Titan Enterprises Continues To Break Ground In The Mining Industry

Page 4

Issue 43 worldwide-engineering.com

3D Inspection in a “Snapshot” with SICK Visionary T Mini AP

Page 16

PTC works with BAE Systems to bring next generation fighter pilot helmet to market

Page 20

Contents

Worldwide Engineering Magazine

Providing timely industry news, exclusive features on advancing technology, equipment, materials, show previews, content marketing services for our valued clients and much more!

4

Titan Enterprises Continues To Break Ground In The Mining Industry

8

RanLOS and Anritsu Unveil Innovative 5G Vehicle OTA Test Solution

16 20

3D Inspection in a “Snapshot” with SICK Visionary T Mini AP

PTC works with BAE Systems to bring next generation fighter pilot helmet to market

22

World leading virtual reality teaching facility opens at the University of Nottingham

Gary Tidy

24

UK Government commits to funding more autonomous vehicle projects

Publication Manager: gary@worldwide-enegineering.com

Jonathan Toney

Sales Manager: jonathan@worldwide-enegineering.com

Katie Sirdefield

Editorial Assistant: katie@worldwide-enegineering.com

Orla McGill

Newsletter/Editorial Assistant: orla@worldwide-enegineering.com

Titan Enterprises Continues To Break Ground In The Mining Industry

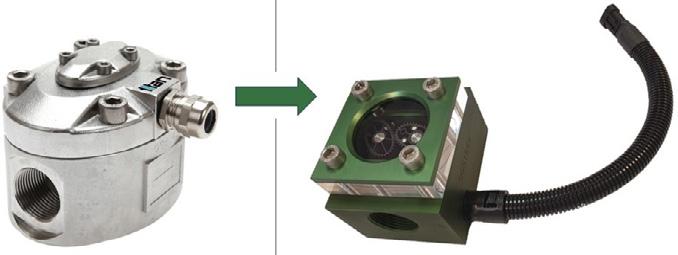

For over 25 years, Titan Enterprises’ Oval Gear flowmeters have been incorporated into heavy drilling and rock crushing machinery for use in the Mining and Aggregate industry. Due to their rugged design, these meters provide reliable performance in extreme conditions.

Initially working with JCB, Titan developed a bi-directional / dual flow Oval Gear flow meter that was fitted to drilling rigs in salt mines. These underground drill

rigs are machines designated for drilling in the rock face as well as in concrete and ground. The relatively small flow measuring devices are incorporated into these vast

Large rock crushers and other equipment are used to break and remove rocks of various hardness and toughness, to extract the mineral-rich material, and process the ore by extracting the desired compounds and metals. McCloskey International is one such heavy machinery manufacturer specialising in crushers and mining processing equipment.

McCloskey International approached Titan to see if we could make a flowmeter able to monitor the oil flow on a rock crushing machine. The requirements were for a much bigger thread than would normally be used for the specified flow range. They also wanted to see the meter in operation. The central ‘drum’ of the crusher which does

4

machines to monitor the flow of oil and additives.

Titan’s oval gear flowmeters used in mining heavy machinery and equipment

McCloskey Rock Crushing Machinery

the hard work is basically a huge cylinder rotating on large bearings. These bearings had to withstand the side load induced during the rock crushing so the oil flow and pressure are critical. It was vital that the flowmeter did not impede this flow and so had to have a low pressure drop even at full flow with cold, highly viscous oil.

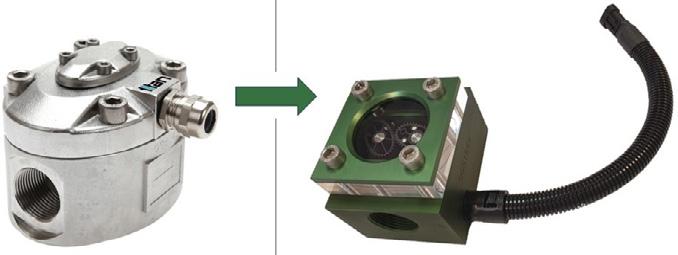

Titan’s OG5 model fitted the flow requirements but the standard unit’s 1” BSP threads were considered too small, risking a restricted oil flow.

We set about redesigning the OG5 model in aluminium and with 1¼” connections to reduce the pressure drop at minimum temperature and maximum flow. We installed an acrylic cap, a see-through cover so that the operator could visually verify oil flow. A cable loom was fitted so that the flowmeter could be plugged directly into the customer’s wiring loom. The final touch was to anodise the body of the meter to match the colour of the machines they were being fitted into, making these meters a very distinct OEM product. The

resulting flow device has proved to be very reliable and to date over 600 of these specialised flowmeters have been installed in the McCloskey family of rock crushers over the last 10 years.

As well as adapting designs to meet customers’ specific process needs, such as high-pressure requirements and to aid chemical compatibility, Titan’s standard OG5 flowmeter has since been redesigned. These compact rugged positive displacement flowmeters incorporate a new machined stainless-steel, high viscosity design for both the body and caps, which has also enabled an increase in the standard design pressure for these units.

