ec

te

d

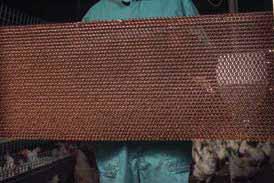

Weight loss and uniformity Within a batch of eggs, large variations in egg size and weight loss during incubation can occur. On average, hatching eggs lose 10-12% of their initial weight during the first 18 days of the incubation process. The relative humidity significantly influences how much weight is lost. With high relative humidity (RH) the eggs lose less weight. The weight loss is higher with lower relative humidity. Problems are often only seen with individual eggs that have lost less than 5-6% weight or more than 16-17%. This effect varies according to the breed and is also influenced by the age of the parent stock. Uniformity in weight loss is higher at high relative humidity and gets poorer at low relative humidity.

pr ot

Weight loss and uniformity

5%

9%

15%

drowning

dehydration Chicks are small and have dehydrated legs that feel dry and hard

12%

co

py

rig

Optimal zone weight loss

Lots of chicks with bellies that are too large/full and feel puffy

ht

Once you understand the incubation process of a single egg or a clutch of eggs, you still have to translate this knowledge to make it applicable in a hatchery with thousands of eggs. In addition to different origins of the hatching eggs, hatching egg treatment and hatching egg quality, each incubator also adds another layer of variance to the incubating conditions. So it is evident that not every individual egg will be incubated under the optimal conditions. The embryos have different needs, but a wide variation can also occur between different positions in the incubator, which is mainly due to how the temperature is distributed in an incubator. As soon as you incubate large numbers of eggs all together, the priority is uniformity. Each embryo must be incubated optimally. And because you cannot treat each egg individually but have to treat all the eggs as a batch (incubator), it is vital to get this batch off to the most uniform start possible, so it can be treated as uniformly as possible. The purpose of all the processes is to maintain the optimal conditions and minimise variations within a batch. Taking this approach will ultimately produce dayold chicks with high uniformity. If the day-old chicks show poor uniformity, the broiler producer or rearing farm will start the cycle with a less uniform flock and then supply less uniform animals to the abattoir or layer farmer. This applies to all the links further along in the chain, the higher the uniformity, the better they can start and complete their processes.

Proportion of eggs (%)

The importance of uniformity

2. Th e i n c u b a t i o n p ro c e s s

Weight loss at 18 days (% of egg weight) The average weight loss is a less critical factor if the weight loss of individual eggs is very uniform. In that case, fewer eggs will have lost too little or too much moisture, even if the average is a bit below the recommended value. The humidity during the incubation process will have less impact on the final result. However, when large variations between individual eggs occur, it is important to keep the average moisture loss within a narrow margin and closely monitor humidity levels during incubation, even if the average value seems OK (12%).

27