from the original 1977–2001 series for the BBC. Premiering on October 20, 2002, the program primarily focuses on the assessment and evaluation of motor vehicles, with an initial emphasis on cars. However, as the series progressed, it expanded its content to include challenges, special races, timed laps featuring notable cars, and celebrity timed laps on a specially designed course. In comparison to Extreme Engineering, Top Gear mainly focuses on entertainment value, while sprinkling in some informative discussions regarding the cars, motors, or wheels that are the focus of each episode.

A particularly interesting episode of Top Gear premiered in 2008, during the show’s 11th season. In this episode, the presenters Jeremy Clarkson, Richard Hammond, and James May embark on a series of challenges to test the practicality and usability of electric cars. The episode begins with an introduction to the concept of electric vehicles and the advancements in battery

technology that have made them increasingly viable alternatives to traditional gasoline-powered cars. The presenters then proceeded to test a selection of electric cars in various real-world scenarios. This includes assessing their range, performance, and recharging capabilities. Throughout the challenges, they provide

commentary on the advantages and limitations of electric cars compared to conventional vehicles, touching on topics such as environmental impact, running costs, and infrastructure requirements for widespread adoption.

One memorable segment from this episode involves the presenters attempting to drive electric cars from the seaside town of Aldeburgh in Su olk to the city of Edinburgh in Scotland, a distance of approximately 60 miles. Along the way, they encounter various challenges related to range anxiety, charging infrastructure, and the practicality of electric cars for long-distance journeys. Top Gear provides viewers with

a comprehensive and entertaining look at the state of electric cars in 2008, o ering valuable insights into their potential as sustainable transportation solutions and highlighting the challenges that need to be addressed for their widespread adoption.

Top Gear’s primary focus is not on the engineering behind the cars they utilize for their episodes, but on the entertainment value. Nevertheless, Top Gear, as described above, does incorporate some aspects of engineering to delve deeper into the plot of each episode, leaving the viewers with increased curiosity concerning the topic at hand.

“MythBusters,” which aired from 2003 to 2016 on the Discovery Channel, focused on testing the validity of myths, rumors, movie scenes, and urban legends using scienti c methods and experimentation. Each episode tackled one or more myths, which the hosts attempted to prove or debunk through a series of elaborate experiments. These experiments often involved building custom contraptions, conducting controlled demonstrations, and scienti cally analyzing data.

Throughout its run, “MythBusters” explored a diverse array of topics, from everyday misconceptions to Hollywood stunts and historical legends. Notable myths tested included whether swimming in syrup is faster than in water, if it’s possible to survive a fall by landing in a dumpster, and if a hat can be shot o someone’s head without causing injury.

One of the most intriguing episodes, “Supersized Myths,” aired in the show’s 7th season. It tested whether ring a handgun in a small, con ned space could propel a person backward, a

common action movie trope. The MythBusters team built a rig to simulate handgun recoil and concluded that such a scenario was possible. Another segment of the episode explored the feasibility of cooking a turkey using a jet engine. The team designed a rig to withstand extreme temperatures and proved that this was indeed possible.

“MythBusters” served as a fun and engaging way to test engineering concepts while debunking popular myths. It allowed viewers to explore the world from a scienti c perspective, providing entertainment and inspiration for engineers and science enthusiasts alike.

In conclusion, shows like “Extreme Engineering,” “Top Gear,” and “MythBusters” make mechanical engineering accessible and exciting. They inspire curiosity and appreciation by blending entertainment with education, showcasing ambitious projects and innovative solutions, and highlighting engineering’s impact on our lives.

In the dynamic realm of aerospace engineering, where innovation knows no bounds, WFS PRO has a big role in connecting talent with groundbreaking projects. At the helm of this journey stand Kevin Meesters and Mike Tuk, engineers whose expertise and ingenuity t perfectly with the spirit of collaboration fostered by WFS PRO. With a background deeply rooted in engineering and a wealth of experience garnered from their tenure at Fokker Elmo, Kevin and Mike started working on this revolutionary project at Vertical Aerospace in 2021, a trailblazing project spearheading the development of electric Vertical Takeo and Landing (VTOL) aircraft.

The landscape of aviation is undergoing a seismic shift, propelled by the fusion of electric helicopter and drone technologies for human travel. Vertical Aerospace is one of the scale-ups that dared to compete in this evolution. With its ambitious fully electric VTOL aircraft project, they have a working prototype to illustrate the possibilities of this type of airtravel. Kevin and Mike are working on this evolution with Fokker Elmo. This company, a division of GKN Aerospace, specializes in the design, manufacture, and integration of electrical wiring systems for the aerospace industry. With a focus on innovation and quality, Fokker Elmo plays a crucial role in providing cutting-edge electrical solutions for aircraft.

The aircraft that Vertical Aerospace is working on is called the VX4. The aircraft is all electric, providing emission-free air transportation. The VX4 is a ve-seat design with a pilot in the front and four passengers. It runs a total of eight large propellers – two ve-blade props along the front edge of each of its large wings, and two scissor-folding four-blade props along the back of each wing. For vertical takeo and landing, these all point upwards, but the front bank of props is designed to tilt forward and deliver horizontal thrust for e cient wing-borne cruise ight, while the rear props will stop and tuck themselves into a low-drag con guration until they’re needed again.

The company has revealed that the VX4 eVTOL aircraft can achieve noise levels which are 30 times quieter than the equivalent helicopter. Because the aircraft is aerodynamically e cient, it will be able to y its missions with far less energy than a helicopter would need.

WRITTEN BY STEFAN GEERTS

Vertical Aerospace claims an impressive top speed of 202 mph (325 km/h), and a decent range somewhere over 100 miles (161 km), rounding out a set of specs that position this machine as a solid-looking cross-town air taxi capable of doing some light regional duties as well. The market seems to have responded favourably; VA claims it’s already taken a whopping 1,400 conditional pre-orders from a range of airlines, tourism groups and other operators. Only about 1,000 helicopters a year are being sold into civil service worldwide, so you can see how aggressively these new, cheaper, quieter electric aircraft are going to start ooding the skies once they’re certi ed and into mass production.

As the project developed further and got to a phase closer to designing the fuselage, Kevin and Mike were brought in to provide knowledge on the wiring of the aircraft. “This sector is drawing inspiration from the automotive industry on the highvoltage cabling. Here, advancements in battery technology have paved the way for electric mobility. However, tech ow does not only go one way. The automotive industry has always looked to aviation for the regular voltage cabling possibilities. In aviation, every aspect has to be optimized for weight and safety. This is something that was also needed in the automotive world.”

“The transition from traditional fuel systems to high-voltage battery lines presents a big shift in aircraft design”, Kevin and Mike explain. “Since we are at the forefront of this transition, everything has to be developed from scratch. There is no guide on how to build an electric plane since it has never been done

before at this scale. The bene t of this is the exibility we get as engineers. The entire plane has to be developed from scratch. If something in the wiring becomes a problem for another division, a work-around can be developed. This is not the case when modifying regular aircraft that were designed without this in mind.”

The experience at Fokker Elmo, a bastion of aviation knowledge, provides a solid foundation upon which they contribute to Vertical Aerospace’s groundbreaking project.

Beyond their technical roles, Kevin and Mike’s journey underscores the importance of collaboration and industry networking, facilitated by WFS PRO. “WFS PRO’s expertise in talent acquisition and placement ensures that projects have access to the best minds in the industry, driving innovation and progress forward.”

“We were both working in this industry before we were linked to WFS PRO. They help us with getting the right people for the right jobs”, Kevin and Mike explain. “Your skills can be used in a lot of industries and WFS PRO helps with getting you to the right place. In such a small industry, knowing people is key. That is what WFS PRO is very good at.”

The story of Kevin and Mike serves as a beacon of inspiration for aspiring engineers and aviation enthusiasts alike. It illuminates the boundless possibilities that await within the electrified skies. As companies like Vertical Aerospace continue to reach new milestones, fueled by the expertise of individuals like Kevin and Mike, the future of aviation remains as electrifying as ever.

The journey of Kevin and Mike not only exempli es the transformative potential of electric ight but also underscores the vital role played by companies like WFS PRO in shaping the future of aviation. As the demand for sustainable air travel continues to grow, the collaboration between industry leaders and innovative startups, facilitated by organizations like WFS PRO, will be crucial in driving progress and ushering in a new era of aviation excellence.

Looking ahead, the path to widespread adoption of electric ight may present challenges, but with visionaries like Kevin and Mike at the helm, the possibilities are limitless. From pioneering new technologies to forging strategic partnerships, their journey serves as a testament to the power of innovation and collaboration in shaping the future of aviation.

WFS PRO delivers innovative and tailor-made services in the eld of Recruitment Services and Recruitment Process Outsourcing, both nationally and internationally. With their extensive network of interesting clients in the Aerospace, High-Tech Machinery, Marine & O shore, and Renewables industries, they are the platform for your next career move.

We would like to thank Kevin and Mike for the interview!

If you want to know more about WFS PRO, make sure to visit their website wfspro.nl

In conclusion, as Vertical Aerospace’s VTOL project takes ight and electric propulsion becomes increasingly prevalent in the aerospace industry, the contribution of engineers with a vision, supported by organizations like WFS PRO, will continue to be instrumental in driving progress and shaping the future of aviation. With their unwavering dedication and pioneering spirit, they stand as trailblazers in a new era of electri ed skies, inspiring generations to come.

Everyone knows about climate change, and how we need to transition towards a more sustainable future of generating energy. There are many di erent topics of research into the scene of alternative, renewable fuels. To name a few: biofuels - a fuel recovered from bio waste like vegetable oil -, metal fuels, ammonia, and probably the most well known option: hydrogen. Not one or the other of these fuels is ‘the best fuel’ and will solve all of our problems, for di erent applications we will be using di erent fuels that work best. However still a lot of research needs to be done on these fuels, and in this article I will tell a bit about my graduation project, which focuses on hydrogen. WRITTEN BY

FENNE PEETERS

Since we are talking about setting stu on re, it might not be a surprise to you that I am doing my graduation project in the research section of Power&Flow. My project is part of a larger project that is going on: the Argon Power Cycle (APC) project. In this project, both experimental and numerical research is being conducted into hydrogen combustion with argon as the working uid, for example in compression ignition (CI) engines. Where engines exist in many di erent forms and types, most people will know the CI as the engine used in diesel cars or trucks. In most engines, the fuel is burned by using air. Air is a mixture of nitrogen and oxygen. In the case of the Argon Power Cycle, the working uid (nitrogen) is swapped for argon.

