Routing at the hatchery Good hatchery design takes into account a clean zone (inside the hatchery) and a dirty zone (outside the hatchery). The borders between the clean and dirty zone are at the egg reception and chick dispatch. The use of separate truck bays for egg delivery and chick dispatch helps to prevent cross contamination. If eggs are disinfected immediately on arrival, the storage room is considered to be a clean zone. If eggs are stored first and only disinfected just before setting, the storage room is considered to be a dirty zone.

Setter trays

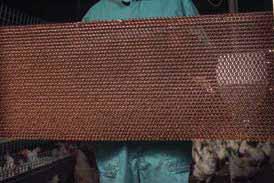

Hatcher baskets

Chick boxes

py

Farm materials

rig

ht

pr ot

ec

te

d

Biosecurity zones imply using strict routes and separations to prevent contamination and transmission between the various zones. The movement of material and people between zones should be limited. Transitions between zones have to be obvious: hygiene locks and/or doors form a barrier to prevent too much easy traffic of personnel between zones. The group that poses the greatest risk is the technical service team. Their work involves all parts of the hatchery where troubleshooting or maintenance is required. And it is tempting to just walk from one area to the other without respecting the hygiene rules.

co

Materials must be cleaned and disinfected in the zone where they are used. This means that a hatchery has numerous cleaning and disinfection areas.

The personnel must also follow their own route. This illustration clearly shows that the changing rooms and canteen are risk areas, because they are places used by all the personnel. It also clearly shows how the technical personnel (black) move through the entire hatchery. 5. B io s e c u r i t y

65