OCTOBER 2025

DIGITAL PUBLISHING SOLUTIONS

DIGITAL PRINT, PACKAGING, AND PUBLISHING

dpsmagazine.com

DIGITAL PRINT, PACKAGING, AND PUBLISHING

dpsmagazine.com

To optimize the benefits of digital print, print providers look to the latest technology tools to ensure seamless integration and streamlined production.

Web to print (W2P) tools expand the reach of print providers with online ordering. Integrations with plug-ins like ecommerce systems promote ease of use for end users and fuel adoption. We discuss the evolution of W2P in Seamless Integration.

To optimize the benefits of digital print, print providers look to the latest technology tools to ensure seamless integration and streamlined production.

Our cover story, Digital Folding Carton Production, discusses ways in which the folding carton market is evolving in the digital print landscape, whether it be through the media, inks, or coatings used to ensure the perfect print.

One way to expand your reach is through partnerships with wholesale/ trade print organizations. We discuss what’s hot in this market in our Best Practices column.

We wrap up the issue with the second of two PRINTING United Expo previews. For additional show highlights, check our September issue and content online at dpsmagazine.com.

Best regards,

Cassandra Balentine, editor cbalentine@rockportpubs.com

EDITOR IN CHIEF

Thomas Tetreault 978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Maco Boer

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

300 Newburyport Turnpike, Ste. 11 Rowley, MA 01969

Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 300 Newburyport Turnpike, Ste. 11 Rowley, MA 01969

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy Tyler

By OPS Magazine Staff

PRINTING United Expo 2025 takes place from October 22 to 24, 2025 at the Orange County Convention Center in Orlando, FL. Hosted by the Printing United Alliance, a member-based printing and graphic arts association, the event promises global product launches, forward-looking education, and opportunities for networking.

Among the hundreds of vendors expected to exhibit, here are a few highlights. Also, refer to our September issue for part one ofthis preview.

Alwan Color Expertise, booth 2595, highlights the Hydra Color Engine, HydraProfiling, HydraFix, andHydraSpot. Alwan's spectral prediction engine, Hydra, is integratedacross a range of commercial, packaging, textile, and other specialty print applications. Hydra conquers challenges that have hindered the industry for decades-high costs, long processingtimes,andunnecessarycomplexity. INFO#200

C.P. Bourg, booth 5448, showcases a range of products such as perfect binding, booklet making, and book block preparation. This includes the new BBM40/60+ booklet maker that is capable of 60-plus sheet/240-plus page

booklets. All solutions are available inline withadigitalprinter, near-line, or in dualmode. INFO#201

Canon, booth 2642, displays its diverse range of production and large format technologies, including the varioPRINT iXl700 sheetfed inkjet press and the Canon Colorado MS. Attendees can explore printers from the imagePRESS, Arizona, and imagePROGRAF product families, plus Canon's PRISMA workflow solutions. INFO#202

The Challenge Machinery Company, booth 1830, exhibits the new Titan 230Pro hydraulic powered paper cutter along with its CMT-130TC book trimmer and other print finishing machines. INFO# 203