When combusting hydrogen the temperatures can reach quite high values, creating the perfect environment for nitrogen oxides (NOx) to form, if one were to use air. Argon is an inert gas, meaning it will not react with other species. The only product of combustion of hydrogen with oxygen would be water. The exhaust gases would therefore be water and argon, which are easily separable.

Next to this, the e ciency of a thermal power cycle is limited by the speci c heat ratio gamma of the working uid. Argon has a higher speci c heat ratio as compared to air, about 25%. This is because argon is a monoatomic gas, whereas nitrogen is a diatomic gas.

There are no rotational and vibrational modes in monoatomic gases, which results in a higher speci c heat ratio. In theory, this could result in an e ciency of the APC of almost 80%, whereas in regular combustion systems, this is around 50%.

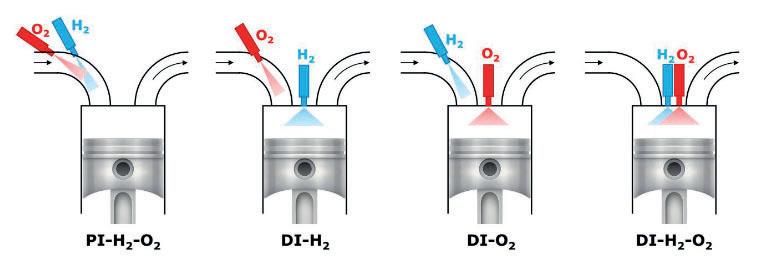

A major challenge is the injection of the oxygen and hydrogen into the combustion chamber, where the working uid (argon) is

present. The combustion behaviour, about which very little is known, can be studied for di erent injection approaches: port injection (PI) of both hydrogen and oxygen, direct injection (DI) of H2, DI of O2, or double DI of both H2 and O2. My project focuses on modelling the e ect of the oxidizer (argon+oxygen) composition on combustion, mimicking di erent injection strategies. I am looking into DI of H2 and double DI in particular.

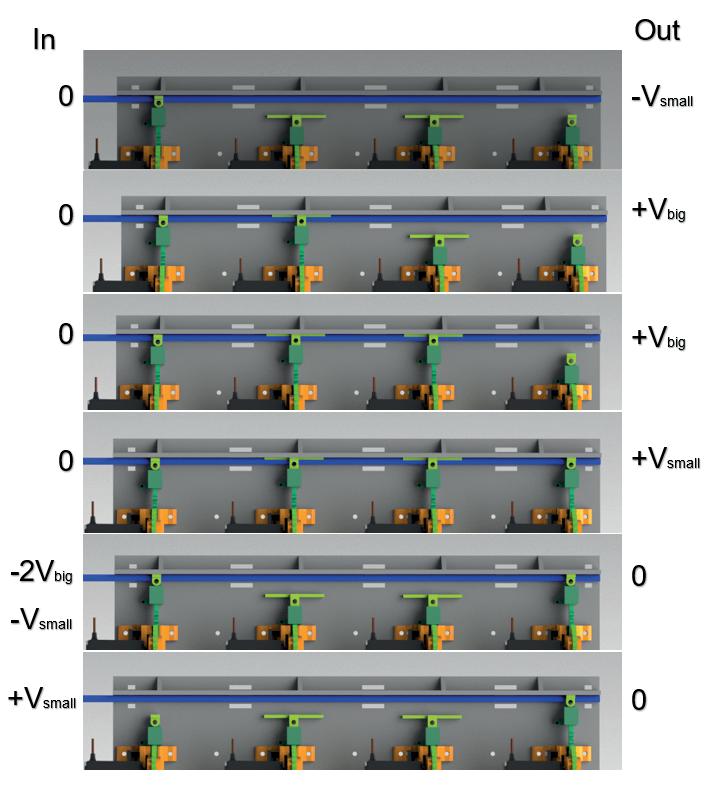

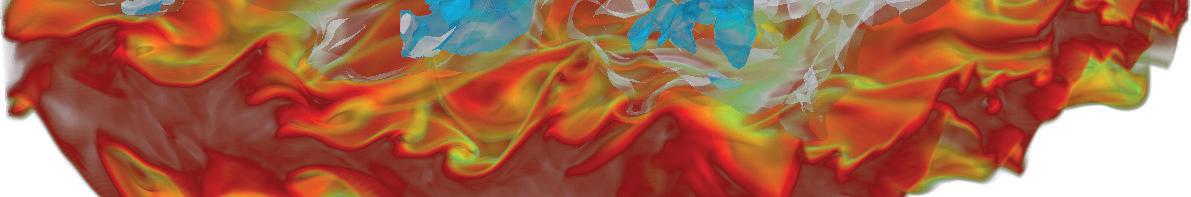

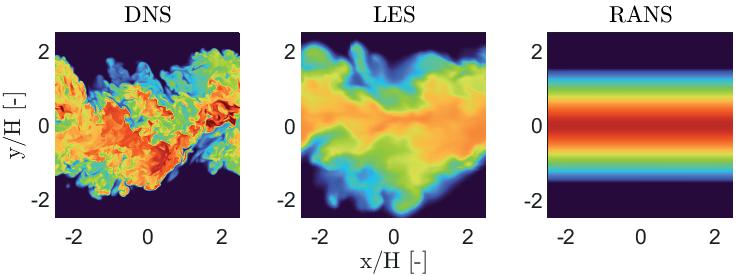

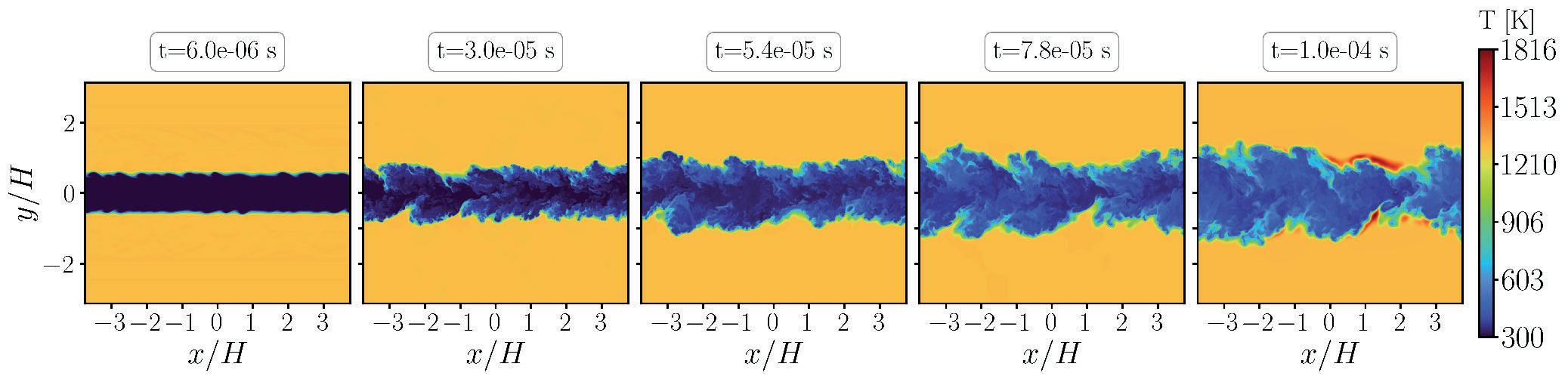

Modelling H2 combustion in these conditions, asks for a fully compressible turbulence model in CFD (Computational Fluid Dynamics). There are several options for this, di ering in solving methods and computational power that is needed. One option is to directly solve for the conservation equations of Navier-Stokes, without using any modelling assumptions, called Direct Numerical Simulation (DNS). All relevant scales in both time and space are resolved, making it the most computationally expensive option. This is the numerical method I am using in my project. Luckily, supercomputing facilities are available in order to be able to run massive cases. The other options are LES (Large Eddy Simulation) and RANS (Reynolds-Averaged NavierStokes), which model parts of the simulation using modelling assumptions. LES resolves for the bigger scales, and models the smaller scales. RANS models all scales. In the gure below you can see the di erence in details of the solutions.

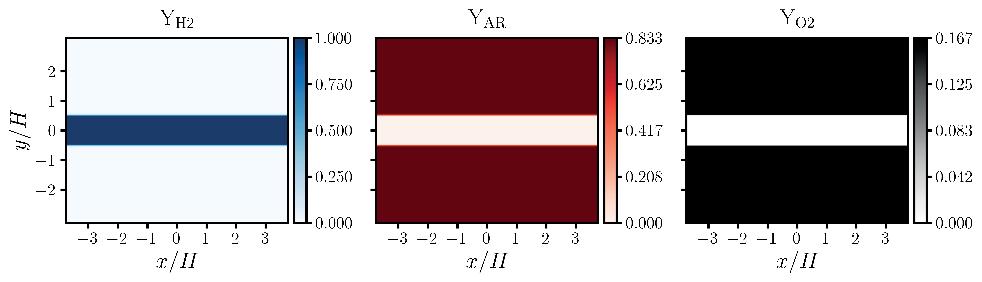

In the case of researching double direct injection, the oxidizer composition as we see above can be changed from a homogeneous mixture to a heterogeneous mixture. For this I had to adapt the initialization case in Fortran in order to create the heterogeneous oxidizer mixture. The oxidizer eld now has a variation in oxygen concentration, corresponding to a situation where oxygen is also injected separately in an argon environment. This mixture has an average composition corresponding to a 10/90 % mole fraction composition.

