Vendors Bring Their Latest to PRINTING United

by Digital Output Sta

In a continuation of our September issue, additional vendors exhibiting at PRINTING United Expo in Orlando, FL later this month share their plans for the show. Visit the Orange County Convention Center from October 22 to 24, 2025 to see the following companies and much more!

3A Composites, booth 1221, invites attendees to experience the power of printing with the classics. From trusted favorites like FOME-COR and SINTRA to newcomers like POLAR, GP APEX, and SWEDBOARD FIBRE, 3A Composites’ range of products is uniquely crafted to deliver an unforgettable experience. When you choose 3A rigid substrates, you don’t just print—you print better. INFO#185

Advanced Greig Laminators, Inc. (AGL), booth 4263, showcases the AGL Compadre laminator. As an entrylevel, wide format graphics laminator, the Compadre combines features typically found in high-end models. It delivers high performance, efficiency, and an impressive return on investment. The Compadre features six-inch diameter silicone covered nip rolls that reduce print distortion and wrinkling, along with preset heat assist for smooth, high-quality output. INFO#186

Afford Inks, booth 2253, displays its ink portfolio. Examples include its latest ink technology designed to meet the most stringent regulatory requirements such as TPO-free inks and non-CMR inks. In addition to Afford’s line of inks for graphics applications, it presents customized inks for direct to film, direct to packaging, and direct to object digital printing. INFO#187

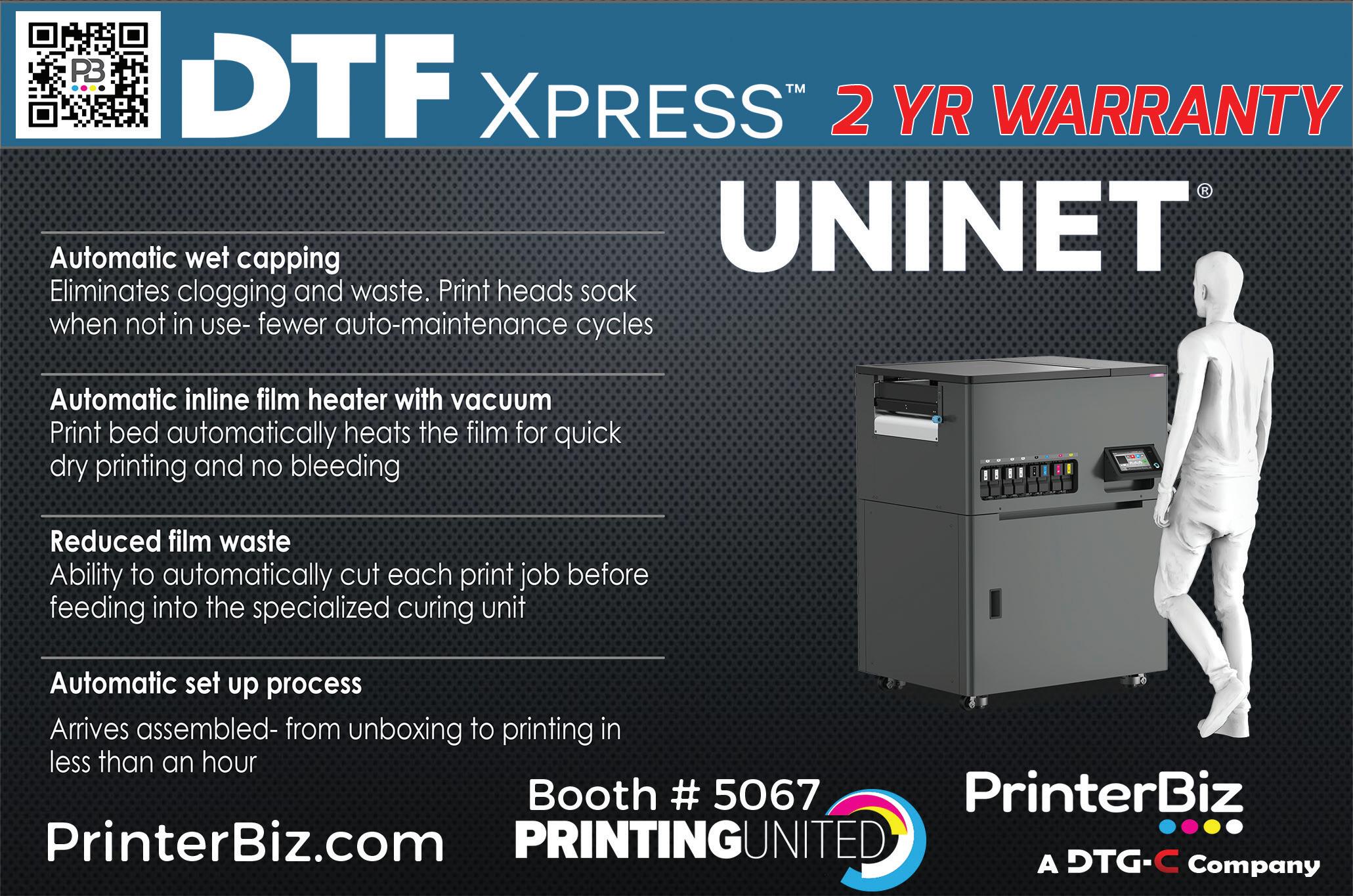

American Print and Supply, booth 686, demonstrates its line of direct to film (DTF) printers, from compact entrylevel models to high-volume production systems. The centerpiece is the Kraken, an eight printhead, 32-inch powerhouse printing more than 650 square feet per hour. With a dual rail magnetic drive for precision and speed, paired with an extended smart duster featuring dual ovens, it delivers unmatched workflow efficiency. INFO#188

Beaver Paper, a member of Koehler Paper, booth 1261, highlights two new products focused on industrial and high-volume environments—TexPrint XP 80gsm and TexPrint Sports+ 72gsm. TexPrint XP 80gsm expands its Extreme Performance line of sublimation papers with fast dry time and high-level vibrancy. TexPrint

1) Lintec of America, booth 2766, showcases its latest innovations in optically clear printable films. 2) General Formulations, booth 1521, partners with the Guy Harvey Foundation in its mission to conserve ocean eco-systems.

