Bright, eye-catching graphics warrant attention. Going beyond the traditional CMYK is now possible thanks to innovations in ink technologies and color gamut. Neon greens, pinks, oranges, yellows—the sky is the limit. Why not take advantage of these vibrant options when possible?

Neon greens, pinks, oranges, yellows—the sky is the limit.

Our cover story, Glow Up, shares how Infinity Images of Portland, OR does just that with help from its swissQprint Kudu hybrid UV printer, which is equipped with not only CMYK, orange, white, primer, and varnish but neon yellow and neon pink ink as well. It’s found success using neon ink printing to highlight specific areas of an application like logos or text. This adds an extra pop to the design. Read more about Infinity Images on page 7.

Elsewhere in this issue find discussions on various vehicle graphics materials, the increased adoption of dye-sublimation printing, and tips and tricks to achieve a successful window media install.

Whether you are looking to revive existing service offerings with a new material or grow your business by introducing a fresh technology, Digital Output provides topics to fuel your print shop. Make sure to visit us online at digitaloutput.net to find web-exclusive articles, register for/view our monthly webinars, and subscribe to our weekly eNewsletter.

EDITOR IN CHIEF

Thomas Tetreault ttetreault@rockportpubs.com

EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ASSOCIATE EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

WEB EDITOR

Melissa Mueller

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

CONTRIBUTORS

Marco Boer, Olivia Cahoon, Tim Greene, Melinda Tetreault, Amber Watson

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

NATIONAL ACCOUNT EXECUTIVES

Amanda Doyon adoyon@rockportpubs.com 978-921-7850, Ext. 170

Subscribe online at digitaloutput.net

CORPORATE & PUBLISHING OFFICE

300 Newburyport Turnpike, Ste. 11 Rowley, Massachusetts 01969

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

Digital Output is published monthly by Rockport Custom Publishing LLC. ©Rockport Custom Publishing, LLC 2025. Reproduction by any means of the whole or part of Digital Output without written permission from the publisher is prohibited. Views expressed in the editorial pages do not imply our endorsement.

Cheers, Melissa Donovan, editor mdonovan@rockportpubs.com

Vendors: We welcome your product news. Include prices, slides, photos, and digital files with your press release. Please forward product samples and media kits to Reviews Editor, Digital Output, 300 Newburyport Turnpike, Ste. 11, Rowley, MA 01969. We cannot be responsible for unsolicited product samples.

SUBSCRIPTION RATES

U.S.: $82.95 per year; $165 for 2 years; single copies: $6.95; Canada and Mexico: $99.50 per year (U.S.D.); Other international subscriptions: $275 per year (U.S.D.)

POSTMASTER

Please send address changes and form No. 3579 to: Digital Output 300 Newburyport Turnpike, Ste. 11, Rowley, MA 01969. Periodical Class postage rates paid at Rowley, Massachusetts and additional mailing offices.

CHANGE OF ADDRESS NOTICE

Six to eight weeks prior to moving, please clip the mailing label from the most recent issue and send it along with your new address (including zip code) to: Digital Output magazine, change of address notice, 300 Newburyport Turnpike, Ste. 11, Rowley, MA, 01969. Attention: Circulation Department.

EVOLV Gloss Metallic Launch Green EVOLV introduces its newest addition to the Color PPF lineup, Gloss Metallic Launch Green. This shade is more than just a new color, it’s a statement, combining EVOLV's advanced paint protection technology with a finish that demands attention.

Launch Green brings a unique energy to the road. With a rich mid-tone base infused with metallic flake, this film shifts beautifully under light, offering vibrance in the sun and depth in the shadows. The glossy surface enhances every reflection, giving vehicles a refined, yet bold presence.

It’s the perfect blend of performance attitude and luxury styling—versatile enough to elevate sports cars, SUVs, and high-end sedans alike.

Launch Green is powered by EVOLV DRY-X technology, engineered to make installation smoother and cleaner with the flexibility of both dry and wet application. #190

Fujifilm Unveils New ACUITY TR

FUJIFILM North America Corporation, Business Innovation Division, announces the U.S. launch of the ACUITY TR, a 63-inch roll-fed printer. Equipped with Fujifilm’s AQUAFUZE waterbased UV ink technology, the ACUITY TR delivers print quality and versatility offering users a flexible, eco-conscious printing solution.

The ACUITY TR’s AQUAFUZE inkjet technology combines photopolymer dispersion with waterbased UV curing to reduce printhead nozzle clogging, improve ink ejection, and eliminate the need for primers, optimizers, or topcoats on a range of substrates. Offering a low odor, water-based alternative to traditional solvent and latex inks, AQUAFUZE inkjet technology delivers strong adhesion, scratch resistance, and excellent rub resistance. #191

Addition to Mimaki’s 200 Series of Products

Mimaki Engineering launches the TS200-1600, an advanced 64-inch dye-sublimation printer. The TS200-1600 offers significantly faster production speeds and an expanded feature set, making it the ideal solution for small shops, start ups, and businesses looking to expand into on demand textile and customized goods production.

Powered by a single printhead from Mimaki’s higher end 330 Series, the TS200-1600 ensures exceptional print quality with smooth gradients and vivid colors. Its extended eight-color ink set includes new orange and violet inks for a wider color gamut, as well as newly developed fluorescent pink and yellow inks.

The printer utilizes Mimaki’s OEKO-TEX ECOPASSPORT certified Sb411 inks, providing a sustainable solution that meets the environmental standards required by textile brands and ecoconscious consumers. #192

Canon U.S.A., Inc. announces the Colorado XL-series, new 3.4-meter/11-foot printers. Set to be available in hybrid and roll-to-roll configurations, the modular, field upgradable platform is designed to deliver versatility and productivity for both flexible and rigid media applications. The Colorado XL-series comprises of two easy-tooperate models, the Colorado XL7R roll-to-roll printer and Colorado XL7H hybrid printer.

With print speeds of up to 753 square feet per hour (sf/h) in quality mode, up to 1,140 sf/h in production mode, and up to 2,271 sf/h in express mode, the system is designed to deliver the productivity needed for demanding production environments while accommodating substrates up to two inches thick for rigid applications and rolls up to 12 inches in diameter.

The Colorado XL-series introduces the UVgel 860 gel set, which is optimized to cover both rigid and flexible applications. It is also designed to provide the proven benefits of UVgel, odorless and quick dry prints, high mechanical and chemical robustness, dimensional stability due to lowtemperature curing, excellent color consistency, TPO- and VCL-free inks, and matte and gloss finish without the need of a separate varnish.

