Just imagine the next bottle of pineapple juice you drink being made from the same pineapples. The Celal-Mex team is here to make it happen.

Just imagine the next bottle of pineapple juice you drink being made from the same pineapples. The Celal-Mex team is here to make it happen.

The increasing demand for plastics and their presence in our daily lives is a reality. It is clear that we cannot avoid using plastic from one day to the next. As a result, we have committed ourselves to finding environmentally sustainable alternatives that will allow us to mitigate the problem and satisfy demand competitively.

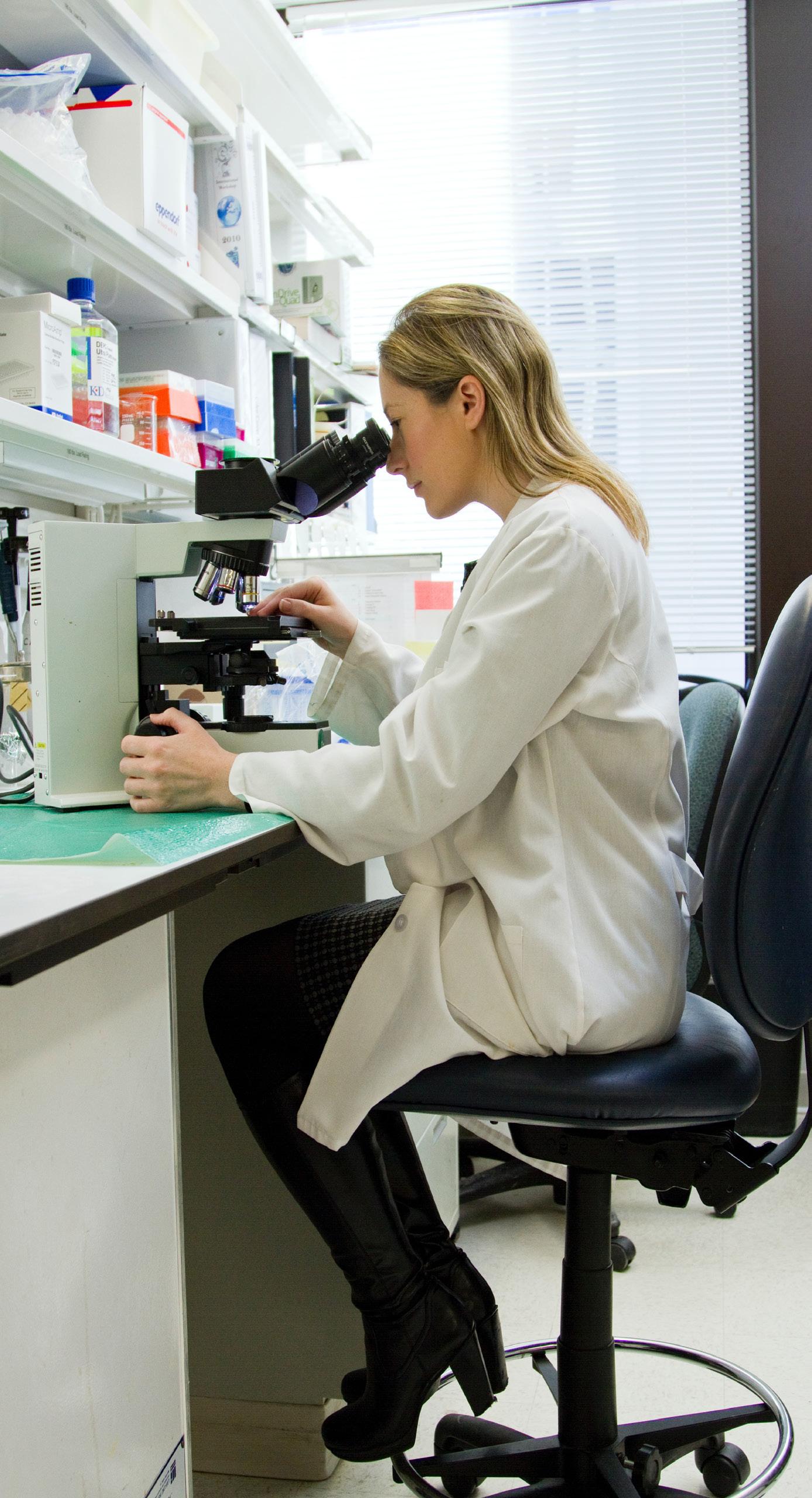

CELAL-MEX is a biotechnology-based company specialized in the development of environmentally sustainable alternatives and substitutes for the agricultural and industrial sectors. We are dedicated to recovering agricultural by-products and processing them into biopolymers for industrial use.

