MACPLAS INTERNATIONAL

EDITOR’S LETTER

10 The four days of Milan

MARKETING

12 Massimo Margaglione is the new president of Amaplast

18 From here to the next two years

23 Automation, creativity and technology

26 Ambienta acquired the majority of Previero

26 All Novamont to Versalis

PLASTICS AND ENVIRONMENT

29 Sustainability between economy and trust relationships

34 Making the European Green Deal happen

37 Calculate your company’s carbon footprint

39 Investments drive EU recycling

MACHINERY AND EQUIPMENT

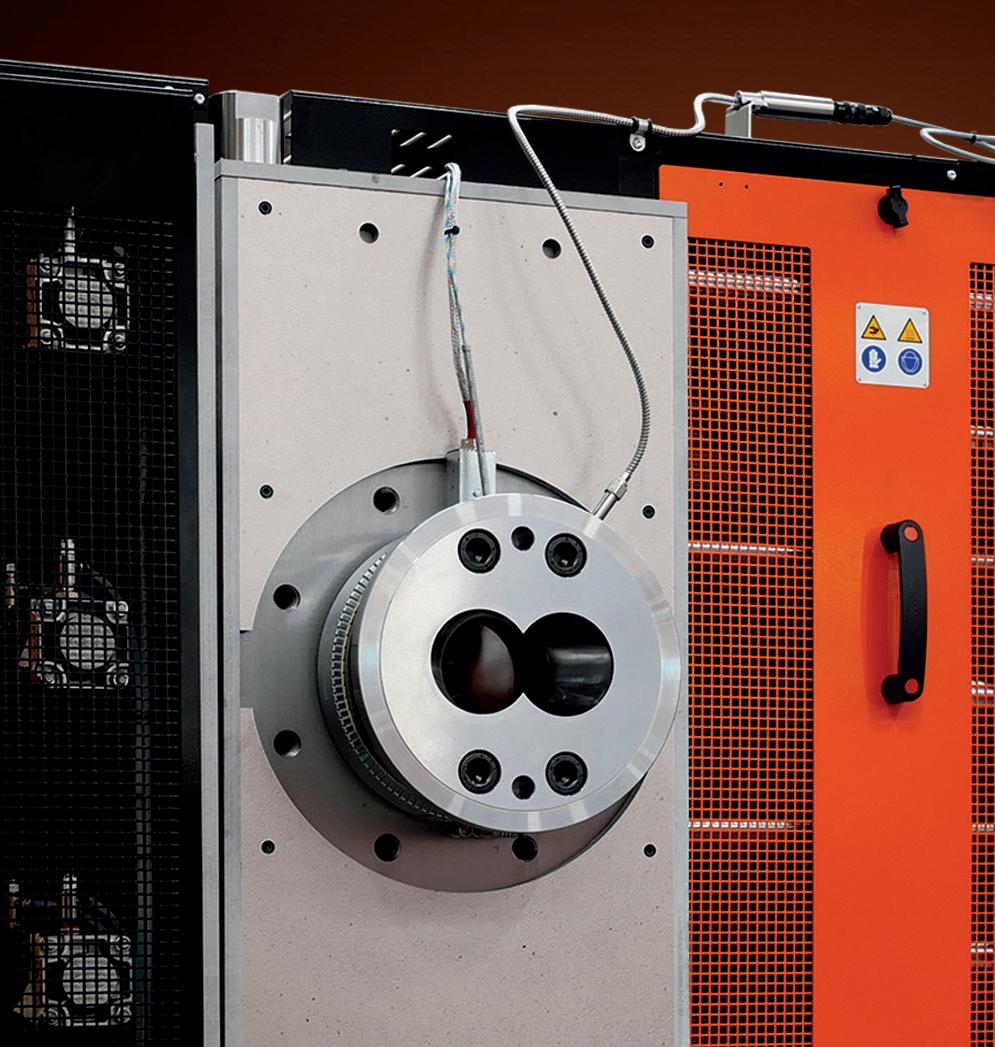

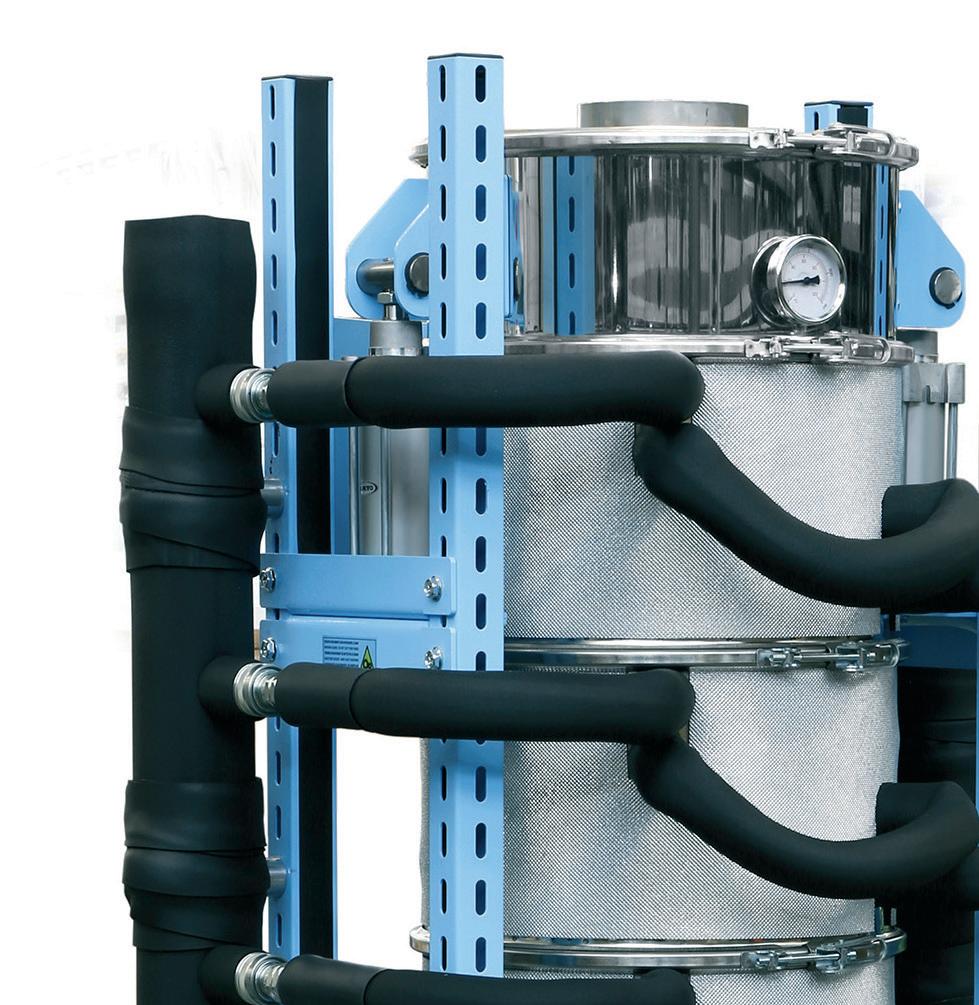

40 Attention to technological details simplifies delicate process steps

44 An offer spanning over 40 years

47 How to deal with the green transition

50 Say goodbye to the unpleasant smell of post-consumer recycled plastic

54 New modular solution for different needs of PET recycling

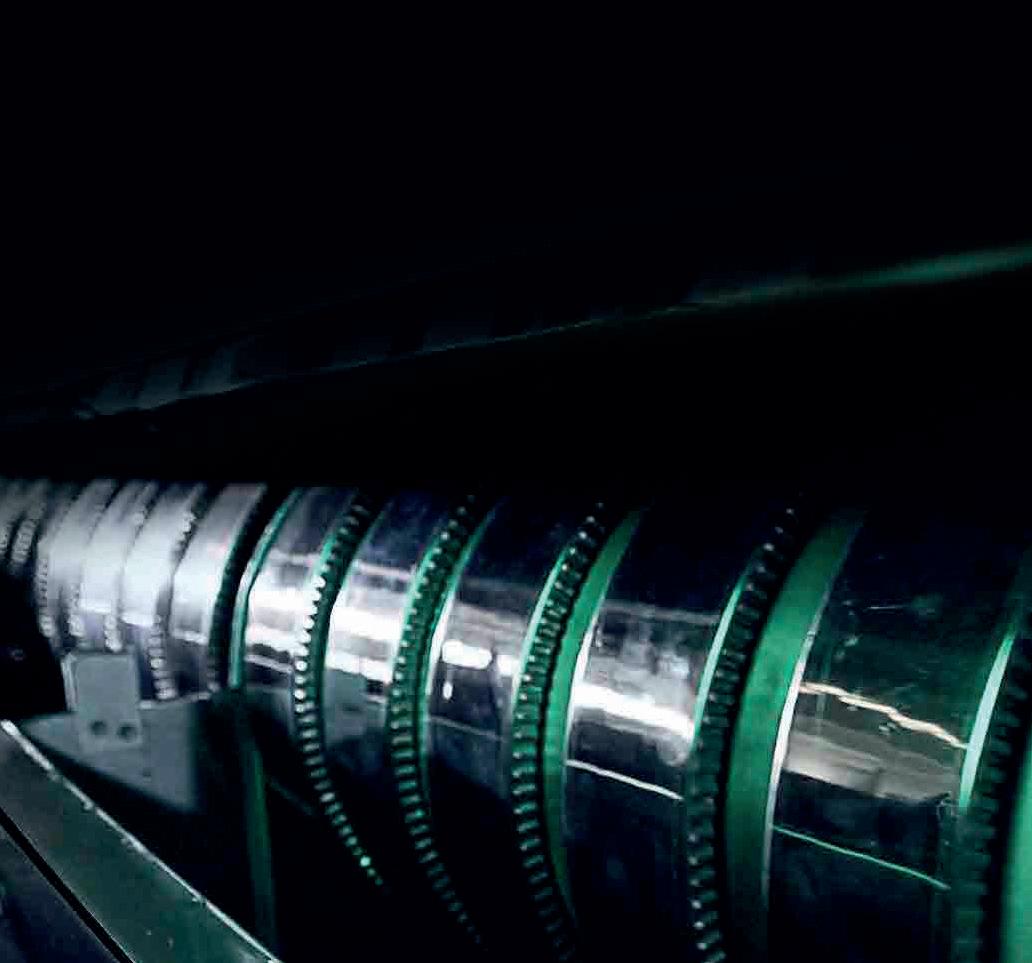

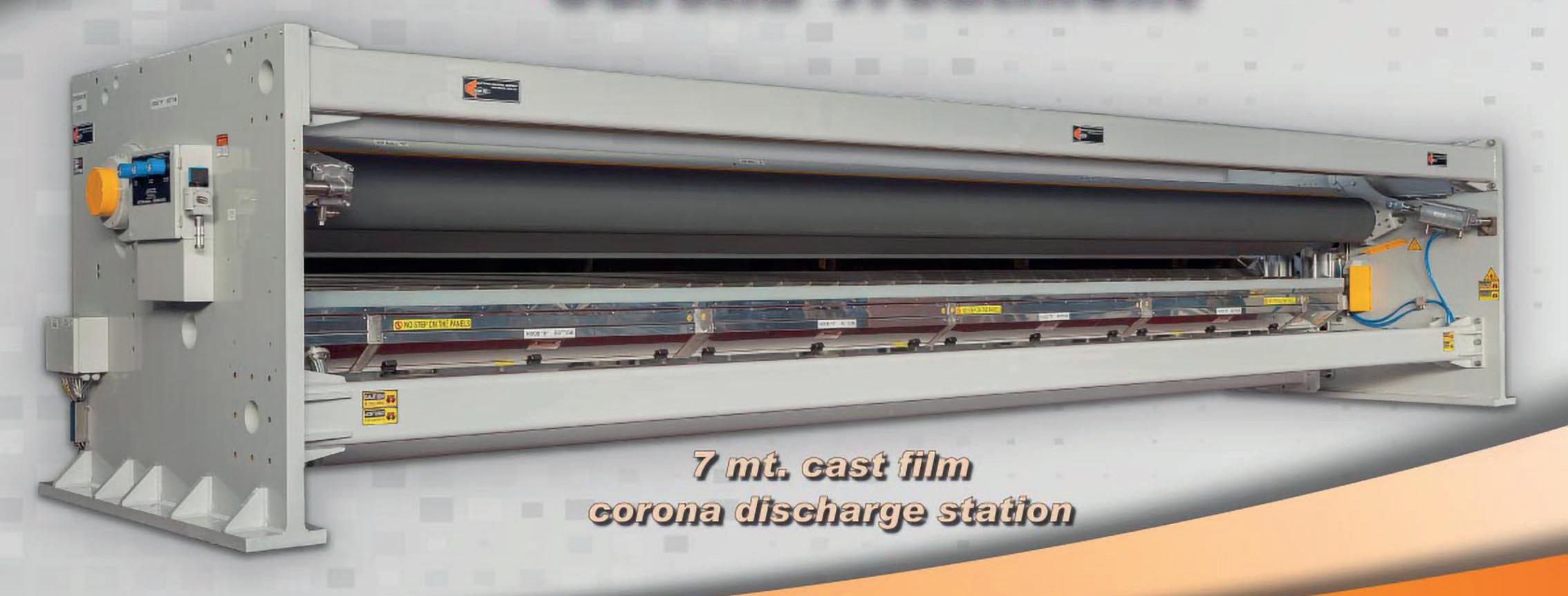

58 Corona and plasma treatment made in Italy

62 Top-quality corona treatment

64 Getting industry and nature to live together

