It is with great excitement and anticipation that we welcome you to the Future Aluminium Forum 2024, in Istanbul. Turkey has been a desirable location to host the Forum for many years and something we have been in talks with the Turkish Aluminium Industrialists Association (TALSAD) about, during numerous other meetings, so I am very pleased to finally be here and able to welcome you.

The Future Aluminium Forum was originally conceived to explore the transformative potential of digital technologies in the aluminium industry, and by hosting this edition in Istanbul, we aim to uncover the opportunities that lie within Turkey and its surrounding regions.

As we gather major aluminium manufacturers, suppliers of digital and sustainable technologies, and industry experts under one roof, our goal is to foster collaboration, knowledge-sharing, and innovation, ultimately paving the way for a more efficient, sustainable, and competitive aluminium sector.

At this year’s forum, you can expect to discover the latest advancements in digital manufacturing and Industry 4.0 technologies that promise to revolutionise production processes, improve quality standards, and enhance overall efficiency in the aluminium industry.

Additionally, in response to the growing demand for discussions on sustainability, we will be featuring a live session dedicated to ‘Greener Aluminium’. This session will showcase technologies that promote energy efficiency, waste reduction, and eco-friendly manufacturing practices, reflecting our commitment to driving positive change within the industry.

Turkey’s strategic geographic location and thriving aluminium industry make it the perfect backdrop for this regional event. With its steady growth and significant contributions to the global aluminium market, Turkey serves as a hub for both regional and global players, offering a dynamic environment ripe for exploration and collaboration.

Through our collaboration with TALSAD, we aim to support the adoption of digital technologies in the Turkish aluminium sector, driving economic growth, attracting investments, and fostering innovation that will contribute to the overall development of the region.

As you immerse yourself in the wealth of knowledge, networking opportunities, and cutting-edge innovations that await you at the Future Aluminium Forum 2024, we encourage you to make the most of this invaluable experience. Connect with fellow delegates, engage with suppliers showcasing their products and projects, and seize the opportunity to be at the forefront of shaping the future of the aluminium industry.

Nadine Bloxsome Content Director

Vertical saws

Horizontal saws

Saws for the aerospace industry

Saws for T-bars, rolling ingots, slabs, billets

Contour saws

Automation technology

Conductivity measurement

www.moessner-kg.de

The UAE’s Artificial Intelligence, Digital Economy and Remote Work Applications office and Emirates Global Aluminium have signed a memorandum of understanding to promote the adoption of artificial intelligence in the industrial sector.

The agreement was signed by His Excellency Omar Sultan Al Olama, Minister of State for Artificial Intelligence, Digital Economy and Remote Work Applications, and Abdulnasser Bin Kalban, Chief Executive Officer of EGA, at the World Governments Summit 2024 in Dubai.

HE Omar Sultan Al Olama affirmed that digitising various vital sectors by adopting artificial intelligence applications is a fundamental cornerstone in enhancing the UAE’s competitive position globally and accelerate the pace of digital transformation in all industrial sectors.

His Excellency praised the proactive efforts of Emirates Global Aluminium Company in enhancing the applications of Fourth Industrial Revolution solutions in its operations, including artificial intelligence solutions.

Abdulnasser Bin Kalban, Chief Executive Officer of Emirates Global Aluminium, said: “At EGA, we fully recognise the power of artificial intelligence to transform everything we do, from automating industrial processes to improving employees’ experience at work. Many of the opportunities ahead of us are shared with others. Through the Artificial Intelligence Office of the Government, we look forward to delivering our own transformation faster and more effectively while inspiring other companies with what is possible.”

Under the agreement, the Artificial Intelligence, Digital Economy and Remote Work Applications office and EGA will work

together to develop research partnerships for artificial intelligence, including for use in developing new aluminium alloys. As well, they will also cooperate to upskill EGA staff on artificial intelligence, jointly promote career opportunities to UAE National students, and work with universities to ensure their curricula meet the needs of industry.

EGA began its own Industry 4.0 transformation in 2021 to further improve operational efficiency, with the goal of becoming a digital lighthouse for the region and the global aluminium industry.

The agreement supports the company’s efforts to implement Fourth Industrial Revolution solutions using artificial intelligence in various fields, including improving supply chain, enhancing automated quality testing, and strengthening safety procedures in its factories.

Saudi Arabian mining company Ma’aden, and Hexagon have announced that they have partnered to launch the Middle East’s very first digital mine.

Hexagon’s life-of-mine technology solutions are being successfully deployed at Mansoura Massarah mine, combining sensor, software, and autonomous technologies to enhance efficiency, productivity, quality and safety across the mine’s operations.

Duncan Bradford, Executive Vice President Base Metals and New Metals, Ma’aden, said: “This partnership strongly aligns with our digitisation strategy, as we work to use the vast amounts of data that we mine to make our mine safer and more efficient. We look forward to working closely with Hexagon to implement and utilise the region’s first digital mine to elevate Mansourah Massara’s operations.”

Nick Hare, President of Hexagon’s Mining

division, said: “We are excited to help bring to life this important shift toward digitisation of the mine, one that holistically leverages intelligent data and automation across workflows to minimise the impacts of mining while simultaneously improving safety, productivity and operational efficiency. This is about coauthoring the next chapter of mining in this region with a partner who shares in our drive toward a sustainable future.”

With the testing of emission-free plasma technology in the casthouse at Sunndal, Hydro is pursuing its goal to achieve zero CO2 emissions in aluminium production. Hydro has been granted soft funding from the Norwegian Government for a project that could have global impact on hard-to-abate industries.

Re-melting aluminium into new products requires extremely high temperatures, an energy intensive process which is hard to achieve without fossil energy in the form of natural gas. However, new plasma technology will enable electrification of the process, using the same renewable energy that powers Hydro’s primary smelters.

“We aim to change the game for aluminium production. Plasma technology is both high tech and future oriented. If we succeed with the pilot project at Sunndal it will not only affect the aluminium industry, but also other hardto-abate industries worldwide,” says Eivind Kallevik, Executive Vice President for Hydro

Hydro aims to melt the first aluminium with near zero emissions from the casthouse at Sunndal in the fourth quarter of 2025. The pilot will reduce carbon emissions by over 500 tonnes annually, but the global potential for reducing emissions from aluminium casthouses and recyclers is about 11 million tonnes of CO2. Enova, an enterprise established by the Norwegian Government to facilitate the transition to a low-emission society, has granted NOK 39.6 million in support of the project.

Hydro’s goal is to achieve zero emissions in the entire aluminium value chain by 2050. Hydro Sunndal, Europe’s largest and most modern aluminium plant, also serves as test site for capturing carbon emissions from the existing electrolysis. In the fall of 2023, Hydro also decided to invest in a test facility in Porsgrunn

to further develop HalZero, an entirely new technology for primary aluminium production that will eliminate carbon emissions from both electrolysis and anode baking.

“We are working closely with Europe’s most demanding customers to help them achieve their climate ambitions through the use of low-carbon and recycled aluminium. We are proud to offer aluminium based on renewable energy and with 75 percent lower carbon footprint than the global average,” says Kallevik.

In today’s fast-paced world, ensuring complete traceability from raw material to finished product is of paramount importance. coilDNA, as a 100% subsidiary of AMAG Austria Metall AG, is a start-up in the field of digitalisation based in Linz/Austria. The business is based on a patented technology for marking and tracking continuously produced semi-finished products. These include coils and sheets, extruded or roll-formed profiles, as well as hoses or cables made of different materials such as steel, aluminium or plastic.

When it comes to marking the aluminium strips, sheets and plates produced in Ranshofen, AMAG uses LEIBINGER printers to meet the diverse requirements of its customers from different industries incl. aero-space, automotive, packaging, construction and mechanical engineering, electronics, sporting goods, radiators and heat exchangers. This is also the case with the coilDNA code - a constantly changing alphanumeric code which is applied over the entire length of the rolled products, often ranging from several 100 to 1000 metres, in the final phase of production.

When marking aluminium coils at AMAG Austria Metall AG, the flexible positioning of the print heads relative to the rolling strip on the different lines posed a challenge. Especially on the longitudinal slitting lines, up to 8 lanes had to be printed with different markings from above and from below.

Reliable, continuous

The coilDNA code consists of 14 clear alphanumeric characters that are strung together in the code track – and which are never repeated. Each individual code element allows its exact position on the product to be determined. If data is assigned to these code elements, it can be retrieved in subsequent processing steps, regardless of how the semi-finished product was split. This enables seamless tracking of the material, its properties and manufacturing conditions over several stages of the value chain – and ideally all the way through to the end product.

The solution: LEIBINGER’s specially developed interface software for high process speed

The need to print the constantly changing coilDNA code was solved by means of a specially developed interface software based on LEIBINGER’s messaging protocol. Thanks to the printers’ high data processing speed, the coilDNA code can now be printed with re- producible results at process speeds of up to 500 m/min.

“The installation of the printers and related equipment during ongoing production –without interrupting it – presented the team with a special challenge, which was solved to our complete satisfaction and on schedule thanks to excellent project coordination”, says Dr. Werner Aumayr, Head of AMAG IT.

The flexible positioning and easy

manipulation of the LEIBINGER print heads on the line enable the printing of the rolled strips at almost any width position, even in several lanes if required. This means that the slit strips produced on the longitudinal slitting lines can be marked individually.

Excellent legibility of the dot-matrix font used is ensured even in this high speed range. Leopold Pöcksteiner, Managing Director of coilDNA, confirmed: “When it comes to printing the coilDNA code, high process speeds of up to 500 m/min on the longitudinal slitting machines combined with excellent code legibility, even in the high speed range, are impressive.“

The result: All marking requirements were met 100%

By using coilDNA technology, AMAG can now offer its customers new services. “By using close to 30 LEIBINGER printers on a variety of systems in the AMAG rolling mills, the wide-ranging marking requirements of our customers from different industries are met to the fullest – and with an exceptional degree of flexibility.“ says Dr. Werner Aumayr, Head of AMAG IT.

coilDNA-marked strips allow seamless traceability of the delivered strips and sheets, as well as the parts created from them through further processing, including their properties and manufacturing parameters. Specially developed coilDNA apps enable AMAG customers to communicate and coordinate quickly, easily and by product once the coilDNA code has been scanned. Achieving this was only possible with LEIBINGER‘s highly reliable coding & marking technology.

Conclusion and recommendation

“The key finding from the project was that, using standard LEIBINGER printing protocols, even markings not provided for in the standard, such as the coilDNA code, can also be applied at high speeds,” says Dr. Werner Aumayr, Head of AMAG IT.

“I recommend that, before using CIJ printers in the metal producing industry, it makes sense to carry out extensive tests in terms of the material surface, marking resistance, process speed, ambient conditions and code legibility. LEIBINGER and its partner carried out extremely valuable preliminary work and provided comprehensive advice. We would be happy to recommend working with them to other companies requiring this expertise.”

Alcoa to supply Nexans with low-carbon aluminium, including metal from ELYSIS™ technology

Alcoa to supply Nexans with low-carbon aluminium, including metal from ELYSIS™ technology

Alcoa have announced that it will supply global cable producer Nexans with aluminium produced from a revolutionary process that eliminates all direct greenhouse gas emissions from the traditional smelting process.

Nexans will be the world’s first cable manufacturer to use metal from the breakthrough ELYSIS™ process, which replaces all greenhouse gas emissions with oxygen. The technology uses proprietary materials, including inert anodes, first developed at the Alcoa Technical Center near Pittsburgh. That research and development work became the technological basis for ELYSIS™, a technology partnership that is working to ramp up the process to commercial scale.

Several Nexans facilities in Western Europe and Scandinavia will use aluminium produced from the ELYSIS™ process to start qualifications for the metal’s use in various types of cables, from low, medium to high voltage. Aluminium rod produced with this breakthrough ELYSIS™ technology could eliminate a significant portion of carbon dioxide emissions in the future.

This latest announcement further builds on the two companies’ historic long-term relationship. Alcoa already supplies Nexans with EcoLum™, a primary aluminium with a carbon footprint that is nearly three times lower than the industry average.

Since the launch of ELYSIS™ in 2018, the technology company has produced R&D quantities of the metal. Alcoa is marketing and selling its share of the ELYSIS metal, which has also been used for the wheels on the Audi eTron GT, the automaker’s first electric sports car. Apple is also an investor in the technology and has used ELYSIS metal for some of its

products.

ELYSIS is a key component in Alcoa’s technology roadmap of research and development projects that also includes projects such as the ASTRAEA™ metal purification process and the Refinery of the Future.

This agreement fully highlights Nexans’ position at the forefront of the sustainable electrification of the world and regarding crucial issues such as low-carbon emissions.

Renato Bacchi – Executive Vice President and Chief Commercial Officer at Alcoa: “Alcoa is well positioned to supply low carbon aluminium for the world’s transition to renewable energy, as we know that the true impact of decarbonization will also include the choice of materials used to build the infrastructure for generation, transmission and distribution networks. While we are developing ELYSIS™for the future, we are also supplying low-carbon aluminium today with our EcoLum™metal, which can help customers meet their own sustainability goals and lower their carbon footprints.”

