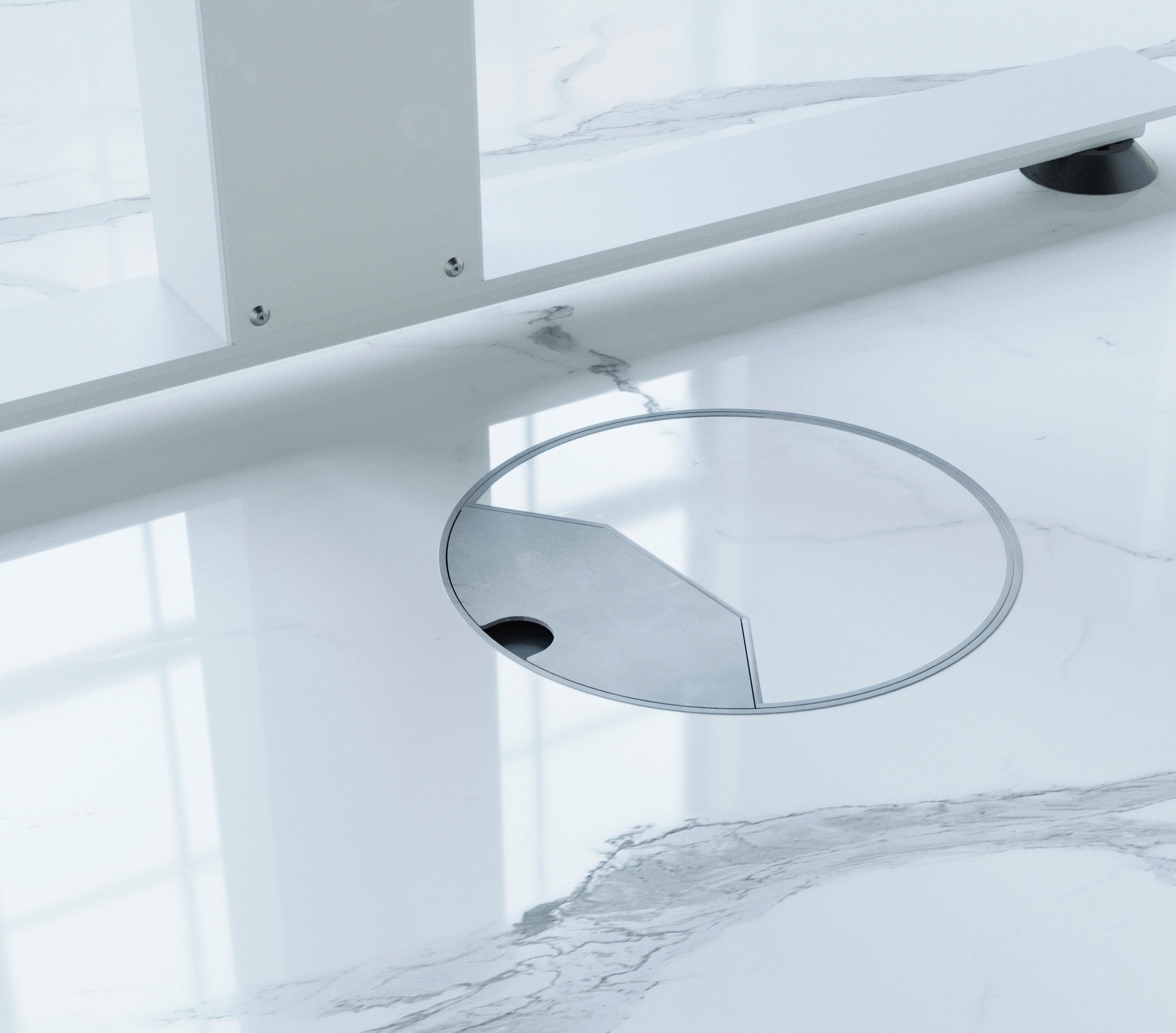

Our Stainless Steel Grommet is an elegant, premium quality floor-access solution that allows you to connect seamlessly with your underfloor power distribution system.

The Stainless Steel Grommet is designed for use in high-end commercial environments and is suitable for raised floor applications. It can be installed in a range of flexible and efficient configurations that permit safe and easy of access to power and data services within the under-floor void.

Stainless Steel Flanged Trim for carpet installations.

Steel Tramline

for premium floor tile installations.

4, 6, 8, 9, 16, 18, 23, 24, 45, 51

Awards

10 Managing product information under the building safety act

Contractor Corner

14 How technology relieves admin burdens and drives growth

Features

LIGHTING

20 Circular Lighting Live: Industry unites for sustainable change

22 Why we need to prioritise lighting controls this winter

EV

26 Darren Harris at Believ unpicks EV rollout challenge

28 eHGVs risk stalling in the UK it and how will it fall short?

30 Wonderful world of Type 3 SPDs

FIRE, SAFETY AND SECURITY

32 The two sides of solar safety

34 Why follow british standards?

36 C-TEC’s CAST ZFP and CAST-PRO specified for £250m development

Alarming rise in fake ATEX equipment threatens worker safety 39 Why rigorous testing and handover matter in domestic fire safety

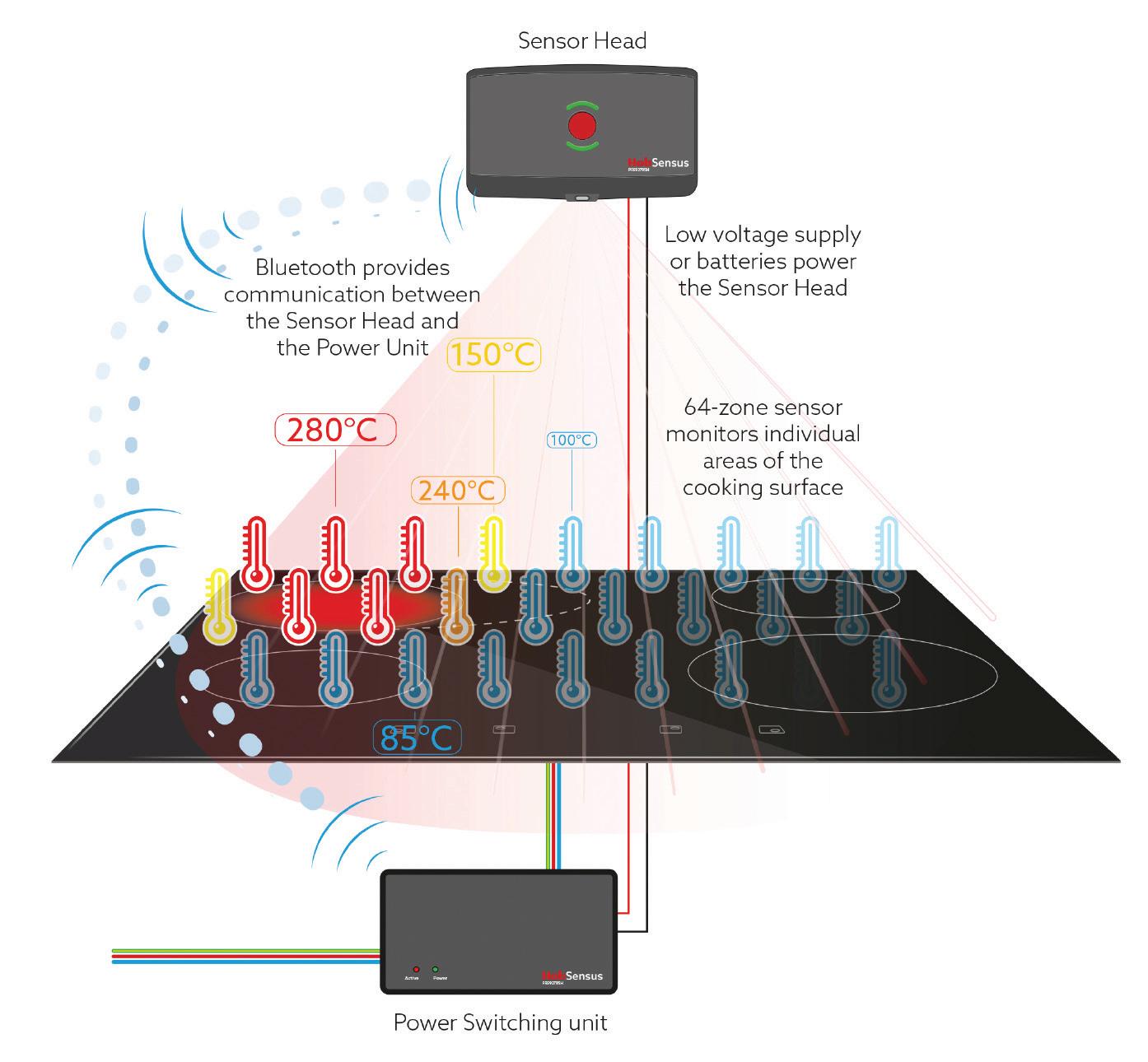

A game-changer for kitchen safety

& MEASUREMENT 42 How to use a circuit tracer to locate a dead short

EV charger installation and maintenance set to surge

The unsung hero of operational resilience and safety

Anna Mazzoleni, ABB

Snowdon at night: Dan Griffiths leads the team to the summit

How project failures begin before construction starts Editor

The Electrical Industry Awards 2025 once again shone a spotlight on excellence, innovation and achievement across the UK’s electrical sector.

