Look at PRINTING United Expo

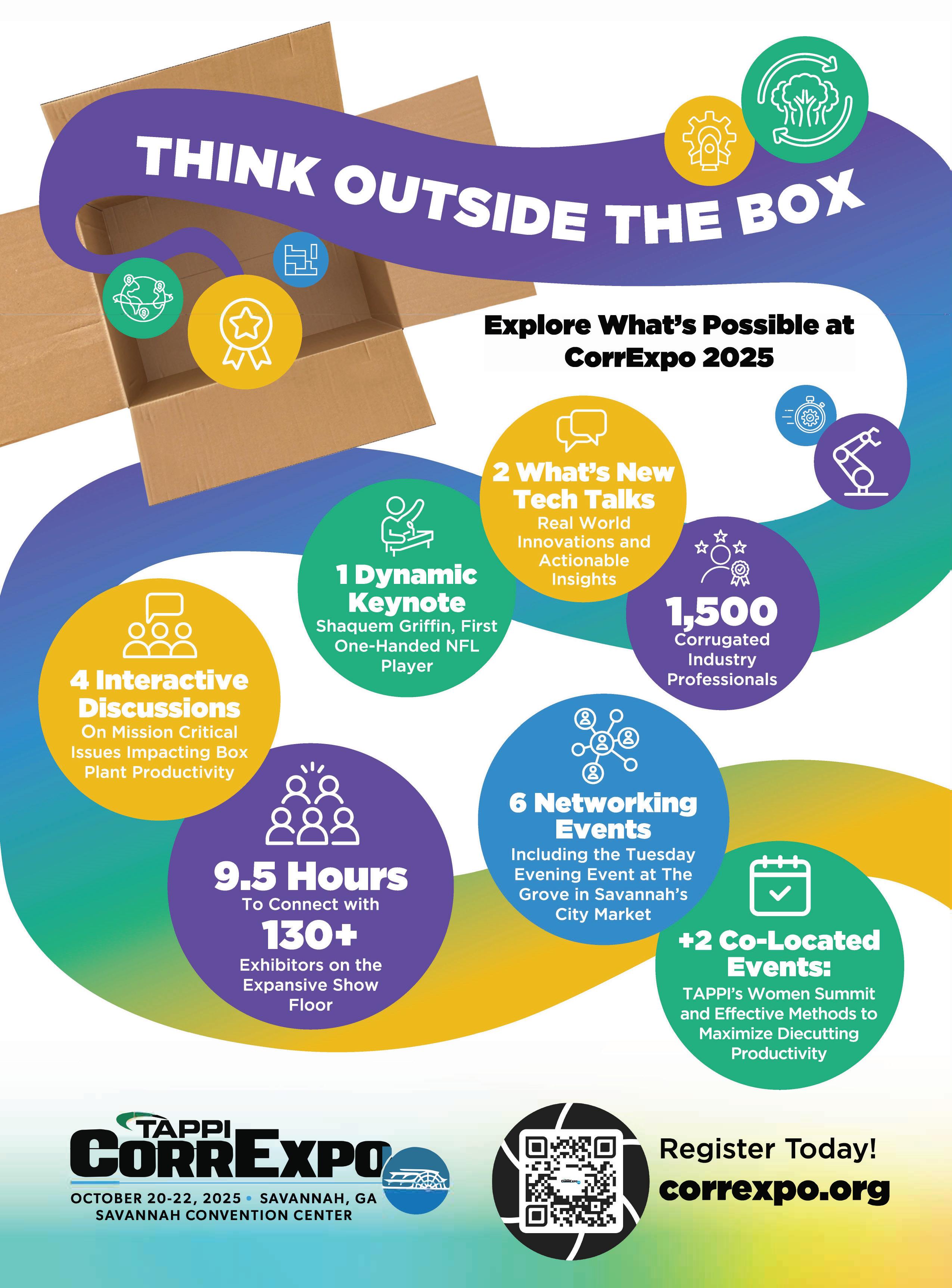

PRINTING United Expo heads back to Orlando, FL this October, with the PRINTING United Alliance’s marque event taking place at the Orange County Convention Center from October 22 to 24. Billed as where to “see the entire printing industry in one place” the show combines every printing segment to cater to print providers looking for a one-stop shop when it comes to hardware, media, software, and services.

We reached out to those exhibiting at the show and asked them to share their plans.

Aleyant, booth 2632, showcases the latest advancements in its suite of print automation solutions—Pressero, PrintJobManager, tFlow, and the new PDF2Press Core & Pro. PDF2Press, a nextgeneration prepress workflow automation software, eliminates the need for scripting or JavaScript, empowering users to create robust, customized workflows through an intuitive interface. Whether sourcing files from web to print systems like Pressero, cloud drives, email inboxes, or APIs, PDF2Press handles it all. It automatically preflights and corrects common file issues, generates proofs at checkout, or sends email proofs—streamlining the entire production process. With integrated pricing logic and rule-based automation, PDF2Press intelligently routes jobs based on customer selections. INFO# 160

P5 530 HS D4. Durst also brings a Tau 340 RSC E label printer. INFO# 162

Cutworx USA, booth 848, exhibits a spectrum of new and flagship technologies. Debuting innovations include the COMAGRAV Notus Plus 3000 for industrial routing, Neolt Factory’s fully automated XY cutter system, and FASTSEWN’s high-speed textile finishing solution. Attendees can explore the company’s core lineup—the CWT Worktools Flatbed Applicator Table and 1700 Series, the magnetic drive Apex M Series flatbed cutter, and advanced Vision Scan Systems designed for roll-to-roll textile processing. INFO# 161

Durst North America, booth 3156, brings the latest innovations and pioneering technologies. For the first time in North America, the P5 500 TEX iSUB superwide dye-sublimation printer is shown. Alongside it, the P5 X true flatbed and roll-toroll printer. Rounding out the wide format lineup is the Durst

Epson, booth 3970, showcases a range of professional print solutions, as well as new products being introduced at the show, ideal for a variety of applications—indoor and outdoor signage, photography, graphics, and textile. One new product on display is the SureColor S7170 64-inch entry-level solvent printer. It touts a new, wider 1.33-inch PrecisionCore Micro TFP printhead with Nozzle Verification Technology, UltraChrome GS3 four-color solvent ink, and a precise media handling system to deliver renowned detail and color performance on a wide spectrum of media, ideal for indoor and outdoor signs, banners, stickers, and vehicle wraps. INFO# 163

Fluid Color, booth 2042, exhibits its UV LED inkjet technology, offering a little bit of everything from its portfolio. Attendees can expect to see the ZR126, a ten-foot wide, roll-to-roll printer built for high-speed, high-volume production. Also featured is the ZH126, a ten-foot wide hybrid printer running live—demonstrating its flexibility across rigid and flexible substrates. Rounding out the lineup is the RF84, a high gantry flatbed printer

1. Vision, booth 2410, displays its 25 Series Router, 1624 Pro Engraver, and VE 810 Engraver. 2. Techkon, booth 4817, educates attendees on the SpectroDens color spectrophotometer/densitometer, SpectroDrive scanning solution, and SpectroPlate digital microscope color management tool.

designed for oversized and heavy materials, with a true 4x8-foot bed and a print height of up to 19.68 inches. INFO# 164

Inkcups, booth 1530, manufactures high-quality industrial machines for a range of industries, including apparel, drinkware, promotional, electronic, medical, sporting goods, and automotive markets. The Inkcups direct to object UV inkjet portfolio includes the Helix range of cylindrical inkjet printers and UV inkjet flatbed printers including the XJET Switch direct to bag printer and the X5-T High Throw, pretreatment systems, pad printing machines, as well as inks.