Vincent Dessale – Nexans Chief Operating Officer Senior Executive VP:

“In the fight against climate change, solutions that support the world’s energy transition make a real difference. By increasing our use of low-carbon aluminium, we want to lead the way toward a sustainable electrification of the world: the rod produced with this breakthrough technology could eliminate a significant portion of carbon dioxide emissions in the future. We are proud to be the world’s first cable manufacturer to use metal from the breakthrough technology ELYSIS™.”

Registration open from 8am

9am – 9.05am

Welcome to the Future Aluminium Forum 2024

Nadine Bloxsome, Editor, Aluminium International Today

9.05am – 9.15am

Welcome on Behalf of TALSAD, Supporting Association

TALSAD Board Representative

9.15am – 9.45am

Market Update: Overview of the Turkish Aluminium Industry

TALSAD Representative

OPENING ADDRESS

9.45am – 10.15am

The Aluminium Industry: What is driving change in the industry? Where have we been, where are we now, where are we going?

Ron Knapp, Adviser and Office of the Chairman, China Hongqiao Group Limited (HK)

KEYNOTE PRESENTATION

10.15am – 10.30am

Pioneering Industry 4.0 at Emirates Global Aluminium

Carlo K Nizam, Chief Digital Officer, Emirates Global Aluminium

10.30am – 11am

Forging a Sustainable Aluminium Business with Integrated Data and Next Generation Business Processes

Amadou Ndiaye, Senior Director, Industry Advisory for Energy and Natural Resources, SAP EMEA

NETWORKING BREAK

11am – 11.30am

SESSION 1: Greener Aluminium

11.30am – 12noon

Sustainable Aluminium: Ambition to Action

Pernelle Nunez, Deputy Secretary General, Director – Sustainability, International Aluminium Institute (IAI)

12noon – 12.30pm

HAIend Aluminium Solutions for a Sustainable Performance: How HAI SustainAl Products Can Help Customers Cut Their Carbon Footprint

Marcus Oberhofer, Managing Director, Sales Extrusions HAI

12.30pm – 1pm

Forging a Sustainable Future: Storvik’s Initiatives Towards Greener Aluminium

Siri Sande, Marketing Manager, Storvik Group

LUNCH

1pm – 2pm

SESSION 2: The Future of Aluminium Production and Processing

2pm – 2.30pm

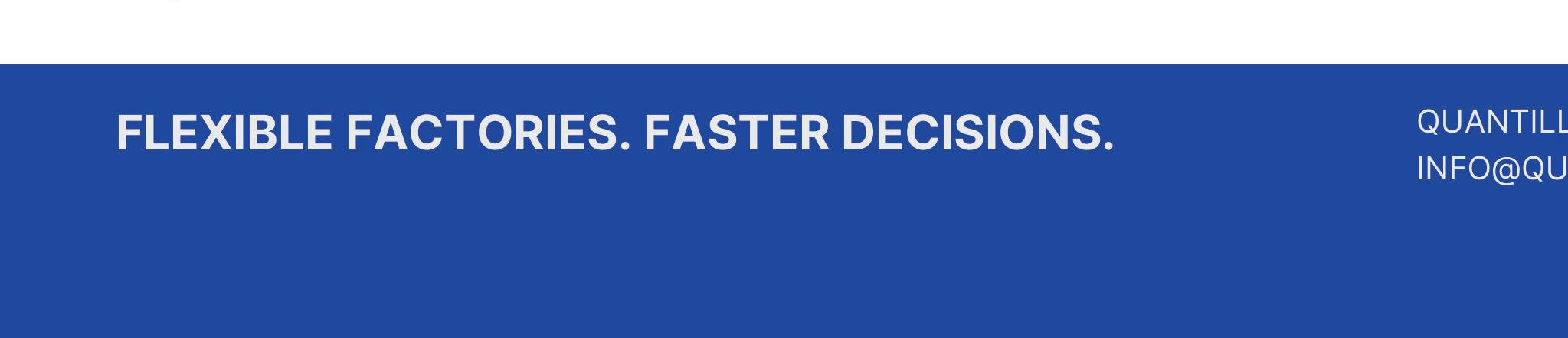

How Flexible Operations Enable the Transition from Manual to Autonomous Processes

Carl Schwarz, Business Analyst, Quantillion

2.30pm – 3pm

Boost Your Production with AI Prediction Models

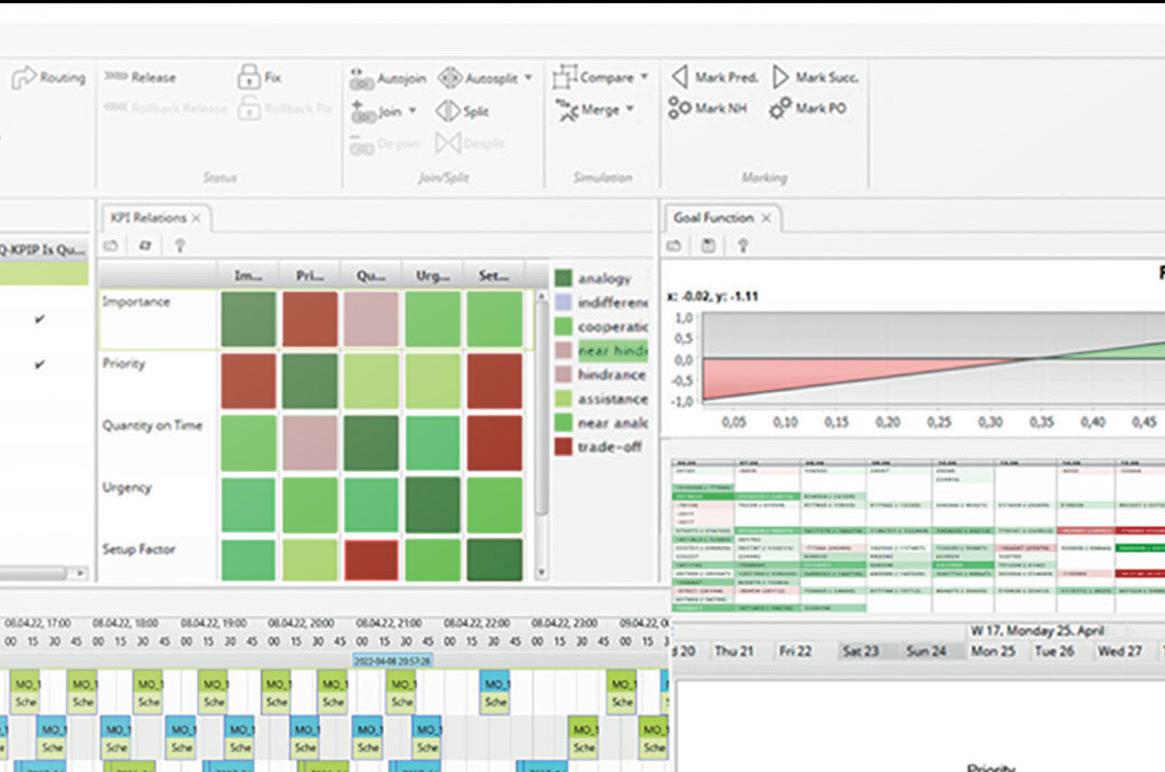

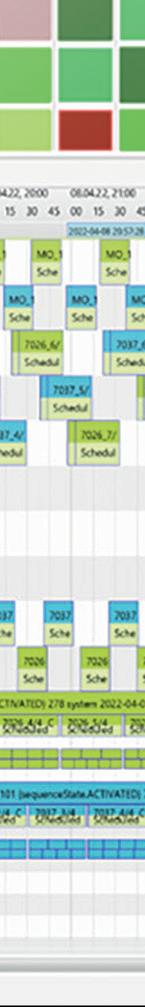

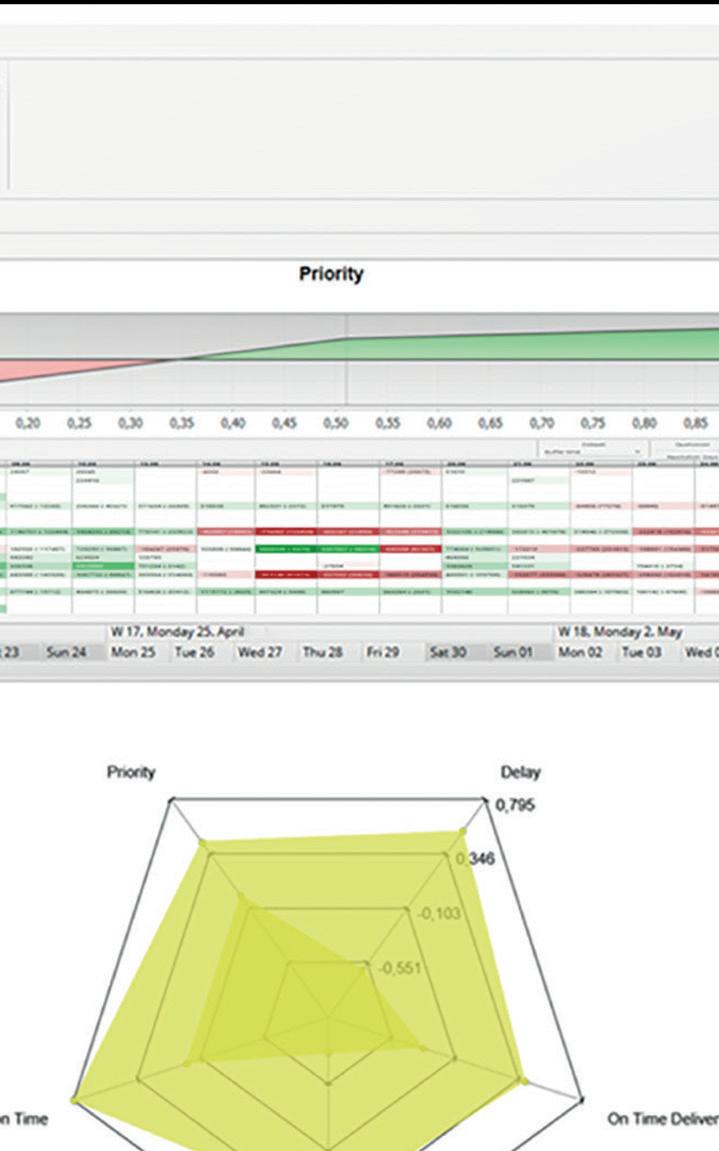

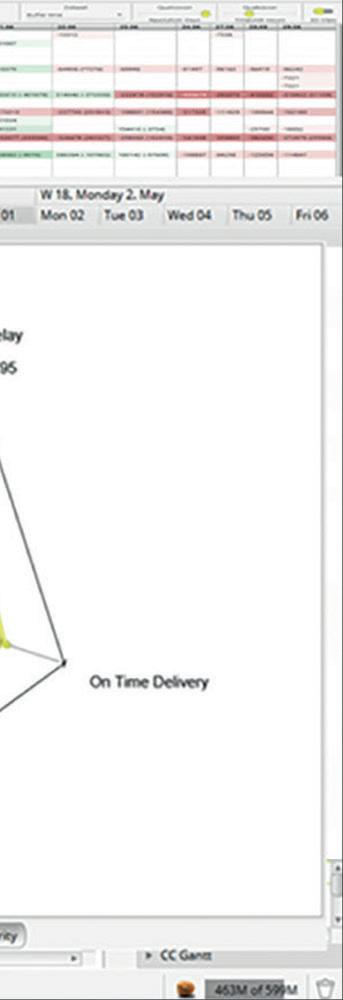

Gunther Schober, Sales Manager, PSI Metals Non Ferrous GmbH

NETWORKING BREAK

3pm – 3.30pm

3.30pm – 4pm

Next-Gen Analytics: Transforming Aluminium Production with Real-Time Molten Metal Analysis

Karl Ágúst Matthíasson, CEO, DTE

4pm – 4.30pm

Maximising Recovery Rates: Choosing the Right Technology for Aluminium Recycling

Ramona Averina, Area Sales Manager, GHI Hornos

4.30pm – 5pm

Digital Eco-system for Green Secondary Aluminium Production

Erman Car, Technical Consultant, MetAllic Engineering Solutions

DAY 1 CONFERENCE CLOSE

BREAKFAST BRIEFING: AI Workshop

9am – 10am

Leveraging AI in the Aluminium Industry

Abhimanyu Prakash, CEO, Al Circle

10am – 10.30am

Solving the Data Connectivity Problem in the Aluminium Industry with the Unified Namespace