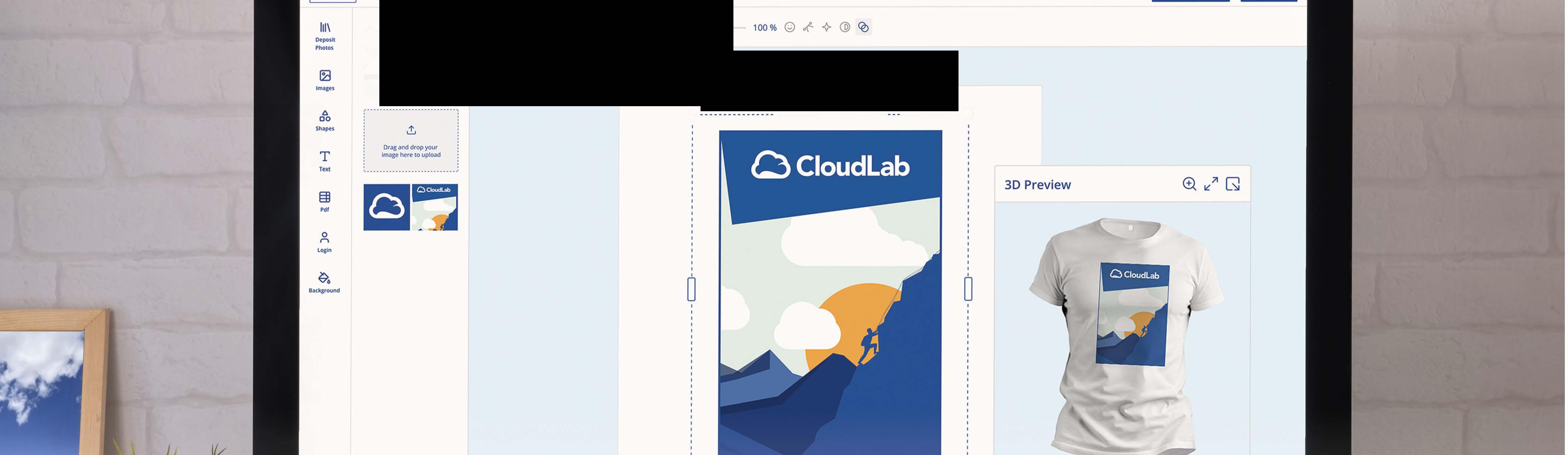

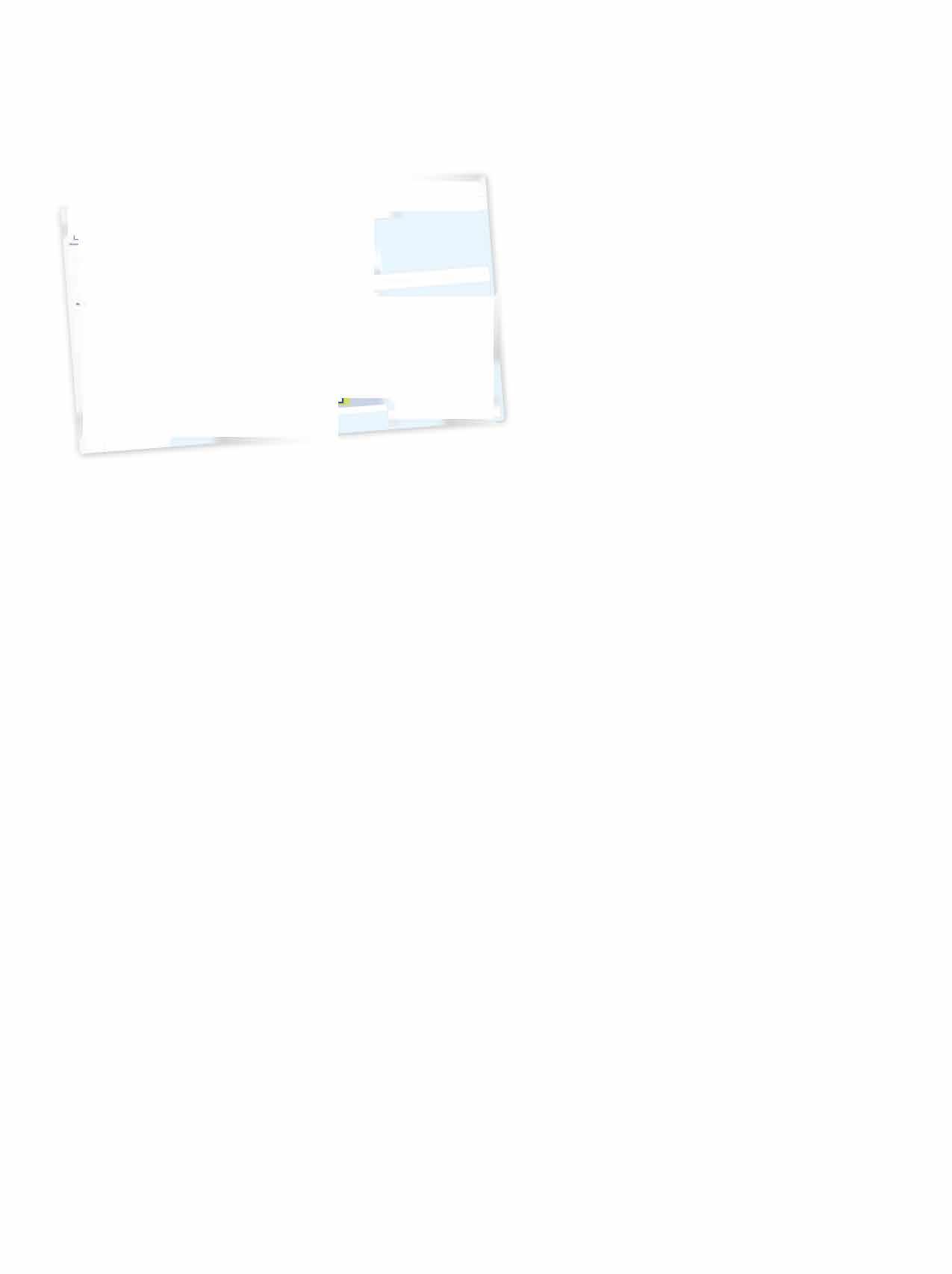

Customer's Canvas, booth 2730, features its suite of web to print solutions built for both business to business

and business to consumer focused print providers, enabling them to deliver customized products online with robust personalization, proofing, andautomated prepress tools. New this year-broader support for traditional printing technologies, from predefined spot colors in screenprintingtoadvancedfinishessuch asfoiling,engraving,andembossing,plus scalablerenderingofprint-readyfilesand Al-assisteddesignediting. INFO#204

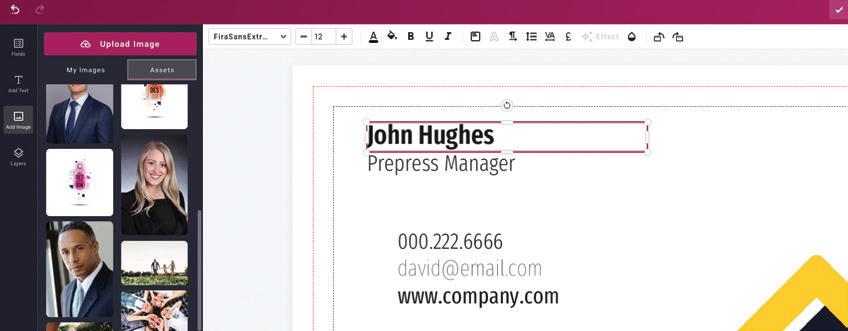

Datatech Smartsoft, booth 1903, shows attendees how to reduce touches fromprint workflows withPressWise, the end-to-end web to print, MIS, and workflowautomationplatform. INFO#205

1. Kongsberg Precision Cutting Systems showcasesthreeofitsadvanced cuttingsolutionsforthe printandsignageindustryinbooth2200. 2.Kyocera showcases itsTASKalfa Pro 15000c inkjettechnologyinbooth3906.

DirectMail2.0, booth 2712, known for enhancing direct mail campaigns through omni-channel marketing, launches DM20.ai. Learn about this technology and be the first to leverage the power of AI to forecast your success and guide your next move. INFO# 206

Duplo, booth 3921, showcases the latest and greatest in on demand print embellishment, finishing, and packaging. The company displays its range of solutions designed to transform your print business in its largest booth yet. INFO# 207

EMT International, booth 2449, highlights a range of advanced technologies. The centerpiece of EMT’s presence is a new cutting technology demonstration that features toolless setup and easy, repeatable adjustments; open access for maintenance and blade changes, and adaptive cutting technology that adjusts

across substrates and changeovers. Alongside this debut, EMT also features a range of solutions designed to address today’s most pressing production needs including dynamic cross creasing, heavyduty perf technology, and Videk Vision Inspection. INFO# 208

Fiery, booth 935, brings its Print Genius solutions that take your business to the next level. Stop by the booth to see the latest Fiery technologies, from AI-empowered workflow systems to variable data printing software to superpower all your digital printing needs. INFO# 209

Graphic Whizard, booth 3910, highlights select finishing equipment from its portfolio of slit/crease/cutters, perfect binders, UV coaters, laminators, folders, and digital die cutters. INFO# 210

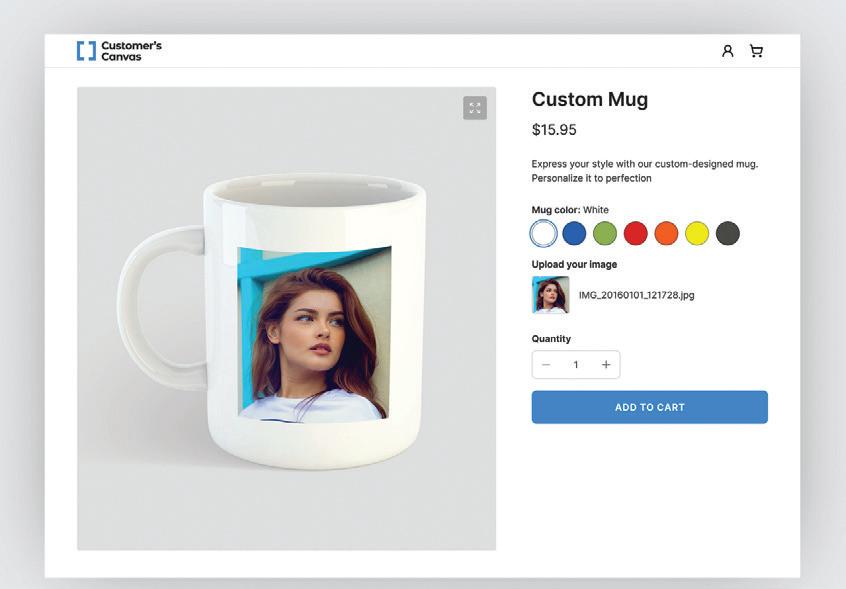

Infigo, booth 4514, showcases how its web to print and ecommerce platform

empowers print providers to streamline workflows, unlock new revenue streams, and deliver personalized online ordering experiences. See live demonstrations and discover how it helps printers scale their businesses. INFO# 211

Kongsberg Precision Cutting Systems, booth 2200, demonstrates how its products, customer support, and materials expertise combine to empower businesses to push creative boundaries while improving overall efficiency and productivity. INFO# 212

Kyocera Document Solutions America, booth 3906, showcases the TASKalfa Pro 15000c inkjet technology alongside exciting new finishing options that allow more printers to say “yes.” INFO # 213

MBM Corporation, booth 4855, provides finishing products for today’s digital and offset print industries. Its product line

includes Triumph and VRCut Ready Triumph cutters, AeroCut digital print finishing systems, folders, creasers, collators, and bookletmakers. INFO# 214

MBO America, booth 5242, features a complete live production line featuring MBO’s splicer, perf & score, contour cutter, sheeter, folder, and stacker systems in action. Experience how its integrated solutions deliver faster, smarter, and more flexible finishing for commercial and packaging print. INFO# 215

MGX, booth 2242, showcases its New ReadyMAG pre-magnetized paper designed to simplify magnet production. Visit the booth to explore this cutting-edge substrate and its full line of specialty print materials. INFO# 216