INFO# 165

Kongsberg Precision Cutting Systems (PCS), booth 2200, demonstrates its “Shaping Your Future Together” campaign. The campaign highlights how its industry leading products, customer support, and materials expertise combine to empower businesses to push creative boundaries while improving overall efficiency and productivity. Kongsberg PCS showcases three of its advanced cutting solutions for print and signage, including the new Entro 24 entry-level cutting and milling solution, the Ultimate 64 digital cutting table, and the MultiCam Apex3R Evo CNC router. Visitors can also discover the C24 table paired with Digitech’s X3 printer with IMC stacker in the Digitech booth 3016. INFO# 166

PrintFactory, booth 2864, demonstrates how its cloud-based RIP workflow software is transforming print operations around the world. Visit the booth to see how it helps print shops streamline production, improve color consistency, and reduce media and ink waste, all from a single platform. Cloud job management, automated color management tools, and easy device calibration are demonstrated across wide format, textile, and industrial print environments. INFO# 167

Summa, booth 4336, displays a range of cutting solutions, including its S series of vinyl cutters, the V and F series

of flatbed cutters, and the L series of laser cutters; the new 5x8-foot flatbed cutter F1625 takes center stage at the show. Summa’s F1625 flatbed cutter is engineered for professionals in signage, display, and packaging who want a 5x8foot working area. It handles both rigid and flexible media, with no additional feeding for 4x8-foot boards. INFO# 168

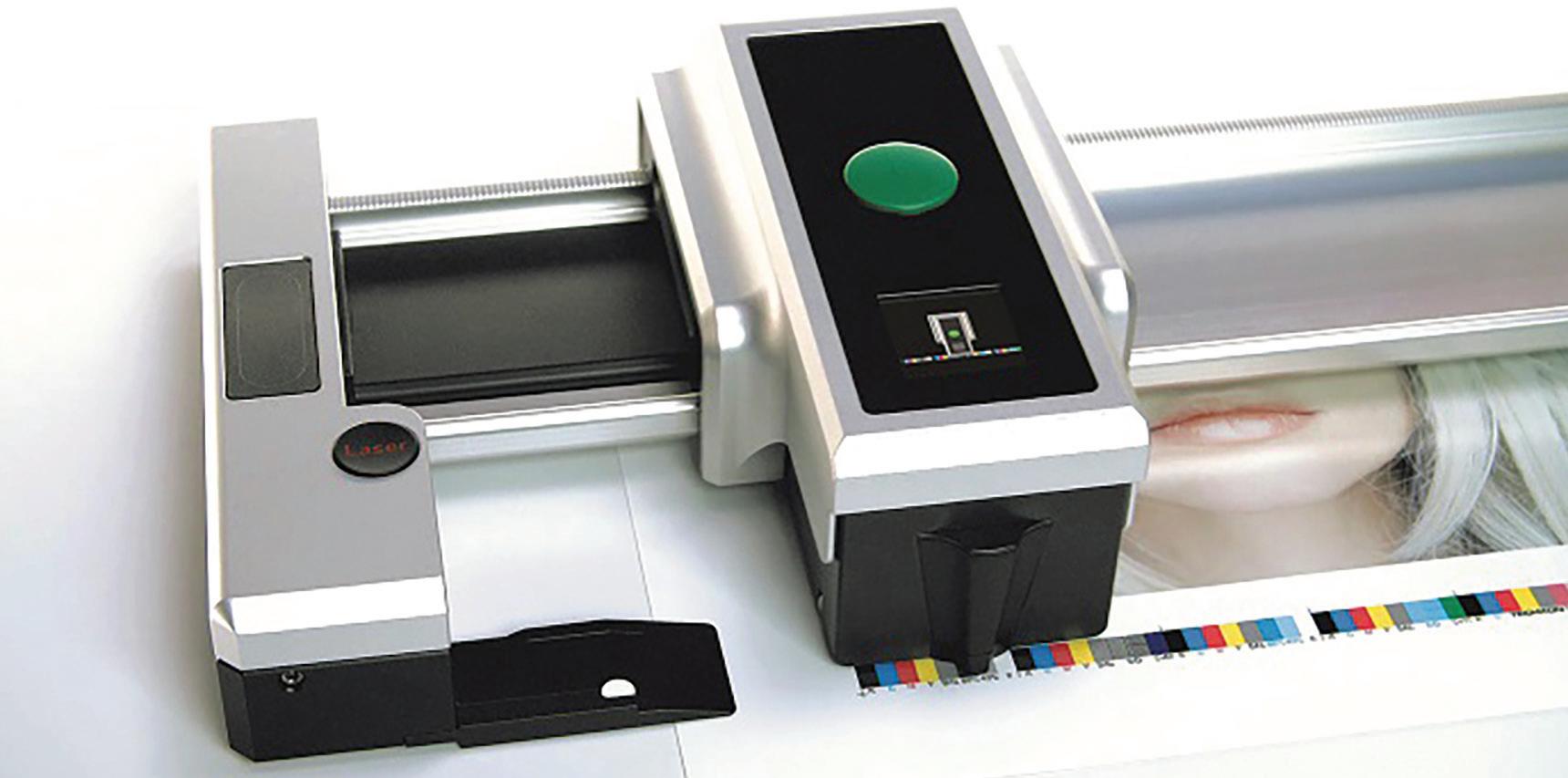

Techkon, booth 4817, educates attendees on SpectroDens, a combined color spectrophotometer and densitometer to help control process, spot, Pantone, or other brand colors. SpectroDrive is a press-side, automated, scanning solution for offset presses. SpectroPlate is a highresolution, multi-functional digital microscope used to inspect and measure printing plates. This device can measure dot percentage; screen angles; lines per inch per centimeter; dot gain; and AM, FM, or hybrid screens of traditional offset or process-less, chemistry-free printing plates. ChromaQA 6 with SmartInk is a comprehensive color quality software platform designed to simplify workflows. Colibri ink formulation software is the most sophisticated ink formulation platform available. INFO# 169

Vanguard Digital Printing Systems –

A Durst Group Company , booth 3162, showcases its Radnor hybrid printer and the VK3220T-HS ultra-productive flatbed printer with a new, automated offloading option. It also debuts its next evolution of a trusted Vanguard

solution, which is a testament to the company’s commitment to offering the best equipment available to all print service providers. INFO# 170

Vision Engraving, booth 2410, displays its 25 Series Router, 1624 Pro Engraver, and VE 810 Engraver. Vision’s 25 Series offers a 25x25- or 25x50-inch work area and has multiple options, including an Auto Braille Inserter, Oscillating Knife, New Drag Knife, New Creasing Wheel, Print-To-Cut, and more. The 1624 Pro Engraver has a 16x24-inch T-slot table and is ideal for light to heavy duty sign applications. The VE810 has a compact, space-saving form factor, allowing it to fit on most desktops. Make a variety of signage with Vision’s machines, including dimensional letters, print-to-cut, and braille. Work with dibond, coroplast, metal, wood, plastic, and other materials. Vision software is graphically advanced, with many tools found in professional-grade graphics software. INFO# 171

From automated finishing hardware launches to printer debuts and everything in between, the PRINTING United Expo promises to bring some of the most innovative products to the convention center floor. Look for more information about exhibiting vendors at industrialprintmagazine.com throughout the month of September. IPM

by Melissa Donovan

Printing direct to object (DTO) means many things, from flat drink coasters to more challenging coffee mugs. Luckily, technology that handles both ends of the spectrum and everything in between is accessible to both novice and experienced users.

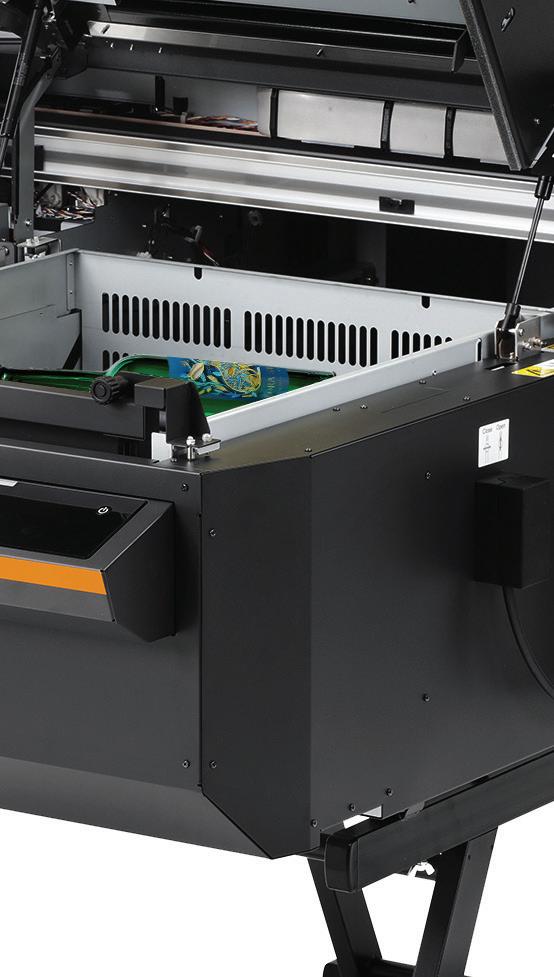

For introductory purposes, a desktopsize UV digital printer is practical and cost effective. Especially for cylindrical objects. It’s easy enough to print a small, flat object and then either place a jig or rotary tool into the printer—if applicable—to print directly to a cylindrical item.