Denis Gontcharov, Data Engineer

11am

DAY TWO CONFERENCE CLOSE

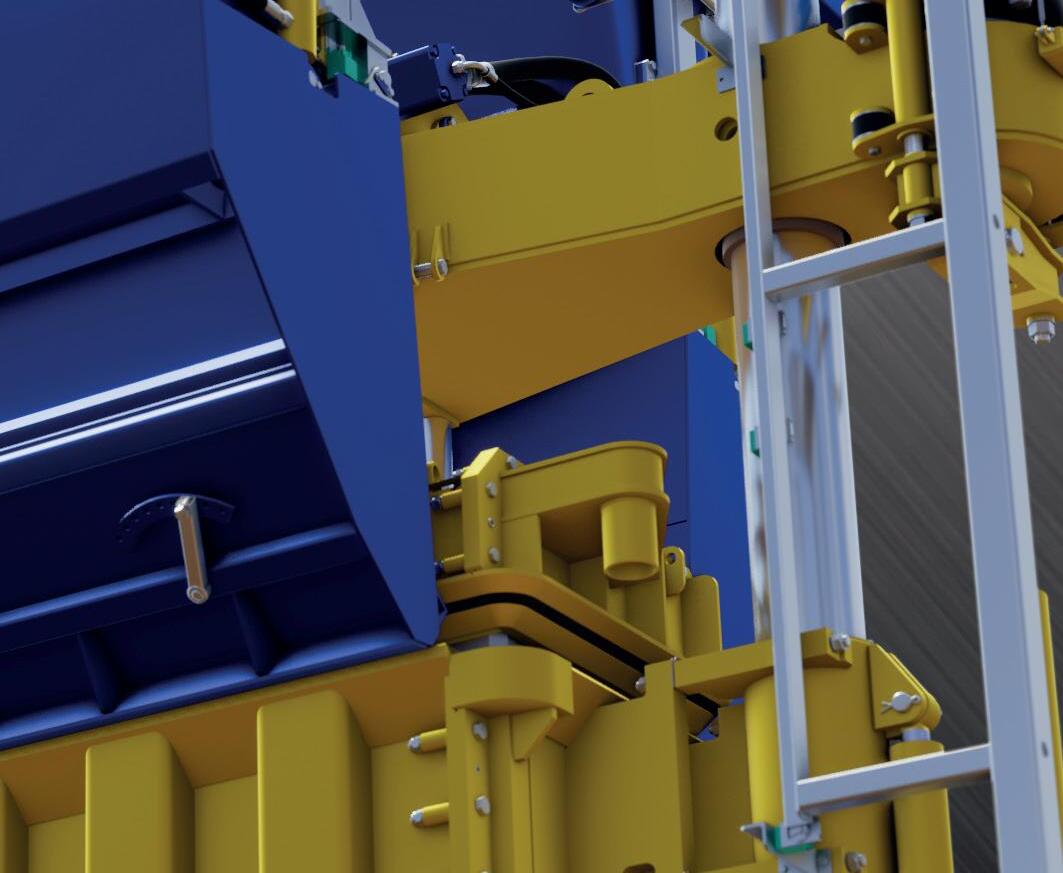

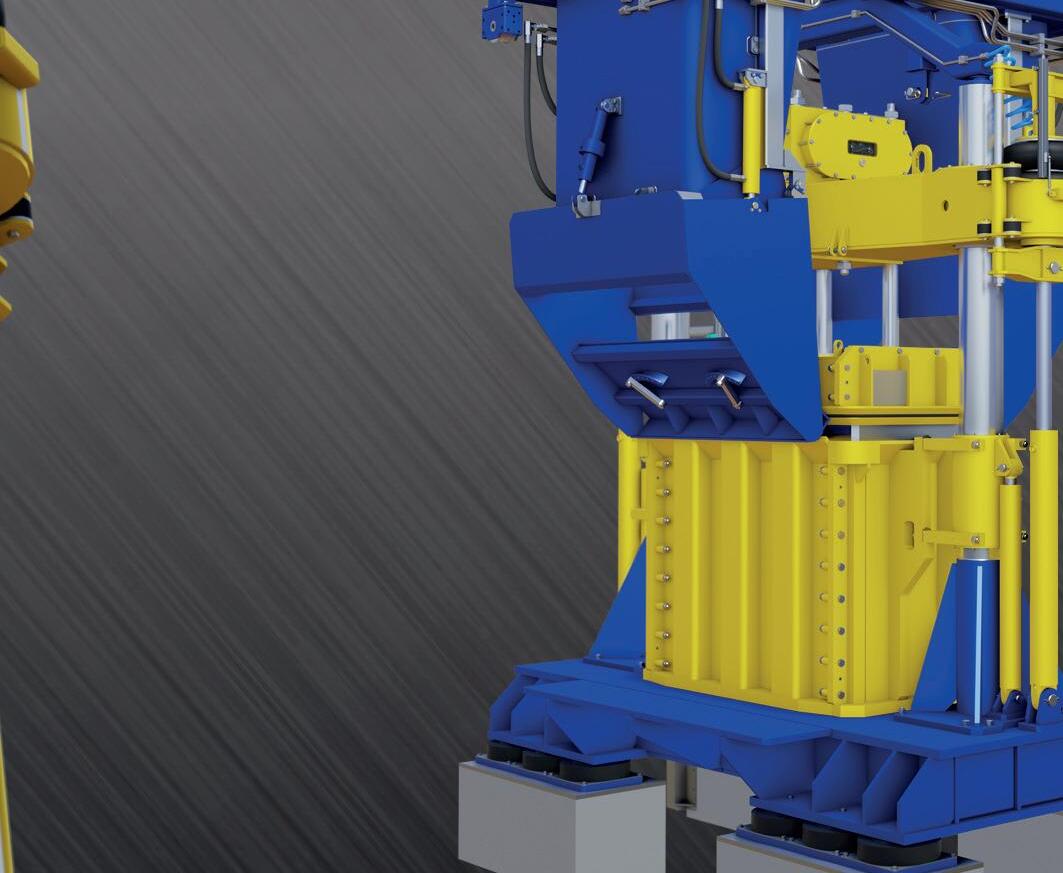

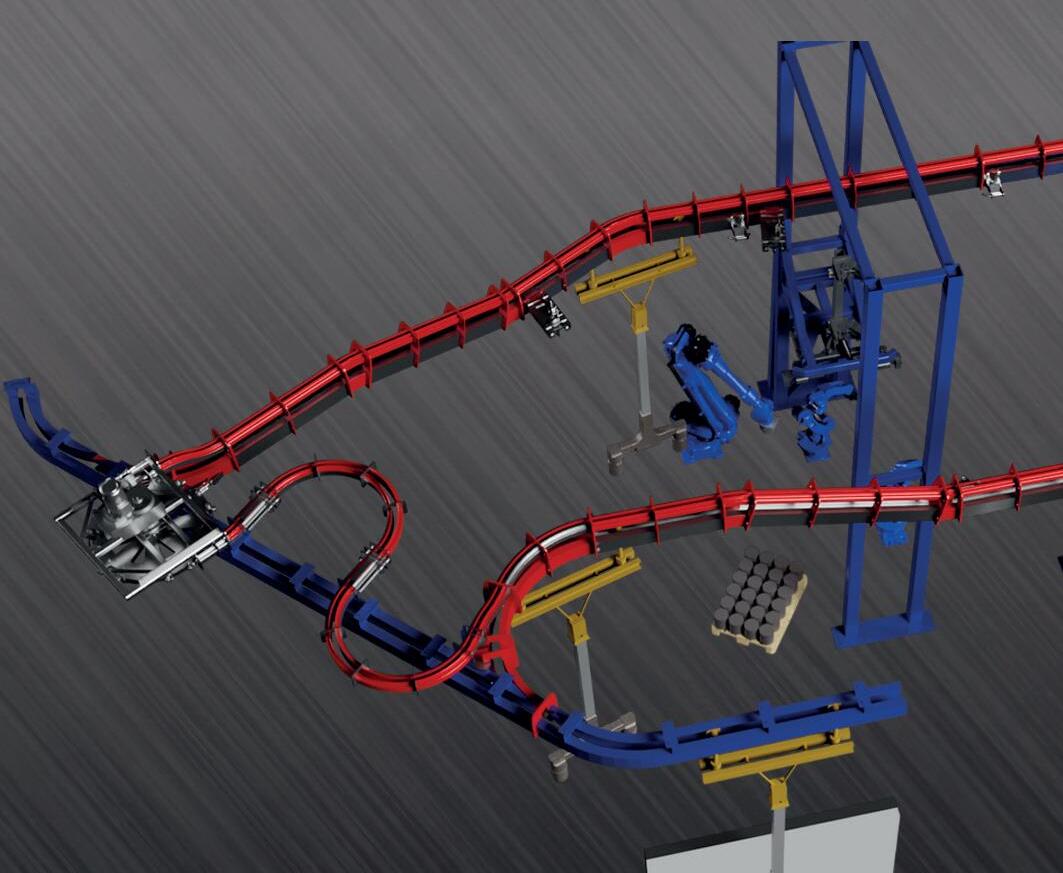

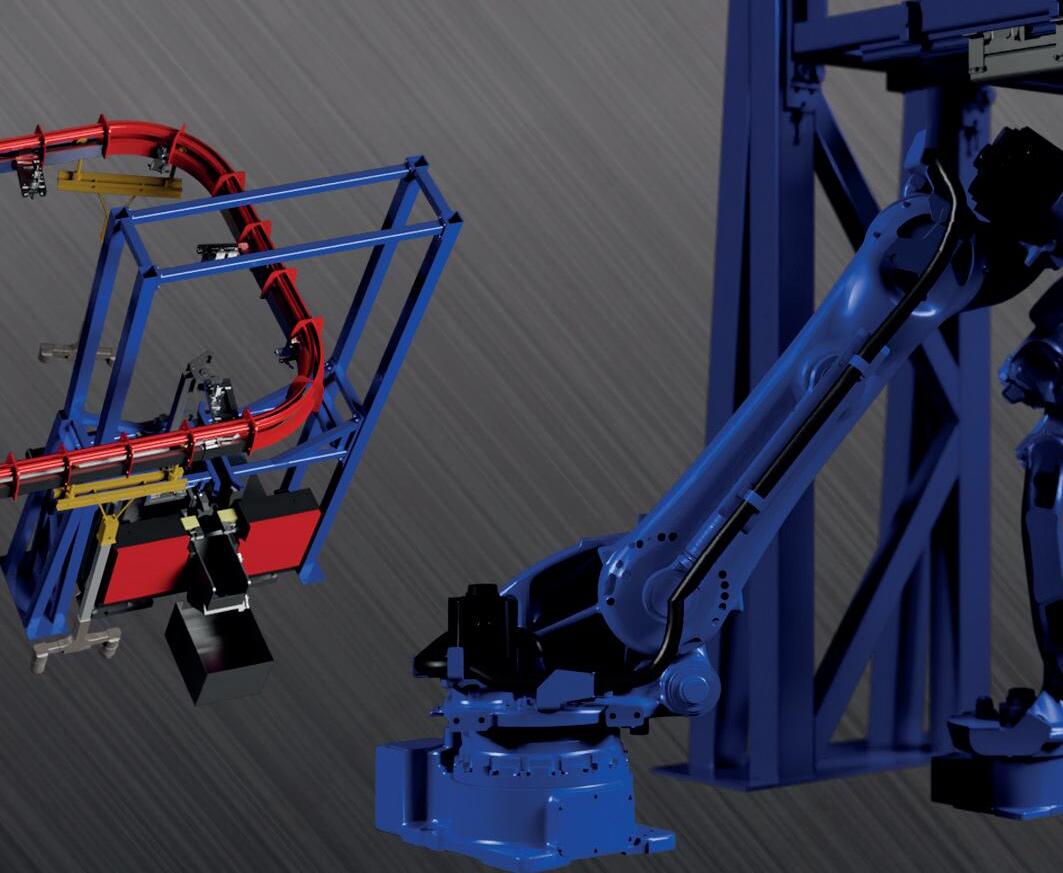

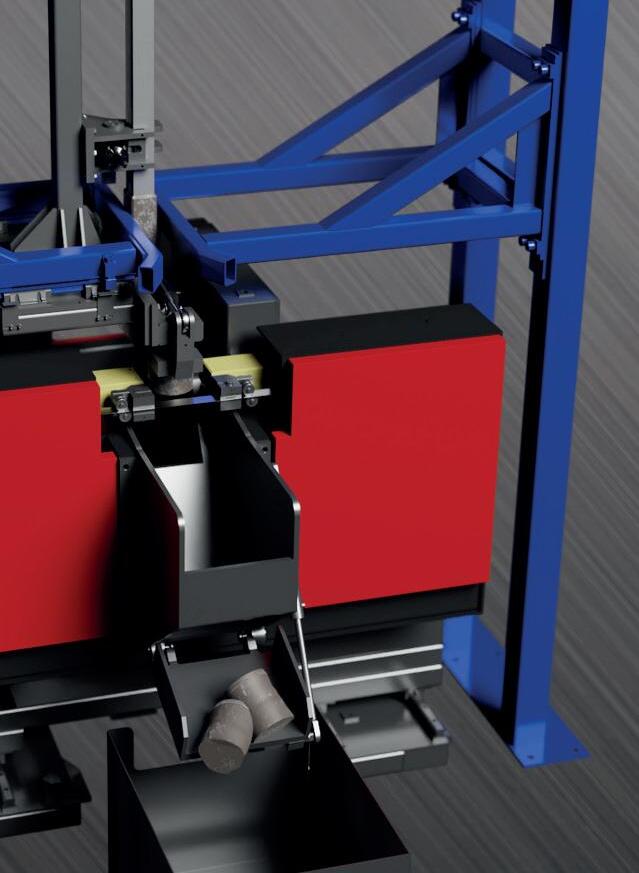

For an organized billet handling, trust branded EPIQ AD’s Billet batch homogenizing system that offers:

A touchless aluminium billets gantry system.