Titan’s OG Series of flow meters are designed to give reliable, high performance across a wide range of applications. Almost immune from the effects of varying liquid viscosity, density and temperature, the measurement performance of oval gear flowmeters improves as liquid viscosity increases.

Visit Titan Enterprises’ website for further information on flow measurement or to discuss specific OEM applications, please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk.

Titan Enterprises is a leading design and manufacturer of innovative end user and OEM high-performance flowmeters and flow measurement instrumentation, used within a wide range of processes, environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• NSF-Approved mini turbine flowmeters

Titan’s liquid flowmeters are designed and manufactured to ISO 9001 with traceable calibrations.

5

Innovative Liquid Flow Measurement Solutions Ultrasonic Flowmeters Turbine Flowmeters Oval Gear Flowmeters Instrumentation +44 (0)1935 812790 sales@flowmeters.co.uk www.flowmeters.co.uk REQUEST A FREE QUOTE TODAY Breakthrough Flowmeter Technology

Titan’s original Oval Gear model adapted for McCloskey International

Top 2024 manufacturing trends to watch

Jason Alexander, Industrials Leader, Principal, RSM US LLP,

examines the six most critical areas of focus for manufacturers in 2024 and beyond.

Change is constant in the manufacturing industry, and the supply disruptions and global shifts of the past few years have highlighted how critical it is for industrial companies to focus on resiliency. Here are the top six manufacturing trends RSM has identified for the manufacturing industry:

1. Data and smart manufacturing

Machines, assembly lines, smart sensors, robots and other devices generate enormous amounts of industrial data that, historically, manufacturers have not taken advantage of. As more companies implement advanced technologies and more ‘factories of the future’ take shape, a robust data strategy becomes paramount. Shifting to a data-driven decision model will provide businesses with predictive insights that can optimise processes, strengthen risk assessment procedures and ultimately help them maintain a competitive edge.

To have a successful datadriven manufacturing operation, companies also need the information technology infrastructure to support advanced Industry 4.0 technologies; this area is where many middle market manufacturers are further behind their larger counterparts. Organisations need a flexible, scalable and interconnected IT architecture to support the shift to more data-driven operations and meet future challenges.

2. The continuing urgency of cyber security

While advanced technologies are streamlining many aspects of traditional manufacturing operations and breaking down longtime barriers that can impede innovation and collaboration across the entire value chain, they are also creating more opportunities for cyber criminals to compromise manufacturers.

According to data from the 2023 RSM US Middle Market Business Index survey special report on cyber security, 20% of middle market executives claimed their company experienced a data breach within the last year. Also in this year’s data, 35% of middle market executives disclosed that they experienced a ransomware attack or demand, up from 23% last year.

Manufacturers – and any third parties they work with – need to raise the bar on protecting themselves in an environment where workers, machines, supply chains and organisations are becoming ever more digitally connected. Understanding which critical information and intellectual property assets need protection from potential cyber attacks—and taking action to put those protections in place – will increasingly become a source of competitive advantage.

3. Reimagining global supply chains

While manufacturers historically have focused on making their supply chains more cost-efficient, few have considered addressing vulnerability to trade risks or global pandemics. The past few years have shown that companies that have invested in technology and focused on supply chain agility have an edge against their competition, and that will continue to be true as we look to the future.

Manufacturers need to take advantage of technology to create more connected supply chains, providing an opportunity to link various pieces of the supply chain together to receive more data. Companies prioritising digitising their supply chains will be more resilient and better positioned to respond to future supply and demand disruptions (for instance, the manufacturing construction boom in 2023). Digitisation will be essential in the new era of

6

globalisation as companies diversify where they source and make their goods.

4. The battle for manufacturing talent

As manufacturers grapple with technology’s increasing role throughout their organisations, the impact on their workforce will be significant. The dynamic and fastpaced environment created by today’s advanced technologies –from intelligent robotics to big data and the industrial Internet of Things – will require the current workforce to adapt. It will also require companies to be more intentional and creative in attracting and retaining talent.

We expect this will bring a renewed emphasis on cultivating new skills for an environment where analytics increasingly drive business decisions and humans more commonly coexist with robots. Manufacturers will need to reassess and update their training and workforce development strategies to keep pace with this industry shift. Companies will also need to have a clear understanding of which core offerings to focus on and which might make sense to outsource.

5.

Economic pressures and market shifts

The era of low inflation, rapid growth and inexpensive capital is transitioning to a new state. Globalisation is not dead, but the makeup of its participants has shifted as businesses diversify where they source and make their goods. The impact of these structural changes is profound, and amid margin pressures in a highercost environment, manufacturers will need to focus on optimising operations.

In the US, legislation in recent years – including the Inflation Reduction Act and the CHIPS and Science Act of 2022 – has also shaped a new era of industrial policy that is driving increased construction investment for US-based semiconductor manufacturing and green technologies that support the energy transition.

Manufacturers need to understand how to take advantage of opportunities in these policy changes to capitalise on this wave of opportunity. The fact that clean energy incentives are a significant component of recent legislation underscores the importance of

environmental, sustainability and governance (ESG) issues for manufacturers, too. As ESG gains more traction among various stakeholders, decarbonisation will likely need to become a bigger priority for manufacturing, automotive and energy companies.

