AOn a Transfer Kick Supply DTF Uniforms

by Digital Output Sta

print provider is constantly evolving and changing its business alongside current trends. Digital Output wrote about bFIVE40 of Little River, SC back in August of 2020—not even a year into the COVID-19 pandemic.

At the time of the interview, the company was kneedeep in creating customized inflatable punching bags, referred to as Bonk Fit.

The popularity of this application allowed bFIVE40 to ramp up production. The result, bringing dye-sublimation and latex printing technology, a heat press, digital cutters, and automated sewing machines all under the roof of a 7,000 square foot production facility.

In 2020, bFIVE40 staffed seven employees and five years later that

number has grown to 15 members. Business is good, and not surprisingly expanding into new markets.

Sportswear Offering

Growing in line with the employees is the product lineup. bFIVE40 got into producing sublimation baseball uniforms in 2021 and shortly thereafter introduced sportswear line BFIT540 to include basketball, soccer, volleyball, and golf. Thanks to DTF, it is able to offer a low-cost custom print alternative for teams that are budget conscious.

We added DTF in 2024 as a low-cost alternative for sublimated sports uniforms.

— Donna Brin, founder and managing member, bFIVE40/BFIT540

Donna Brin, founder and managing member, bFIVE40/ BFIT540, saw the benefit of DTF early on. “We added DTF in 2024 as a low-cost alternative for sublimated sports uniforms. It allows us to work with sports teams whose budgets

vary and we can offer a less expensive product for developmental teams, new leagues, and smaller organizations.”

Instead of purchasing a DTF printer, bFIVE40/BFIT540 outsources to Ninja Transfers. Ninja Transfers leverages over a decade of experience in custom apparel. Initially the company created transfers for its own apparel, but today it helps decorators and businesses nationwide.

DTF transfers are ordered based on size, with pricing according to the website as low as $0.02 per square inch. The graphics are printed directly by Ninja Transfers and then shipped out to customers.

bFIVE40/BFIT540 uploads predesigned graphics for clients directly to ninjatransfers.com. The printed transfers are then sent to bFIVE40/BFIT540 for heat pressing in house with a Stahls’ Hotronix heat press machine.

When deciding to bring DTF in house or outsource to a partner like Ninja Transfers, Brin says key in her decision was achieving cost savings for her customers as well as speeding up the delivery time of every one of the customized orders.

Eight months into this endeavor, both goals are met. “The designs come fast from Ninja Transfers and are ready to execute right out of the shipping container, which means we are not tying up resources on our end with employees wasting valuable time,” explains Brin.

Sports Job

A recent example, Coastal Rays National turned to bFIVE40/ BFIT540 for uniforms and fan apparel for a travel baseball tournament in FL.

“There was less than 48 hours to produce more than 100 custom uniforms with no available print capacity and a full pipeline. DTF enabled us to provide a quality product at a good price point with fast turn,” shares Brin.

Once graphics and the appropriate player names were acquired, everything was sent off to Ninja Transfers. Turnaround was quick and bFIVE40/BFIT540

had everything it needed to begin the transfer process within days. Each transfer took less than two minutes including setup.

The Coastal Rays National team was pleased with the final results and enjoyed wearing the uniforms at the tournament.

Next Steps

DTF printing continues to be a popular topic of conversation. For those interested, but weary of taking the technology on in house, outsourcing to a site like Ninja Transfers might be the answer. Doing so serves as a great stepping stone to offering a new service for customers.

This is exactly what bFIVE40/ BFIT540 has done.

Brin is a creative entrepreneur as evidenced by her start as a business owner. Recognizing the potential of DTF beyond sportswear, she utilizes DTF to personalize shirts and ribbons for oversized stuffed animals as a contract manufacturer for bigplush.com—coming full circle in the toy business.

No doubt, in five more years, we’ll be speaking with Brin to learn about more exciting innovations bFIVE40/BFIT540 has taken on. D

See page 20 for more info.

SUPPLY55, INC.

Innovative Flexible Magnetic Materials

Newlife Magnetics is the world’s largest manufacturer of flexible magnetic materials. Our company’s focus on science and engineering has led to our success in leading the magnet industry through research and development of exciting new products that solve customer problems, increase e ciency, and improve our customers’ lives without harming our environment. We currently o er the thinnest, widest, lightest, and strongest magnetic materials on the market. We o er a wide variety of products, but we are known for our printable magnet media up to 60 inches wide. Our flexible magnetic print media is a great way to display any graphic in a store, classroom, or car. The magnet application is easy and reusable. Learn more at newlifemagnetics.com. INFO# 7

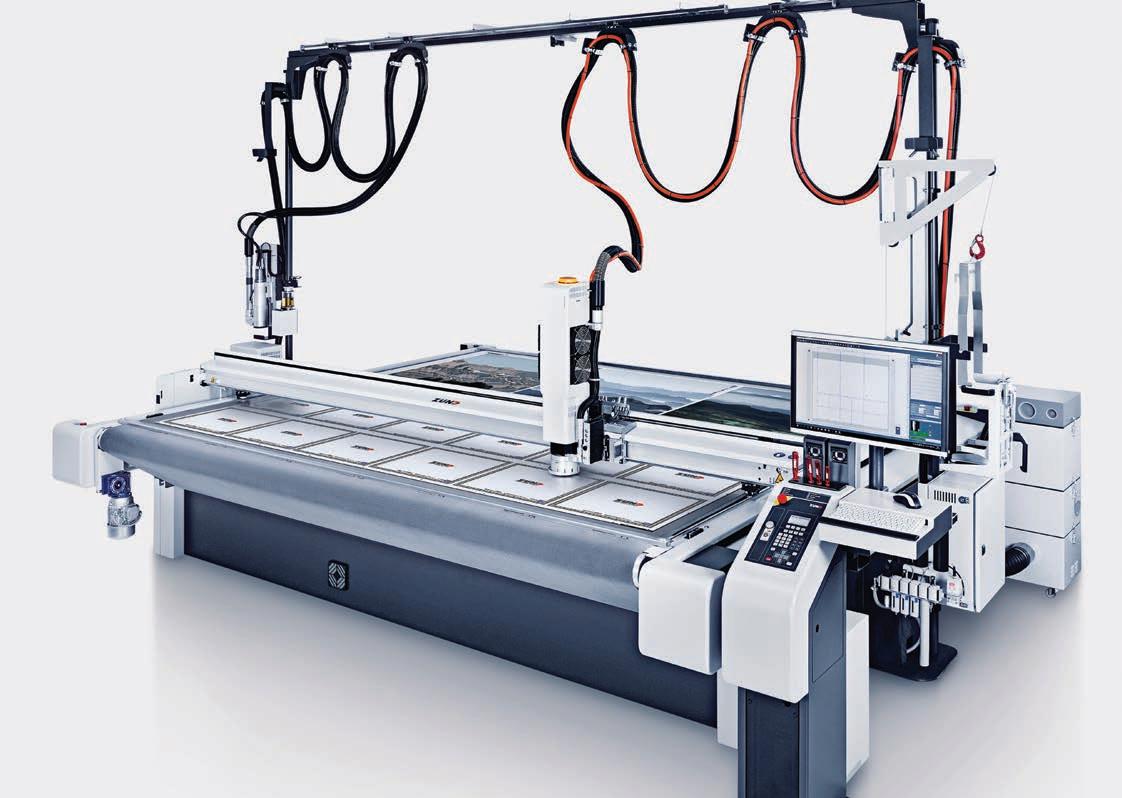

World Class Converting Centers from NEPATA and Supply55

NEPATA converting centers are the most successful and widely used converting centers worldwide. Engineered and manufactured in Germany to the highest quality standards, NEPATA converting equipment utilizes the latest in computer numerical control technology resulting in unprecedented control and accuracy over the converting process. NEPATA converting centers deliver precise material cuts, highly accurate rewinds, and advanced inventory control, allowing for quick delivery times across a range of media. For more information visit supply55.com or contact Supply55, Inc. at 734-668-0755 or sales@supply55.com. Take control of your workflow today with NEPATA converting equipment. INFO# 8