A fully automated homogenizing sequence on to sawing and batching operations.

Only linear motions for increased reliability and better positioning.

Abhimanyu Prakash, CEO, of AL Circle is a fifth-generation entrepreneur, an architect, and an urban designer by education at Columbia University, New York. Based on 4 decades of domain knowledge of the parent group, Abhimanyu heads AL Circle, the world’s first virtual ecosystem dedicated to the entire Aluminium value chain. Abhimanyu’s passion for sustainability got him hooked on the 100% recyclable metal and its industry and he was intrigued by innumerable possibilities with technology AL Circle was a natural fit for him. With a foundation of up to 10 Mn hits per month on the news platform, readership across 195 countries, and a recently launched online marketplace with over 6000+ products from all parts of the Aluminium value chain, Abhimanyu and his team are building a set of interconnected digital services for all of you and the Aluminium industry to get more connected, efficient, and better each day.

AI, the more popular acronym cousin to AL. These acronyms AI - artificial intelligence and AL - aluminium are destined to be synonymous with our global aluminium industry, but this session will showcase the potential and challenge this possibility, all at the same time. Historical trends around the limited digital advancements in our industry have often left innovators wanting more. Still, there have been some notable adoptions of AI in our ALuminium domain in recent times. In our field,

we are positioned to learn from the successes and failures of several other similar and allied industries around the applications of AI and leapfrog to greater success rates. What does AI mean for us and our industry - bigger, better, faster, safer, and cleaner? Or will it bring more than what is visible to the eye? The workshop-style format of this session will discuss the role of AI in our aluminium value chain and in particular, delve deeper into its applications to accelerate our journey

to net zero. With a single focus agenda of sustainability for our global aluminium family, AI could hold the answer to many of our Scope 1, Scope 2, and Scope 3 emissions. Interactive tools throughout the session will allow participants to engage and opine on the benefits and not-so-positives of AI for our AL industry and also imagine the endless possibilities that AI can open up for aluminium, our industry, our people, and our products.

Amadou is a business transformation expert and an innovation advocate. He holds a degree in Financial Performance and Business Strategy. During the past 12 years, Amadou has supported the digital transformation of several Metals, Aluminium, O&G, and Mining organisations across Europe, Middle East, and Africa. His approach focuses on leveraging new technologies as a catalyst to significantly improve business processes efficiency, achieve sustainability ambitions and boost the top/bottom line. Amadou helps organisations not only keep up but also thrive in today’s ever-changing business world.

Aluminium manufacturers face a range of challenges from a volatile and uncertain world and changing customer, employee and stakeholder expectations. AI is bringing change to all industries and companies are working to understand the benefits and risks and how to stay ahead of the curve. Successfully navigating this changing world will depend heavily on driving efficient and sustainable operations and on having reliable data. An integrated digital platform can help companies make the right decisions

about new markets to enter, keeping assets in shape, reaching customers more profitably and improving efficiency and sustainability. This session will discuss examples of industry leaders who are using digital technology including Business AI and analytics to innovate and grow including how to:

� Reduce risk and improve supply chain agility using digital technologies such as Business AI, Machine Learning and IOT

� Establish a transparent and auditable enterprise system of record for corporate

� Benchmark operations and value chains to find areas for optimisation and sustainability, using more granular data and predictive technologies

� Collaborate within and across industries to better use data as we move to a circular economy

� Sell to new markets using an integrated digital commerce platform

Carl Schwarz is a Business Analyst at Quantillion with a sharp focus on real-time autonomous decision-making in complex environments. Carl thrives on collaboration with passionate individuals, channelling their collective energy to create tangible value from domain knowledge and insights. For Carl, data is not a mere analytical tool; it is a catalyst for action.

Drawing from his background in M&A and operational analyses, Carl leverages his experience to navigate intricate landscapes, optimising processes for enhanced efficiency. Through Quantillion, Carl empowers the heavy industry with dynamic multi-agent planning and autonomous decision-making. Through Quantillion’s integrated software solutions, Carl aims to guide the industry towards a future of fully autonomous processes.

The aluminium industry is witnessing a notable shift towards automation, aimed at optimising processes and boosting efficiency.

Flexible operational designs are essential for seamlessly integrating automation in aluminium smelters. In this presentation we emphasise on the crucial link between flexibility and successful automation implementation, underscoring the pivotal role of agile operational frameworks in navigating this transformation.

Flexibility, in this context, refers to the capacity

to swiftly adjust to changes in demand, production requirements, operational environment, and external variables. A flexible operational environment accommodates dynamic shifts without compromising operational efficiency. It establishes the groundwork upon which automation can flourish, ensuring the integration of automated technologies is smooth and efficient. Moreover, a flexible operational framework enables dynamic decision-making, ensuring that automation strategies align with ever-

changing demands.

The integration of automation in aluminium smelters is not a standalone initiative; it is intricately linked to the flexibility of operations. By nurturing adaptability, responsiveness, and resource optimisation, flexible operations pave the way for aluminium smelters to unlock the full potential of automation, ushering in a new era of operational efficiency and competitiveness.

Carlo K Nizam is the first Chief Digital Officer of Emirates Global Aluminium. Mr. Nizam joined EGA in 2021 from Airbus, where he was Chief Information Officer for India & South Asia. He worked for Airbus for more than two decades in various roles spanning aircraft design, procurement, supply chain management, IT and digitalisation. Throughout his career, Mr. Nizam has leveraged technology to create business value through industrial scale transformations with a real world impact.

Mr. Nizam was honoured with the Don Percival award by the Association for Automatic Identification and Mobility in 2010 and the special lifetime achievement award from RFID Journal in 2015 for his industry leadership in the Internet of Things. Mr. Nizam is also a non-executive board member of Wakelet, a UK technology start up. Mr. Nizam holds a Master’s degree in Aeronautical Engineering from the University of Bristol, and has completed executive leadership programmes from Warwick Manufacturing Group and the University of Oxford. He holds a number of patents for his innovations.

Industry 4.0 is revolutionising most industries in the world and the aluminium is part of this. This presentation is about leveraging the exponential development of digital capabilities to transform the way industries operate. Nobody can ignore the power of Artificial Intelligence, Internet of Things or Augmented Reality just to name a few of these technologies. All companies adopting digital, and Industry 4.0 are focusing on speed, agility, and technology mastering and as a result are reaping significantly improved performance. Emirates Global Aluminium is leveraging 10 digital capabilities to digitise, digitalise and digitally transform its operations and business.

At EGA, the journey started a few years ago. We are now moving into the third phase out of four of our transformation programme. This phase is all about industrialising the

way we define, develop, deploy use cases through our digital factory to provide value to EGA. It also means putting in place strong foundations such as strategically aligned roadmaps, teams upskilling, deploying cutting edge technical platforms, and transforming the way of working with Agile frameworks as they help speed up and scale up our impact to the company operations and business. Value can be realised in different stages of the aluminium value chain as can be illustrated by some of the use cases EGA deploys in Carbon, in Reduction, in Supply Chain or in Marketing & Sales.

At EGA we are looking at three levels of transformation, from “digitisation” which is about turning the analogue into digital, then onto “digitalisation” which is about improving the game by embedding the digital into a transformed process and then towards “digital

transformation” which means changing the game, changing the business into a more complete digitally inspired change. All of this requires strong digital platforms and foundations to be enabled.

Many technologies have seen incredible development in the last decade. For EGA the 10 digital capabilities that we want to leverage are shown below (Figure 1). They represent a wide range of capabilities, and we will progressively use them all.

EGA has adopted a statement to materialise its digital ambition: “As a digital lighthouse for our region, we democratise digital capabilities to ‘change the game’ and create inspiring experiences for ourselves, our customers and our partners.” This is ambitious and inspiring for all team members involved and is guiding us on how we implement our digital transformation at EGA.

DENIS GONTCHAROV

DENIS GONTCHAROV

Denis is a data engineer who helps aluminium smelters refine process data into actionable information. For the past five years, he has supported the aluminium industry with IT and data services as an independent contractor. Previously, Denis was employed as a data engineer at Novelis in Germany, a leading aluminium rolling and recycling enterprise, where he played a pivotal role in transferring process data from production machinery to cloud systems. Prior to this, he was employed as a process engineer at TRIMET’s aluminium smelters in France and Germany, developing control software for the electrolysis process. Denis is a graduate in Materials Engineering from KU Leuven, Belgium, and is currently based in Berlin.

In the aluminium industry, the rapid advancement of digital technologies has presented both significant opportunities and daunting challenges. Chief among these challenges is the issue of data connectivity: the ability to seamlessly integrate and utilise data from a multitude of disparate sources across the business. Traditional methods of managing this data have often led to siloed information systems, impeding operational efficiency and flexibility.

The introduction of the Unified Namespace (UNS) as a centralised data management framework offers a solution to these

challenges by standardising data access and representation across all levels of operation. The UNS operates by creating a single source of truth that spans the entire business. It incorporates real-time data from various sources, such as PLCs, SCADA systems, MES, and ERP systems, into a common data model with intuitive naming conventions. While the concept of a single source of truth is not new, what sets the UNS apart from earlier approaches is its open architecture that’s rooted in modern IT best practices. The presentation will start by highlighting the data connectivity issue within the aluminium

industry, pinpointing the challenges of integrating disparate data sources. It then proposes the Unified Namespace (UNS) as a solution, avoiding technical jargon for clear understanding. The session concludes with practical steps on implementing a UNS at your plant, providing a straightforward roadmap for post-conference action. This approach aims to equip attendees with the practical knowledge of how a modern data infrastructure can enable digital transformation at their company.

Erman Car is a metallurgical engineer in the aluminium and magnesium industry around 30 years in Europe, Turkey and ex-Soviet countries. Still working as a general manager of MetAllic Engineering Solutions. His main interests are aluminium and magnesium recycling, low grade ore and waste processing and digitalisation.

In short and mid-term aluminium recycling is the most reliable tool to reach zero carbon targets for the aluminium industry. But, in secondary aluminium production we have also many problems. Mainly scrap availability, scrap quality, scrap sorting, metal efficiency, solid wastes (dross/salt cake) generation, carbon and equivalent emissions, and metal refining and secondary metal quality.

In this paper we have studied for solutions and try to create “digital eco-system”

in aluminium recycling plant by using digital tools, models and processes like AI applications, furnace monitoring, robotisation and lesson learned system based on data mining.”

Gunther Schober, born November 21, 1970 in Leoben, Austria, graduated in 1994 as Metallurgical Engineer with focus on industrial and energy economics at the Mining University of Leoben.

After his first experience as sales engineer and sales manager, he took over management responsibility as Head of Sales & Marketing for AVL DiTEST, an international automotive company.

In 2007, he joined PSI Metals. As Senior Consultant, Project Manager and Sales Manager, his expertise in metals and international experience in process development and Supply Chain Management is highly sought after.

With more than 15 years of experience in the field of Production Management Solutions encompassing Supply Chain Management and Planning, Product Design, Quality Management, Production Execution and Logistics, he has become a recognised expert in these areas. PSI Metals, known as an innovative company, became the metal industry’s partner for Industry 4.0. Gunther Schober’s expertise together with PSI Metals’ innovative approach make him a demanded contact for future solutions.

Artificial Intelligence (AI) used in the industrial context has special requirements above smart tools known from the internet and the press. Existing systems such as Manufacturing Execution Systems (MES) need to converge with AI. In the special process-oriented production of aluminium, AI became an important force in driving operational excellence and transforming manufacturing strategies. By utilising AI’s

predictive capabilities and qualitative labelling, MES can anticipate potential production disruptions, thereby enabling timely process intervention, reducing quality failures and minimising downtime. The collaboration between the MES and AI frameworks represents a significant step towards achieving Industry 4.0 principles. By harnessing the strengths of both technologies, aluminium producers can

achieve unprecedented levels of operational excellence, quality, and responsiveness, positioning themselves for sustainable success in the ever-evolving manufacturing landscape. Obtain significant productivity enhancements through the combination of PSI Metals and PSI Qualicision AI, thereby enhancing financial viability.

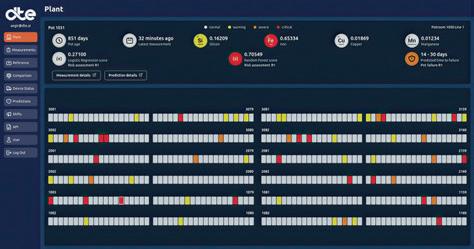

As the co-founder of DTE, Karl brings a wealth of experience from the metals industry. With a career of over 20 years, he has played a pivotal role in management, safety, and process control, focusing on advancing aluminium production. His hands-on approach and strategic thinking have been instrumental in shaping DTE’s business strategies and market presence. Karl’s leadership is defined by his commitment to practical, value-driven solutions and clear company growth vision.