On Thursday, October 23, the finalists and winners of this year’s Electrical Industry Awards were announced at a virtual ceremony by BBC weather presenter Sarah Keith-Lucas.

This year’s ceremony celebrated the professionals, companies and products driving the industry forward – from groundbreaking technologies and sustainable projects to exceptional training initiatives and community impact.

The judging panel, comprising representatives from leading industry bodies including the ECA, JIB, LIA, NAPIT and NICEIC, praised the exceptional quality and innovation demonstrated across all categories.

A total of 12 awards were presented, recognising standout achievements across products, projects, contracting, and wholesaling. The event was supported by main sponsor Luckins Live, section sponsor Aico, and category sponsors WISKA, and NAPIT.

A huge congratulations to the winners and a big thank you to the sponsors and judging panel for their invaluable support.

To watch the ceremony, visit: www.electricaltimes.co.uk

Lisa Peake, EDITOR, lisa.peake@purplems.com @electricaltimes

Phil Thompson, former Procurement Data Manager at NG Bailey, has joined the team as Manager - ETIM UK and Ireland Limited.

This is a new role reflecting the increased demand by businesses for technical and practical ETIM support. Phil will divide his time between the Electrical Distributors’ Association (EDA) and their ETIM work in the electrotechnical sector, and the Builders Merchants Federation (BMF), covering businesses in the building materials, HVAC and plumbing sectors. The EDA and BMF are partners in ETIM UK and Ireland.

Freedom Heat Pumps has announced the appointment of Graham McCracken as its new Managing Director, a move that marks the start of a new chapter, positioning Freedom Heat Pumps as a leading independent distributor.

Graham brings over 20 years of experience in customer insight and strategic leadership, including a decade at Certas Energy, the UK’s largest independent fuel and energy distributor.

Logic4training, the South East’s leading building services engineering training provider, has strengthened its growing apprenticeship provision with the appointment of Iza Salegui as Head of Apprenticeships and Funding.

Iza brings a wealth of experience in training, quality improvement and funding management across education and employment sectors, at both local and national levels. Iza’s skills and leadership will drive Logic4training’s mission to support industry employers and learners in tackling skills shortages.

Corpay, the global S&P 500 corporate payments company, has appointed Matt Hanks as Vice President Marketing for UK Fleet, a new role created to accelerate growth across its UK fleet and payments brands, including Allstar, Keyfuels and The Fuelcard Company (TFC).

ABB celebrates half a century of innovation and energy efficiency with variable speed drives

October 2025 marked the 50th anniversary of the Low Voltage Variable Speed Drive (LV VSD), which was used in a commercial application for the first time at a sawmill in Finland, in 1975. It was developed in the 1970s by Strömberg, a predecessor to ABB.

The LV VSD addressed a long-standing limitation of the traditional squirrel-cage induction motor, which had remained fixed-speed since its invention by Nikola Tesla in 1888.

Martti Harmoinen (pictured), the Strömberg engineer credited with leading the original development team, received the Finnish Engineering Award in 1981 and the honorary title of Professor in 1995.

Independent studies suggest that if VSDs were applied more broadly, including both constant and variable flow applications like pumps, fans, and compressors, annual energy consumption in EU could be reduced by around 140 terawatt-hours. ABB

estimates that using VSDs in these scenarios can lead to energy savings of up to 12 per cent per installation.

Though Martti Harmoinen passed away in 2023, his work remains central to ABB’s mission to advance smart, efficient motor systems worldwide.

For more about the history and impact of the Low Voltage Variable Speed Drive, visit https://campaign-mo.abb.com/drives50

Vent-Axia’s Sentinel Apex gains Passivhaus

Vent-Axia is proud to have gained Passivhaus Certification for its award-winning Sentinel Apex commercial Mechanical Ventilation with Heat Recovery (MVHR) range.

Passivhaus is a method of creating buildings that require very little energy for heating or cooling whilst maintaining exceptional indoor comfort. The certification is a performance-based standard that is increasingly important to specifiers who need the lowest carbon building solutions. With its class-leading performance number, gaining this certification confirms that the Sentinel Apex is ideal for low and zero-carbon buildings, especially beneficial with the Net Zero 2050 deadline approaching. The Sentinel Apex also continues to deliver, ‘Simply more as Standard’, as the Passivhaus Certified models are available at no extra cost.

“We are delighted that our Sentinel Apex commercial MVHR units have achieved the globally recognised Passivhaus Certification thanks to their excellent performance number and thermal efficiency. The Sentinel Apex has been designed to help specifiers on their decarbonisation journey, maximising its energy efficiency and performance, while providing excellent IAQ, ultra-low sound levels, and thermal comfort, making the units ideal for Passivhaus projects. Not only that, but as Passivhaus buildings use up to 90 per cent less heating and cooling than conventional buildings, end-users can benefit from lower energy bills too,” said Alexis Roberts, Channel Marketing Manager at Vent-Axia.

For further information on Vent-Axia and the Sentinel Apex, visit www.vent-axia.com.

Evolt Charging partners with CatStrap to bring robust and durable EV cable protection solution to the UK market

Evolt Charging, part of SWARCO Smart Charging, one of the UK’s leading electric vehicle (EV) charging businesses, has announced a new agreement to become the exclusive UK distributor for CatStrap – EV Cable Protector, a robust protection system that is specifically designed to prevent EV charger cable theft.

Cable theft is a nationwide challenge that continues to affect all UK Charge Point Operators (CPOs), with hundreds of incidents of theft and vandalism reported within the last few years. Despite the relatively low resale value of the copper wiring within EV charging cables, each stolen cable can cost the CPO thousands to replace.

CatStrap combines dual steel materials in a proprietary armoured sleeve design that successfully deters saws, cable cutters, and other handheld or powered cutting tools. The robust protection system features three layers of steel strip, four times harder than stainless steel, and aircraft-grade cable for superior theft protection.

Evolt has rigorously tested the CatStrap in real-world conditions, proving its exceptional resistance to cutting and theft attempts.

“We’re proud to partner with Evolt Charging to bring our EV Cable Protector technology to the UK,” said David Birsen, Vice President of CatStrap. “After protecting thousands of public chargers across North America in high-theft areas with virtually 100 per cent success, we’re excited to extend that protection to UK operators. Evolt’s nationwide service capability, operational excellence, and expertise in charge point hardware make them the ideal partner to ensure consistent, high-quality installations and successful implementation of our products.”

While earliergeneration PHEVs offered electric-only ranges of just 20 to 30 miles, new and upcoming models are providing range suitable for daily driving.

This trend aligns with what drivers are saying: most daily travel needs fall within the 30-to-40-mile range, and with these new PHEVs the use of petrol can be the exception rather than the rule.

Viktors said: “Our research underlines the growing importance of destination charging – being able to charge where the vehicle is parked during a stay or visit, such as at hotels, tourist attractions, restaurants or shopping centres. Many PHEV drivers are now comfortable using petrol occasionally but prefer to recharge whenever possible –especially while staying somewhere for a few hours or overnight.

“I heard another EV driver say, ‘We used petrol on the motorway, sure, but we charged at our hotel and used only electricity for all our local driving the next day. That made the trip feel cleaner – and more relaxed.’”

Modern PHEVs don’t just go further – they now charge faster. Many support 11kW 3-phase AC, allowing a full recharge in under two hours. That means destination charging doesn’t need to be limited to overnight stays. Short stops for a meal, event or shopping trip can easily restore a full battery – if the chargers are there.

CTEK’s findings confirm a major evolution in PHEV use: electricity for the everyday, fuel only when needed. The growth in battery size, real-world EV range and smart charging capability has turned PHEVs into highly capable, low-emission travel tools.

As world leaders prepare to gather in Brazil for COP30, a new major study from Siemens reveals geopolitics is reshaping infrastructure strategy, with national energy security overtaking global climate cooperation as the primary driver of the energy transition. The Siemens Infrastructure Transition Monitor 2025 reveals senior leaders believe a resilient energy supply should be the top governmental priority among infrastructure transition goals – up from third place in 2023. Meanwhile, national energy independence and the proactive management of climate risks have seen the most significant growth in priority.

mitigate the use of energy as a geopolitical tool, governments are prioritising security, independence, and preparedness alongside climate mitigation.

The report, based on a global survey of 1,400 senior executives and government representatives in 19 countries, highlights a shift: from a multilateral vision of clean energy to one increasingly centered on sovereign resilience and regional production. With mounting pressure on public and private energy systems amid overlapping climate, geopolitical, and market challenges, it finds that energy resilience is now seen as a critical enabler of the clean energy transition – not a trade-off.

Rising global instability is intensifying market and supply chain volatility. To

Report: siemens.com/global/en/company/insights/infrastructure-transition-monitor-2025

Experts in a diverse range of skills in fire safety are becoming the fire aware educators to help guide those in the supply chain trying to find their way around the wave of legislation and compliance currently being introduced.

Gavin Skelly, Fire Aware CEO, said members specifically provide training courses relating to fire safety and management relevant for designers, main contractors, domestic trades, material suppliers, building management, hotel and leisure, commercial and private landlords and local authorities.