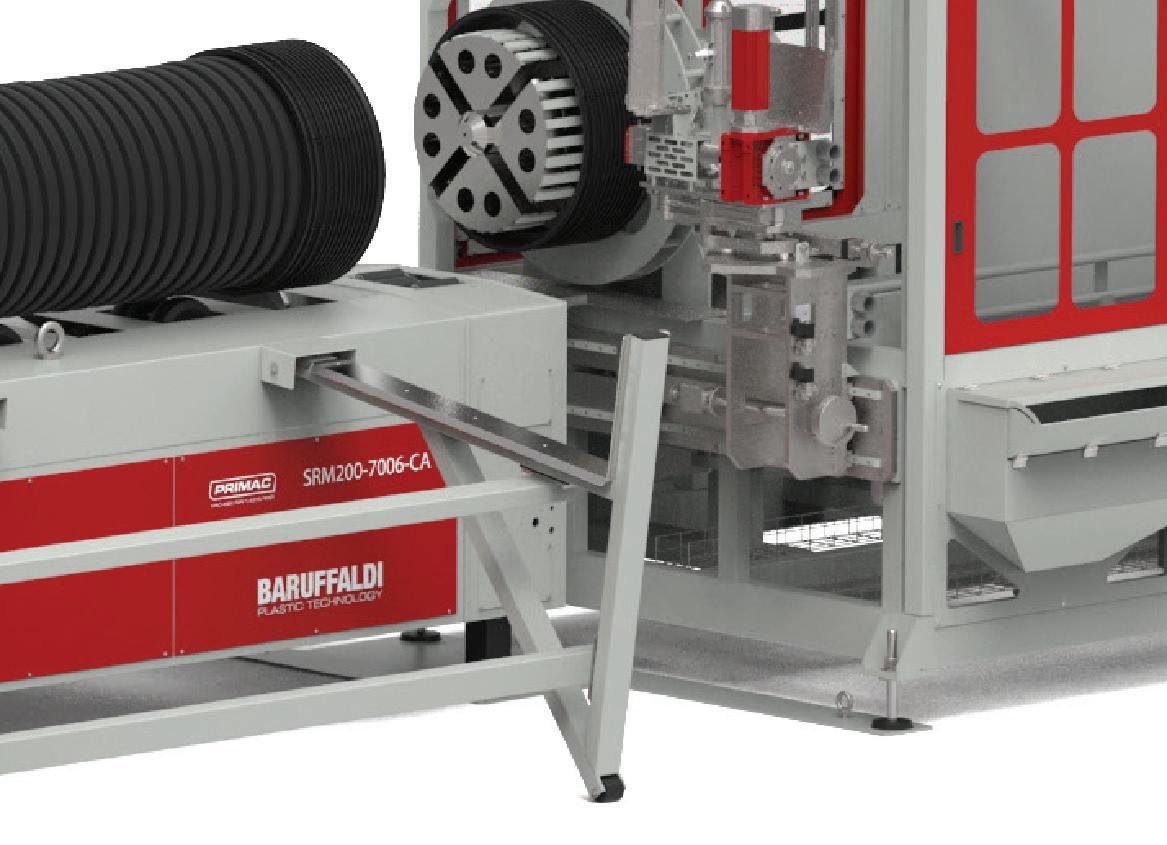

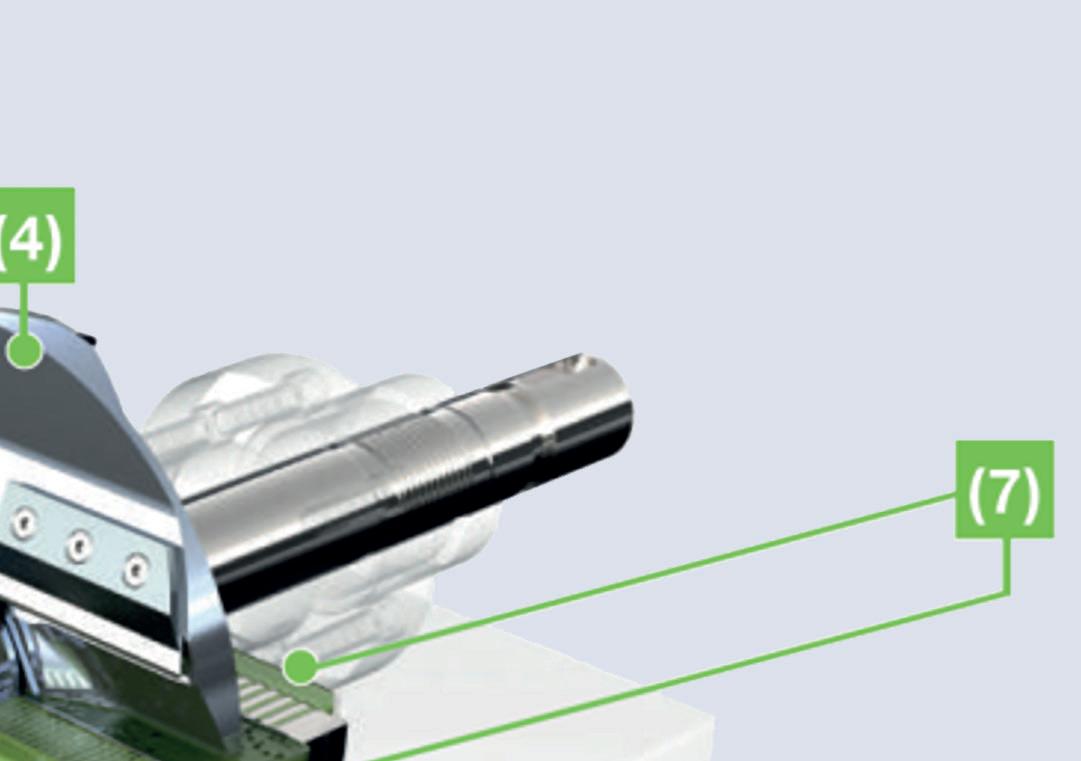

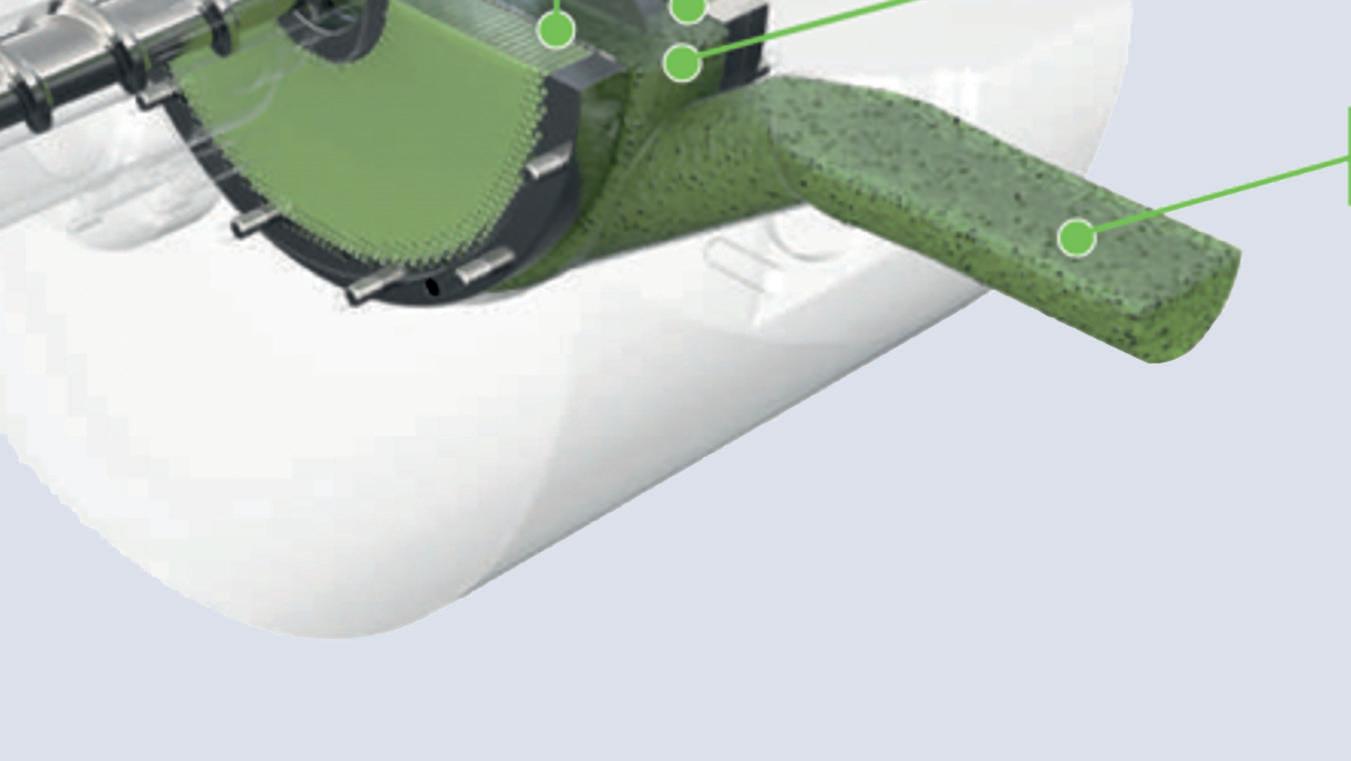

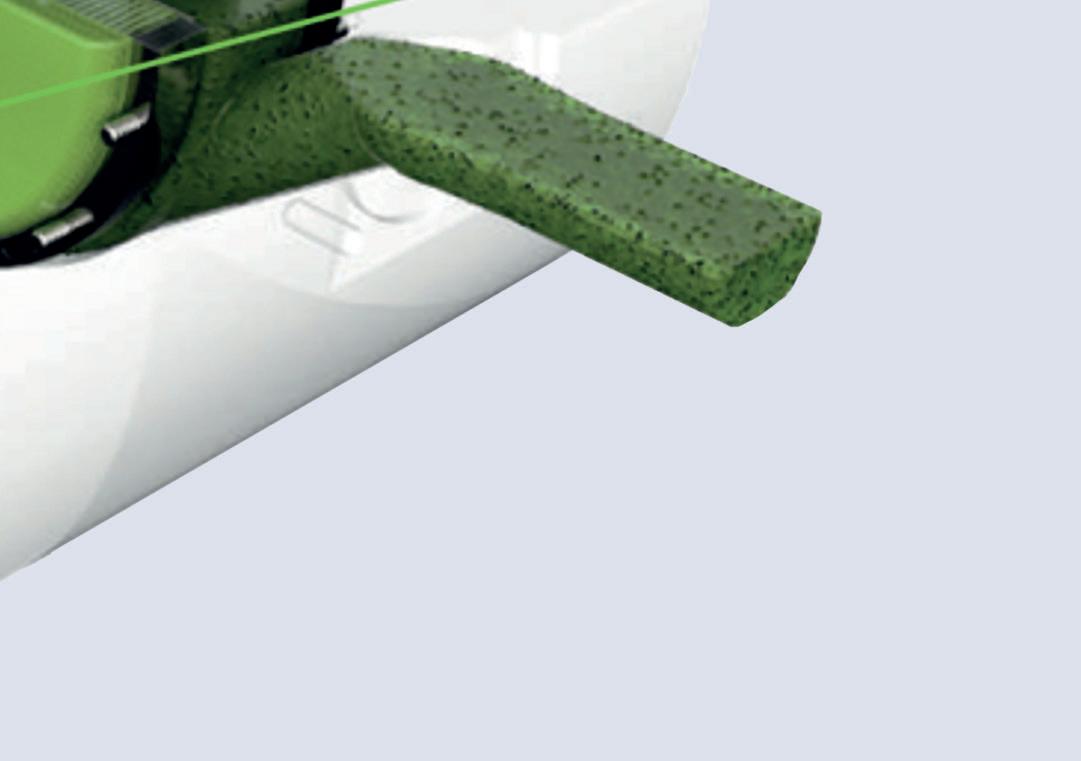

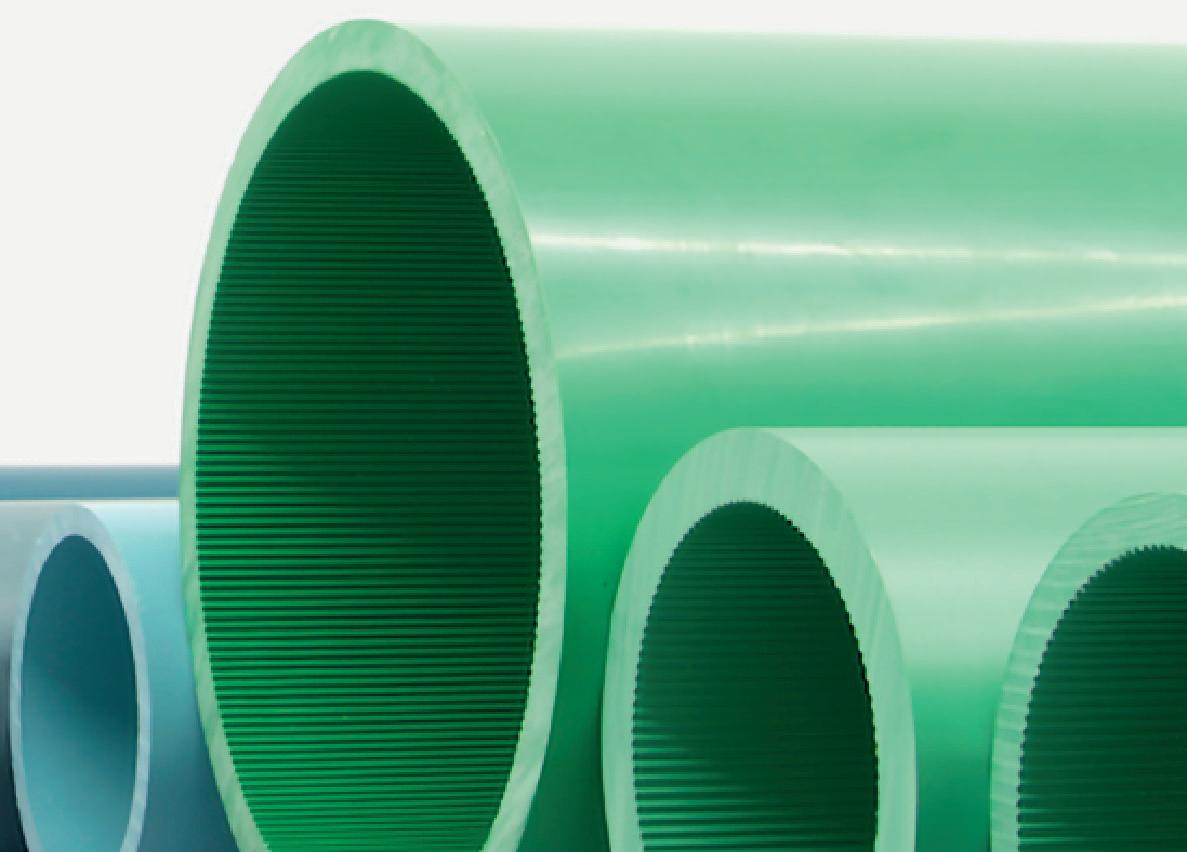

66 A concentrate of pipe extrusion technology

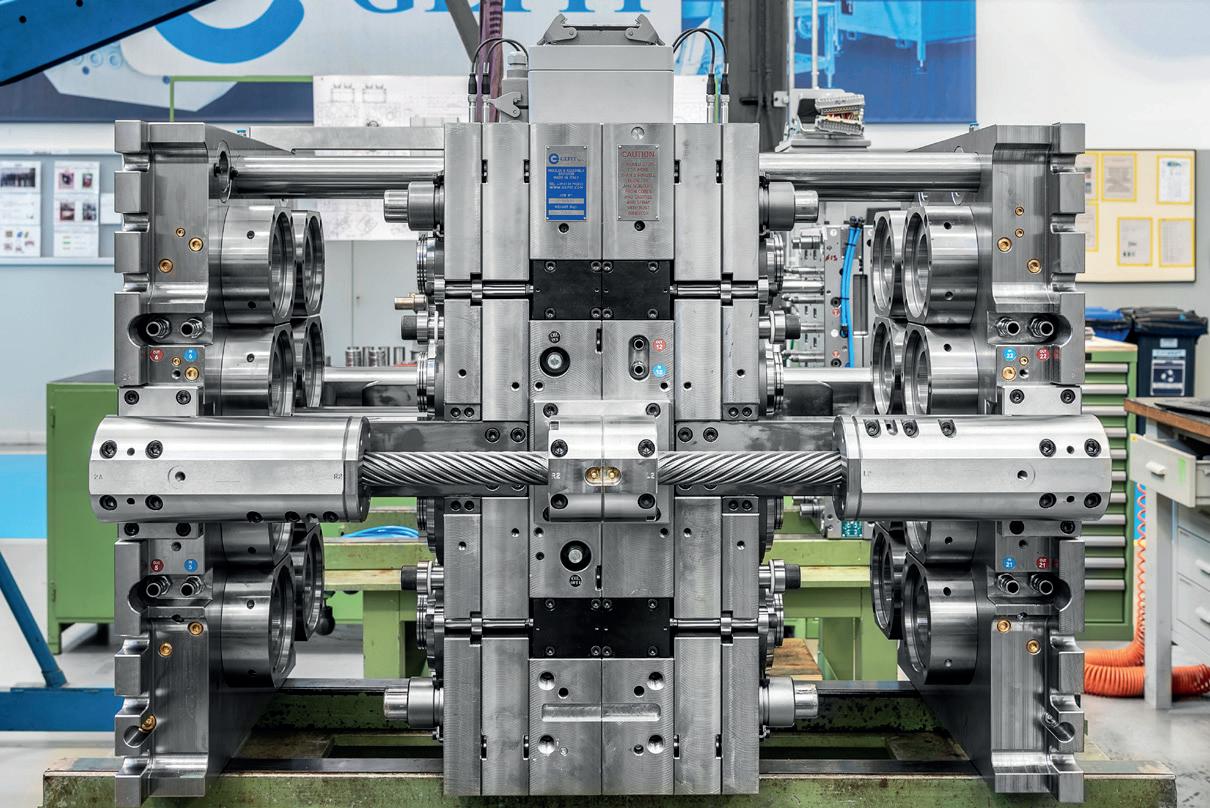

70 Advanced technologies for precision applications

74 A combination in name and in fact

76 Towards a more ethical and sustainable way of doing industry

80 A virtual journey through real technologies

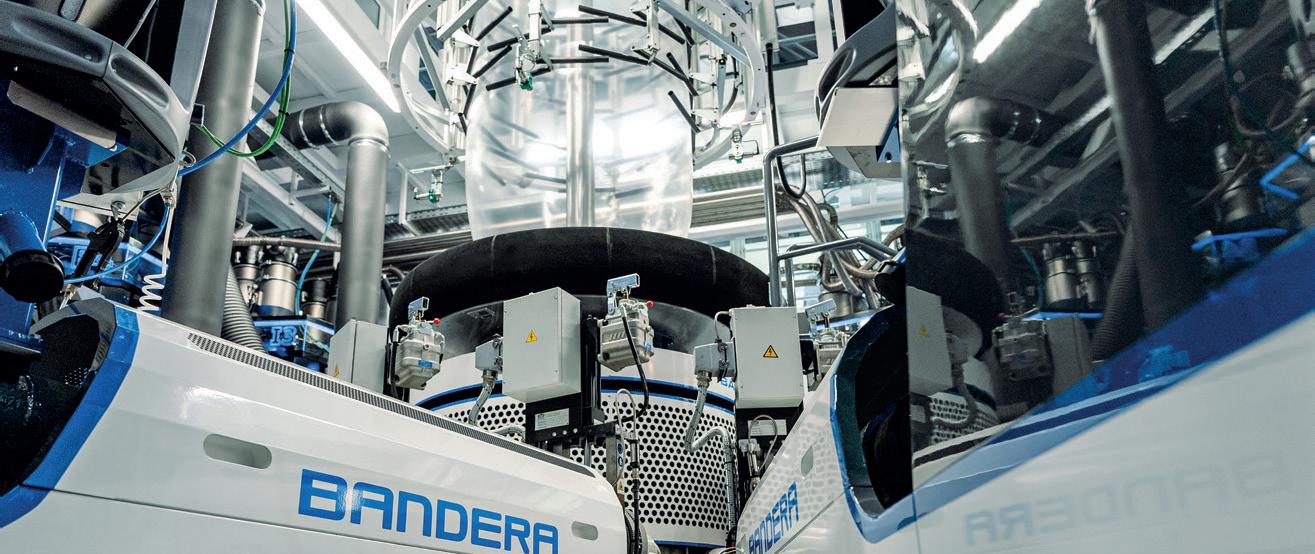

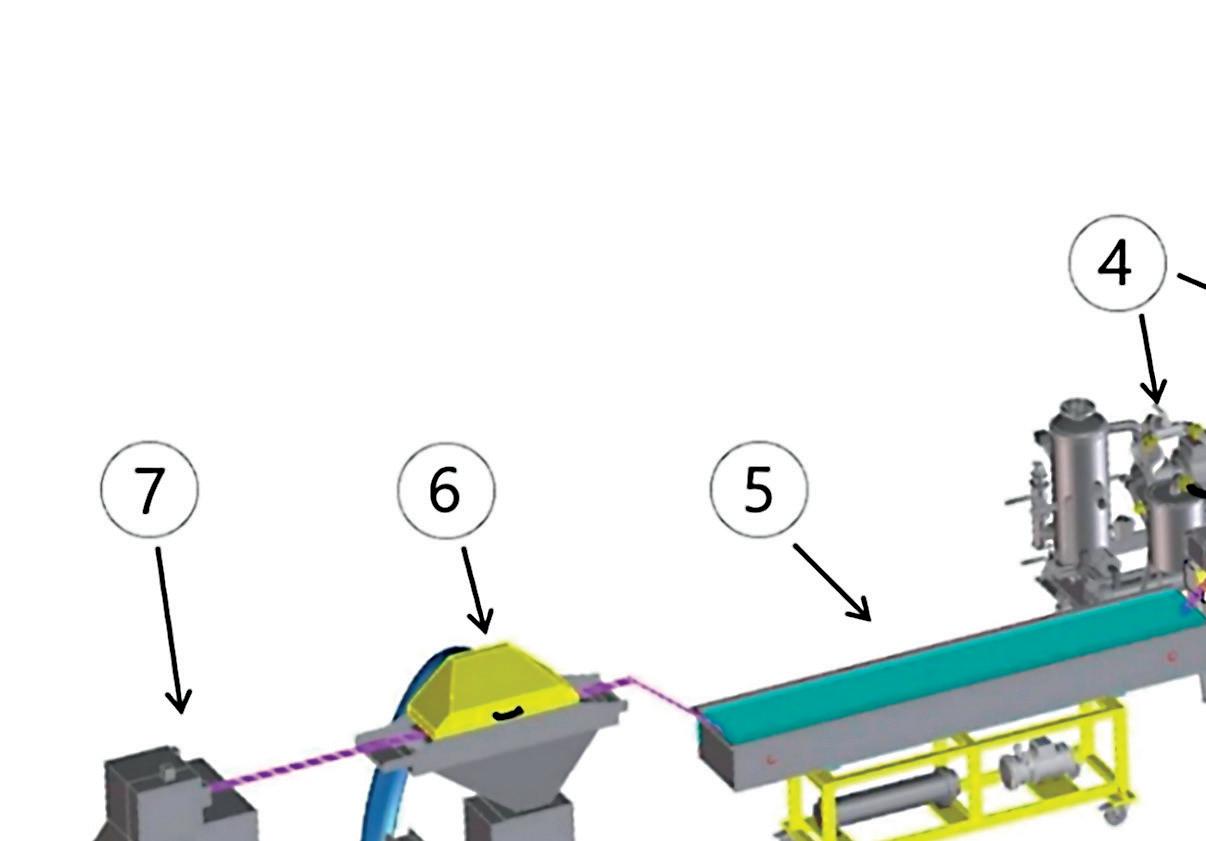

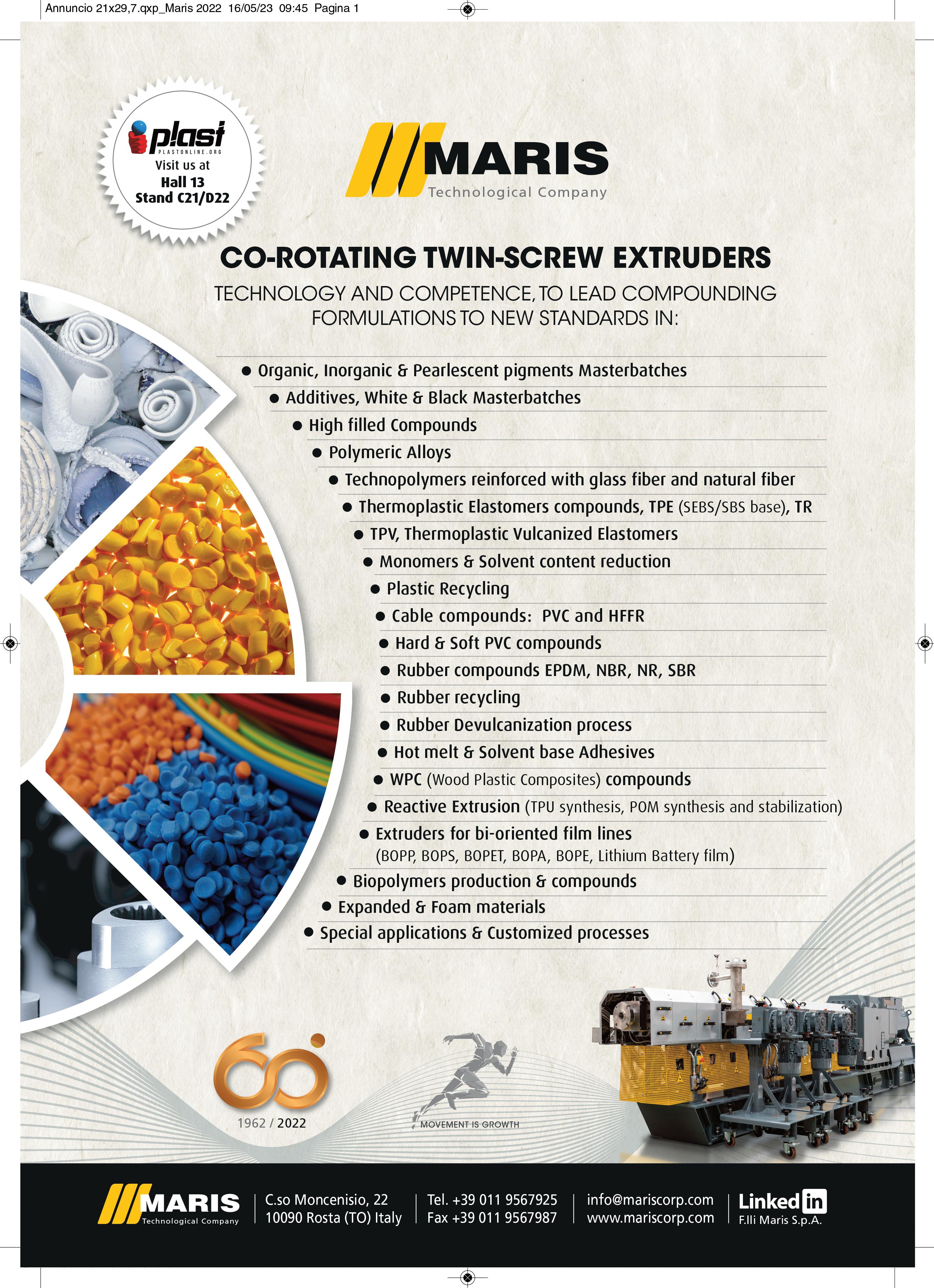

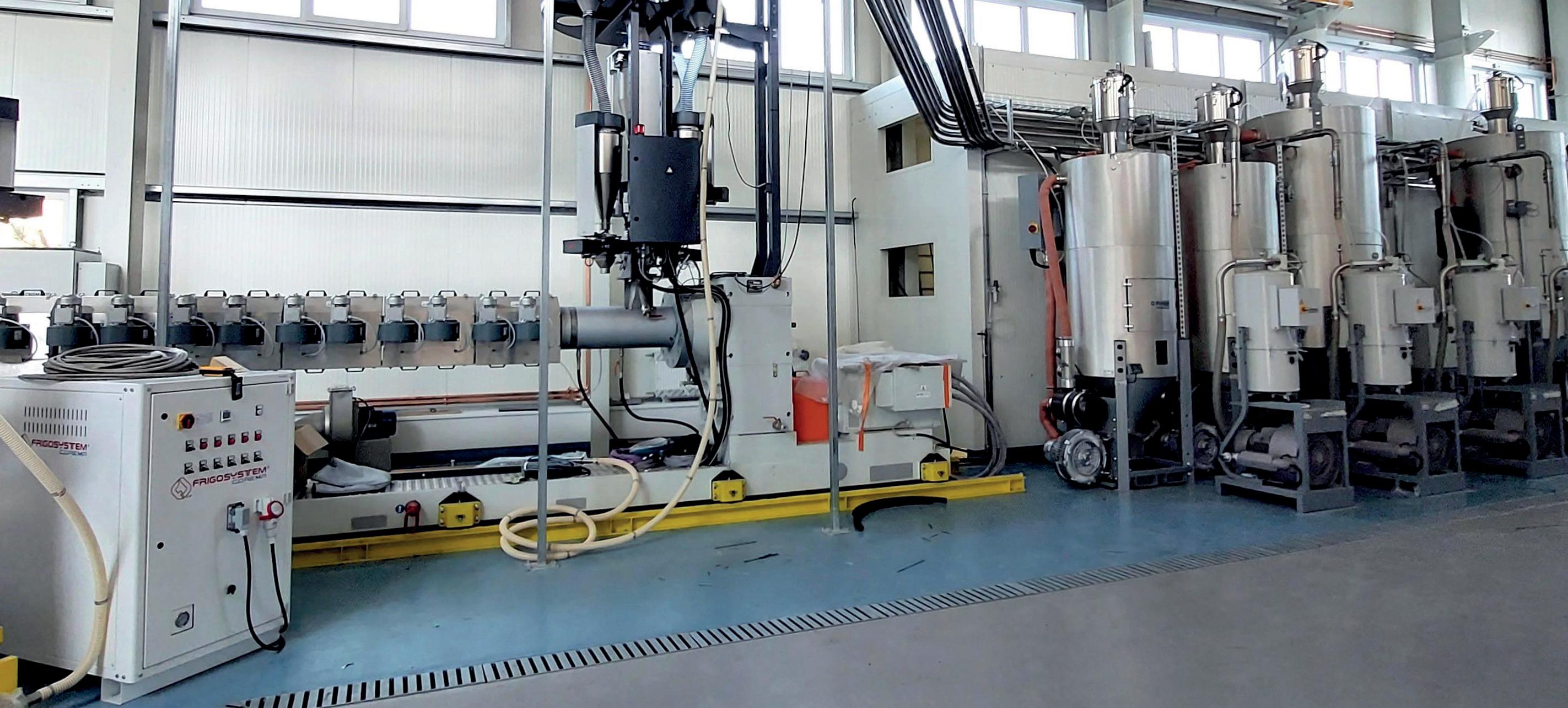

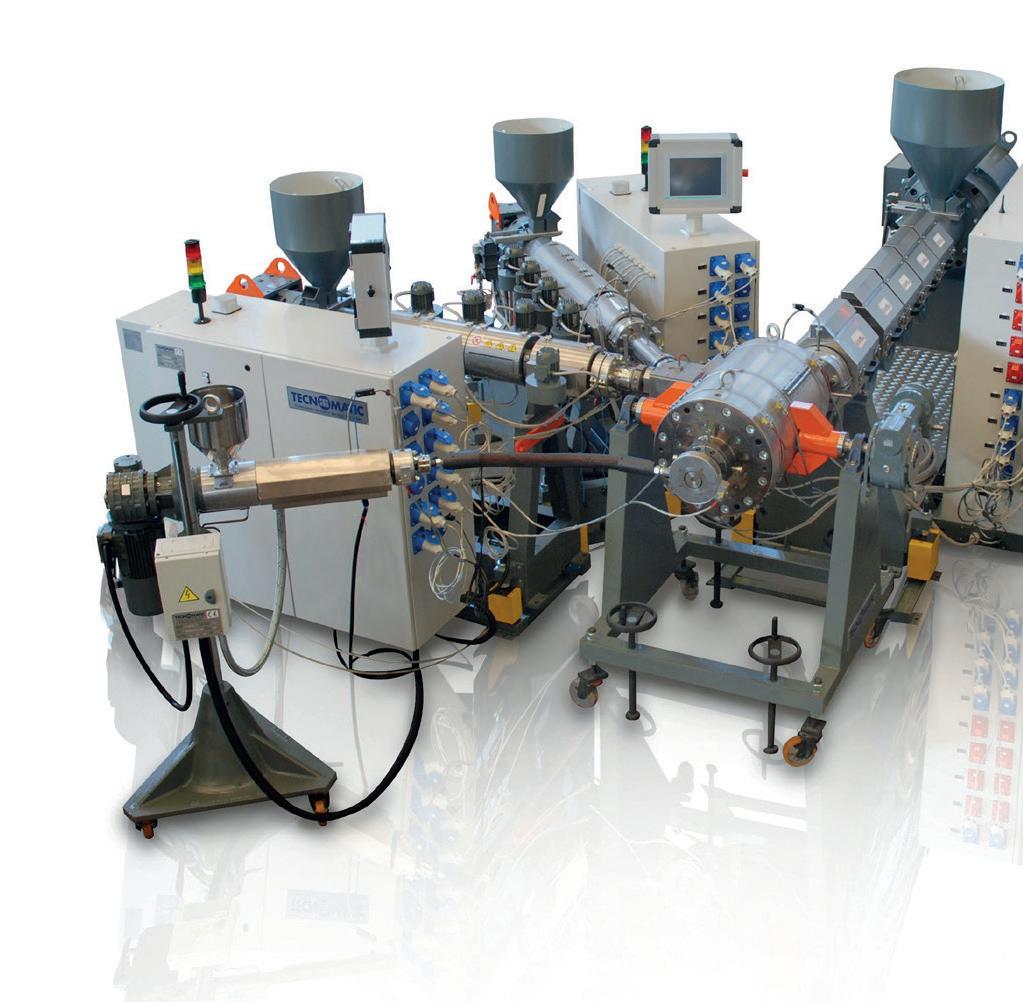

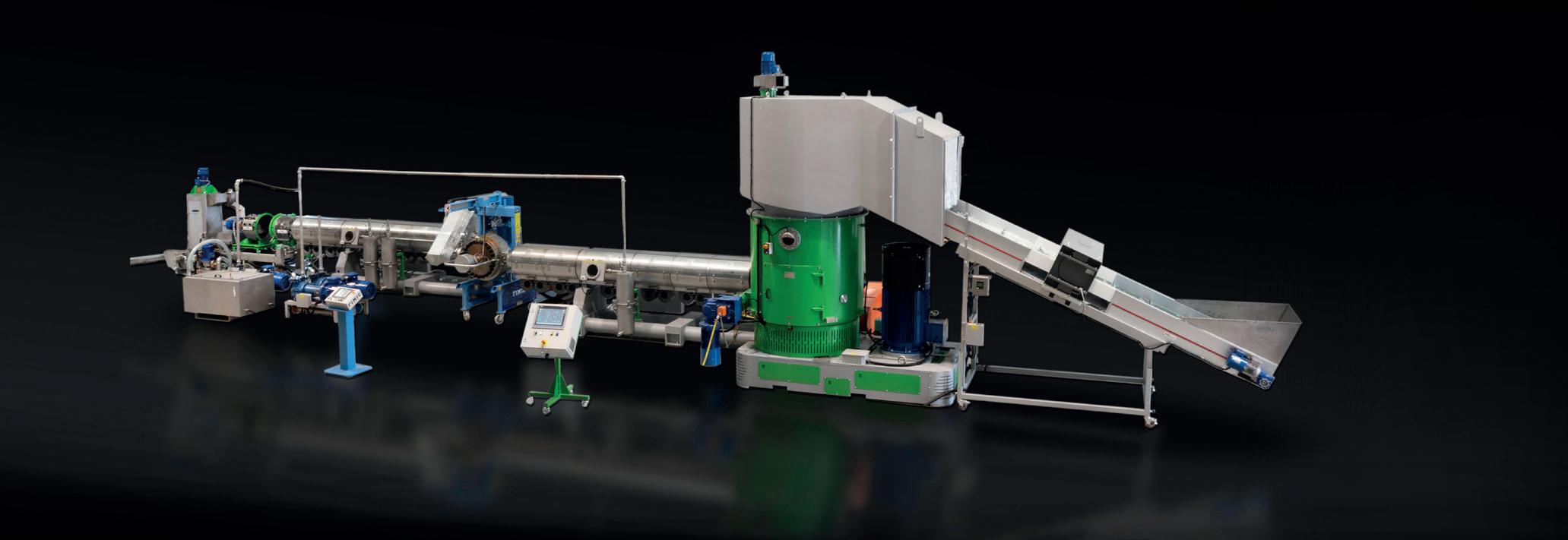

81 Regeneration and compounding line with co-rotating twin-screw extruder

85 Technologies for responding to changing needs

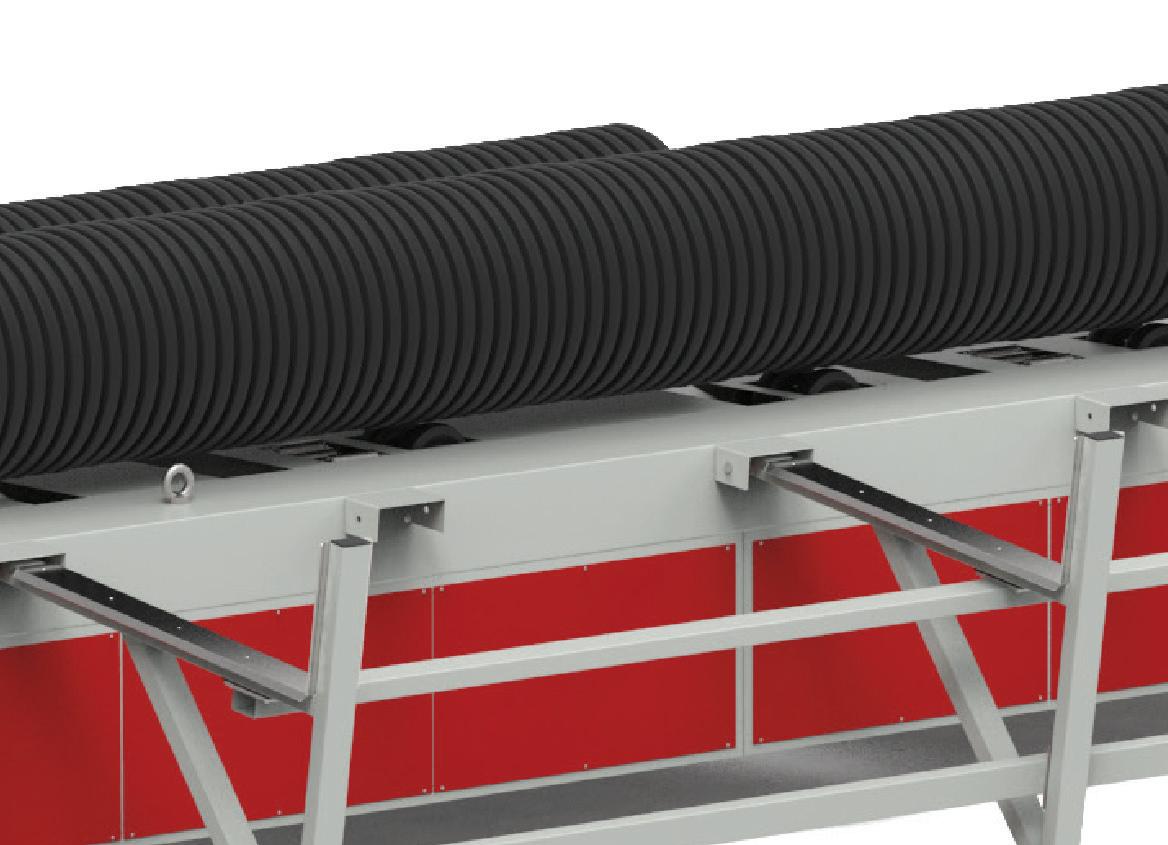

87 Fast corrugator

88 Over seventy years of experience at the service of printing and decoration

89 Robots for every need

91 Robotic solutions for extrusion