The aluminium industry is undergoing a significant transformation, propelled by the advent of Industry 4.0. This paradigm shift is characterised by the integration of advanced digital technologies to enhance manufacturing processes. Central to this transition is implementing innovative technologies and methodologies reshaping production landscapes. DTE’s groundbreaking solutions are at the forefront of this change, providing real-time compositional analysis of molten aluminium, coupled with advanced data analytics. These solutions facilitate unparalleled process improvements and decision-making. The ability to analyse molten metal in real time opens numerous opportunities for process improvements, allowing for immediate adjustments and optimisation of the production process, boosting efficiency and throughput.

DTE‘s solutions are engineered to withstand challenging industrial conditions while providing precise, consistent and repeatable results. Due to DTE‘s proprietary technology, the solution offers unprecedented stability

of results, minimising need for calibration or standardisation. Maintenance of the solution is minimal as no disposable or consumable components are needed, offering the customer a complete piece of mind. DTE’s solutions are highly configurable and can be integrated into various process points throughout a plant. This flexibility ensures that they can be adopted in different setups, from smelters to secondary processing facilities. The configurable nature of DTE’s solutions means they can be tailored to fit the unique requirements of different facilities, from large-scale smelters to specialised secondary processors. This adaptability is key in a diverse and evolving industry. DTE offers solutions that can monitor melt composition at all process points, in smelter potrooms, transfer crucibles, furnaces and launders, both in primary and secondary processing.

DTE’s solutions unlock new optimisation possibilities. Leveraging previously unavailable real-time data into actionable intelligence, efficiency can be increased at every process point. DTE’s solutions can therefore

enhance decision making throughout the entire process from tapping, to batching and casting in primary production, ensuring that the production is always within specification and eliminating the need for over-processing and guaranteeing efficient use of valuable resources. In secondary processing such as recycling, the technology aids in better scrap and resource utilisation and overall process efficiency, increasing the scrap content in finished products and allowing for optimal batching for every single batch. By eliminating waste in the production process, DTE’s solutions can help to reduce the carbon footprint, a critical factor given the increasing focus on environmental sustainability in manufacturing.

DTE’s next-gen analytics and real-time molten metal analysis represent a significant advancement in aluminium production. By offering a solution that enhances efficiency, improves product quality, and reduces environmental impact, DTE is not only contributing to the evolution of the aluminium industry, but also ensuring its sustainability.

Combination of sensors and analytics to maximize process efficiency and value

Real-time analysis of ever y pot before tapping

Real-time quality monitoring in the launder during casting

Real-time quality check of each crucible before batching

Real-time furnace analysis during batching and alloying

Live over view of the whole plant with unprecedented process insights for optimizing scheduling and minimizing rework

Marcus Oberhofer is managing directors Sales Extrusions within the HAI Group. He is responsible for the B&C markets as well as all industrial customers. Marcus joined HAI in January 2021 to strengthen the dynamic growth strategy after extending HAIs extrusion capabilities in acquiring the extrusion plant in Romania. He has been in the Aluminium industry for more than 20 years, working for Klöckner&Co as a GM for Austria and then for the Holding internationally.

Hammerer Aluminium Industries (short: HAI) is a supplier of complete solutions to the aluminium industry, from recycling to high-tech aluminium profiles and finished components. It caters its aluminium products to various end-user industries, including transportation, building and construction, the industrial sector, and others. Hammerer Aluminium Industries is headquartered in Ranshofen, Austria, and operates seven other locations in Germany, Romania, and Poland. Besides being a key player in the aluminium industry, it is a member of associations such as the Aluminium Stewardship Initiative, Aluminium Deutschland, Bureau of International Recycling (BIR), and European Aluminium underscoring its commitment for a more sustainable aluminium industry. SustainAl is the brand name of Hammerer Aluminium Industries’ low-carbon aluminium product. This product line is especially climate-friendly by using up to 80% recycled material, while the primary aluminium is generated entirely with electricity from renewable sources. With a casting capacity of around 250,000 tons and extrusion capacity of 120,000 tons, the company boasts a large consumer base globally.

An exceptionally high recycling rate, such as that offered by HAI, is only possible thanks

to a wide range of processed scrap types, extensive knowledge of materials, production processes as well as many years of recycling expertise of our employees. To ensure optimal use of scrap, considerable investments have been made in plant engineering, furnace technology, residue management and scrap processing in recent years. The two HAI foundries are among the most modern and flexible ones in Europe.

The goals of the Paris Agreement on climate protection are clear: by 2050, the industry must be CO2-neutral. This also increases the pressure on supply chains and, as a result, customer demand for low-CO2 products. Since HAI has already been dedicated to sustainability and circular economy for years, bringing new, more sustainable products to the market was an obvious choice. We see the industry’s commitment to climate targets as an immense opportunity.

In 2021, HAI launched its low-carbon product lines, the SustainAl 2.0 and SustainAl 4.0 alloys, to offer customers a transparent contribution to sustainability. With our high recycling competence and selected partners, we now offer high quality alloys with one of the world’s lowest footprints in the market. SustainAl 2.0 has a carbon footprint of only 2 tons CO2 per ton aluminium and SustainAl

4.0 has a carbon footprint of 4 tons CO2 per ton aluminium. This is well below the European average of 6.7 tons and the global average of 18 tons. Sustainable corporate governance, aluminium recycling, green sourcing and green energy as well as environmentally friendly processes are the pillars for this. All company divisions are involved in the project, as it affects the entire process chain.

The SustainAl family is available in the 6xxx aluminium class. This alloy series is known for its above-average strength, corrosion resistance, good machinability and is used in a wide range of industries from construction to automotive.

Since the launch, three years ago,acceptance in the market has grown rapidly. In the meantime, we have a solid share of SustainAl alloys throughout all market segments. Customers have realised that by using HAI’s CO2 reduced alloys, they can easily and significantly cut their carbon emissions. At the same time, ambiguity with respect to the importance of recycling rates, different methodologies used in determining the carbon footprint, available data and certifications are big topics. HAI Group can address these questions with its extensive expertise, ensuring transparency and authenticity without greenwashing.

THE TIME TO ACT IS NOW

REEL is on a journey to contribute towards a net-zero aluminium industry.

REEL Aluminium is a major solution provider dedicated to the reduction of the Aluminium industry‘s carbon footprint. This is achieved through both internal and external collaborations and partnerships, new ways of understanding the problem, and the development of innovative technological advancements to achieve net-zero solutions within the Aluminium industry. These efforts assist in REEL‘s goals on its path to decarbonization and a greener Aluminium future.

Pernelle Nunez is the Deputy Secretary General and Director of Sustainability at the International Aluminium Institute (IAI). Established in 1972, the IAI is the only body representing the global primary aluminium industry. Pernelle is responsible for the Institute’s broad sustainability work program and has led a range of collaborative industry projects encompassing aluminium life cycle impact assessment, sustainable waste management and GHG emissions reduction pathways and accounting. She also leads the IAI’s work on social impact and issues across the sector. Pernelle holds a MSci Geology (Hons) from the Royal School of Mines, Imperial College London, and a Postgraduate Certificate in Sustainable Value Chains from the University of Cambridge’s Institute for Sustainability Leadership.

GHG emissions have been the central focus of the aluminium industry’s sustainability ambitions for a number of years. Aluminium production can be emissions intensive because of the high electricity and thermal energy requirements during the smelting and refining process and climate change remains a priority issue globally. It is increasingly clear though, that in order to produce truly sustainable metal, a holistic and integrated approach, beyond GHG emissions, is

essential. Today, the industry is working actively to demonstrate its sustainability ambitions across all major ESG issues alongside ramping up critical decarbonisation action at a pivotal moment in global climate efforts. This presentation will focus on the sustainability challenges and opportunities for the aluminium sector over the coming years as both demand and societal expectations grow. The industry will have to overcome significant sustainability challenges to maintain

the sector’s social licence to operate and its position against other competing materials. Aluminium has an important role to play in many energy transition technologies and it is integral in modern societies – it is essential that the industry continues to take action across the value chain to maximise opportunities for improvement and continue to position aluminium as a sustainable material of choice for the future.

Ramona Averina is a multilingual Sales Area Manager with a background in Social Sciences, currently contributing her expertise at GHI SMART FURNACES. Her diverse cultural experiences and fluency in five languages enrich her work in the business development department. With a passion for innovation and sustainability, she eagerly seeks to actively contribute to positive change and shape the future of the aluminium industry.

In the pursuit of sustainable practices and resource conservation, aluminium recycling plays a crucial role. The success of recycling programmes heavily relies on maximising recovery rates, which necessitates the selection of appropriate technologies. This presentation, titled “Maximising Recovery Rates: Choosing the Right Technology for Aluminium Recycling,” aims to address key factors that contribute to enhanced recovery rates and the implications of improper choices.

The session begins by exploring methods to optimise recovery rates, discussing definitions and precautions to be taken into account. The presentation emphasises three essential factors to consider when selecting a melting furnace, as this choice significantly influences the overall efficiency of the recycling process. Additionally, attendees will gain insights into the consequences of exceeding 1% VOCs (volatile organic compounds) in reverberatory furnaces, shedding light on potential challenges and environmental concerns.

Moreover, distinguishing between clean scrap and contaminated scrap becomes imperative to achieve higher recovery rates and maintain the quality of recycled aluminium.

Join this informative session to understand the intricacies of aluminium recycling technology selection and discover how to make conscious decisions to maximise recovery rates while upholding sustainability and environmental responsibility.

Ron joined China Hongqiao Group in January 2020, following 11 years as Secretary General of the International Aluminium Institute (London). Previous roles include Executive Director of the Australian Aluminium Council (2002 to 2008), Chief Executive of the World Coal Institute London (1997 to 2001) and senior positions with the Minerals Council of Australia (1987 to 1996). Prior to these appointments, Ron was an economist with the Australian Government (1976 to 1987). Ron is an Australian with a small beef cattle farm in Australia.

Key thoughts to develop –

� 20 years of change (the past), the new look of the present (old world, new world, global relocation), what is the Future?

� What does the future look like, what is driving change?

� Energy, carbon, ESG, industrial efficiency, technology advance

� Success needs engagement with governments, communities, research partners, suppliers

� Investing for the future: slow speed, high speed, right speed?

Siri is a dynamic marketing manager at Storvik, renowned for her innovative approach to marketing communications and her pivotal role in enhancing the company’s digital presence globally. With a Bachelor’s degree in International Marketing from Nanyang Technological University, Singapore, and an MBA from Victoria University, Melbourne, Australia, Siri brings a wealth of knowledge and expertise to her role. Since joining Storvik in 2020, she has been instrumental in elevating the group’s brand, significantly contributing to its digital footprint across various platforms. Beyond her marketing competence, Siri is deeply passionate about sustainability, actively engaging in initiatives that promote sustainable practices and the circular economy within the Storvik Group. Her efforts have not only bolstered Storvik’s commitment to sustainable responsibility but have also been crucial in local large-scale processes, including the recruitment of skilled workers. As a valued member of the group’s management, Siri’s influence extends beyond marketing, embodying Storvik’s dedication to innovation, sustainability, and community engagement. Her leadership and strategic vision are key drivers in Storvik’s journey towards a more sustainable future in the aluminium industry.

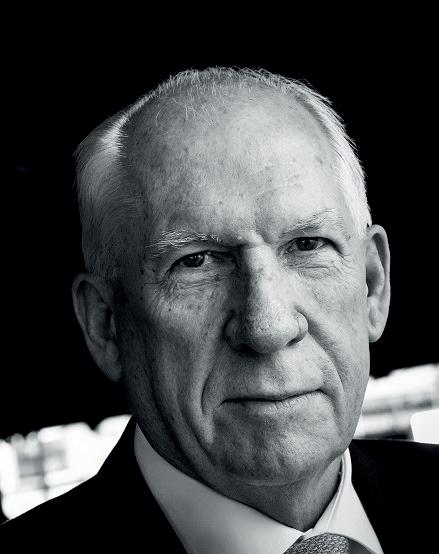

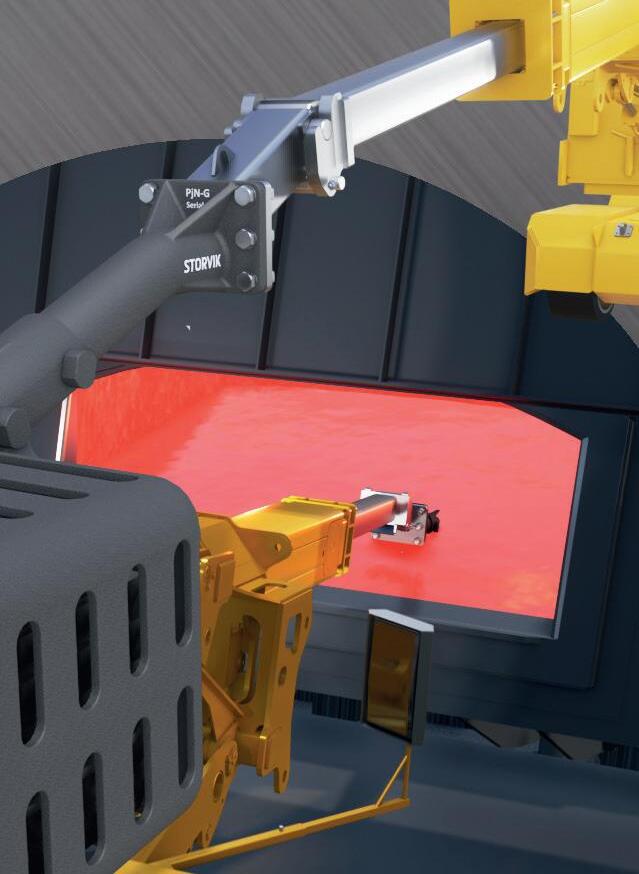

Founded in 1913 by Nils Storvik, a visionary farmer, Storvik began as a local smithy on the Sande farm, focusing on producing and repairing agricultural tools. This origin grounded Storvik in principles of sustainability, emphasising durable, high-quality products designed for longevity and repairability. Over the years, this philosophy has not only remained central to our operations but also evolved to address the pressing needs of environmental responsibility in the aluminium industry.