He said: “At a time of increasing concern for the safety of the public who use our buildings and spaces, the fire safety industry is under increasing scrutiny and those with a duty of care should understand this is more than a job, it is a vocation.

“We believe there is enough legislation to ensure safety if they are understood and followed. We have specialists who can help guide anyone in the supply chain around some of this new legislation because it can be challenging given its complexity and scale.”

The expanding industry body is leading the way by focusing on the moral responsibility of all those working in the fire safety supply chain including designers, developers, asset owners, managers and other stakeholders. It aims to change the culture of the built environment sector by introducing a moral code of conduct.

InstaVolt is set to begin construction on Monday on the country’s first ever motorway services featuring on-site battery storage directly connected to its chargers.

The revolutionary project at Welcome Break Corley Services is located between Junctions 3 and 3A on the M6. It will mark a major milestone in the development of ultra-rapid EV charging infrastructure in the UK with two large battery storage units being installed on either side of the motorway.

The system, will store electricity on-site and distribute it directly to the chargers, allowing for a smaller grid connection and ensuring consistent ultra-rapid charging performance even during periods of high demand.

Saving on standing and capacity charges this innovation further supports InstaVolt’s off

peak charging rate of 60p per kWh between the hours of 8pm to 7am.

This is just the start of the battery rollout programme with an additional 12 batteries to be installed across the InstaVolt network over the coming weeks with its next battery sites in North Wales and Eastbourne.

Once completed, the upgraded Corley Services on the M6 will enhance driver

convenience and fleet efficiency along one of the UK’s busiest transport corridors, providing faster, cleaner and more resilient charging to motorists on the move.

In addition to the battery installation, InstaVolt will also upgrade the existing chargers from 62.5kW to 160kW ultra rapid chargers, further improving charge times for drivers. The northbound site will feature eight chargers, while the southbound site will provide seven chargers for drivers travelling in the opposite direction.

With more than 2,200 chargers already operating nationwide at 99 per cent+ uptime and powered by 100 per cent renewable energy, the company continues to set new standards excellence and accessibility.

For more information visit: InstaVolt.co.uk

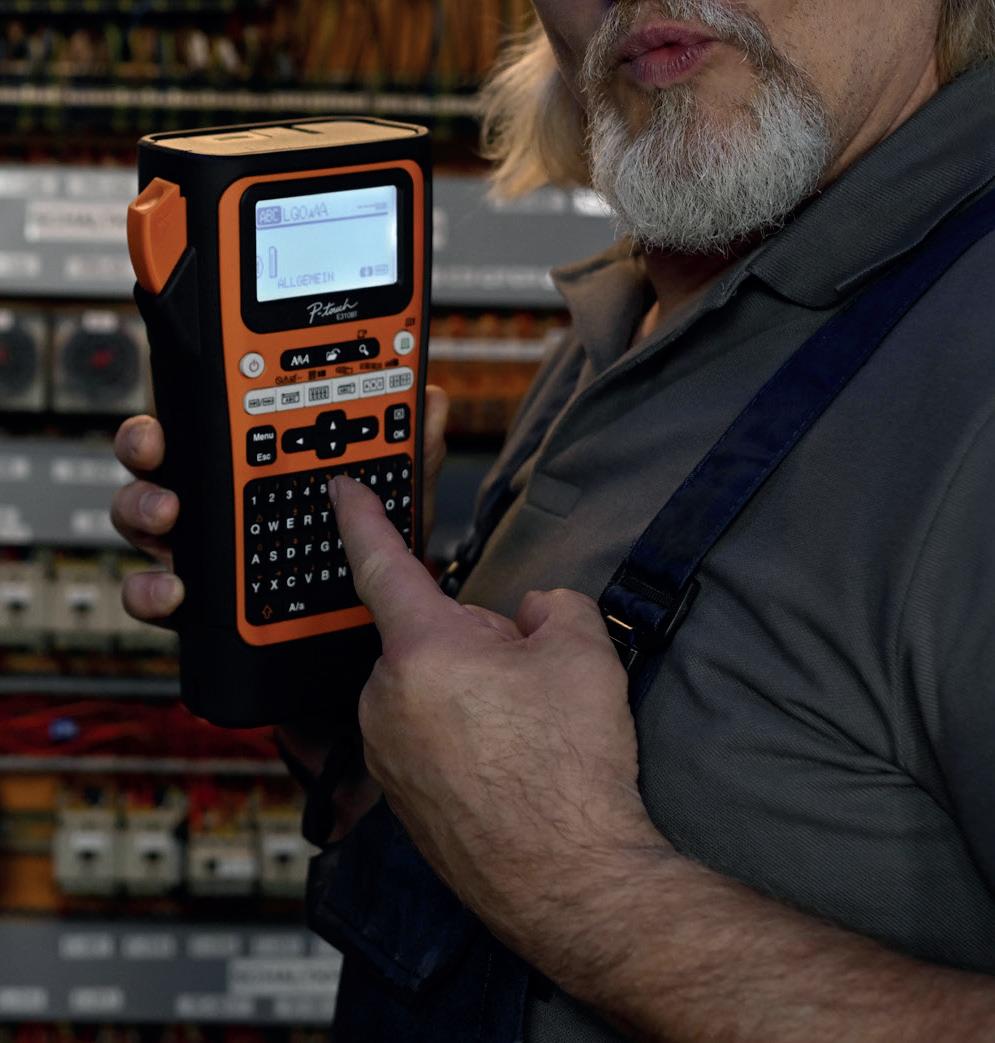

Design

Pro

Industrial-grade

Label

Store

Last Mile, the multi-utility infrastructure group that designs, builds, owns and manages more than 910,000 connections across Great Britain, has announced the appointment of Sofia Arhall Bergendorff and Helen Moore as NonExecutive Directors (NEDs).

Sofia Arhall Bergendorff is an experienced infrastructure and technology professional, with an extensive 35-year track record in property development.

Nexans has announced that its Board of Directors has resolved to appoint Julien Hueber as the new Chief Executive Officer and to part ways with Christopher Guérin. These decisions will take effect immediately; Christopher will be available to Julien until October 31, 2025.

Julien Hueber has solid experience in supply chain and purchasing, in-depth knowledge of the Asia-Pacific region.

Stiebel Eltron UK has strengthened its South West operations with the appointment of a new specification manager who will drive forward the adoption of renewable heating solutions across the region.

Helping to promote Stiebel Eltron’s range of air and ground source heat pumps and ventilation products, Claire will play a key role in strengthening existing relationships and developing new partnerships in the region.

Ovia, part of the Scolmore Group, is pleased to announce the appointment of Jordan Charran as the new Area Sales Manager for the Southwest region.

Jordan brings a wealth of industry experience to the role, with over a decade in the electrical sector, beginning his career with one of the UK’s largest electrical wholesalers, where he spent seven years progressing through a variety of roles from the warehouse to external sales.

phs Compliance has appointed Jonathan Mackie as Managing Director.

Jonathan Mackie joins phs Compliance, which is part of the phs Group, with over 25 years’ experience as a commercial director and an extensive background in global service links.

Scolmore Group is pleased to announce the expansion of its Click sales team with the appointment of three new Area Sales Managers.

Alistair Lishman, James Louriero, and Paul Sawyer join the business, bringing with them a wealth of industry knowledge, technical expertise, and commercial experience.

The appointments mark a significant step in the ongoing development of the Click Scolmore brand. Their combined experience and regional expertise will ensure that customers across these key areas continue to receive the highest level of service, support, and access to innovative wiring accessories and circuit protection products.

Ten Greater Manchester firms will get rare access to Bosch’s German hydrogen operations, in a new challenge designed to give UK businesses the knowledge to compete in the emerging hydrogen economy.

Delivered by GM Business Growth Hub with Bosch and Manchester Metropolitan University, the Hydrogen Supply Chain Innovation Challenge will give selected firms direct insight into how hydrogen systems are designed and tested.

The launch comes as the Greater Manchester Combined Authority (GMCA), working with Manchester Met, opens consultation on its new hydrogen and fuel cell strategy. Firms will take part in a site visit to Bosch Germany in January 2026, as well as workshops and development sessions. The challenge runs until March 2026, with further support beyond that.

Alongside the Bosch visit, participants will receive mentoring and commercial support from the Hub, and opportunities to connect with a network of industry leaders.

Janine Smith, Director at GM Business Growth Hub, said: “Manchester was the birthplace of the Industrial Revolution and now, across Greater Manchester, we’re once again driving the next wave of change - this time through clean energy.

“This challenge gives our firms a front-row seat with Bosch, one of the global leaders in hydrogen technology, and the opportunity to help shape the supply chains of the future.” Applications are now open: https://www.businessgrowthhub.com/programmes/gmhydrogen-supply-chain-innovation-challenge/.

Rolec and Go Zero are joining forces on a mission to accelerate the deployment of EV infrastructure across the UK’s hospitality sector, providing leisure destinations and hotels with reliable and scalable charging solutions.