NEWLIFE MAGNETICS

edia manufacturers work to offer dependable substrates for graphics applications. Sometimes development is taken a step further when niche products are introduced.

Specialty media featuring digitally printable surfaces that double as a chalkboard

or even whiteboard are available. They are hidden in plain sight. These can be pressure-sensitive vinyls and film, or also magnetic-receptive materials.

Demand is There

Chalkboard, whiteboard, and dry erase print media options are not a frequent

topic of conversation, but it’s important we address it. Demand is there, it’s just a different kind. All of the surface materials, chalkboard, whiteboard, and dry erase, are found in very specific environments.

Above) Drytac’s ReTac ChalkMate o ers a traditional chalkboard finish that can be used with both standard chalk and liquid chalk markers.

“ es, there is still a market for these types of finishes, office applications for the dry erase, and retail and restaurant applications for chalkboard,” admits Matthew Adams, sales executive North America, Newlife Magnetics LLC.

At Newlife Magnetics, Adams says more of its customers choose magnetic-receptive media with finishes like chalkboard and whiteboard/dry erase than just magnets, because they can be used with its magnets like a traditional dry erase or chalkboard, which allows for written notes and designs.

Jay roll, director of product education, General Formulations, believes “chalkboard vinyl has a more limited range of applications but remains popular for craft-cut labels on jars and bottles, as well as interactive wall displays in retail settings. Its combination of printability and functionality makes it a unique, niche solution.”

Advancements in ink sets promote use, especially chalkboard specialty material. “We see a resurgence in chalkboard materials as access to white ink becomes more readily available,” says Dennis Leblanc, senior

product and business development manager, Drytac.

Whiteboard material is considered more prevalent compared to chalkboard, this may be because offices and other places where people meet prefer writing with a marker versus chalk. “Whiteboard materials are widely used, commonly found in schools, offices, restaurants, and hospitals,” says roll.

“Whiteboard or dry erase provide a dual solution to clients where branding and imaging can be incorporated with an interactive surface,” admits Leblanc.

Material Advancement

Constantly changing, adapting, reworking—that is a media manufacturer’s job. Addressing trends, demands, and of course how to function in a overwhelmingly shrinking economy. Despite these challenges, construction of specialty materials like chalkboard and whiteboard products continues to evolve.

Improved adhesives and enhanced durability, more sustainable components as part of the construction as well as manufacturing process—these are all significant advancements that Kroll has witnessed as of late.

“At the same time, printing technologies and equipment have evolved, making it easier and more effective to print and

companies mentioned

process these films,” continues Kroll. Changes to media handling and how the media runs through a printer are all beneficial here.

125ASLAN Selbstklebefolien GmbH aslanvinyls.com

126 Drytac drytac.com

127 FDC Graphic Films, Inc. fdcfilms.com

128Flexcon flexcon.com

129General Formulations generalformulations.com

130Gri Paper and Film thegri network.com

131Nekoosa nekoosa.com

132 Neschen neschen.de

133Newlife Magnetics LLC newlifemagnetics.com See page 20 for more info.

Ink development is part of the advancement. “White ink has been integral in the resurgence of chalkboard media. With whiteboard surfaces, UV ink improvements have helped with a direct print option,” shares Leblanc.

1) GF 290 ChalkMark is a 5-mil ma e black embossed chalkboard vinyl from General Formulations. 2) GF 110 EraseMark Pro and GF 111 EraseMark from General Formulations can turn any graphic into a dry erase surface. 3) Drytac ChalkMate utilizes ReTac ultra removable adhesive technology to create impromptu self-adhesive chalkboard walls.

Popular Placement

Schools, offices, restaurants, hospitals—the list goes on. Wherever one might find a traditional chalkboard or whiteboard, expect to find a digitally printed option as well.

According to roll, when used as film, chalkboard and whiteboard are typically utilized for smaller signs that are applied to a plasticade a-frame sign found outside a retail shop. Another option, a wall mounted sign

for communicating a patient’s status in a medical setting. “These smaller, one-off signs mean that sign shops will generally have a roll of these specialty laminates or base materials available for those opportunities when they come around.”

“Specialty medias are everywhere from retail, hospitality, and event to board rooms and residential areas. All have a feeling of interactivity with the viewer. In both chalkboard and

whiteboard applications, it’s a marriage of branding and interactivity,” notes Leblanc.