Sports+ 72gsm increases its thermal tack sublimation paper product family and offers ink savings and fast transfer times with high-tack adhesion. INFO#189

Caldera, booth 5039, shows PrimeCenter, a prepress solution that optimizes job preparation for digital printing and cutting. Automating repetitive tasks such as preflight, nesting, as well as adding cut marks and annotations guarantees less bottlenecks, significant time and media savings, and increased productivity. Optimize job preparation with Caldera PrimeCenter. INFO#190

Canon U.S.A., Inc., booth 2642, presents its diverse range of production and large format technologies, including the varioPRINT iX1700 sheetfed inkjet press and the Canon Colorado M5. Attendees can explore printers from the imagePRESS, Arizona, and imagePROGRAF product families, plus Canon’s PRISMA workflow solutions. INFO#191

Colex Finishing, Inc./Fotoba, booth 1525, exhibits the new Fotoba XLA320 Automatic X/Y Cutter featuring automatic vertical blade positioning, offering automation and allowing cutting of multiple sizes without operator intervention. The XLA320 handles flexible media up to 126 inches wide and 40-mil thick. INFO#192

DuPont Artistri, booth 4367, previews its powder-less direct to film (DTF) solution. Designed to work with Artistri P1600 inks and Artistri DTF-120 film, this eliminates the need for traditional TPU powder. Print providers and apparel decorators benefit from a simplified workflow, improved hand feel, and enhanced print quality. INFO#193

EngView Systems, booth 1929, presents the latest version of EngView Package & Display Designer. The software streamlines the design and production of boxes and point of purchase/sale displays. EngView’s integration with Adobe Illustrator enables graphic designers to easily apply artwork onto structural drawings and preview results in a realistic 3D environment. INFO#194

3) Quality Media and Laminating Solutions, booth 2486, displays the AppliKator 3000.

FASTSEWN, booth 848, is hosted by Cutworx. It demonstrates a fully operational capability for sewing and cutting, including feeding, sewing, and cutting of keder strips for use in silicone edge graphic frames, dual-sided pillowcase banners, and security gate covers. INFO#195

Fiery, booth 935, brings Print Genius solutions that take business to the next level. Stop by to see the latest Fiery technologies, from AIempowered workflow systems to cutting-edge variable data printing software to superpower all your digital printing needs. INFO#196

Fisher Textiles, booth 3676, highlights DD7703 Lined Flag, with a built-in liner for vivid doublesided flags; and DD1001 Impression Backlit, delivering premium depth and color for illuminated silicone edge graphics displays. New eco-friendly options made from post-consumer recycled bottles include ET9608 Power Stretch and ET9848 EZ Stretch Premium, with excellent stretch and print performance; and ET9860 Silver Back and ET9118 White-Out with built-in liners to streamline production. INFO#197

General Formulations, booth 1521, partners with the Guy Harvey Foundation in support of its mission to conserve ocean eco-systems. Alongside showcasing this vibrant collaboration, GF donates and helps raise funds for the foundation while showcasing its new line of Economy Solutions made in the U.S, including GF 160 and GF 162 gloss and matte clear vinyl laminates that are now printable. INFO#198

Jessup Manufacturing, booth 1885, invites attendees to explore TenaciousTac, its high-tack adhesive film designed to perform when nothing else sticks—perfect for challenging surfaces and demanding applications. Also on display is Print n’ Go, a versatile graphics media that combines easy handling with outstanding print quality. INFO#199

Leister Technologies, booth 2412, showcases the VARIANT 700 automatic welder, designed to maximize efficiency and quality in banner, tarpaulin, and wide format graphic production. Engineered for high-speed overlap welding, the VARIANT 700 combines precision control with

rugged durability, helping fabricators meet tight deadlines without sacrificing quality. INFO#200

Lintec of America, booth 2766, displays its latest innovations in optically clear printable films. Headlining the display are the ECO-2100 ZC and ECO-2104 ZC, both produced from 100 percent recycled polyester content. These environmentally friendly films deliver exceptional optical clarity and are fully compatible with UV printing, offering sustainability without compromise on quality. INFO#201

Mactac, booth 2438, presents the Gruv print media product line, including Gruv 7 Air Egress cast

media and Gruv 4 and 5 Air Egress vinyl media. It introduces the new Gruv Slideable, which excels in conformability, printability, adhesion, removability, appearance, and durability. INFO#202

Mimaki USA, booths 1555 and 1255, exhibits a range of printing and cutting solutions prioritizing high image quality, productivity, ease of use, and value. The new TS200-1600 64-inch dye-sublimation printer is shown for the first time. The TS200-1600 offers expanded gamut output with orange, violet, and fluorescent pink and yellow inks. The JFX6002513 UV LED flatbed printer is paired with the high-speed CFX-2513 flatbed cutter for a full

end-to-end packaging solution. Attendees also can get hands on with the UJV300DTF-75 UV-DTF System. INFO#203

Mutoh America, Inc., booth 1516, invites attendees to experience the future of printing with its latest innovations and full line of printers, from the compact and powerful XpertJet C641SR Pro 24-inch eco-solvent printer/ cutter to the ValueJet 1638UH Mark II 64-inch UV LED hybrid printer. INFO#204

Nazdar SourceOne, booth 1561, offers a portfolio of wide format equipment and ink. The company has you covered from roll to roll, true flatbed, and hybrid models in

various production classes to fit your business needs. EFI Pro 16h+ and 30f+ printers lead the way in hybrid and flatbed printing, delivering exceptional quality, speed, and versatility. INFO#205

Onyx Graphics Inc., booth 3033, demonstrates the latest version

of its flagship RIP software, ONYX 25, and powerful print shop management and quoting solution, ONYX Align. Don’t miss out on exclusive show discounts available on select products. INFO#206

Photo Tex Group, booth 3771, shows its third generation

Quality

opaque/blockout selfadhesive polyester fabric, designed to handle today’s paints. It also demonstrates its version of the same material in non-opaque form for outdoor windows. If you have UV inks, Photo Tex offers a new certified high-tack version for smooth floors as well as tight-weave carpets. INFO#207

