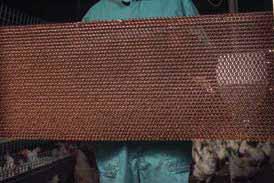

Working at the take-off table The chicks are taken to the take-off table for selection after hatching. First grade chicks are separated here from poorer quality chicks. The percentage of chicks selected out should be less than 1-2%, otherwise there is cause for concern. The percentage of saleable chicks varies with hatching egg quality, storage duration, and parent stock age. The incubation process also plays a significant role.

te

pr ot

Displays the number of chicks needed to fill 90 per crate. Counts the number of chicks you reject.

Crate with selected chicks

co

py

rig

ht

Even though the speed of the conveyor belt is high, you can assess chick quality by running your hands through the chicks. Observing the number of pale chicks will give you an overview of quality as well.

ec

Good quality chicks to fill the number in the crates up to 90.

d

Work in sessions lasting no more than 90 consecutive minutes, to ensure good concentration.

In this system the number of chicks in the crate is known, because unhatched eggs have been counted. Chicks are selected out at the take-off table and counted as they pass through the chute. The employee can see on the display how many chicks are needed to make the number up to 90 in each crate.

Running your hand through a crate of chicks will also quickly give you an impression of chick vitality.

Sit or stand at the take-off table, depending on your preference. It is best to alternate between sitting and standing. 10. C h i c k q u a l i t y

A counter at the end of the belt after the take-off table puts the same number of chicks in each basket. 161