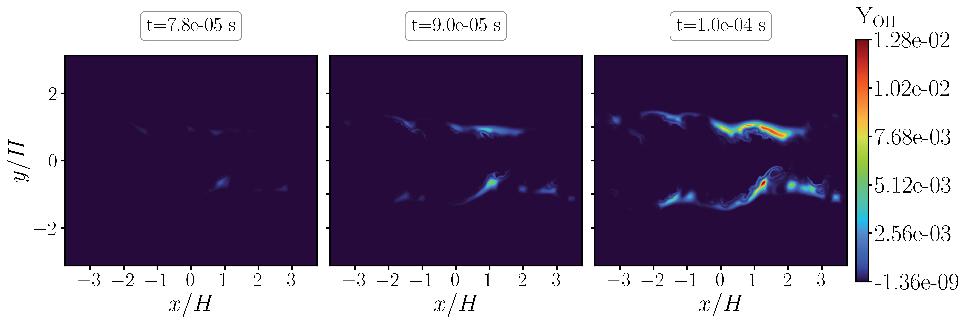

As an example, for the case of H2 DI this is what the evolution of temperature in time would look like:

DNS is useful for unraveling the fundamental processes that are happening, that cannot be studied by using experimental techniques. The data acquired by DNS studies can be used in further development of LES and RANS models and serve as a baseline to compare results from these models to. My supervisor has provided me with an in-house developed DNS code in Fortran called Disco, and the data handling and post processing is done with Python.

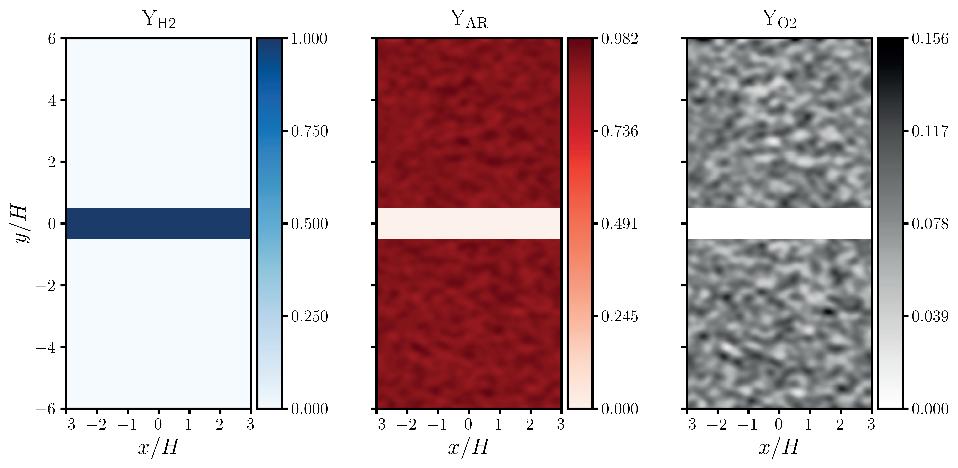

Well, as mentioned, I am looking at mimicking DI of H2 and double DI. For DI of H2, this can be modelled using a mixing layer of pure hydrogen in an environment of premixed oxygenargon. The mass fractions of the initial species would look like the following. You can see, there is no variation in concentration for the argon and oxygen, it is a homogeneous mixture corresponding to a 20/80 % O2/Ar mole fraction composition.

In my research I am most interested in where ignition starts and why. One way of identifying igniting kernels is by looking at the evolution of the radical OH.

So in short, I am doing a thorough analysis, both qualitatively and quantitatively, of the huge amount of data produced with 3D DNS simulations on hydrogen combustion in an argon environment. By changing the composition of the oxidizer, I want to gain more insight on the e ect of injection approaches on the combustion process. The results can be compared to 1D solutions in order to study the e ect of turbulence. p

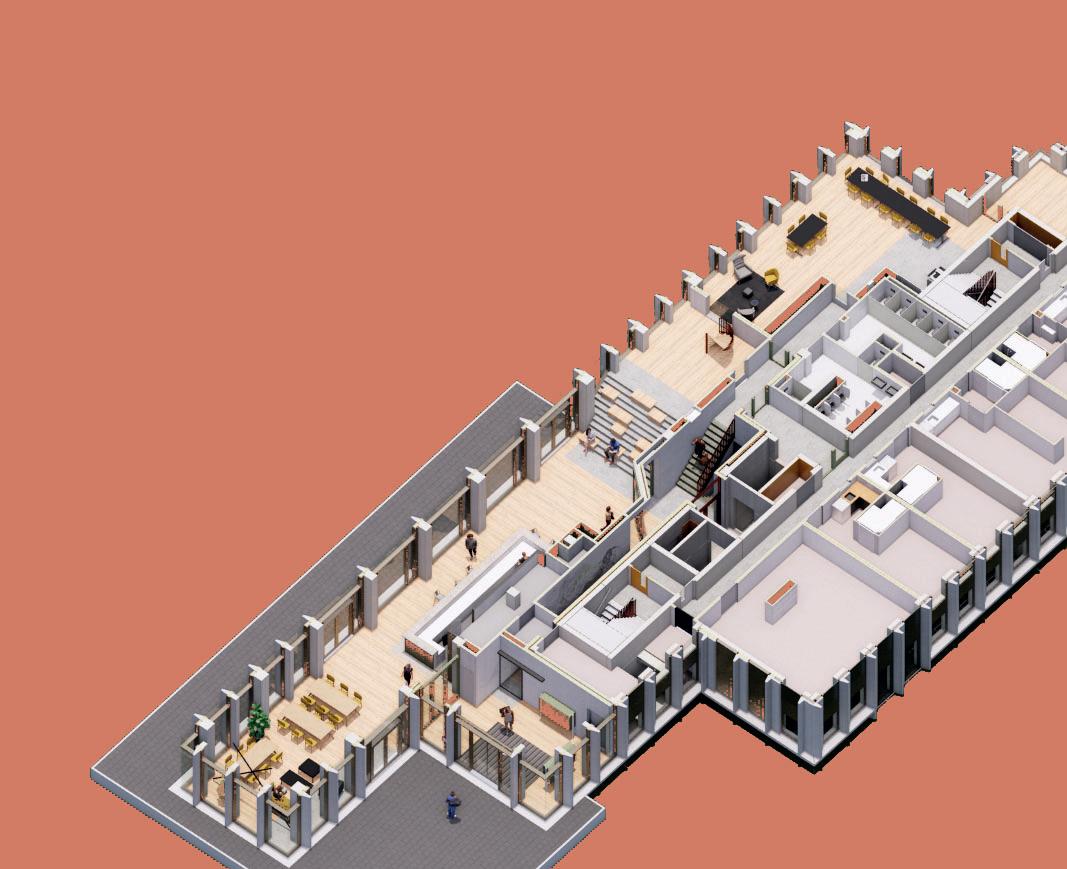

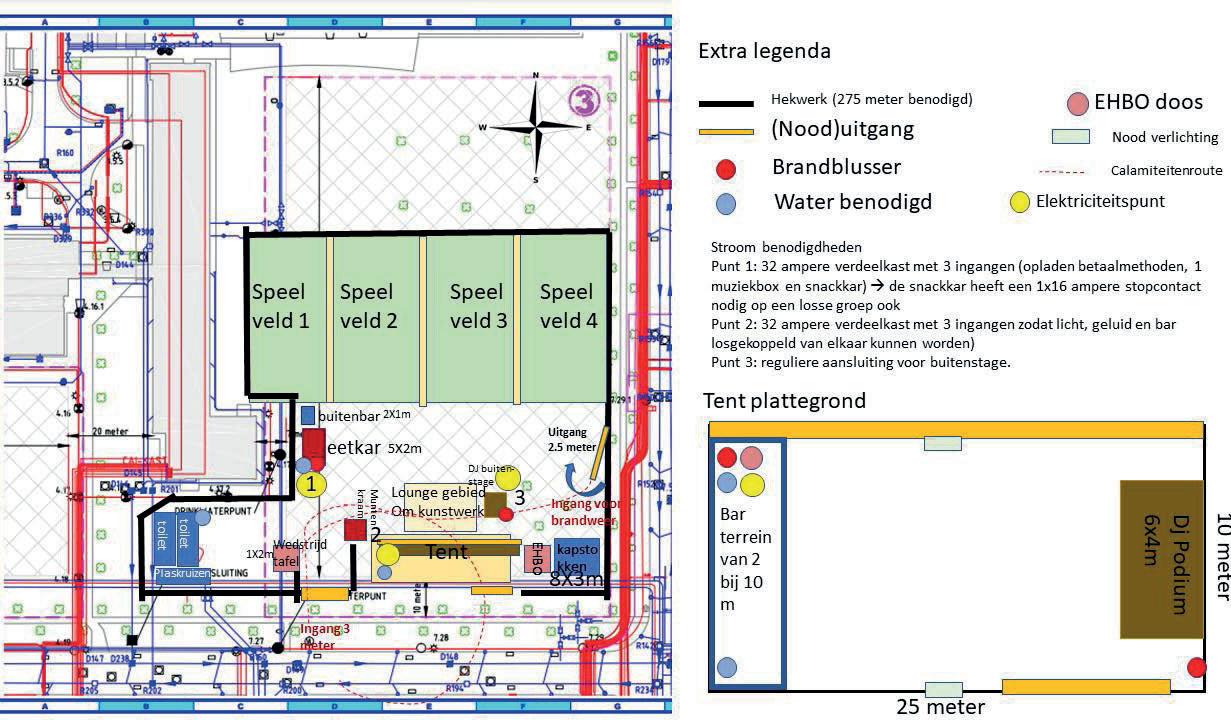

As summer approaches, excitement builds among our study association members as we prepare to move back into the newly renovated Gemini-North building. Our member spaces have undergone a signi cant transformation, promising a fresh and invigorating atmosphere that contrasts sharply with the darker, pub-like vibe of the past. We spoke to Vione van Leeuwen about the latest updates regarding the Association room.

The decision to create a lighter, more open atmosphere in our new member spaces was not taken lightly. An independent working group comprising both study associations and an interior architect was established to ensure the new design would meet our needs and preferences. This process, which began in 2022, involved extensive input from members about how they envisioned the new space and what kind of ambience they wanted.