EV drivers are no longer a niche group, they are business commuters, families, and international visitors, and increasingly, they expect to plug in as easily as they connect to Wi-Fi when they arrive at a hotel. With a £100M debt financing facility secured by Go Zero, this partnership has the financial strength to roll out multibay EV hubs at scale through Go Zero’s VendEx model, removing large upfront capital expenditure for businesses.

With Go Zero and Rolec working together, financial barriers are removed, enabling businesses to implement charging infrastructure quickly and efficiently.

Andy Taylor, CEO of Go Zero, said: “Securing this £100M debt facility is a strong vote of confidence in Go Zero’s strategy and growth prospects within hospitality. With funding in place, we can fully deliver our current project pipeline, expand rapidly across key hotel locations, and continue providing scalable, guestfriendly charging solutions. Partnering with Rolec for hardware supply ensures faster installation, multi-bay EV hubs, and a bigger national footprint, bringing our vision of 10,000 sockets closer to reality.”

GTEC Training has announced the launch of its Commercial Solar PV Installation & Design course. It’s the first dedicated programme in the UK focused specifically on the design, planning, and delivery of large-scale rooftop solar systems for commercial and industrial buildings.

The course is endorsed by LCL Awards and sets a new benchmark for professional development in the UK’s fast-growing commercial solar market.

Delivered over two intensive days, the programme provides a comprehensive foundation in commercial solar PV design,

specification and management. Participants will gain a deep understanding of system design and supervision, array layout, electrical configuration, and the use of solar PV software for performance modelling and feasibility studies. The course also covers project planning and preparation for complex installations, large-scale health and safety protocols, professional documentation and specification standards, and best practice for monitoring and maintaining long-term system performance.

The commercial solar PV course is now open for enrolment, with additional regional sessions planned for 2026.

LiGHT Expo London isn’t just another trade show lined with rows of exhibitors.

It’s a space for discoverywhere designers, specifiers, contractors, architects and beyond come together to explore how light shapes the built environment, how innovation drives design forward, and how collaboration continues to define the lighting community.

With over 200 exhibitors, thoughtprovoking talks and dedicated networking areas, LiGHT 25 offers visitors the chance to experience light in all its dimensions.

Following the success of 2024’s Intra-Spectrum by light artist Frankie Boyle, LiGHT 25 proudly welcomes a bold new light art immersive centrepiece: Re:Vision, a creative collaboration between Speirs

Major Light Architecture and formalighting.

Re:Vision invites visitors to step into a world of light and perception - a sensory journey that challenges how we see and understand the visual experience of other species. Using custom spectral profiles and reimagined Ishihara colour blindness test patterns, the installation explores how different life forms perceive colour and light in ways entirely distinct from our own.

For visitors to LiGHT 25, Re:Vision is more than an installation - it’s an experience that stays with you. It will make you pause, question, and perhaps even see your own work differently. Re:Vision is a symbol of what LiGHT 25 is all about: imagination, exploration and connection.

OCS builds on ESG progress, driving social mobility and sustainability across the UK & Ireland

OCS has published its UK & Ireland ESG Impact Report, building on the progress made in social value creation, environmental performance, and governance standards. The report underscores OCS’s commitment to doing business responsibly while delivering measurable impact for colleagues, customers and communities.

The report highlights that in 2024, OCS supported 378 individuals into employment through its People into Work programme, and delivered 564 active apprenticeships, reinforcing its mission to create inclusive pathways into employment. Community engagement also grew, with OCS colleagues raising over £143,000 for charities and contributing 1,072 volunteering hours across the UK and Ireland.

Environmental performance remained a key focus, with 92 per cent of electricity procured from renewable sources and 99 per cent of waste diverted from landfill. OCS also continued its transition to a low-emission fleet and invested in energy efficiency measures across its operations. This year also saw the strategic acquisition of FES FM and FES Support Services, significantly enhancing OCS’s capabilities in energy efficiency and decarbonisation. Governance improvements included strengthened anti-bribery measures, ISO 27001 certification for information security, and enhanced modern slavery risk assessments across the supply chain.

The findings come at a time when ESG performance is under increasing scrutiny from investors, customers, and regulators. Across industries, there is growing pressure for businesses to demonstrate not just intent,

but measurable progress on sustainability and social value. Regulatory frameworks such as the EU Corporate Sustainability Reporting Directive (CSRD) and the UK’s evolving climate disclosure requirements are raising the bar for transparency, while stakeholder demands and the need for risk mitigation are making ESG credentials increasingly weighted in the procurement process.

Jacky So, Sustainability Director OCS UK & Ireland, says: “ESG is no longer a ‘nice to have’. Stakeholders expect transparency, measurable targets, and tangible social impact. We’re seeing a clear trend; organisations that embed ESG into their core strategy are outperforming on resilience, reputation, and long-term value creation. This isn’t just about compliance; it’s about competitive advantage. Companies that fail to act risk losing trust, talent, and market share.”

OCS’s approach links social mobility initiatives with environmental commitments and strong governance, reflecting best practice in the sector. “

Download the full ESG Impact Report at: https://ocs.com/uk/esg/esg-impactreport-2024/

Thousands of trade businesses unprepared for 2026

Thousands of trade businesses across Scotland and the UK are said to be unprepared for tax changes coming in April 2026, prompting experts to urge early action to stay compliant.

From next year, tradespeople operating as sole traders and landlords earning more than £50,000 will be required under Making Tax Digital (MTD) to report income and expenses quarterly using specialist bookkeeping software, as tax returns move fully online.

Christine Nisbet, Finance Director from FBR Seed’s bookkeeping and payroll team, said: “We speak to sole traders every week who still don’t realise this change is coming, or how close it is.

“From April next year, manual tax returns will no longer be accepted. Instead, submissions must be made quarterly through HMRC-recognised software like Xero or Sage.

“This is a big shift for people used to paper records or Excel spreadsheets. Many are simply unaware of the changes, or unsure how to go about getting set up, and we want to make sure as many businesses as possible understand what’s coming, so they can stay compliant and avoid unnecessary headaches down the road.”

While MTD will first apply to those earning over £50,000, the threshold will fall to £30,000 in 2027 and £20,000 in 2028, eventually covering all sole traders. Originally introduced for VAT-registered businesses in 2019, the reforms now represent the most significant shift yet for the self-employed, with digital reporting set to become the default for millions across the UK.

As a certified Silver Xero Partner, FBR Seed is helping clients access Xero’s MTDready package, available from just £7 per month. Its bookkeeping and payroll team can aid sole traders and small businesses of all kinds across Scotland and Northern England, from tradespeople and retailers to service providers and beyond.

With a heritage dating back to 1966, FBR Seed was officially formed in 2019 following the merger of Seed & Company and FBR Ltd. Continued growth and further acquisitions have shaped it into a 25-strong, multi-disciplinary advisory, with offices in Kelso, Haddington, Brechin and Duns.

To learn more about FBR Seed, please visit: https://www.fbrseed.com/

As the evenings grow darker, Steve Kaye from Forum Lighting Solutions discusses why now is the time to focus on outdoor lighting to create a welcoming atmosphere for the colder months and to improve safety

As the darker months close in, outdoor lighting suddenly moves from a “nice to have” to an operational necessity. Whether it’s a pathway to the front door, driveway, garden patio or public walkway, outdoor lighting plays a crucial role in safety, security, and energy efficiency. Yet every year, too many properties limp through winter with outdated fittings, inconsistent illumination, and rising energy bills.

Now is the perfect time to review, upgrade, and future-proof your outdoor lighting. And with smart, controllable solutions now more accessible than ever, there’s never been a better opportunity to get it right.

The shift toward smarter, connected lighting

In recent years, outdoor lighting has undergone a quiet revolution. Advances in LED efficiency, coupled with the rise of intelligent control systems, mean lighting can now do far more than simply switch on and off at dusk.

At Forum, we’ve been at the coal face for 30 years and we’ve seen a growing demand for connected systems like our Kinetic control platform, which allows multiple outdoor luminaires to be managed remotely. With a Wi-Fi enabled Kinetic receiver, users can group fittings, schedule operation times, adjust brightness levels, and monitor performance via the Tuya app or controlled through Alexa or Google home.

This kind of control isn’t just convenient; it delivers tangible value. For example, a homeowner can set outdoor lights to come on at set times, or at dusk. Turn on garden lights

Energy efficiency that pays for itself

Switching to high-efficiency LED lighting remains one of the fastest ways to improve energy performance. Outdoor lighting is often left running for long hours, sometimes all night, so every watt saved has a measurable impact on operating costs.

Forum’s latest outdoor luminaires, such as the Tetbury and Ren ranges use advanced LEDs and efficient drivers to maximise light output while minimising energy draw. Combined with Kinetic control, these products allow for adaptive dimming, which reduces brightness during low-activity periods or off-peak hours.

With energy prices remaining unpredictable, these savings matter more than ever.

Compliance and safety - lighting you can trust

Outdoor lighting plays a vital role in ensuring safe environments. Poorly lit drive ways, walkways, and entrances are not only inconvenient, but can be unsafe for pedestrians and vehicles.

Forum’s luminaires are engineered to deliver consistent illumination and meet the relevant regulations, ensuring that businesses and local authorities can demonstrate due diligence in safety and accessibility.