Taking the UV LED curing process to the next level, the Colorado XL-series introduces UVgel FullBeam Curing. This technology uses a unique, 11-foot-wide LED curing array that is designed to deliver consistent UV light dosing across the entire print width when combined with a mirror system.

Optional features for the Colorado XL-series include UVgel White ink, FLXfinish for producing either a velvety matte or vibrant gloss finish, and FLXture for textured finishes that mimic materials like leather, wood, and fabric. #193

1) The Canon Colorado XL-series is designed for demanding production environments while accomodating both rigid and roll substrates.

Two New Printers from swissQprint swissQprint introduces two new flatbed models tailored to users with high-quality requirements and small- to mediumproduction volumes. Topi 5 and Oryx 5 are the new models completing the Generation 5 lineup that was launched to acclaim in January 2025.

The two differently sized models are available right now. Topi 5 is a 3.2x2-meter flatbed printer capable of producing up to 126 meters squared per hour. Oryx 5 is its 2.5-meter wide counterpart with an output of up to 114 square meters per hour, 26 percent more than the Oryx 4 predecessor model. Both machines facilitate maximum versatility and are highly precise. Learn more at swissqprint.com. INFO# 195

New HP Latex FS70 W

The HP Latex FS70 W Printer is HP’s most productive HP Latex printer to date, providing stunning output, robust productivity, and sustainable design that scales seamlessly as businesses grow. It delivers vibrant color at 1,259 square feet per hour (sf/h) outdoors and 980 sf/h indoors, with a maximum speed of up to 1,744 sf/h, enabling accelerated turnaround without compromising quality. The addition of a 6L white ink cartridge allows print service providers to grow into higher margin applications while providing confidence in unattended overnight printing. For more information visit hp.com. INFO# 196

Engineered and manufactured by Saga, the ExpressCutPRO reduces labor and increases profits by eliminating the time-consuming task of manually cutting direct to film (DTF) or UV DTF transfers. Featuring an integrated conveyor belt and quick response code workflow, it allows for a fully unattended workflow experience. Increase your output while reducing operation costs with ExpressCutPRO DTF Cutters. Visit supply55.com, call 734-668-0755, or email sales@supply55.com. Simplify your cutting operation today with ExpressCutPRO. INFO# 9

Catalyst Nanos Business Ready Package

DPI Laboratory launches its Catalyst Nanos Business Ready Package, a fully equipped UV printing system designed to break down barriers of cost and complexity. For the first time, businesses can access a complete, professional-grade UV printing solution for under $20,000, a fraction of the traditional $40,000 entry point.

Powered by the latest Epson printhead technology and paired with professional RIP software, U.S.-made inks, and full support, the Catalyst Nanos offers industrial-grade reliability in a compact, accessible system. Visit the website dpi-lab.com/uvprinters for more information. INFO# 197

Kongsberg PCS Launches Semi-Automated SMH

Kongsberg Precision Cutting Systems (PCS) launches its Smart Material Handler (SMH), a modular, sheet handling solution for the digital cutting of sign, display, folding carton, and corrugated.

The new solution from Kongsberg PCS is designed to enhance the productivity of a user’s cutting table in multiple ways. It enables operators to load new materials while the cutter is still processing the previous sheet, acting as a buffer zone and allowing one operator to handle tasks that typically require two people.

The SMH comprises of a loading table with an optional Underside Camera or USC that automatically detects registration marks and adjusts positioning, and an offloading table. Together, they act as extensions to the existing Kongsberg PCS cutting table, semi-automating the production workflow, enabling smoother loading and offloading and bringing more flexibility to production.

The loading table is suitable for rigid substrates but has the option to be quickly replaced with a roll feeder, offering flexible workflows for different material handling requirements and faster changeovers. In addition, the SMH can be used in landscape and portrait modes.

Connected to the other side of the cutting table, the offload table is positioned at a fixed 12-degree incline with integrated stoppers to securely hold finishing materials in place, facilitating smooth material unload and reducing potential costly errors.

The SMH is available as an add-on unit on all bed sizes for Kongsberg C-series and Ultimate series and can be retrofitted to existing machines. #194

by Melissa Donovan

In business since 2000, Infinity Images of Portland, OR works out of a 58,000 square foot facility with over 70 employees. It offers project management, design, engineering, prepress, large format printing and cutting, three-dimensional fabrication, finishing, installation, and fulfillment to customers across 15 different countries.

When asked what sets the print service provider (PSP) apart from the competition, Keith Gaumont, director of technology, Infinity Images, says the company “is a one-stop shop for brands with a story to tell. With design, engineering, printing, cutting, fabrication, and installation all under one roof, our project managers can oversee each step, ensure successful quality control, and save clients both time and money.”

One way the PSP achieves differentiation in the market is by investing in new technologies. In June 2024, it became one of the first owners of a swissQprint Kudu hybrid UV printer outfitted with ten colors—CMYK, orange, neon yellow, neon pink, white, primer, and varnish.

The device can print pure neon inks, but it also offers the capability to combine neon spot color ink dots with CMYK process color ink dots, creating colors that typical printing processes cannot achieve.

The addition of our swissQprint Kudu printer greatly expanded our color gamut and proved vital to hi ing our client’s primary Super Bowl LIX campaign colors—neon green and neon orange.

— Keith Gaumont, director of technology, Infinity Images

Infinity Images is no stranger to swissQprint, as it owned a swissQprint Nyala 2 for eight years before upgrading to the newest device.

“We chose the swissQprint Kudu as the platform for entering the world

of neon ink color printing based on our positive experience with the Nyala 2 and swissQprint’s attention to quality and customer support, as well as its proven dedication to ongoing improvements to its existing UV print platforms,” states Gaumont.

Learning how to successfully print with neon color graphics is no simple task. Gaumont credits swissQprint’s Lory output software that drives the Kudu as well as a custom-built print driver from PrintFactory as instrumental to achieving relative ease of use.

One of the biggest challenges according to Gaumont is learning and understanding the limitations of and best applications for neon color graphics. For example, through testing, Infinity Images learned that swissQprint’s neon ink set is not fade resistant to UV light, so it is best suited for indoor applications. “However, neon inks fluoresce in normal indoor lighting and significantly more so when illuminated by black light sources, which opens

applications not possible with traditional process UV ink sets.”

