Critical batches, locations and moments Being aware of and focusing on risk situations in your management practices can help prevent many problems. This applies to certain critical batches, places or moments in the hatching process.

co

py

d

te ec

rig

ht

Critical locations There are critical locations in each hatchery where there is a higher risk of potential problems. Points known to be critical should be inspected daily, such as day-old chicks that might be held in a place that is too cold: this causes mortality in the first week. Try to make an inventory of these locations and optimise the conditions. Eggs placed in the middle of paper egg flats/pulp trays in the centre of the trolley are another example of a critical location. These eggs will have difficulty cooling. Or what about a hygiene lock where people are sometimes very creative in by-passing the protocols (e.g. a director who is just giving visitors a quick look at the hatchery and forgets about all the hygiene regulations).

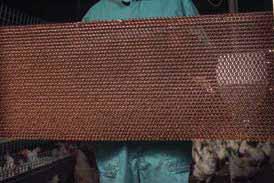

Critical batches: dirty eggs should not be put in the setter at all in order to avoid cross contamination. High mortality in the first week and other problems with the flock can be so serious that using these eggs is not worthwhile. If you decide to incubate them anyway, make sure dirty eggs and washed eggs (as shown here) are marked with a special label in the setter tray to flag up that these eggs need special treatment. Place these eggs at the bottom of the trolley.

pr ot

Critical batches It is always possible to identify critical, at-risk eggs in the batches of hatching eggs. For example, eggs from older breeder flocks. These eggs have a thinner eggshell and less weight uniformity. Or floor eggs that have been washed and still added to the batch in the setter. Think about any critical eggs that may be present in each batch delivered, which problems could occur and how to respond in a timely and correct way.

1. Intro d u c t i o n

A critical location: water accumulating on the floor of the setter is a breeding ground for bacteria. The machines must be completely dry before being refilled with eggs. Evaporating water uses so much energy that the hatching eggs at the bottom of the trolleys will be incubated at too low temperatures for too long. This will have a negative impact on uniformity and hatch window.

A power outage (power cut, voltage dip, emergency power test) can make the incubators suddenly jump to another phase of the program, restart or even jump to the pre-heat program. The same applies to the climate control systems (frequency controller failure). This is a critical moment. Modern hatchery equipment is less susceptible to this, but always check if unexpected situations occur.

15