Industry 4.0

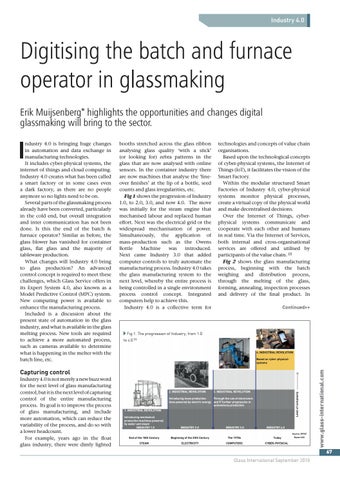

Digitising the batch and furnace operator in glassmaking Erik Muijsenberg* highlights the opportunities and changes digital glassmaking will bring to the sector. booths stretched across the glass ribbon analysing glass quality ‘with a stick’ (or looking for) zebra patterns in the glass that are now analysed with online sensors. In the container industry there are now machines that analyse the ‘lineover finishes’ at the lip of a bottle, seed counts and glass irregularities, etc. Fig 1 shows the progression of Industry 1.0, to 2.0, 3.0, and now 4.0. The move was initially for the steam engine that mechanised labour and replaced human effort. Next was the electrical grid or the widespread mechanisation of power. Simultaneously, the application of mass-production such as the Owens Bottle Machine was introduced. Next came Industry 3.0 that added computer controls to truly automate the manufacturing process. Industry 4.0 takes the glass manufacturing system to the next level, whereby the entire process is being controlled in a single environment process control concept. Integrated computers help to achieve this. Industry 4.0 is a collective term for

technologies and concepts of value chain organisations. Based upon the technological concepts of cyber-physical systems, the Internet of Things (IoT), it facilitates the vision of the Smart Factory. Within the modular structured Smart Factories of Industry 4.0, cyber-physical systems monitor physical processes, create a virtual copy of the physical world and make decentralised decisions. Over the Internet of Things, cyberphysical systems communicate and cooperate with each other and humans in real time. Via the Internet of Services, both internal and cross-organisational services are offered and utilised by participants of the value chain. [2] Fig 2 shows the glass manufacturing process, beginning with the batch weighing and distribution process, through the melting of the glass, forming, annealing, inspection processes and delivery of the final product. In Continued>>

� Fig 1. The progression of Industry, from 1.0 to 4.0 [1] 4. INDUSTRIAL REVOLUTION Based on cyber-physicalsystems

Capturing control 2. INDUSTRIAL REVOLUTION

3. INDUSTRIAL REVOLUTION

Level of complexity

Industry 4.0 is not merely a new buzz word for the next level of glass manufacturing control, but it is the next level of capturing control of the entire manufacturing process. Its goal is to improve the process of glass manufacturing, and include more automation, which can reduce the variability of the process, and do so with a lower headcount. For example, years ago in the float glass industry, there were dimly lighted

Introducing mass production Through the use of electronics lines powered by electric energy and IT further progression in autonomous production 1. INDUSTRIAL REVOLUTION Introducing mechanical production machines powered by water and steam INDUSTRY 1.0

INDUSTRY 2.0

INDUSTRY 3.0

End of the 18th Century

Beginning of the 20th Century

The 1970s

Today

STEAM

ELECTRICITY

COMPUTERS

CYBER-PHYSICAL

INDUSTRY 4.0 Source: DFKI/ Bauer IAO

www.glass-international.com

I

ndustry 4.0 is bringing huge changes in automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the internet of things and cloud computing. Industry 4.0 creates what has been called a smart factory or in some cases even a dark factory, as there are no people anymore so no lights need to be on. Several parts of the glassmaking process already have been converted, particularly in the cold end, but overall integration and inter communication has not been done. Is this the end of the batch & furnace operator? Similar as before, the glass blower has vanished for container glass, flat glass and the majority of tableware production. What changes will Industry 4.0 bring to glass production? An advanced control concept is required to meet these challenges, which Glass Service offers in its Expert System 4.0, also known as a Model Predictive Control (MPC) system. New computing power is available to enhance the manufacturing process. Included is a discussion about the present state of automation in the glass industry, and what is available in the glass melting process. New tools are required to achieve a more automated process, such as cameras available to determine what is happening in the melter with the batch line, etc.

67 Glass International September 2018

Glass service industry 4.0.indd 1

14/09/2018 08:19:48