Common cylindrical-type objects that can be printed on a desktop UV flatbed printer, according to David Bistrovic, product manager, Professional Imaging, Epson America, Inc., include tumblers and water bottles, glassware, mugs, golf balls, pens, yo-yos, flashlights, and small containers.

“Desktop flatbeds are great cylindrical printers because they provide flexibility. Cylindrical is one function, but you also get the other benefits of a fully capable DTO printer for decorating small objects and even producing UV DTF stickers with compatible inks,” explains Lon Riley, founder/CEO, The DPI Laboratory.

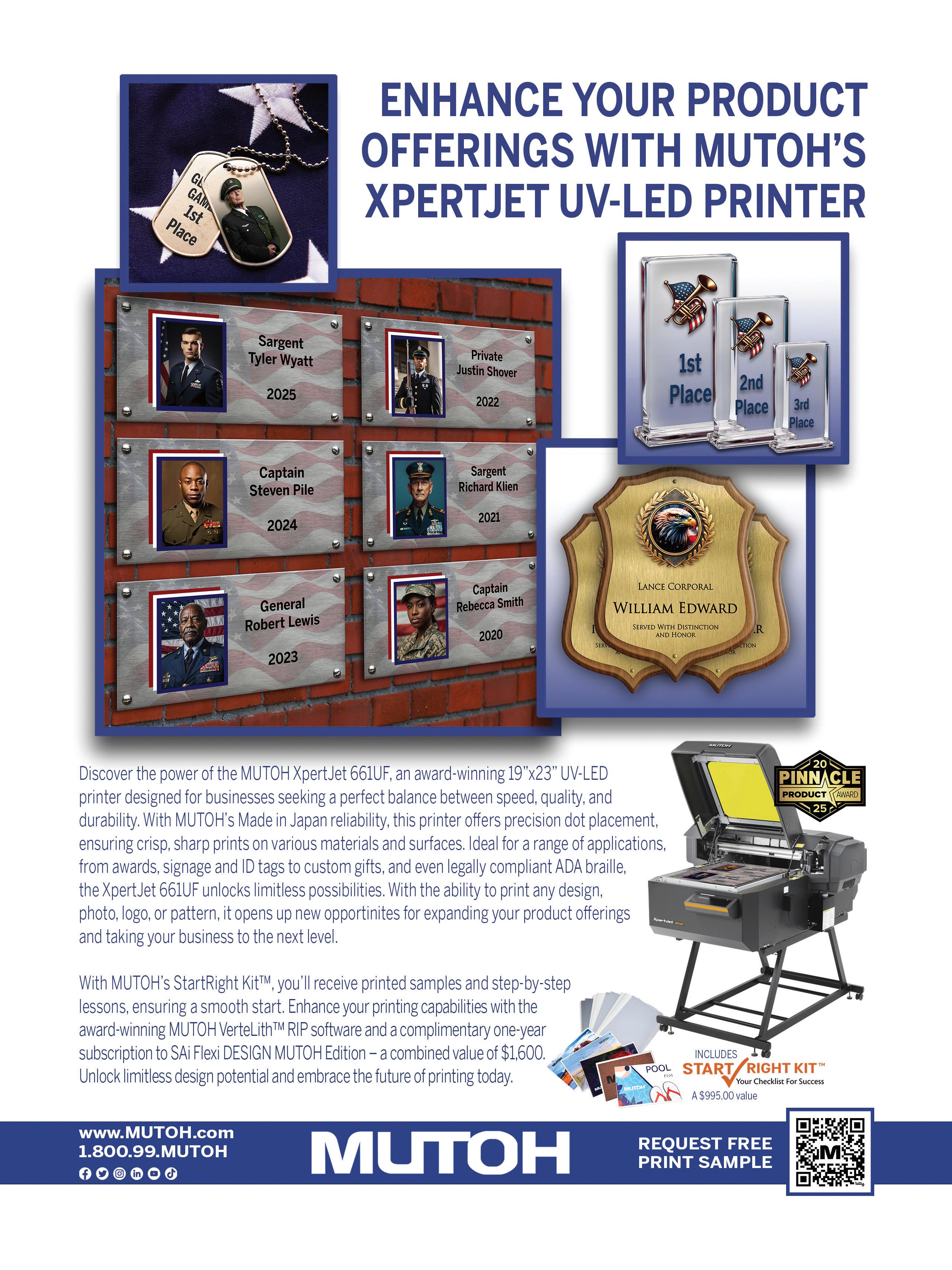

Businesses short on space, but big on ideas, can easily take advantage. “Desktop-size UV flatbed printers are an excellent choice for printing cylindrical objects because they offer a compact footprint without sacrificing capability. The printer can be placed on a table or mounted on a stand, making it ideal for tight workspaces,” notes Emilio Rangel, UV product manager, Mutoh America, Inc.

The technology on today’s devices, more specifically the UV ink sets, make it all possible. “Desktop-sized UV flatbed printers are compact and versatile solutions for printing on cylindrical objects. UV ink adheres to most materials, cures instantly under UV light, is scratch resistant, and offers high durability, ideal for high-use cylindrical objects such as pens, golf balls, and glassware,” says Bistrovic.

A desktop-size flatbed UV printer may be equipped with a rotary tool or have the capability to handle

Desktop flatbeds are great cylindical printers because they

provide

flexibility.

— Lon Riley, founder/CEO, The DPI Laboratory

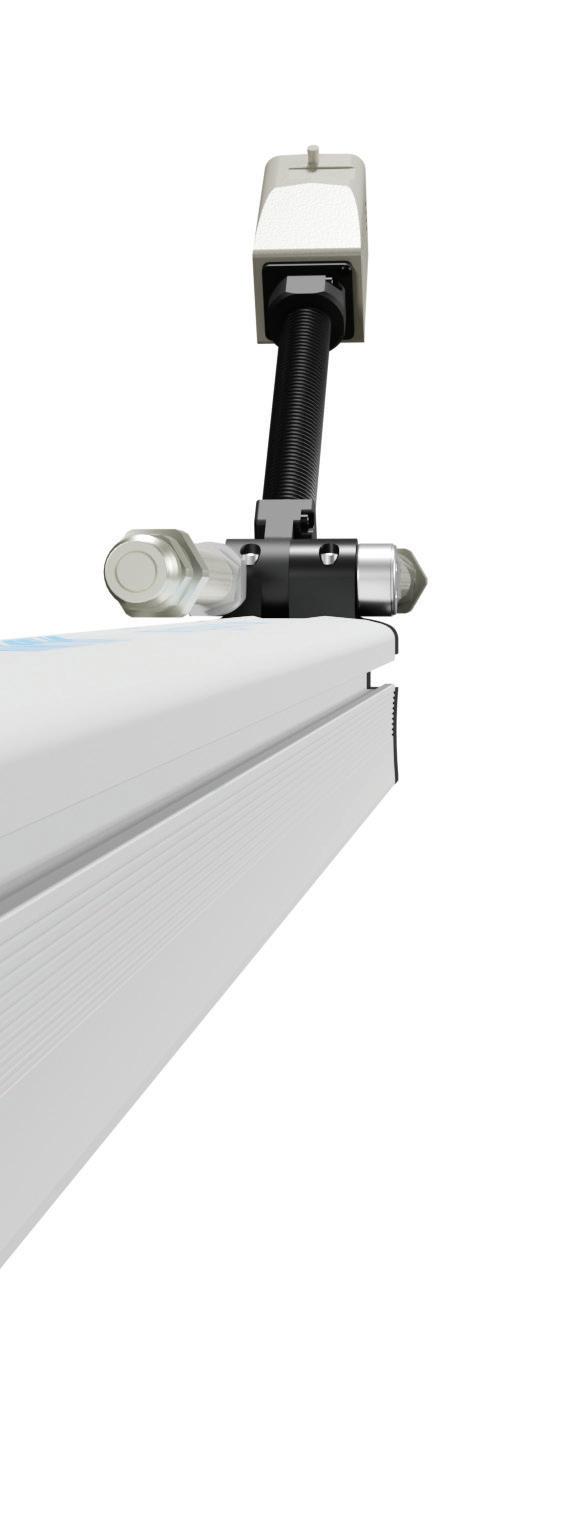

1. Mutoh’s XPJ-661UF is the company’s flagship desktop-size UV flatbed printer designed for versatility—including the ability to print on cylindrical objects.