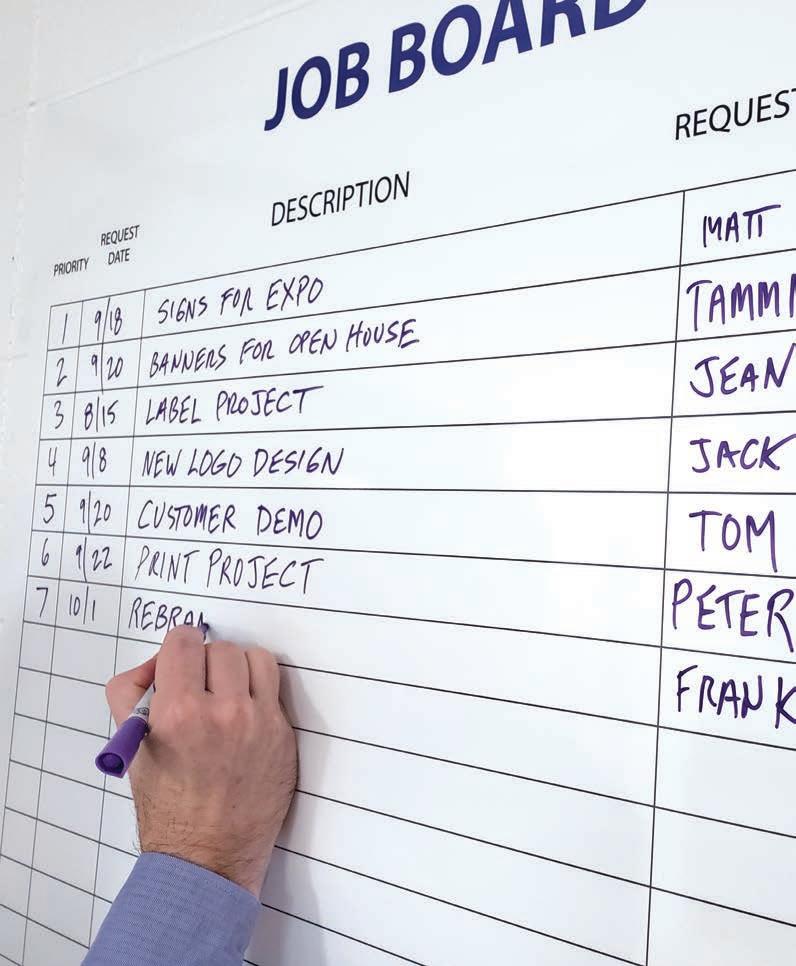

At Newlife Magnetics, a popular customer application is created with custom dry erase boards using the company’s magnetic products. “Customers take our matte white, magnetic-receptive media with a pressuresensitive adhesive on the back, print the custom graphic, and then laminate our high-quality dry erase laminate to create beautiful dry erase graphics that are write on/wipe off and magnets attract to them just like a steel-backed dry erase board. The profit margins are high for these types of custom dry erase boards and our print customers love that,” shares Adams.

Ink Compatibility

especially true when paired with a printer that includes white ink. “This is important because standard translucent inks alone

won’t show well on the dark, textured surface they may only create a subtle sheen rather than vibrant color.”

UV, latex, eco-solvent, and solvent are main contenders when it comes to printing graphics media with chalkboard, whiteboard, or dry erase surfaces.

Leblanc doesn’t believe a specific ink set is preferred over the other, but in his experience the majority of applications use UV or latex/ resin due to durability.

For chalkboard-based materials, roll says UV ink is best. This is

WHITEBOARD/DRY ERASE

ASLAN SELBSTKLEBEFOLIEN GMBH

ClearboardMa ASLAN CB 75

Clearboard ASLAN CB 90

Whiteboard Dryapply ASLAN WBL 995

WhiteboardMa ASLAN WB 975

DRYTAC

WipeErase Clear

FDC GRAPHIC FILMS, INC.

FDC Series 4308

Lumina by FDC 7005 Series

Lumina by FDC 4323 Series

FLEXCON

Flexcon MarkWrite OP 100 CLEAR V-29 100 POLY H-9

GENERAL FORMULATIONS

GF 110 EraseMark Pro

GF 111 EraseMar

GRIFF PAPER AND FILM

Gri Dry Erase Film

NEKOOSA

Polyester Overlaminate - Dry Erase 1 mil. Gloss Clear - #LM1DE

NEWLIFE MAGNETICS LLC

4mil High Gloss Clear PET Dry Erase Laminate

5mil High Gloss White PET Dry Erase Silicone Film

20mil High Gloss White PET Dry Erase Magnet

20mil Semi-Gloss White PET Magnet Receptive

20mil Gloss White PET Magnet Receptive with PSA

20mil Gloss White PET Magnet Receptive

12mil Gloss White PET Magnet Receptive

CHALKBOARD

ASLAN SELBSTKLEBEFOLIEN GMBH

PremiumBlackboard ASLAN BB 910

Blackboard ASLAN C 61

Blackboard AntiScratch ASLAN CR 62

ClearChalk ASLAN CR 63

FerroSo Blackboard ASLAN FF 540

FerroSo Whiteboard ASLAN FF 550

DRYTAC

ReTac ChalkMate

FDC GRAPHIC FILMS, INC.

FDC 4308 Series

FDC 4310 Series

GENERAL FORMULATIONS

GF 290 ChalkMark

GRIFF PAPER AND FILM Gri Chalkboard Vinyl

NEKOOSA

ChalkTalk Chalkboard Film

Depending on the product, to achieve an erasable whiteboard surface a dry erase laminate is applied over a base film—which negates the need for ink choice. “This flexibility allows for compatibility with multiple ink sets, depending on the intended application,” shares Kroll.

According to Leblanc, an overlaminate is preferred for whiteboard applications due to the consistent interaction with the surface and required cleaning.

“You can print UV on dry erase surfaces but the downside is that the residue from the dry erase markers will get stuck in the recesses of the print and make it difficult to clean. That is why laminating the dry erase laminate after printing is suggested, for a smooth surface,” adds Adams.

Hidden Gems

NESCHEN

Easy Dot Chalkboard Green

Easy Dot Chalkboard Black

NEWLIFE MAGNETICS LLC

Black PVC Chalkboard Magnet Receptive

Specialty media like chalkboard and whiteboard— whether vinyl, film, or magnetic—is used often. The demand continues as end users find different ways to leverage these products.

“As the user base grows, so does the demand for innovative applications. This expanding interest drives new ideas and pushes the boundaries of what these materials can do, fueling the next wave of product development and performance improvements,” states Kroll. D

#10

#13

#11

#9 #12

160 Agfa Avinci CX3200

agfa.com/na

161Amica Systems XB18

amicasystems.com CR33

164 DigiFab Systems, Inc. StampaJet XP-64

1,01063.31,440$38,900 digifab.com StampaJet EN-64

K2-190

StampaJet EN-75

PIGM, REA, D, A, SUB15,820130600CM P5 Tex iSUB DDS, DDP, TDSWB, D, DS 4,120133800CM 166 EFI Reggiani VOGUE DDPWB 3,500

167 Epson, continued

proimaging.epson.com

168HP Inc.

hp.com

169 Kornit Digital

kornit.com

170 Kyocera Document Solutions Inc.FOREARTH

kyoceradocumentsolutions.com

171 Mimaki USA, Inc.

mimakiusa.com

= Acid

= Aqueous

= Contact Manufacturer

= Disperse

= Direct Digital Print

= Direct Dye-Sub

= Dye-Sublimation

= Pigment

= Reactive

= Resin

= Sublimation

= Transfer Dye-Sub

= Water-Based

JV300-160 Plus TDSDS 1,14063.41,440CM

Tiger 600-1800TS TDSDS 5,92072.8600CM TS100-1600 TDSDS 753 63.3900CM

TDSDS

TX300P-1800B DDP, DDSA, D, PIGM, REA, SUB 58174.81,440CM

TX300P-1800 MkII DDP, DDS, TDSSUB, D, PIGM, REA, A 516 75.61,440CM

TS500P-3200 TDSDS 1,937129.51,080CM

TX500P-3200DS DDP, DDSSUB 1,399 1301,080CM

172 MS Printing Solutions JP4 EVO TDS, DDSAQ, D, DS 4,682125600x600CM msitaly.com JP7 TDS, DDSAQ, D, DS, PIGM, REA, A 6,000 70 600x600CM JPK EVO 180 TDS, DDSAQ, D, DS, PIGM, REA, A 12,000 70 600x600CM JPK EVO 320 TDS, DDSAQ, D, DS, PIGM, REA, A 12,000 126 600x600CM

