Setting eggs

LOOK-THINK-ACT

te

d

You should aim to only place eggs from 1 breeder, 1 house, and 1 breed into the setter. An average breeder farm produces 30,000 to 40,000 eggs per day. The eggs are collected from breeder farms every 3 days, which means that about 100,000 eggs must be placed in the setter. An incubator can hold from 5,000 to 200,000 eggs. For example, there can be 150 eggs in a tray, 2 trays per level, 16 levels per trolley (150 * 2 * 16 = 4,800 eggs). With 12 trolleys in a setter, you have a total of 57,600 eggs. Often, more eggs are delivered than the number required to fill the incubator. Hatcheries often ‘overbook’ on the capacity of their incubators. It is actually better to sell or dispose of excess eggs than to have empty spaces in the incubator. The machine needs to be loaded to full capacity to function properly. If you do have empty spaces, leave the lower or upper positions in the trolley empty.

ec

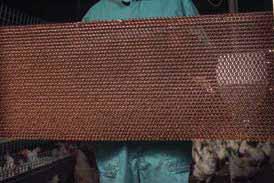

What does this thermal image show you?

py

rig

ht

pr ot

This infrared image shows that the temperature in the trays is not the same everywhere. The eggs are much warmer in the middle. The ones on the bottom tray are colder. Some unfertilised eggs remain even darker coloured (produce no heat). This is due to poor air circulation. Good heat distribution starts with preheating. Eggs are preheated in the machine or in the pre-hatching room (min. 12 hours) with plenty of space between the trolleys so that the eggs all warm up well and uniformly. The temperature must be maintained uniformly throughout the machine, with no more than 1% variation.

co

Before starting up, check that all sensors (temperature, CO2, and RH) are functioning properly, their protective caps are removed, and the automatic turner is operational. Turning is essential during the first seven days.

Do you always have to fill the incubator completely?

Separate incubator for risk-eggs

The incubator design is based on it working at full capacity. The incubator works best in this situation. The effect of air velocity is sometimes difficult to recognise. There is always the risk that the airflow will take the route of least resistance: so any empty spaces can affect the air circulation around the eggs and in turn the heat transfer from individual eggs. So, this is a good reason to always fill the incubator completely. But sometimes it is better to leave a few spaces empty, such as spots where, structurally, high eggshell temperatures are measured. This will prevent chick quality problems.

Some hatcheries use separate setters for risk-eggs, such as dirty or washed eggs. These machines have separate exhaust systems that discharge directly outdoors. Every week, suspect eggs and suchlike are removed and disposed of in a bath of disinfectant. Always handle these eggs at the end of the working day, to avoid cross contamination. Lay paper in the hatcher baskets, to avoid contaminating the other chicks. Take off these chicks manually, to prevent extra bacterial contamination on the automated systems. Preferably, put these chicks in a special ‘emergency farms’. This will prevent administering antibiotics to the entire broiler flock. If you do still deliver them to a broiler producer, supply them separately, so the farmer can decide what to do with the chicks. But deliver them with other eggs from the same origin (so that there is common maternal immunity).

7. S et t i n g

99