Singlestage

Multistage

Single-stage benefit

Hatchability

87%

84%

3%

Hatch of fertile

94%

91%

3%

1st grade chicks

86%

83%

3%

0.80%

0.95%

0.15%

Liveability

96%

94%

2%

Average chick weight

45 g

44 g

1g

Average broiler weight

2,750 g

2,700 g

50 g

Average daily gain

60 g/day

59 g/day

1 g/day

7-day mortality

Advantages and disadvantages of incubation systems Multi-stage

Single-stage

+ Setpoint for incubator temperature, humidity and ventilation are set to a constant value. + In the early stages, the eggs with young embryos are warmed by the older eggs. These eggs contain an embryo at a more advanced development stage that produces heat itself.

+ Climate can be adapted well to suit the embryos. + More constant embryo temperature. + Before set, the setter can be cleaned and disinfected (all-in all-out).

- More fluctuations in embryo temperature. - The machine is never empty; it must be specifically emptied for cleaning every six weeks. - Risk of cross contamination between batches.

- Requires more cooling, heating and ventilation.

py

rig

ht

pr ot

ec

te

Single-stage systems are preferred worldwide, because the advantages of multi-stage are outweighed by the disadvantages. Seemingly minor differences can have major implications on the results of the entire production chain. For example, just a few points difference in the feed conversion rate per chick will make a significant difference for a broiler producer. If the feed conversion rate improves by five points (1.55 instead of 1.60) for a 2 kg broiler, this converts to a difference in feed intake of 100 grams. Translated to a 60,000-egg incubator, with 90% hatchability and 18.5 hatching cycles per year, that adds up to 100 tons of feed! At a feed price of € 300 per ton, this is € 30,000 per incubator. And for that sum you can buy a new machine with an ROI of less than a year.

Examples of differences between incubation systems

d

Minor differences, major implications

co

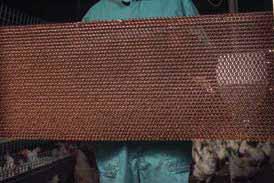

The central aisle in this large multi-stage setter allows easy access to the trolleys. It is filled with six sets of 15,552 eggs, in total 93,312 eggs.

Small hatcheries often start with a multi-stage system. This incubator is loaded at the front and emptied at the back. The setter trolleys are therefore always moving to the back. It is not empty every three weeks, and available for cleaning, so you have to plan cleaning very consciously and first empty the setter completely.

3. P r in c i p l e s o f a r t i f i c i al i n cu bati o n

A colour code indicates the various age groups in a multi-stage machine. In this small hatchery, the trays are coded alternately using black, red, green. This is a way of trying to achieve the most uniform temperature distribution possible.

43