Each incubator is different

py

rig

ht

pr ot

ec

te

d

Has a new machine arrived? Then you will have a lot of fine-tuning and experimentation to do. Getting the settings right takes a few incubation cycles. Always adjust one parameter of the incubation process at a time in small steps to monitor the effect. When a new incubator is installed and started up, a specialist from the incubator manufacturer is usually on hand to help.

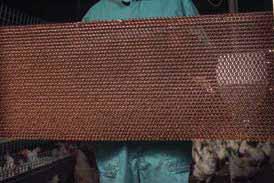

Each incubator manufacturer has its own view on how to control and regulate the microclimate around each individual egg. And each incubator is different. For example, there are differences in relation to air direction and air velocity. The incubation program is specific to a machine in a particular hatchery and is not interchangeable for use with other machines in other hatcheries. The quality of the incubation process depends largely on the quality of the incubator. But always remember: ‘Success is the combination of a good incubator, good hatching eggs and a good team.’ Every hatchery manager can learn to work with any make/type of incubator - it just takes time, patience and trust in your experience and intuition. If you work with different makes of incubators, you will become familiar with the specific strengths and weaknesses of each incubator and adapt your incubation programs accordingly. One machine is maybe more suitable for eggs from young parent stock and another for older parent stock. The flow of air can vary in strength and direction due to the position of eggs and setter trays and therefore the heat and gas exchange too. The position of the air inlet/outlet and the cooling/heating elements and sprayers is also important. What is the cooling capacity? If you switch to using a different incubator, you also need to change the incubation program. But the goal is always the same: to hatch the highest possible percentage of good quality chicks, regardless of the type of incubator used.

co

Someone must be assigned responsibility for the results. For example, there should be clear guidelines in place about who is authorised to enter the initial settings for the incubation programs, or adjust temperature settings in certain situations.

Create logbook per incubator Make sure that a good (digital) log is kept with technical faults. You register repairs and all other technical interventions to the incubator. You can link this later to hatching results. Or see a link between certain repairs.

Tip!

You can assess the results of the different brands or types of incubators by placing trolleys with hatching eggs from the same source in different incubators simultaneously. Or by exchanging eggs or data with another hatchery. This will help you to evaluate and adjust machine settings.

8

It’s a good idea to rotate personnel so they work in each department. This helps them understand and appreciate how the procedures work in different departments. After all, everyone at the hatchery is a member of one team working to achieve the same results!

Ha tc he ry S i gnal s