Process steps in the hatchery

d

te

ec

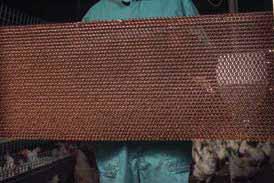

8. Hatcher room/hatchers 9. Chick room (counting, grading, sexing, vaccinating, packing) 10. Chick holding area 11. Day-old chick dispatch 12. Clean setter trays/trolley storage 13. Cleaning and disinfection

14. Clean hatcher basket storage 15. Waste disposal 16. Vaccine storage 17. Laboratory 18. Clean chick box storage 19. Cleaning and disinfection of hatcher baskets and chick boxes, setter trays and trolleys

py

rig

Incoming eggs Egg receiving area Disinfection lock Transfer to setter trays Storage Setter room/setters Candling and transfer

co

1. 2. 3. 4. 5. 6. 7.

In the majority of cases, eggs are disinfected before incubation. Eggs can be disinfected at three points: immediately after collection and cooling (at the breeder farm), on arrival at the hatchery or just before the eggs are placed in the incubator - i.e., after storage. The timing of disinfection mainly depends on how the eggs are delivered. If they are supplied on plastic setter trays they can be disinfected at once. If the eggs are supplied on paper egg flats or in boxes, they must be transferred to setter trays first. Disinfectant cannot reach the eggs properly on paper egg flats. The disinfectant may be absorbed by the paper and hazardous fumes can be released afterwards. If the breeder farm and the hatchery are closely linked - as is the case with an integration - the eggs are often delivered already in setter trays. But if hatching eggs are traded on the free market, they are often delivered on paper egg flats as returning the setter trays involves more complex logistics. Delivery in setter trays is becoming increasingly common, so the eggs can be disinfected immediately on arrival. These eggs are also stored for a while. There might even be a storage room for eggs before and after disinfection. If the eggs are disinfected early in the process, there is a risk of reinfection. If the eggs are disinfected several times in a short period, this has a negative effect on hatchability. Sometimes eggs are disinfected just before incubation. Formalin gases might be released in the setter, especially when ventilation is closed. This will kill a certain percentage of embryos.

ht

Hatchery layout

When to disinfect?

pr ot

The different areas in the hatchery design directly reflect the steps in the incubation process. This design is also determined by biosecurity considerations. Biosecurity at a hatchery is vital to prevent pathogens, e.g., Avian Influenza and Salmonella from entering, multiplying or spreading. Hygiene is especially important because: • Eggs that carry pathogens arrive from many different farms. • The climate conditions are ideal for pathogens to thrive and multiply: heat, moisture, nutrients (spoiled egg contents). • Many opportunities for pathogen survival (in the pores of the eggshell, in faecal residues on the eggshell, in or on the chicks, in ventilation ducts, and in other places that are difficult to clean). • There are many routes for transmission and spread of pathogens (air, feathers, personnel, and materials). • The chicks are then dispatched to various farms (laying hen/broiler, etc.).

20. Technical facilities 21. Offices 22. Canteen 23. Toilets 24. Changing room and showers male personnel 25. Changing room and showers female personnel

10

6

7

11

8 16

5

17 9

12

13 24

4

23 21

2

3

25

14

22

18

20 19

15

1 The design of the hatchery represents the steps in the entire process from arrival to dispatch. Using compartmentalised zones is not only practical logistically, but also, and primarily, essential for strict hygiene and biosecurity. 5. B io s e c u r i t y

63