Muller Martini, booth 3234, highlights the Antaro Digital, which exemplifies state-of-the-art automation, offering

seamless production workflows and precision for today’s modern print businesses. Its newly integrated endsheet tipper provides for both softcover and hardcover book production capabilities within the same machine. Coupled with the InfiniTrim “Robotic” trimming system and the Solema Mini-Sol stacker with Omega693 cobot palletizer, this solution offers the ultimate in short-run digital book manufacturing with minimal labor and zero make-ready capabilities. Meanwhile, the Hunkeler GEN8 EVO rollto-stack solution sets a new benchmark in production efficiency. Its robust design, increased speeds, and reduced waste deliver high-quality output while minimizing operating costs. Its intuitive operation and future-proof platform ensure adaptability for evolving customer needs, solidifying its role in print finishing. INFO# 217

Nobelus, booth 4838, showcases three unique thermal laminators ranging from entry-level lamination to double-sided production volumes. Visit the booth to see these units in action and explore the company’s comprehensive portfolio of specialty laminate finishes, all-PE thermal sealants, and innovative pre-lams for flexible packaging. INFO# 218

printIQ, booth 2208, invites attendees to discover why print businesses globally trust its robust and flexible, cloud-based platform as their single source of truth, connecting every operation from quote to delivery with real-time visibility and seamless workflow automation. See how printIQ’s V49 release takes this foundation to the next level with enhanced inventory planning, product cataloging, and intelligent mass distribution tools that eliminate operational chaos. INFO# 219

Ricoh, booth 5621, features a host of solutions on display, such as the RICOH Pro VC80000, the RICOH Pro C9500, and the RICOH Pro C5410S. INFO# 220

Roland DGA, booth 1536, offers a firsthand look at Roland DGA’s latest digital imaging technologies designed to maximize productivity, output quality, and profitability. INFO# 221

Rollem International, booth 3227, offers live demonstrations featuring the Insignia Series Die-Cutters. The Insignia7H die-cutter features a 30-inch capacity, which is ideal for B2 cutsheet presses. Visitors see automated carton production while witnessing speed, ease of operation, and die changeovers. This is a great opportunity for print service providers to see first-hand this production geared system while learning about its many functions. The Insignia Series Die-Cutters are proudly manufactured

in the U.S. Along with its U.S. production, Rollem International sells, installs, and supports the die-cutters with an inhouse team of technical support representatives. INFO# 222

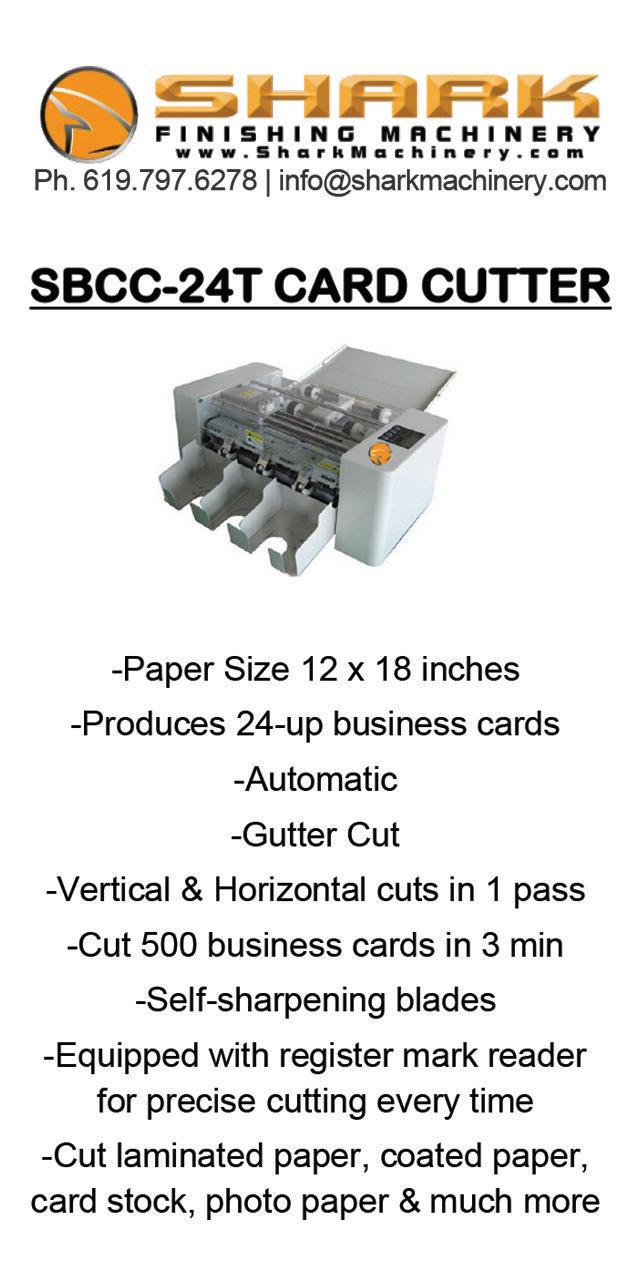

Shark Finishing Machinery, booth 4215, features its line of digital print finishing solutions which includes digital creasers, perforators, paper cutter, business card cutters, digital die cutters, corner rounders, stitchers, UV coaters, perfect binders, and paper joggers. See the new 32.2-inch hydraulic paper cutter, which is completely programmable with air bed, cutline light, safety beams, micro adjustment, auto push out, electronic soft clamp, side tables, and more. INFO# 223

Sharp, booth 4242, encourages attendees to stop by and preview its latest innovations in digital press technology, including the expanded BP-1200S Color Press Series with six-color single-pass output

and tactile embellishments; streamlined monochrome production with GBC FuturoPunch ProUpcoming BP-80C80 entry-level platform, bridging office and light production; and its updated partner ecosystem—featuring Fiery, Color-Logic, Duplo, Plockmatic, Taktiful—enabling end-to-end, profitable workflows. Plus, try your swing on the Sharp Golf Simulator for a chance to win a PGA National golf getaway. INFO# 224

Standard Finishing Systems, booth 3930, offers demonstrations of over 20 finishing solutions from Hunkeler and Horizon in their 5,000 square foot booth, including the Horizon BQ-300 Perfect Binder, the Horizon AFV-566FKT Folder, and the Hunkeler/Horizon Roll-to-Saddlestitch combination solution. INFO# 225

Viesus, booth 2627, invites attendees to see the Viesus 12 in action—delivering next-gen AI upscaling, facial reconstruction, and artifact removal across cloud, on-premise, and SDK workflows, including seamless plug-and-play integration with Enfocus Switch. Also featured, the new PDF Enhancer, bringing unattended, high-quality image correction directly into print-ready PDFs. INFO# 226

Xerox, booth 4521, invites you to experience the evolution of production print with the debut of three new production presses and advanced digital embellishment capabilities that open and expand market opportunities for print service providers. Visitors will also see workflow automation in action with FreeFlow Core and Vision Connect designed to accelerate productivity and bring a connected print ecosystem to life. Explore XMPie’s omni-channel marketing platform for personalized communications across print and digital and be inspired by standout client work in the 2025 Xerox Best of the Best Awards. INFO# 227

Find expanded show highlights online at dpsmagazine.com as well as in our September print issue. dps

By Cassandra Balentine

As with any industry, the role of print continues to shift to support evolving consumer demands. The wholesale portion of the print industry is no exception.

Trade-only wholesale printers are well adapt at creating high volumes of applications. They can act as a business extension, help print providers test new markets, and be relied upon in a pinch.

Several trends impact the trade-only wholesale print space today.

“The trade print landscape has shifted dramatically. COVID and the post-pandemic supply chain crisis exposed weaknesses across the industry—long lead times, material shortages, and inconsistent service disrupted many distributor relationships. Those challenges forced distributors to rethink their vendor mix and prioritize reliability, speed, and communication,” shares Jennifer Hoyt, director of marketing and ecommerce, Stouse.

At the same time, demand for customized products and faster turnarounds has grown. Advancements in digital printing and automation raised the bar, making flexibility and responsiveness critical to staying competitive. “Distributors now lean harder on trade partners who simplify the process, deliver consistently, and offer a range of solutions,” adds Hoyt.