173 Mutoh America, Inc. RJ900X TDS AQ 676 44.62,880$7,560 mutoh.com ValueJet 1948WX TDS AQ 2,19974.81,440$49,995 ValueJet 1938WX TDS AQ 1,32774.81,440$31,995

ValueJet 2638WX TDS AQ 1,168103.61,440$49,995 XpertJet 1682WR TDS

1642WR Pro TDS AQ 1,32563.61,200$19,995

174 Roland DGA TrueVIS AP-640 DDP RES CM63.51,200$11,495 rolanddga.com

175 SPGPrints Violet

spgprints.com

176 StratoJet Piranha XT-500 Pro DS

stratojetusa.com

177 Zimmer Austria Colaris

zimmer-austria.com

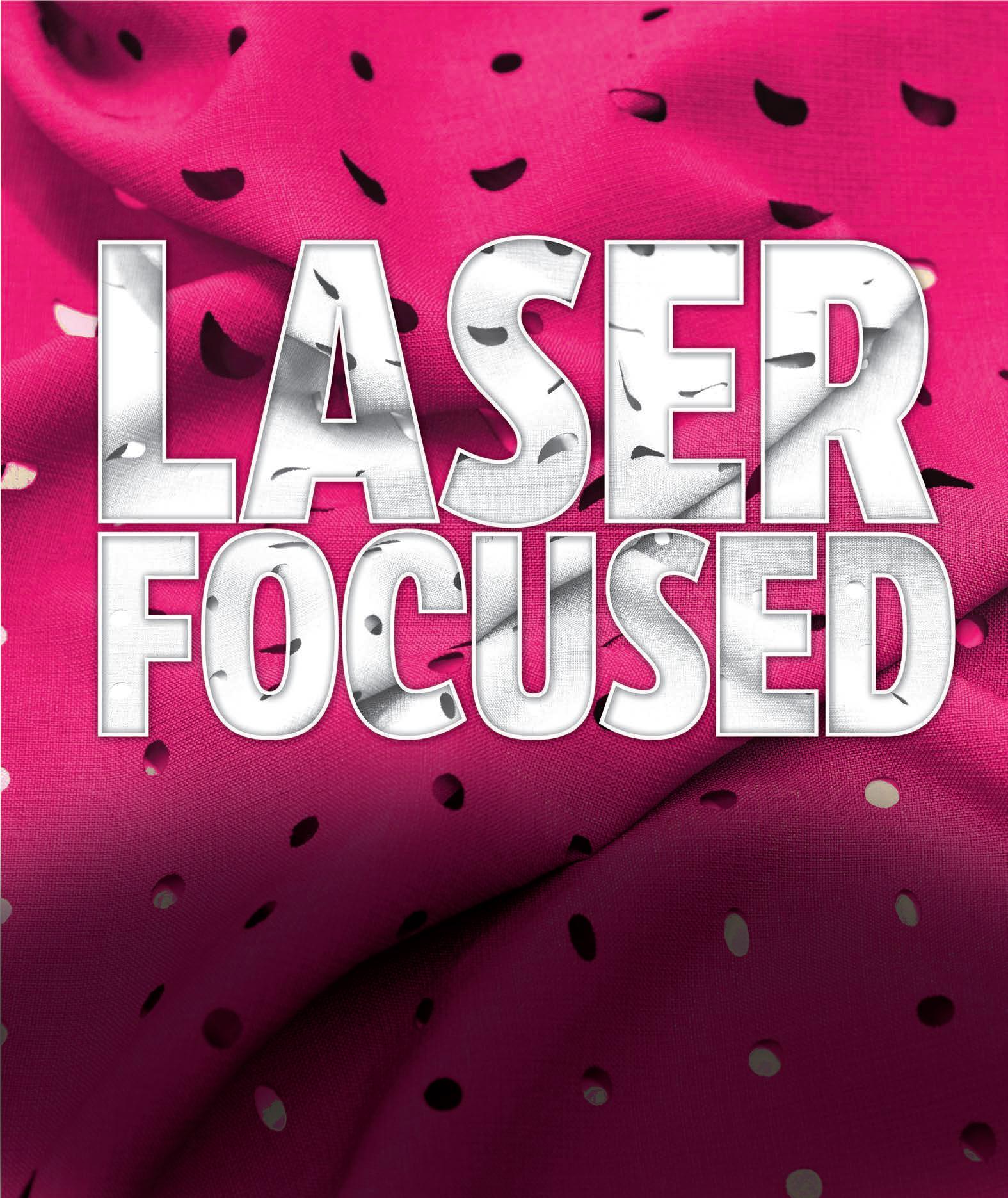

aser cutting solutions give print providers the capability to finish a variety of digitally printed fabric applications, from soft signage to apparel and even décor.

This is in response to changing market demands in an increasingly digital industry. “Businesses expect faster processing speeds, automation features, and consistent edge quality to meet increased order quantities without sacrificing precision,” shares Corey elly, marketing manager, Trotec Laser.

by Cassandra Balentine

Laser technology has become an industry standard for soft signage applications. “Unlike flatbed systems, which can struggle with stretchable materials, laser cutters offer greater versatility and precision,” comments Randi erkaert, product manager, Summa. “Additionally, the laser’s ability to seal fabric edges simplifies the sewing process. Compared to traditional knife-based systems, which often require monthly or even weekly blade replacements, lasers offer longer operational life and lower maintenance needs.”

Changing Demands

The market is demanding higher cutting speeds and improved quality, especially with the rise of digitally printed textiles for short- and medium-run lengths across a range of verticals, including retail, residential, and signage.

“There’s interest in on demand garment customization from monograms and patches to full-cut pattern personalization. This trend expands laser cutting into athleisure, team uniforms, dancewear, and

promotional gear—especially when paired with direct-to-garment printing or embroidery,” shares Kelly.

Steven Leibin, president, Matik, Inc., says laser cutters can offer fast, on-the-fly cutting from a printed roll sealed edges for better quality; as well as higher overall throughput.

Beatrice Drury, communications manager, und America, Inc., sees manufacturers turn to digital cutting solutions for greater efficiency and precision. “This is true both for laser- and blade-based cutting systems, although the latter still offers much greater flexibility, which is precisely where modularity comes into play. The ability to easily switch from one type of cutting technology to another helps overcome the inherent limitations of single-purpose laser systems in terms of material compatibility, edge quality, slower throughput, emissions, and safety concerns.”

Necessary Features

ey features for fabric laser cutting include automated material handling, edge-sealing capabilities, and high-precision optics. “ ver time, these functions have been enhanced with faster processing speeds, improved safety systems, and smarter material recognition,” offers erkaert.

As is the case with all types of digital cutting/ finishing, Drury sees workflow automation as a must. “From tension-free material advancing to efficient, automated nesting and precise vision registration that reliably matches cut to print, automation reduces manual involvement, which means greater output quality and consistency, productivity, and ultimately, profitability.”

intelligent workflow integration, especially when it comes to textile applications.

elly agrees, adding that printand-cut camera systems are a necessity for digitally printed fabrics. “The ability to size, scale, and skew your cut files to match any deviations in print is a game changer for print companies.”