At present, the most popular application for neon ink printing is using almost-pure neon ink color mixes to highlight specific areas, logos, or text in a graphic. This adds an extra pop to the design. In particular, Gaumont says retail customers appreciate the attentiongrabbing fluorescence of the neon color print products.

After trial and error, Infinity Images determined that the neon color inks print best on a white surface, and ideally one with optical brighteners, as it helps enhance the fluorescent appearance of the neon colors. However, since the swissQprint Kudu is equipped with white ink, it allows for the printing of a white ink base layer on any material and then a neon ink layer printed on top.

“This includes clear, colored, or chrome vinyl films; acrylic or wood panels; and black-faced boards or films, to name a few. Printing neon colors over a white ink base in specific spot areas on

black-faced materials is a visually stunning application, particularly when black lit,” admits Gaumont.

Infinity Images also realized that mixing the traditional ink colors with the neon ink colors affects the vibrance of the resulting process in addition to the neon ink hues. To solve this, Infinity Images invested in a subscription to the Touch7 Neon ink color swatch system by Khaos Technology.

“This solution has been a real boon in providing a printed swatch-based system that our customers can use for reliably consistent neon and neon-plusprocess color output. It also includes an Adobe Photoshop plug-in allowing for the incorporation of one or both of our Kudu’s neon ink colors into existing photographic or raster imagery,” explains Gaumont.

Finally, neon color graphics also present a learning curve when it comes to the PSP’s customers. Gaumont points out that there is a bit of an education in regards to managing client expectations.

“In terms of designing and creating graphics with neon ink colors, there is no real way to soft proof them on screen, so printed proofs are required. With these considerations in mind, we spend more time educating our customers to help them understand how to work with the limitations and strengths of neon ink printing to achieve best results,” he adds.

A solid example of where neon ink colors glowed is Infinity Images’ work for Nike leading up to Super Bowl LIX in 2025 when the Kansas City Chiefs played the Philadelphia Eagles in New Orleans, LA.

The PSP was tasked with creating an attention-grabbing immersive retail event that blended New Orleans community touch points with Nike and NFL branding, featuring imagery of the Kansas City Chiefs and Philadelphia Eagles. Its sixth Super Bowl collaboration with Nike, Infinity Images was tasked with designing, producing, and installing these graphics at a Nike retail store located near the Super Bowl arena.

The project began almost two months in advance of the proposed February 2025 deadline. However, Gaumont says despite the long lead time, one of the biggest challenges was time.

Nike and NFL brand leadership had to provide approval of each individual design component. 185x50-inch dimensional roof pop-off graphics required certification from a structural engineer

as well as approval from the city and landlord. A 6,650 square foot exterior vinyl wrap required seven full working installation days. Exterior graphics were printed using the company’s Rho 1312 from Durst Image Technology US LLC.

Inside of the building, store walls and furniture were wrapped in addition to other printed pieces installed throughout. All of these graphics were printed using the swissQprint Kudu. “The addition of our swissQprint Kudu printer greatly expanded our color gamut and proved vital to hitting our client’s primary Super Bowl LIX

campaign colors—neon green and neon orange,” shares Gaumont.

The swissQprint Kudu printed all of the interior vinyl and acrylic graphics, and Infinity Images color matched the green across the powder-coated aluminum mesh walls and both the orange and green to the painted turf.

Turf, aluminum, vinyl, acrylic, plywood, and mirrors were cut using either a Zund America, Inc. G33XL, Vytek Laser Systems’ L-Star laser, or Biesse Rover Plast CNC.

Nike leadership was thrilled with the final product. The pop-up

store was live for five days in February of 2025 and in that time tens of thousands of customers stopped in.

Infinity Images was also happy with the final result. “Wrapping an entire building façade was a first for Infinity Images, and the overall design impact was greater than any other project to date,” notes Gaumont.

Currently, around five percent of what Infinity Images prints incorporates neon ink colors. At press time, the PSP was in the process of revamping its neon

marketing sample materials and with that in the works, hopes to see increased interest in neon ink offerings in 2026.

In addition to neon ink printing being used as an accent on graphics found in retail settings like the Nike Super Bowl LIX retail experience, Gaumont says the team promotes the use of neon colors to enhance photographic imagery.

It is an exciting time at Infinity Images thanks to the acquisition of the swissQprint Kudu and its neon ink set. D See page 16 for more info.

by Melissa Donovan

nstallation can make or break a graphic. Even when printed using the best inks, on the highest quality media, one mistake during application makes the entire print moot. This is true for any job, whether it be floor graphics, wallcoverings, a vehicle wrap, or window graphics. There

are similarities when it comes to best practices for applying materials across all genres, however each presents its own particular nuances.

For window graphics, the surface offers challenges. Clear glass or glass-like windows require proper preparation

prior to applying graphics, cleaning with incorrect solutions can lead to graphics failure. Also, depending on the type of window material used—perforated or unperforated, ink choice, and adhesive type installation practices vary.