6. The rise of artificial intelligence

Manufacturing is one of many sectors across the economy adopting generative artificial intelligence (AI) and exploring its potential to revolutionise processes and unlock new human capabilities.

For manufacturing companies, the potential of AI-generative or otherwise – to enhance predictive maintenance, optimise the supply chain and improve quality control is only the beginning. Increased productivity, enhanced decision making and improved cost savings will continue to drive broader adoption of the technology across the middle market. While challenges exist, if companies plan carefully, invest in infrastructure and focus on ethics, AI will continue to revolutionise the industry.

7

RanLOS and Anritsu Unveil Innovative 5G

Vehicle OTA Test Solution

Versatile and cost-effective antenna OTA test solution designed for seamless integration with existing EMC chambers

8

RanLOS, TOYO Corporation (TOYO), AeroGT Labs, and Anritsu today announced the availability of the first 5G antenna over-the-air (OTA) measurement system engineered with RanLOS’ OTA test solution and Anritsu’s 5G Radio Communication Test Station MT8000A. The new system represents a significant step forward in enabling advancements in 5G connected vehicles.

As autonomous driving gains momentum, and the demand for connected vehicles surge, the adoption of 5G for automotive use comes with performance requirements for successful implementation. To enable the seamless flow of dynamic, realtime data communication, highly reliable antenna performance is a key necessity to ensure the safety of autonomous and connected vehicles and to enable advanced infotainment. This requirement is addressed by optimizing and validating antenna design and installation on a vehicle. However, to accomplish this critical task, design engineers need a consistent, reliable, and controllable test environment that can emulate real-world conditions.

RanLOS and Anritsu collaborated to meet this need by integrating a portable antenna test system with a wide dynamic range base station simulation. The combined solution supports the measurement of throughput and antenna radiation patterns under static conditions and the evaluation of throughput degradation in vehicles operating on a dynamometer. It is well-suited for assessing the performance of antennas on transportation vehicles such as

automobiles, vans, minibuses, and autonomous transport systems. What sets the solution apart is its distinctive capability to be seamlessly integrated into preexisting EMC chambers, providing manufacturers with an opportunity to establish an essential testing environment while keeping the initial investment to a minimum.

As measurement solution providers, TOYO and AeroGT Labs, a TOYOaffiliated company specializing in OTA measurements, view this solution as an optimal choice for customers requiring a 5G OTA measurement solution for advancing next-generation mobility. Drawing from their broad EMC and antenna measurement business experiences, TOYO and AeroGT Labs lead the go-to-market efforts.

“It’s a major step to have 5G capabilities integrated into our offering”, comments Louice Rosdahl, CEO of RanLOS. “5G is 100 times faster than 4G at peak speed and will be an enabler for safer connected cars. We are grateful for the collaboration with Anritsu and look forward to delivering the benefits of this new offering to our users and customers.”

“While the 5G wireless communication quality evaluation is indispensable for the development of the nextgeneration mobility including connected and autonomous vehicles, no standard test method has been established. In this context, the solution created by integrating Anritsu and RanLOS products offers a simple and intelligent way to evaluate the 5G on-vehicle wireless communications and

minimize initial investment,” said Yoshimichi Imaizumi, Director, Senior VP at TOYO. “By promoting this sophisticated yet cost-effective solution to the mobility industry, we contribute to the building of a safer and more trusted traffic network.”

“As transportation vehicles advance further toward an allinterconnected future, holistically evaluating and gauging 5G antenna performance in connected vehicles becomes more than a benchmarking and testing effort,” said Steve Wong, Chief Marketing Officer at AeroGT Labs. “This critical process lays the foundation for a transportation future characterized by elevated safety and enhanced efficiency.”

“This leading technology is the result of our partnership with RanLOS,” said Takeshi Shima, Director, Senior Vice President, Test & Measurement Company President at Anritsu. “By integrating the Anritsu MT8000A 5G network simulator with the RanLOS system, we offer the automobile test marketplace an advanced solution with technologically and cost-effective benefits. With the constant and rapid progress in autonomous services, in-vehicle antenna performance significantly matters. The solution ultimately equates to an improved user experience, which benefits the evolution of widely spreading smart society. We are thrilled to promote it globally, collaborating with TOYO and AeroGT Labs.”

The 5G antenna OTA measurement solution is shipping now. Please contact any one of the companies named in this news release for further information or to book a demo.

9

To Meet And Exceed Heightened Automotive Secure Authentication Requirements, Microchip Releases Its Latest TrustAnchor Security IC

Available as a CryptoAuthentication™ or CryptoAutomotive™ Secure IC, the new TA101 device focuses on larger key sizes and enhanced cybersecurity requirements

As vehicles become more connected and technologically advanced, the need for heightened security measures also rises. New government and automotive OEM cybersecurity requirements are

beginning to include larger key sizes and Edwards Curve ed25519 algorithm standards. In response, Microchip Technology (Nasdaq: MCHP) has launched its latest TrustAnchor Security IC, the TA101,

which can accommodate complex automotive and embedded security use cases. The TA101 supports large key sizes up to ECC P521, SHA512, RSA-4K and AES256 with greater security strength,

10

exceeding current standards and allowing room for future adjustments while maintaining backwards compatibility for smaller keys. The TA101 is offered as an industrial-grade CryptoAuthentication™ Security IC and as a CryptoAutomotive™ Security IC supporting AEC-Q100 Grade 1 qualified devices.