Automation in the Future

The past few years experienced major strides in automation and

“This is true for all system components, with smarter, more adaptive material handling faster and more precise registration mark capture advanced nesting

algorithms integrated, automatic file retrieval and automated/ robotic picking/sorting and off loading,” suggests Drury.

elly concurs, noting that automation in laser cutting for fabric is being adopted across garment manufacturing sites as well as

Le , Opening Image) Matik o ers a range of SEI Laser solutions designed for cu ing fabrics for various applications. 1) Any of Trotec’s range of flatbed laser systems, from the Speedy 50 to the SP 500, are ideal for cu ing digitally printed fabric. 2) The Summa L1810 laser cu er is well suited for textile applications such as sportswear and dye-sublimated garments.

technical textile industries. The reasoning behind this adoption is the fact that “print-to-cut systems enable continuous, highprecision cutting and support growing demand for customization and speed.”

Automation is often driven by advanced software tools.

For example, all of Summa’s digital cutting systems—including roll cutters, flatbeds, and laser cutters—are powered by the company’s proprietary GoProduce workflow automation software. “A standout feature is VisionTrace, which enables on-thefly creation of cut files. This eliminates production bottlenecks by removing the need for preprepared cut files. The system automatically recognizes the shape to be cut and intelligently avoids mistakenly cutting white lettering or printed elements on the fabric,” explains erkaert.

Trotec’s Ruby software is a powerful, all-in-one platform that streamlines the laser workflow from design to production. With an intuitive interface, it allows users to create, edit, and manage jobs directly within the software—no need for external design programs. Features like the job queue, materials database, and

direct-to-laser functionality help boost productivity, while the open API integration supports automation and custom workflows for businesses of all sizes.

“With improved registration technology, seamless Ruby software integration, and support for high-mix, short-run production, Trotec’s print-and-cut camera systems have become faster, more precise, and easier to use,” explains Kelly.

All software offered for running nd cutting systems can be tailored to specific applications and production needs. For

graphics applications, regardless of application and processing methods, nd Cut Center CC V.4 makes everything from file preparation to production automation more intuitive, efficient, and reliable, with options for automatic data import in almost any format, job queues, and data exchange with ERP/RIP and other systems. From the touchscreen to the integrated material base and step-by-step guidance through setup, CC is geared towards user-friendly, efficient, error-free operation.

As with most technologies, artificial intelligence AI plays an

increasing role in the future of automated finishing.

“Automation—and in a broad sense AI—is already playing a role in many different aspects of digital cutting processes. It is most evident in camera registration and automatic adjustments of cut paths, in smart nesting and pattern recognition, cut job and workflow optimization, projection-guided or robotic picking/sorting, and other advanced production workflows,” states Drury.

elly sees AI improving pattern recognition and optimizing

nesting layouts to reduce waste. “Trotec’s Ruby software already incorporates smart features like nesting, which efficiently arranges designs to minimize waste. As AI continues to evolve, it will further streamline workflows and reduce manual input, paving the way for smarter, faster production.”

Automated Sewing

In addition to cutting, sewing is an essential part of the finishing process for multiple textile applications. The task of sewing is becoming easier and less labor intensive through automation, easing bottlenecks due to

manual processes and making efficient laser cutting even more valuable to users.

Many of the processes used by large format print service

providers PSPs are automated from design through print to cutting. Computers provide the controls necessary to end up with a cut-to-shape print. “However, if that print is a textile and