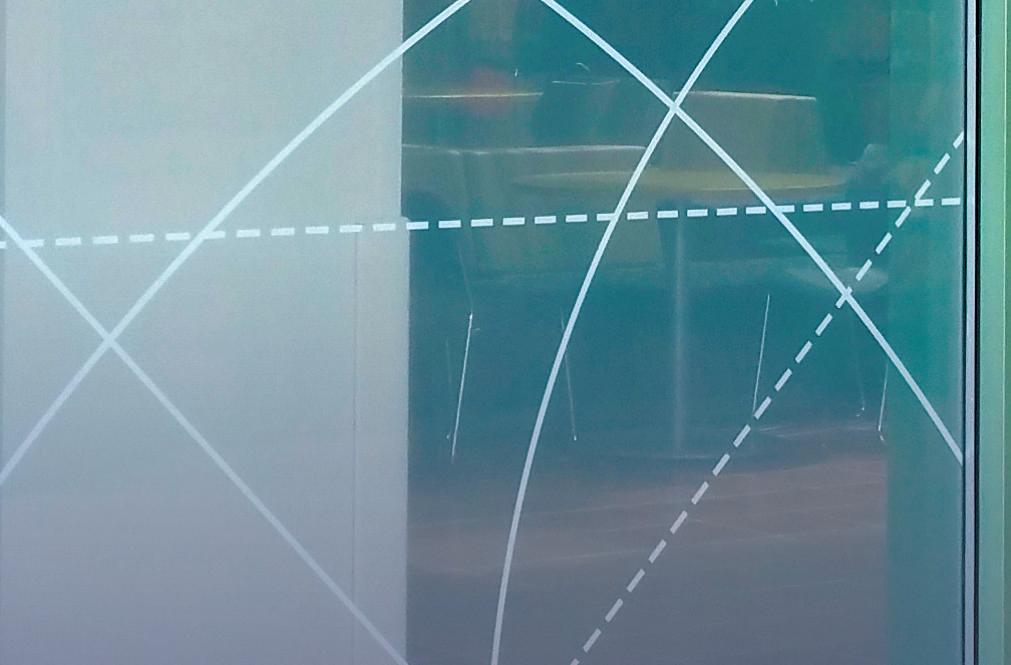

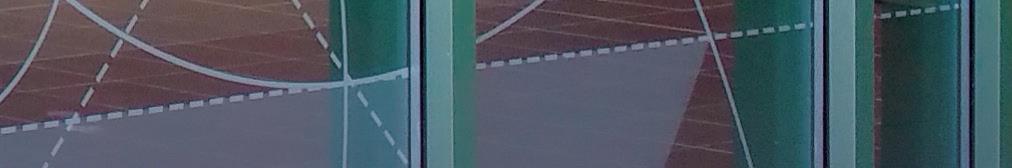

Above) Solar Graphics has installed thousands of residential and commercial film window projects.

Driven by the need for easier installation methods, advancements in media have recently focused on air egress adhesive materials with built-in channels that allow air bubbles to escape during installation. Additionally, improvements in air release liners are simplifying positioning and repositioning.

Both of these are notable, especially as professionals are not necessarily the ones applying window graphics, but instead store employees or some other novice unfamiliar with the graphics industry.

Basic guidelines for installing media onto windows involve cleanliness, preparation, and the right tools.

“Proper cleaning of the window is absolutely essential for a successful installation—it’s one of the most critical steps in the entire process,” attests Karen Peppel, associate product marketing manager, GBC/SEAL.

In terms of cleanliness, Amanda Smith, marketing communications manager, Mactac, recommends proper cleaning because it plays a crucial role in maintaining the longevity of the installation.

“A clean surface ensures maximum adhesion and prevents issues such as peeling or bubbling later. Dust, dirt, grease, or any residue can create barriers between the adhesive and the glass. This can compromise the bond, leading to an ineffective installation. A clean window helps

ensure that the result is clear, vibrant, and visually appealing,” continues Smith.

Continental Grafix USA, Inc. recommends an ammonia-free cleaning solution, followed by a final rinse with water only, and dry with a lint-free cloth. “If isopropyl alcohol is used to break down grease or grime, a thorough rinse with water afterward is essential to ensure the surface is completely free of contaminates that could compromise adhesion,” suggests Michelle Kempf, VP, sales and marketing, Continental Grafix USA, Inc.

Preparation is key. “Planning before application is essential— measure, align, and lightly tack graphics before committing to full adhesion,” notes Dennis Leblanc,

senior product and business development manager, Drytac.

Planning involves visiting the site beforehand to get a feel for what is needed. “Clear communication is a critical first step—understanding the client’s expectations for longevity, visibility, and aesthetics will help guide the installation approach. Advanced planning of the installation via a site visit or detailed reference images helps anticipate challenges and mitigates surprises during the installation process,” advises Kempf.

Having the right tools on hand is helpful. “A squeegee can help to smoothly apply the graphic and push out air bubbles. Start from the center and work your way outwards to ensure a strong, even

adhesion without imperfections,” recommends Smith.

“Patience pays off when applying the material steadily and working air outward rather than rushing,” adds Leblanc.

Temperature and climate play a major role in window graphic installation success.

“A moderate indoor temperature is best—not too cold and not excessively hot. Extreme heat can cause the film to dry too quickly before you’ve had time to squeegee properly, while very cold conditions can make the material stiff and harder to handle,” cautions Jim Halloran, VP, sales and marketing, Lintec of America, Inc.

Dave Hawkes, media product manager, Roland DGA Corporation, believes the “sweet spot”

for window graphics is between 50 and 85 degrees Fahrenheit.

“The media applies better when

the temperature of the media is in sync with the temperature of the substrate. If there is a great

temperature difference, it can result in tunneling, which can leave a large wrinkle in your graphic.”

Moderate humidity is acceptable, but excessive moisture or condensation on the glass needs to be avoided, continues Halloran. With good airflow, when a wet apply solution is used, the wet solution dries out evenly after squeegeeing.

The sun and heat are a challenge. “Installing on windows in direct sunlight can be quite problematic. With your slip solution evaporating almost instantly, you may need to lift and

1) The Lintec product line is compatible with new inkjet technologies. 2) Window installation at the Mactac plant in Minneapolis, MN with B-free Frosted Bubble Free Window Film.

reapply two to three times. We try to avoid those scenarios when possible. Start your install on West facing windows in the morning and move East as the sun gets up over the building,” suggests Mike Butler, owner, Solar Graphics.

Finally, Kempf says edge curling is influenced by temperature conditions, so proper trimming of the window media during installation is key. “Proper trimming of ⅛ to ¼ inches away from window edges or gaskets is critical to avoid the potential of edge curling as the window naturally expands and contracts with temperature changes.”

It’s true that universal recommendations exist in terms of window graphic application. However, diving deeper, nuances between media, adhesive, and ink dictate installation technique.

The base film is an influence.

PVC or PP substrates “can be softer and more pliable, which may make alignment trickier and increase the chance of stretching. They also may not lay as flat, requiring more careful squeegee work,” suggests Halloran.

Polyester or PET films are dimensionally stable, but less conformable, which makes installation more challenging, says Leblanc.

“Especially with hard coated PET window film, installation is typically easier and faster. The hard coat resists scratching during handling, allowing for smoother squeegeeing

and quicker installs. It’s also more dimensionally stable than softer films, so it won’t stretch or distort as easily,” explains Halloran.

Polyester materials require a wet apply method. When installing with a wet apply method, choosing the correct wet solution is key. “Polyester window films only require soap and water—nothing fancy or harsh. A few drops of baby shampoo or mild dish soap in a spray bottle of water is ideal. This helps the film slide into place during installation. Spraying the glass generously with the solution before applying the film allows the film to float on the surface, making it easy to position correctly before squeegeeing. Keeping the surface wet gives you working time, and the squeegee removes excess

fluid and air bubbles, ensuring the film adheres smoothly and evenly. Proper squeegee technique prevents wrinkles, creases, and trapped air,” recommends Halloran.