By 2020, Storvik undertook a significant transformation to formalise our sustainability approach, establishing clear goals and a comprehensive strategy aimed at minimising our environmental impact. A cornerstone of this initiative is our pursuit of Science-Based Targets (SBT) approval, underscoring our dedication to actionable and measurable environmental responsibility.

Our commitment extends beyond mere operational adjustments; it encompasses a thorough examination of our carbon footprint since 2021, including a detailed productlevel analysis across our cast product line. This introspective approach enables us to

identify key areas for innovation, ensuring that both our processes and products actively contribute to a more sustainable environment. However, our vision extends beyond our immediate operations. We recognise the profound impact that our products and solutions can have on the global stage. By focusing on helping our clients and partners reduce their carbon footprint, we contribute to a larger, collective effort to mitigate CO2 emissions worldwide. Through advanced aluminium production technologies and a steadfast commitment to quality and sustainability, we offer solutions that not only meet the industry’s current needs but also forge a path toward a greener future.

Among our notable contributions are:

� The development of PjN-G, a proprietary iron quality structure that significantly extends the lifespan of furnace tending tools, enhancing sustainability in aluminium production.

� The pioneering Cathode Potshell Reset Project in Norway, offering a sustainable alternative by repairing and resetting wornout cathode potshells instead of producing new ones, thus markedly reducing the carbon

footprint.

� ICON, an innovative method for removing alkaline metals during liquid metal tapping, developed in cooperation with Hydro Sunndal, Europe’s largest primary smelter. This technique stands as a testament to our commitment to reducing CO2 emissions through collaborative innovation.

As Storvik gears up for the Future Aluminium Forum, we’re focused on highlighting our role in advancing sustainable aluminium production. Our efforts are driven by a belief in collaboration and innovation as key drivers of industry-wide change, promoting sustainable practices that will help secure aluminium’s role in a global green economy. As a central supplier to both primary aluminium production and recycling plants, our efforts are critical in the collective push towards net-zero emissions by 2050. Each step we take is a testament to our commitment to forging a greener future, demonstrating that every contribution, no matter the size, is vital in our shared environmental responsibility.

Cast Products

Project & Engineering

Machine Building & Fabrication

Mechanical Operations

Come see us at our table during the event, and don’t miss Storvik’s presentation on ‘Forging a Sustainable Future: Storvik’s Initiatives Towards Greener Aluminium’ at the Future Aluminium Forum.

www.storvikgroup.com

post@storvikgroup.com

+4771699500

Storvik Group HQ: Industrivegen 13, 6600 Sunndal, NORWAY

AL Circle is the world’s most popular digital platform dedicated to Aluminium - the world’s most sustainable metal. With a series of interconnected digital platforms AL Circle has been building a virtual ecosystem for the aluminium industry to create a one-stop solution with the motto of ‘Think Aluminium, Think AL Circle’. With over 40,000 global readers each month from over 190 countries, AL Circle continues to bring curated content to the industry in newsletters, reports, and e-magazines. Building on the traction of a vibrant news portal, AL Circle launched AL Biz, the world’s first and largest online B2B marketplace for the Aluminium value chain, bringing together the organized top-of-the-funnel companies alongside the disconnected small and medium players at the bottom of the value-chain pyramids. Leveraging the power of technology, AL Circle continues to innovate and build new digital services to get the global Aluminium industry more connected, more efficient, and greener than ever before.

https://www.

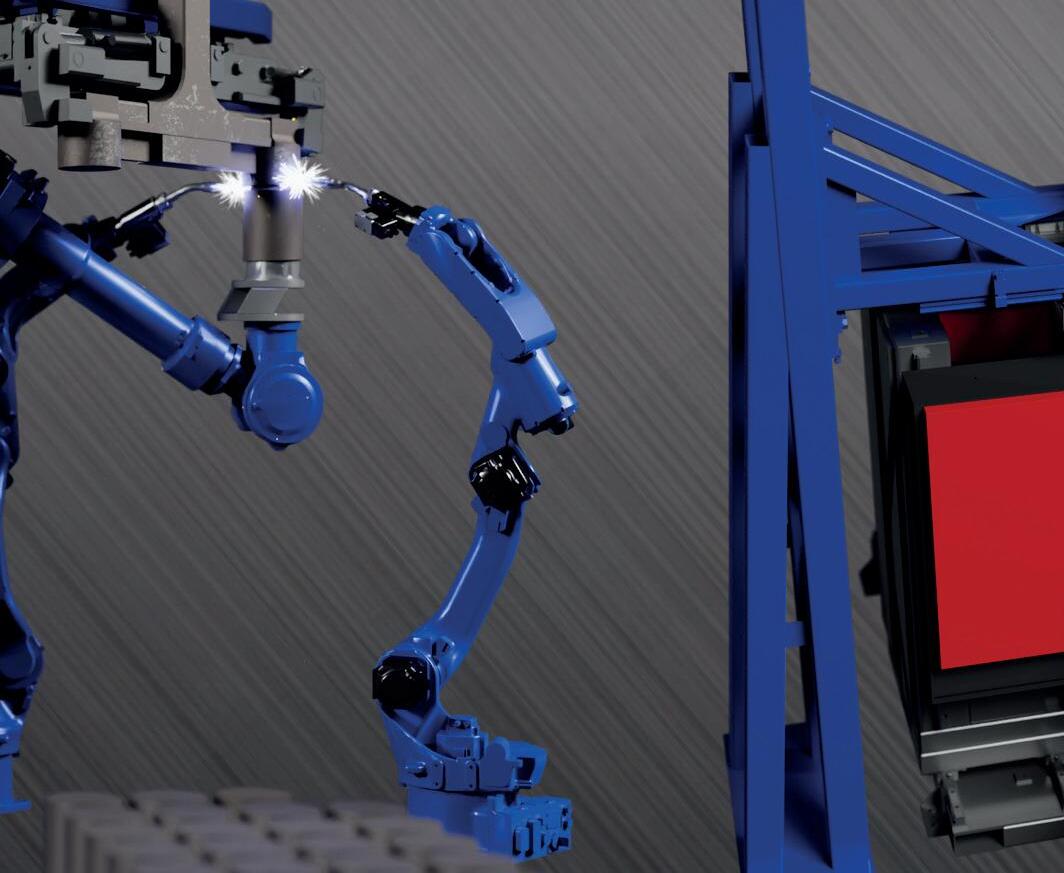

Mössner develops and builds special solutions in the fields of mechanical engineering, automation technology and robotics. With our 140 employees we can handle even larger projectswithout losing the necessary flexibility for your special solutions. At our location in Eschach, Germany we develop, manufacture and assemble your system and commission it for our customers worldwide.

In the field of aluminium technology, we offer precise sawing and milling systems for primary and secondary aluminium production. These enable the processing of rolling ingots, T-bars, blanks, contours, round blanks, samples, ingots and plates.

Whether system components or turnkey casting and finishing lines - our special machines stand for reliable and automated system technology. This includes core handling, automation of casting machines, cooling and industrial marking, decoring, sawing, milling and deburring, as well as all necessary sub-processes of your casting production.

For more than 130 years our band saws have been known for their durability, robustness and precise cutting performance on a wide range of materials. The saws are manufactured and assembled exclusively at our location in Eschach. Spare parts supply is guaranteed even decades after the purchase.

In addition to handling tasks, our machines take over the processing steps of drilling, milling and sawing. As a complete supplier, we supply systems for all areas of quality control, conveyor technology and nuclear decommissioning.

Engineering

Our engineering department supports you in all questions of planning, optimisation, simulation and programming of robot applications. We offer automation in the field of robotics and control engineering as well as image processing for automated inspection stations and the digitisation of workpieces by 3D scanning.

https://www.moessner-kg.de/en/

China Hongqiao Group is one of the largest fully integrated aluminium company in the world with extensive activities along the whole production chain, based on major direct investments and long-term strategic partnerships. Production is dominated by operations in China, combined with key resource developments in Indonesia and Guinea.

China Hongqiao attaches great importance environmental protection, energy conservation and sustainable development. with clean green production and higher value products as core business goals. China Hongqiao seeks to continuously improve the full industrial chain by building unique aluminium industry clusters. Central to the industrial cluster philosophy is the development of surrounding enterprises and the cities in which the plants are located. China Hongqiao is committed to helping achieve China’s carbon peak and carbon neutral goals – and has adopted a roadmap to take positive actions to optimise the energy structure, carry out industrial upgrading, and promote low-carbon transformation of the industry. The goal is to achieve peak carbon emissions before 2025 and net-zero carbon emissions in Scope 1 and 2 before 2055.

http://en.hongqiaochina.com/

Only now, process control in the metal industry has been limited by the need to manually cast a solid sample from the melt for offline analysis, delaying the feedback of vital information about the chemical composition of the molten metal. DTE‘s industry-leading LP-LIBSTM technology solves this decades-old industry problem by delivering instant elemental analyses directly from molten metal. DTE‘s revolutionary technology improves process efficiency, sustainability, and safety for metal manufacturing and recycling. DTE‘s primary focus is to set the new benchmark for in-line chemical analysis of molten metal.

https://www.dte.ai/

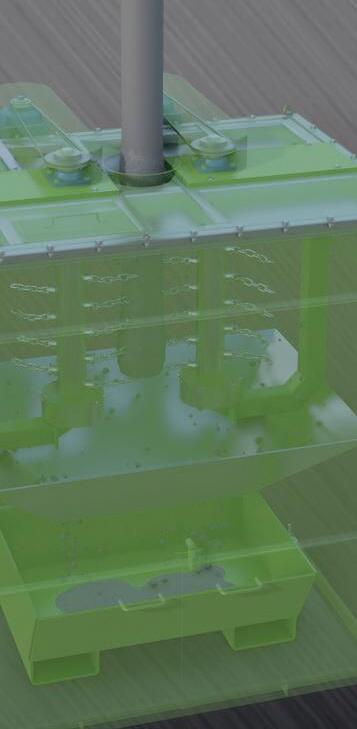

Equibras is an equipment supplier for the aluminium industry since more than 20 years. With more than 5000 products distributed in nearly 30 aluminium plants worldwide, the company is the world leader in equipment for the potlining of the electrolysis cells.

Sectors of Activity

Various industrial sectors, including the aluminium sector.

Products

Turnkey tools and equipment for:

� Potlining of electrolysis cells

� Cells & superstructures repair

� Lifting and handling

� Safety and access

� Customised equipment

� Heating Services

� Equipment supply

� Equipment rental

� Design, optimisation and manufacturing

� Technical consultation for engineering firm

https://equibras.com/

Emirates Global Aluminium (EGA) is the world’s largest ‘premium aluminium’ producer and the biggest industrial company in the United Arab Emirates outside oil and gas.

EGA is owned by Mubadala Investment Company of Abu Dhabi and Investment Corporation of Dubai, and is the largest company jointly owned by the two Emirates.

As a team of more than 6,700 people around the world, we share a drive to fulfil our purpose and achieve our mission, while living our values.

Our leadership ensures that we demonstrate a culture of innovation and responsibility as well as a robust corporate governance for our long-term success.

Aluminium is among the world’s most versatile metals, and our global customers transform it into products that make modern life possible.

Our aluminium is the biggest made-in-the-UAE export after oil and gas. We produce one-in-every 25 tonnes of aluminium made worldwide - four per cent of the world’s total production and almost half of the aluminium produced in the Gulf.