Hoyt expects distributors to continue to demand more—more product variety, more speed, more support, and more flexibility. “That shift already drives

COVID and the post-pandemic supply chain crisis exposed weaknesses across the industry...

— Jennifer Hoyt, director of marketing and ecommerce, Stouse

change across trade printing, and it won’t slow down. The most successful trade partners will invest in automation, expand digital capabilities, and remove friction from every stage of the process, from quoting to production to delivery.”

Supply chain pressure also hasn’t disappeared. Hoyt stresses that printers need smarter sourcing strategies, stronger vendor relationships, and better systems to adapt quickly when challenges hit.

Bob Saunders, VP of sales, Wise, sees a rise of trade print through industry consolidation. “Over the past five years, one of the most significant shifts in the trade print business is the opportunity

1. Stouse combines deep printing expertise, flexible technologies, and unmatched customer service. 2. Wise is a trade-only print manufacturer specializing in traditional business forms.

created by consolidation among directselling manufacturers. Just within the past six months we have seen multiple closures of printing facilities producing business forms. But there are still customers for these forms, so that volume has to go somewhere. Ironically, while these companies are shuttering facilities, we’re seeing a growth in our plants.”

Saunders suggests thinking about it this way, “let’s say you have a company with 100 sales reps selling printed products, and you have a plant dedicated just to those reps. If there is a decline in key product lines, you still have to feed that plant. Increasingly, there’s not enough business to support a dedicated facility. So you may still want to offer that product line, but it doesn’t make sense to carry all that overhead. So you shut it down and send that business to a trade manufacturer. The result? More business for trade printers and fewer barriers for commercial printers or resellers who want to maintain access to these product lines.”

Another notable evolution in the trade print space, according to Saunders, is the growing number of commercial printers entering the reselling market. “This allows them to expand their offerings and meet customer needs without expanding their own production capabilities. This trend is especially visible at major industry events where entire exhibit halls are now devoted to promotional products.”

A variety of trade-only wholesale printers are available to assist. Here are a few trade-only print providers serving the industry today.

Headquartered in Blue Springs, MO, Print Rail Wholesale produces direct to film (DTF), UVDTF, stickers, and completed tees at wholesale prices.

The company started selling DTF transfers in October 2022. It ships from Kansas City, MO.

Signs365 is a grand format, trade-only wholesale printer. The Shelby Township, MI-based company offers a variety of fullcolor, high-quality printed products all produced in 24 hours.

Wholesale trade printer SinaLite celebrates over 20 years in business. It operates out of a 100,000 square foot facility in Dublin, OH. In addition to large format printing of wholesale signs, banners, and wall decals, it also provides clients with business cards, promotional materials, stationery, labels and packaging, and apparel.

Stouse Sign Service began in the early 1950s, specializing in hand-painted signs and billboards. New ownership took over in 1977 and expanded Stouse’s product line to include bumper stickers and other screenprinted products. Since then, Stouse has evolved as a trade printer, supporting the distributor channel for nearly five decades.

Stouse ships across the U.S. and Canada, with the majority of orders delivered to distributor locations or blind-shipped directly to end customers. Its production model supports coast-to-coast reach with fast, reliable fulfillment.

In business since 1969, Wise is a tradeonly print manufacturer specializing in traditional business forms—including continuous, cut sheet, unit sets, jumbo rolls, and checks, along with industrial and prime labels, tags, and digital printing solutions tailored exclusively for resellers. Wise maintains multiple production locations across the U.S. to support nationwide—but primarily Midwest, East Coast, and Southeast—reseller coverage.

Using a trusted trade-only wholesale printer for certain jobs or applications can be a win-win situation. It is essential to form strong relationships that serve your needs and requirements. dps

See page 26 for more information.

l¼iAR f" ;� BLEND OF G IEUCAf Yl?T!Js'

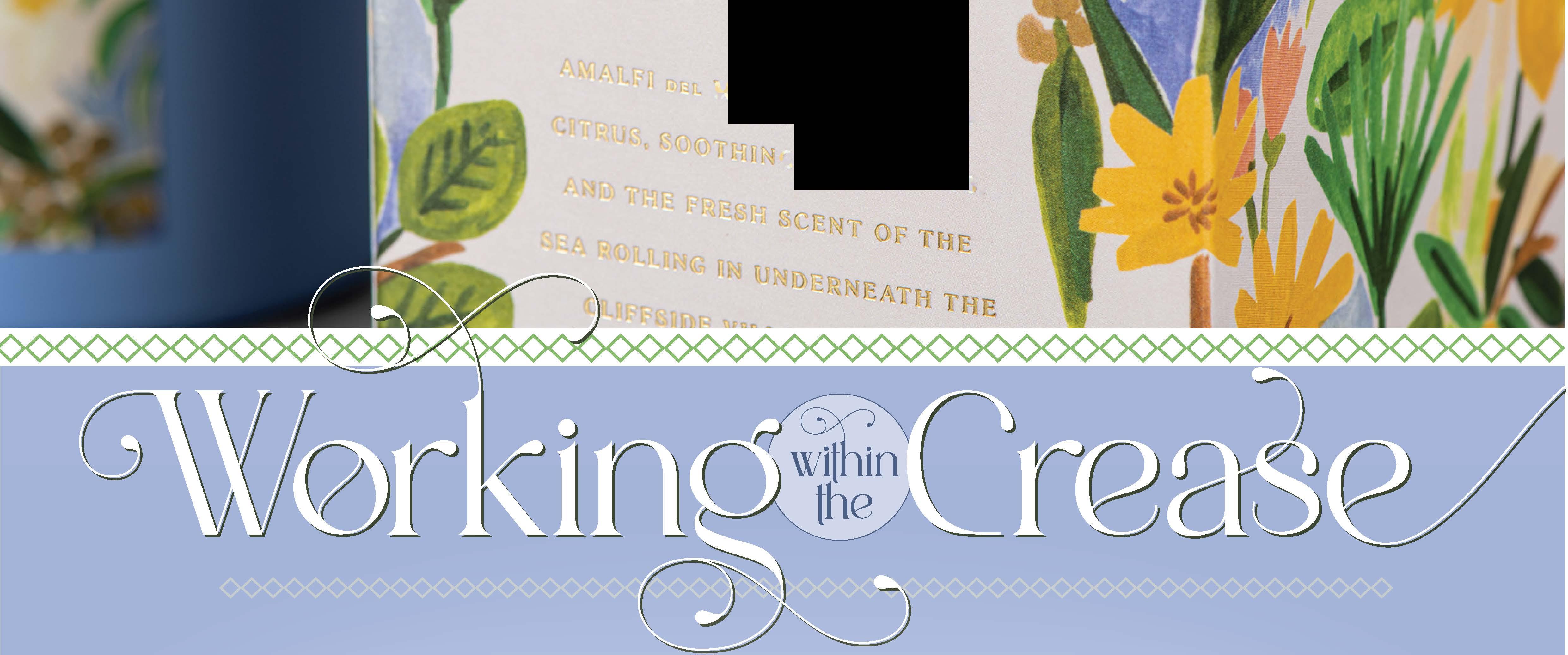

hen sourcing media for digitally printed folding carton production the type of ink used-water-based or UV inkjet in addition to toner-plays a pivotal role. A range of substrates are compatible with each technology but testing is important to determine the best material for the job. The appearance of the final print must match the customers' vision and sometimes this means adding coatings-even barrier coatingsor embellishments like varnish or foil.

Popular folding carton options include paperboard like solid bleached sulfate board and folding box board. These may be comprised of recycled materials, include barrier coatings, or incorporate metallized variants. Most of these materials range from 200 to 600 microns in thickness.