93 High efficiency and a major redesign coming soon

96 Two is better than one

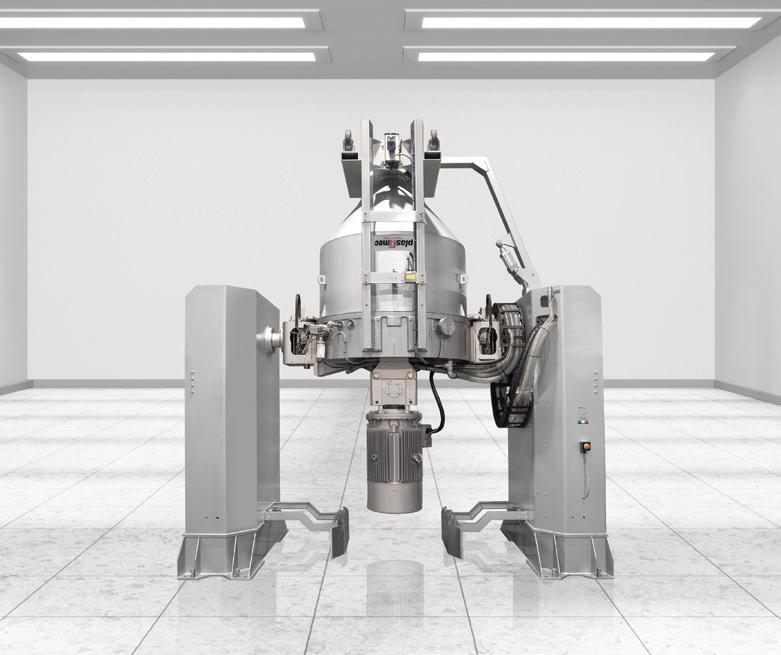

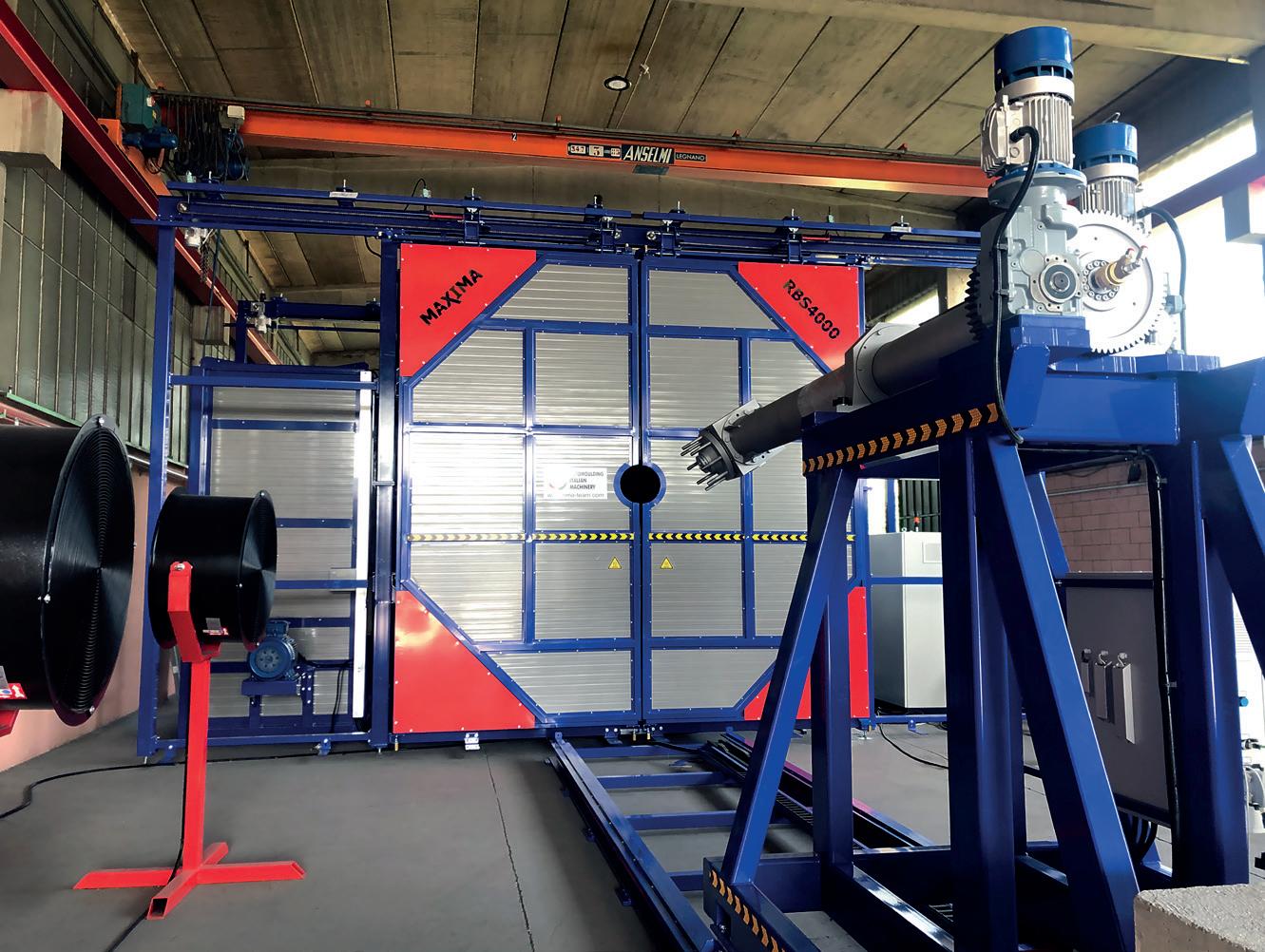

97 Innovating the rotomoulding and mixing tradition

99 Press and hardness testers on display

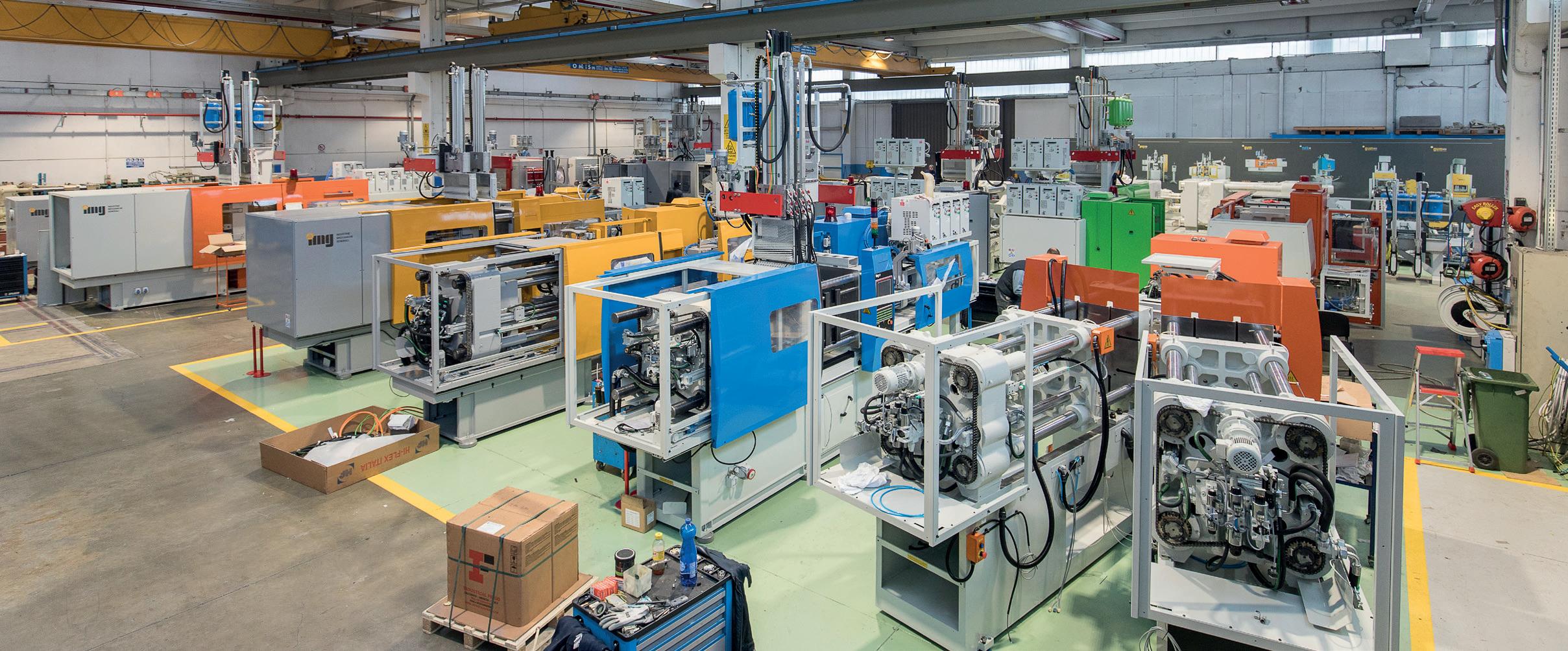

102 Two injection moulding machines in a big way

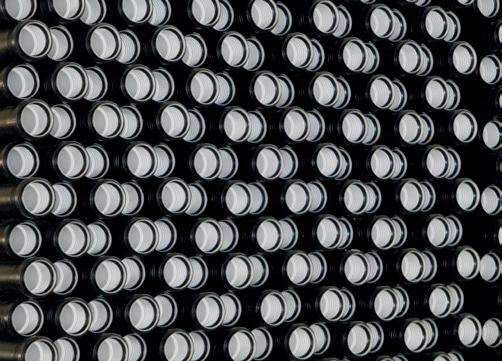

102 72 Stations for wine closures

103 Two “new” novelties for converting

105 Automatic and semi-automatic coilers for all types of pipe

105 Recycling wet waste is no longer a problem

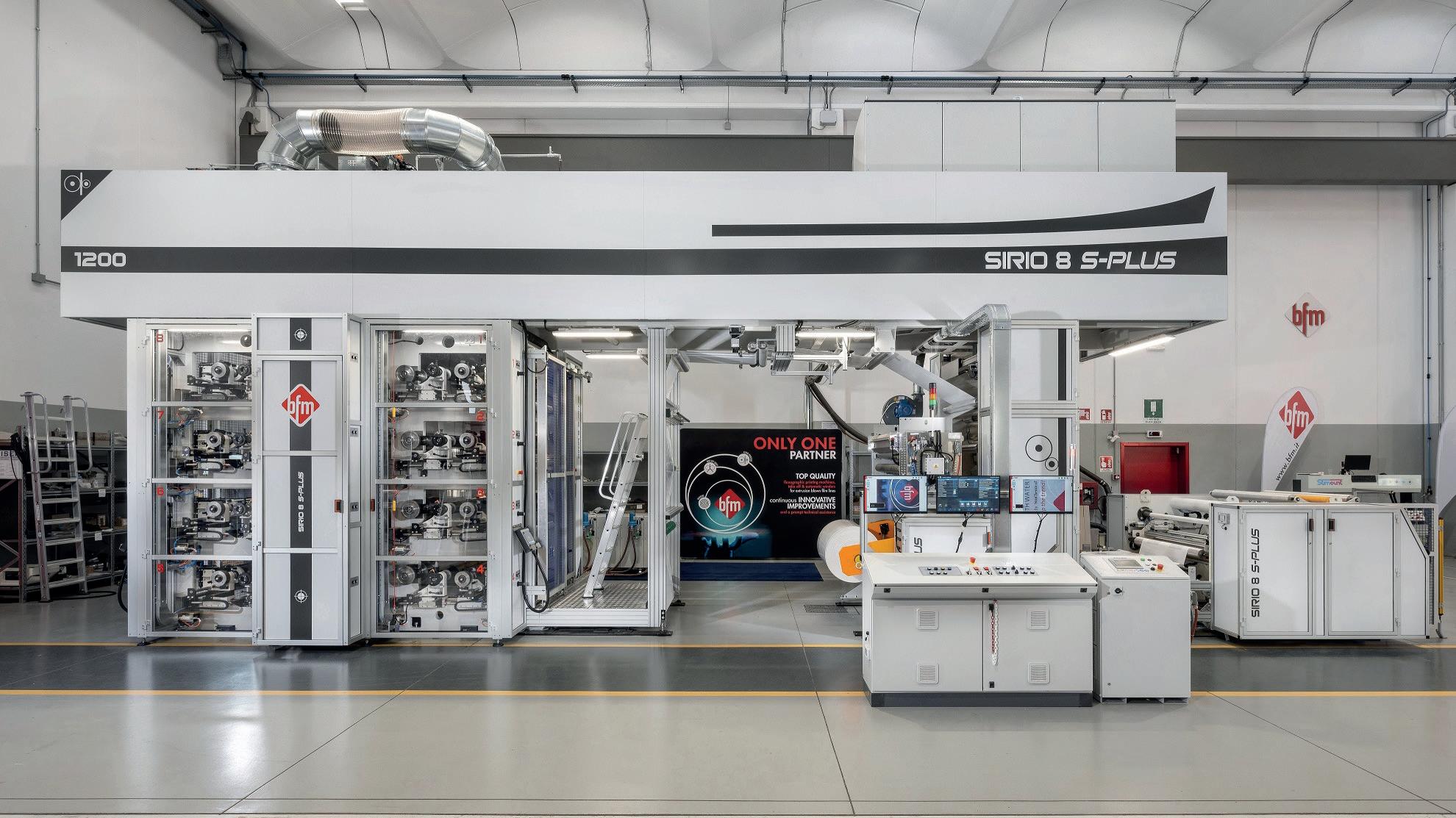

106 The eight colours of sustainability

107 Welding the socket to the end of the pipes

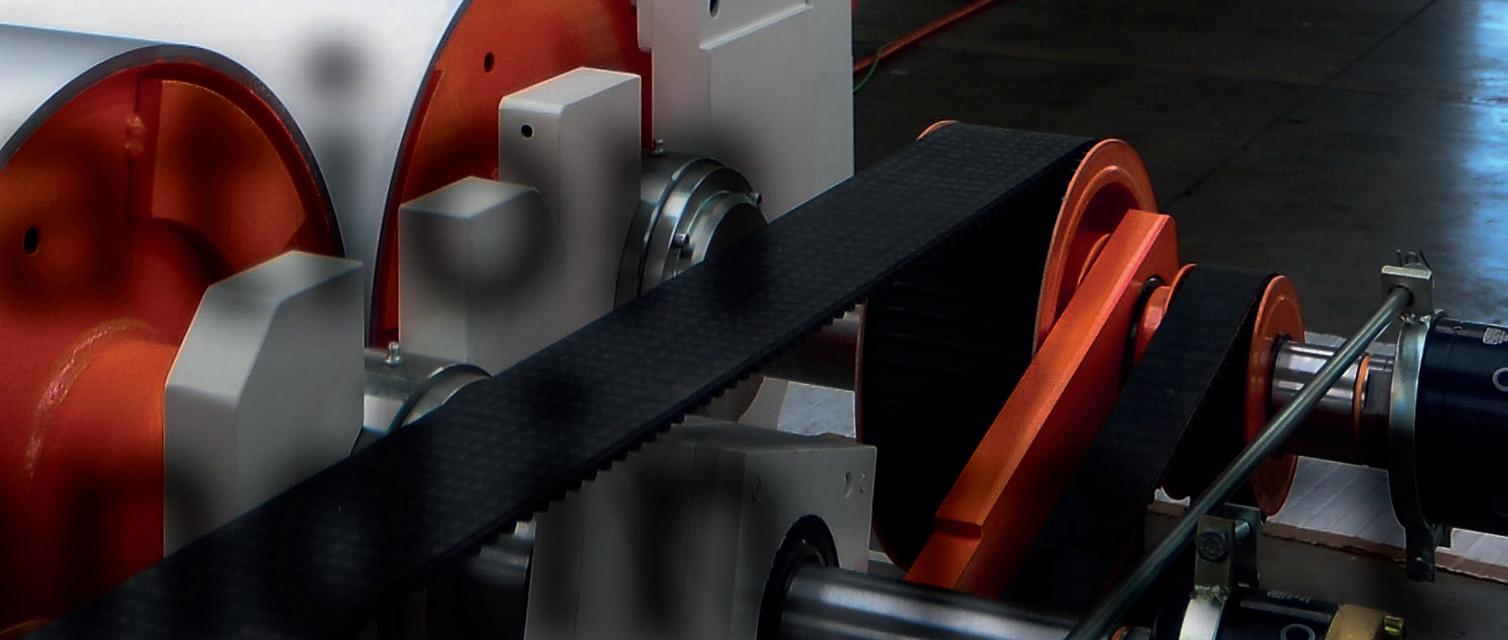

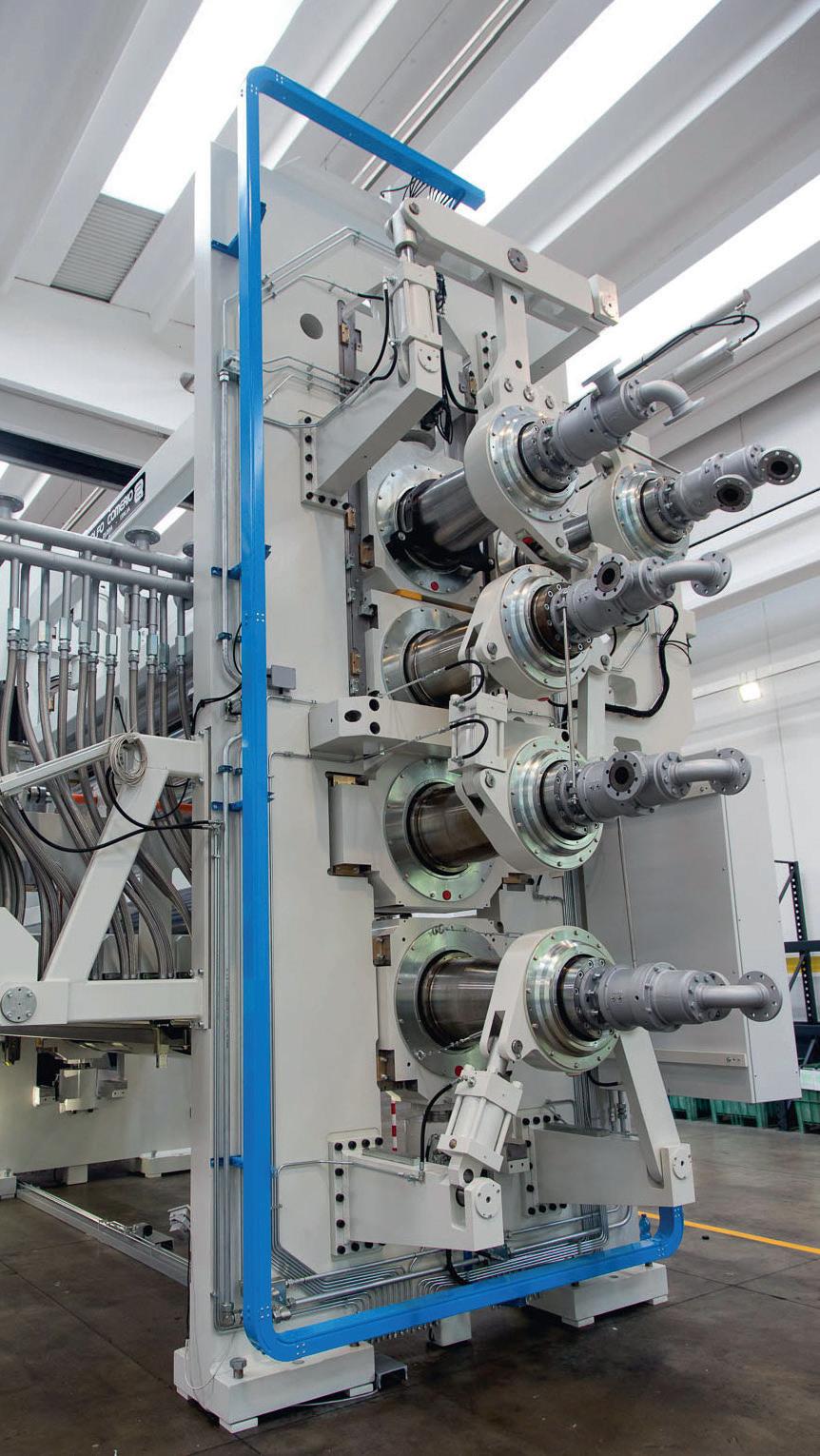

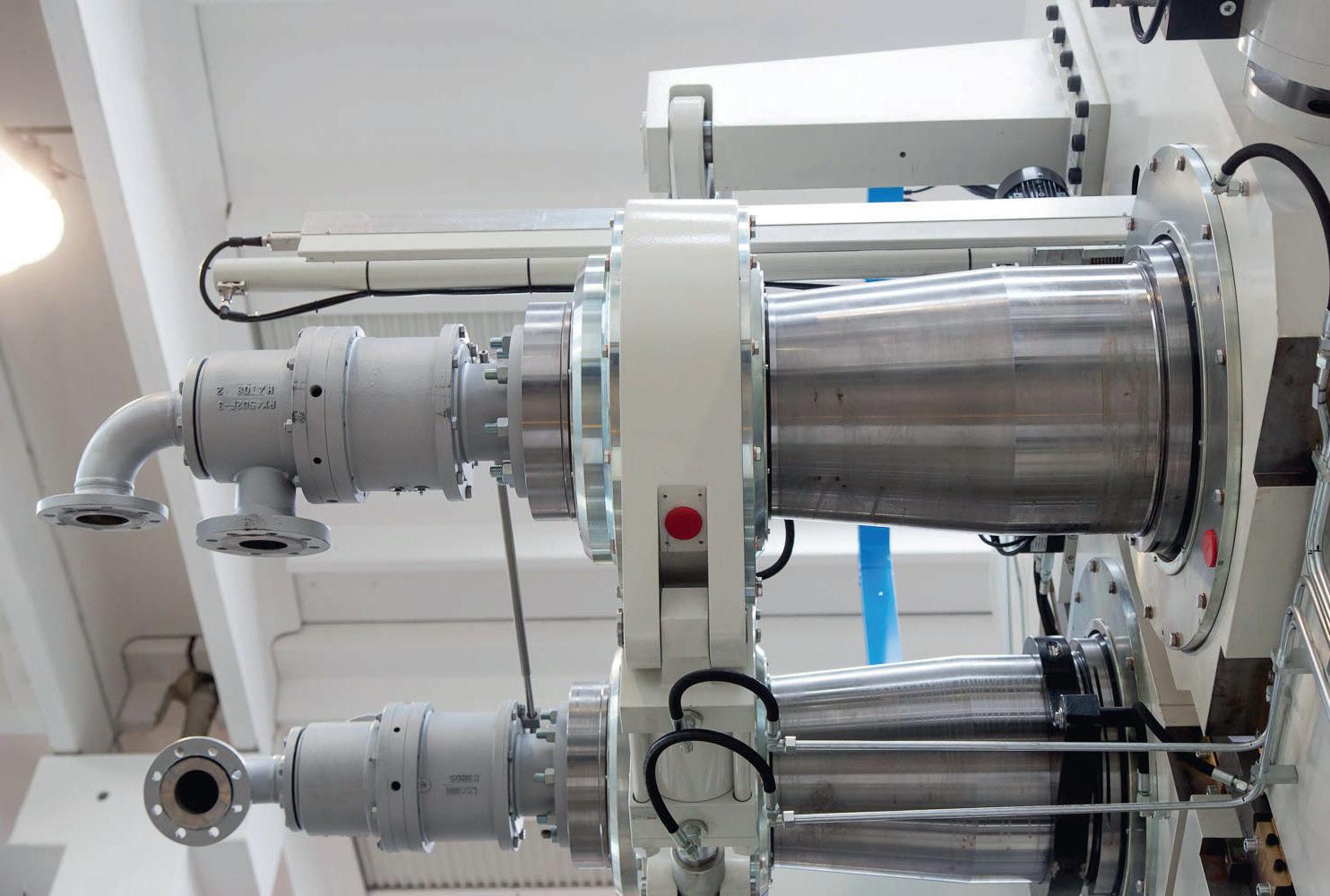

107 Everything for calendering 4.0

108 The second generation

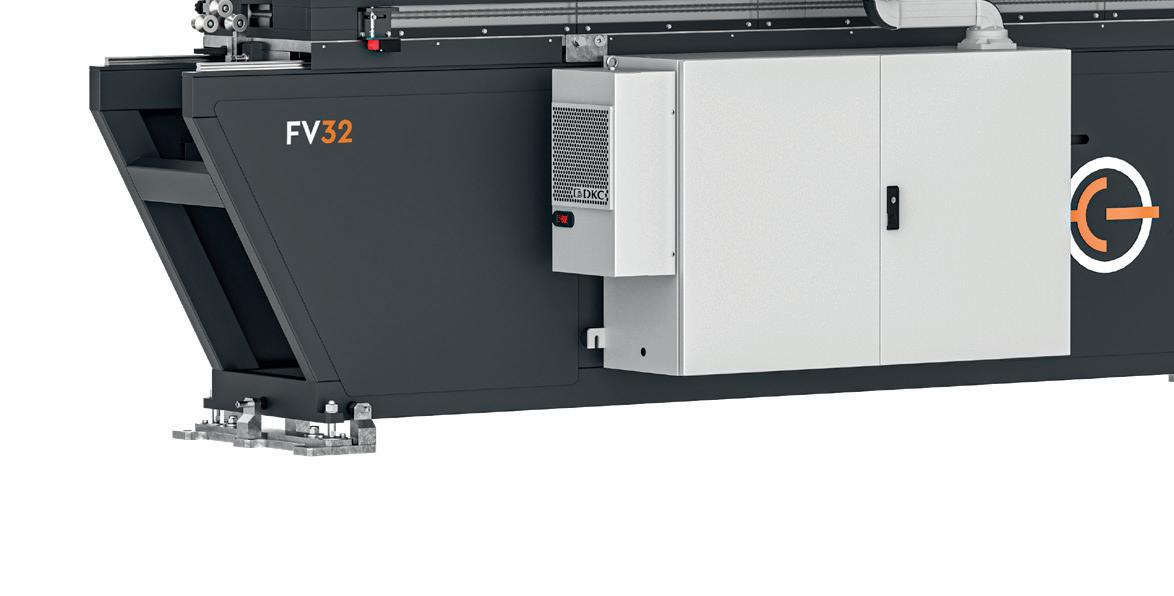

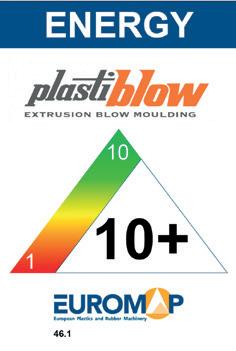

108 Energy-efficient electric multi-layer extrusion blow-moulding

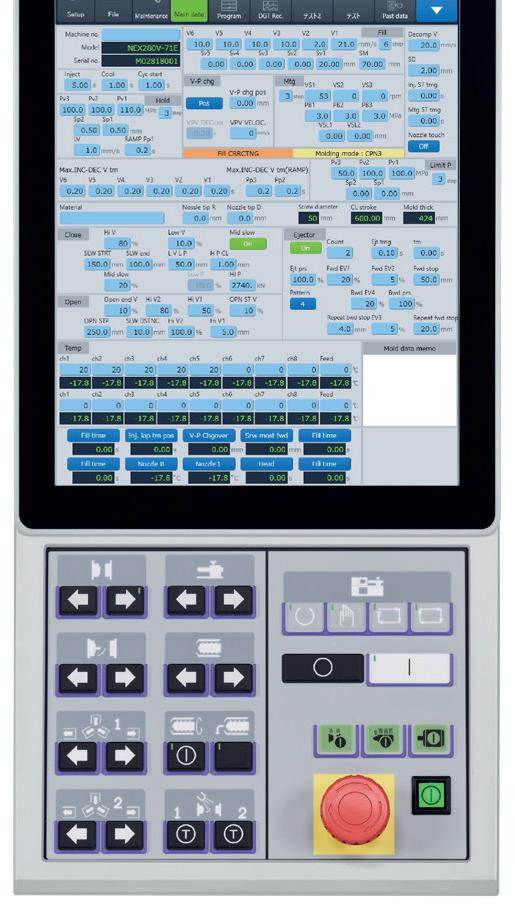