Whether the material is perforated or not is of importance. “Perforated window film is more delicate, requires edge sealing, and visibility for install location is important. Non-perforated window film is more forgiving, can be applied wet or dry, and is easier to remove bubbles,” admits Peppel.

Butler says perforated vinyls can be installed either wet or dry. “The wet method allows for realignment and prevents stretching. There is the drawback of drying time, but it is minimal due to perforations.”

“Yes, non-perforated can be installed with wet application fluid, so you don’t always have to laminate. Perforated films are recommended to laminate because you are typically working with half the amount of film—because of the holes—and without a laminate you risk overstretching the film/graphic when installing. Laminating perforated film gives you more rigidity for the application and helps protect the film from getting dirt and debris in the holes of the perforation,” explains Mike Aldrich, product manager, digital print solutions, General Formulations.

Hawkes seconds that “as you would expect, perforated media has less surface adhesion because the media has holes in it. They may be small holes, but they are

holes just the same. Some perforated medias can have half the adhesive area as a typical vinyl graphic. As a result, it is extremely important to pay attention to surface preparation to get the

best performance from the adhesive surface.”

Which adhesives are used depend on the intended duration of the

application. “Shortterm promotional graphics require different adhesives than long-term signage,” explains Leblanc.

Ink type plays a role. “Solvent, latex, or UV inks affect surface tension and curing, which can influence adhesion,” notes Leblanc.

“Heavy ink coverage can stiffen the material, making it less flexible. Some inks also make the surface more delicate, requiring lighter squeegee pressure,” adds Halloran.

Media manufacturers continue to advance materials with a focus on easing the installation process.

“Advancements are mostly in adhesives. A removable adhesive made for short-term point of purchase application offers easy removal for the next ad for new specials. Air egress options help eliminate bubbles that can get trapped behind the film for ease of application,” admits Aldrich.

One such technology is dot pattern adhesives, which make

bubble-free application possible without special tools, says Leblanc.

“Air egress and micro-dot adhesive materials now feature built-in channels. These innovations enable air bubbles to escape easily during application, resulting in a smoother finish that requires less extensive squeegeeing,” explains Smith.

Air release liners also experience improvements that lead to simplifying positioning and repositioning during installation, says Leblanc.

“The advancement in textured liners, which creates channels in the adhesive for air egress and dot adhesive technology have made window installations for novices and store personnel more achievable with successful results,” agrees Kempf.

Also of note, Leblanc believes lighter weight films entering the market improve handling during installation. This is ideal for less experienced installers.

Window graphics are popular options to promote sales and events or simply to decorate an office. No matter where they are placed, specific installation challenges are inherent. Each material as well as environment presents possibilities to succeed or fail. Understanding the nuances prior to install is paramount to success.

Learn more about installing window graphics by viewing Digital Output’s most recent webinar which took place in October on digitaloutput.net. D

110

2

7 Signs365 28 signs365.com

8 Summa 25 summa.com

ehicle graphics and wraps come in many variations. From commercial printed graphics to solid color change, reflective, and pinstriping media, there is a product to transform any vehicle. Depending on

by Cassandra Balentine

the application, there is a range of available media options.

Printed vehicle graphics and wraps are offered by commercial print providers.

Commercial wraps are effective for building a brand. “They are one of the most effective forms of advertising a business can

Above) Fellers offers several options of cast and calendered vehicle wraps. Many of these films range in price, durability, warranty, and other services that remain brand specific.

have. Think of a commercial vehicle wrap as a moving billboard that can promote a business—its brand, location, and services,” shares Joey Heiob, East regional technical service representative, Avery Dennison Graphics Solutions.

Jay Kroll, director of product education, General Formulations, agrees, noting that businesses look to print vehicle graphics and wraps to build brand awareness with a relatively small investment to produce. “For any commercial

vehicle that is regularly on the road or on a job site, a wrapped vehicle with good branding acts as a mobile billboard to promote the business.”

The popularity of commercial wraps comes from the ease of customization. “Designs, colors, and messages can be tailored to a specific audience or to promote a brand and business. Having a business name on the vehicle and creating mobile advertising is a great way to promote a business. There are instructional videos online that allow an easy, no-cost way to learn installation techniques—allowing a

wider range of sign shops the capability to provide the service,” comments Nate Goodman, product manager graphics, Mactac.

Businesses use many types of vehicles for printed vehicle graphics, but the most popular are trucks, trailers, and service vans.

“Another more subtle example may be a local police department or emergency vehicle, and transportation graphics seen on buses and taxis displaying their branded livery through printed graphics,” adds Kroll.

When it comes to material selection, Josh Robertson, director of product management, Fellers, says most vehicle wraps are done with a cast vinyl film. “Cast refers to the film manufacturing process. This type of film is less susceptible to shrinking over time and is more conformable during installation.”

Cast vinyl with a repositionable adhesive where the bond increases over 24 hours and an air egress liner is a common type of media for printed, commercial vehicle wraps. “A clear cast vinyl overlaminate should be used to protect and enhance the print media after printing. This combination will last many years and should still be removable when the wrap needs to be changed.

The repositionable adhesive allows for easier installation and the removal of wrinkles. The air egress liner imparts channels into the adhesive so bubbles can be removed from behind the graphics during the installation process,” explains Goodman.

Heiob also feels that the best and most used materials for commercial vehicle wraps are cast digitally printable films and cast overlaminates. “This combination provides the strongest durability and best conformability for today’s vehicles. These films usually include air egress technology that allows for fast and bubble-free installation. Some films employ adhesive technology that allows the film to be easily repositioned and slideable, which makes the install easier and faster, especially for smaller shops.”

Robertson cautions that while calendered films are typically cheaper, they lack the technology of a cast film. “In general, vinyl is by far more cost effective than other materials and remains the popular choice. Some applications require the introduction of urethane-based films to achieve the desired level of installation. Common applications include deep recesses, extreme curves, or extended life expectancy. Regardless of what film you choose, most wrap films come with air channels for ease of installation and repositionable adhesive to make positioning the vinyl much easier. A typical commercial wrap can last three to five years with proper care. Many factors like excessive use and lack of proper care will contribute to a shorter life span of the wrap.”

High-performance calendered films can be used for partial wraps. “A partial wrap refers to wrapping part of the vehicle, typically flat or slightly curved areas such as the center of a hood or the vehicle sides. It is important to understand the conformability needs and life expectancy when picking the material,” stresses Robertson.