As the latest device in Microchip’s portfolio of security ICs, the TA101 is specifically designed to support automotive security, data center and industrial applications. The cryptographic companion device works alongside a microcontroller (MCU) or microprocessor (MPU) to handle cryptographic functions including public key infrastructure, certificate management and secure key storage requirements. The TA101 offers easy patch updates, message authentication, Transport Layer Security (TLS), secure boot, High-bandwidth Digital Content Protection (HDCP), firmware updates, security upgrades, transfer of ownership, key management and WPC Qi® 1.3 authentication.

“It is critically important for OEMs to not only comply with current standards but to stay a step ahead when it comes to security. By introducing key sizes associated with 256 bits of security strength, the TA101 offers great key strength

diversity now and for future applications,” said Nuri Dagdeviren, corporate vice president of Microchip’s Secure Computing Group. “Additionally, Microchip’s modular security solution approach allows customers to choose an optimally sized and priced MCU based on the focus application of the module, while standardizing a single security solution that satisfies virtually all security requirements.”

The TA101 delivers an alternative architecture to on-die multicore MCU/MPU management of invehicle networking by offering an off-chip component to handle secure boot and message authentication. The device is compatible with a wide range of MCUs or MPUs, enabling flexible solutions that can help lower costs and reduce time to market.

The TA101 offers the Commercial National Security Algorithm (CNSA) required 1.0 suite of algorithms and the ed25519 curve in a single IC. Reducing the risk associated with secure code development and implementation, it comes preprogrammed and preprovisioned in Microchip Common Criteria ALC_DVS.2 certified facilities. To learn more about Microchip’s automotive security portfolio, visit the CryptoAutomotive Security IC page on the company’s website.

Development Tools

The TA101 is supported by the CryptoAuth Trust Platform Development Kit and several TA101 socket boards that feature a mikroBUS™ connector. These socket boards can also be used with the mikroBUS Xplained Pro Extension Board, which connects to a wide variety of Xplained Pro boards for developing designs with SAM MCUs.

The TA101 AUTOSAR® Microcontroller Abstraction Layer (MCAL) is ASPICE Level 2 compliant. Microchip’s CryptoAuthentication Library of software allows seamless integration into industry-standard operating systems or customized software stacks for crypto functions. The Trust Platform Development Suite (TPDS) can be used to configure prototypes and prepare them for provisioning at Microchip’s secure factories.

Pricing and Availability

The TA101 is available starting at $1.60 each in 10,000-unit quantities. For additional information and to purchase, contact a Microchip sales representative, authorized worldwide distributor or visit Microchip’s Purchasing and Client Services website, www.microchipdirect.com.

11

Fluke’s two new Advanced Wire Tracers deliver superior accuracy and safety when locating electric cables in walls, ceilings and floors

Tracer kits simplify the process of troubleshooting energised and de-energised wires in residential, commercial and industrial environments up to safety rating CAT IV 600 V

Fluke, a global technology leader in the manufacture of compact, professional electronic test and measurement tools and software, has launched two new wire tracers that simplify the process of tracing and troubleshooting at energised and de-energised wires in residential, commercial and industrial environments with a safety rating of CAT IV 600 V.

The Fluke 2052 Advanced Wire Tracer and 2062 Advanced Pro Wire Tracer kits consist of two essential pieces of equipment – receiver and transmitter. Both kits also include the i400 AC current clamp accessory for safely inducing a tracing signal on cables without contact to live wires. Also included in the kits are test leads, alligator clips, outlet adapters, magnetic hanger and batteries.

Both kits - which work by detecting signals transmitted via an electromagnetic field rather than locating metal parts or voltage – deliver superior accuracy and safety levels for electricians and technicians who need to locate electric cables quickly in walls, ceilings and floors, find out if there are any breaks or opens and shorts, or identify breakers and fuses. The devices can also be used to trace non-metallic pipes and conduits as well as low voltage wires and data cables.

Passive and active tracing

The new Advanced Wire Tracers use two methods to detect the signal in wires and cables: passive tracing without a transmitter for

non-contact voltage detection and active tracing with the Fluke 2000T transmitter for all other modes. The transmitter automatically senses whether the system is energised or de-energised and selects a 6.25 kHz or 32.768 kHz output signal frequency accordingly.

Following the Fluke philosophy of offering the maximum number of features and capabilities at an affordable price, the new Advanced Wire Tracers incorporate three transmitter modes (high signal, low signal and loop), four receiver tracing modes and eight sensitivity levels for greater flexibility and accuracy when tracing. Additionally, durability and ruggedness are built-in, with all units 1 meter drop tested, IP40rated and backed by a one-year warranty.

The tracers’ four tracing modes are: breaker mode for easy breaker and fuse identification based on the highest recorded signal detected from the transmitter; non-contact voltage (NCV) detection mode to trace energised wires without the use of the transmitter, quick scan mode for quick signal identification (the Fluke 2052); and precision mode for more precise detection of a wire (Fluke 2052).