Media and Laminating

Solutions, booth 2486, displays a full range of finishing solutions and media innovations. Highlights include the GinkoLam, the KALA Mistral 1650, and the AppliKator 3000. Visitors also see a variety of exciting and fresh digital print media, such as Berger Textiles’ latest fabrics, Continental Graphix’s Two Way Vision Film, and the new Brava Wallcovering brand. INFO#208

Roland DGA, booth 1536, showcases TrueVIS large format eco-solvent inkjets—the XP-640 printer and XG-640 printer/cutter. VersaOBJECT MO Series benchtop UV flatbed printers are also front and center, along with the advanced VersaOBJECT CO-640i-F3 large format UV flatbed. In addition, show-goers can check out the new DIMENSE DA-640 dimensional surface printer. INFO#209

SAi, booth 4849, brings its Flexi software to life with a bold, application-focused booth experience. Flexi simplifies the jobs you

do every day. Stop by for live demonstrations, get hands-on with the software, and explore how Flexi fits into your workflow, whether you’re wrapping a car or running a print-and-cut job. INFO#210

Splash of Color, booth 5255, invites attendees to experience its latest finishing solutions. It demonstrates the KalaXY PRO Automatic XY Cutter, delivering precise sheeted output from printed rolls with edge tracking and easy workflow integration. The ExpressCutPRO flatbed cutter is also on display. Rounding out the lineup is the NEPATA Rewinder/ Slitter. INFO#211

StratoJet, booth 1551, launches its true print hybrid technology— Jaguar. StratoJet is improving the efficiency and growth of print service providers with its new hybrid print technology along with builtin upgradability. Throughout the show it offers live demonstrations of the Jaguar—printing numerous applications and showcasing its simplistic workflow. INFO#212

Summa, booth 4336, exhibits the Summa F1625, a powerful 5x8foot flatbed cutter built for sign and display professionals. The F1625 tackles everything from vinyl and foam board to PVC, ACM, and corrugated media with unmatched precision and speed. With intelligent features like tandem workflow, automatic tool recognition, and a dedicated operator zone, the F1625 is the ultimate business accelerator. INFO#213

swissQprint America, booth 2870, demonstrates the Kudu UV LED flatbed printer, delivering

4) Colex Finishing, Inc./Fotoba, booth 1525, exhibits the new Fotoba XLA320 Automatic X/Y Cutter featuring automatic vertical blade positioning.

unmatched precision, productivity, and quality. See the Karibu 2 rollto-roll printer in action, designed for ultimate flexibility and reliability. Explore swissQprint application worlds, showcasing innovative, high-value print solutions that can open new revenue opportunities for your business. INFO#214

Trotec Laser, booth 2855, unveils its new Vision Design & Position (VDP) camera lids for the Speedy 100 and Speedy 300 laser systems. These integrated lid cameras provide a live view of the work area, making it easier than ever to align jobs with speed and accuracy. With the VDP option, users

can quickly position artwork on irregularly shaped pieces or pre-cut items. INFO#215

TVF, booth 1258, presents its newest blockout print media fabric, PureNight Pro, a 100 percent recycled polyester blackback alternative. Designed for sustainability and engineered without a polyurethane coating for direct or transfer printing with dye-sublimation inks, PureNight Pro 8668SDWGFS is engineered by G+O Friedrich in Germany. INFO#216

Ultraflex, booth 2876, proves that print materials are anything but routine. They can be bold,

personalized, and downright fun, and its booth is an arcade of possibilities. Explore interactive displays of soft signage made with recycled yarns, a breakthrough PE material designed for small and large print applications, optical illusion flooring, bold wallcovering displays, and a variety of substrates to bring creative visions to life. INFO#217

Zünd America, booth 2021, showcases a Zünd G3 3XL-1600 digital cutting system with high-precision UNDERCAM technology for retrieving job files and registering printed materials from below. The combination with newly available,

fully integrated board handling automation, including IMC’s Vector Feeder and Stacker, is a highly efficient, fully automated setup that delivers outstanding productivity with minimal space requirements. Also on display is a compact yet versatile Zünd S3 L-1600 system with an OCC Over-Cutter Camera, designed for print providers looking for an affordable cutting solution capable of reducing cost of operation while delivering performance. INFO#218

Digital Output plans to be on the show floor and report on the newest technologies. For relevant coverage visit digitaloutput.net. D

Floor Graphics Spotlight C2 Imaging

by Melissa Donovan

When you have the talent but lack the bandwidth to reach a broader customer base, joining forces with a larger organization is a great option.

In 2010, print service provider C2 Imaging became a member of the The Vomela Companies, adding a specialized focus in small format and digital print to the already impressive company.

“Throughout its 75-plus history, The Vomela Companies has grown and diversified its services through an everexpanding North American network that now includes more than 21 locations and over 1.1 million square feet of production,” notes Teri Mascotti, senior director of marketing, The Vomela Companies.

With over 20 locations, the group expands its expertise across an array of services including point of purchase and promotional,

exhibits and events, consumables and collateral, as well as retail décor and branding.

Floor Graphics

One of the products the C2 Imaging team leads the way in is floor graphics. The application has always been part of its offerings and suggested to customers for various uses.

With our work in retail and events, we would consult and recommend brand extension by way of fl oor applications.

— Teri Mascotti, senior director of marketing, The Vomela Companies

“With our work in retail and events, we would consult and recommend brand extension by way of floor applications. During the pandemic, the use of floor graphics expanded to accommodate distancing and wayfinding,” explains Mascotti. It regularly works with media from Jessup Manufacturing Co. One popular choice is SportWalk. SportWalk is a white textured, printable media. It

is a one-step solution for indoor and outdoor event graphics, best used on smooth concrete surfaces such as roads and sidewalks. It adheres to a variety of smooth surfaces, is safe for pedestrian traffic, and maintains its non-slip properties when wet. It is ideal for marathons, parades, retail point of purchase, trade shows, sporting, and other short-term outdoor events. SportWalk is ASTM D-2047 certified and UL410 certified for slip resistance.

Mascotti notes that Jessup SportWalk’s strengths are that it ensures a clean result—especially in high-pressure scenarios where there is zero room for error like weekend or overnight installs.