With a biotechnological approach, we develop sustainable alternatives to conventional polymers utilizing agricultural waste. We are committed to guide this sector towards a circular transformation that reduces its environmental impact and maintains its international standards.

We strive to be world leaders in the use of agricultural by-products and a benchmark for Mexican exports of sustainable alternatives.

Commitment to environment

Innovation

Circular thinking

Sustainability

Optimization

Constant change

Exponential and sustainable growth

Biotechnology as an ally

We have been part of associations that promote social entrepreneurship and research, such as Enactus, Tec de Monterrey Institute for Obesity and the American Institute of Chemical Engineers. Strategic

We have participated in more than 10 national competitions during 2021, 2022 and 2023, and have won the following:

3rd national place at Inc Prototype 2021 in Monterrey, México:

https://fs.hubspotusercontent00.net/hubfs/6340004/Memorias%202021/Prototype21.pdf

2nd national place at ENACTUS 2022 in Aguascalientes, México

Top 100 finalists at Jump Chile 2022

3rd place national atl UNITEC prize of sustainable development for social innovation 2022 at Mexico City: https://blogs.unitec.mx/unitec-hoy/premiosunitec-a-la-innovacion-tecnologica-para-el-desarrollo-social/

Inc Mty named us as 1 of the best 20 startups in 2022 and we were present at the Inc Mty Startup Expo :

https://www.instagram.com/reel/CmmU5cYDkxB/?igshid=YmMyMTA2M2Y=

Top 50 finalists at MIT Solv[ED] 2023 (en espera de resultados finales)

Speakers at 5th FOODIE in Davis, California

1st national place GSEA 2023 Mexico

Speakers at Tec Science Summit 2023 (March 3, 2023)

It can be used as:

Filler in melamine compounds

Packaging

Plastic formulations

Differentiation:

Price below the market

Use of 3 times less water for its production

Less use of chemicals

Sourced from agricultural residues

It can be used as:

Industrial additive

Ceramic manufacturing

Adhesives and binders

Differentiation: Improved gelatinization properties

Avoids corn waste

Sourced from agricultural residues

We operate on a business-to-business model (B2B). We receive agricultural by-products from our suppliers, which we transform into raw materials for packaging companies, extruders, and manufacturers that supply food companies, retailers, and parcel services.

dls/ton

$3.22

61,57% Overhead costs

17,3% Taxes

21,13% Profit margin

Net International Trade in Chemical Cellulose and its Derivatives, not Specified or Included Elsewhere, in Primary Forms Annual Flow, according to data from customs tape

imports production

In Mexico, cellulose imports are increasing by 2.6% annually, mainly from Canada at $1,100 per ton and from the United States at $1,200, which gives us a competitive price advantage.

The companies in the country with which we compete are: Ecofilter, Georgia Pacific, International paper and Kimberly Clark.

$203 MILLIONS DLS

Cellulose

$26.4 MILLIONS DLS

by: Data México

$5.63 BILLIONS DLS

$1.4 BILLIONS DLS

To continuously improve our products, our team continues to research the optimization of our processes.

Meanwhile, we participate in contests in order to enrich our company with new strategic alliances. This is all in order to find financing for the installation of an industrial facility that allows us to scale our production.

We envision using more organic agricultural wastes in the future, including banana, papaya, and agave, among others. The company intends to become the first biotechnology unicorn in México and to debut on the Mexican Stock Exchange in order to promote the creation of public companies in the country.

In the near future, we plan to cover 2% of the Mexican pulp market and 5% of the starch market. Finally, CelalMex seeks to venture into upcoming markets such as bioplastics, nanocellulose, phenolic compounds and fungi to treat agro-industrial waste.

WE ARE CELAL-MEX