9 Advanced Greig Laminators, Inc. 13 aglinc.com

10 Alpina Manufacturing, LLC 13 fastchangeframes.com

11 Alpina Manufacturing, LLC 13 bannerups.com

12 Budnick Converting/Banner Ups 13 bannerups.com

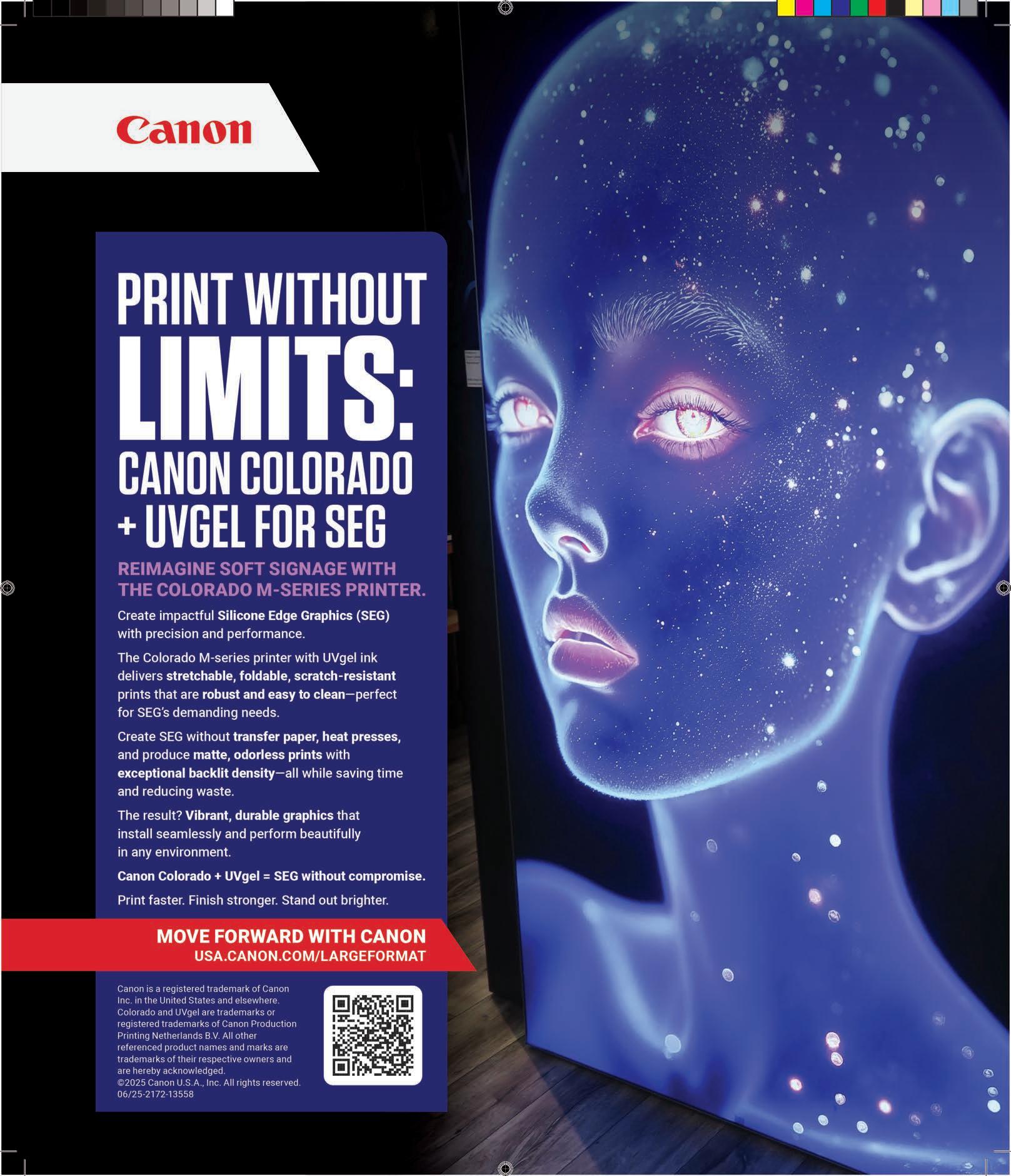

1 Canon U.S.A., Inc. 2 usa.canon.com/largeformat

13 Delivery Signs 13 yardsignsresellers.com

2 FDC Graphic Films, Inc. 9 fdcfilms.com

3 Infinite Motion Control, Inc. 19 infinitemc.com

7 Newlife Magnetics LLC 7 newlifemagnetics.com

4 Newlife Magnetics LLC 11 newlifemagnetics.com

14 PrinterBiz 21 printerbiz.biz

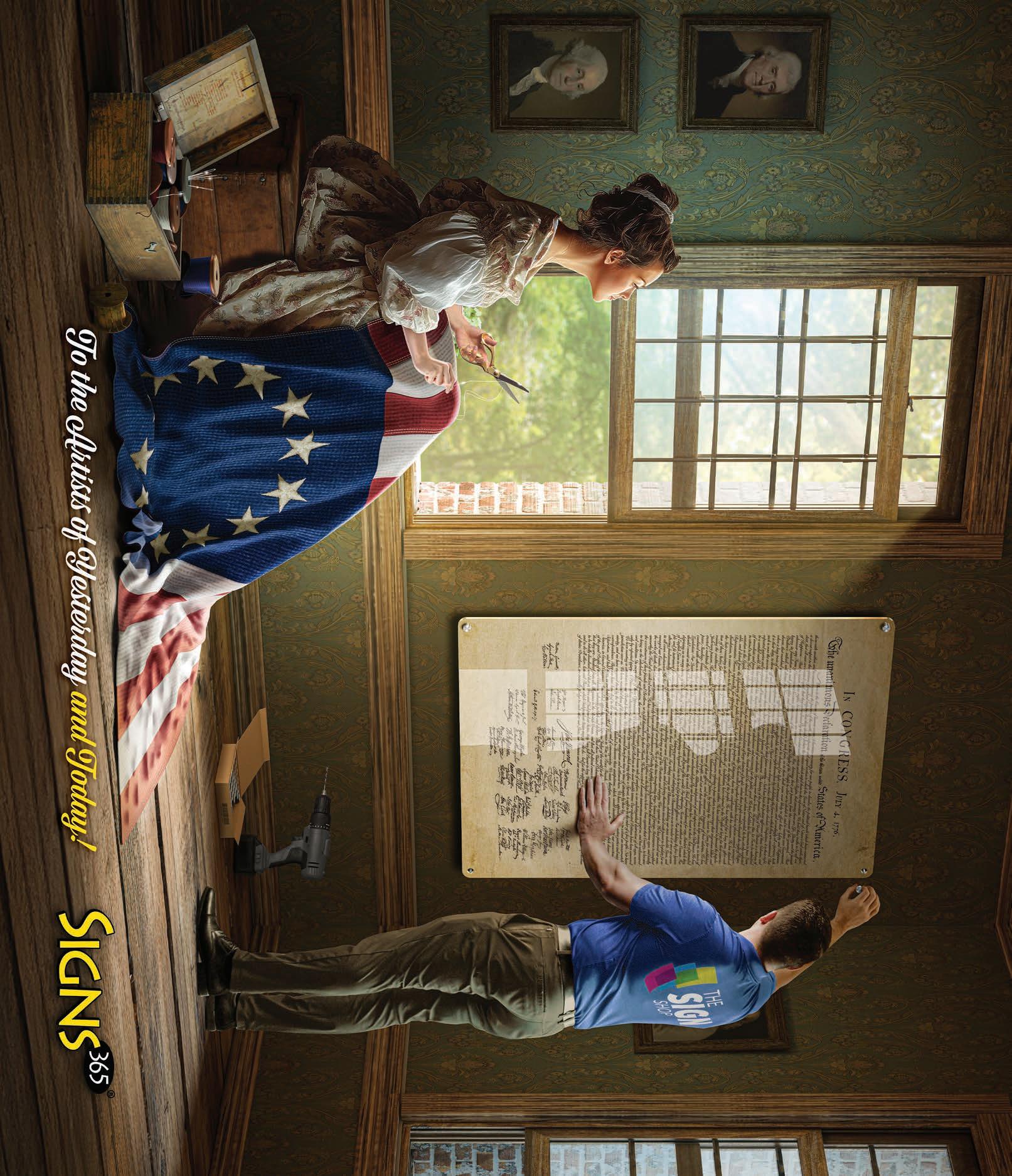

5 Signs365 28 signs365.com

8 Supply55, Inc. 7 supply55.com

6 swissQprint 27 swissqprint.com

15 TVF 15 tvfinc.com

must be sewn to complete a finished product, there is another labor intensive department with sewing personnel moving the textile under a stationary sewing needle. Much manual dexterity and movement is necessary to finish the sewn pieces, and as we know skilled labor is in very short supply,” shares Steve Aranoff, business development manager, Fastsewn dba Mikkelsen Innovation ApS.

However, he explains Fastsewn’s Moving Cavity Technology is a system that looks much like a flatbed cutter, but with the ability to have a sewing bobbin under the textile being sewn while the needle is on the traverse—just like any cutting tool, automated sewing allows for domestic production without the need to find and train staff. “Today, most PSPs are unable to profitably grow their sewing capabilities due to lack of such staff. With Fastsewn, anyone who can operate a cutter handles the sewing simultaneously,” shares Aranoff.

The Fastsewn family of systems provides a fully automated capability to sew and laser cut from up to two rolls of textiles. “This system unrolls and sews keder strips before laser cutting for silicone edge graphics, including the ability to do this in any shape for which an aluminum frame can be built. Two-sided graphics

can be easily registered with an optional underside vision registration system,” adds Aranoff.

Tara Giffin Lamb, president, Global Imaging Inc., sees automated sewing becoming increasingly imperative in today’s evolving workforce due to several converging factors.

“The high speed of modern fabric printers demands equally efficient post-processing to keep up with production flow. At the same time, the rising cost of labor and growing demand for fabric graphics put pressure on manufacturers to optimize efficiency and reduce operational costs. Compounding these challenges is a shortage of skilled labor and employee turnover, making automation a critical solution for maintaining consistency, quality, and productivity,” notes Lamb.

The Miller Weldmaster Digitran, distributed by Global Imaging, sews at up to 0 meters per minute, and the conveyer measures 10x .5 feet. The conveyor is synchronized with the sewing head for smooth material transport. It also integrates tension-free keder feeding as well as automatic, programmable backstitch and thread cutting.