Above: All Neenah Folding Board Digital items are completely recyclable. Whilemostprint, foil, anddecorationcanalsoberecycleditisvery specifictotheactualembellishment.

compatibility. It is commonly referenced and can serve as a benchmark when evaluating press/media combinations.

Media is only as good as the ink printed on it. The role of inks and coatings is important in folding cartons.

“They’re central. The ink or toner defines color intensity, food safety, and print durability. Xeikon’s dry toners, for instance, offer offset-quality color with food safe compliance and no odor—ideal for confectionery or cosmetics packaging. A protective overprint varnish adds scratch resistance for automated packing. In water-based inkjet, the right primer is essential to control dot gain and adhesion. UV inks cure instantly but require careful chemistry choices for sensitive applications,” explains Wolford.

For UV inks, Lance Martin, VP product marketing, Komori America, says the ink set produces durable and scratch-resistant output. In addition, UV LED cured inks exhibit a glossier finish, which may reduce or even eliminate the need for additional coatings depending on the application.

Water-based inks offer high print quality and a host of other advantages, according to Jochen Sproll, senior business development manager, Koenig & Bauer Durst. “The VariJET 106 uses water-based inkjet inks, primers,

and coatings to provide the highest print quality at a most competitive cost level, while supporting current and upcoming food safety and sustainability regulation. The water-based inks are Swiss Ordinance compliant for food safety. Standard offset grade media can be used, with a primer coat applied before it reaches the inkjet engine.”

Waddington believes “inks and coatings are critical to the overall performance of digitally printed folding cartons. Proper selection directly impacts adhesion, visual quality, fold performance, embellishment compatibility, and recyclability.”

“The interaction between ink and media can either enhance or detract the graphic being applied to the package. Coatings can greatly enhance both the appearance or tactile qualities,” adds Stevens.

Interestingly, Jennifer Dietz, senior product manager, folding board and label, Neenah, a Mativ Brand, says that inks and coatings used for uncoated board are typically secondary to the actual finish of the material, which is the biggest draw.

“Depending on the art, an uncoated board can accentuate it—such as the watercolor image on the Neenah Rifle Candle box, drawing customers in by replicating the feel of the original painting. In another example, using the solid Neenah Deep Black board eliminates the need for flood coating, banishes white

edges, and provides a premium luxe feel with simple decoration such as gold foil or white ink,” shares Dietz.

A offshoot of coatings is a barrier coating, which is not necessary in every scenario. Barrier coatings serve as a protective purpose. “Barrier coatings can be used for a range of reasons from moisture resistance, grease proofing, and UV protection to enhancing product safety and shelf life,” shares Sproll.

“Barrier coatings are appropriate anytime resistance to penetration of a particular element is required—water, water vapor, oxygen, or aroma. These can be applied by the media manufacturer or the packaging converter,” notes Stevens.

Wolford says barrier coatings are typically used in frozen food, snacks, or bakery cartons. “Today’s water-based or bio-based barriers can be applied offline via flexography or gravure, and many are repulpable—making them both functional and sustainable. It’s essential to test compatibility with your chosen digital print process, but Xeikon’s toner technology tolerates most barrier layers without compromise,” he continues.

While barrier coatings are beneficial, since they enhance packaging functionality, Waddington suggests they be considered separately from inkjet primers. “Some barrier coatings also support recyclability goals, particularly those designed for delamination or improved deinking, and may work in tandem with washable inks, though digital versions of these inks remain limited.”

Embellishments like varnish and foil are attractive, used as a way for a packaging piece to standout on the shelf. It’s predictable that folding cartons would be affected by this trend.

Foil is often used on Neenah’s uncoated board. Dietz says it provides a sophisticated elegance.

“When it comes to varnish on uncoated, many printers will use it to ‘seal’ the surface when using heavy coverage or four-color process, to help protect from scuffing or ink offsetting—a common practice in commercial printing as well. The point to make clear to the designers and brands looking to achieve specific effects is that a varnish will not show up on an uncoated board. To get the shiny contrast you would need to use a clear foil,” explains Dietz.

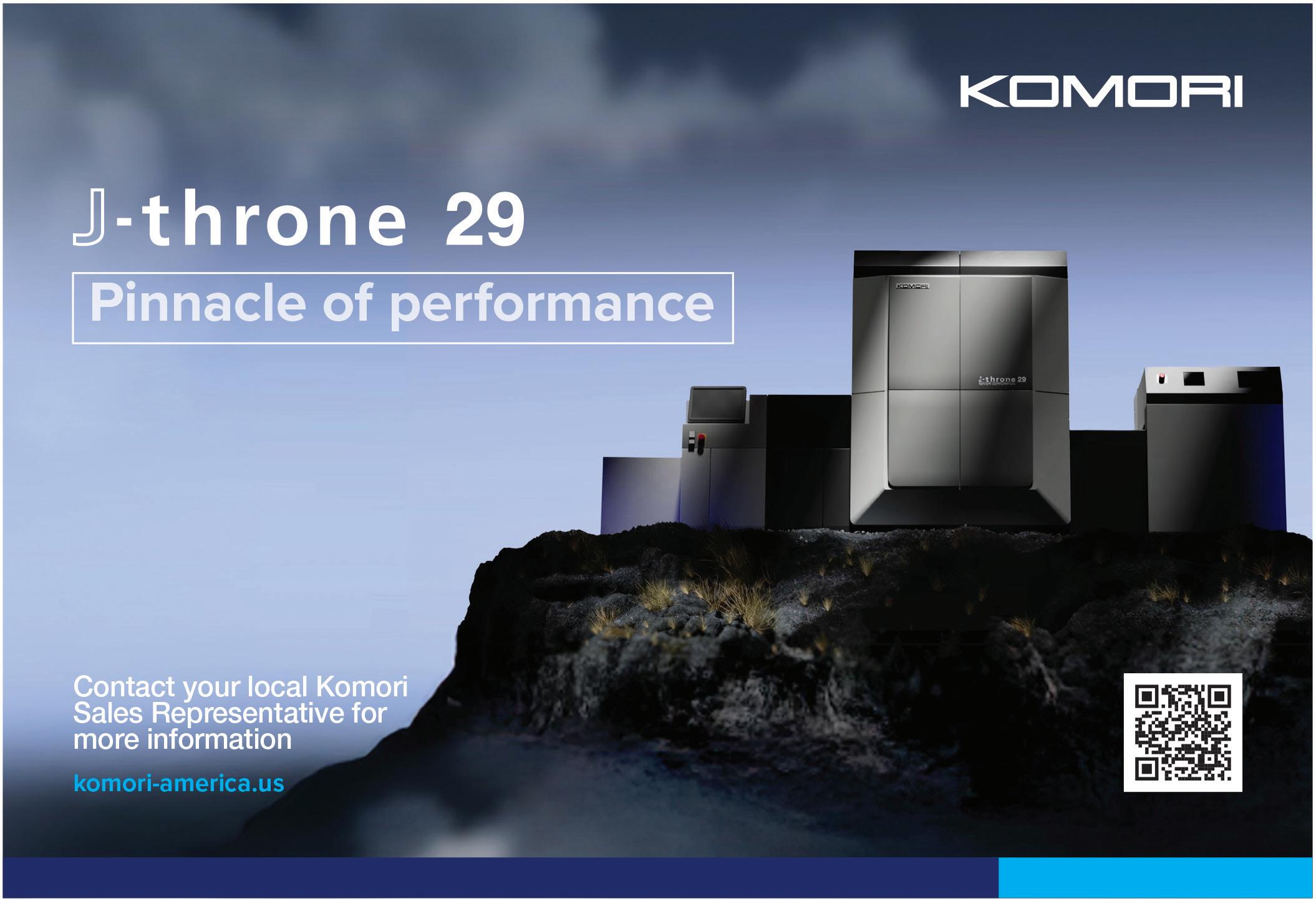

According to Stevens, Mohawk Folding Board supports a wide array of print finishing techniques, including letterpress, foil stamping, and engraving. “For optimal results, it is recommended that you collaborate closely with your print partner and conduct thorough testing to ensure the paper performs to your expectations,” she offers.

