Biosecurity zones at the hatchery

d

py

rig

ht

pr ot

ec

te

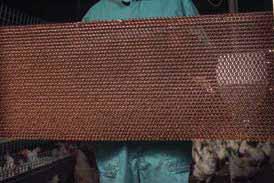

The biosecurity zones are visible in all installations, for example segregated drainage and air circulation. At a hatchery, different air pressures are set for each zone. Large filter units that treat the incoming air can often be seen on one side of a hatchery, and exhaust air outlets on the other.

A hatchery is divided into biosecurity zones. These separate zones apply to human contacts, but also to materials that have to stay in a certain zone, and separate ventilation and drainage systems. The ideal design includes five, defined biosecurity zones. 1. Egg receiving and storage zone 2. Setter zone 3. Candling and transfer zone 4. Hatching zone 5. Chick processing and dispatch It is sensible to separate the candling and transfer zones, as this is a relatively ‘dirty’ zone, certainly if the batch contains bangers. However, you will have to keep returning to the setter room to collect new trolleys... The number of zones can also be reduced to three main zones, particularly in smaller hatcheries. 1. Egg receiving and storage 2. Setter zone 3. Chick zone (hatching, sexing, treatments and grading)

co

Pathogens can enter a hatchery via many different routes. These vectors include: eggs, personnel, materials, visitors, rodents and outside air. Egg receiving and storage zone

Setter zone

Candling and transfer zone

Hatching zone

Chick zone

The biosecurity zones are separated with regard to movement of personnel, ventilation and drainage systems. 64

Ha tc he ry S i gnal s