Influence of incubation temperature on incubation time and hatchability

100 90 80 70 60 50 40 30 20 10 0

24

hatchability

Hatchability %

23 22 21

incubation time

96°F 35.6°C

98°F 36.7°C

20 100°F 37.8°C

19 104°F 40.0°C

102°F 38.9°C

Eggshell temperature (°F/°C) Setting a higher temperature in the incubator slightly reduces the incubation time. There is a clear optimal peak in the hatchability percentage here.

te

d

Only start the incubation process when the eggs are pre-warmed. The pre-warming time is not part of the incubating time. In a single-stage incubator, the air temperature is adjusted in line with embryo growth and the increasing heat production of the embryos. The machine temperature is high to start with, and then reduced in stages. When incubating a batch of eggs with a high fertilisation rate, the total heat production will also be high. In this case, it is difficult to regulate the climate balance in the incubator. This is why good air circulation in the incubator is so important, to ensure that all the eggs have the optimal temperature regardless of fertility.

Average incubation time (days)

Climate conditions during setting

Filling the machine

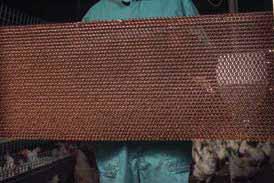

There seem to be two hotspots in this incubator (white spots) and a cool spot at the bottom left. A hotspot is often caused by poor air circulation. Do not take temperature uniformity for granted. Check the number of revolutions of the pulsator annually/semi-annually and replace the pulley motor if necessary.

Heat and temperature during the incubation process development

growth

internal external plateau phase pipping pipping

350

104/40.0

300

103/39.4

250

102/38.9

200

101/38.3

heat production

100/37.8

150 heat loss by evaporation

50 0

0

2

4

embryo temperature machine temperature 6 7 8 10 12 14 Incubation time (days)

16

18

20

99/37.2

Temperature (°C/°F)

co

The terms air velocity/airflow/air speed are often mixed with the term ventilation. But these are two different things. Ventilation is the exchange of air. Incoming air is different than air that is exhausted in terms of composition (CO2, O2, RH) and air temperature. This is determined by the inlet opening and expressed as the ventilation rate (m3/h). Air velocity is all about the flow of air within an incubator, influencing heat exchange. Air that is not moving has an insulating effect, whereas moving air facilitates heat exchange and moisture loss. This is determined by the fan speed and expressed as speed (m/s). In fact, you can have a high air velocity without any ventilation (closed incubator). However, a high ventilation rate without air velocity is not possible.

Heat production or loss (mW)

py

Air velocity ≠ ventilation rate

rig

ht

pr ot

ec

In a multi-stage system, the air temperature in the setter must be kept as constant as possible. The machine must be filled in the correct way to ensure a stable temperature (not too empty or full, and well distributed). Some multi-stage machines work best when alternating setter trays with cold and warm eggs are placed in the trolleys (fixed rack system).

98/36.7

The transition point here is day 7: from that moment, cool the eggs instead of warming them. This precise moment depends on heat transfer. The air velocity over the eggs has the greatest influence on this (also see page 41). In machines with higher air velocity, the transition point can be day 10 or day 11. 7. S et t i n g

101