Patented Smart Sensor™

In addition, the Fluke 2062 Pro Wire Tracer features a patented Smart Sensor™ which identifies the orientation of located energised wires and displays the information on a 3.5-inch TFT LCD colour display. Also, a tip sensor on the Fluke 2062

makes it ideal for tracing wires in corners, tight spaces and junction boxes.

With the safety rating CAT IV 600 V, both Fluke devices offer the highest protection available of any wire tracer on the market (others tend to be CAT III rated). Measurement category CAT IV rating is designed to protect users from the most dangerous levels of transient overvoltage (spikes up to 8,000V) that can occur in industrial and utility environments.

Hans-Dieter Schuessele, Application & Technology Expert, Fluke, says: “Whether fixing equipment to walls or wanting to find cable routings, electricians and technicians need to detect electric cables quickly and accurately and our two new Advanced Wire Tracers simplify this process while ensuring operator safety. Offering such options as embedded help screens for simple, error-free set-up (on the Fluke 2062), we believe these kits will be welcomed by everybody who is tasked with locating energised and de-energised wires and who is looking for an easy-to-use solution.”

For more information, visit www.fluke.com.

12

13

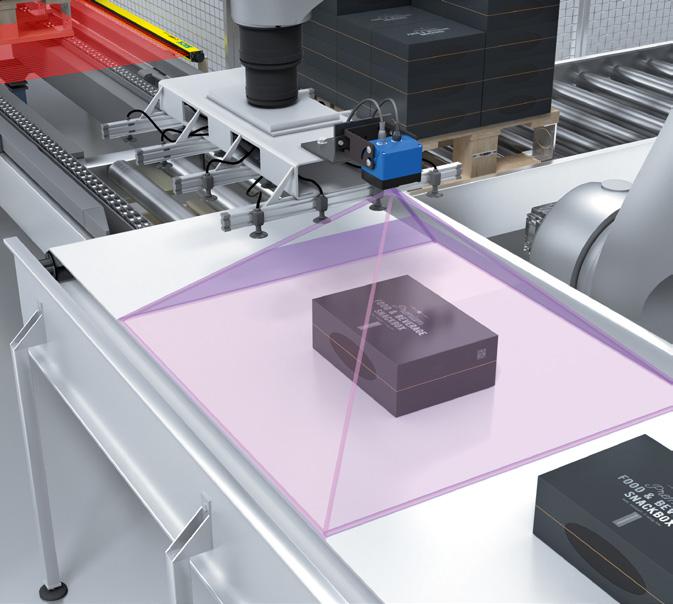

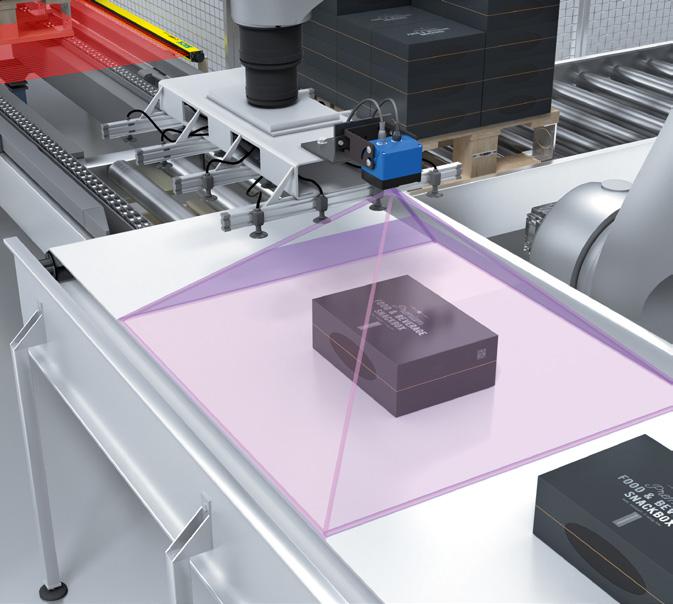

3D Inspection in a “Snapshot” with SICK Visionary T Mini AP

Configuring machine vision inspections in 3D is now possible in a “snapshot”, thanks to the combination of SICK’s powerful and compact Visionary-T Mini AP camera with the new easy-to-use SICK Nova 3D Presence Inspection sensorApp.

The SICK Visionary-T Mini AP uses best-in-class time-of-flight snapshot technology to set new standards of data accuracy for detailed environmental perception at rapid production speeds. It captures both the 3D depth and 2D intensity values of every pixel at an exceptional (512 × 424 px) resolution in a single shot of light, at up to 30 3D frames per second.

Common 3D Vision Tasks

Common 3D inspection tasks in factory automation and logistics, such as completeness, fill level monitoring, or robot palletising, can be set up rapidly and costeffectively to run onboard the Visionary-T Mini AP camera using the SICK Nova 3D Presence Inspection sensorApp. Users simply select the 3D machine vision tools they need via an easy graphic user interface and the Visionary-T Mini AP camera is soon delivering reliable inspection results via I/O to the machine controller or over TCP/ IP.