Timing Is everything

Autumn and early winter are ideal times to assess and upgrade lighting systems. The nights draw in, the need becomes visible, and installation work can be planned ahead of the

peak demand period. Contractors can help clients see the long-term benefits: lower running costs, reduced maintenance, and a safer, more welcoming environment.

Forum has these tips for autumn and winter outdoor lighting:

Prioritise safety

Illuminate pathways, steps, and potential hazards with task lighting to prevent accidents in the dark.

Embrace the warm glow

Use warm-toned light, such as oranges and warm yellows, to create a cozy and relaxing ambiance as the weather cools.

Highlight features with accent lighting

Use spotlights to draw attention to specific features like trees, sculptures, or walls, creating a visually interesting scene from inside a property.

Play with light and shadow

A successful lighting scheme uses contrast. For example, avoid flooding an entire garden with light, and instead, strategically highlight key areas to create drama and dimension.

Consider “moonlighting”

This trend mimics the effect of moonlight by using a light source positioned high up to create a soft, dappled effect on the ground below.

Minimise environmental impact

If lighting for wildlife is a concern, concentrate lights on paths and steps, keep the light low and directed, and use warm, dim light colours.

Think about year-round enjoyment

Choose fixtures that can be enjoyed throughout the year. Evergreen trees are great focal points for accent lighting.

At Forum, we believe the future of outdoor lighting is intelligent, efficient, and adaptable. Our new generation of outdoor luminaires gives users all the tools they need to manage their lighting smartly and sustainably.

So, before winter’s darkness really sets in, take the opportunity to review your lighting. A modern, well-designed outdoor lighting system doesn’t just illuminate spaces - it adds safety, efficiency, and value for years to come.

The Building Safety Act 2022 has introduced transformative changes in how the construction and maintenance industries approach safety. Electrical Industry Awards 2025 sponsor Trimble Luckins looks at how the Act impacts the industry and the steps stakeholders must take to manage product information effectively

While health and safety on construction sites have long been a focus, the Act extends this responsibility across the entire lifecycle of a building, ensuring the safety of occupants over time. A central aspect of this new framework is the management of product information, which is vital for ensuring compliance and safety standards are upheld.

Accurate documentation and record-keeping: a new priority

A cornerstone of the Building Safety Act is its emphasis on precise documentation and thorough record-keeping. Reliable information about the materials and products

used during construction and maintenance is critical for ensuring compliance and longterm safety. Manufacturers now play a pivotal role in this process, providing accurate and regularly updated product data.

To meet these requirements, many in the industry have turned to datapools—centralised platforms that store verifi ed product information. These platforms simplify compliance by offering easily accessible, up-to-date data for contractors, sub-contractors, engineers, and building owners. For example, the use of a unique TSI code for each product ensures quick reference to critical information, streamlining integration into internal systems and project documentation. This approach

reduces administrative burdens while ensuring compliance with the Act’s rigorous standards.

“Golden thread” of information: a continuous record

The concept of the Golden Thread—a continuous digital record of a building’s design, construction, and maintenance— is a game-changer introduced by the Act. This ensures that every product used during the building process is documented and that the information remains accessible throughout the building’s lifecycle. Highrise buildings, where safety is especially critical, benefi t most from this approach.

The Act mandates that this documentation be retained for at least 15 years, a shift requiring signifi cant changes in working practices. By leveraging datapools, contractors can integrate expert-curated data from manufacturers and wholesalers into their digital

records, creating a robust, accessible evidence base.

Product traceability is critical for ensuring that the materials specifi ed in a building’s design match those installed on-site. In the past, substitutions were common due to availability or convenience, often introducing safety risks. The Building Safety Act now requires a traceable thread of information from specifi cation through to installation and maintenance. Traceability ensures that any replacements or repairs over the building’s lifespan align with the original specifi cations. For instance, in the event of a repair 10 or 20 years later, accurate records allow for like-for-like replacements, preserving the building’s integrity. Verifi ed databases ensure all stakeholders can access accurate, up-to-date information, mitigating risks and enhancing safety.

A digital twin—a detailed, asbuilt digital representation of a building—has become a standard deliverable upon project completion. These models store comprehensive data about the building’s systems, materials, and products, making it easier for building owners and maintenance teams to perform repairs or upgrades. By integrating product information into digital twins,

stakeholders can quickly retrieve specifi cations, installation guides, and safety certifi cations. This approach not only saves time but also ensures that any future work maintains the building’s original safety standards.

The Building Safety Act imposes new obligations across the supply chain, ensuring collaborative accountability:

• Manufacturers must provide accurate product data in formats compatible with supply chain systems and prove compliance with safety regulations.

• Wholesalers are tasked with supplying specifi ed products without substitutions driven by stock or pricing considerations.

• Contractors are responsible for assembling and maintaining comprehensive documentation throughout a building’s lifecycle.

• Building owners must ensure ongoing access to this information for maintenance and compliance purposes.

This collective effort ensures safer buildings, where every participant plays a role in upholding the new standards.

The Building Safety Act marks a turning point in construction, introducing robust standards for managing product information. Focusing on accuracy, traceability, accessibility and safety, the Act ensures that buildings are safer for occupants throughout their lifespan. Leveraging centralised databases, digital twins, and collaborative processes, the industry can rise to meet these challenges. Ultimately, the Act not only ensures compliance but also fosters confidence in the longterm safety and performance of our built environment.

For more information, visit luckinslive.com.

By Billy Price, Managing Director of Field Services at ClearCourse

Electrical contractors across the country are facing a painful paradox. With demand rising for EV charging points, renewable installations, and energyefficient upgrades, contractors are busier than ever, but the systems that support their work haven’t always kept pace. According to Checkatrade, they are eager to scale up and contribute to the government’s growth agenda but rising business costs and taxes are holding them back.

When growing suddenly feels like a risk, rather than an opportunity, this highlights a bigger problem in the sector. While these businesses are winning more work than ever, many aren’t taking advantage of the technology solutions available to help them overcome obstacles to growth. Whether it’s tool costs, and theft, addressing the skills gap or managing margins – integrated solutions such as inventory and asset management, automated job status updates, and invoicing solutions all support a business ready to take on new customers.

Add to the fact that we’re experiencing a nation-wide shortage of skilled tradespeople, which is projected to cost the UK £98 billion in missed growth opportunity by 2030 - it becomes clear that we need to find smarter ways to ensure the sector can deliver on its ambitions to scale up and boost economic growth. To support the great talent we do have, businesses need to consider how technology can boost their efforts, save time and help them expand to win new customers. That’s where technology steps in, not as a luxury, but as a necessity for modern electrical businesses ready to grow without adding unnecessary strain.

A lot of qualified contractors start out as a sole trader, but when business starts to come in thick and fast, the team quickly expands. The basic or even paper-based management systems that worked for a sole operator quickly become incapable of handling multiple traders across different locations, managing multiple call outs. Paper diaries and disjointed spreadsheets are not equipped to handle the real-time logistics required of a modern electrical contractor. When an urgent customer call requires a rapid rerouting, or when a job overruns and impacts

Growing electrical businesses often find themselves caught in the middle: too small to benefit from the expensive enterprise systems of the big players, yet too big to rely on their original, non-integrated or paper-based processes.

the rest of the day, an inefficient management system forces the business owner to manually coordinate, which can waste time, lead to inaccuracies or mistakes, and can impact customer satisfaction.

Smart job management software changes this dynamic entirely. By moving to an easy-to-use, integrated platform, independent traders can leverage seamless, real-time coordination features like drag-and-drop scheduling, automated route optimisation, and mobile updates, making it easy to manage multiple jobs at the same time.

flow

For a lot of micro electrician businesses, invoicing, quoting and chasing small payments is handled after hours by family members or founders after the tools are put away. This not only burdens the business owner’s personal life but is an inefficient way to handle payments that can drain cash flow.

According to the Federation of Small Businesses (FSB), small trades businesses

lose approximately £22,000 annually to late payments, contributing to the 50,000 closures seen each year - money which could otherwise fund training, equipment, or business expansion. Modern management platforms combat this by integrating finance with field operations. Built-in payment features can automate invoicing immediately upon job completion, send payment links to customers on site, and automatically chase outstanding payments when they become overdue. By digitising the back-office process, business owners are freed from late-night admin to focus on the job at hand, and more importantly, they can stabilise their cash flow, which is the lifeblood of any growing SME

Levelling the playing field

Growing electrical businesses often find themselves caught in the middle: too small to benefit from the expensive enterprise systems of the big players, yet too big to rely on their original, nonintegrated or paper-based processes. The perception is that only large corporate competitors can afford high-end operational tools, but the reality is that accessible, integrated tech is now the fastest way to level the playing field. Software platforms like Eworks Manager equip smaller businesses with professional features that mirror the services of their biggest rivals, without the corresponding overheads. This includes smart job scheduling, digital documentation and compliance, inventory and asset management, real-time job updates via SMS, and transparent financial tools that ensure every quote is accurate and every payment is instantly tracked.

These automated features not only help build and maintain customer trust but allows independent traders to compete on service quality and efficiency, not just price.