The DPI Laboratory offers two flatbed machines, which come with a rotary system as part of the core package. The Catalyst Nanos is an A3-sized printer with a rotary capable of accepting objects up to 3.5 inches in diameter. The larger Aventra system has a 900x600 millimeter print area and what makes it unique is the almost 36-inch width combined with a seven-inch clearance, which means it can rotate much longer and thicker objects.

The Epson SureColor V1070 desktop UV flatbed leverages six-color CMYK, plus white and varnish to produce prints on a variety of media and objects. The addition of white ink supports printing on colored substrates as well as clear and acrylic by printing a white base layer prior to the color ink to make prints stand out. The SureColor V1070 can use custom jig inserts for small cylindrical objects, including keychains, golf balls, pens, water bottles, and tumblers.

One of LogoJET Inc.’s latest products is the Inspira UVx45i with a 18x24-inch print area and a maximum substrate height of five inches. It is equipped with Inspira Series H2DX UV-curable ink. The newly engineered ink set offers enhanced adhesion and ink flexibility for broader product applications. Enhanced clear varnish spot printing is also available.

Mimaki USA, Inc. offers the UJF3042 MkII e desktop-size UV LED flatbed printer. Available in a bed size of 11.8x16.5 inches and offering the ability to print on objects up to six inches thick, the included Rasterlink7 RIP software

offers variable data and jig printing functionality. Applicable is the Kebab option, which enables 360 degree direct printing on a range of objects, such as stainless steel tumblers, bottles, cans, vases, packaging, and candle holders.

Mutoh’s XpertJet (XPJ) 661UF is the company’s flagship, desktop-size UV flatbed printer designed for versatility—including the ability to print on cylindrical objects. With a 19x23-inch bed size, it fits easily in compact spaces while still offering enough capacity for a range of applications. When paired with a rotary unit, the XPJ661UF handles cylindrical items like bottles, tumblers, and glassware with precision and ease. What sets it apart is the combination of advanced printhead technology, strong ink adhesion, and user-friendly design. The Mutoh XPJ661UF printer supports layered printing, including ADA-compliant braille, as well as texture and gloss effects, without complicating the workflow.

Desktop-sized UV flatbed printers offer the flexibility to print to all types of cylindrical items, from traditional bottles, tumblers, and glassware to curved, irregularly shaped products like golf balls, ornaments, cosmetic cases, and writing utensils. Depending on the printer, jigs or rotary attachments enable the decoration of cylindrical objects. IPM

Preparation Software

by Industrial Print Magazine Staff

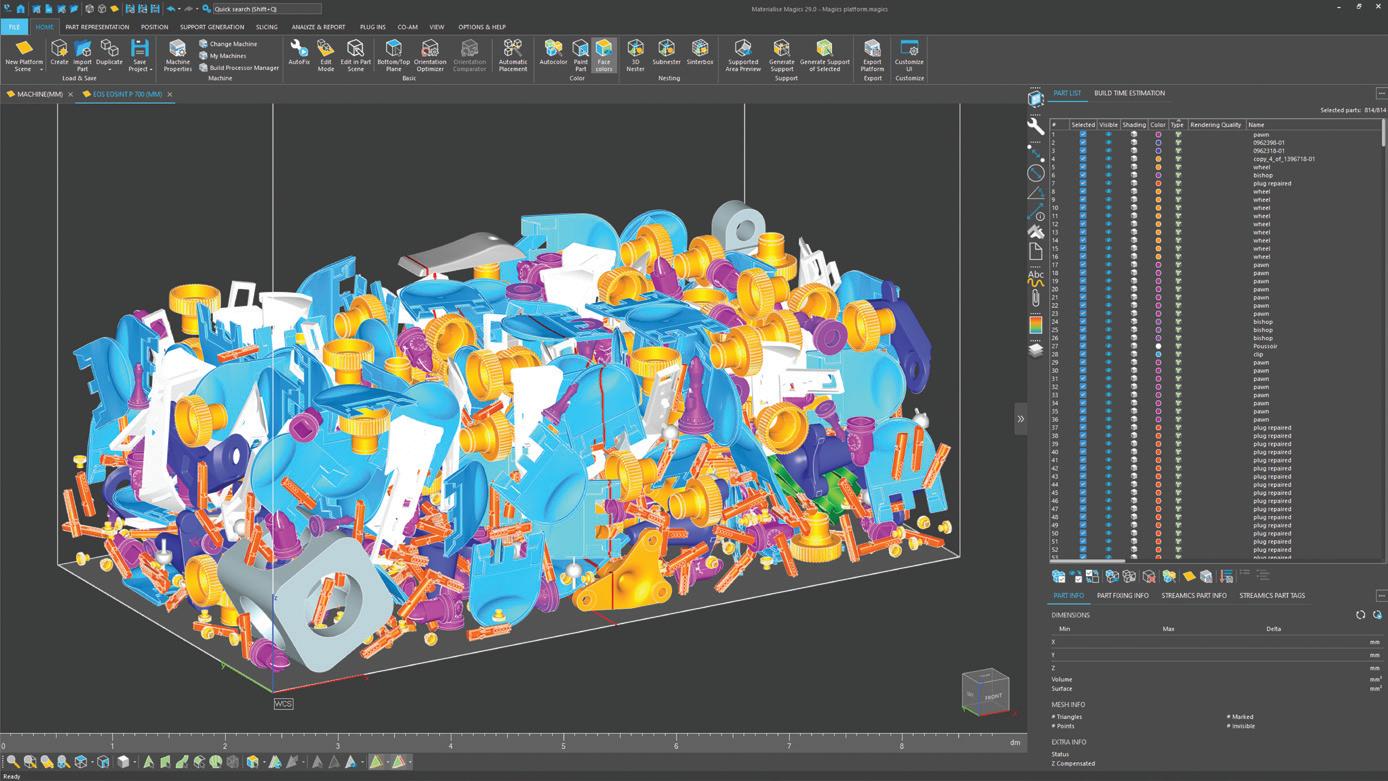

Software plays a pivotal role in the manufacture of a three-dimensional (3D) part. Many facets of the creation process benefit from software solutions, like product inventory management and designing a structure. It helps to cut down on time as well as expenses.

One tool used in additive manufacturing (AM) is build preparation software. According to Ajay Bharadwaj, head of software product development, Intech Additive Solutions Private Limited, build preparation software is essential to AM, as it handles all the critical functions for achieving high-quality prints.

“It manages everything from part orientation, support generation, and slicing to laser path planning and simulation. It also offers support-reduction options, enables cost analysis, facilitates connection to ERP systems, and helps determine process parameters based on geometry,” continues Bharadwaj.

Build preparation software is a necessity in today’s AM world.