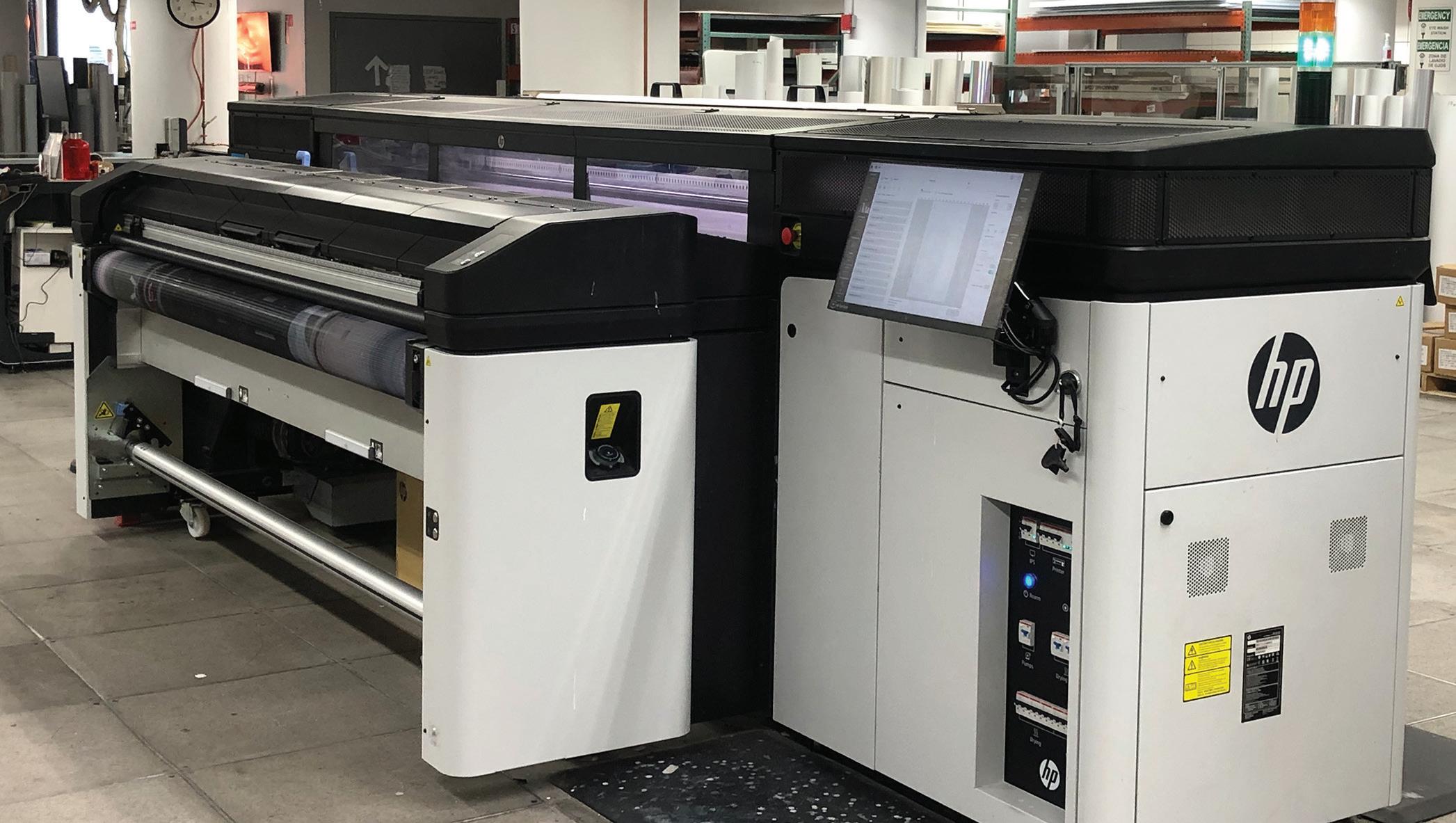

HP Inc. printers are a common choice when printing to Jessup’s materials. One device that handles a lot of this type of work for C2 Imaging is the 98-inch HP Latex R2000 Plus Printer, with an Onyx Graphics, Inc. Onyx Thrive RIP powering the production. A Zund America, Inc. cutter is used to finish the floor graphics to the exact shape and size required by the customer.

Connected Network

C2 Imaging has completed floor graphics for a number of customers that are used indoors

and outdoors; retail environments, zoos, pop-up events, and conference halls—any place where a messaging opportunity is prevalent.

Connections made within the greater The Vomela Companies network empowers its success. D

See page 19 for more info.

Flexible Magnetic Materials

Newlife Magnetics is the world’s largest manufacturer of flexible magnetic materials. Our company’s focus on science and engineering has led to our success in leading the magnet industry through research and development of exciting new products that solve customer problems, increase efficiency, and improve our customers’ lives without harming our environment. We offer a wide variety of products, but we are known for our printable magnet media up to 60 inches wide. Our flexible magnetic print media is a great way to display any graphic in a store, classroom, or car. The magnet application is easy and reusable. Learn more at newlifemagnetics.com. INFO#20

Automate DTF Cutting

Engineered and manufactured by Saga, the ExpressCutPRO reduces labor and increases profits by eliminating the time-consuming task of manually cutting direct to film (DTF) or UV DTF transfers. Featuring an integrated conveyor belt and quick response code workflow, it allows for a fully unattended workflow experience. Increase your output while reducing operation costs with ExpressCutPRO DTF Cutters. Simplify your cutting operation today with ExpressCutPRO. For more information visit supply55.com, call 734-668-0755, or email sales@supply55.com. INFO#21

Stand Out in the Industry

Featuring a table size of 55x27 inches, the XpertJet 1462UF allows for increased production capacity and profitability, enabling users to print on objects up to 5.91 inches thick. Whether you’re looking to enhance your existing UV printer or venture into new areas such as ADA compliant braille, awards, packaging, signage, or home décor, the XpertJet 1462UF UV LED printer is the ideal solution. Enhance your printing capabilities with the award-winning MUTOH VerteLith RIP Software and a complimentary one year subscription to SAi Flexi DESIGN MUTOH Edition. Visit mutoh.com. INFO#19

NEWLIFE MAGNETICS, LLC

SUPPLY55, INC.