EGA is an integrated aluminium producer, with operations from bauxite mining to the production of cast metal. EGA’s operations include an aluminium smelter and an alumina refinery in Abu Dhabi, an aluminium smelter in Dubai, and a bauxite mine in the Republic of Guinea.

https://www.ega.ae/en

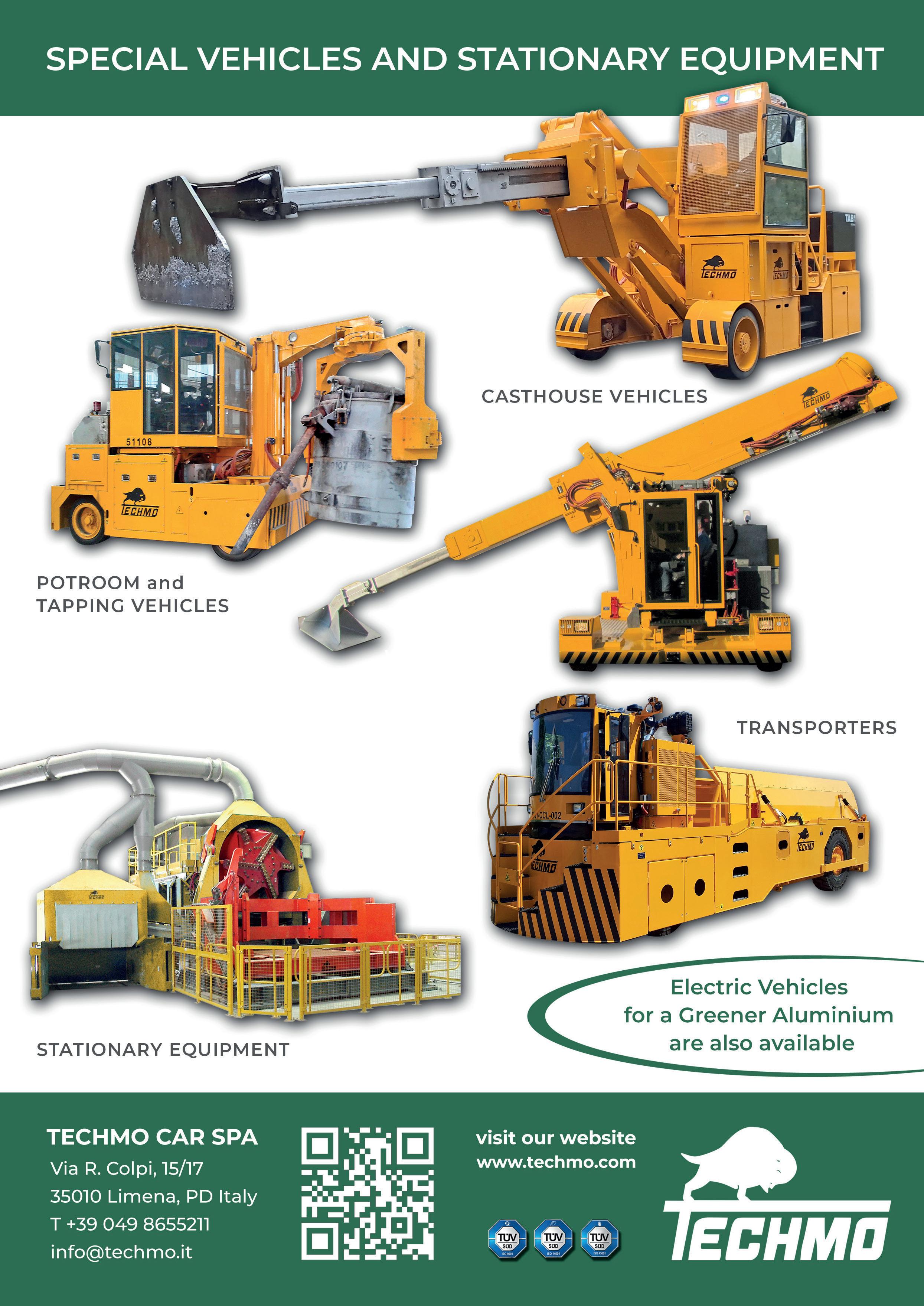

GLAMA Maschinenbau GmbH designs and builds heavy-duty Equipment for Aluminium pot rooms, cast houses and anode rodding shops throughout the world for more than 60 years now.

Over the years we have built up a valuable wealth of experience and have specialised in custom designed solutions and the following machine types

� Anode Changing Vehicles

� Hammer Crustbreakers

� Tapping Trucks

� Anode Pallet Transporters

� Furnace Charging Machines

� Furnace Tending Machines

� Ladle Charging Trucks

� Butt Cleaning Manipulators

� Coil Lift Trucks

� Molten Metal Carriers

GLAMA Maschinenbau GmbH delivers machines with a unique combination of advanced control, big data and artificial intelligence and rugged, reliable construction. GLAMA equipment withstands the heat, dust, vibration and battering of heavy industry while delivering precise handling performance according to customer’s demand with lifetime expectations over 20 years.

A qualified and experienced team of German engineers work on optimised products on customers’ requirements to simplify operation methods at remarkable low operational cost.

As a result, we are a loyal partner to a customer base of over 2000 machines at appr. 150 different customers.

https://www.glama.de/de/index.php

The HAI Group, headquartered in Ranshofen/Braunau (Upper Austria) produces complete aluminium solutions (profiles and processed products) for the construction, transport, electrical and mechanical engineering and plant engineering sectors. Hammerer Aluminium Industries (HAI) has existed in this form since 2007 and has achieved extremely rapid, dynamic and at the same time healthy growth in recent years.

Hammerer Aluminium Industries employs around 2,000 people. Founded in 2007, the company is headquartered in Ranshofen, Upper Austria, and has eight other locations in Germany, Romania, Poland and South Korea. In 2022, HAI achieved a turnover of 990 million euros. The HAI Group’s products can be found in the construction sector (including solar) as well as in automotive and transport technology (e-mobility), electrical engineering and mechanical and plant engineering.

HAI offers innovative solutions made of aluminium and covers the entire value chain - from recycled input material to sophisticated profiles and complex components - taking into account all sustainability aspects. To this end, we rely on state-of-the-art production facilities, comprehensive research and development, especially with regard to new alloys.

Our mission is to build trusting, long-term partnerships with our customers in the process and to drive forward joint, dynamic further development. This means that we quickly launch innovative solutions, produce technologically sophisticated products with the highest quality standards and always deliver them reliably. In doing so, we pay special attention to the topics of occupational safety, environmental protection and sustainability and bring the whole thing into effective harmony - for our benefit and that of our customers.

Accordingly, we pursue our vision as a clear goal, in which we are recognised as the most dynamic and sustainable supplier of highquality aluminium products and solutions from our end-to-end value chain.

https://www.hai-aluminium.com/en/

The International Aluminium Institute (IAI) is the only body representing the global primary aluminium industry. The IAI was established in 1972 and current IAI membership includes global bauxite, alumina and aluminium companies in all the major producing regions. IAI member companies are engaged in the production of bauxite, alumina, aluminium, the recycling of aluminium, or fabrication of aluminium and are committed to improvements in sustainable production, use and recycling of aluminium. Through the IAI, the aluminium industry aims to promote a wider understanding of its activities and to demonstrate both its responsibility in producing the metal and the potential benefits to be realised through its use in sustainable applications and recycling. The IAI provides authoritative and reliable statistical data that promotes the responsible and sustainable use of aluminium and acts as a forum for industry to engage and lead initiatives on issues of common interest.

https://international-aluminium.org/

MetAllic was established in 2023 and provides technological solutions and services for aluminium, magnesium and steel industry included process design, smarter plant flow, recycling solutions, interface design between recycling plant/ casthouse and downstream processes, feasibility study preparation, digitalisation of metallurgical processes and training.

https://metallicco.com/about/

always thedurable solution

Costeffectiveheavyduty mobileequipment

foraluminiumindustries...

GLAMAMaschinenbauGmbH

Headquarters:

Hornstraße19

D-45964Gladbeck/Germany

Fon:+49(0)204397380

Fax:+49(0)2043973850

email:info@glama.de

GLAMAUSAInc.

60HelwigSt.,Berea,Ohio44017

Fon:+18774526266

Email:sales@glama-us.com

Precimeter is a leading provider of high-performance premium products in measurement technology and flow control for foundries, operating globally. With a strong ownership and a corporate culture rooted in values such as longevity, quality, customer focus, and commitment, we are positioned to continue our journey as an industry leader.

At Precimeter, we strive to shape the future of industry by offering innovative solutions that enhance precision, efficiency, and sustainability in various production processes. We focus on delivering tailored measurement systems and monitoring tools that meet our customers’ unique needs. Our technologies are used in areas such as metallurgy, mining, foundries, and other manufacturing industries.

https://www.precimeter.com/

PSI Metals is the leading provider of innovative production management software for the metals industry, combining Supply Chain Management, Advanced Planning Scheduling and Manufacturing Execution System within one Service Platform (SP). It also specialises in business consulting that pro-vide strategic information services, which help metals producers define a stepby-step digitalisation and decarbonisation transformation plan.

PSI Metals is a subsidiary of PSI Software SE, a publicly traded company that focuses on software for energy, mobility and production management.

Our end-to-end solutions enable aluminium and steel producers stay competitive by delivering tailored and configurable solutions since 1969. To support all processes such as planning, production, quality, logistics and energy, the PSImetals Service Platform allows sustainable and highly integrated solutions. PSImetals FutureLab investigates and develops the solutions of tomorrow based on PSImetals SP while taking into consideration the latest industry development. Therefore, PSI considers latest developments in the field of digitalisation and user empowerment and supports its clients on their decarbonisation missions.

With our global presence in four continents and headquarters in Duesseldorf, Germany, PSI Metals employs more than 300 committed experts that ensure smooth operations of the company in 10 countries. https://www.psimetals.com/