‘We asked questions about the activities you organise, the desired atmosphere, and how the space is used during normal working hours. All these factors were considered for the nal design’, Vione explained. ‘Based on this feedback, the interior architect crafted a design that re ected the collective vision, emphasizing large windows and a light, airy look. The bar layout, initially sketched out, has now been nalized with signi cant input from our members, ensuring it meets our needs and enhances the overall experience.’ Key elements representing our association, like the WOF and member table have been thoughtfully integrated into the design, distinguishing our space within the larger building while maintaining a cohesive aesthetic with the rest of the campus.

‘The connectivity within the building has been carefully planned. The member space will be easily accessible via the bicycle basement or outside doors, which includes lockers and ensures minimal disturbance to other areas. Members will pass by the communal pub areas, creating a sense of ow and community.’ Ventilation has also been a key consideration, with the system designed to accommodate the varying number of occupants, ensuring a comfortable environment at all times.

‘Outside the member space, attention has also been given to the ‘Koekoek’ area. While the exact design of benches and such is not yet known, the steps, designed with both high and low tiers, o er outside seating options for all students.’ The benches o er space for activities and space to have lunch for example. The ‘koekoek’ will be shared with Protagoras. The outdoor space remains exible, designed to adapt to various activities and needs.

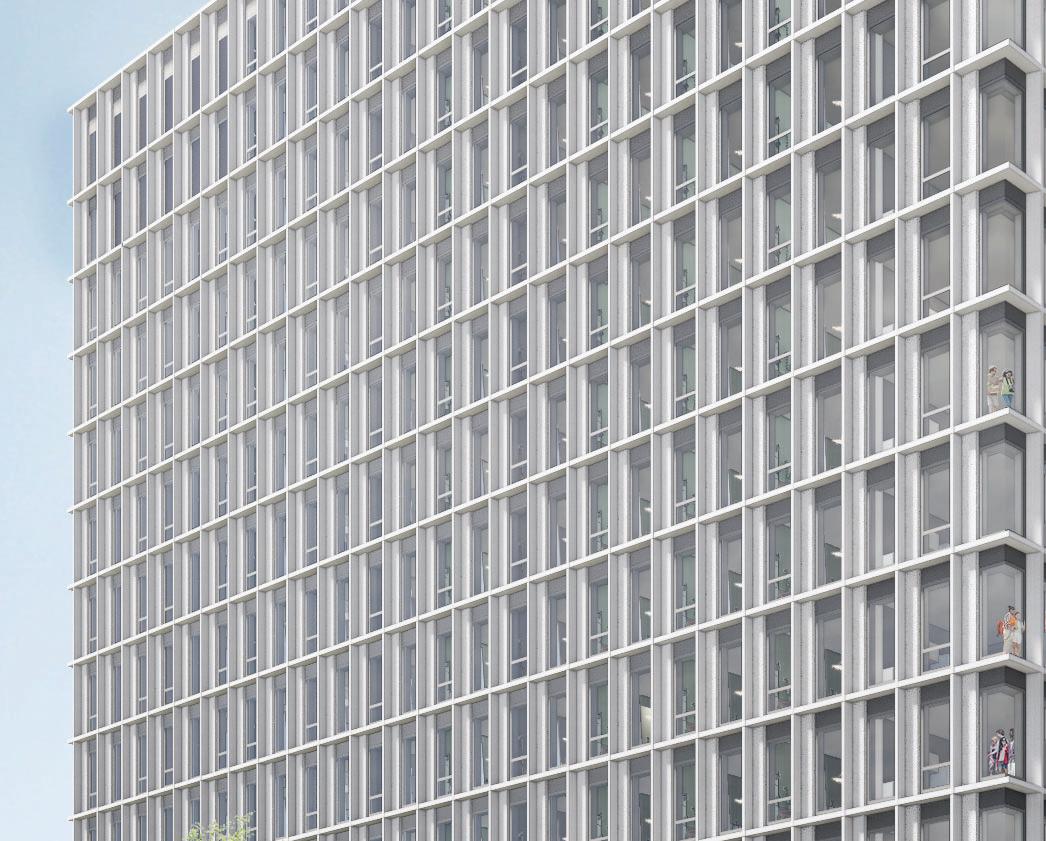

The renovation is progressing smoothly and remains on schedule. The exterior work on the facade is currently underway, with interior walls being constructed. Decisions regarding furniture are being nalized, balancing budgetary constraints and spatial requirements. Custom elements, such as the bars and pantries, are being crafted to t perfectly within the space.

The project will be completed in two phases. The rst phase, covering the pub areas to the last footbridge, is scheduled for completion rst, followed by the nal section beyond the last footbridge. By Q3, we expect to begin relocating, including moving our lectures and other activities.

As we look forward to moving back into Gemini-North, the new spaces promise to create a vibrant, engaging environment for all members. The thoughtful design, based on extensive member input, ensures that our new home will be both functional and welcoming, setting the stage for many productive and enjoyable years ahead.

The renovation involves numerous parties, all working in concert to ensure a successful outcome. The exterior work was managed by the main architect, while the interior architect oversees the interior design and keeps in contact with furniture suppliers in coordinating custom and standard furnishings. This collaborative e ort includes input from FMC and the departments, emphasizing sustainability with the use of second-life furniture.

Demolition was carried out by RGS, followed by a comprehensive tender process for all subsequent work. TWIN, a collaboration between Team V architects and Royal HaskoningDHV, has coordinated all advisory roles, including installation and construction. He mans, having won the tender for the nishings, will handle the nal stages of the renovation.

WRITTEN BY DANNY LIU

In the vibrant academic landscape of TU/e, the history of study associations weaves a compelling narrative of innovation, collaboration, and student engagement. From their inception to their present-day signi cance, these associations have played a pivotal role in shaping student life and fostering a sense of community within the university. Of course, such a rich tapestry of tradition didn’t emerge overnight. This article delves into the origins of each association, o ering a glimpse into their humble beginnings and the remarkable journey that has brought them to where they stand today.

1956

1981

The study, Computer sciences, is introduced

1972

Industrial Engineering is o cially a new study at the university

The Technische Hogeschool Eindhoven (roughly translates to: The University of Applied Sciences Eindhoven) was founded. The rst three studies were Mechanical Engineering, Electrical Engineering and Chemical Engineering

Did you know that Industrial Engineering has its roots in Mechanical Engineering? In 1962, Industrial Engineering started as a multidisciplinary (Mechanical Engineering and Electrical Engineering) master group. Before becoming an o cial department, it was rst an experimental study in 1966. is is also the reason why Industria is older than the department it represents.

1957

Three study associations were introduced this year:

W.S.V. Simon Stevin (Oct 30th), etsv Thor (nov 28th) and TSV Jan Pieter Minckelers (Dec 6th)

1967 – 1970

R4, a study association for Built environment, was founded and later disestablished

Did you know that Land yachts were not always a part of W.S.V. Simon Stevin? To celebrate the second lustrum of the Association, we organized a race for Land yachts in 1967. Since then, the Land yachts have been an integral part of the Association.

1960

Two new studies are introduced: Applied Physics and Applied Mathematics. On October 6th, SVTN Van der Waals, the study association for Applied Physics, is founded

1962 - 1975

1967

A new study, Built Environment, is introduced

Nov 27th 1963

Industria, the study association for Industrial Engineering, is founded

Sunya, a study association for Applied mathematics, was founded and later disestablished

Jun 28th 1982

The study association for Applied Mathematics and Computer science, GEWIS, is founded

1983

A new study Technology and Society (techniek en Maatschapp ) is introduced. This study was the predecessor to Psychology and technology and Sustainable innovation

Did you know that GEWIS is a very speci c acronym? GEWIS stands for “Gemeenschap voor Wiskunde en Informatica studenten” which roughly translates to “Community for Mathematics and Computer Science students”.

Oct 4th 1984

The study association for Techniek en Maatschapp (Later: Psychology and Technology and Sustainable Innovation), Intermate, is founded

Dec 12th 1985

CHEOPS, the study association for Built Environment, is founded.

Did you know that Intermate is also an acronym? e name stands for “Inter (between) Maatschapp en Techniek”. Translated to English it means: “Between Society and Technology”.

Did you know that CHEOPS has some characteristics of an umbrella association? Since the dismantling of R4, the di erent specializations within Built Environment have their own association. ese associations are sometimes even older than CHEOPS. KOers, the subsidiary association for structural design, for example was founded in 1978.

The Technische Hogeschool Eindhoven changes her name tot he Technische universiteit Eindhoven (Technical University of Eindhoven)

Werktuigkundige Medische Technologie (Mechanical medical technologies), a post propaedeutic study is formed within Mechanical Engineering.