Ultimately, the goal for every growing electrical contractor is to maintain the service quality of a sole trader while managing the capacity of a scaling business. Technology is the bridge that makes this possible. By adopting simple, integrated management solutions, independent tradespeople can focus on what they do best. If small electrical firms embrace these tools, they’ll not only future-proof their businesses but play a key role in driving the UK’s wider growth and net-zero ambitions.”

The rise in interconnected systems has amplified the impact of transient overvoltages across industrial and commercial environments. Effective surge protection is now vital to safeguard assets, maintain compliance, and ensure the reliability of modern electrical installations, says David Williams, VP Transactional Business and Major Pursuits UK&I at Schneider Electric

Transient overvoltage events can have serious consequences for organisations that rely heavily on electronic systems.

A single surge can halt production, corrupt data, and damage vital infrastructure - often at considerable financial and operational cost. Beyond the immediate disruption, these incidents can also present safety risks to workers.

As digitalisation accelerates, these risks are intensifying. With more systems connected across networks and facilities, a single transient event can propagate rapidly, multiplying its effect across devices and operations.

Transient overvoltage events pose a real threat to business-critical systems and can lead to unexpected and unplanned downtime.

Manufacturing facilities have experienced production halts when voltage spikes have damaged motors, drives, and robotic systems. In fact, research from IDS-INDATA, suggests that downtime will cost UK and European manufacturers £80bn this year. At a time when businesses are facing multi-pronged headwinds, with profit margins often under 10 per cent, most have little buffer against disruption.

IT infrastructure is equally vulnerable; data centres servers may crash, resulting in data loss or corruption.

Looking beyond equipment concerns, transient overvoltage events can present safety hazards, including fire risk and electrical shock leading to potentially serious injury.

There is an increasing expectation that businesses must proactively manage electrical risks. In practice, this means adopting robust protection measures to comply with regulations. Protecting people, equipment, and operations cannot be an afterthought.

business impact

Beyond the immediate operational impact, the effects of repeated transient overvoltage events are often underestimated. Equipment lifespan may be shortened, and maintenance costs way higher than they should be.

Repeated exposure to transient overvoltage can degrade sensitive electronic equipment, including servers, networking devices, and industrial control systems. Even in the absence of immediate failure, the cumulative stress can accelerate component aging, leading to increased maintenance requirements and reduced operational lifespan.

Powering a safer, resilient future

Ensuring operational continuity and the integrity of electrical assets demands proactive risk management. Transient overvoltages can’t be eliminated entirely, but it can be effectively controlled. Surge Protection Devices (SPDs) provide the most practical and economical defence, preventing the costly downtime, equipment damage, and safety hazards associated with overvoltages.

By safely diverting excess voltage to earth, SPDs protect critical equipment from harm. Even the best-engineered installations can contain weak points, and without coordinated surge protection, those vulnerabilities can be exposed.

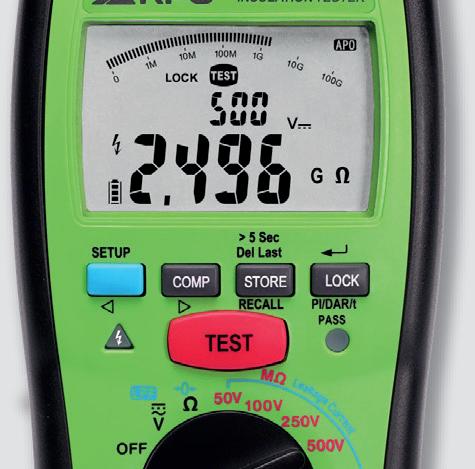

Surge Protective Devices (SPDs) are typically deployed in a coordinated, multi-stage approach to ensure comprehensive protection across an electrical installation:

Type 1 SPDs are installed at the origin of the electrical installation, typically where the supply enters the building. They are designed to divert high-energy surges caused by direct lightning strikes and are mandatory in buildings equipped with a structural Lightning Protection System or connected to overhead power lines. These

devices can handle the most severe surge conditions.

Type 2 SPDs serve as the primary protection layer for all low-voltage installations. They are installed at main or sub-distribution boards and protect against transient overvoltage events resulting from indirect lightning strikes or switching operations.

Type 3 SPDs provide localised protection for sensitive electronic equipment such as servers, computers, and control systems. These are installed as close as possible to the equipment and must be used in conjunction with a Type 2 SPD. They are designed to handle short-duration voltage and current transients, with a lower discharge capacity suited for fine protection.

For modern organisations, transient overvoltage protection is no longer just a safety measure - it’s a cornerstone of operational strategy. Those that prioritise resilience, safeguard their assets, and ensure compliance will not only minimise risk but also strengthen their competitive position in the digital economy.

A school in Market Bosworth, rural Leicestershire, has been equipped with special outdoor wall lighting designed to preserve dark skies for multiple species of local bats and other nocturnal animals. Glamox, a world leader in lighting, is providing energy-efficient LED wall lights, specifically designed to minimise light spillage and approved by DarkSky International, a nonprofit organisation that aims to restore the nighttime environment and protect communities and wildlife from light pollution.

Hinckley House School is an independent day school designed specifically for students with special educational needs. It serves children aged 5 to 11 with Social, Emotional and Mental Health (SEMH) needs, alongside a range of other associated conditions.

The school is housed in a Grade II-listed Old Rectory within a conservation area. During its renovation, careful effort was made to preserve and enhance its historic character while protecting local wildlife.

“In 2018, a bat detection study identified five distinct bat species and indicated a thriving bat community with a variety of roosting and foraging sites,” said Jake Smith, Senior Electrical Engineer at Crookes Walter Consulting, the electrical design consultant on the Hinckley House School renovation project. “For lighting the school perimeter, we specified lighting that was durable, energy efficient, and which would provide sufficient illumination for the safety of pupils and staff whilst minimising light spillage that could affect nocturnal species. Our goal was to preserve the nighttime environment as best we could.”

DarkSky approved and environmentally friendly

Glamox provided the DarkSky-approved version of its O21-W wall light for lighting the perimeter of the school building. The tough luminaire emits light only where it is needed, in a downward direction, minimising light spill into the night sky.

“Artificial light can adversely affect wildlife and plants, interfering with their perception of day and night and disrupting their natural behaviour. The lighting for this project has a warm colour temperature of 3000 K and uses special optics to restrict light spillage,” said David Hunt, Managing Director of Glamox’s business in the United Kingdom & Ireland.

“The wall light also supports a circular economy, which is the opposite of a throwaway society. It’s been designed to be disassembled, enabling parts to be replaced to extend its lifespan. Additionally, parts can be reused or recycled at the end of their life. Around 45 per cent of the wall light’s housing is made from recycled aluminium,” added Hunt.

lights up energy-efficient forecourts for St1

In an ongoing refurbishment project, Glamox, a global leader in lighting, is providing energyefficient LED lighting to 120 of St1’s station forecourts in Norway.

In total, Glamox is providing 3,220 energyefficient LED luminaires that will be installed under the forecourt canopies and used to illuminate the EV charging bays and station perimeters. The luminaires feature a light sensor, enabling them to switch on and off automatically based on daylight levels (see Notes to Editors for lighting details).

St1’s replacement of old fluorescent lighting with LED luminaires will improve light quality and reduce the electricity used for lighting the forecourts by up to 60 per cent.

“Through this refurbishment, we aim to reduce the amount of electricity used for lighting the forecourts at many of our retail sites across Norway,” says Erlend Føleide, Marketing Director at St1. “Importantly, the project will

Thorn and Zumtobel Lighting have announced the launch of their new customer websites for the UK & Ireland, bringing lighting professionals a streamlined digital experience with cleaner navigation, faster search and direct access to support. Built around the needs of specifiers, designers, contractors and distributors, the refreshed sites provide 24/7 access to solutions and services with a single login across both brands.

The new experience makes it simple to explore complete product ranges, review technical content, and plan projects end-to-end. Key updates include enhanced product discovery and filters, family pages with side-by-side comparison, wish lists, “request a quote”, and customer-portal login with order and quotation overviews. Rich technical data, planning tools and configurators are integrated to help reduce admin and speed up decision-making.

“Our goal is to make it faster to move from inspiration to specification,” said Neil Raithatha, Head of Marketing, Thorn and Zumtobel Lighting UK & Ireland. “With streamlined search, cleaner product pages and a single login to manage requests, we’re helping project teams save time and work more confidently, while giving them round-the-clock access to the essentials across both brands.”

For customers, the new sites mean seamless browsing on mobile or desktop, on-demand access to case studies and expert guides, and a simpler way to manage quotes and orders. One account provides smooth access to the wider Zumtobel Group portfolio, so users can switch between Thorn and Zumtobel without losing their place.

Access products, tools and services at the usual brand URLs: thornlighting.co.uk or zumtobel.co.uk

also align our forecourts with the EU directive that phases out fluorescent lighting.”

In August 2023, the Restriction of Hazardous Substances (RoHS) directive began the phaseout of the most popular types of fluorescent

lighting, including the most common linear (T5 and T8) fluorescent tubes. The goal is to reduce harmful substances in electronic waste, like mercury in fluorescent tubes. In Norway alone, more than 10 million fluorescent luminaires need to be replaced.