There are many factors to consider with film and adhesive selection, including the desired lifespan of the wrap, complexity of the surfaces where it is applied, and even the skill of the installer who handles the films. “Wrapping race cars with frequent graphic changes, for example, may be best served using a premium calendered vinyl versus a cast vinyl. The exchange offers a lower price point when costs for a slightly less conformable film option and longer durability is not necessary. Fortunately, a good install method and clear understanding of the film and adhesive characteristics go a long way towards helping a film reach full potential,” notes Kroll.

Solid color change graphics are utilized to wrap vehicles in a specific color, generally without printed designs. Color change wraps can be used for both commercial and private vehicles.

Solid color wraps are an alternative to paint and provide excellent color control, as well as speed and ease of application. “For twotone trailer wraps with cut graphics, color change films are a more economical option,” offers Kroll.

Solid color change wraps remain popular for complete vehicle transformations, but the trend is shifting—color paint protection film is rapidly taking over this market segment. “Many car owners now prefer the dual benefit of a color change and paint protection in one product. Traditionally, solid wraps were most popular in urban areas, luxury car hubs, and among enthusiasts who value a distinctive, factoryquality look without a permanent paint job. They’re also favored in fleet applications for achieving a uniform appearance. The appeal comes from achieving unique finishes—matte, satin, gloss, metallic—while still protecting the original paint,” says Mattia Casarotto, area manager, Evolv.

Color change wrap films allow for a new, distinct look for the vehicle with generally a lower cost, shorter time period than painting. Goodman points out that these wraps are also much easier to revert back to the original look if desired. The wraps protect the paint and preserve the resale value of the car while allowing a customized one-of-a-kind look.

Color change wraps are popular in the automotive restyling or automotive aftermarket spaces. “It allows vehicle owners to customize their vehicle without the commitment of repainting. Vinyl also provides different finishes, textures, or color combinations that are hard to create with paint,” says Robertson.

Luxury and performance cars, high-end SUVs, and commercial

fleets are the most common candidates for color change wraps. “However, personal daily drivers, motorcycles, and even specialty vehicles also use solid wraps to refresh their look or protect paint for resale,” adds Casarotto.

Robertson typically sees full color changes on specialty vehicles or sports cars. “Though this is not exclusively true, the ability to customize accent pieces with color change film remains very popular on everyday vehicles.”

According to Casarotto, cast vinyl is the go-to for full wraps due to its superior conformability, minimal shrinkage, and longterm durability.

“Color change films are generally cast PVC with solvent adhesive,

relatively easy to install with the proper training and experience, and feature air egress and repositionability,” says Kroll.

“Like commercial vehicle wraps, color change should be cast vinyl with a repositionable adhesive with the bond increasing over 24 hours and an air egress liner for a bubble-free installation. It will last many years and should still be removable when the wrap needs to be changed,” recommends Goodman.

Robertson adds that the same technology exists in color change film as it does in printed vinyl. “Cast and calendered as well as repositionable, air release adhesive technology. It typically comes down to the application and budget.”

Reflective media is also used on vehicles, offering special effects like shimmer or holographic.

Reflective films are popular among emergency management vehicles, police cruisers, and other municipal vehicles requiring easy identification in low light situations. “Though the technology exists for wrapping a full vehicle in reflective, it’s typically prohibitive to do so because of cost,” shares Robertson.

Heiob agrees, noting that full vehicle wraps aren’t generally

done with reflective films, with the exception of oil tankers.

“That doesn’t mean you can’t use reflective films as a full vehicle wrap. Typically—and most commonly—reflective films are used as accents on a wrap or as overlay graphics on top of a wrap. Reflective films and conspicuous tapes are often used for safety markings and increased visibility for fleet vehicles.”

These films are typically used to accent the most important part of the graphic or lettering. “Other finishes and textures such as carbon fiber are used to create

unique accents to a vehicle’s hood, side mirrors, or interior,” notes Robertson.

Robertson points out that a lot of special effect films are sold but many do not come with the same outdoor life expectancy or adhesive technology for vehicle installation and removability.

“It’s important to ensure a film is designed for vehicle wraps before ordering,” he cautions.

Mactac refers to this category as color shift wraps. “They are niche but really make the vehicle

2) Mactac offers a new product called Gruv Slideable that it has spent time developing for the commercial vehicle graphic space. It is a 2-mil cast vinyl gloss white highly conformable and durable print media with gray block out adhesive that has a low initial tack for ease of installation. 3) Evolve offers a range of premium solid color change films with Italian

and

stand out. They have many of the advantages of color change but add extra bling. Special raw materials and pigments reflect light differently depending on the angle of approach. The color shift wraps are meant to catch the eye and draw attention to the vehicle,” comments Goodman.

“Typically, reflective films are applied on commercial wraps to highlight the business phone number or company logo to improve visibility at night. Reflective films from Avery Dennison are also applied to the rear doors of ox trucks, trailers, and emergency vehicles to also enhance nighttime visibility,” shares Heiob.

Goodman describes the media as typically cast vinyl with a repositionable adhesive with the bond increasing over 24 hours but with a PET liner so the adhesive is extra smooth and does not add a texture to the specialized film. “The durability is not as long as other types of wrap products because of the specialty nature of the materials and the tendency it has to show scratches and wear.”

Striping or pinstriping media is used when only part of the vehicle requires a line or several lines of material.

Goodman says thin lines of film striping add character and color

to a painted vehicle for a very low cost by highlighting its curves and providing a unique design.

“Striping allows the owner to customize the vehicle and tailor it to their liking. Multiple stripes can be used as well as different thicknesses to add dynamic appeal.”

“Pinstriping is an easy embellishment for painted or wrapped vehicles that can be used to extend the detail of a partial wrap or spread graphic details to other areas of the vehicle, maximizing its visual impact while keeping the costs minimized,” adds Kroll.

Robertson feels that pinstriping is not as popular in today’s culture and many of the fine detail gets printed as it’s more cost efficient and faster to process. “However, some car enthusiasts may require a finish that is not possible with printing.”

Robertson points out that several films can be ordered in narrow

widths that can be applied to the vehicle for the desired effect.

Pinstriping isn’t limited to specific uses, according to Kroll, and can be found everywhere from consumer vehicles to commercial fleets, scooters to semis, cars to cargo trains.