2017

D.S.A. Pattern, the study association for Data Science, is founded

2016

The study, Data Science, is introduced

Dec 7th 1988

svBMT Protagoras, a study association for Werktuigkundige Medische Technologie (later for Biomedical Engineering), is founded

Di st D stud best serv should it be op

86 of tag n 19 ests I res on inte

Did you know that Protagoras may never have become a study Association? In 1986, people were debating how to best serve the interests of the new MWT students. Should they start a separate fraternity within Simon Stevin or should it be a full study association? Eventually they chose the second option and Protagoras was founded. ve eparate nd ntua atio

id k tudy A serve the rt a separate fra stud shoul hose

Jan 10th 2002

The study association for Industrial Design, s.v.i.d. Lucid, is founded

2001

The study, Industrial Design, is introduced

WRITTEN BY JOOST

VAN DER KRAAN

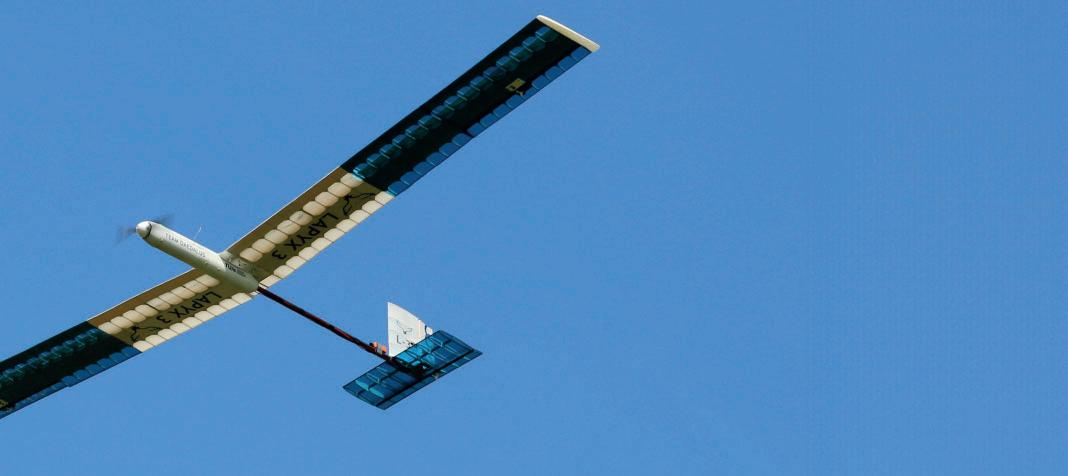

The maiden ight of Lapyx 2-1 (L2-1) took place in November 2023, marking the rst fully successful prototype that we at Team Daedalus had been working on. The previous aircraft, Lapyx 2 had already managed to take o and climb to an altitude of over 20 meters before experiencing vigorous wing utter and major loss of control. Before that, Lapyx 1 had set a low bar by nose diving into the ground after an awkward second or two following its launch.

As many engineers might know, hydrogen is one of the cornerstones of the energy transition. It’s a gas that can be produced by electrolysis, making it a renewable source of energy which can be used in many industrial processes as a replacement for natural gas to reduce carbon emissions. Yet, just producing enough green (or renewable) hydrogen won’t solve the energy transition. Luckily, SOLID might just have the solution for that.

Many industries in the Netherlands make use of natural gas for their processes because of the need for high temperatures, making the industrial sector called ‘the high heat industry’. These high temperatures can only be reached by using furnaces that actually combust a gas because there are no electric furnaces on the market able to reach such temperatures. Examples of such factories are glass, ceramic and paper factories, of which there are quite some in the Netherlands.

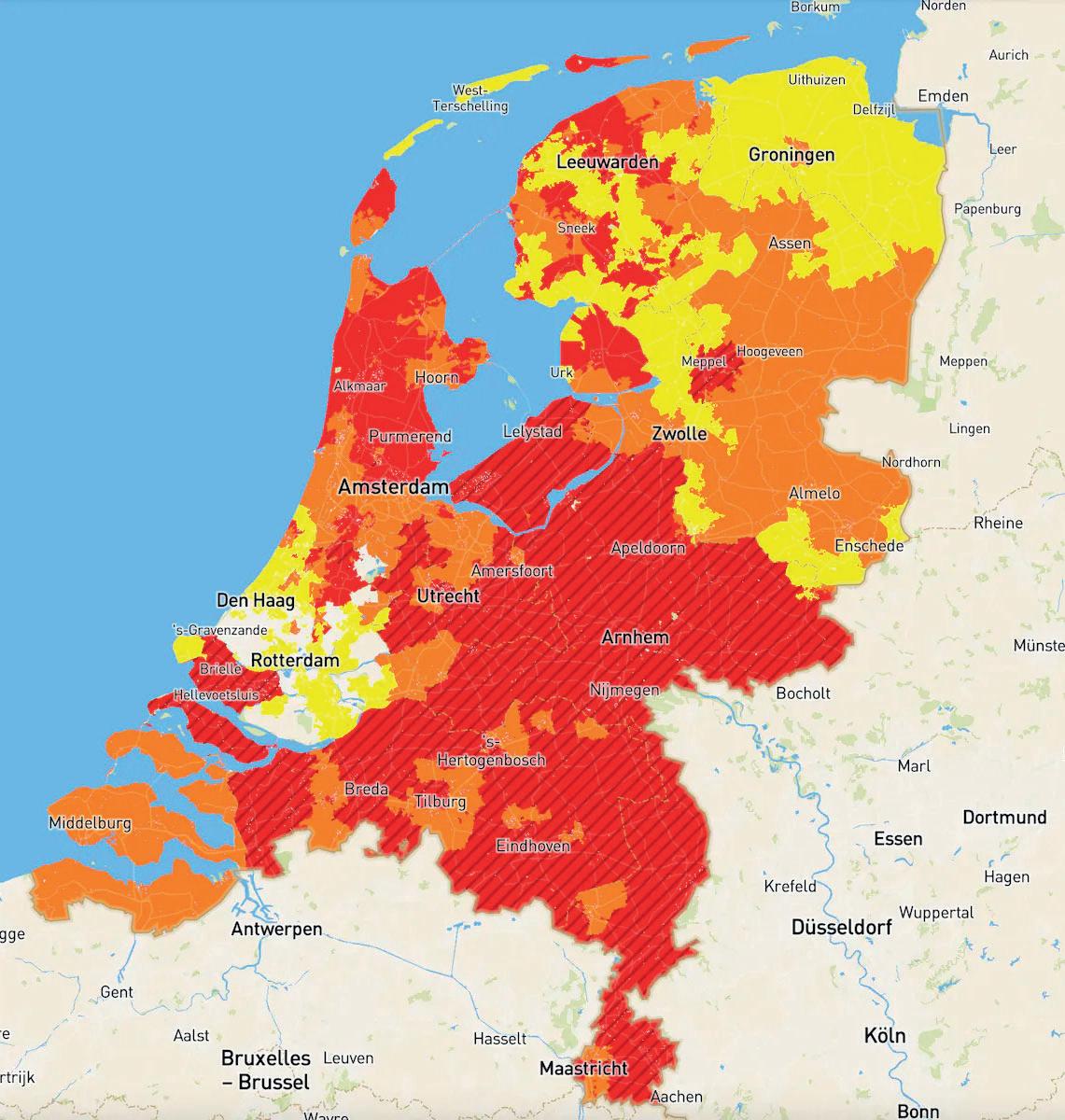

Even if there were electric furnaces available to help these factories reduce carbon emissions we would run into a new problem: net congestion. Practically all of the Netherlands is not able to get a new grid connection due to the congestion on the grid, a well known problem. Hence, the only way for these factories to decarbonize according to the goals set by the Dutch government, meaning 55% reduction in 2030, would be to switch to hydrogen.

Now, switching to hydrogen is where the real challenges come in: even though most furnaces would be able to switch to hydrogen quite easily, there is no actual feasible supply yet. Currently, the

Dutch government and Gasunie, a natural gas infrastructure company, are building a hydrogen backbone consisting of pipelines for the industry, which should be nished by 2030. This backbone will be lled by the green hydrogen produced in electrolysis factories such as the one built by Shell on the Maasvlakte. However, this backbone will only supply ve out of the six major industrial clusters in the Netherlands: these include companies such as Shell, Tata Steel, Yara or Chemelot.

Figure 1: netcongestion in the Netherlands (red means no new connection)

The aforementioned sixth cluster consists of all companies that don’t fall into the rst ve clusters. This means that each small to medium business that needs a gas to burn and doesn’t fall into the big ve has no way to decarbonize. Well why don’t they build their own pipeline you might ask? These pipelines are expensive, costing about 5 million euros per kilometer, which is far beyond what any average company can a ord. Another option would be to transport hydrogen using trucks or trains, and although already possible, this is ludicrously expensive.

Hydrogen in its gaseous form is everything but energy dense, as gasses take up a lot of space. One way around this is to cool it down to very low temperatures or store it under very high pressure to turn it into a liquid. Again, this is already possible, but not feasible. Besides the massive costs that come with cooling or applying pressure, it’s also dangerous, as you’re still transporting an explosive and ammable gas, over the open road. So what happens now? Do these companies just stop existing or keep polluting? No, SOLID has found a possible solution, which could take the energy transition by storm.

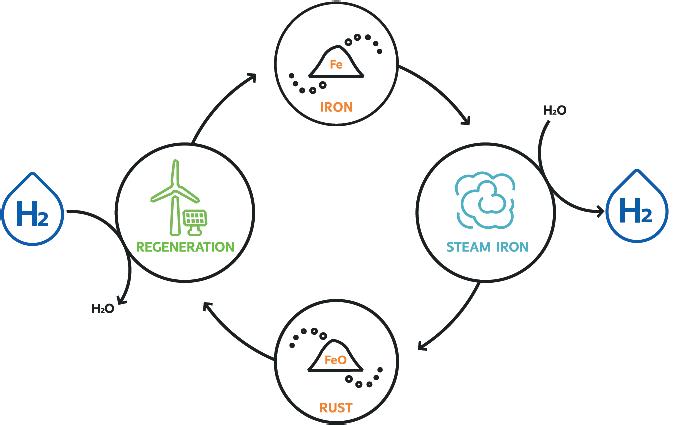

In the last two years, SOLID has been developing Iron-based Hydrogen Storage (IRHYS), a revolutionary way to store and transport hydrogen using iron pellets. It works as follows: ironoxide (FeO), otherwise known as rust (yes, the same rust as on your bike!) can react with hydrogen (H2) to form iron (Fe) and water (H2O). Ideally, this step of the reaction is done in a location where green energy, and thus hydrogen, is cheap like Marocco. This ‘charged’ iron can then be transported in a compact, safe and a ordable way to the Netherlands using conventional means such as bulk carriers.

At the location where there is hydrogen demand, this iron can then be steamed using water heated up to high temperatures. The result is once again, hydrogen and ironoxide. This creates a circular process where iron acts as a renewable energy carrier for hydrogen, minimizing the risk of explosion and more importantly, iron is able to store three times as much energy in one cubic meter as hydrogen in its gaseous form.