MUTOH AMERICA, INC. 3

by Digital Output Staff

co-friendly rigid media is a popular choice for sign applications where environmental initiatives are a focus, but they are also gaining traction as a viable option due to their appearance, durability, and print quality. Demand has evolved considerably over the years as hardware manufacturers adapt their

devices to work with nuances like warping, bowing, and curling; lower surface energy levels; and thicker materials. Print service providers (PSPs) are far more aware of what to expect when it comes to printing to ecofriendly rigid materials, whether they be recyclable, compostable/biodegradable, or made from recycled content.

Defining It

The term eco-friendly rigid media is broad. Depending on the vendor the definition varies. Most include recyclability, whether the material is made from recycled product or can be recycled after use.

Above) 3A Composites’ SWEDBOARD FIBRE utilized for unique furniture displays in a trade show booth.

“Eco-friendly rigid media refers to solid, printable substrates made from renewable, recyclable, or repulpable materials, designed to minimize environmental impact across their lifecycle. These materials are often used in place of traditional rigid substrates like PVC, MDF, or foam board,” explains Rowan Maher, CMO, Xanita.

We should look at the term ecofriendly media holistically, says Chuck Kunze, director product management and marketing, 3A Composites USA. This means “considering not only the lifecycle of the finished product, but the materials and processes used during the manufacturing of the product.”

Similarly, Fluid Color defines ecofriendly media as any rigid substrate that reduces environmental impact throughout its lifecycle, from raw material extraction to post-use disposal. “These materials are engineered to meet both print performance and environmental compliance standards,” notes Adam Tourville, channel manager, Fluid Color.

Xanita classifies eco-friendly rigid media as sustainable, fiberbased boards or engineered paper boards—depending on the structure and composition. This includes “low environmental footprint, often made from postconsumer recycled content and/or

responsibly sourced virgin fibers. No harmful additives, such as volatile organic compounds (VOCs), formaldehyde, or synthetic plastics are involved,” adds Maher.

“Eco-friendly rigid media is any rigid substrate made from natural fibers and designed with environmental responsibility in mind. This includes rigid substrates made from materials that are natural, recycled, and recyclable, such as paper, cardboard, bamboo, and wood,” shares David Bistrovic, product manager, Professional Imaging, Epson America, Inc.

Recyclability is a primary consideration when discussing

eco-friendly rigid media. “A key characteristic of eco-friendly rigid media is recyclability or repulpability, allowing the material to reenter the paper or fiber recovery stream after use,” asserts Maher.

Supplier sourcing is also part of the “green” equation. For example, 3A Composites prioritizes sourcing from suppliers with a Forest Management Certification as well as those that participate in sustainable forestry practices.

Printing to Rigid Media

Depending on the type of material there are considerations to take into account during the printing process.

“Each substrate has its own surface energy, porosity, and structural integrity, which directly impacts how ink behaves during application and curing. At Fluid Color, we emphasize the importance of understanding the nature of the media before running a job,” asserts Tourville.

Paper-board based rigid media is sensitive to temperature fluctuations. “We recommend letting the panels acclimate prior to printing for at least 24 hours, which should be done in the same room conditions as where the printing takes place,” recommends Kunze.

Another way to anticipate change in paper board is to store it in a flat, dry, indoor area with regulated temperature and humidity.

“This ensures that the boards are

as flat and stable as possible during the printing process to avoid costly printhead strikes or ink misplacement, achieving the clearest, most vibrant print possible,” suggests Kunze.

“If any bowing occurs, flatten them before printing. An uneven surface can lead to ink misting, blurred lines, or even nozzle damage,” adds Maher.

Compared to paper boards, recyclable foam board materials are less sensitive to changes in temperature, notes Kunze, which leads to minimal acclimatization prior to printing.

Due to the nature of fiber-based media, Tourville notes it can shed particulate matter during handling and printing. This means that a

printer’s vacuum table and print carriage be meticulously cleaned.

Static can be an issue in regards to recycled plastics. “Static control can greatly affect the quality of the print. Using an ionization control system helps to mitigate static thus giving a higher quality,” recommends Mark Crawford, product and business development manager, Vanguard Digital Printing Systems, a Durst Group company.

Bioplastics derived from renewable resources present surface energy challenges. Tourville says a dyne pen is helpful to determine the surface energy. “If the surface energy is under 40 dynes the substrate will have poor adhesion. An adhesion promotor or flame treatment helps increase the surface energy and provide better adhesion. In my experience, some bioplastics also have a film on them that do not allow the ink to adhere properly. Cleaning with an IPA is very important,” suggests Tourville.

“Eco-friendly materials like corrugated board, fiberboard, or recycled plastics can often have differing dyne levels. This can lead to issues like chipping, poor color, or reduced durability unless primers or adhesion promoters are used,” adds Crawford.

Another caveat to be aware of is the porous nature of certain ecofriendly rigid board. “I recommend

always testing the media prior to printing the job to ensure proper ink adhesion. Some eco-friendly materials, such as cardboards, are more porous, requiring adjustments to the ink lay down or curing settings to achieve the best results,” advises Bistrovic.

Ink Sets

Common ink sets used in rigid board printing include UV and latex. When it comes to eco-friendly rigid boards, there are pros and cons to working with each.

UV inks offer several advantages. “Excellent adhesion to uncoated liners, fast curing, and vibrant color reproduction, making them suitable for structural or decorative applications,” lists Maher.

Tourville says “one primary advantage of UV LED inks is their ability to cure instantly at low temperatures, making them safe for use on substrates that might otherwise deform or discolor under traditional curing systems. Another critical benefit is the absence of VOCs, which support environmentally responsible printing practices.”

Disadvantages of using UV ink vary by ink set and how they behave on each eco-friendly rigid material. “For example, porous media may require adjustments in ink density and curing parameters to achieve optimal color

fidelity and durability. Additionally, gloss levels may appear more subdued compared to high-density PVC substrates, and the color vibrancy may need fine tuning,” warns Tourville.