Finishing Automation

When it comes to finishing digitally printed graphics on textiles, laser-based cutting and automated sewing are key to quality and profitability. The technology is in need more than ever due to labor shortages. Textile-focused PSPs should consider implementing.

by Melissa Donovan

he transfer sublimation process is multi-faceted but that doesn’t mean it’s difficult or challenging by any means. Indeed, Ryan Filip, business development, AW Specialty Papers, LLC, believes transfer sublimation offers control, flexibility, and reliability—three highly sought after characteristics in any print process.

From high-end work such as décor to jobs where consistency and speed matter—medium runs of sport apparel—transfer sublimation is what Filip refers to as a “dependable and cost-effective choice in the long run.”

Long Live Transfer

Direct-to-fabric sublimation is admittedly popular due to removing the step of transfer paper,

however transfer sublimation is preferred by many for several reasons. An established process, it offers precise, high-quality graphics in an efficient amount of time.

For one thing, Simon Daplyn, product and marketing manager, Sun Chemical, states that Above) Using premium-grade dyes, NUtec sublimation inks deliver rich, vibrant color across the full spectrum.

transfer sublimation “is a well understood and established process. The image quality is less challenging, as interactions between the ink and paper are well known and fixation workflow is optimized.”

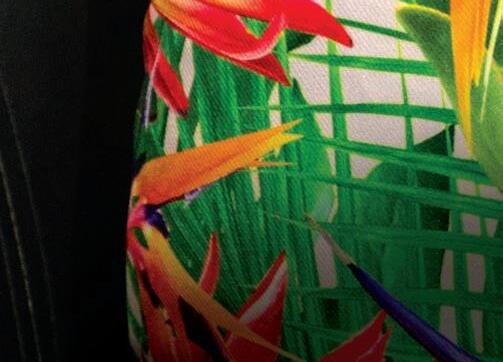

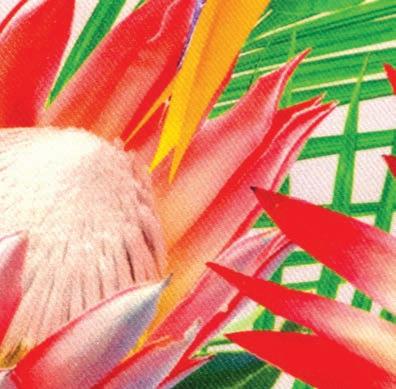

Less challenging image quality equals precision. “Transfer paper allows for better color vibrancy and fidelity, and you do not need the coating that is required for direct transfer. Transfer papers allow for exceptional edge sharpness, which is especially important in high-end fashion, detailed graphics, and small fonts,” says a representative from Beaver Paper & Graphic Media, Inc.

Compared to direct printing, transfer sublimation offers “superior color vibrancy and image clarity, as the transfer process enables more precise ink deposition on treated paper before being thermally bonded to the fabric. This method allows for sharper detail and consistent image reproduction, especially critical in high-end textile applications like fashion, soft signage, and home décor,” agrees Darren Claassens, head of sales and marketing, NUtec Digital Ink.

“In terms of image quality, our clients that produce high-end retail and exhibit displays always choose transfer. Very sharp line work and fine text can be resolved on coated transfer papers and much of this quality is retained as inks are sublimated with paper and fabric sandwiched between

OEKO-TEX Eco Passport, assuring safety for skin contact.

the belt and drum of the transfer press,” admits Dave Mee, partner and textile products manager, American Print Consultants.

While direct sublimation is streamlined thanks to fewer steps, “for most of our applications, especially when dealing with complex designs or when printing on pre-cut fabric pieces, transfer sublimation is more efficient,” notes Rob Super, owner, American Print and Supply.

Another benefit of transfer sublimation is that “it allows printing on a wider range of fabric types, including stretch and coated synthetics, broadening its versatility,” suggests Claassens.

It is considered a cleaner process compared to direct sublimation. “Transfer sublimation keeps equipment cleaner by preventing ink bleed, minimizing downtime, and reducing ink and maintenance costs,” adds Filip.

Additionally, transfer printing does not require a trough for excess ink collection where increased ink needs to be properly disposed. “There is also no need

TRANSFER INK TRENDS

for washing,” notes the team at Beaver Paper.

Transfer sublimation tends to yield less waste. “Stable transport of transfer paper and fabric is the very essence of calendar heat press design. Even stretch and knit fabrics are easily transported, a

Color trends in transfer sublimation printing are bright. In the sign and display market where brand owners look to stand out from the crowd, Simon Daplyn, product and marketing manager, Sun Chemical, sees demand for spot colors such as orange, violet, or blue—these are used to extend the gamut of colors available to the printer.

“Trends in color use are dictated by market requirements and demand,” admits Daplyn.

In activewear as well as promotional branding, Darren Claassens, head of sales and marketing, NUtec Digital Ink, sees

feat only possible on direct printers with very high-cost sticky belt transport systems. Also most calendars allow processing of small, cut pieces of paper and fabric for color strike offs or client sign offs. Think you’re doing this on a direct printer without feet after feet of waste, think again,” warns Mee.

increased demand for fluorescent inks. “These inks add eye-catching appeal and help brands stand out in saturated markets. Fluorescents are also popular in sports apparel and stage costumes where lighting enhances their impact.”

“Fluorescent inks have been around for many years but we’re seeing more people adopt them. Mostly this is in the team and fashion apparel spaces where there is a demand for the boldest and most vivid designs, but I’m surprised not to have seen wider adoption in the graphics and display fields,” notes Dave Mee, partner and textile products manager, American Print Consultants.

1) NUtec sublimation inks are compliant with leading international chemical safety standards and supported by

“If you make a mistake printing it is much easier to catch in process and correct with a paper transfer, not to mention much less costly of an error versus direct printing/fixing inline where you only realize the mistake when it’s too late serving as an extra layer of quality control in your process,” continues Filip.

The Paper Part

Transfer or sublimation paper is a key ingredient in this discussion. Application-specific sublimation

papers as well as multi-purpose papers are used in the wide format digital print process. Depending on the application, it might make sense to use one over the other.

“We feel that the paper choice plays a big role in quality and customer satisfaction,” notes Super.

According to Filip, “choosing the right sublimation transfer paper can impact image quality, ink efficiency, production speed, job profitability, and customer satisfaction. It’s also important to consider equipment and ink chemistry before selecting an application-specific paper. For

example, printers operating in dryer environments often use high glycol content inks to prevent printhead clogging, but they also delay drying and require a specially coated paper tailored to its unique absorption and release characteristics. As a general rule—higher end output demands higher performance paper.”

Application Specific

For apparel applications like sportswear, Super suggests a tacky adhesive transfer paper. “This prevents fabric movement during transfer, essential for stretchable performance fabrics.”

“Tacky paper is a great choice when transferring to cut garment pieces on fabrics prone to shrinking under heat—typically those that are blended with elastine or lycra fibers. Shrinking of fabric during the transfer process causes ‘ghosting’ and blurring of images and tacky paper mitigates this,” explains Mee.

Filip points out that apparel is a diverse category, with performance sportswear and fashion textiles each having their own distinct requirements beyond tacky paper. Where sportswear as aforementioned benefits from tacky sublimation paper, fashion and lifestyle textiles require paper designed to minimize ink bleed and control wicking to ensure sharp lines, color precision, and a soft final product.