No Programming Skills

“Thanks to SICK’s Nova foundation software, you don’t need programming skills to run a readymade sensorApp directly onboard our smart devices,” explains Nathaniel Hofmann, SICK’s Market Product Manager for Machine Vision and Measurement. “With the SICK Nova Presence Inspection toolset, you can easily configure a 3D machine vision solution that exactly matches your application.

“Just select the tools you need from the App to run directly on board the Visionary-T Mini AP. It’s simple to use the graphical user interface, from where you also can also access other industry-standard vision

14

tools. Or you can install one of the ready-made, application-specific solutions should you need them.”

As a programmable device, the SICK Visionary-T Mini AP is easy to configure and commission. A multicam mode is available to process image data from more than one Visionary-T Mini. With rapid 3D data transmission, the Visionary-T Mini is suitable for integration into most industrial applications.

3D Vision Toolset

With a toolset of commonly used 3D vision tools, the SICK Nova Presence Inspection App easily masters tasks like emptiness checks in bins, totes and crates, presence detection of objects in 3D scenes, as well as simple measurements and quality tolerance checks.

“3D quality checks for completeness often need several,

more advanced, machine vision software tools and programming skillset to identify the quality inspection issue, but with SICK Nova Presence Inspection, they are easy to configure,” Hofmann adds. “The camera outputs results, such as confirming all parts are present and at the right locations or verifying a set of measurements.”

Using the SICK Nova Presence Inspection on Visionary T Mini, the position, height and volume of any package can be determined, for example for a robot to pick it and place it in a container or pallet. The Visionary-T Mini’s 3D snapshot technology can also be used for continuous 3D Fill Level monitoring, for example to determine if totes are empty, filled, full or overfull, or it can measure the presence of parts in a bin or presence of ingredients in a vessel, for example.

Visionary-T Mini

With a low-weight and no moving parts, the Visionary-T Mini’s IP65/67 housing measures just 80 mm x 70 mm x 77 mm, ideal for installation in compact robotics and automation solutions. It performs reliably despite the shocks and vibrations of applications such as robot palletising and depalletising. The automatic High Dynamic Range of the Visionary-T Mini ensures even widely-varying contrasts and lighting conditions across a scene are captured in each frame without complex set up, or expert knowledge of time-of-flight settings. The high-density 512 x 424 px resolution is complemented by a 70° x 60° field of view.

The SICK Visionary-T Mini CX provides an alternative option for customers wishing to use the power of the Visionary-T Mini’s snapshot technology to stream 3D data for their own software applications.

www.sick.co.uk

15

New 32-Bit MCU Features an Embedded Hardware Security Module to Safeguard Industrial and Consumer Applications

Highly configurable PIC32CZ CA devices are available with a 300 MHz Arm® Cortex®-M7 processor

Industrial and consumer application designers must consider implementing security functionality in their devices during the development process as security threats evolve and become more sophisticated. To allow designers to easily integrate security into their applications, Microchip Technology (Nasdaq: MCHP) today announces a new family of PIC32CZ CA 32-bit microcontrollers with a 300 MHz Arm Cortex-M7 processor, an integrated Hardware Security Module (HSM), and a wide range of connectivity and Flash memory options for added flexibility.

The new family of PIC32CZ CA devices includes the PIC32CZ CA90 with a HSM or the PIC32CZ CA80 without the integrated HSM.

The HSM in the PIC32CZ CA90 is a monolithic solution that provides advanced security for industrial and consumer applications. The HSM operates as a secure subsystem with a separate MCU on board that runs the firmware and security features including hardware secure boot, key storage, cryptographic acceleration, true random number generator and more.

For products that require added

security, factory provisioning is available on the PIC32CZ CA90 which, upon completion, provides customers with pre-provisioned devices ready to be deployed. Microchip’s Trust Platform Development Suite is an in-house secure provisioning tool that enables a secure supply chain channel at scale or in low-volume production.

“The PIC32CZ CA microcontrollers make it easier for our customers to implement embedded security features into their design,” said Rod Drake, corporate vice president of Microchip’s MCU32 business unit. “These are extremely versatile MCUs with the option of factory provisioning at low-volume production and other customizable configurations such as connectivity and memory to fit many different requirements.”

The PIC32CZ CA MCUs can be configured using a wide range of connectivity options including USART/UART, I2C, SPI, CAN FD, HighSpeed USB and Gigabit Ethernet. The Ethernet option includes Audio Video Bridging (AVB) and Precision Time Protocol (PTP) based on the IEEE 1588 standard. These devices are scalable with 2, 4 or 8 MB of onboard Flash, 1 MB of SRAM and Error

Correction Code (ECC) memory to mitigate data corruption.

The PIC32CZ CA devices are the latest 32-bit MCUs to join Microchip’s broad portfolio of PIC32 and SAM families that provide high-performance, functional capabilities and many features to customize and create innovative products.

Development Tools

The devices are supported by the PIC32CZ CA90 Curiosity Ultra Development Board, the PIC32CZ CA80 Curiosity Ultra Development Board and MPLAB® Harmony v3 to test, program and debug in the design phase.