“Customers across the country are taking steps to align with the directive, as once current stocks run out, that is the end of the road for fluorescent lighting. With the added upside in light quality and energy savings, switching to LED, like St1 is doing, is an allaround great investment,” says Toril Bache Jenssen, Sales Director for Glamox in Norway. To ensure consistent deliveries to St1 across Norway, Glamox established a stockpile of LED luminaires. Its contract for the project is with installer OneCo, which delivers services and projects within electrical engineering, automation, telecoms, mobile, security, electrical power and technical infrastructure.

CU Phosco, in collaboration with 5G Synergiewerk and Telefónica, has completed the successful installation of six Connected Urban smart poles in Munich. Strategically placed near key subway stations, the smart poles were deployed to eliminate mobile coverage blackspots and increase network capacity ahead of Oktoberfest, one of the world’s most attended public festivals.

The project follows previous successful installations of Connected Urban smart poles in Augsburg, Cologne, Frankfurt, Hannover and Würzburg and reinforces CU Phosco’s growing reputation as a smart city infrastructure leader across Germany. Each pole combines cutting-edge lighting with integrated 4G/5G radio equipment, all within a compact and aesthetically sympathetic footprint designed to suit the urban landscape. The base section comprises two x 900mm door openings and the overall height of the poles ranges from 11.9m to 13.9m including the tri sector cannister antenna on the top of each pole.

The Munich installation supports Telefónica’s wider densification strategy, increasing mobile network performance where demand is greatest. The smart poles offer a dual benefit: improved network coverage for safety and situational awareness, and enhanced connectivity for high-density public use.

Connected Urban smart poles are modular and highly adaptable, able to host a range of smart city applications – from antennas and CCTV to public address systems – all from one discreet structure. These poles are a direct replacement for traditional street lighting columns and are designed to integrate seamlessly into existing streetscapes.

The first installation was marked by a high-profile demonstration event attended by Telefónica and key government officials, highlighting the importance of smart infrastructure in modern urban planning.

In addition to supporting Oktoberfest, the upgraded infrastructure is expected to serve future large-scale events and daily use, especially in the surrounding transport zones.

With further rollouts anticipated in other key international cities, including London, CU Phosco continues to redefine the role street-lighting infrastructure plays in modern city.

For more information on Connected Urban, visit www.cuphosco.com.

Lucy Zodion has secured a Build Back Better GREEN Award for HAWK3, its nextgeneration photocell designed to meet the evolving needs of modern street lighting.

The award highlights Lucy Zodion’s leadership in sustainable innovation, with HAWK3 moving beyond outdated standards to deliver unmatched switching accuracy, ultra-low power consumption, and a design philosophy rooted in longterm circularity.

The Build Back Better Awards celebrate products that combine engineering excellence with environmental responsibility. HAWK3 impressed the judging panel by pairing digital switching precision with energy use as low as 0.1W, while embedding cradle-to-cradle principles at every stage of design and manufacture. Developed as a complete redesign of Lucy Zodion’s photocell range, HAWK3 reflects extensive feedback from local authorities, contractors, and asset managers. The result is a product that not only reduces operating costs and energy consumption but also supports recyclability and longer asset life, helping customers align with their Net Zero goals.

John Fox, Managing Director at Lucy Zodion, commented: “Receiving the Build Back Better GREEN Award is a brilliant recognition of our journey with HAWK3. We’ve listened closely to what customers need from their photocells, not just in terms of accuracy and reliability, but also sustainability and future resilience. HAWK3 reflects our continued ambition to set the standard for what smart street lighting control should look like in the years ahead.”

For more information about HAWK3 or to arrange a product demo, visit: lucyzodion.com/product/hawk3/

Collingwood Lighting has supplied the lighting to help artist Sarah Nelson realise her dream of a net zero carbon home which featured on Channel 4’s Grand Designs TV show.

In the living areas Sarah specified Collingwood’s 1901 spotlights, which she can rotate and tilt to direct light where she wants it. The fittings have a contemporary black cylindrical design and produce a warm light of 2700K for a relaxing atmosphere.

To create an intimate but modern feel around the eating area, the company also supplied its Linear Prism fitting in black which is suspended above the table. With colour switchable options to choose what light source she wanted, Sarah opted for a warm light of 3,000K.

For the gallery hall, Sarah chose the OKTO 4 architectural lights. They have a similar sleek black cylindrical design as the 1901 spotlights and provide ambient lighting for large areas with their 85o beam angle.

Commenting on the installation Sarah explains: “I wanted energy efficient LED lighting with a modern contemporary design. The black, sleek design of all the fittings really work as a visual statement, especially when set against the textured grey Hempcrete walls.”

In the studio, where she works, Sarah specified industrial looking lights with Collingwood’s Caiman Versa anticorrosive

fitting. The two fittings are suspended from the steel ridge beams, and their steel bodies work well set against the bare hempcrete walls and this exposed metal girder. With plenty of glazing facing north, the studio has an abundance of natural diffuse light for her work, which the light fittings supplement as it gets dark with a cool white light of 5700K that is similar to natural light.

The building has also got an air source heat pump and solar panels to provide power.

Commenting on her new home and studio she says: “I have shown that you can build a sustainable zero carbon building that is very individual and good looking. My emphasis has been on energy saving solutions, but that does not mean that you must sacrifice style.

“As an artist light is very important to me and Collingwood’s fittings allow me to achieve what I believe in and create and showcase a space that is visually stunning.”

Recolight isn't just about recycling, we help the lighting industry take real steps toward a sustainable future. From our Reuse Hub and Circular Lighting Live Conference, to workshops, webinars, and Life Cycle Assessments, we support businesses in taking practical actions to embrace the Circular Economy. What’s more, we can provide carbon footprint data for every waste collection. Make your lighting more sustainable. Make it circular.

Circular Lighting Live 2025

reaffirmed its role as the UK’s leading sustainability platform for the lighting sector. Organised by Recolight and hosted in London, the event brought together 35 expert speakers and leading lighting brands, with over 200 delegates determined to accelerate the industry’s shift towards a circular economy.

The conference atmosphere captured much of the urgency and optimism expressed by many of the speakers. There was wide recognition among many of the delegates, sponsors, and panellists that a linear economy business as usual is no longer viable, and that the lighting industry must fully embrace new approaches built on sustainability, resource efficiency, and the circular economy.

Rethinking industry practices

Several speakers noted that misplaced perceptions of risk often slow progress in the adoption of reused and remanufactured luminaires. Solutions to those perceived barriers, including warranties, remaining luminaire lifetime, and client acceptance were discussed by panels.

The call was clear: the industry must shift from talking about change to embedding it as standard practice.

Emerging trends and key insights

The programme highlighted the technical and regulatory developments reshaping the sector:

• Environmental Product Declarations (EPDs) seem likely to become a market requirement, providing the transparency needed to evaluate products fairly.

• TM65 and TM66 have gained momentum as key tools to measure embodied carbon and assess circularity.

• Legislative updates from the UK and EU offered insight into current and forthcoming

regulations that will impact lighting product development and compliance.

• Reuse, refurbishment, and energy transition were recurrent themes, particularly for designers seeking to cut carbon at every stage.

• Design for repairability, decarbonisation strategies, and skills development all featured, pointing to the cultural change required to embed circularity.

Nigel Harvey, CEO of Recolight, summed up the energy of the event: “Circular Lighting Live this year was buzzing with ideas and opportunities. It was inspiring to hear new approaches to tackling sustainability and the circular economy. It was particularly pleasing to note the tangible desire to press on, despite political headwinds elsewhere.”

Industry support

The event drew wide support from leading brands including Signify, Sylvania Group, Glamox, KKDC, Prime Light Group, Prolojik, Thorlux Lighting, Trojan Lighting Solutions, NVC Lighting UK, Mymesh by Chess UK, SMART SYSTEMS UK, and ALBIS Distribution, and from supporters including A1 Lighting, the Society of Light and Lighting, the Lightmongers, and Material Index.

Delegate feedback underlined the impact of Circular Lighting Live:

“10/10 best year yet! Relevant & engaging topics… Circular Lighting Live was a vital catalyst in the evolution in these topics.” Justine Walmsey, Signify

“Circular Lighting Live this year showed that meaningful change is underway… Business as usual is no good, we must challenge, and we must change.” Gary Thronton, Nulty

“An important conversation about circular design in lighting. Events like this are vital in

helping our industry move from talking about circularity to embedding it as standard practice.”

Paul Beale, 18 Degrees.

“Prolojik was proud to sponsor Circular Lighting Live and be part of such an inspiring event. It was fantastic to be in a space where innovation, collaboration, and sustainability truly come together.” Darcy Hudson, Prolojik

“Circular Lighting Live was an inspiring event, full of passionate people driving change in the industry.” Nicholas Holmes, Ambit

“Circular Lighting Live is a great event that brings the industry together in a common goal. Positive and Inspiring!” Nick Revell, Philip Payne Limited.

“Commercial lighting companies dedication to carbon reduction is an inspiration to KKDC, we feel that reducing waste and reducing carbon are both key, no matter on the industry sector or size.” Tom Hall, KKDC

Looking ahead

Co-organiser Ray Molony captured the forwardlooking spirit of the conference:

“With sustainability now at the heart of lighting product development, design, and specification, Circular Lighting Live has become a vital platform for collaboration and innovation. By tackling barriers, sharing knowledge, and embedding circularity as standard practice, the UK lighting industry is leading the way towards a truly sustainable future.”