And remember adhesion. “Adhesion can sometimes be a challenge on low surface energy materials like recycled polypropylene unless primers or surface treatments are used,” notes Crawford.

Maher says some UV ink sets can become brittle when bent, so a flexible option is recommended for foldable or structural pieces.

“A semi-flexible ink set that is designed to adhere to both rigid and flexible materials can withstand slight bending or handling without cracking or flaking, increasing media and substrate versatility for print shops,” recommends Bistrovic.

Water-based latex inks feature low VOCs, which make for an excellent pairing with already green material. “They also offer flexibility, strong color output, and minimal odor,” states Maher.

There are limitations when working with latex ink, however, with drying being the biggest issue. “Latex printers typically use heatassisted drying, so care must be taken not to overheat or warp lightweight boards. Boards should be flat, and drying temperatures may need adjustment depending on thickness,” advises Maher.

Run Smooth

Flatbed printers need to take a few things into account when

#8

#7

printing to ecofriendly counterparts.

Maximum print height and vacuum system hold down are two important considerations.

Many of these boards are lighter in weight, this requires a vacuum hold down across the bed that is strong to keep the board flat. “Many sustainable boards—such as corrugated, fiber based, or wood composite panels—are more prone to warping or bowing.

1)

This makes a strong, responsive vacuum hold down system critical,” notes Crawford.

In this instance, it is ideal that the flatbed printer features zoned vacuum control, “allowing the print provider to activate specific quadrants to match the media size and thickness. This ensures proper media loading and prevents printhead strikes, improving overall image quality,” states Bistrovic.

Maher suggests “adjusting vacuum zones to match the sheet size

and position, and making sure the vacuum strength is high enough to pull the board flush to the print bed for optimal print quality and printhead clearance.”

Printhead height is another concern. “Eco-friendly boards can vary in thickness—often six to 16 millimeters, so the printhead carriage must be adjusted accordingly. Setting the correct gap between the printhead and media helps maintain print quality while preventing printhead strikes— especially if the board has slight bowing,” recommends Maher.

“Having a UV flatbed printer with an adjustable print height is critical to achieving a highquality print. Eco-friendly rigid substrates vary in thickness, so the printer must be able to

accommodate these differences with precise height adjustments,” seconds Bistrovic.

The carriage mechanism is also a consideration. It must be able to traverse the media smoothly and accurately, explains Tourville. Servo-driven systems help ensure dot placement, even when boards are perfectly flat.

A flatbed printer that features white ink is important. “White ink creates vibrant prints on non-white rigid substrates, such as wood. For any colored or natural toned eco-friendly rigid substrates, printing a solid white base layer first then layering the colored image on top is best, to ensure the print is vibrant and eye catching,” recommends Bistrovic.

Taking Advantage

Today’s flatbed printers are equipped with tools that yield a successful print to eco-friendly rigid board. While these materials offer challenges like warping or curling and low surface energy, features like zoned vacuum systems and printhead height detection combat—if not eliminate— them from occurring.

“Advances in printhead technology and substrate mapping have made it possible to achieve outstanding print quality on these alternative materials,” explains Tourville.

In this way, PSPs regard ecofriendly rigid board in a positive light, and enjoy not only the sustainability benefits but also leverage the natural, smooth appearance to portray a high-end aesthetic. D

Xanita Board is a high-performance board that is ultra-lightweight, fully repulpable, and strong enough for structural use.

1

by Melissa Donovan

lass decoration for display and point of purchase (POP) is one of the first things a consumer sees, whether outside of a shopping mall or directly on the windows of a retail store, restaurant, or commercial building. There are a number of media solutions for print service providers

(PSPs) with customers requesting POP displays that catch passerby’s eyes.

One option is printable dichroic film, which changes light and creates an eyecatching effect. This particularly standout material is ideal for display and POP for a number of reasons. “In a visually crowded world, eye-catching films—like

dichroic etched glass effect materials— create instant intrigue through light, color, and reflection,” explains René Bourgeois, VP Sales North America – ASLAN brand, ASLAN Selbstklebefolien GmbH.

Above) General Formulations’ GF 790AE Print-N-Privacy features a refined etched glass finish and is compatible with eco-solvent, UV, and latex printers, making it versatile across multiple platforms.

Other media substrates are trending when it comes to display and POP in windows. “Every storefront window offers the opportunity to communicate a message, brand, or call to action to passersby and there is a myriad of solutions that achieve those goals,” shares Michelle Kempf, VP, sales and marketing, Continental Grafix USA, Inc.

Clear and frosted printable films, dry apply materials, perforated one-way vision, and optically clear products are also used.

Catching Passerby

Retail, restaurant, and commercial spaces turn to glass structures to promote sales, advertise services, and much more. Windows are prime real estate and provide endless opportunity.

“Window media feels as timeless as a swinging sign on the general store porch or hand painted lettering across the glass of a local bakery or hardware store,” states Jay Kroll, director of product education, General Formulations.

The difference is, while window graphics still take advantage of the prime real estate and timeless branding space, window media is advanced—with more sophistication than just a paint and brush, continues Kroll. “Window media has advanced to printable films with adhesive technology and decorative finishes to offer a versatile range of options for PSPs.”

“Trends like experience-driven retail and fast-changing campaigns demand flexible, high-impact solutions. Window films allow quick updates without major

#15

#17

renovations and help brands stay visually relevant. Storefronts are a brand’s first impression. Using them creatively is essential—not optional,” says Bourgeois.

Windows are a great way to capitalize on some of the trends seen in pop-up shops and even pop-up restaurants. “If you look at how the industry has evolved, windows have become one of the fastest, most effective ways to broadcast a new promotion, seasonal change, or brand message. The push for retail pop-up shops and restaurants has further pushed windows as premier marketing spaces. These are shops and cafés that take advantage of short-term existence then move out. You might call it ‘experience-first’ retail, but at the end of the day, if you aren’t using your window to tell your

story, you’re missing out on one of the simplest, most direct ways to connect with your audience,” advises Dan Lawellin, business development manager - global, Kernow North America Inc.