To ensure the embellishment applies properly, the surface of the folding carton media is critical and of course so is the ink or toner used. “Xeikon’s dry toner prints have excellent surface energy, so they’re compatible with most embellishments—whether it’s water-based or UV varnish, hot foil, cold foil, or even digital foil. Our Fusion Embellishment Unit allows converters to apply spot varnish, tactile varnish, and foil in perfect register to the print—all inline and without the need for priming. This unlocks high-impact packaging while reducing touchpoints,” notes Wolford.

Sproll says that the VariJET enables all-in-one production with inline embellishment using conventional Rapida coating stations and off-the-shelf consumables in B1 standard offset format.

“In the case of Komori’s J-throne 29, the use of UV LED cured inks provides a printed sheet with optimal surface energy or dyne level for common postpress embellishment using traditional methods. Komori has demonstrated that sheets printed on the J-throne 29 can be successfully coated using UV and aqueous common coatings,” shares Martin.

A common concern with folding cartons is cracking on the fold lines, especially if there is heavy ink coverage.

Depending on the media manufacturer, there are different ways to combat this. Mohawk “typically alters the fiber compositions of the base sheet and includes surface treatment materials to improve the durability and flexibility of folding carton media,” says Stevens.

Wolfordbelievestherearethreekey factorstoconsiderintermsofavoiding cracking-the ink/toner used, creasing technology,andboardhumidity.

"Using Xeikon's dry toner, the image layer is ultra thin-around five microns-which allows the fibers in the material to flex naturally even under dense ink coverage. Secondly, converters should use a high-quality creasing technology like multi-channel rotary scoring or digital creasing systems to distribute stress in the fold. Finally, maintaining consistentboardhumidity duringfinishinghelpspreventcracking alongthegrain,"saysWolford.

Scoringisdefinitelyaculpritwhenit comes to cracking. "Fold cracking can be exacerbated by poor scoring. Good qualitymale-femalescoringruleblades with properly adjusted cycle depths, matched to the stock thickness, will yieldthebestresults,"addsMartin.

2. Mohawk offers folding boards crafted from virgin, recycled, and alternative fibers, which are availableinapalette ofpopularshades.

AsWolford alludes to, the technologyoftheprintingpressplaysarole,like Xeikon'sdrytonerandhowitenablesan ultrathinimage.

ThesameissaidofKoenigBauer& Durst'swater-basedtechnologywithits feedingmechanismsandhowtheyhelp preventcracking. "Oursheettransport, feeding, delivery, press control, and makereadyuseexistingRapidatechnologyandensurehighestqualityproduction"saysSproll.

"From a UV ink formulation perspective,incorporatingpolyesterresins into the formulation can significantly improve flexibility and reduce cracking,"explainsWaddington.

Additionally, any topcoats or laminates used should be designed with flexibilityinmindtoensurecompatibilitywiththeinklayerandthemechanical demandsoffolding,hesuggests.

In a society whererecyclingand reuse istopofmind,thisisacommonrequest

forbuyersofdigitallyprintedfoldingcartonpackaging.Themedia,ink,andcoatings all impact recyclability. However, therearechallengeswithinstitutingthis onaglobalscale.

Europeans are ahead of the U.S. in terms ofrecyclability mandates. "In Europe, the Packaging and Packaging Waste Regulation (PPWR) that came into force this year represents a significant regulatory intervention in the packaging market. With the primary goalbeingtoreduce,reuse,andrecycle packagingwiththefocusonpromotinga functioningcirculareconomy.PPWR is goodfor fiber-basedpackaging suchas foldingcartons,"explainsSproll.

"Regulations are evolving, by 2025, halfofallplasticsusedinEUpackaging must berecyclable, increasing demand formaterialslikerPET.Assustainability standardsrise, innovationsinwashable inksandbarriertechnologieswilllikely accelerate,"admitsWaddington.

Stevens believes the biggest impact on recyclability for folding carton applicationsregardless ofthe print applicationsisbarrier coatingsorfilmlaminates. "This is a rapidly changing area with improvements in recyclability of barriermaterialsoccurringinrealtime."

The folding carton market is evolving, and digital printingtechnologiesplay a roleinthistransformation.

"Digital printing is reshaping the folding carton marketby enabling rapid, flexible, andsustainableproduction solutions,"saysSproll.

mohawkconnects.com

Neenah, a Mativ Brand neenahpaper.com Xeikon NorthAmerica xeikon.com

Whileit'snotareplacementfortraditionalmethods,itsroleisgrowing,particularly for shorter runs, design flexibility, versioning, and agile production needs.''Alargeportionoffoldingcarton convertersseethefutureofthepackagingindustryasahybridapproach,combiningdigitalandconventionalprinting to balance cost, scale, and customizationneeds,"concludesSproll.dps

By Cassandra Balentine

eb to print (W2P) solutions help print providers expand reach.

Integrations further the opportunity, including the ability to seamlessly connect to ecommerce and marketplace ecosystems.

According to Ayelet Szabo-Melamed, VP marketing, XMPie, the demand for ecommerce and marketplace plugins

for W2P solutions is not only increasing, but integration flexibility is becoming essential.

W2P market growth is driven by customer demand for fast, seamless, and personalized experiences. ''At the same time, businesses are placing increased emphasis on maintaining brand consistency and ensuring that their W2P solutions integrate smoothly within

their broader digital ecosystems," adds David Graves, CEO, Aleyant.

This leads to an increased demand for plugins that assist with more automation and efficiencies as they pertain to W2P. "For example, chatbots, integrated shipping rates, and product tagging can assist in providing better customer service,