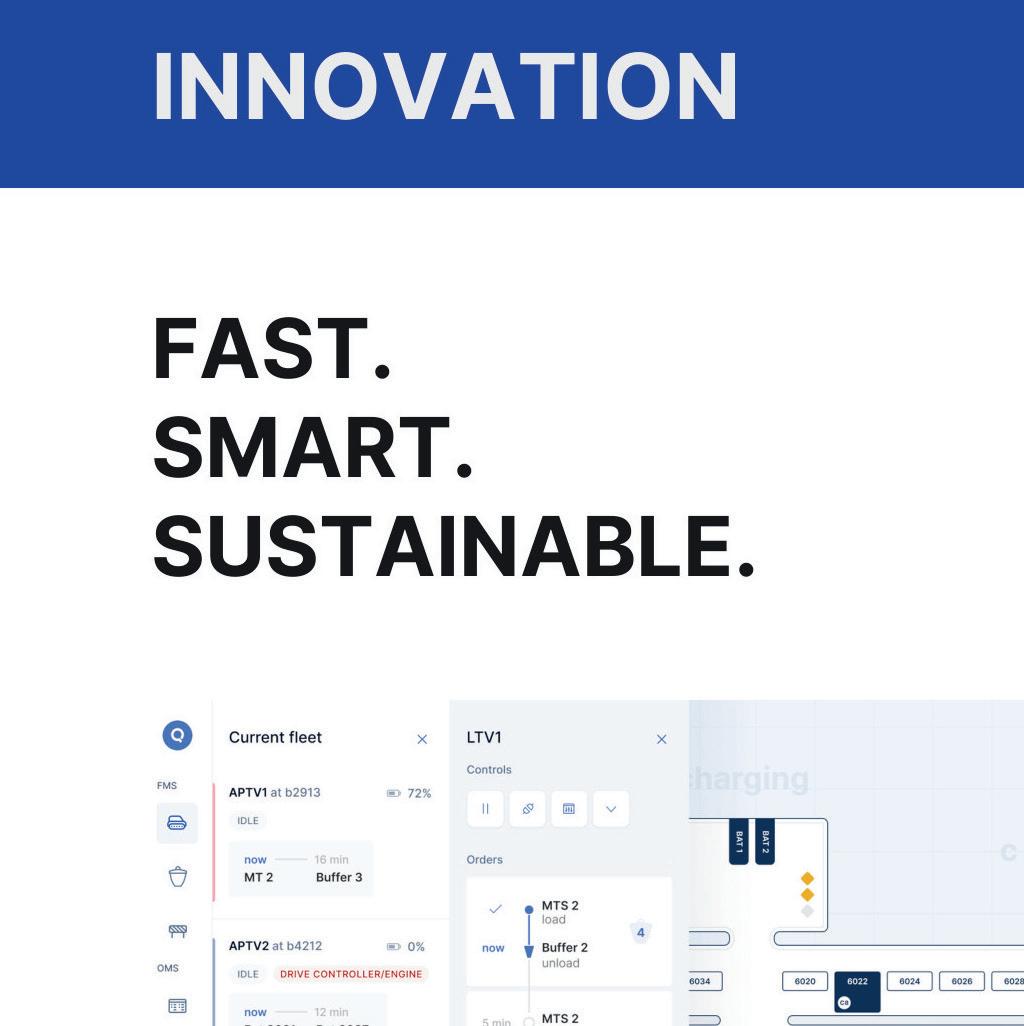

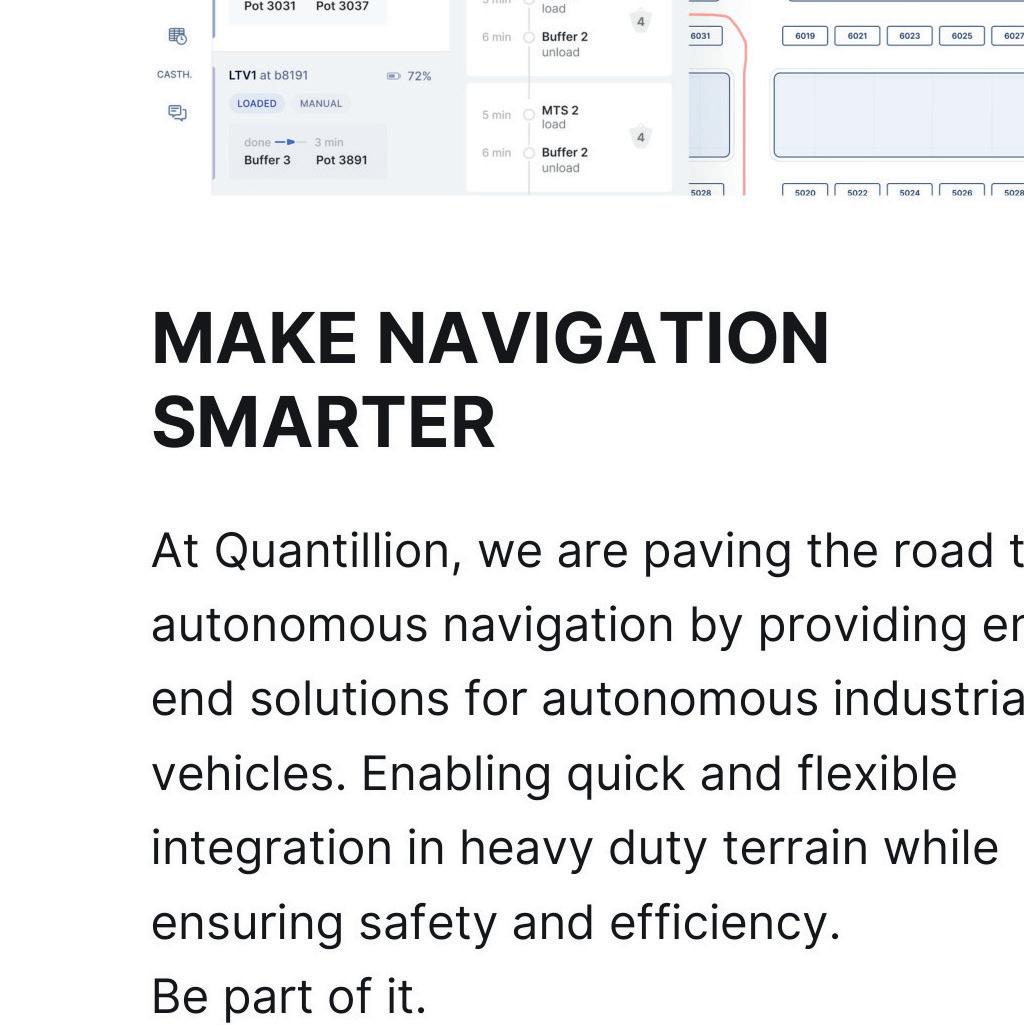

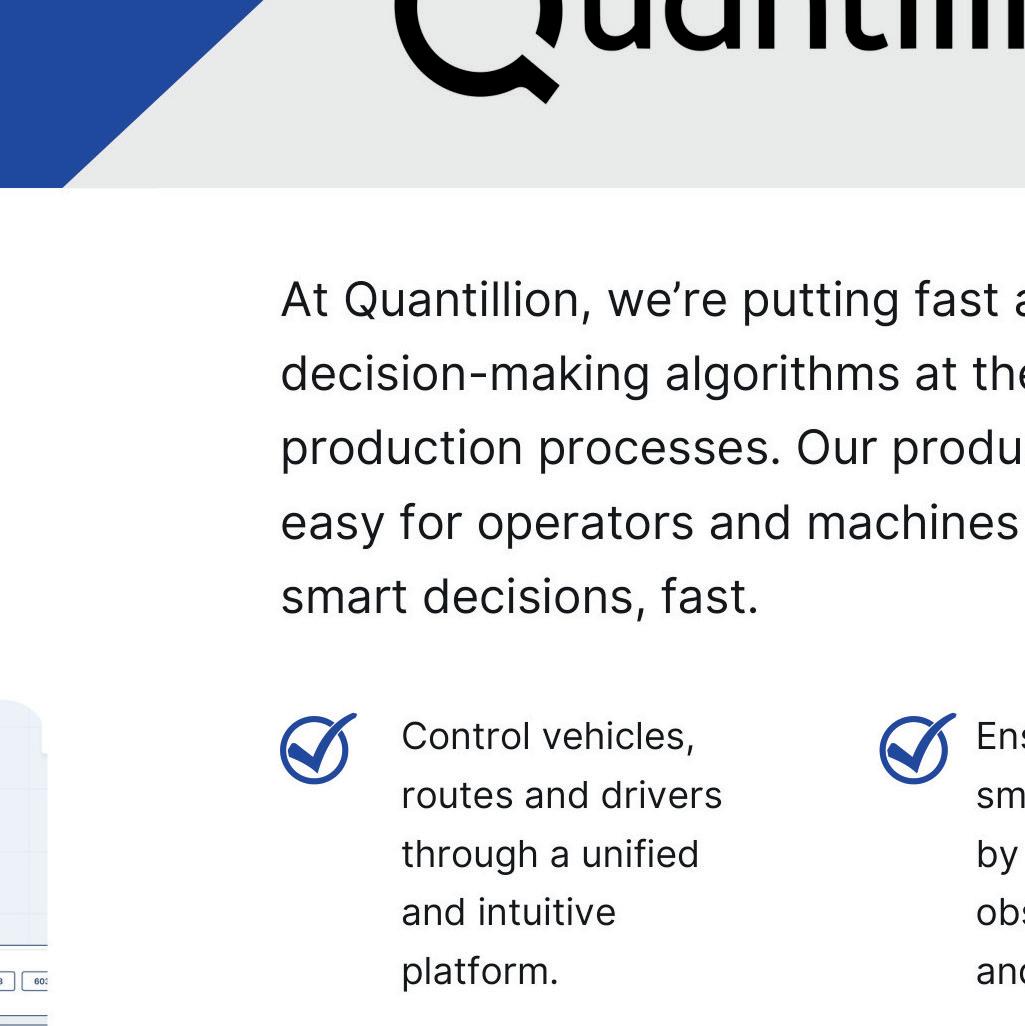

Quantillion’s mission is to empower Smarter, Greener and Safer industrial operations. We do this by combining high tech equipment, our unique integration layer and process optimisation techniques. Through this we are able to deliver flexible, profitable, and sustainable logistics for the heavy industry.

We believe that new technology enables world leading industries to become more agile. Not only will industries be able to adapt to outer change, but also to the changes they face in their day-to-day operations. Therefore, we are putting fast and powerful decisionmaking algorithms at the heart of production processes. Our products make it easy for operators and machines to make smart decisions, fast.

Quantillion originally started with automating logistics within primary aluminium. Since then we have grown to be a strong integration provider acting as a key link between the smelters and their numerous equipment suppliers.

For the past few years Quantillion has developed and deployed autonomous decision systems, which have executed over 300,000 critical operational tasks within the heavy industry. With our order management system and traffic management system we are streamlining logistical decisions within the heavy industry. We support the industry with the autonomisation of core operations by connecting all separate workflows and agents, either human or machine. By integrating our software with our client’s business operations and IT, we create more profitable, more efficient, and more responsive operations. All of this is done in one environment, with a layer of business logic and artificial intelligence. This results in an easy-to-use user interface for precise control and process management.

Due to our strong focus on primary aluminium, we have a deep understanding of the industry and of the logistical operations that are at the heart of the numerous processes in a smelter. We have become specialised in bringing new data technology to aluminium smelters as a pioneer in autonomising industrial operations. Quantillion contributes to Industry 4.0 through revolutionising the way equipment and operators collaborate and how workflows are optimised. At Quantillion we enable the heavy industry to capitalise on these improvements with our Navigation Kit, Traffic Management System and Order Management System.

By having both humans and machines inter-connected, our execution system allows for a more efficient and intelligent way of working. Through this we create fully autonomous processes instead

of single implemented automated (mobile) equipment. With our centralised system we automatically find the most optimal scenario given any circumstance.

Headquartered in Amsterdam, our highly skilled and passionate people make sure to introduce new technology to the industry and put the data to work!

https://www.quantillion.io/

Efficient furnace practices with low-cost production standards, start with automated charging and skimming. Using the right technology enables a significant reduction of energy consumption, minimum cycle times, reduced furnace maintenance and most importantly a safer environment for the operators. RiA has been focusing on the development and manufacturing of charging and skimming equipment since 1997 and in particular, is now focused on innovative automation and process optimisation solutions and the safest and most efficient systems possible. RiA charging and skimming machines utilise full artificial intelligence (AI) to make charging and skimming cutting-edge technology, without operator interaction. The latest innovation in skimming is In-Furnace Dross Processing (IFDP), squeezing the dross whilst still in the furnace, releasing liquid aluminium which remains with the bath, increasing recoveries. Recent additions to the product portfolio include Fioscope air-cooled smart In-Furnace cameras and laser bath height measurement systems. Initially established as a local maintenance service and special equipment supplier for the German aluminium industry, over the last two decades RiA became an important International partner for aluminium remelt cast houses worldwide, now with more than 80 charging and skimming machines supplied to major aluminium companies around the globe. Building on high quality standards and continuous improvement has resulted in the most reliable, robust, maintenance friendly and custom-made furnace tending equipment on the market.

RiA charging machines can charge up to 30 tonnes of material in one push in under two minutes, deep into the furnace and evenly distributed to ensure maximum melt rates. RiA skimming machines can skim, stir, mix and clean the furnace with precise position-controlled contact, hence minimal refractory wear. RiA/Fioscope air cooled cameras allow a view into the furnace 24/7 from a safe location with the door closed. RiA bath height measurement systems allow accurate determination of liquid heels ensuring on spec alloying first time and also prevent short cast rejects. RiA systems achieve the lowest possible operational cost and the safest operating environment for all important stages of the cast house process. https://www.ria-casthouse-engineering.de/en

Proudly Canadian, Royer stands as a global leader in safety footwear design and manufacturing. We specialize in crafting top-tier safety footwear using cutting-edge technology and premium materials to meet the demands of the toughest conditions worldwide. Our relentless pursuit of perfection drives us to continually innovate, ensuring our products set the industry standard for quality and durability. At Royer, we’re not just manufacturers; we’re innovators, committed to providing our customers with the best possible protection, since 1934.

One hallmark of our innovation is our leadership in Metguard protection, particularly in the smelting industry. Our Metguard technology offers unparalleled defense against hazards like molten metal splashes, setting a new standard for safety in demanding environments.

With Royer, you’re not just investing in safety footwear; you’re investing in peace of mind. Join us in shaping the future of safety footwear.

https://royer.com/

SAP has 40 years’ experience working closely with thousands of industrial manufacturers including aluminium, steel and building materials across the globe to use digital innovation and artificial intelligence to anticipate real-time demand and supply, enhance process excellence for operational efficiency, operate resilient supply chains, and innovate the customer experience. In addition, SAP can help companies manage stakeholder expectations to produce environmentally responsible products and services, reduce GHG emissions, minimise waste, increase circularity and use socially responsible business practices across product lifecycles and value chains.

As the market leader in enterprise application software, we help companies of all sizes and in all industries run at their best: SAP customers generate 87% of total global commerce. Our machine learning, Artificial Intelligence (AI), Internet of Things (IoT) and advanced analytics technologies help turn customers’ businesses into best run businesses. Our end-to-end suite of applications and services enables our customers to operate profitably, adapt continuously, and make a difference. We simplify technology for

companies so they can consume our software the way they want – without disruption. With a global network of customers, partners, employees and thought leaders, SAP helps the world run better and improve people’s lives. For more information, visit website for how SAP works with metals, building materials and other industrial manufacturing industries.

https://www.sap.com/uk/index.html

At Sistem Teknik, we specialise in providing turnkey solutions for the aluminium industry. Our tailored approach to design allows us to offer a wide portfolio of equipment for melting, alloying, casting, homogenising, and heat treatment, ensuring each solution meets the unique needs of aluminium producers. Operating from two state-ofthe-art factories in Bulgaria and Turkey, our in-house manufacturing capabilities enable us to deliver seamless turnkey solutions, ensuring optimal performance and efficiency every step of the way. With a dedicated team of over 250 engineers and technicians, we’ve successfully commissioned more than 1,500 projects across 37 countries.

Established in 1979, Sistem Teknik has grown to become one of the largest suppliers of furnace technology globally. Our ambition is clear: to lead the transformation of the aluminium industry towards a greener future. Committed to reducing the environmental footprint of the aluminium industry, we’ve spearheaded numerous R&D projects over the past 5 years, developing innovations such as laser-induced breakdown spectroscopy solutions for alloying, delacquering lines, and smart heat recuperation systems. Automation and control systems are at the heart of what we do. Our skimming and charging machines leverage image processing technology for automatic operation to maximise energy and material efficiency. Partnering with the Horizon EU platform, our R&D centre continues to engineer the future of aluminium technology.

Did you know we have furnaces that have been running since 1990? With 45 years of experience, we provide after sales services that prolong equipment lifetime and boost performance. Housing a dedicated service team of 20 technicians and engineers, we ensure equipment longevity through comprehensive after-sales support, transcending borders to serve our clients wherever they may be.

https://www.sistemteknik.com/