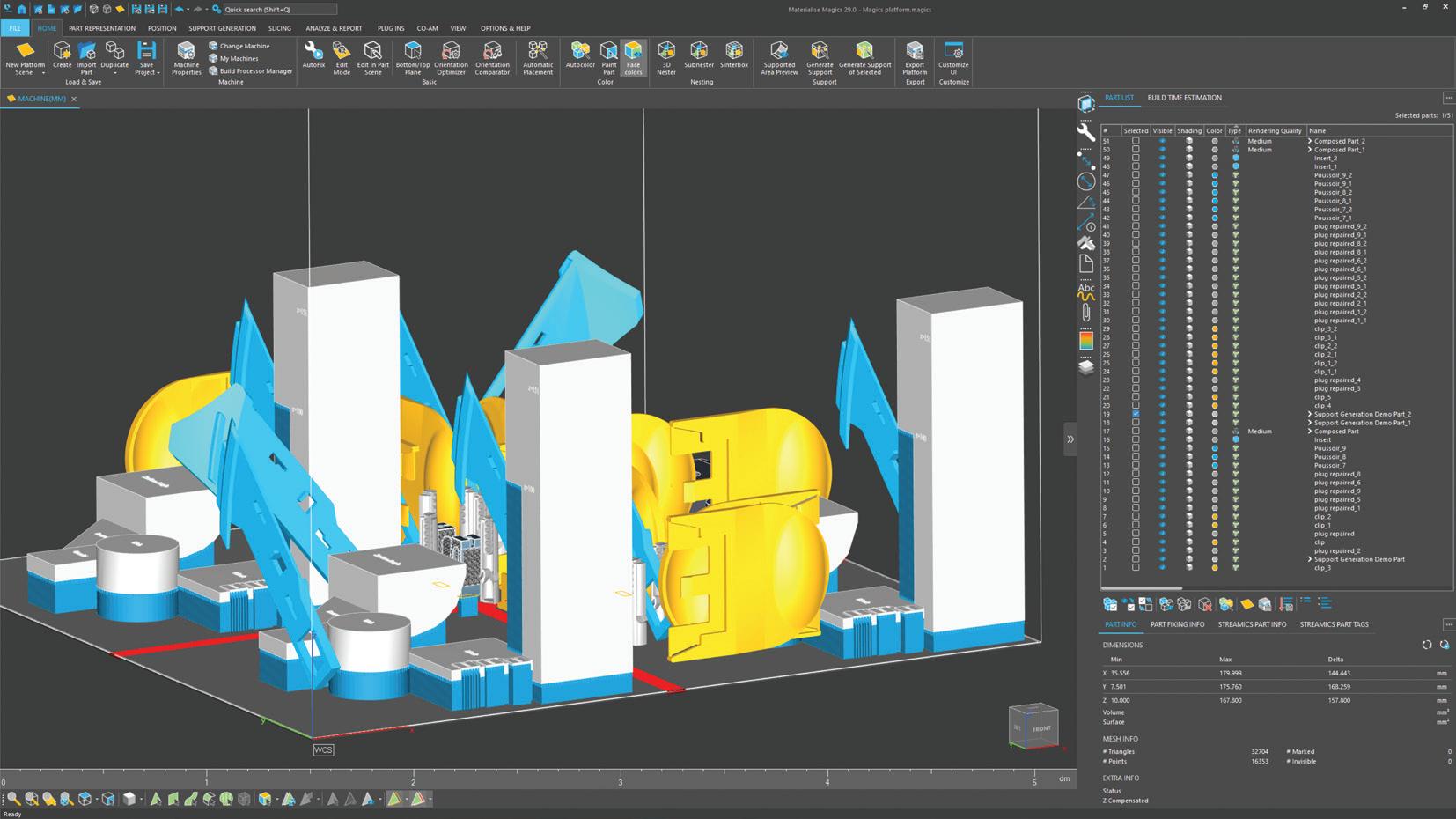

According to Egwin Bovyn, business line manager, Materialise Software, the way a build is prepared directly impacts cost, quality, and repeatability. “Build preparation software determines how well your machine performs, from orientation and support strategy to slicing, laser pathing, and thermal behavior. Intelligent build preparation software defines these parameters to optimize for machine and materials being used.”

Build preparation software is integral, especially as AM scales from prototyping to production printing.

“When transitioning AM from prototyping to production, there is a critical challenge—the CAD-to-print process isn’t plug and play. This is precisely where build preparation software becomes indispensable. Without robust data preparation software, scaling AM beyond prototyping would be incredibly difficult,” explains Bharadwaj.

Build preparation software can save users money and time. It is also beneficial in avoiding wasting physical resources.

It manages everything from part orientation, support generation, and slicing to laser path planning and simulation.

— Ajay

Bharadwaj,

head of software product development,

Intech Additive

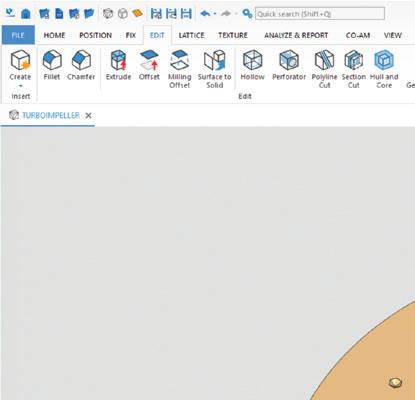

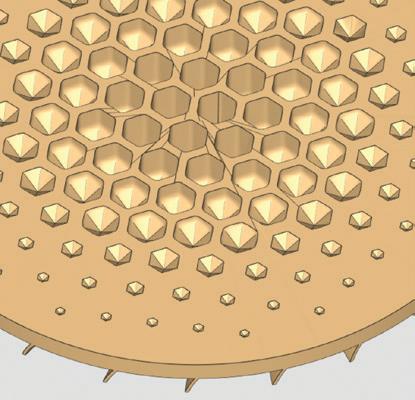

Production of an AM-built part generally leaves room for error. Bharadwaj says this is due to AM being a less 1. Magics from Materialise centralizes every step of the AM process, from CAD import and data repair to part editing, labeling, nesting, support generation, slicing, and machine file output.

mature build process, compared to say CNC machining. When using AM, issues can result like build failures— warping and re-coater interference, internal defects like porosity and lack of fusions, as well as inflated post-processing costs.

In the first year of metal 3D printing, Bovyn says customers typically scrap about 50 percent of their builds as they learn. Build preparation software can dramatically reduce iteration cycles. “Reducing iterations from six to two or even one is a huge time and cost savings. When dealing with expensive materials like titanium or Inconel, this translates to thousands of dollars saved per part development cycle,” continues Bovyn.

The aforementioned challenges are solved with build preparation software. “Such a product can serve as an invaluable tool, automating complex decisions and educating users, thereby

enabling them to achieve right-first-time parts and significantly reducing overall operational costs,” says Bharadwaj.

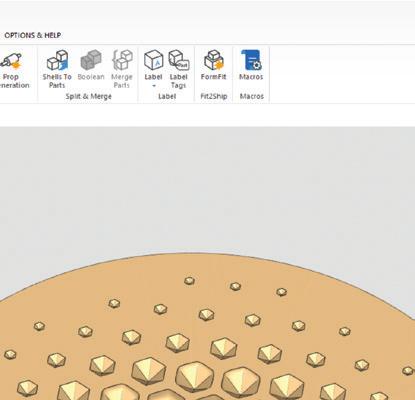

The automated aspect of software, specifically build preparation software, is a time saver, agrees Bovyn. “Features such as nesting and labeling can be completed in minutes or even seconds instead of hours of manual work. This frees up skilled labor to focus on higher value tasks rather than repetitive preparation work.”

“Build preparation involves a sequence of steps that can be highly repetitive, especially if you’re printing a high volume of similar parts. Wherever there’s repetition, there’s an opportunity for automation,” agrees Safouan Itahriouan, AM senior application engineer EMEA, Qqton, in a blog post, How Allin-One AM Software Removes the Most Common Workflow Bottlenecks

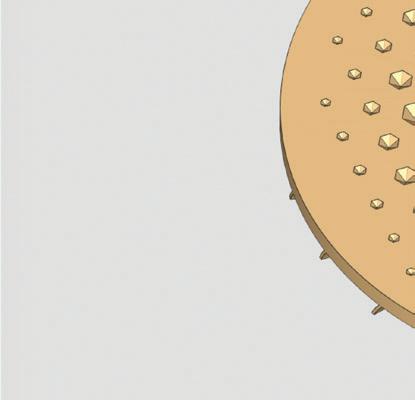

Another example of the 3D print process that benefits from automation

is supports. “They are essential for printing overhangs or bridges, fixing the part to the build plate, and even removing heat. On the flip side, supports drive up costs due to additional material use as well as post-processing work. You can save on time and material if you optimize and automate support generation,” explains Itahriouan.