As stated earlier, SOLID has been developing IRHYS now for two years, and in those two years, we’ve gone from a theoretical paper, to a proof-of-concept system: the Steam Iron Reactor 1 (SIR1). This system is able to both store and release one kilogram of hydrogen with an output of 10 kW. This system is used to learn about the fundamentals of the reaction and create knowledge for further improvements

The team doesn’t want to stop here, as SOLID, we don’t just develop a technology, we want to create an entirely new ecosystem. In the coming year, our team will start designing the SIR2, a more e cient and bigger industrial test setup that will be used to validate the IRHYS chain, from the Port of Rotterdam to a company in the sixth cluster in the Netherlands. Besides that, it will do a feasibility study on the aforementioned chain, to ensure that each company knows the exact costs of the implementation of IRHYS.

In conclusion, large parts of the Dutch industry are stuck, having no light at the end of the tunnel when it comes to the energy transition and decarbonization. Although large e orts are made to produce and transport green energy, all current solutions fall short of supplying the entirety of the Netherlands. SOLID hopes to enable access to clean and renewable access for anyone, at any one time by developing the IRHYS ecosystem. If you’re an engineer who wants to make an impact on this transition, then don’t hesitate to contact us and be part of the metal fuel revolution.

WRITTEN BY TOM SLANGEN

‘Te land, ter zee en in de lucht’ is one of the well-known programs of TROS and also the longest-running entertainment program on Dutch television. In this program, people attempt to navigate a course in homemade cars, boats, planes and any other way of transportation.

One day, René Stokvis saw a picture in an English newspaper of a pilot jumping o the Tower Bridge with a contraption. At that moment, he had an idea: he wanted to try to make people y by staying in the air as long as possible with homemade “airplanes”. In 1973, this became a reality with the TV game show “Vlieg er eens uit” (Fly Out) Candidates had to jump o a platform with a self-made “airplane” and stay in the air for as long as possible. The rst episode was recorded at the Drommedaris in Enkhuizen. Where after many places in the Netherlands were visited.

The program developed and in 1978 was named ‘Te land, ter zee en in de lucht’. The phrase ‘te land, ter zee en in de lucht’ originates from a translation of a re ection by Winston Churchill about Allied cooperation during the First World War in his book “The World Crisis.” Di erent versions of the course were created. Almost in every course, a bell must be rung at the end. There are di erent prizes which can be achieved during the program. The rst is

the one who rings the bell the fastest. The course is completed in the shortest time. The second prize can be won by creating the most original transportation. The last prize is for the contestant who has bad luck. Thick of just missing the nish, or someone gets injured, a lot of time has been spent on a vehicle and it does not even work.

A few years ago W.S.V. Simon Stevin had a committee named after this program. “First and second-year students enjoy getting hands-on with mechanical engineering. That’s why we established a ‘Te Land, ter Zee en in de Lucht’ committee a few years ago. We’ve participated in various events, and this year marks our third time in ‘Hoog en Droog’. For this, we had to build a cart that would ride over two steel cables stretched over water as quickly as possible, ring a bell on the other side.” tells Van de Heijning.

Second-year student Hanno Schouten was the driver. Van de Heijning added, “We had to be one of the rst to start. We made a very fast time, but unfortunately, it was surpassed by two teams right at the end.” The third place earned the student team nothing more than a participation certi cate, as there’s only a prize for the rst place. Van de Heijning nds the practical experience gained from participating in the program enjoyable. “They learn it from a book, but now they get to do it for real.”

The Efteling announced on May 3, 2024, that they will be recording four new episodes of the program in the spring of the same year. These episodes are scheduled to air during the summer on RTL 4.

The Dutch caretaker government has unveiled Project Beethoven, a €2.5 billion investment aimed at bolstering the Brainport Eindhoven region, speci cally targeting tech giants like ASML. The project, responding to concerns from Eindhoven-based companies, seeks to mitigate issues like recent tax changes, housing shortages, and infrastructure de ciencies. ASML, a key player in the chip production industry, has highlighted the adverse impacts of the new tax regulations, particularly the removal of dividend tax exemptions for share buybacks, and the reduced tax bene ts for expats, which a ect 40% of its workforce.

Project Beethoven allocates substantial funds to education and talent development, including a €450 million investment until 2030 and an annual €80 million thereafter to attract and train technical talent. Infrastructure enhancements are also prioritized, with signi cant investments in public transportation and housing to support the region’s growth.

Despite these measures, ASML has not committed to staying exclusively in the Netherlands but prefers to expand there if conditions improve. The company’s expansion plans are critical, given the projected growth of the chip sector to a trillion-dollar industry by 2030. Other tech rms, including NXP and ASM International, support the initiative but emphasize the need for broader and consistent policy support amidst a uctuating political environment.

WRITTEN BY STEFAN GEERTS

The main task of a pilot is to control their airplane, but what makes it possible to move a 200-ton aircraft while ying over 30 kilometers from the ground? In addition, how can one determine the speed of an airplane? In this article, the ight controls of an aircraft and its speed determination are being investigated.

WRITTEN BY ARYAN BAKERMANS &

DANIËL KLEINJAN

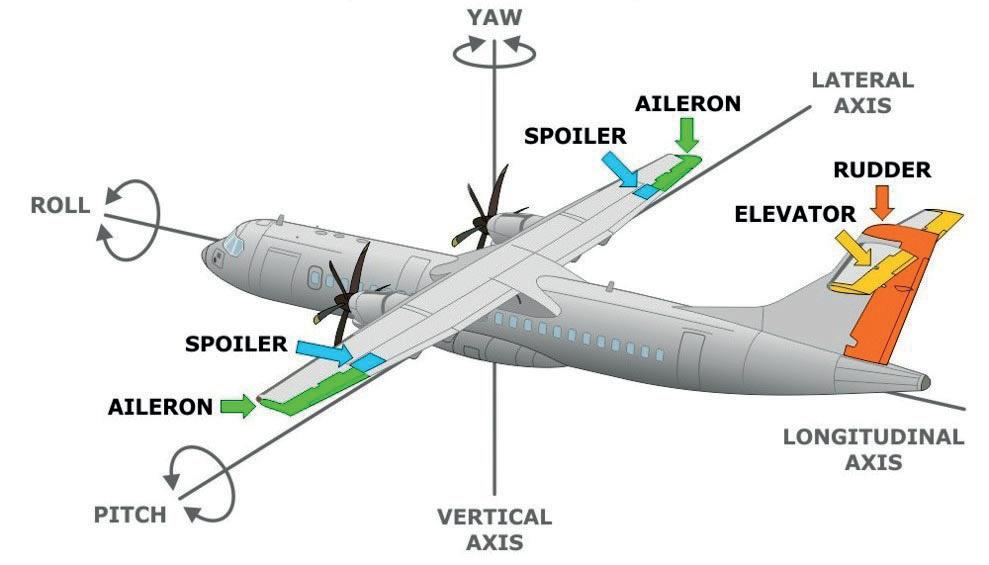

Compared to driving a normal road car, ying an airplane has more degrees of freedom. In the horizontal 2D plane, it can translate, turn, and rotate in and around the axis of the ying direction. Additionally, in 3D, the plane can move up or down. On an airplane, there are three main ight controls. Additionally, the secondary ight controls give the pilot extra control of the aircraft.

In an airplane, there a three main ight controls. The rst one is the elevator that controls the pitch of the plane, which a ects the position of the nose. Pitching up means that the nose of the plane points upwards, causing the plane to gain altitude, whereas pitch down causes the plane to lose altitude, as the nose points downwards. The second main ight controls are the ailerons, located on both wings of the plane. They move opposite from each other to make the plane roll left or right. Finally, there is the rudder, which allows the plane to turn left and right around the vertical axis, also referred to as ‘yaw’.

The secondary ight controls give a pilot extra control of the airplane, consisting of the aps and slats, the trim control, and the spoilers or airbrakes. The aps and slats are located on the leading (front) and leading (back) edges of both wings and allow the general shape of the wing to change, by extending or retracting to increase or decrease the amount of lift that is

generated. Moreover, the slates can help prevent the airplane from stalling, by extending and increasing the e ective curvature of the wing is increased. The e ect of stalling occurs when the wing’s angle of attack becomes too large and the wings cannot generate enough lift to keep the plane airborne.

Then there is the trim, located at the control surfaces of the primary control systems. The trim helps the pilot to keep the plane in a certain condition, for example during climbing to cruising altitude (where it operates at its maximum e ciency). During climbing, the airplane is in the nose-up position to gain altitude which requires the pilot to move the steering column. Using the trim on the elevator, the input of the pilot can be mimicked, preventing the plane from levelling out if the pilot removes the input.

Next on the wing are the speed brakes and spoilers, which can move upwards to break the air ow and cause drag (friction) to decrease the speed. During the ight, the speed brakes can be used to decrease the airplane’s velocity. During landing (or a rejected take-o ), the spoilers are used to both decrease the speed and create downforce to the ground, which enhances the brake e ciency of the landing gear, since it is pushed to the ground. Finally, the roll spoilers can help the airplane to roll or in case of a malfunction of the ailerons.

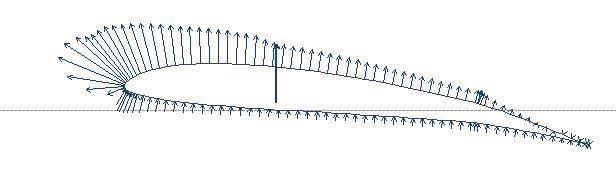

The main ight controls and spoilers of an airplane.

In the cockpit, the pilot controls the airplane via a control column, which operates the primary and secondary ight controls. In a traditional aircraft, the elevator, ailerons, and rudder were physically operated by wires. For example, when the pilot pushed the control column backward, the wires would be tensioned to change the position of the elevator. For smaller aircraft, this was ne, but as the planes became larger, so did the hydrodynamic forces on the airplane and hence the force required by the pilot to control the plane. To solve this issue, hydraulic pumps were added to solve this issue, as hydraulic components can increase the force on the plane.

