First few days: ventilation inlets closed

CO2 concentration increases In the beginning, the ventilation is restricted, or the setter is fully sealed (ventilation inlets closed). The CO2 level then increases sharply to 0.8%. This occurs particularly with eggs stored for only a short period because the CO2 concentration of their albumen (egg white) is high. This principle can be used to regulate the hatch window: it will become shorter. So the hatching times of the chicks will be more uniform. The embryos can cope well with a CO2 concentration in the air of up to 1% during the first 48 hours. They have more difficulty with this value between days 2 and 6. The CO2 concentration does not rise so much during the first week because the embryo only produces a very limited amount of heat. Higher ventilation is required during the last phase, to remove excess CO2. A CO2 concentration of 3,500 ppm (0.35%) is a good guideline for the entire incubation period.

Risks of reduced ventilation

•

d

Insufficient eggshell porosity. Insufficient ventilation.

te

Carbon dioxide • combined with water forms an acid. This • leads to acidification and retarded growth.

pr ot

Excessive CO2 in the egg

Insufficient eggshell porosity or pores clogged by contamination and/or a disinfectant. Insufficient ventilation (high CO2 concentration).

ht

•

Causes

Acidification of tissue • -> reduced growth and weaker chicks. The heart has to work harder to deliver sufficient oxygen to the tissue. • Possibly the beginning of ascites (water belly).

rig

•

ec

Problems Insufficient oxygen

Fresh air ventilation strategy during the incubation process After day 4

Part 2 of the incubation process

py

Day 0-4 Regulate based on uniform temperature.

Regulate based on humidity.

Regulate based on CO2.

Closed ventilation inlets High RH (60-80%).

Stimulate moisture evaporation from the egg.

CO2 as a measurement of metabolic activity (O2 is required).

co

You often keep the ventilation inlets closed, to hold heat and humidity inside the cabinet, and to minimise temperature variations. This causes the CO2 concentration to rise. In a hermetically-sealed incubator, this can increase up to 6,000-8,000 ppm within 4-5 days. The relative humidity will also be high, which means the eggs will lose very little moisture during the first week. This is not necessarily a problem, as long as it is possible to keep the humidity low enough by increasing the ventilation in the second phase of the incubation process (non-linear moisture loss). So, set the RH to around 35-40%. A maximum CO2 concentration of 3,500 ppm is often applied throughout the incubation process (outdoor air has around 400 ppm). This has another positive effect: a higher CO2 concentration during the first few days promotes better blood vessel development because the embryo has to work harder to absorb oxygen. A robust vascular system prepares the embryo better to cope with the ‘stuffy’ conditions it will experience during the later growth and maturation stage. When there is sufficient ventilation, the embryo has extra oxygen available. Be aware: as a result of disinfection, there may still be disinfectant in the pores of the egg shell. If you do not ventilate at the beginning, this cannot disperse and this is harmful to the young embryos.

Restricting ventilation a little during the first days is a commonly used strategy. The humidity level then rises. This moisture is removed more quickly. During the last phase of the incubation process, the focus shifts to regulating based on CO2.

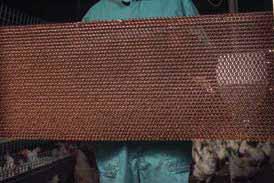

Sensors for measuring various gas concentrations in the air: a temperature sensor, relative humidity meter, and a CO2 sensor. The red cap with the CO2sensor allows it to be covered while cleaning the incubator. 104

A drive belt for the fan in the setter runs through the ceiling, and causes an air leak. For optimal climate control, the incubator must be hermetically sealed. Ha tc he ry S i gnal s