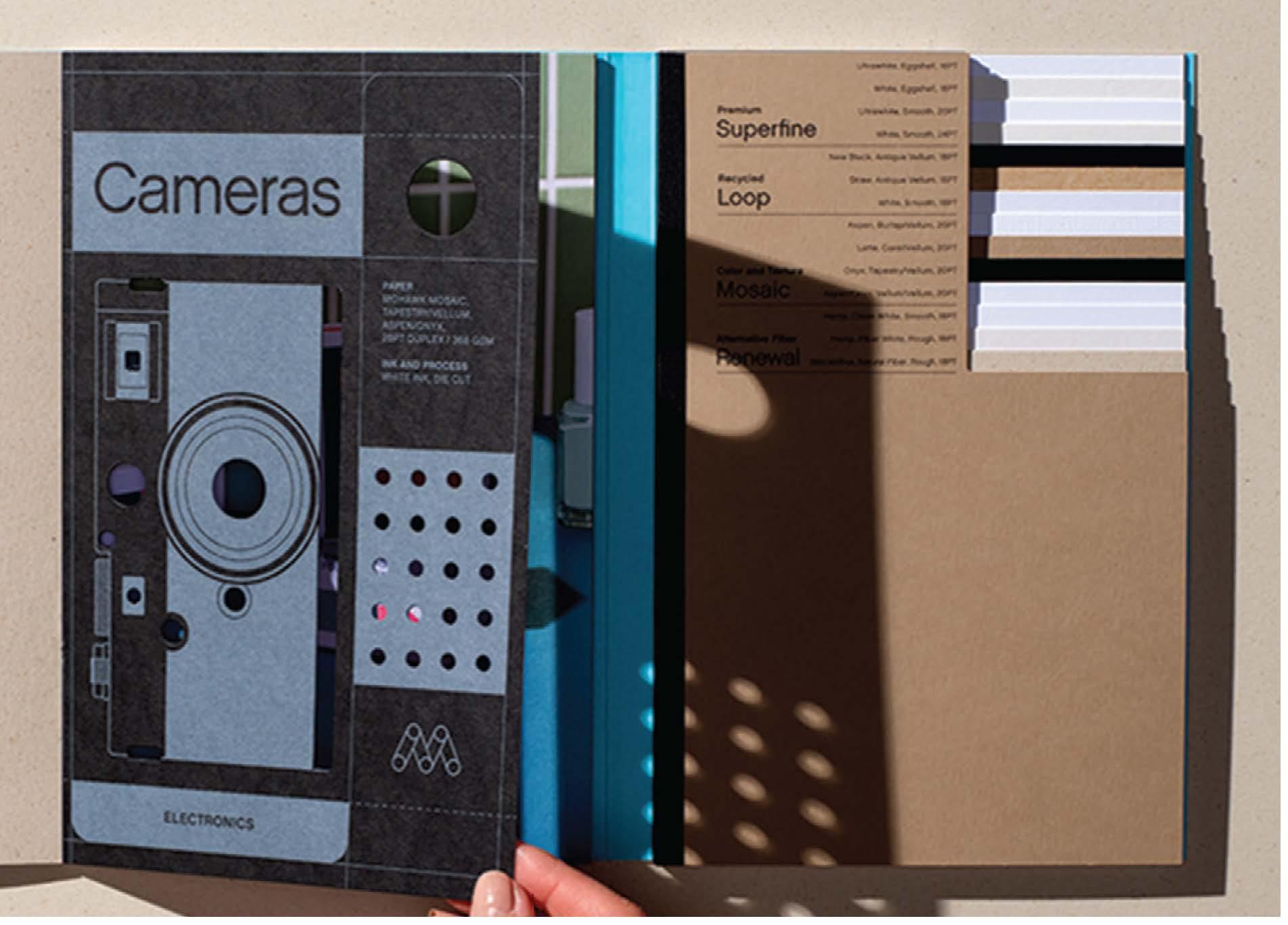

Above: Cloudlab's printQ printstoresoftware helps automateorderprocesses.

" .,

saving on shipping costs, and increasing sales through product recommendations and add-on products for orders placed," says Heather Willovit, principal consultant business consulting practice, Ricoh Advisory Service Group.

Naimish Patel, VP of sales, OnPrintShop, says printbusinesses aim to reach wider audiences and diversify sales channels as the rise of online shopping and personalized print products continues. Integration with ecommerce platforms like Shopify, WooCommerce, and marketplaces such as Etsy and Amazon have become essential. "These integrations allow printers to streamline operations, sync orders across channels, and meet customer expectations for convenience and speed."

Austin Wyman, marketing director, Propago, believes that print providers seek to embed ordering systems into broader ecommerce or marketplace ecosystems to enable interoperability across channels. "Clients want unified shopping experiences-orders from Shopify, corporate intranets, or marketplaces feeding into a printer's W2P portal. This increases visibility, simplifies procurement, and supports client digital transformation."

1. From the folding point to the price calculation, Cloudlab's packQ processes data down to the last detail. 2. Agfa's Apogee StoreFront and Asanti StoreFront enable PSPs to create stores in which customerscanorderavarietyofprintproducts.

As the market shifts towards online

"More businesses-both in B2B and B2C-see the value of product personalization. From custom chocolate bars to ordering in branded soap dispensers, end custom0.

print, customers increasingly expect the same seamless, self-service experience that they get from any other modem ecommerce platform. 'W2P has evolved far from being a perk for early adopters and is now fundamental to remaining competitive;' stresses Piet De Pauw, head of marketing and ecommerce, Enfocus.

Key drivers behind the demand for W2P integrations, specifically ecommerce, include mass customization, e-procurement print, and the need to stay online.

"Print buyers-whether business to business (B2B) or business to consumer (B2C)-expect frictionless digital ordering experiences that align with their preferred ecommerce ecosystems. Additionally, the rise of microbrands, influencers, and enterpriseclientsleveraging platforms like Shopify, Etsy, andAmazon force print providers to meet customers where they are. SeamlessW2P-to-ecommerce integration is no longer a luxury-it's table stakes for growth and competitiveness," says Reuben James, CEO, Web to Print Solutions.

Dmitry Sevostyanov, CEO, Customer's Canvas, states that ecommerce plugins have been gaining popularity for some time, especially among printers who may not have the internal development resources to build and maintain custom storefronts. "These plugins offer a quicker, more cost-effective path to launching online ordering workflows, making them an attractive alternative to building proprietary systems from scratch," he explains.

ers love to make products their own. It's a powerful business model that brings print back into the spotlight," shares Nico Olejniczak, CMO, CloudLab Web to Print Solutions.

Further, e-procurement print streamlined processes and solid workflows are essential for marketing and procurement departments looking to reduce costs. Olejniczak explains that this is not just large enterprises. Mid-sized companies with 200-plus employees also require solutions for marketing asset management. Whether it's managing marketing materials, placing optimized orders, using personalization templates, or handling campaign logistics-he sees CloudLab's closed shop customer base growing daily.

In fact, Olejniczak feels that print shops simply can't afford to stay offline. "Gone are the days when printers could thrive without an ecommerce strategy. While it's probably not viable for a ten-person print shop in rural TX to mimic a full-service model likeVistaprint, that doesn't mean that there is no online opportunity. Whether offering a closed marketing portal to lock in clients or a niche shop for promotional calendars, every print service provider in 2025 needs an online strategy. Our job is to help them make that digital transition successfully."

Marketplace integrations-while more recent and inherently more complex due to limited API accessandstricter platform policies-are also gaining attention. "The main appeal is clear access to a large, built-incustomerbase. Formanyprintproviders, the potential exposure and sales volume from joining platforms like Amazon or Etsyoutweighthe technical andoperationalchallenges," notes Sevostyanov.

Print providers should evaluate several factors when integrating with third-party

tools, including ecommerce and marketplace ecosystems. While specific considerations largely depend on a print provider's specific digital strategy, several points are worth noting.

De Pauw points out that capturing orders online is merely the first step when it comes to integrating ecommerce plugins for W2P. He says the main challenge is moving those orders through production without delays or costly errors. "That's why providers should prioritize both the front-end experience and the ability to tie directly into a fully automated workflow when evaluating ecommerce plugin integrations."

Inventory management, mobile responsiveness, and API flexibility are top considerations, according toWillovit.

Wyman suggests looking for plugins that keep products, pricing, and orders in sync across platforms; features that maintain brand standards; and plugins with strong reporting tools and clear API connections. These factors help streamline operations and customer experience.

"Real-time pricing andestimation tools are also crucial, giving customers instant, accurate quotes based on selected configurations, quantities, and materials;' suggests Sevostyanov, adding that the ecommerce plugin should also sync order data, customerinformation, andjob statuses automaticallybetween the storefront and the productionsystemtoreducemanualinput.

A user-friendly shopping experience should be a priority, along with customer-centric design; pricing and product configuration for print; personalization/ customization capabilities; seamless integration with existing systems and workflows; internal or third-party production coordination; reliable shipping processes with trackable delivery dates; modem payment options for smooth transactions; and cost control, are key considerations, according to Olejniczak. "This avoids too many vendors cutting into margins."

Security remains a key priority for any online integration, and linking W2P

Shopping Cut Items

8�1nessCuds a�r�Dumortffr �l�ry!Printcardsforrne

Yourownp�ter DSC02TU.pdf (1page,841x1,189mm)

Pric:uexdudetaxuandshippingco,ts(lfapp!ic.oble)

platforms with ecommerce plugins is no exception. "It is vital that print providers protect client data, transactions, and intellectual property-for example, by implementing invisible reCAPTCHA technology to protect against bots and other unwanted interactions;' shares Michael Dupre, head of software, Agfa Digital Printing Solutions.

Security features including SSL encryption, secure file uploads, and customer data protection are non-negotiable requirements, stresses Willovit.