Modern aircraft however are operated using a ‘ y by wire’ system, which converts mechanical pilot inputs to electrical signals for actuators to move the control systems. In addition, the input from the pilot is analyzed by a computer to determine how to move the control surface to achieve the desired performance. The y-by-wire system is safer, as there are no more physical cables that are susceptible to wear and failure and it does not require the muscle power of a pilot to be able to control the plane. Additionally, it saves weight, which increases the e ciency of the aircraft.

Operating an airplane di ers among manufactures like Boing and Arbus. In Aircraft produced by Boeing, the ight controls are operated via a steering column central to the pilot. Contrary, airplanes built by Airbus are using a joystick, located at the side of the pilot, operated with only one hand. Moreover, the way the FBW system is operated is di erent as well. For example, pilots who y an airplane from Airbus are restricted by the computer to y within the ight envelope, which refers to the operational limits of the aircraft. The pilots of Boeing-manufactured airplanes have more control and are allowed to work outside the ight envelope.

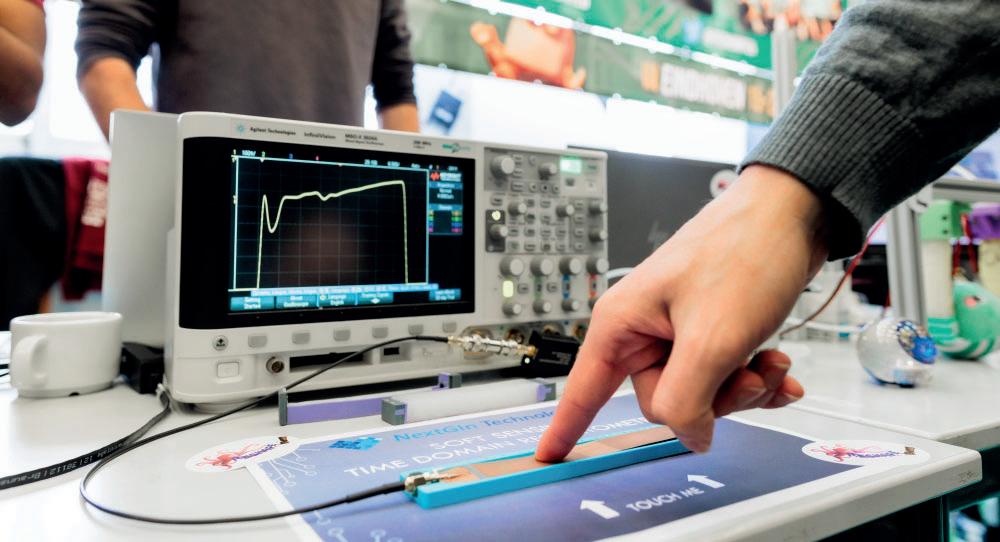

Closely related to an airplane’s ght control system, is the instrument panel, of which the airspeed indicator is arguably the most important gauge to be found. But how does one measure airspeed?

To answer that question, rst a distinction has to be made between the di erent speed types. There are two basic aircraftrelated speed types, “ground speed” and “airspeed”. Ground speed indicates your relative velocity to the ground, since the ground is stationary, ground speed is often referred to as just “speed”, which is true for example in cars or a GPS measurement. The term airspeed is a bit more complex as di erent measuring techniques have di erent designations, of which the most common is the Indicated Airspeed (IAS) and True airspeed (TAS), which have been used in aircraft as early as 1912 and are still used today. IAS is a measurement of how much air ow passes your aircraft, and TAS indicates your speed relative to the mass of air, which is essentially the same at low altitudes and speeds, but starts to deviate once the air density lowers.

Mostly, IAS is an important factor for a pilot. Due to the wings providing lift by air passing by, theoretically speaking, a plane can have a groundspeed of 0 while being airborne, this is possible if the nosewind is strong enough. This means that depending on the wind direction, your IAS will be higher or lower compared to

your ground speed. Indicating the importance of IAS as it tells the pilot whether the plane’s wings have enough lift to y, or if he has to increase speed to avoid falling from the sky. Typically, a small aircraft like a Cessna needs to have an IAS of 100kph, whereas a jetliner needs 240kph.

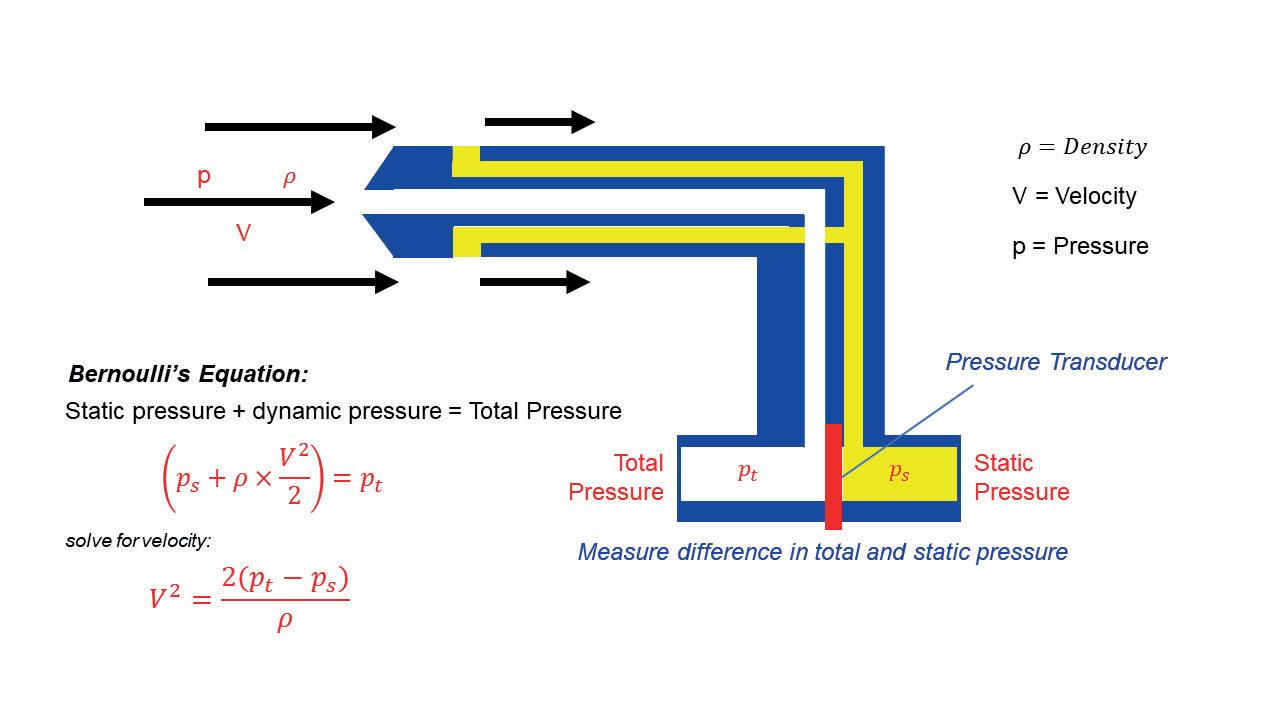

Coming back to the question stated earlier, how does an aircraft measure its speed? As seen, IAS is coherent to the air ow passing an aircraft, and as expected, it relies on the basic concept of applying Bernoulli’s equation on a pitot static tube as you might have seen in your introductory course on transport phenomena.

The pitot tube can be easily spotted on most aircraft, ranging from the long spike on the nose of a ghter jet or a more sophisticated “antenna-like” hook on the side of an aircraft. These tubes typically have a length of about 25cm and a diameter of 1cm, which is nice to know, but doesn’t matter too much for the general equation below.

The second equation represents IAS speed as a function of the pressure di erence in the points in the tube as seen in the picture. Depending on the aircraft, this measurement is electronic or mechanical as is its conversion to the gauge on your instrument panel, giving the pilot a measure for the speed.

You might’ve noticed some new towers popping up in the TU/e campus skyline. They resemble the older Aurora building, a building for student housing owned by Vestide. But do not be mistaken, these new buildings are not just any ordinary student apartments. This extraordinary project was made with the help of student input and might be the turning point in student housing in the Netherlands. In this article, we have interviewed Stijn van Giezen (Senior real estate developer) and Michiel Moelker (Residential consultant) about what makes this project so interesting.

Haven, the newest project by Woonbedr f, will o er 735 rooms on campus, accommodating both single and shared rooms for students. It consists of 3 buildings: 2 high-rise buildings of 14 oor each and one lowrise building called Castor, Pollux and Terra. These buildings, together with the surrounding projects of Aurora and Lombokpad, aim to create a strong community of students living on and around the campus.

The project was won by Woonbedr f at the end of 2020 and has since been developed very fast, but always with the input of students alongside it.

What was the central idea behind this project?

It all started when the TU/e announced a shortage of housing and a need for more places for students to live on campus. Around this time there was also research being done by DAS, who wanted to know what the main need of students is when it comes to a nice place to live, and the answer was loud and clear: Community. It should be easy for new students to integrate with their living space and the design of these places can be crucial in the ght against loneliness. This has been the main principle for the design of the project.

How were students involved in the design process?

Students were involved since the start when it became clear through student input that community was one of the main needs. Ideas for the interior of the rooms and winter gardens (large community spaces on the facade of the building) were also given by students and the rooms were designed with these in mind. For example, the height of the room is more than normally used such that loft beds could t comfortably. The central theme, Metamorphosis, was also an idea of a student and has been used throughout the building. One example of this is the wallpaper used in the winter gardens, metamorphosing from the bottom of the building to the top. The idea and design were created in cooperation with a student from the Built Environment.

What kind of rooms will be available?

Studio’s, and (shared) apartments. The shared apartments will be lled by use of matching nights to nd housemates who t you. The entire student mix for these buildings is composed of 50% internationals and 50% Dutch students, further improving the community diversity.

Are there any new, innovative ideas that are being tested out in this project?

The community has been incorporated into all parts of the buildings. Hallways have been designed to create “spontaneous interaction”. For example, shared spaces like washing rooms have been placed at the entrance of buildings so that anyone who enters might see someone they know washing their clothes, creating a spontaneous interaction. The idea of the matching nights is also new and hopes to improve bonds between housemates. This way, students who are new to the TU/e have a nicer way of integrating into the community.