“With support templates, meta templates, and scripts you can apply the same strategy to similar builds. Even if a customer comes with an engineering order change a month after the initial print, you can apply all the same build preparation presets by replacing the old part version with the new one,” continues Itahriouan.

Build preparation software is offered by either 3D printer manufacturers or third-party suppliers, through which the 3D printer manufacturer has vetted the solution to work with their device.

The advantage of working with thirdparty software is its vendor-agnostic characteristics, which enables a unified workflow across multiple machine brands and AM technologies, explains Bovyn. “This provides the flexibility necessary to adapt build preparation functionality to unique production requirements. This flexibility is critical in AM, especially given the huge variety of systems and technologies available in the market. AM requires far more

2. Tools such as e-Stage for Metal+ found in Materialise’s Magics enable automated support generation, saving time, material, and post-processing effort. 3. Magics from Materialise focuses on optimization, enabling new possibilities and providing advanced features including automation, simulation, labeling, and traceability.

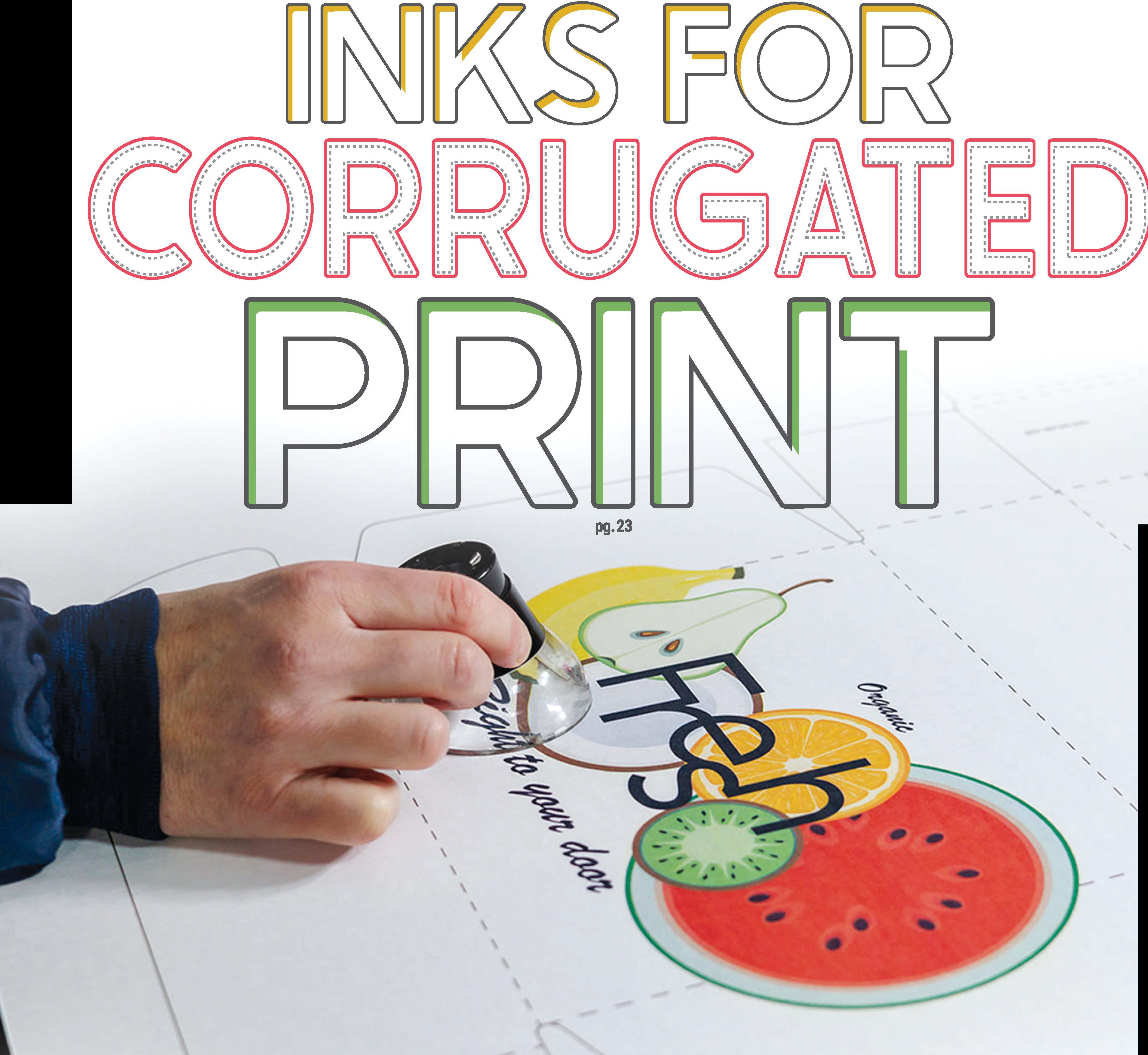

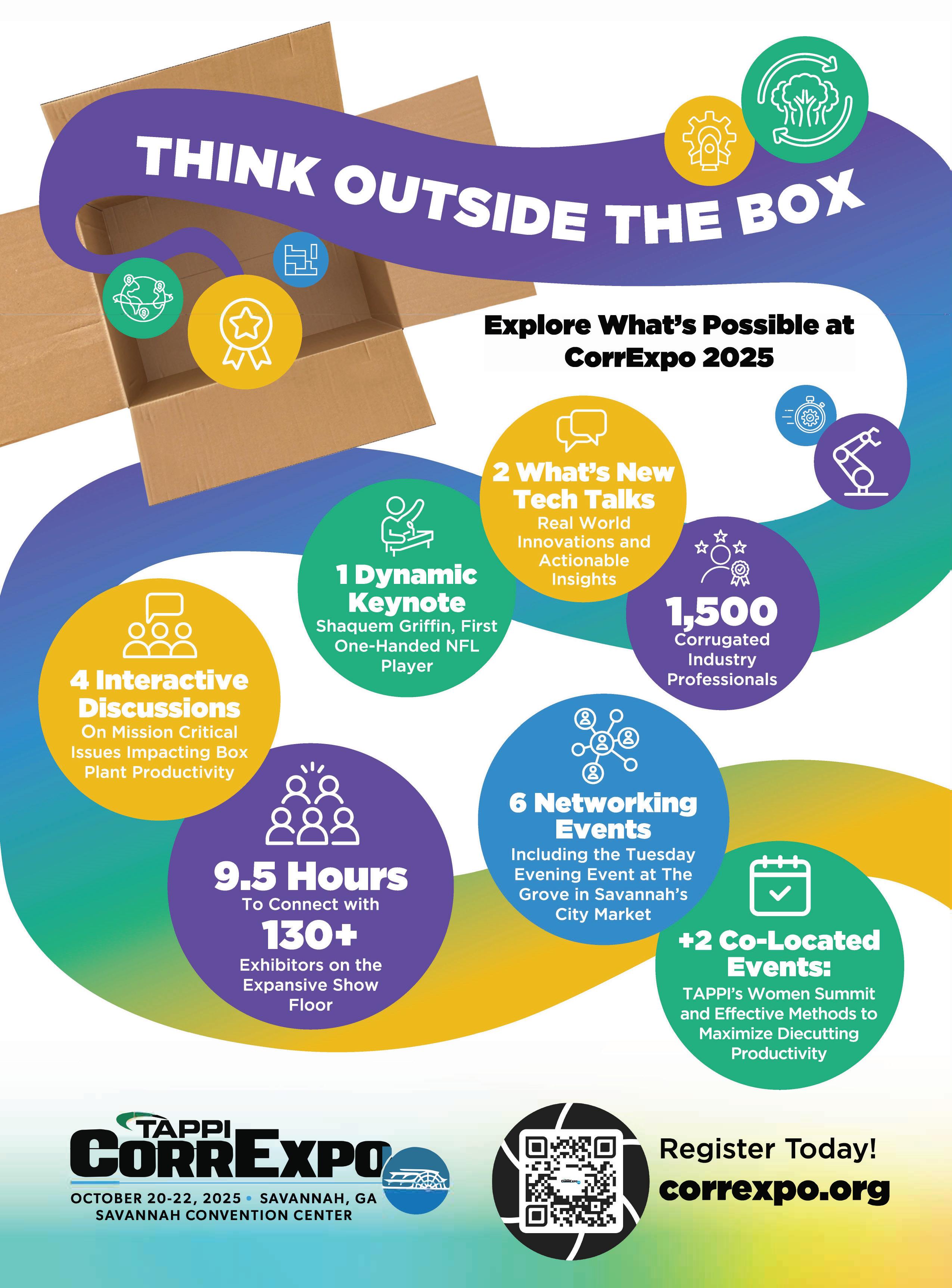

Ink sets for corrugated board printing are listed below. In September, visit our website industrialprintmagazine.com to read in more detail about what each company offers.