Printable Dichroic Film

A number of materials are used to decorate glass. As previously mentioned, one option is printable dichroic film, which comes in finishes like etched, frosted, and translucent variations.

“Printable dichroic films are eye catching and especially effective in high-contrast spaces like glass doors, entryways, and product displays,” says Kroll.

Etched versions, according to Bourgeois, instantly grab passerbys’ attention with “shifting colors and

an etched glass look. It adds depth and movement to glass surfaces, creating a premium, modern feel.”

Clear options of dichroic films are also possible, which Bourgeois says still “deliver striking dichroic effects without an etched finish, offering even more creative flexibility for designers.”

In recent years printable dichroic film has evolved, with media advancements making it more user friendly to print to and install.

“Recent advancements offer more stable base films and print-friendly coatings, allowing compatibility with latex, UV, and eco-solvent systems. Enhanced liner and adhesive systems also reduce static, improve handling, and make alignment on glass surfaces much easier,” shares Kroll.

Other Trending Materials

Other media options for windows include clear and frosted printable window films, dry apply materials, perforated one-way vision, and optically clear products.

“The range of options continues to grow—clear, dusted, frosted. All less expensive options for the print-for-pay providers and the end client,” says Angel Georgiou, product marketing specialist, senior, Canon U.S.A., Inc.

According to Kroll, “each offers a unique combination of privacy, vibrancy, and light control, depending on the application.” In many of these options, Kroll notes advancements in ink adhesion, improvements in lay flat liners, and refinements of the adhesive

systems, which allow for ease of repositioning in install without sacrificing clarity to edge stability.

“Printable films have come a long way from static cling and adhesivebased solutions that many people think of. The newest innovations allow for fast and easy installation by both professionals and DIYers alike. In other words, the headache factor has been dramatically reduced. Whether you’re installing a huge graphic for a chain retailer or a single decal for a small café, modern films are built for quick turns and everyday use,” adds Lawellin.

Amanda Smith, marketing communications manager, graphic and signage solutions, Mactac, says overall user friendliness has significantly been enhanced, providing improved outcomes in both printing and installation.

Clear and Frosted

Clear printable window films now offer more in terms of design with the advanced capabilities of white ink.

“Printers with white ink now have the option to print on clear media, replicating these looks for another customization option,” shares John Coyne, sales manager, Lintec of America, Inc.

Frosted printable window films serve a dual purpose—decoration and privacy. Coyne notes that these are available as either cast vinyl or polyester films and mimic etched or sandblasted glass.

Dry Apply

Dry apply materials are favorable because the install process

eliminates water. “No water, dry apply films offer removable and repositionable adhesives with micro-grooved/air egress releaser liners that evacuate air without fluid,” explains Coyne.

Without water, dry apply “reduces mess and speeds up the process without requiring changes over time,” adds Bourgeois.

“Air egress liner technology has evolved to make install easier because it gives a channel for air bubbles to escape and negates the need for a wet install, which is the traditional method for clear window films,” adds Kempf.

Focus on dry apply air egress systems is also a goal of Kernow’s. “Traditionally installs would need a wet application to get a truly bubble-free install. With our new air egress options, decorative films can go up and be smoothed out with the back of a hand, resulting in flawless results,” explains Lawellin.

Perforated

Perforated window film continues to be popular, “as it allows those inside a building to see out while people outside see a solid, vibrant graphic,” says Shaun Jaycox, product manager, Brand Management Group.

“Perforated window films allow for bold, full coverage graphics from the outside while maintaining a clear view line of site from inside,” notes Kempf.

Optically Clear

Optically clear printable film is a solid consideration, especially polyester-based options.

#9

“Optically clear allows printed graphics to appear as if they are printed directly on the glass while maintaining full transparency on unprinted areas,” notes Jaycox.

When properly designed and installed, viewers can’t tell if the graphic is an original part of the glass or a separate material. “Logos, patterns, or graphics look like they’re floating with no visible film around them,” shares Lawellin.

PSPs ahead of the curve use optically clear media to replicate oneway vision film. “Printers reverse printing lines instead of perforations. This allows for complete customization of the outside print image and the see-through visibility range. The see-through

visibility can be easily adjusted on the same optically clear media and even on the same image,” explains Coyne.

It’s also a good substitute for traditional cut vinyl. “Optically clear PET window film is a great replacement for more traditional cut vinyl that allows for intricate spot graphics with easy installation and removal,” suggests Kempf.

Even More

Another innovation is two-way vision film, available from Continental Grafix, which is preferred for day-to-night viewing. “Unlike optically clear options, panoRama

TwoWay Vision prints like a standard front lit film and doesn’t require white ink so it integrates

into the production process of almost any printer,” says Kempf.

PSPs look for a perfect balance of quality and cost effectiveness for many POP displays, notes Heather A. Strong, marketing communications manager, FDC Graphic Films, Inc. Lumina by FDC 7204 Print Media: Promotional is one such option. “Its glossy white finish is bright and visually appealing, while its clear, permanent acrylic adhesive makes graphics adhere well to the surface for a short-term promotional period,” notes Strong.

Holographic films are another alternative. ASLAN Holographic ASLAN SE 72 and HoloStripe ASLAN SE 74 bring vibrant, eyecatching effects to glass, which Bourgeois suggests as ideal for bold, modern brand expressions.

Environmental Focus

Print providers and their customers look to media vendors

to address environmental claims. Using “green” materials can help in building processes, for example in achieving LEED credits. This is becoming more common.

“The wide format film market is shifting from PVC to recyclable PET, lower volatile organic compound adhesives, and sustainably sourced polymers tailored for greener POP and display graphics. This shift is expected to expand as environment factors become increasingly more important to suppliers, printers, and end users,” explains Coyne.

For example, polyester or PET film is replacing PVC due to better optical clarity, environment friendliness, and clean removability, suggests Coyne.

“More brands are asking for greener choices, and now there are polypropylene and polyesterbased films that are both high performing and more eco-friendly,” agrees Lawellin.

Storytelling Surfaces

“Retailers and commercial spaces use window media more than ever because windows have become valuable storytelling surfaces,” admits Bourgeois.