There will also be facilities available in the complex which aim to create an “inclusive student town”. These are independent shops that are also aimed to improve the community. “We want to utilize real estate for the goal of community”. These facilities have not been chosen yet, but one that will likely be there is a Mensa: a restaurant with cheaper food aimed at students.

The buildings are set to be delivered in August of this year. The renting period starts on the 26th of April and lasts a week.

The average reader of the OpenME might now about the following rubric: How is life in ‘internship country x’? Of course, these articles create relevant insight into the life of students, but in this big and scary world there are bigger sh to fry and questions to answer. Such as: How is the war in Ukraine going? Why is the economy stagnating? What can we do about our worsening business climate?

WRITTEN BY JOOST VAN DER KRAAN, SANDER VISSER

Ever since the COVID crisis the Dutch economy has been stagnant, years of low and slow growth get compensated by years of marginal economic downturn. To make matters worse: that growth was only caused by rampant government spending, which in part, has caused massive in ation, something we have all noticed when ordering a beer in our beloved Sgt. Peppers.

Obviously, government spending isn’t the sole reason for the massive in ation of the last years. The core cause for this is the energy crisis, which was caused by the Russian invasion of Ukraine and the sanctions that followed. Speaking of that war: from a NATO perspective the war isn’t going entirely to plan. The promised summer o ensive from Ukraine, where they supposedly should have smashed the Russian lines with beautiful Western technology such as Leopard 2A6’s failed miserably. As a matter of fact, the Russians have regained the initiative of the battle eld, and have pushed Ukraine back from strategic positions such as Adiivka. How is that possible, even with all that fancy equipment? The answer is simple: all those shiny killing machines aren’t very useful if you don’t have bullets to re with them. Of all the munition that the European Union has promised, only 30% has actually been delivered, which means that Ukraine has to revert to Soviet-era weaponry.

Even though we like to believe that all solutions are found on the TU/e, sometimes we must think smaller, sometimes solutions can actually be found in Limburg. Yes, that’s right, this small province, known for its fake Belgian accent and delicious pie actually has another competency which is often overlooked: the German speciality of assembling cars! Sadly, the Dutch manufacturing industry has been under pressure, due to exploding costs. One such factory struggling with this is VDL Nedcar from Born. Due to these aforementioned costs the facility, which normally assembles BMW’s and Mini’s, has been closed. Yet, it could provide a solution to our problem.

As Europe we are waiting in suspense on the American and German ammunition companies to solve our shortages, but what if we took matters into our own hands? Our vision is to turn Limburg into the epicentre of the new European militaryindustrial complex. The facilities are already there, the province needs the jobs and revitalizing a loss-making factory into an e cient ammunition factory is like tying your shoelaces for family Van der Leegte.

We know what you’re thinking: what bene t does an ammunition factory bring to the Limburgers? Ukraine is what you might call a ‘far from your trench show’. Yet, geopolitics isn’t that simple. If Russia manages to conquer Ukraine due to a lack of European support, it will give Putin and his regime of war criminals the conformation that Europe is there for the taking, at that we can’t save ourselves. After all, if we can’t even support Ukraine with enough guns and bullets, how would we support our own armies if an actual world war were to happen? To make matters worse, according to high ranking o cial Rob Bauer of Nato, our ammunition reserves are already running out, and that’s before our impressive F35’s have red a single rocket.

The envisioned factory, called VDL NedShell, won’t just produce ammunition for Ukraine, but it will supply the entirety of Europe. Due to the war in Ukraine, Europe has seen a sharp increase in defence spending, in the hope of repelling Russian aggression. This means that there is more than enough potential market demand to ful l, which is important for the business perspective, Dutch economy and government nances. In addition to that, the Netherlands will add a geopolitical bonus to itself, by having the supply of ammunition it will provide a similar to e ect as ASML has on the semiconductor sector. The B.V. Nederland: main producer of all your chips and ammunition, a major player.

Besides geopolitical bene ts, the Netherlands also bene ts from this factory in nancial terms. There is a massive shortage of ammunition in Europe, creating large scale investment in defence. Just this year, NATO has signed a contract where they have invested 1.1 billion euros in artillery ammunition. According to Reuters this money will go to 220.000 pieces of 155 mm shells. If we decide, at this very moment, to join in on this ‘bullet collective’, part of this production can be brought to the Netherlands. This won’t only grow our economy, but also speed up the delivery time of ammunition.

In addition to that, this new sector for the economy will grow the diversity of our manufacturing industry. Joining in on the war economy that NATO needs is absolutely worth our while. For re ection: the Russian economy has grown 5.6% in two years thanks to their war economy. Although it is well known that a war economy isn’t sustainable on the long term, we must still act now, as it would be naïve not to prepare our economies for the prospect of war with the east.

Obviously, we must think of the moral consequences of the productions of weapons and ammunition. Producing such machinery means that someone will use it, sooner or later. It would be disastrous if our guns would fall into the hands of advisories. Hence, it is of great importance that we only sell our produce to countries that we trust, using carefully crafted trade deals. This will encourage further European integration and unity, as we want to create independence from the United States.

No matter the moral constraints, we must take matters into our own hands. Refusing to create independence when it comes to ammunition and guns supply, is of the utmost arrogance and naivete. For too long have large EU countries relied on the support of NATO (the United States). We didn’t need to invest into our militaries, as big Uncle Sam would come to save us if necessary. We thought that just applying diplomatic pressure was enough because most people that economic incentives were enough to ght o the prospect of war. Yet now, we have to conclude that this is a fairy situation, where the last thirty years were merely a lucky coincidence.

Now that there is a real chance that the United States won’t guarantee European defence, it is time to wake up, and build our own military-industrial complex. The Netherlands can play a major role in this crisis, we only have to look at the moral stances our advisories take to conclude that we must allow ourselves to arm the military accordingly, and do the necessary ‘dirty jobs’.

The goal of this article isn’t to create panic, or keep you up at night due to worrying about a possible Russian invasion. That’s why we want to nish on a positive note: the European Union has proved to be resilient against crisis, and that it can handle itself adequately on the world stage.

Furthermore, we recommend you to read the book ‘De Slag om Europa’ by Rob de W k, in which an explanation is given on how the EU is put under pressure by outside forces, and how no matter what, we get stronger from that as a union. On a nal note, this article should make you think again about ammunition production in the Netherlands, as there are more bene ts to it than you might think.

WRITTEN BY : BEN GORTEMAKER

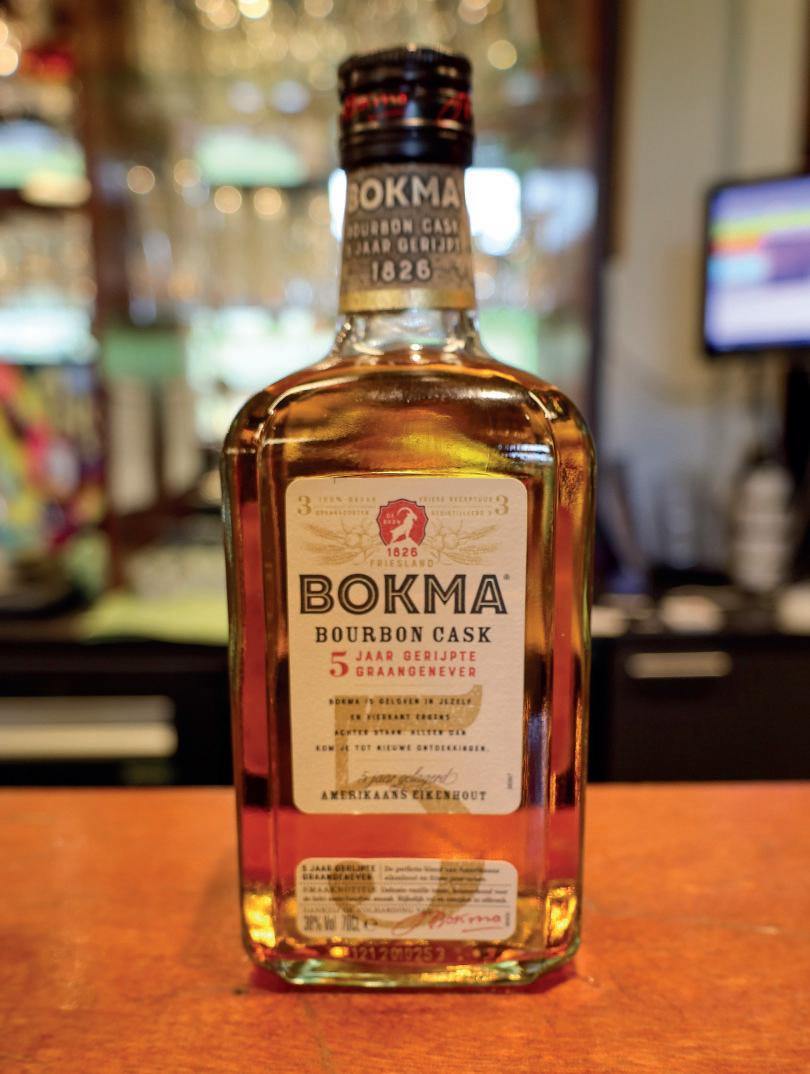

Jenever, a traditional Dutch liquor that has existed for over 400 years in the Netherlands. Many of you might have already tried this tasty Dutch delight, maybe pure, as a kopstoot with your beer or in your Tiki Taki. The jenever at our Association is Jonge Bokma, however next to this there are also other kinds of Bokma you want to hear about.

To start o with the drink that we all know: Jonge Bokma. When it comes to jenever the young kind is unique in its avour. It generally has a very sharp taste, which generally is found to be undesirable. For this reason, it is recommended that Jonge Bokma is cold such that these harsh avours are muted. However, aged jenever does not have this attribute and is therefore drunk at room temperature. When the Bokma is cold the taste of juniper, honey and a slight grain taste come to the foreground, combined with the soft and round mouthfeel the liquor becomes very nice and refreshing.