Pricing and Availability

The PIC32CZ CA80 is available for $14.80 each in 10,000-unit quantities and the PIC32CZ CA90 is available for $15.54 each in 10,000-unit quantities in a BGA 208 package. For additional information and to purchase, contact a Microchip sales representative, authorized worldwide distributor or visit Microchip’s Purchasing and Client Services website, www.microchipdirect.com.

16

ACOPOS 6D allows you to move products freely through an open manufacturing space – unbound by the limits of one-dimensional production flow. Magnetic levitation providessixdegreesoffreedomfor unprecedented processing density on a fraction of the floorspace. www.br-automation.com/ACOPOS6D ACOPOS 6D Creating

adaptive manufacturing

new dimensions of

PTC works with BAE Systems to bring next generation fighter pilot helmet to market

One of the UK’s leading authorities on digital transformation is playing a role in the development of the world’s most advanced fighter pilot helmet.

PTC’s Creo software is being used in the design and development of mechanical parts for BAE Systems’ Striker® II Helmet Mounted Display, which displays data directly onto the pilot’s helmet visor to give an augmented reality view of the world alongside mission critical information, right before their eyes.

George White, Lead Mechanical Engineer at BAE Systems, commented: “We have been working with PTC’s Creo for more than 20 years across a host of different projects, and the solution has helped us create the mechanical design and manufacturing drawings for Striker II.

“The fact that our engineers working on this new technology are so well versed on the capabilities of PTC’s solution has certainly supported our development programme.”

Creo is a 3D Computer Aided Design (CAD) Solution that helps firms to build better products faster. Easy to learn, it uses a model-

based approach to seamlessly take users from the earliest phases of product design to manufacture and beyond.

“This is our latest involvement in pushing the boundaries of aviation technology and I’m really pleased Creo is contributing to the design phase of bringing Striker II to life,” explained Elliot Clarke, UK Director at PTC.

“It further strengthens our relationship with BAE Systems, one of the leading suppliers to the aerospace and defence sectors.”

Tune into a recent episode of The Third Angle podcast to learn more about BAE Systems and Striker II.

For further information, please visit www.ptc.com

18

Perfect slicing results even at warmer product temperatures

Groundbreaking in their operation, ergonomics and hygiene

High yield and reduced give-away

Better slicing.

MULTIVAC slicers are highly impressive with their perfect slicing results within a wide temperature range.

The rapid set-up and conversion of the slicers, as well as their particularly ergonomic operation, ensure the highest possible level of flexibility is achieved.

When you choose MULTIVAC, you are opting for an innovative and cost-effective slicer, the most efficient slicing line, and our unparalleled reliability.

19 Category Title to go here www.multivac.com

World leading virtual reality teaching facility opens at the University of Nottingham

University of Nottingham Product Design and Manufacture students trying out the new virtual reality (VR) classroom in the university’s Engineering Science and Learning Centre

This year’s cohort of second year Product Design and Manufacture students at the University of Nottingham are the first in the country to benefit from a brandnew virtual reality (VR) classroom that revolutionises the teaching of VR software.

Based in the university’s Engineering Science and Learning Centre (ESLC), the classroom enables remote viewing and communication between lecturers and students in a way that’s never been done before. Containing 40, high image quality VR headsets, 35 of which are tethered overhead to individual high-power PCs with the remaining five consisting of more traditional desk-based systems with display screens, students can choose the way they want to learn and experience VR.

In addition to the in-situ technology, 90 wireless headsets are available to loan to students. These can be used in any location so that they can continue their studies outside the classroom. There is also staff and student access to several 3D

scanners and 360 stereoscopic cameras.

Professor Joel Segal, Head of Mechanical Materials and Manufacturing Engineering (M3) in the Faculty of Engineering, said: “While many universities, including us, have existing VR labs, these are nowhere near the scale of our newly unveiled facilities, which will provide our students with access to cutting edge tools and technologies unlike anything else on offer across the globe.

The room can also be used flexibly for other teaching purposes as, when not in use the headsets can be raised into the ceiling space.

“We have a desire to be at the forefront of technology in teaching and we’ve already been making strides in this area in recent years in our smaller VR labs. Now, however, we have the opportunity to take the lead in the UK and further build our reputation for producing engineers that are ready to shape the real world.”

Another aim of the facilities is

to allow real time collaboration across international campuses, as Nottingham’s Ningbo campus has its own VR lab, so that students from across the world can work together in labs or in design-based exercises.

Professor Sam Kingman, ProVice-Chancellor for the Faculty of Engineering, said: “The virtual reality classroom is an incredibly exciting addition to our teaching facilities as we continue to position ourselves at the forefront of VR teaching. We believe that great minds don’t think alike, which is why we want to provide our students with a truly unique experience.

“We’ll also be working to create custom environments and objects that are suitable for teaching a range of engineering and architecture subjects as we widen our remit in the coming years to allow students from other courses access to the VR classroom.”

To find out more about the Faculty of Engineering, please visit: www.nottingham.ac.uk/ engineering/index.aspx

20

UK Government commits to funding more autonomous vehicle projects

The UK Government has issued a rallying call for the nation’s automotive and tech businesses to help Britain become a world-leader in the development of autonomous and connected vehicles.