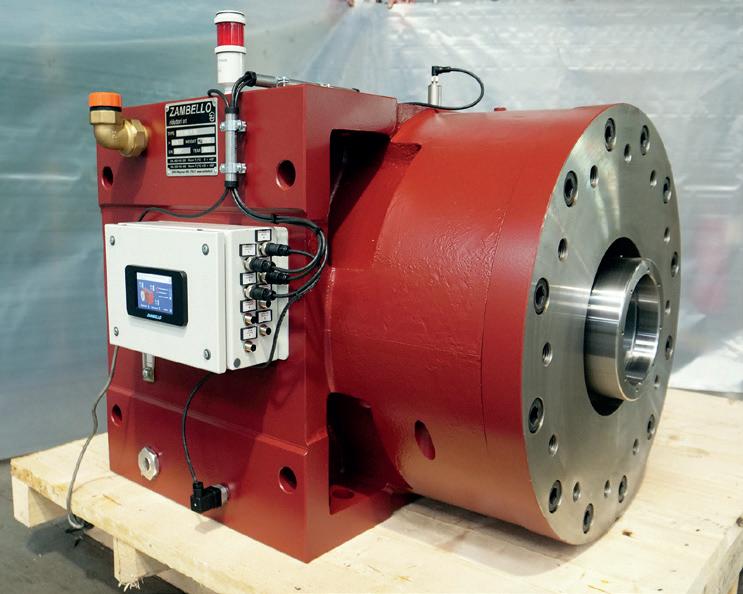

109 Electric drive for process precision and reliability

109 Custom rotational moulding

MATERIALS AND APPLICATIONS

112 Doubling production under the banner of environmental and social sustainability

116 Chemical recycling, an option for the ecological transition

120 New life for PVC: the sustainability challenge

121 The environmental impact of TPE

122 Composite for injection moulding from SLS powder recycling

123 Masterbatches, additives and biocompounds for all resins and particle sizes

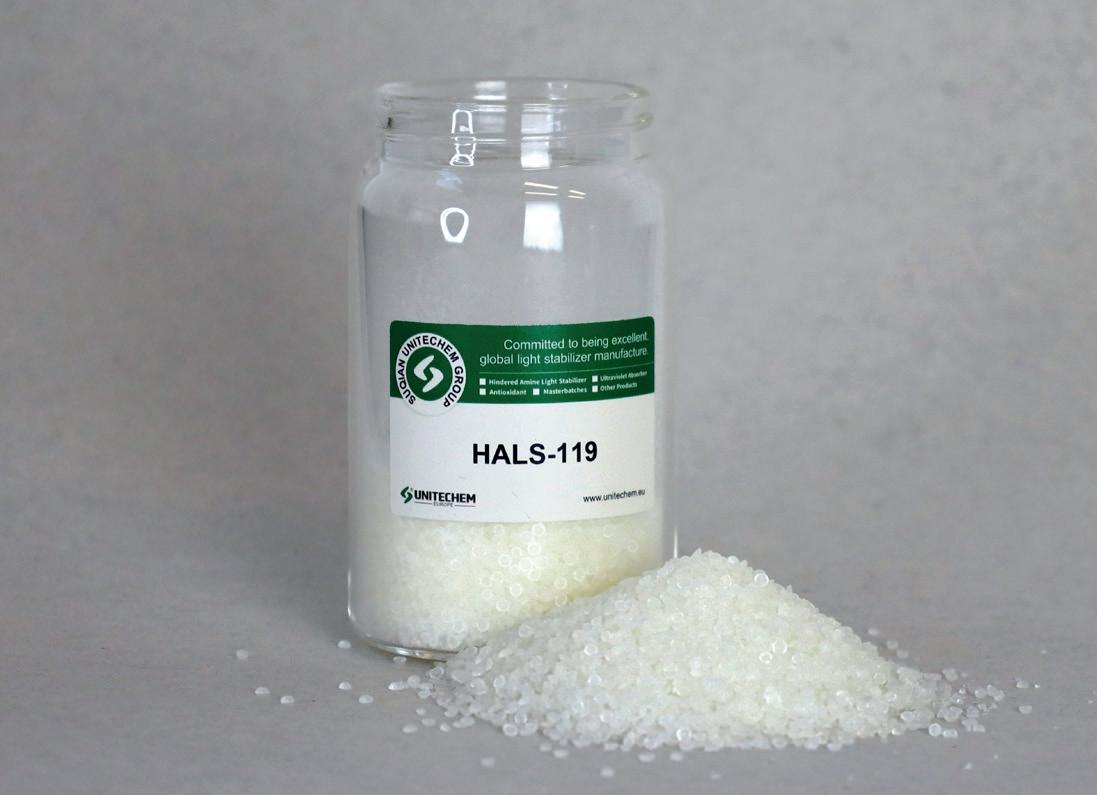

125 Insights into three major domains

TRADE FAIRS AND CONFERENCES

127 Plast 2023: focus on sustainability

129 The first edition in Bologna

131 Kielce trade fair endures

131 Dynamism and cohesion in Barcelona

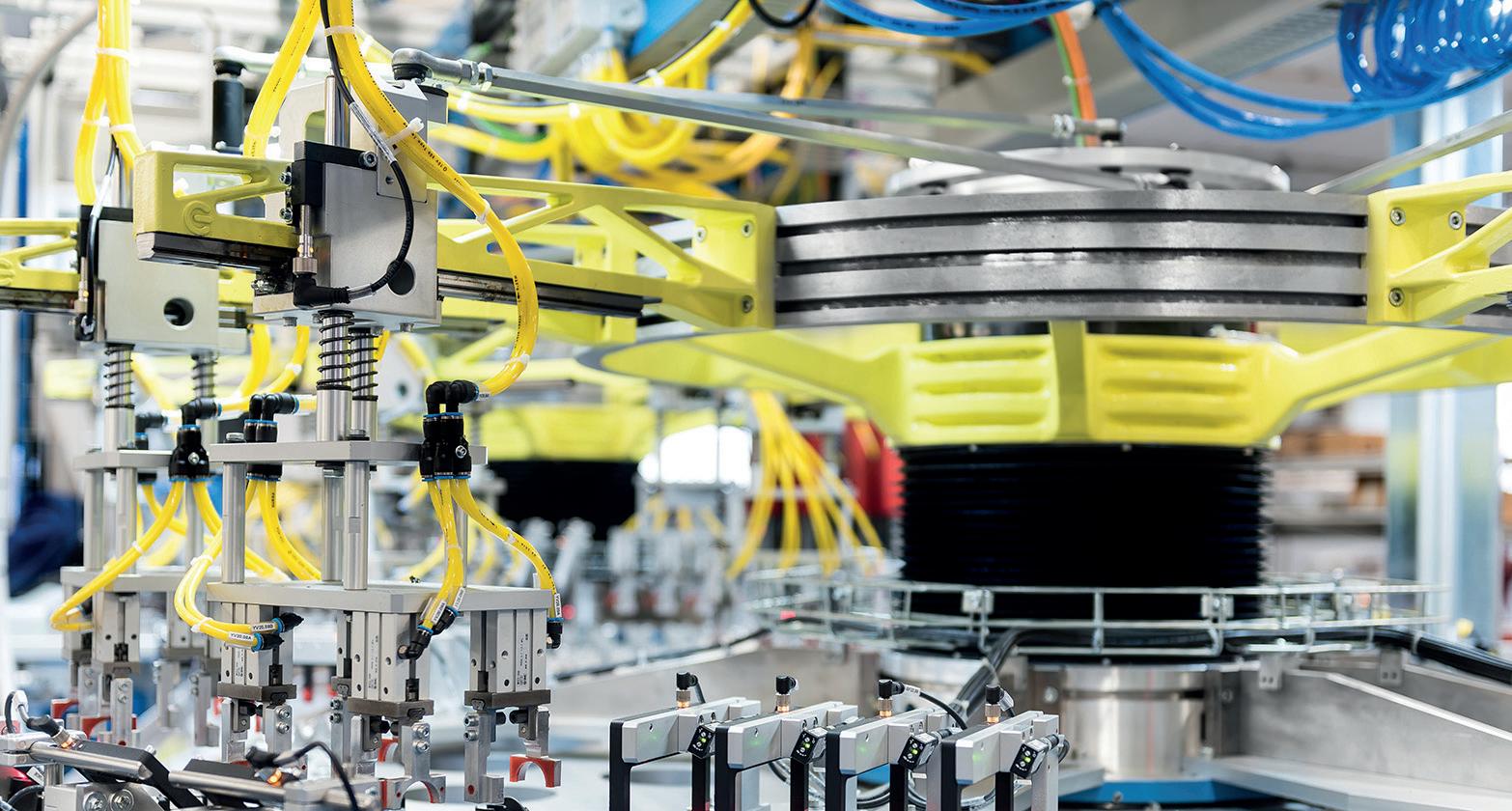

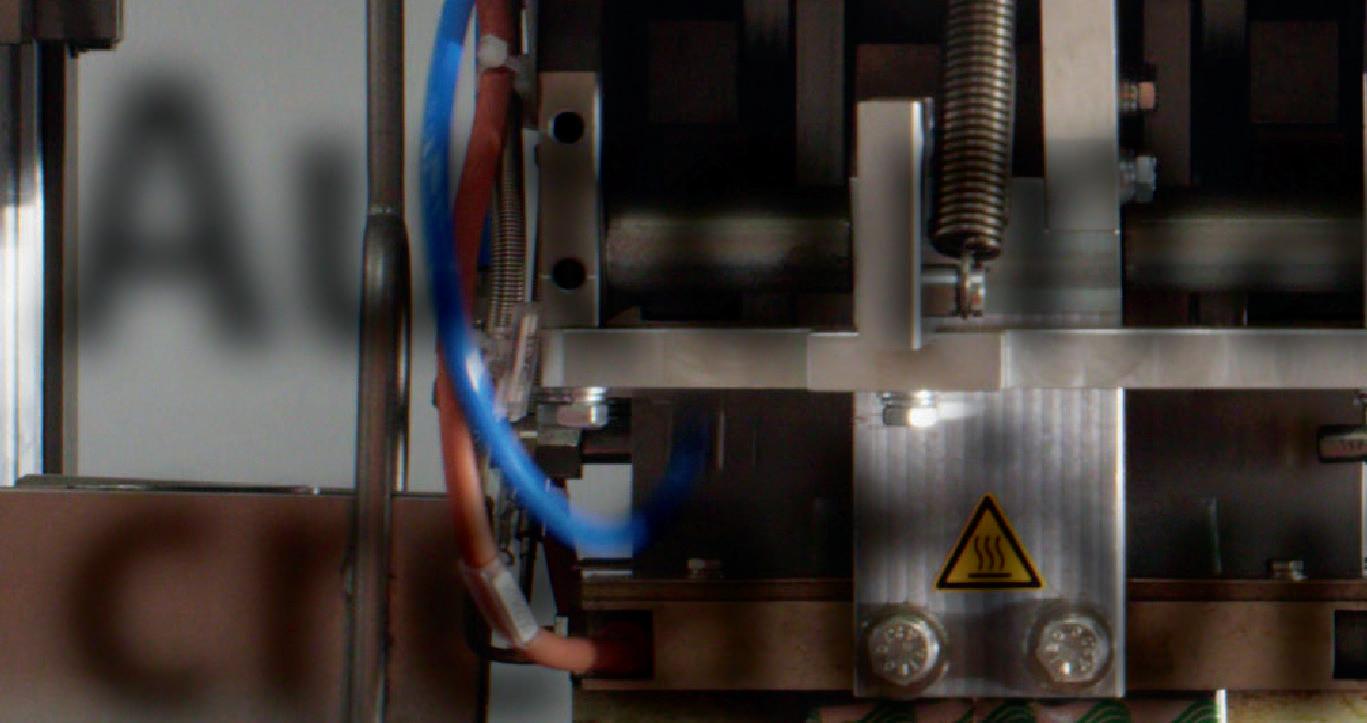

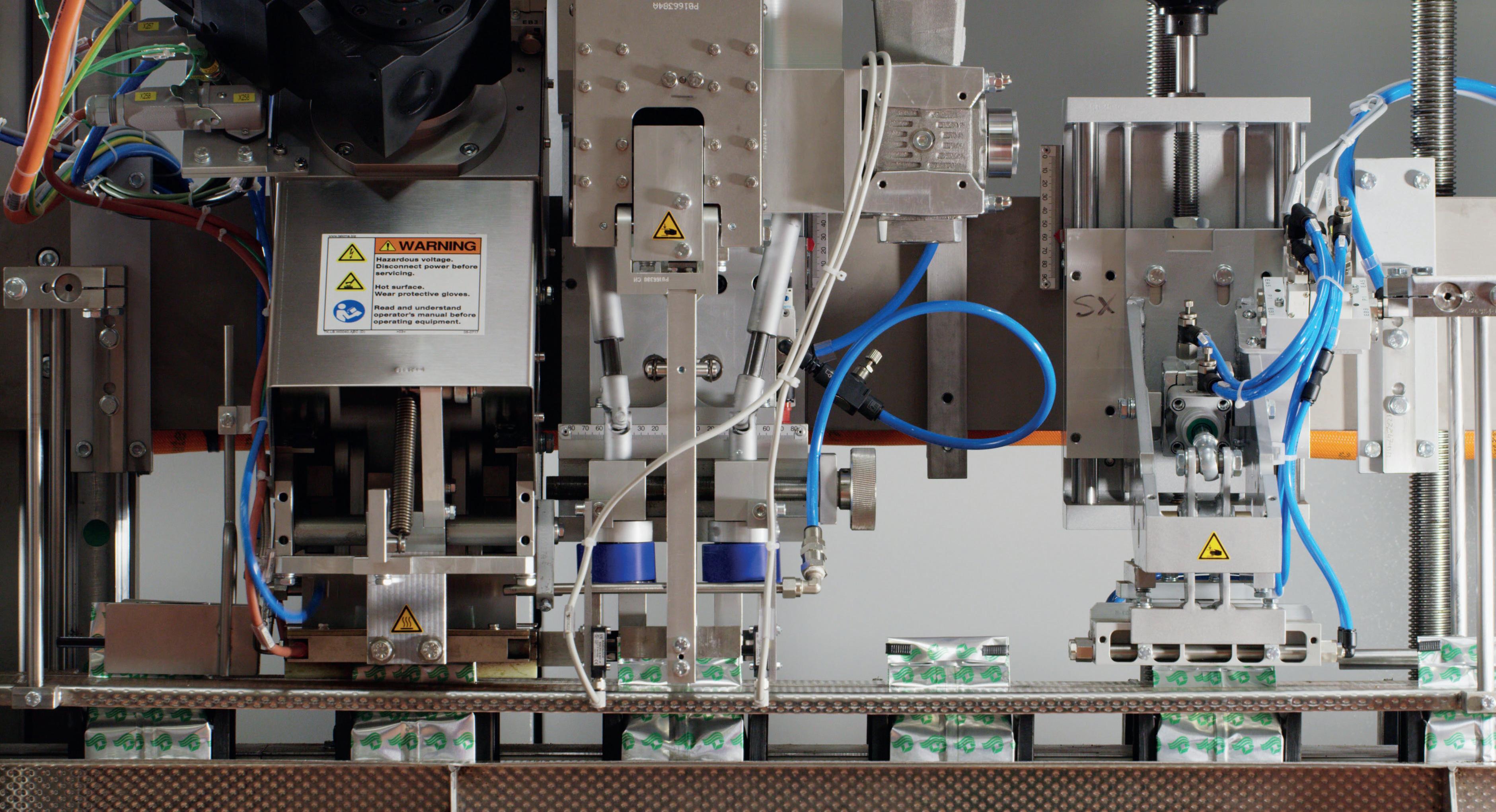

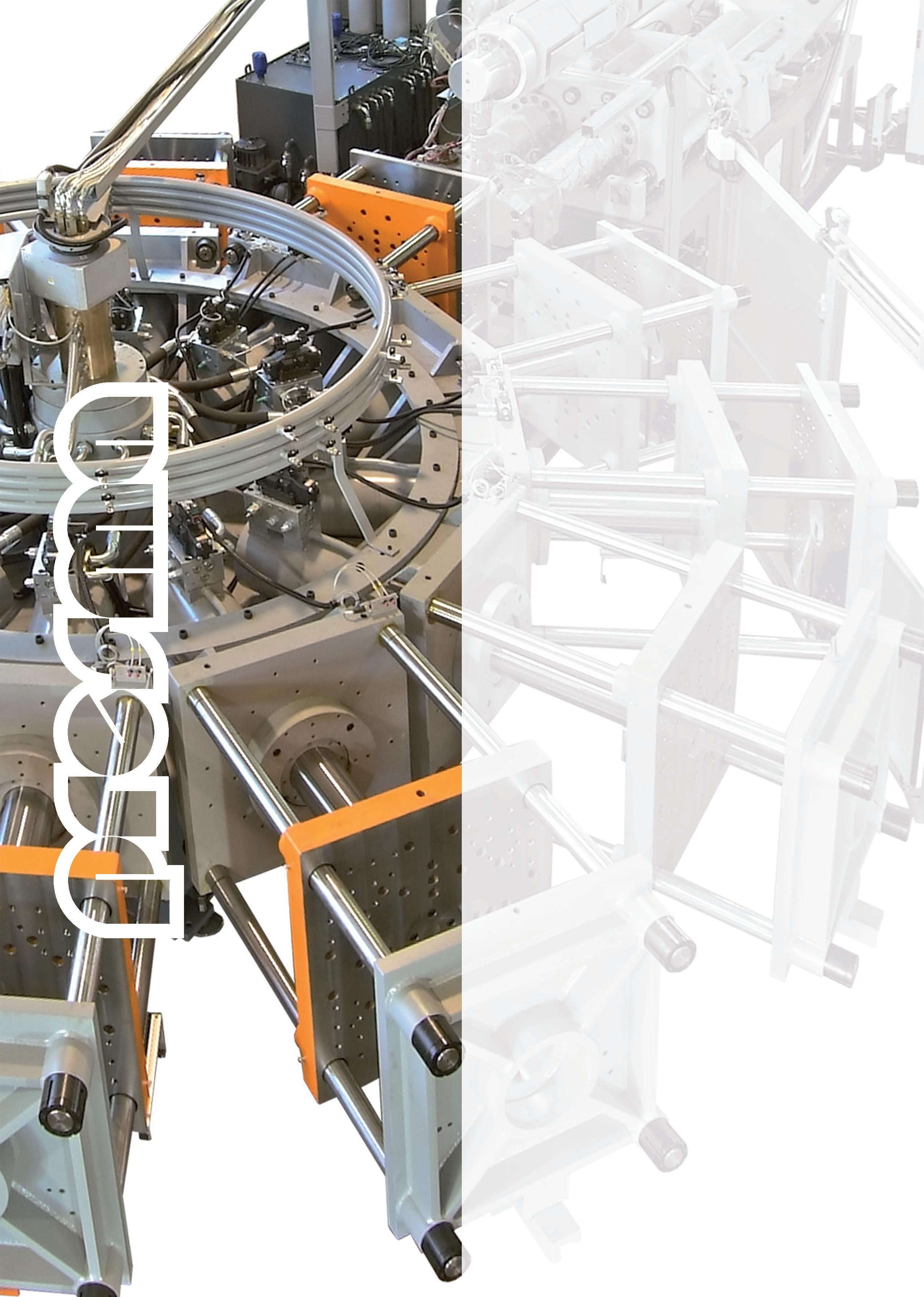

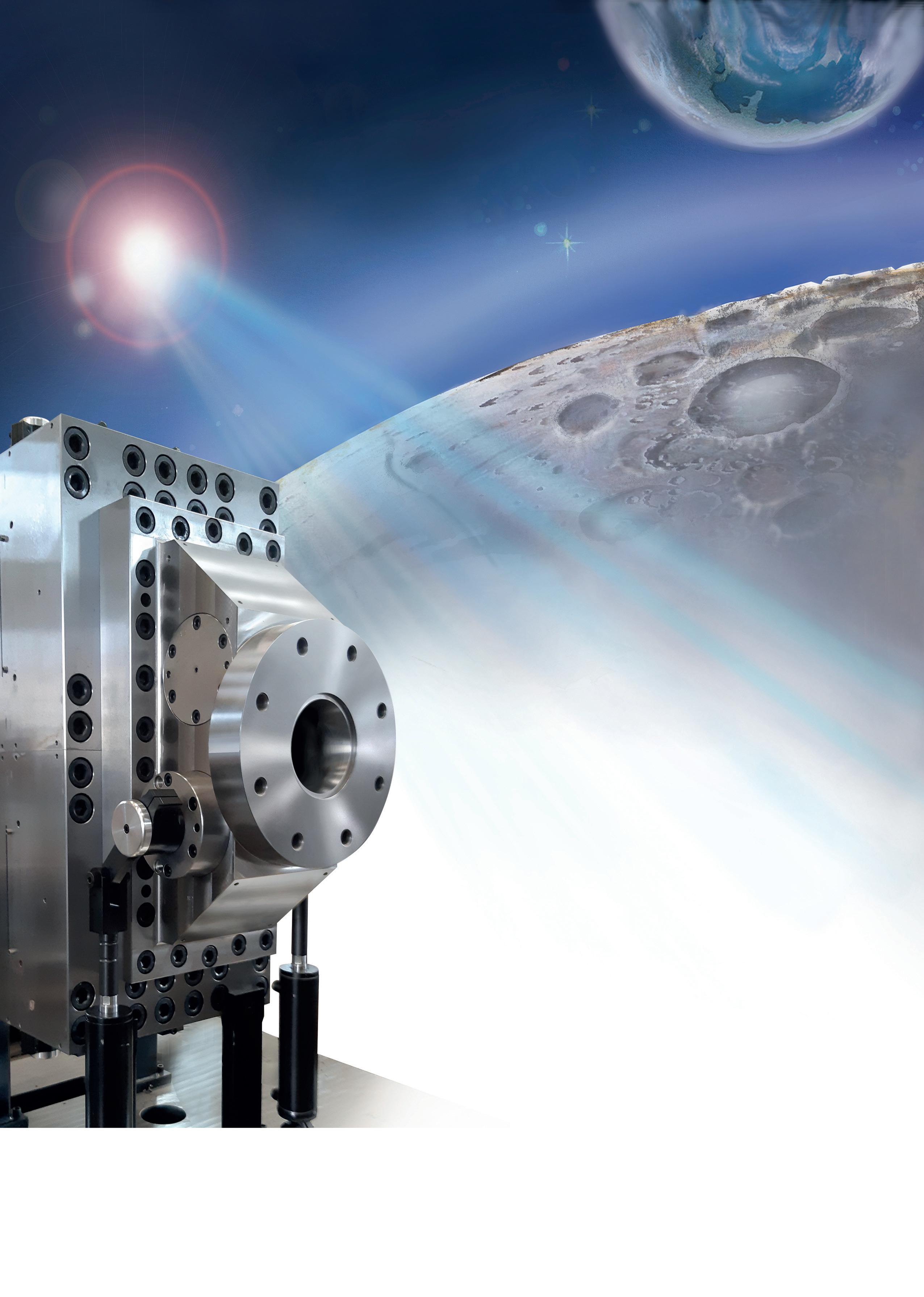

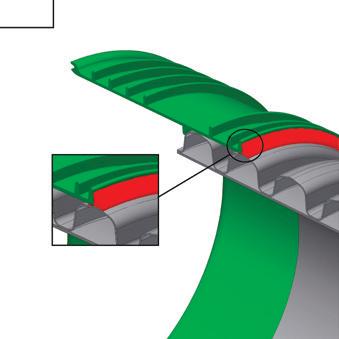

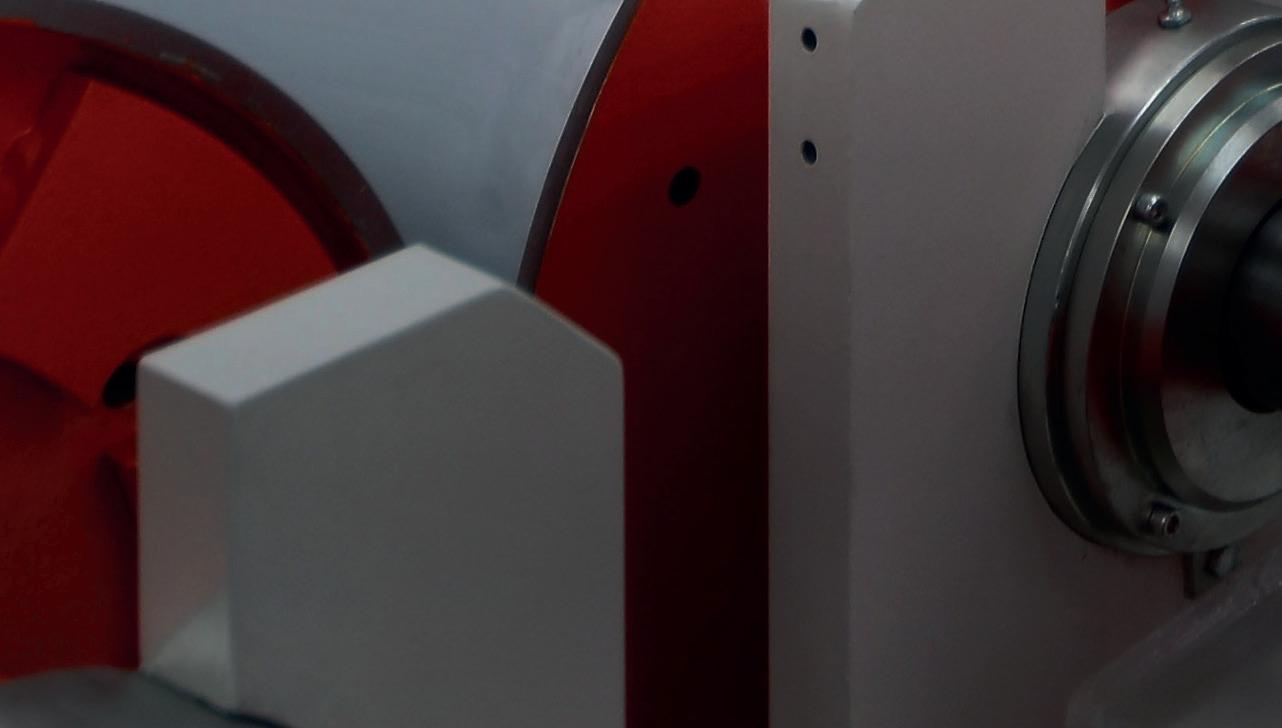