Features to look for in a transfer paper used for soft signage include dimensional stability during the transfer process for sharp edges and fine details, fast drying

for high-production environments, and deep black saturation, lists a representative from Beaver Paper.

Also for soft signage, Super recommends a paper with high ink release to ensure vibrant colors and sharp images.

For certain types of soft signage, there are more specifics to get into. “For backlit and front lit displays on lightweight polyester fabrics, use a fast-drying sublimation paper in the 60 to 105 gsm range with a high-release coating. Backlit signage often requires heavier ink saturation to reduce light bleed, so a slightly heavier paper closer to 90 to 105 gsm can help maintain dimensional stability. The goal is to deliver deep, saturated colors while minimizing cockling/rivering and waviness from excess ink,” attests Filip.

Décor projects benefit from a paper with high ink release. “A highresolution capability captures the intricate designs and patterns found in this type of application,” according to Super.

In this instance the paper should also offer “excellent transfer of fine lines and textures, good handling properties, and compatibility with thicker or textured fabrics,” explains the Beaver Paper representative.

For items in this category—like curtains and upholstery—Filip says mid to heavyweight papers in the 90 to 140 gsm range are preferred. “A smooth, consistent coating is essential for accurate ink transfer and detailed image reproduction. Since these

2) OKC Fabrics Market works with transfer sublimation paper from AW Specialty Papers to create stunning prints. 3) American Print and Supply’s transfer papers are designed to be application specific, achieving high image quality as well as customer satisfaction.

products often involve repeating patterns or geometric designs, paper stability is crucial to avoid skewing or distortion. In highspeed environments, even slight paper movement can affect pattern alignment, so dimensional stability and consistent release are key.”

Multi Purpose

Alternatively, instead of using application-specific solutions, a multi-purpose transfer paper can meet all of the combined needs of the aforementioned applications.

A multi-purpose paper for Filip is something in a heavier gsm weight, he cites Coldenhove’s Jetcol 4000. A laminated 140 gsm, stable product, “it works well with very heavy ink loads as well as being suitable for hard surface transfers, making it a very versatile carrier sheet.”

Beaver Paper offers a multipurpose 95 gsm paper. Its key selling factors are that it offers versatility, a balanced performance, consistent quality, and cost-effective inventory.

“It offers consistent transfer across soft signage, fashion, sportswear, and home décor fabrics. Multi-purpose paper offers fast drying, high dye release as well as excellent dimensional stability. Backed by a rigorous quality control process, repeatable results are ensured on every run. It reduces the need to stock multiple paper types,” notes the Beaver Paper representative.

A multi-purpose transfer paper can indeed hit all those points and

more. At American Print Consultants, the papers sold in the 70 to 105 gsm range are considered multi purpose. “They combine the properties of having a high ink release while also being fast drying. These papers are designed to be stable under high ink loads,” explains Mee.

This makes them preferred by American Print Consultants’ team apparel and exhibit/retail graphics customers as well as those looking to transfer to hard surfaces like ChromaLuxe.

Choose One Vs. the Other

There is no wrong answer, but there are preferences between using specialized transfer papers over multi-purpose options.

“Print providers focused on a single, competitive vertical—like

soft signage, home décor, performance apparel, or fashion typically benefit most from targeted solutions. Conversely, print-forpay shops or those producing a range of promotional goods may prefer the flexibility of a highquality, multi-purpose paper. Ultimately, your paper choice should align with your core business model and the expectations of your customers,” states Filip.

According to Beaver Paper, specialized transfer paper is chosen due to cost, like if someone is looking for a more tailored performance, to maximize results on specific fabrics or print profiles, or if a high-volume production line is being run where seconds and scrap matter.

“Specialized transfer paper is the better choice for professional

results, especially when color accuracy, performance, and applicationspecific durability matter most. The optimization for the material is crucial because each paper is engineered to match the specific characteristics of the fabric or surface. This ensures better adhesion, less ghosting, and cleaner lines. Ultimately this enhances the end product quality,” admits Super.

The choice comes down to production priorities, says the Beaver Paper representative. “Specialized paper is best for optimization, while multi-purpose is best for flexibility. Multi-purpose paper offers convenience and flexibility for print shops managing diverse jobs and a one-sizefits-most solution.

“Multi-purpose sublimation papers are designed to perform

reliably across a range of applications, though there are trade-offs in output quality. While they offer flexibility and reduce the need to switch papers, slight adjustments in color profiling may be needed to achieve optimal results for specific uses,” shares Filip.

Tidbits on Ink

Ink specially formulated for the transfer sublimation process is relevant to this discussion. Certain features are paramount to achieving the right adhesion level to the paper and incidentally the correct transfer to the fabric.

Claassens believes high transfer rates as well as vivid color gamut are two characteristics that must standout. With inks like NUtec’s engineered with optimized dye

diffusion properties, this results in a high-efficiency transfer even at lower in volumes.

“This ensures bold, saturated colors with reduced wastage— saving on both ink and paper. In regards to vivid color gamut, using premium grade dyes, inks can deliver rich, vibrant color across the full spectrum,” continues Claassens.

Agreeing on the topics of high transfer rates and vivid color, Daplyn also lists the following features as important in terms of transfer sublimation ink sets—fast dry time, compliance, fastness, and reliability. The important balance between the ink drying fast but not too fast during the process is noteworthy.

“Inks are required to dry fast on the paper because the time from print to rewinding the paper is short, and wet ink will smear and offset onto the back side of the roll. However, it is important that the inks do not dry too quickly in the printhead as this can lead to dropped nozzles that will require maintenance, wasting both time and ink. As such, the ink formulation is a critical part of achieving the right balance in drying behavior,” explains Daplyn.

American Print Consultants collects data on transfer sublimation ink. Based on Mee’s experience with custom profiling for textiles, he has found key features for success include working with deep and neutral black ink, high chroma colors, and balanced primaries.

In regards to deep and neutral black, “having a high density of black allows us to mix less cyan,

magenta, and yellow inks in the profile or spot color formulas, making for faster drying, more stable paper, and of course saving ink,” explains Mee.

For high chroma colors, when building profiles, the first thing to do is find the point where the maximum chroma or saturation can be achieved from each of the primary colors at the least amount of ink. “Not only does this ensure that customers achieve the most intense colors, it also ensures that paper will be stable and dry well. Lower performing inks require higher, wetter coverage, which can cause numerous issues. Intense blue colors are one of the hardest to achieve in sublimation printing, so for us, a blue with high chroma is the Holy Grail,” shares Mee.

Achieving balanced primaries is an indicator of a good ink set. “What signifies a good ink set is a balance in the chromas of cyan, magenta, and yellow. Having the brightest yellow possible is of little value if the other primaries can’t match it,” admits Mee.

Achieving Control

Transfer sublimation printing offers users control, flexibility, and vivid color—this is especially true when the correct materials, for our discussion transfer paper and ink, are used. View a webinar on this topic at digitaloutput.net and learn more about various parts of the sublimation transfer process. D