• artience (Toyo Ink America) Liojet FW-Series UV inks

• INX International Ink Co.

BSR-06 UV & BECB-06 UV-curable inks

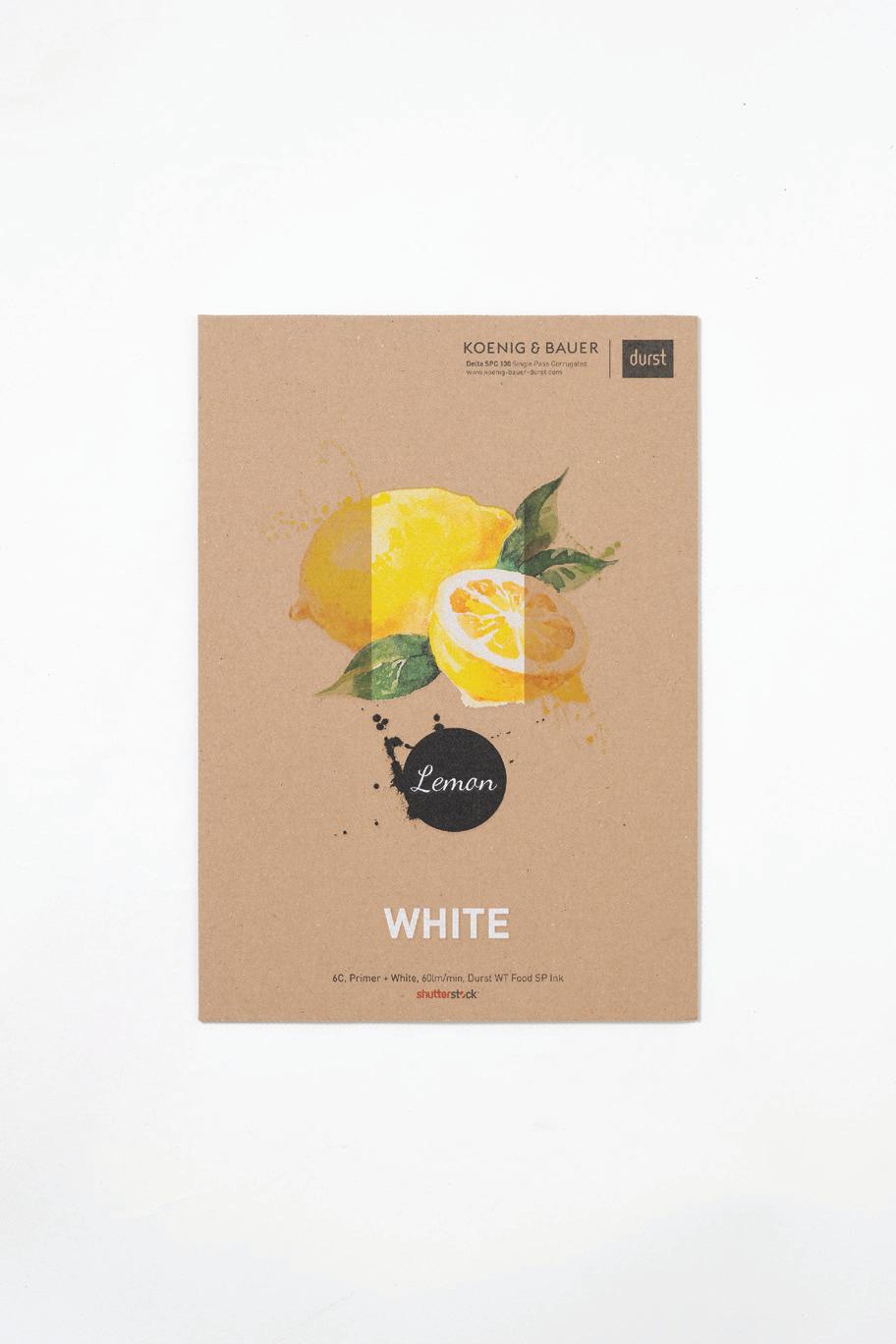

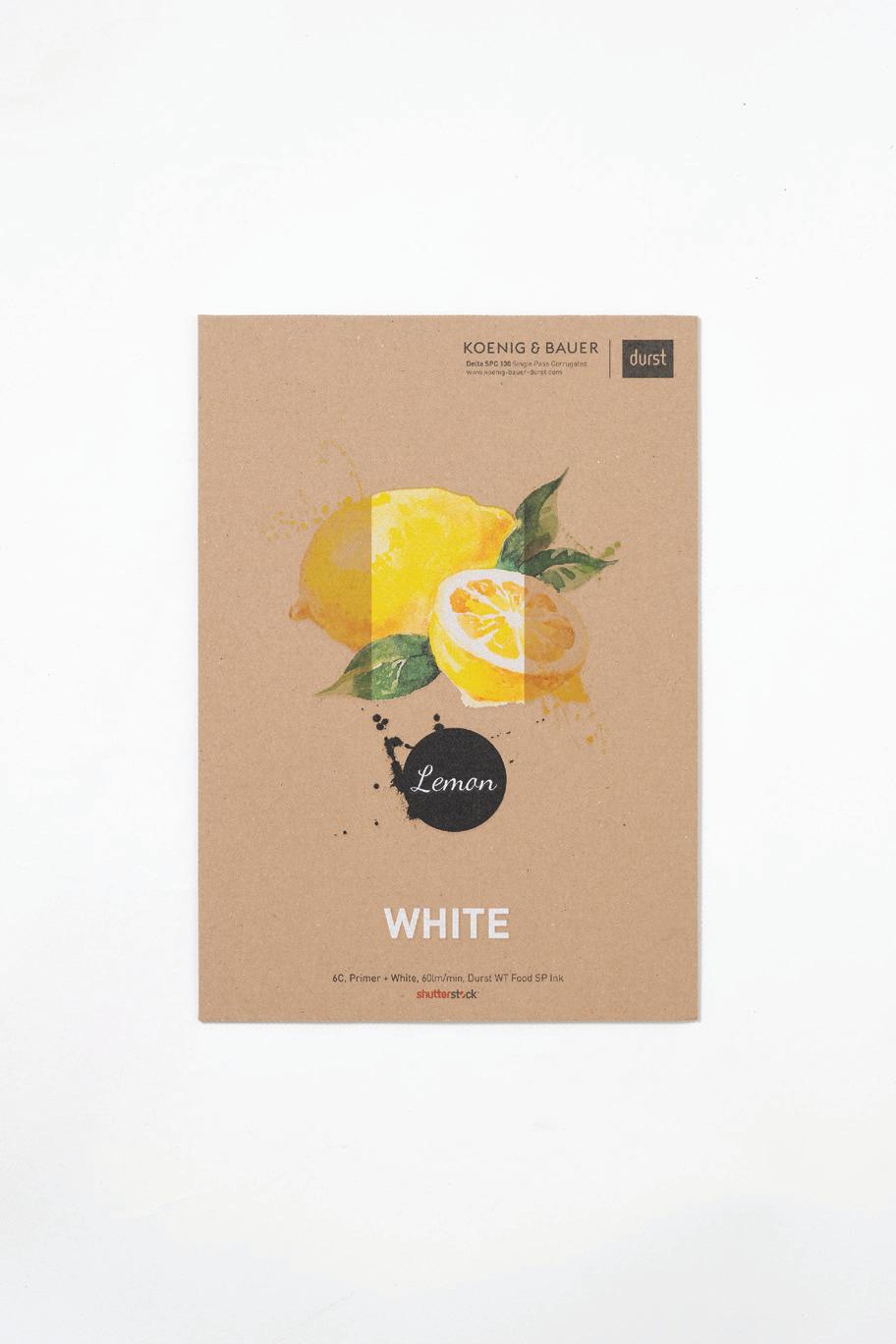

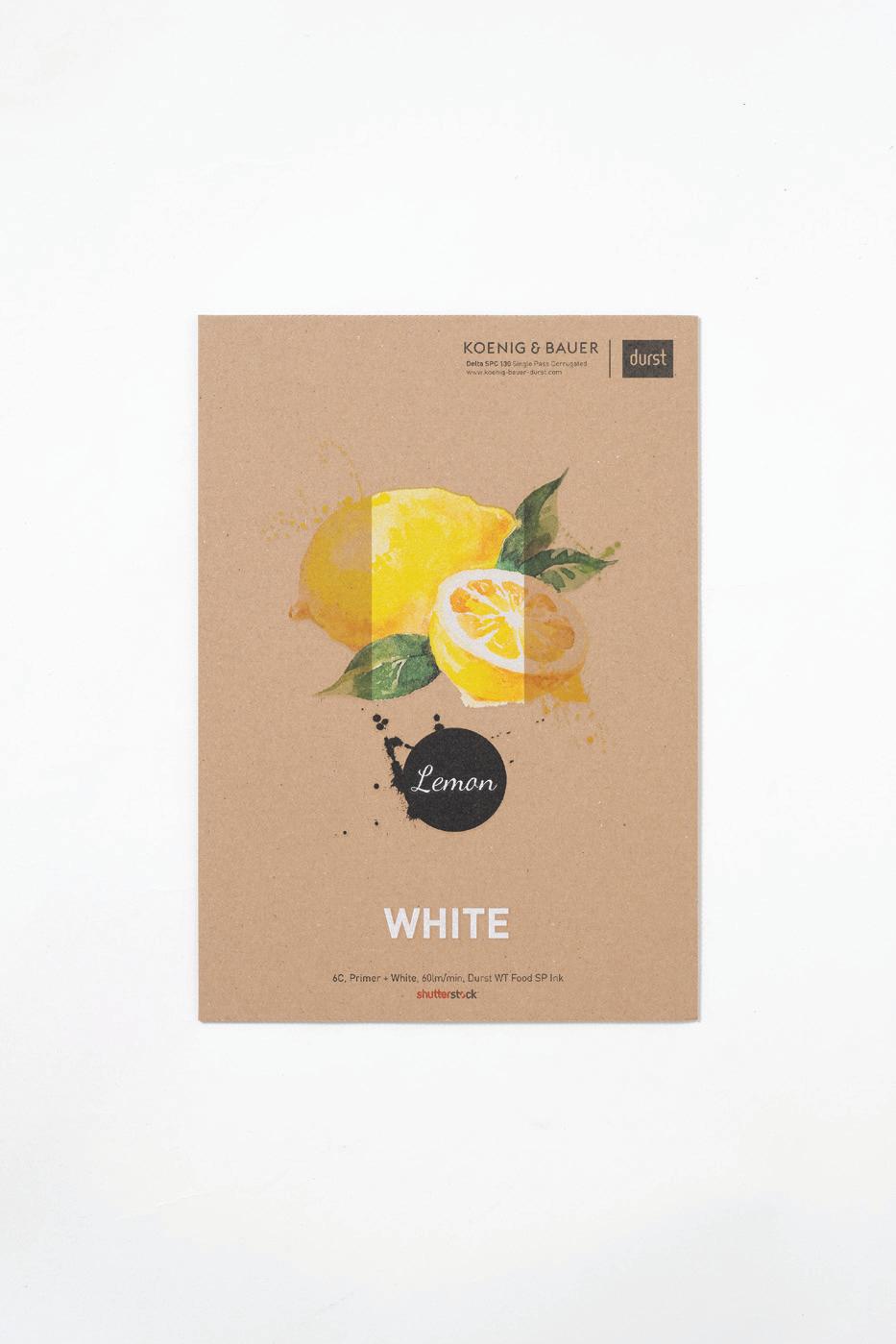

• Koeing & Bauer Durst Water Technology ink

• Mimaki USA, Inc.

LH-100, LUS-120, & LUS-150 UV inks

• Mutoh America, Inc.

MP31 multi-purpose & US11/UH21 UV inks

• Nazdar

HighV Aqua Series water-based ink

• Sun Chemical DigiVisto Inkjet inks

printer that uses its in-house developed Water Technology. The ink is designed with a water-based polymer that is cross linked and cannot migrate due to its molecular weight.

“With these new aqueous high-viscosity inks, single-pass printing is possible, as the required color vibrancy and opacity can be achieved in one pass,” says Cook.

Barberán Jetmaster Series printers are also single pass, but utilize UV ink.

“Water-based single-pass printers are geared towards high value boxes/

COMPANIES MENTIONED

shippers while UV-based single-pass printers print on larger displays as well as corrugated plastic,” explains Harrison.

Those multi-pass printers that are touted as printable to corrugated board are more often than not UV printers.

“They were originally designed for large format sign and display printing, to print retail graphics on plastic-based materials that require UV ink for adhesion and durability. As equipment suppliers focused on selling into the corrugated market they took existing equipment and positioned it for corrugated printing,” explains Lynn.

Stanley agrees that most multi-pass systems, especially those focused on packaging samples, point of purchase displays, or specialty work, lean heavily on UV. “That’s because UV gives you the ability to layer, build texture, and achieve fine detail.”

Water-based, multi-pass printers are not often used for corrugated. “For multi-pass, scanning printheads reduce print speed. Water-based inks applied in multi-pass printers have different absorption rates on different media and also between passes, which introduces greater complexity,” says Brooks.

It is important for buyers in this space, whether they are digital printers, box plants, etc. to have multiple choices when it comes to ink sets for corrugated board printing.