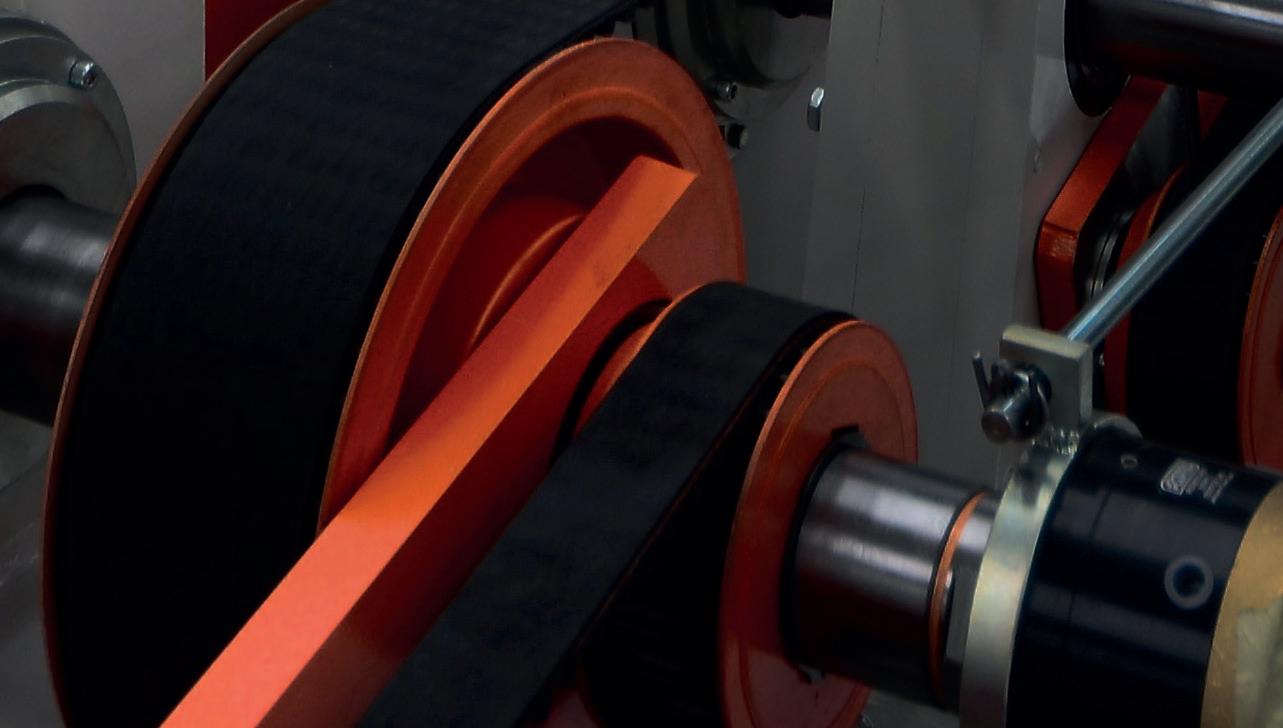

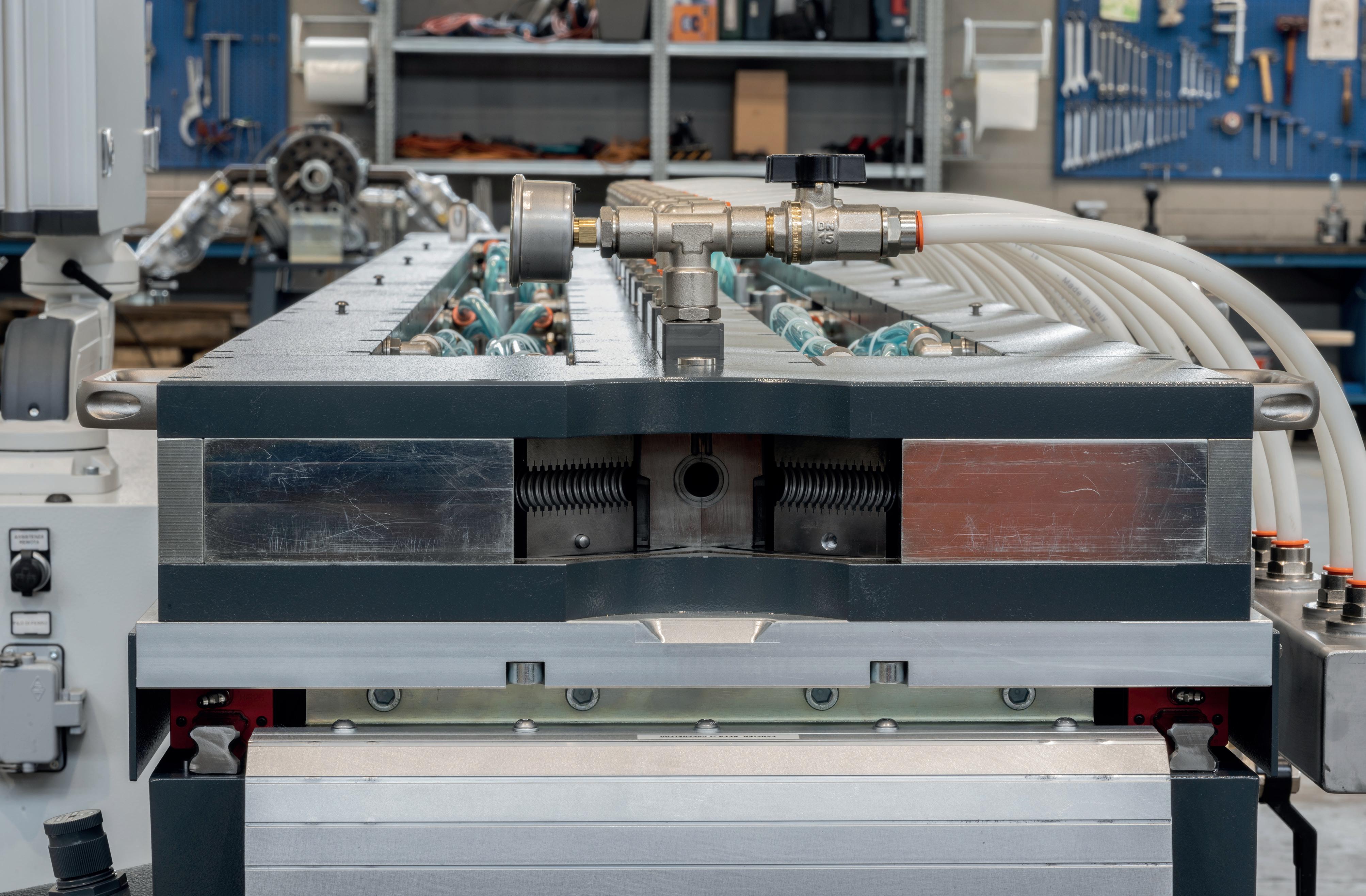

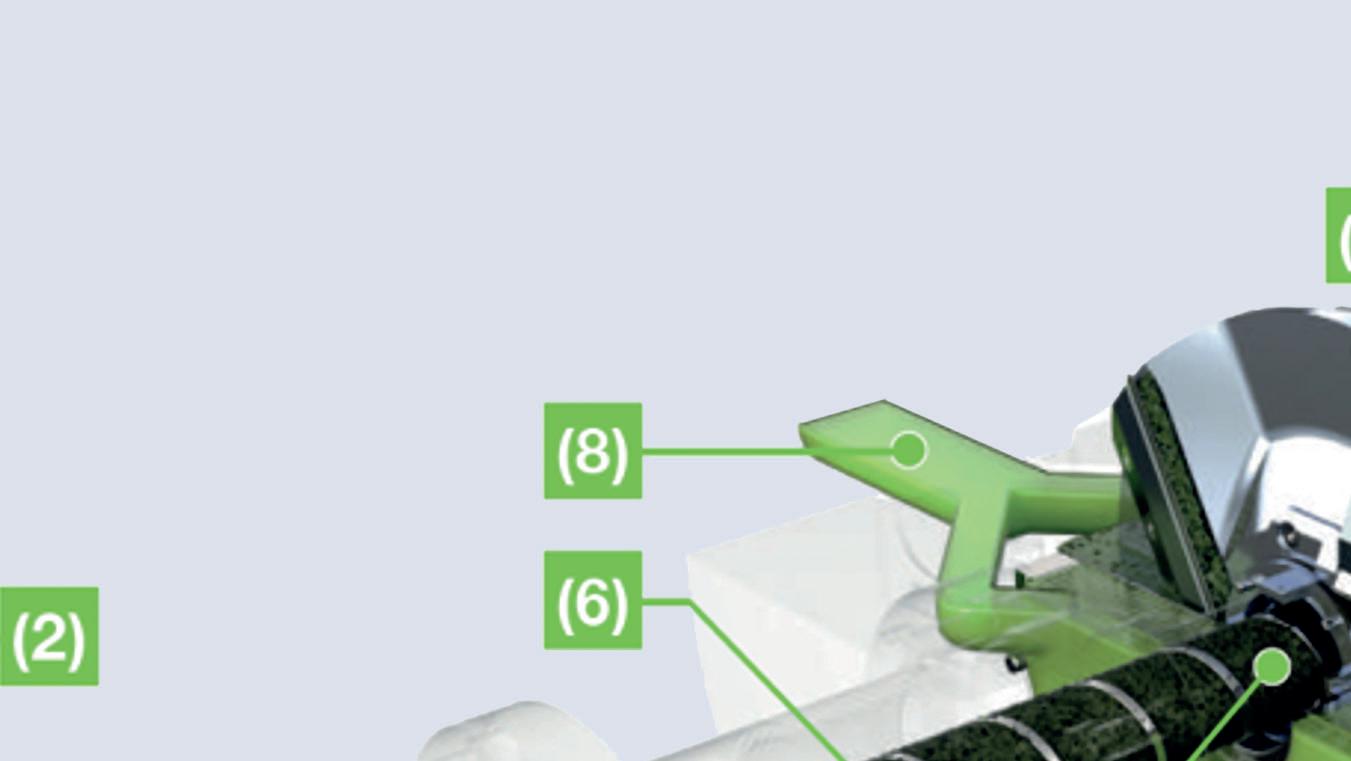

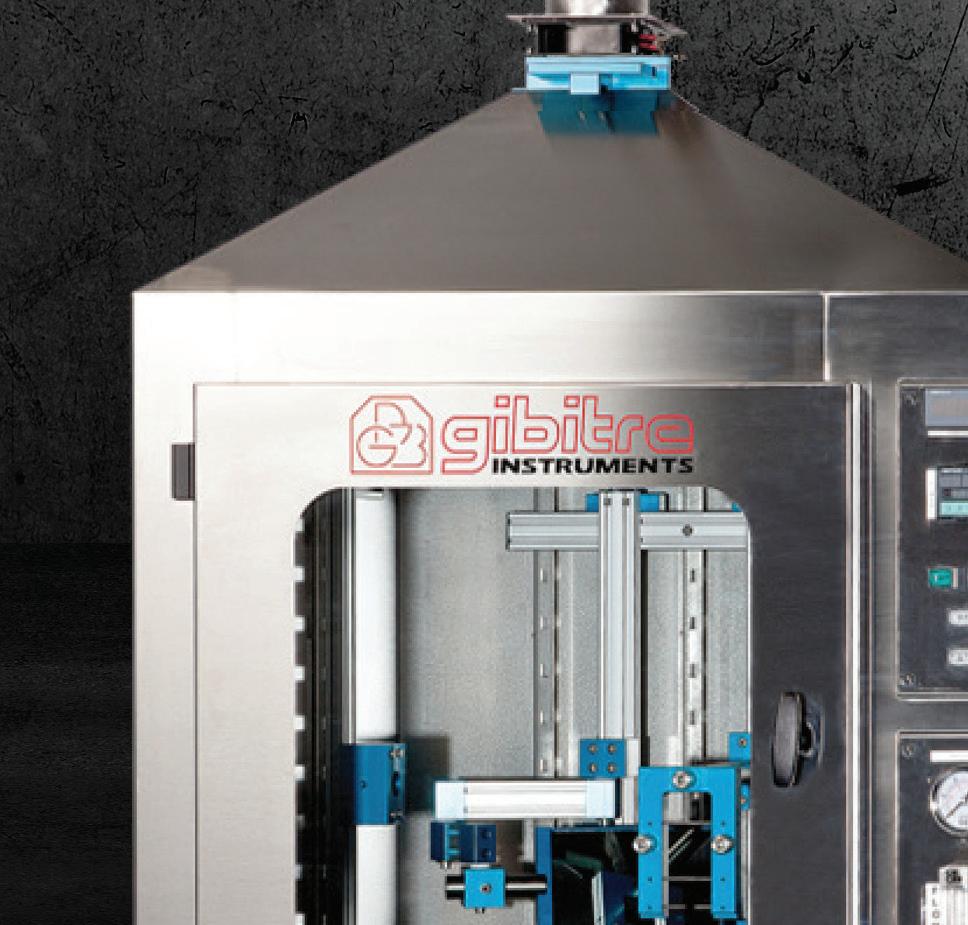

With the Sonderhoff technology portfolio, Henkel (owner of such a trademark) offers customized sealing, bonding, and potting system solutions with the Formed-In-Place (FIP) technology. The user thus receives material, machine, and process automation from a single source. These solutions are specified for a wide range of industrial applications in a variety of sectors.

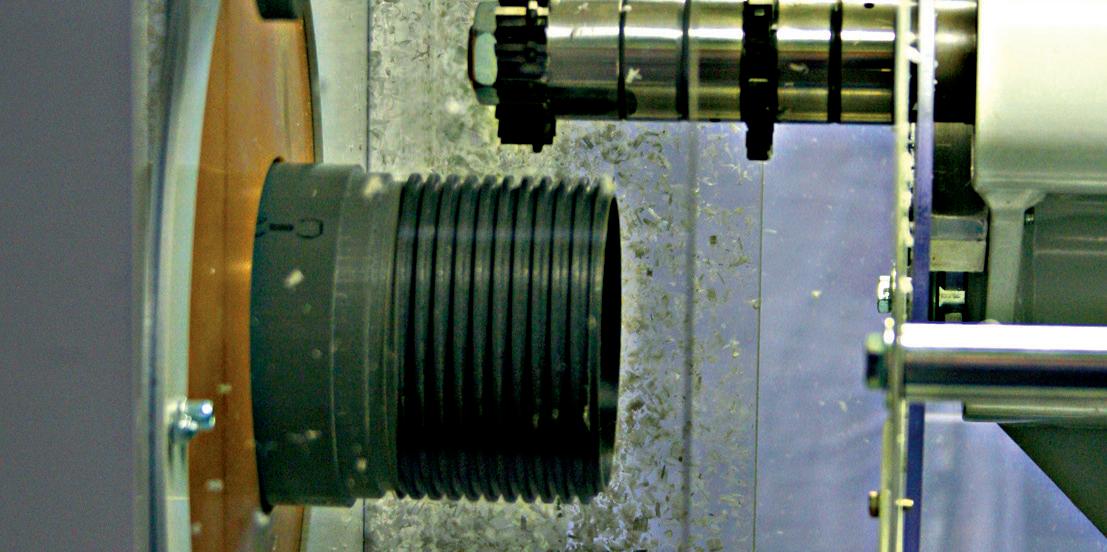

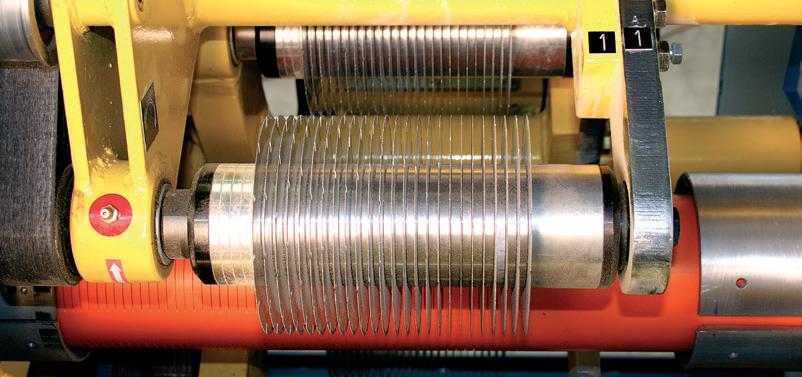

The user can choose between the configurable DM 50x dosing systems for 2 to 4 material components, the Smart-L, or the smaller Smart-M dosing cell, and the standardized 3E PUR or 3E SIL dosing cells for various applications. All the Sonderhoff mixing and dosing machines are equipped with the new DM 50x technology achieving the highest process stability due to many innovative features. For example, the efficient mixing head cooling, improved valve technology with process monitoring