“Striping is popular in a few applications; probably the largest use of reflective and chrome films as accents is when you don’t want the entire vehicle to reflect when hit with light. You can see examples of this on U.S. Postal Service vans, fire trucks, and other emergency vehicles,” shares Eric Norby, product manager, FDC Graphic Films, Inc.

The most obvious applications are emergency vehicles like fire trucks, ambulances, and police cars, but you’ll also see them on semi-trailers and other fleet vehicles. “Striping is a cost-effective way to highlight your brand,

especially if your company’s colors are recognizable,” shares Norby.

“Because striping tends to be less than six inches wide, and thus easier to install, there is not much needed for the advanced adhesive characteristics that are popular with color change and full printed wrap applications. The key aspects to look for are the material’s durability and its dimensional stability—you want to make sure the stripes you are applying last, or for it to have removability over time,” explains Norby. “If your application goes over rivets or complex curves, be sure that the material you choose has the conformability characteristics to be properly installed.”

Cast or calendared vinyl can be used with permanent blockout adhesive and a smooth liner, according to Goodman.

“Pinstriping can be done with either calendered or cast film

and is generally a PVC film with a permanent adhesive. The application method differs depending on size of the feature, potentially being a small stripe that is applied freehand along a ridge or detail on the vehicle, or using premask and specific positioning for larger graphic elements,” shares Kroll.

Robertson adds that in his experience pinstriping is typically added for long-term use so removability is not necessarily required.

Vehicle graphics are popular among businesses and consumers alike. Printed graphics that enforce branding and company messaging to personal expression; color change for paint protection or to sport a new, temporary look; reflective media that stands out in emergency situations and night time viewing; or pinstriping for a low-cost flair—all of these vehicle graphic media options are abundant. D

ide format dye-sublimation (dyesub) printing is used for a number of applications, including but not limited to soft signage and garments. Both transfer and direct sublimation methods are popular among print service providers (PSPs).

According to Grand View Research’s Dye-Sublimation Printing Market Size, Industry Report,

2030 , the global dye-sub printing market size was estimated at USD 16.4 billion in 2025 and is projected to grow at a compound annual growth rate of 11.3 percent from 2025 to 2030. The revenue forecasted in 2024 is set to reach USD 28 billion in 2030.

The report goes on to state that dye-sub is primarily driven by rising demand for customized textiles, the growth of ecommerce, and an increasing shift toward sustainable production methods.

Interest in and ultimately implementation of dye-sub printing continues to grow.

“Wide format, dye-sub printers in the U.S. are being adopted at a steady rate according to mainstream analysts; the market is seeing the most growth and uptake in on-demand production models focused on optimized workflows. U.S. ecommerce, apparel mass customization, and the demand for faster turnaround align perfectly with dye-sub printing and drive the market,” admits Victoria Nelson Harris, senior textile specialist – NA, Mimaki USA, Inc.

Lily Hunter, product manager, Professional Imaging, Epson America, Inc., believes growth is being propelled by two significant shifts. “First, there has been a shift from in-store to online purchasing. As such, buyers have significantly more options and customization in products, including apparel, décor, and gift items such as blankets. Dye-sub enables designers to create and

sell unique designs on a made-toorder basis. To meet the increasing demand, more wide format print shops are bringing dyesub printing in house to better control print quality, lead times,

turnaround times, and customer satisfaction, further fueling market growth.”

Hunter says the second shift involves moving from global and

regional suppliers in response to ongoing shipping and supply constraints. “Regional print shops that installed dye-sub technology a few years ago, during the height of supply chain constraints, are

now realizing its full potential and recognizing its expansive capabilities. With its vast output versatility, low maintenance requirements, and positive environmental impact, print shops are grasping how implementing dye-sub can significantly enhance their business operations and increase their return on investment.”

Mike Syverson, textile manager, North America, Durst Image Technology US, LLC, says growth in particular is seen in print shops looking to expand with

larger, more efficient systems— especially those that feature inline sublimation.

“The demand in the ten-foot or 3.2-meter segment remains solid, and over the past year, we have seen strong interest in the 16-foot or five-meter space in the European market, a trend now building in North America. Innovations like inline sublimation make this a more attractive investment as these new platforms improve workflow, save energy, and reduce labor by combining printing and sublimation into a single process,” explains Syverson.

garment, direct to film, and other print technologies that allow the print provider more options, dye-sub in many respects has slowed growth in areas such as t-shirts, but increasingly grown in others, namely silicone edge graphics (SEG).”

Steve LaMarsh, director, Display Source, Inc.

Tony Simmering, product manager, Mutoh America Inc, points out that “with the advent of direct to

The soft signage sector plays a pivotal role in dye-sub’s growth. “The decade is forecasted to see growth around ten percent or more. The demand for larger displays, higher output speeds, and sustainable products have all brought more PSPs to the place where insourcing these products makes the most sense now than ever before. In certain areas of the country, growth has exceeded 12 to 13 percent,” shares

There is always an argument for why not to implement a certain technology. For dye-sub it might be that color management is too challenging between different fabrics, or the fabrics and/or transfer paper might be to confusing when determining which to choose. Perhaps the finishing component presents difficulties.

makes the most sense now than the country, growth has exceeded 12 to 13 percent,” shares

Printing to “textiles can be intimidating to those who are accustomed to years of producing rigid substrates or other media. The concerns of wasted materials through reprints and missed deadlines keeps some owners on the sidelines,” admits LaMarsh.

Whatever the hesitation, manufacturers address them head on with the newest technologies. “Technology has removed many of obstacles that once kept newcomers from entering the market. If you’re just starting, partner with your printer manufacturer and paper/textile suppliers—they’ll help you match inks, papers, and fabrics to your application for the best results,” suggests Nelson Harris.

Hitting brand colors on textiles does require skill. “Today, RIP

2) Mutoh’s original DH21 dye-sub transfer ink provides optimum media transfer, achieving high density colors with less ink consumption; used on the Mutoh XpertJet 1682WR. 3) The Mutoh XpertJet 1642WR Pro features new extrawide Mutoh AccuFine printheads with best-inclass dot placement accuracy, enabling high print speeds and quality. 4) The Epson SureColor F9570H offers an expanded six-color ink set with multiple configurations.

software and integrated color profiling tools make color calibration far more intuitive and repeatable. That being said, skilled workers are still a necessary part of the equation because even with integrated color profiling tools, it’s still a skill and needs to be considered for every material change,” admit Peter Casasanto, Eastern regional sales manager, and Tara Lamb, president, Global Imaging.