The CAM Scale-Up UK Programme, delivered by Zenzic, was launched by the UK Government in 2020 to help start-ups and SMEs accelerate the development of solutions that could power the self-driving vehicles of tomorrow.

Since then, a total of 22 businesses have had their projects supported through the programme, which has led to the development of autonomous passenger and freight solutions, radar technology to help vehicles navigate extreme weather and AI-enabled perception systems.

Now preparing for its fifth year, the programme is again looking for innovative start-ups and scaleups to take advantage of the CAM opportunity in the UK, with businesses urged to apply to join the programme and apply for funding as part of the 2024 cohort.

Supported by the Centre for Connected and Autonomous Vehicles (CCAV), and in partnership with Plug and Play, the Zenzic CAM Scale-Up UK Programme focuses on giving start-ups and SMEs a unique opportunity to test their products or service in realistic environments across the world leading CAM Testbed UK facilities, significantly accelerating their delivery to market.

Mark Cracknell, Programme Director at Zenzic, said: “Since its launch in 2020, the CAM ScaleUp UK Programme has helped accelerate the development of numerous solutions which have helped advance the CAM ecosystem and position the UK as a world-leader in the development of connected and automated mobility solutions.

“But to ensure we remain at the front of the global race to develop the autonomous and connected transport solutions of tomorrow, it is vital that we continue to support the bright minds and innovative SMEs who play a key role in developing and deploying such solutions, which is why we’d encourage any business from an automotive or tech background with an idea of how they could help drive the sector forward to get in touch and find out more.”

One project which has been supported by the CAM Scale-Up UK Programme is the development of the world’s first self-driving, pothole filling robot, which made headlines across the globe last month when the first videos were released of it in action.

Developed by tech company Daresbury-based Robotiz3d and academics at the University of Liverpool, in partnership with Hertfordshire County Council highways engineers, the CAM Scale-Up UK backed robot will be trialed on roads in Hertfordshire this year in a world-first trial.

Lisa Layzell, CEO of Robotiz3d, said: “Being part of the CAM Scale-Up UK programme connected us to

major players in CAM industry and opened doors for us coming into 2024.

“It also helped us access worldleading testing facilities where we could test ARRES Prevent in as near to a real-world environment as possible to prove its feasibility.

“It is this in-depth support and access to world-leading experts which – alongside the funding –has really helped us accelerate the development of our work and move into a position where we can move to trials on public roads later this year.

“I can’t thank the team at Zenzic enough for their support. This is an opportunity that is something startups and scale-ups won’t have the resources to take by themselves and the support that Zenzic have provided have been incredibly valuable.”

Companies interested in applying for the CAM Scale-Up UK Programme are being encouraged to register their interest by emailing: camscaleup@zenzic.io

To view the programme brochure, visit: CAM Scale-Up UK – Zenzic

22

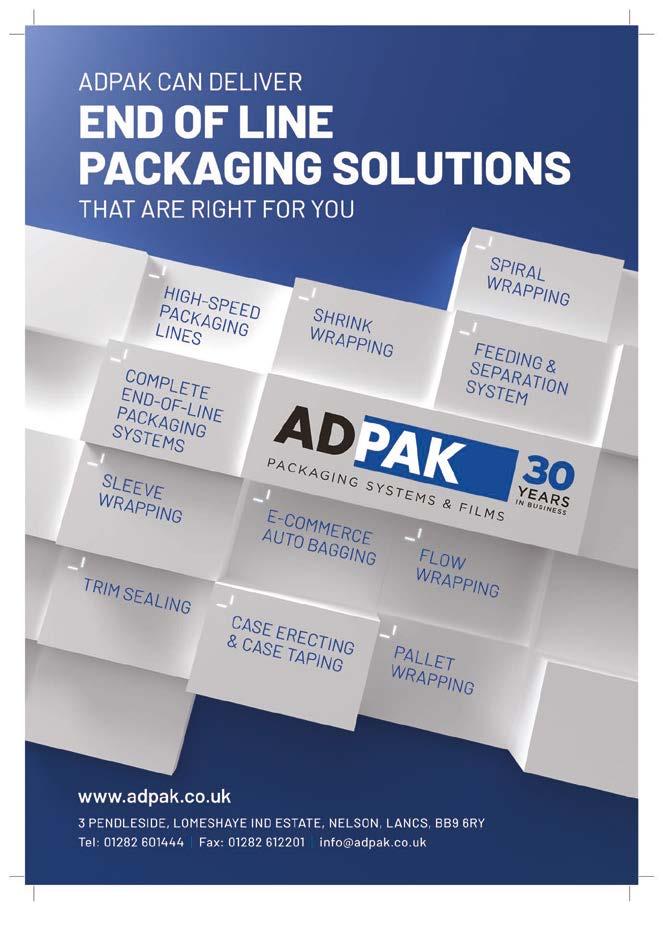

A WORLD OF PACKAGING SOLUTIONS

DESIGNED FOR SUSTAINABILITY. BROUGHT TO LIFE BY SCHUBERT.

23

www.mission-blue.com