and operator interfaces with informative visualization of process data. One of the core competences of the Sonderhoff technologies from Henkel are the quality and precision of the Sonderhoff mixing heads. Greatest possible material homogeneity after mixing 2-component material systems with different viscosities can only be achieved with dynamic mixing, especially in the case of demanding asymmetrical mixing ratios.

Henkel presents the Sonderhoff Smart-M (pictured on the cover) dosing cell with the new DM 50x technology and the newly developed MK 825 PRO mixing head in the version for two material components and with ecological high-pressure water rinsing of the mixing chamber at Fakuma 2023. The Sonderhoff Smart dosing cell is available in two sizes to process parts in different sizes: the Smart-M with the traverse range of 500 x 600 x 250 mm (X, Y and Z axis respectively) and the Smart-L with 1,000 x 800 x 250 mm (X, Y and Z). The new MK 825 PRO mixing head features many measuring sensors providing the machine operator with a comprehensive database on the entire FIP application process: axial position of the agitator shaft in the mixing chamber; the positioning of the dosing needle; the material pressure directly at the valve; the temperature in the mixing chamber.

Summarising, the many measuring sensors installed in the new MK 825 PRO mixing head provide the machine operator with a comprehensive database on the entire FIP application process: the axial position of the agitator shaft in the mixing chamber; the positioning of the dosing needle; the material pressure directly at the valve; the temperature in the mixing chamber.

www.sonderhoff.com

17 - 21/10/2023

Hall A3, stand 3101

Friedrichshafen Germany

17 - 21/10/2023

Hall A3, stand 3101

Friedrichshafen Germany

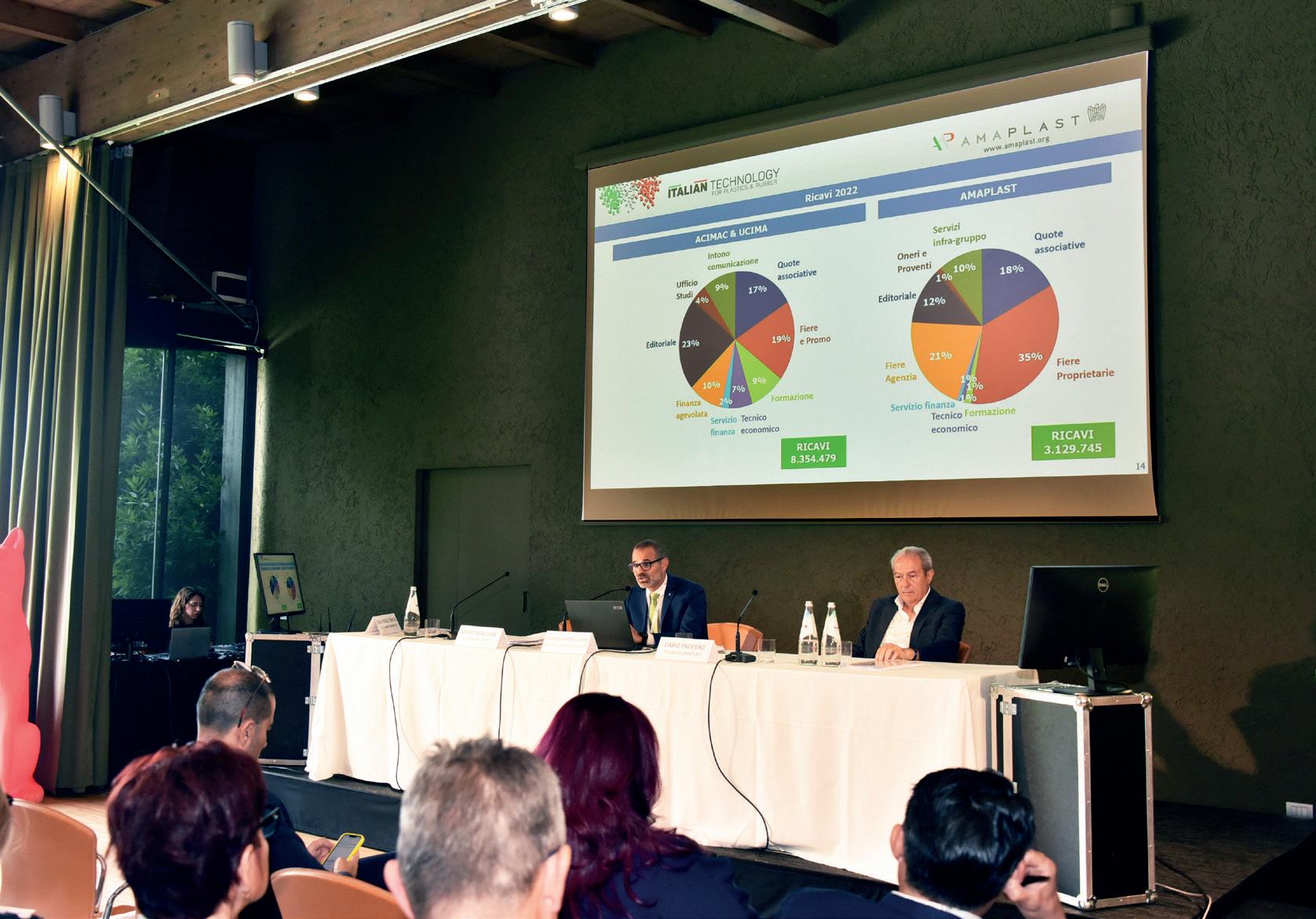

The Italian plastics and rubber processing machinery and moulds manufacturers’ associations has a new leader for the period 2023-2025. The election took place at the annual assembly of its members, where the most topical issues of the moment were also discussed and industry data presented. In addition to launching the final sprint to Plast 2023.