Szabo-Melamedsays data securityand compliance is a growing concern, especiallywhenhandling personalizedcontent that involves customer data. "Print providers must ensure that any integration complies with data protection regulations like GDPR, and that secure protocols are in place for data transfer and storage:'

Automation is another area that should be treated as a priority. "Streamlining the flow of orders from ecommerce storefronts to the print production workflow could result in significantly higher order volumes. Integrating automation features like real-time order processing, automated imposition, and hands-off production tracking, ensures that these volumes can be managed efficiently. As a result, it becomes easy to minimize manual interventions, reduce errors, and accelerate turnaround times," notes Dupre.

"Ultimately, any integration should support automation, scalability, and a seamlessbuyerexperience," statesJames.

Plugins should also support multiple user roles and permissions, handle tax calculations for different jurisdictions, andprovide robustsearchand filtering capabilities to help customers find products quickly, notesWillovit.

Szabo-Melamed suggests printproviders take a strategic approach beyond simply connecting systems when integrating ecommerce plugins into a W2P system. "The goal should be to create a seamless, intelligent, and scalable workflow that supports both operational efficiency and a superior customer experience:'

When integrating ecommerce into your W2P, challenges will arise.

Ensuring that customer-submitted files are a fit for production is a challenge, admits De Pauw. PDFs uploaded by clients can often miss important specifications, contain incorrect color profiles, or feature font and image issues that may compromise the final output. "Failure to catch these problems early may lead to costly reworks and wasted time, resulting in frustration for providers and customers alike."

In Olejniczak's experience, several recurring challenges include lack of internal/external resources, inadequate market and audience analysis, a poorly defined technical roadmap, underdeveloped product/content strategy, subpar UI/UX design, and unrealistic or undefined marketing budget.

Keeping product information accurate across systems and ensuring a smooth user experience is also challenging. “This can be solved by using reliable integration tools and careful planning to align storefronts with backend workflows. Also, setting clear approval rules can help manage brand compliance, and centralizing order fulfillment simplifies operations,” says Wyman.

De Pauw adds that workflow fragmentation is a common challenge, as many print businesses rely on a patchwork of systems that do not communicate effectively, leading to significant bottlenecks and inefficiencies.

Disparate systems that do not integrate with each other, either due to

acquisition or by line of business, may lead to challenges agrees Willovit.

Many print providers operate with a mix of legacy systems and modern platforms, and getting them to communicate seamlessly can be difficult. “This is where having an open, API-driven architecture becomes essential. It allows for flexible integration with third-party tools, whether off-the-shelf or custom-built, reducing the friction between systems,” offers Szabo-Melamed.

In addition to technical issues, Dupre feels that attracting ecommerce customers to a new print storefront can represent a major challenge as simply integrating with a marketplace or ecommerce platform does not automatically bring in traffic or sales. “To address this, print

providers may need to develop targeted outreach and marketing campaigns specifically for users of those ecommerce platforms, highlighting the unique value propositions of their print offerings.”

Enhancing the customer experience with high-quality product previews is another effective way for print providers to capture interest. “Providing transparent order tracking, such as live updates on production status and shipping, helps to build trust and encourages repeat business. Additionally, partnering with the marketplace for featured listings or promotions can help boost initial visibility and traffic while building long-term brand recognition,” adds Dupre.

A common, high-level challenge Sevostyanov sees is a lack of proper planning and cross-functional coordination at the start of a W2P ecommerce integration project. “These initiatives often impact multiple parts of the business, from product strategy and customer experience to production workflows. Yet they’re sometimes approached as isolated IT projects. Without clear goals, risk assessment, and phased implementation plans, teams can quickly run into delays, scope creep, or misaligned expectations.”

Ongoing maintenance and support can be underestimated. “Plug-ins and platforms evolve, and updates can break integrations if not managed carefully. Providers should invest in proper documentation, version control, and testing environments to ensure long-term stability,” cautions Szabo-Melamed.

By anticipating these challenges and building with flexibility, security, and user experience in mind, print providers can create a robust and future-ready W2P ecosystem.

Business applications that rely on personalization at scale, repeat ordering,

3. Propago enables print

and multi-channel customer engagement benefit most from ecommerce integration at W2P.

“If the product can be personalized through templates or predefined options and the ordering process doesn’t require extensive manual involvement, it’s a strong candidate for ecommerce integration. These jobs often have tighter turnaround times and lower margins, so automation through W2P helps preserve profitability by reducing labor in quoting, file handling, and proofing,” says Sevostyanov.

De Pauw suggests that W2P is particularly valuable in sectors where speed, personalization, and volume intersect. “Commercial print, packaging, and labels; wide format and signage; photo products, and personalized print all stand to substantially benefit from ecommerce integration as they typically involve high volumes of short-run, customize jobs. This is precisely the type of work that thrives on automation.”

Corporate stationery portals, franchises, and retail networks often need branded materials for multiple employees across departments or regions.

“An integrated W2P system allows for self-service ordering, approval workflows, and dynamic personalization, all within a controlled, branded environment,” comments Szabo-Melamed.

De Pauw agrees, noting that a centralized, standardized portal connected to back-end automation not only ensures brand consistency across sites but also enables print providers to capture large order volumes while maintaining efficiency.

Finally, education, healthcare, and government sectors increasingly adopt integrated W2P to manage distributed print needs while maintaining data security and operational efficiency.

Dupre also suggests custom home décor products are ideally suited to ecommerce integration because their intuitive design process caters to a broad customer base. “Integration enables these

products to reach larger, pre-established audiences on popular ecommerce platforms, resulting in higher order volumes and smoother customer acquisition.”

Another ideal application is custom packaging for low-volume goods. “Here, integrating the print workflow enables sellers to trigger the production of tailored packaging at the point of sale. This just-in-time approach eliminates the need for advance inventory and reduces logistical overheads, facilitating cost reductions and optimizing logistics for the product seller,” adds Dupre.

While it’s traditionally a post-print segment, Olejniczak says packaging has grown consistently offline for decades and generates high revenue. “With a smart ecommerce strategy, businesses can tap into countless niches and capture untapped market share—even faster than in classic print.”

Promotional and apparel ordering, either in B2C cases or B2B applications is expected to gain from ecommerce integration with W2P.

Wyman suggests this includes event or fundraising storefronts integrated

into event sites or marketplaces and vendor-managed inventory tracking and replenishment—triggered via ecommerce and executed through the W2P back end.

Graves adds that syncing ecommerce data with marketing platforms allows providers to run targeted email campaigns based on purchase behavior, abandoned carts, or reordering patterns.

W2P platforms are increasingly crucial to modern print providers. Integrations with ecommerce platforms broaden their appeal to the masses while amplifying automation.

“A growing number of print providers are turning to marketplace plugins and robust ecommerce integrations to the W2P systems, ensuring that they can efficiently capture orders and adhere to changing customer expectations,” confirms De Pauw.

Learn more about the advantages and challenges of W2P integrations— specifically ecommerce—by watching our October webinar on the topic at dpsmagazine.com/webinars. dps

INFO#Company PageWebsite

1Canon U.S.A., Inc.2 canonproductionprint.com

16CloudLab 23web-to-printq.com

COMPANIES MENTIONED AD

3Duplo U.S.A. Corp.11duplousa.com

4Graphic Whizard17graphicwhizard.com

5Komori America15komori-america.us

6Muller Martini 5mullermartini.com

INFO#Company PageWebsite 7Nobelus 8nobelus.com 14Nobelus 26nobelus.com 2PressWise by Smartsoft27presswise.com 15PressWise by Smartsoft24presswise.com 8Rollem International10rollemusa.com 13 Shark Finishing Machinery 26sharkmachinery.com

INFO#Company PageWebsite 9Sharp Electronics Corp.7business.shapusa.com 10Signs365 28signs365.com 11Standard Finishing9 standardfinishing.com 12Stouse 13stouse.com