The feedback over the last four years confirmed that Circular Lighting Live is more than a just conference; it has been a real catalyst for change. And the 2025 event showed how the industry is moving from aspiration to action, building momentum towards a circular economy. Through innovation, collaboration, and determination, the UK lighting sector is beginning to demonstrate that circularity is not only possible but already taking shape.

For over 75 years, Dimplex has been a dependable name in electric heating, supporting professionals with innovative, energy-efficient solutions.

Market leader in energy-efficient electric heating

Trusted support and BEABapproved safety

Committed to sustainability and smarter energy use

As facilities managers prepare their buildings for another long British winter, the to-do list is already looking full: heating systems, insulation checks, reactive maintenance, energy budgeting - the list goes on. But one area that still too often gets overlooked is lighting control and that can be a costly oversight.

Lighting may seem like a fixed utility - a necessity - but how it’s managed can have a major impact on both running costs and the wellbeing of everyone in the building. In fact, installing intelligent lighting controls is one of the most effective things facilities managers can do this season to make buildings more efficient, comfortable, and sustainable.

At B.E.G., we’ve been working with facilities teams across sectors - from education and healthcare to commercial and public buildings - for over 50 years. And time and again, the same truth emerges: lighting controls deliver immediate wins. They save energy. They lower bills. They improve the occupant experience. And they’re especially powerful in winter.

During the colder, darker months, lighting demand naturally increases. Days are shorter, skies are gloomier, and artificial lighting becomes essential - often for 10–12 hours a day. Without controls in place, lights are frequently left on in empty rooms, unoccupied corridors, and external spaces long after they’re needed.

By Paul Jones, Sales Director

That’s money - and energy - slipping away hour by hour.

With smart controls, that waste stops. Presence detectors ensure lights only switch on when someone is in the room. Daylight sensors automatically dim artificial lighting when there’s sufficient natural light. Timers and astronomical clocks can align exterior lighting with actual sunrise and sunset, adjusting automatically as the year progresses. These systems aren’t theoretical they’re proven. We’ve seen buildings reduce their lighting energy usage by up to 70 per cent just by implementing sensor-based controls.

The financial implications are significant, especially as energy costs remain volatile in the UK. For large sites, such as schools, office blocks, hospitals, this can translate into thousands of pounds saved every year, with a payback period of just a couple of years in many cases. And with carbon reduction targets tightening, these savings aren’t just good for the budget, they’re essential for compliance and corporate responsibility.

But saving money is only half the story. Just as important is how lighting affects the people inside the building. As we head into winter, many building occupants will arrive and leave in darkness. The quality and responsiveness of artificial lighting has a direct impact on how people feel and perform during the day. Poor lighting can cause eye strain, headaches, fatigue, and low mood - especially when daylight is in short supply. That is where HumanCentric Lighting (HCL) comes into play.

At B.E.G., we’re strong advocates for HCL - systems that adjust colour temperature and

intensity throughout the day to better support the body’s natural rhythms. Cooler, brighter light in the morning helps stimulate alertness and focus; warmer tones in the afternoon support calmness and reduce overstimulation. We’ve deployed this kind of lighting in multiple buildings - wherever people spend long hours indoors during the darker months.

The result is a better environment for everyone. Workers report higher satisfaction. Absenteeism tends to decrease. And in environments like hospitals or care homes, where lighting plays a crucial role in health and safety, the benefits can be even more profound. For facilities managers, that means fewer complaints, better working conditions, and tangible proof that their building is supporting wellbeing - not just energy performance.

And the beauty is: you don’t need to start from scratch. Most existing lighting systems can be retrofitted with sensors, control modules, and smart interfaces. Whether it’s a corridor in a school, a stairwell in an office, or external lighting in a hospital, B.E.G. offers flexible, scalable solutions that integrate with common protocols like DALI, KNX, or LON, ensuring you can build a system that fits your site and your budget.

It’s also worth noting that lighting controls are low maintenance. Once installed and correctly commissioned, these systems largely run themselves - adjusting to occupancy, daylight, or schedule without needing constant input. For busy facilities teams juggling dozens of responsibilities, that kind of automation is invaluable.

This winter, the pressure on buildings - and the people managing them - will be intense. Energy budgets are under scrutiny. Occupants expect more from their environments. And sustainability targets are more urgent than ever. Lighting controls are not a silver bullet, but they are one of the most straightforward, costeffective upgrades available. They deliver results quickly, improve the user experience, and contribute meaningfully to long-term carbon goals.

Questions for facilities managers to ask is where is energy being wasted? Where could automation bring consistency and savings? And most importantly - how can lighting be used not just to see, but to support the wellbeing of every person in your building?

Answering those questions helps facilities teams take control of their lighting. Because when the days are short and the bills are high, smart lighting isn’t a luxury. It’s a necessity.

Visit: www.beg-luxomat.com/en

Ansell Lighting has expanded the popular Primo Track lighting range with two innovative new additions, improving both aesthetic and design capabilities across a wide range of applications.

Compatible with the Primo Three Circuit range, the Primo Deco Trackspot is a high-end architectural luminaire developed specifically for projects where visual appeal is paramount.

Distinctively shaped, the Primo Deco Trackspot offers a fresh, circular design that complements modern interiors. Available in a black or white finish, the fitting can be further enhanced with a stylish brass baffle as well as honeycomb, dome and decorative lenses.

Available in 7W, 12W and 25W versions, the fitting delivers high-quality light with excellent colour rendering, thanks to its high CRI performance and 4,000K colour temperature. It also offers 350-degree rotation and 0–90 degree tilt on the bracket, providing excellent adjustability for directional lighting.

The Primo Deco Trackspot comes with Triac dimming as standard, with DALI dimming and OCTO smart control options available, while the Primo Mini is a 24V track system designed for more discreet display applications.

Included within the system is the Primo Mini Trackspot – a compact, 24VDC track light that is lightweight and sleek in appearance. It features 360-degree rotation and a 0–180-degree tilt range for complete flexibility, and incorporates an anti-glare design to enhance visual comfort.

The Primo Mini range also includes a selection of other architectural luminaires suitable for both residential and hospitality settings, allowing the creation of cohesive, layered lighting designs.

For more information on the Primo Track range visit the website. www.ansell-lighting.com

Three Phase Power and Lighting Distribution Boards are critical components in commercial, industrial, and large residential electrical systems. They provide a centralised point for power distribution, control, and protection of electrical circuits, including both lighting and power loads.

Designed with the installer in mind, the Elucian power and lighting boards from Click Scolmore are engineered to deliver reliability, efficiency, and ease of installation for electrical contractors working across a range of projects. Whether upgrading an existing system or building from scratch, Elucian provides a dependable solution for modern electrical demands.

The boards are split into three sections - power, lighting, and accessories. Most distribution boards on the market don't allow isolation of the different compartments. If a board needs amending it simply shuts off both power and lighting sections. However, the Elucian board allows a section of the board to be switched off while the other section is working, allowing for ease of maintenance without compromise.

They feature a built-in Energy Meter for accurate tracking – allowing both power and lighting to be monitored separately on one energy meter rather than on two separate meters. This saves on cabling and space within the board. The boards are also supplied pre-installed as standard with type 1 and type 2 SPDs. This is for easy installation and to save time.

There are 24 different combinations available – from an 8 Way (4 Power / 4 Lighting) 125A Vertical Consumer Unit, through to a 32 Way (20 Power / 12 Lighting) 125A Vertical Consumer Unit.

They each feature quick release doors – fitted with spring clips, making them quick and easy to remove. They also offer device alignment, with the boards maintaining device alignment when fully installed, to ensure a neat and organised appearance.

To view the full range, download the Scolmore app or visit www.elucianuk.com

The new dedicated commercial lighting catalogue from Knightsbridge, is powerful resource for the trade, consolidating the brand commercial solutions into one expert guide.

Created with electricians, specifiers and wholesalers in mind, the catalogue is a response to increasing demand for highperformance lighting across commercial, industrial, and retail settings. From robust floodlights to sleek suspended panels, the catalogue showcases Knightsbridge’s extensive product portfolio – with options designed to meet the demands of both indoor and outdoor environments. Whether tracklights, downlights or batten through to bulkheads, bollards and accessories, the 61pp document really covers it all.

Products are grouped by category with suggested applications, making it easier than ever for professionals to match solutions to project requirements. Each item is accompanied by in-depth technical data, including compliance information, photometric imagery, and performance specifications. Whether assessing lumen output or verifying IP ratings, users can make informed choices with complete confidence.

Recognising the importance of sustainability and energy management, the Knightsbridge catalogue features a broad selection of energy-efficient options, such as wattage switchable and CCT-adjustable fittings.

To enhance accessibility and interactivity, the catalogue incorporates QR codes throughout, giving readers instant access to additional online resources, such as installation guides and detailed product breakdowns.

The catalogue highlights the company’s lighting design service that helps professionals plan and optimise lighting layouts tailored to each project.

The Commercial lighting catalogue is ready to empower the trade with the clarity, versatility, and confidence it needs to deliver outstanding projects. www.mlaccessories.co.uk/marketing-hub