In response, media manufacturers up the game in terms of options by offering printable dichroic, clear and frosted printable window films, dry apply materials, perforated one-way vision, optically clear products, and more.

Learn more about window media in a recent webinar posted on digitaloutput.net. D

V and UV LED curing is utilized to liquid coat printed graphics. The technology brings several benefits to the wide format print space, including the ability to efficiently and quickly protect digitally printed output.

Applications that require less expensive UV protection compared to traditional laminates are ideal for

UV LED cured coatings, notes Nick Howe, GM, Advanced Greig Laminators, Inc. (AGL).

“These coatings provide robust resistance against abrasion, chemicals, UV rays, and graffiti, with proven durability through rigorous testing,” shares Syd Northup, VP of sales, digital U.S., Marabu North America.

In addition to protection, Hayes Holzhauer, partner - SheerKote

by Cassandra Balentine

equipment line, AGL, acknowledges that these clear coatings provide desired finishes like gloss or matte to a printed graphic.

“If I am being honest, I am shocked that there is not more of this technology in print shops and manufacturers across the nation. It can increase productivity and is easy to integrate in print environments while maintaining a low-cost price point for laminating,” comments Northup.

Comparative Benefits

When compared to other finishing techniques, UV coating provides cost savings, energy efficiency, and throughput speeds. “Cost savings bring the cost per square foot for traditional cast laminates from around $0.50 to $0.60 per square foot to $0.05 per square foot,” says Howe.

“When compared to laminate products the cost is significantly lower,” agrees Holzhauer.

Another benefit of LED-based UV curing, the energy efficiency of UV LED lowers the power usage around 90 percent from traditional UV mercury lamps and the lamp lifetime increases from around 1,000 to 30,000 hours.

“The throughput speeds are capable of reaching 50 feet per minute (fpm), which is as fast—if not faster—than current competitors in the marketplace,” explains Howe.

“UV LED is the future in liquid coating as it requires 90 percent less energy, operates at a much lower temperature, provides instant on/off of the UV lamp, and does not require costly ventilation,” states Holzhauer.

Howe anticipates that UV liquid coatings will be the future of the fleet graphics industry given the cost savings. It also minimizes sacrificing throughput speeds and quality.

Northup admits that water-based coating applications can cure quickly via infrared on Marabu’s StarLam liquid laminator. “But it does take 24 hours to fully cross link to media/substrates. With film, you must wait for some inks to outgas before application and it doesn’t leave as smooth of a finish like UV coatings.”

Whether it’s rigid or roll-to-roll substrates, Northup explains that UV-cured coating technology provides extremely fast curing under UV LED or mercury light versus other finishing methods.

Acknowledging Challenges

When it comes to UV LED curing of wide format liquid coating, Howe feels the biggest challenge

is consistent thickness and clean output. However, after testing and many trial runs, “AGL has found the key to success,” he shares.

Some applications have very demanding physical requirements for coating so Holzhauer says they need to be able to achieve high coating flexibility while also providing protection, finish, and competitive cost.

Holzhauer adds that creating coatings that are “universal” and can be used on any ink type in the industry are challenging in terms of adhesion.

In terms of investment, Northup admits the cost of ownership is always the biggest challenge for any company looking into this technology. “Pricing ranges between $80,000 to $250,000.”

Wide Format Coaters

Recent advancements to UV and UV LED curing benefit liquid coaters in the wide format digital print space.

Holzhauer says AGL is the first to bring UV LED curing to liquid coating in large format print. “UV LED has been used in the print process for years and AGL recognized the need to design machinery and coatings that would bring UV LED to liquid coating.”

AGL’s SheerKote UV62 is the first of its kind UV LED liquid coater,

equipped to handle 18-inch diameter, 1,000 lb rolls of vinyl at 50 fpm roll-to-roll throughput speeds. The instant curing process and low operating temperature of UV LED lamps allows for high throughput speeds while continuously providing a consistent coating thickness, and a warrantied five year durability rating.

Howe points out that AGL uses UV LED lamps, which have a 30 times longer life span than UV mercury lamps. “The energy consumption rate of UV LED lamps also allows for a 90 percent energy cost reduction, and no volatile organic compounds, meaning no ventilation stacks to clear the work area.”

Holzhauer adds that with its UV LED technology, AGL created a premium gloss coating that provides optimal adhesion to HP Latex Gen 3 inks, “which is a big need in our industry.”

Alliance Technology Corporation (ATC) offers the XL UV60-2TS and UV80-2TS liquid coating systems. The XL machines are designed for professional, heavy duty operation, specifically for the flatbed printer market. Available in both 60- and 80-inch effective coating widths, the units provide high speed, dry to dry protective lamination for digital inkjet images printed with various types of inks including UV, solvent, and water based.

The units coat both flexible and rigid substrates up to three inches

1) Marabu utilizes UV inhibitors in its product line. 2) The AGL SheerKote UV62 provides energy efficiency, lamp lifetime of 30,000 hours, and throughput speeds of up to 50 fpm, while bringing coating costs down to $0.05 per square foot.

thick. They feature supersized rollers to ensure precise, full width, edge-to-edge coating with a speed range from 30 to 110 fpm. All three rollers are motorized for precise coating control. Coating thickness is adjustable from 0.3- to 0.8-mil. The built-in triple liquid delivery system handles two liquids and a cleaning fluid. All three liquids are filtered. The liquid metering roller and bottom roller scraper are pneumatically controlled.

ATC’s UV-curable liquid coatings can be used for a range of applications including business cards, direct mail pieces, wallcoverings, and point of purchase signage. Its extensive range of UV coatings cover all of the applications seen in the digital printing, pho-

tographic, and packaging markets today.

Burkle’s UV liquid coating line includes its LFC products—1300, 1600, and 2100. The UV coaters include a drying unit for coating primer and protection lacquers as well as processing full-sized finishings of digital printable media, running through with solvent-free, UV lacquers and direct lacquer curing with UV radiation.

The line is suitable for almost all surfaces within digital and screen printing. Key benefits include adjustable UV power for individual coating requirements and an EVG power supply unit.

Future of Coating

There is a lot of potential in terms of UV coating for wide format liquid devices, especially with the debut of UV LED curing. D