Color management is addressed with tools like spectrophotometers, suggests Hunter. “These support a color management workflow by creating color profiles and verifying and calibrating color, to helping print shops save time and resources by avoiding reprints due to inaccuracies.”

SEG frames, as well as the cutting and sewing of the final product, have a higher learning curve than other print methods.”

Color management as well as material selection, argues Syverson, has become far more manageable. “The process for color management is largely the same as with other technologies like UV, and choosing the right fabrics has become much easier with fabric suppliers now offering recommendations for specific applications.”

“Fabric and transfer paper options and combinations are a new set of considerations for many production managers and it can feel overwhelming. Having a good partner to help educate and train on not just equipment use, but material selection and standardizing material offerings, is clutch,” share Casasanto and Lamb.

Syverson believes that the primary hesitation for many print providers lies with finishing. “Sizing jobs for

While dye-sub “is growing quickly, requiring more printers to be ordered and put into

production, the only impediment seems to be the unavailability of quality sewing personnel to go along with the growth of the market requirements,” attests Steve Aranoff, chief business development officer, FASTSEWN dba Mikkelsen Innovation ApS.

However, entry into sewing is easier than ever before with automated devices.

Display Source distributes the Meevo Event SEAS 6C automated stitching system. The SEAS or silicone edge automated stitching

system joins and stitches textile panels with speed and precision. The 6C model features a longer alignment area, which is ideal for handling oversized textiles. Anyone can achieve professional results without being a sewing specialist, boosting productivity up to 25 percent on over twometer panels.

FASTSEWN offers a patented technology that uses a moving cavity, which allows for lockstitch sewing on a flatbed table fed by one or more rolls of textile. “Here, instead of moving the textile under a needle after cutting to shape, the system sews any CNC pattern directly on the flatbed and then cuts to the pattern’s shape. This level of automation significantly reduces the number of sewing personnel, minimizes manual handling of textiles and re-calibrating after being cut, all while improving quality,” explains Aranoff.

“Full automation has come to the finishing department for SEGs like no other time in the product’s history. We’ve seen companies introduce fully automated stitching to the fabric department where an unskilled operator can actually learn the basics to operate a machine to sew and finish SEG panels in as little as

one day. The required skill set is no longer that of a seamstress— but rather a fabric material handler,” notes LaMarsh.

Another challenge—especially when fixation isn’t included in the physical printer—is the heat press, according to Hunter. “While these machines require time and training to master, the investment pays off. The investment in a heat fixation system will last for many years, possibly decades, and does not require frequent updates.”

“A ton of factors can cause hesitation. I believe a large part is lack of institutional knowledge on many items. Finding the right paper, the right press, what fabric or polyester coated rigid item works the best for the application, what inks give the best characteristics for the job—such as fluorescents or outdoor, etc,” adds Simmering.

While the speeds of today’s wide format printers far surpass their predecessors, analog technologies that print to textiles still achieve efficiencies that outperform digital print. However, the advantages digital print provides—customization, versatility, high quality—outweigh any speed concerns.

161 Durst Image Technology US, LLC durstus.com

162 Epson epson.com

163 FASTSEWN dba Mikkelsen Innovation ApS fastsewn.com

164 Global Imaging globalimaginginc.com

165 Meevo meevo.pt

166 Mimaki USA, Inc. mimakiusa.com

167 Mutoh America, Inc. mutoh.com

“Speed is always top of mind. Today’s wide format dye-sub printers typically produce anywhere from 200 to 4,000-plus square feet per hour (sf/h), depending on the model and resolution. That’s competitive with analog screen printing in many applications, with the added flexibility of digital production,” admit Casasanto and Lamb.

Hunter points out, where digital print excels is smaller, highly customized orders—limited production runs, short retail cycles, or seasonal releases. “Although analog printers remain faster for mass production orders, they are less efficient for small runs. They cannot produce one-off personalized items, nor replicate the detailed gradients and fine imagery produced with digital dye-sub.”

“While single-pass digital printer speeds now rival rotary, digital overall still represents only about five present of total textile print volume. Most U.S. dye-sub adopters are multi-pass printers operating at under 800 sf/h,” notes Nelson Harris.

A great example is Mutoh’s XPJ1642WR Pro. Simmering says its 500 sf/h speed for textile work is ideal for small-to-medium capacity print providers that do work for customers like school gear/jerseys and promotional products.

“Manufacturers continue to push speed with wider printheads, adding additional printheads, and developing more inline fixation systems that streamline transfer

and finishing. The goal is reducing touches in the workflow, effectively reducing total production time versus just increasing print speeds,” share Casasanto and Lamb.

And truly, as Syverson points out, digital dye-sub systems do promote efficiency. For example, Durst’s P5 TEX iSUB printer includes inline sublimation—making the time consuming, separate transfer step obsolete, and allows for graphics to be produced at 1,400 sf/h.

Implementing wide format dyesub is advantageous to a print shop. It allows the business to expand into more offerings and provide customers with trending applications to promote their own goods and services.

According to Nelson Harris, “dyesub is a straightforward workflow with broad, high-margin

applications—great for building multiple revenue streams.”

“By bringing the capability in house, shops can significantly expand product offerings and capture new business. Dye-sub opens the door to an array of high-margin applications, including soft signage, backlit displays, trade show graphics, flags, retail graphics, and décor. This allows a print provider to better serve their existing clients and meet the growing demand for fabric-based solutions,” shares Syverson.

On the consumer side, Hunter says popular applications include apparel, ranging from t-shirts and hoodies to accessories such as scarves, socks, and tote bags; as well as home décor, including blankets and throw pillows, curtains, and wall art.

“Keeping everything in house eliminates the risk of sending customers to a competitor. Even if dye-sub

isn’t the highest margin service, its value in strengthening customer loyalty and retention is significant,” suggest Casasanto and Lamb.

Simmering believes dye-sub print providers are a different breed. “In that the entire process, from ink chemistry, pressing, finishing, and the like are much different from other digital methods like UV LED and eco-solvent. The advantage is that you get a product that lasts an extreme amount of time, is easy to clean, and allows for short-run, fully customizable work.”

Dye-sub printing continues to meet the needs of short-run, customized projects whether it be a trade show graphic or tote bag. PSPs taking advantage of the technology by bringing it in house are poised to benefit, especially as challenges like color management, material selection, sewing, and heat presses continue to be addressed with new products and solutions. D