“There is a place for all ink options as the needs of a retail corrugated display printer are very different compared to the needs of a converter manufacturing food safe, sustainable packaging applications. The corrugated market has varied requirements and there is no one-sizefits-all printer or ink combination. It is best to research all options and choose a supplier that can support varied needs in the market,” advises Lynn.

According to Harrison, choice is good. “Larger integrated packaging customers who want to replace high graphics flexography and lithography for boxes with digital can use water-based inks for a similar look and feel as well as for primary packaging—food grade bins for vegetables and fruit. UV offers more flexibility for displays, prototypes, mediumrun samples, and creative boxes using white ink and corrugated plastic. Both have a place in the market.”

“Every customer’s workflow is different. Some need low-odor environments, others need speed, and many look for versatility. Multiple ink options offer the flexibility to choose what fits their business model,” suggests Stanley.

106 artience (Toyo Ink America) artience-toyoinkamerica.com

107 Barberán Corrugated NA jetmasterseries.com

108 Durst North America durstus.com

109 INX International Ink Co. inxinternational.com

110 Koenig & Bauer Durst koenig-bauer-durst.com

111 Mimaki USA, Inc. mimakiusa.com

112 Mutoh America, Inc. mutoh.com

113 Nazdar nazdar.com

114 Sun Chemical sunchemical.com

115 Xaar xaar.com See page 22

Variety encourages innovation, according to Slingerland. “This pushes the industry to prioritize development and improvement of their technology. This in the end benefits the industry. More choices develop the need for differentiation. This translates into enhanced printing performance and better productivity. Also, as companies prioritize different aspects such as eco-friendly inks or higher performance UV inks, the end result is more advances in capabilities for the industry and reduced costs.”

Water-based inks offer advantages as do UV/UV LED curable options for corrugated applications. The best solution is determined based on the job at hand. Our September webinar dives into this in more detail. IPM