BY STEFANIA ARIOLI AND LUCA MEI

BY STEFANIA ARIOLI AND LUCA MEI

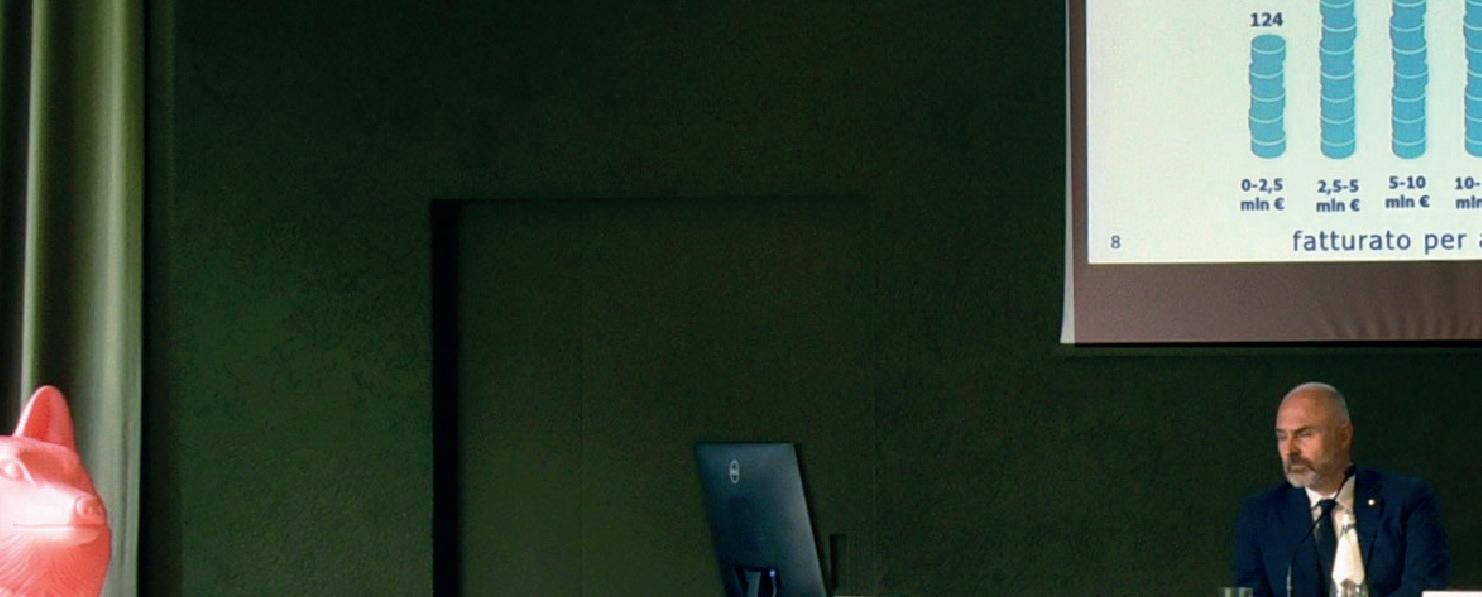

There is a new President at the Amaplast helm for the two-year term 2023-2025: Massimo Margaglione (Gefit), who was Vice President for the past four years and now receives the baton from Dario Previero. Also elected were the two Vice Presidents: Barbara Ulcelli (IMG) in her first term and Gabriele Caccia (Syncro) re-elected for a second term.

The new leadership was elected at the annual member assembly, which took place on 28 June 2023 at the Ca’ del Bosco winery in Erbusco (Brescia, Italy).

In additional to the elections, the Assembly was also the occasion for a broad overview of the sector represented by the association. In his talk, the departing president Dario Previero illustrated the performance of the Italian plastics and rubber processing machinery industry, commenting on the results of the third edition of the National Statistical Survey carried out by the Mecs-Amaplast Statistical Studies Centre of 397 manufacturers (representing 14,447 employees) who generated revenues of 4.35 billion euros in 2022, for an impressive 8.1% gain over 2021 with 72.7% going to exports. This is the second-best performance of all time, achieved in spite of the fact that the sector had to cope with numerous difficulties during the course of the year, such as limitations on exports to Russia, shortages of

raw materials and components, and increases in energy costs, just to name a few. Some of these difficulties have yet to be fully resolved, but probably a constantly changing world situation is the new paradigm to which companies will have to adapt, carefully balancing due caution with a healthy willingness to take risks. And indeed, this is a mindset well represented in recent years by businesses in the sector, which have ably parried many of the economic repercussions of world events occurring during the pandemic and afterwards, always ready to continue moving forward with their eyes on the future.

Dario Previero then reaffirmed the efficacy of the inter-association synergy with Acimac (the association of the Italian manufacturers of machinery and equipment for ceramics) and Ucima (the Italian packaging machinery manufacturers association), which has provided associated companies an increasingly broad range of services to support them in their day-to-day operations. In particular, there is a new environmental service for the drafting of sustainability reports and consulting services to guide the implementation of best practices to reduce a company’s environmental impact. Furthermore, an intensive corporate accreditation project is underway with Ucima to promote the line of thinking of the Italian plastics and packaging industry, especially as regards the new European packaging directive (SUP), which favours reuse of packaging over recycling.

New president Massimo Margaglione laid out the guidelines of

his presidency: “As newly elected president of Amaplast, I feel it is my duty first and foremost to choose continuity with the major initiatives undertaken by my predecessor. To this end I shall undertake to promote, support, and implement the spirit of collaboration that has taken form between Acimac, Ucima, and our association so that we can set up a federated body that strengthens our position within Confindustria. The safeguarding of the interests of the plastics industry and its operating assets is now an unquestionable necessity and priority. We will have to work with governments, institutions, and national organizations in order to guide policies that are favourable to our goals and to counteract the negative perception of our industry, often and unfairly seen as responsible for the adverse environmental impacts that are all around us.

In addition to this, Amaplast will continue providing support services in order to inform and often also train its member companies on such sensitive and now inescapable issues as the sustainability and social responsibility of companies, ecological transition, the circular economy, the SUP Directive, and the upcoming amendments to the European packaging directive. It will also continue to be an informed and active agent assisting member companies in negotiating the shifting legislative maze and in facing the challenges posed by the market while also reaping the opportunities offered by the market. I would like to thank my predecessor, Dario Previero, for the exceptional work he has done over the years. I inherit from him a stronger, more dynamic association, one that plays a greater role in providing quality services to member companies, and unquestionably one that has gained in stature vis-à-vis our national institutions.”

The Assembly was followed by an interesting round table discussion addressing current issues for the industry - economic context, servitization, carbon neutrality - with Marco Fortis, Director and Vice President of Fondazione Edison, Marco Taisch,

According to the results of the third edition of the National Statistical Survey conducted by the Mecs-Amaplast Statistical Studies Centre, the plastics and rubber processing technology industry closed the year 2022 with revenues of 4.35 billion euros, the second highest ever, for an 8.1% increase over 2021. The main factor in this achievement was exports, which recorded a further upturn toward the end of the year and a total val-

biente.

biente.

ue exceeding the threshold of 3 billion euros (3.16 to be precise, +8.5% over 2021).

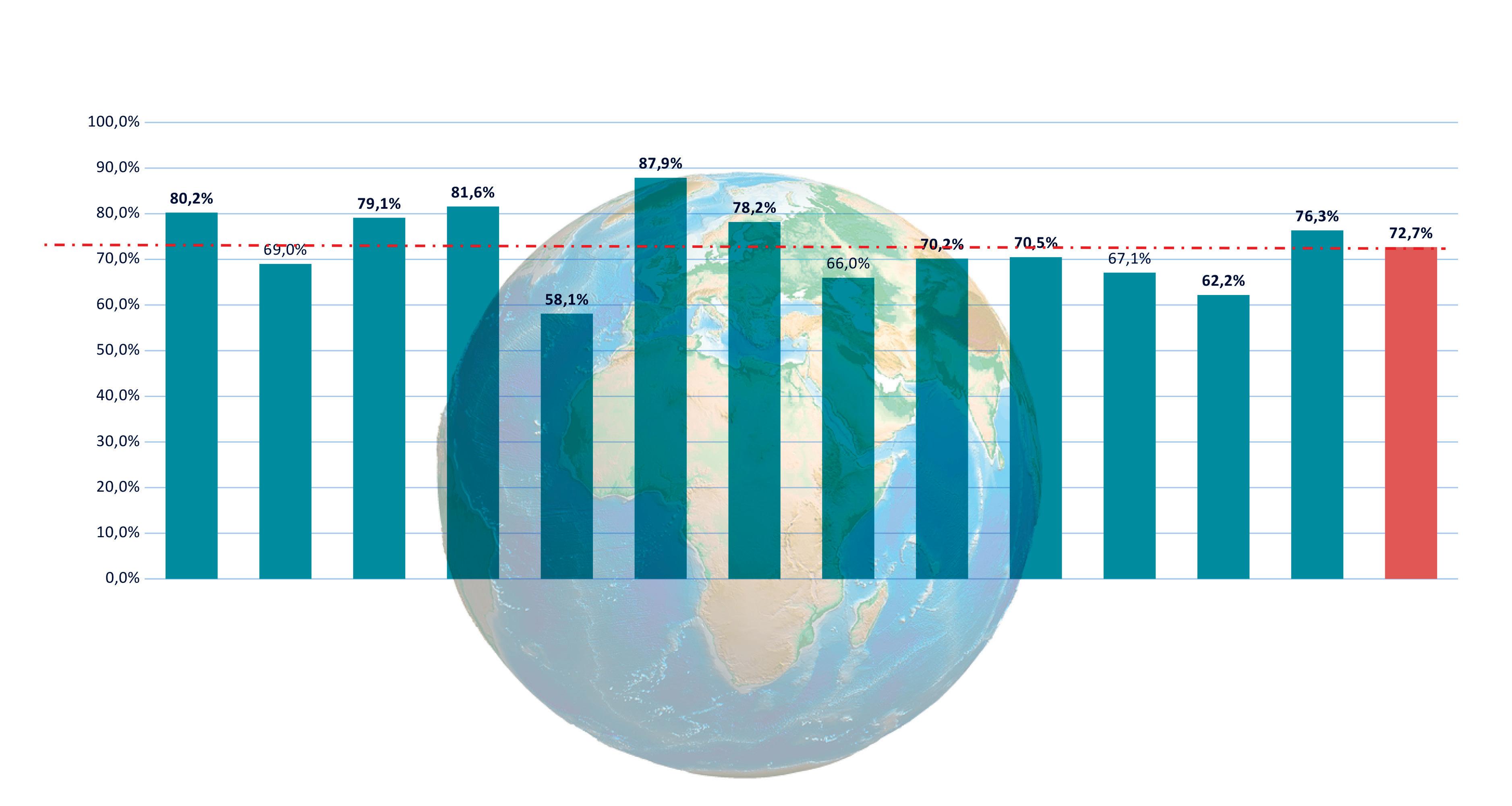

In detail, exports by Italian manufacturers - which represent 72.7% of total production - show sustained growth toward the main geographical zones: EU (+8%), North America (+6.6%), non-EU Europe (+8%), and the Far East (+9%).

As regards exported product categories, extrusion systems hold the lead, bringing in 20.8% of the entire Italian business volume (up 13.7% over 2021), followed by auxiliaries (13.7%), and injection machines (9.5%), with the remaining categories collectively amounting to 24.2%.

The domestic market grew by 6.8% with respect to 2021, with a business volume exceeding 1.18 billion euros.

The top three client sectors are packaging (40.6% of total revenues), automotive (15.9%) and construction (11%).

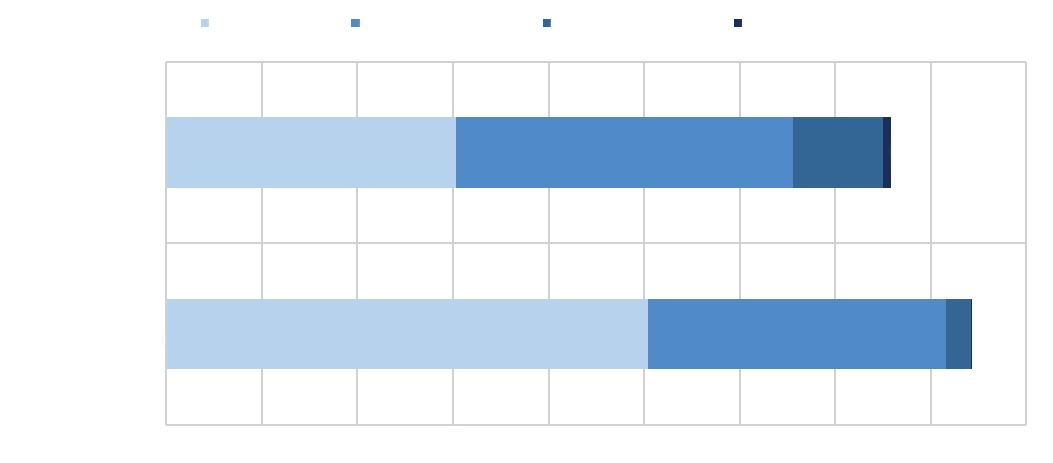

The year 2023 opened for the entire Western industrial complex in a relatively uncertain climate, both due to the fact that the post-Covid rebound was less pronounced than hoped and because of the continuing conflict in Ukraine. This situation is further compounded by rising interest rates and inflation, which have depressed global demand. However, there is a strong sense of optimism among manufacturers of plastics and rubber processing machinery, equipment, and moulds, well above the level suggested by economic indicators: 39% of interviewees expect further improvements in results for 2023, 43% expect stability, while only 18% expressed a pessimistic outlook.

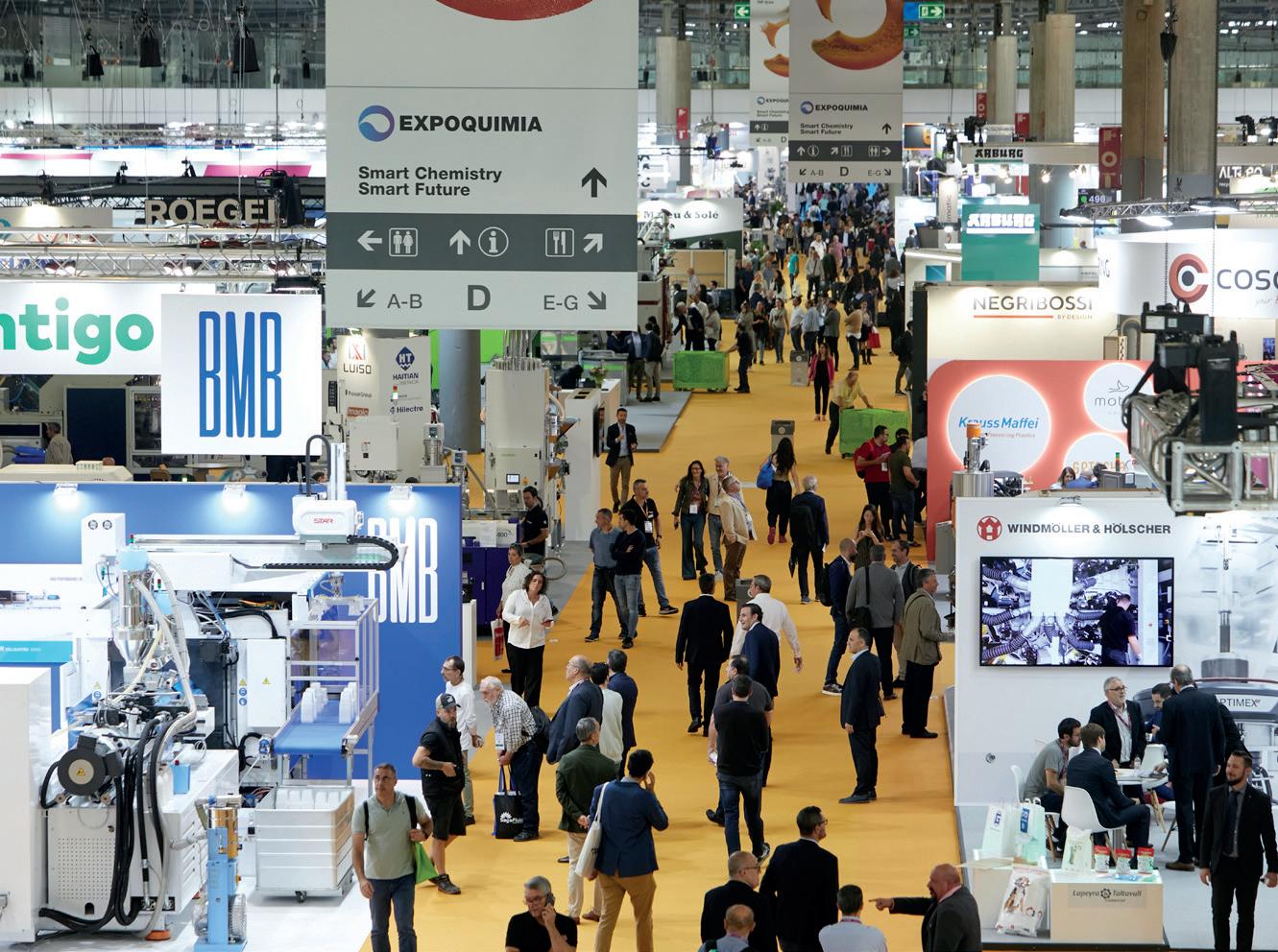

The plastics and rubber industry is gathering at the Fiera Milano fairgrounds in Rho from 5 to 8 September: Plast, the international exhibition for plastics and rubber industries. Organized by Promaplast, Amaplast service company, the event focuses on plastics and rubber processing technologies and materials. Expectations are riding high for one of the keystone fairs with over 1,200 exhibitors, many of them appearing for the first time and approximately one third coming from other countries.

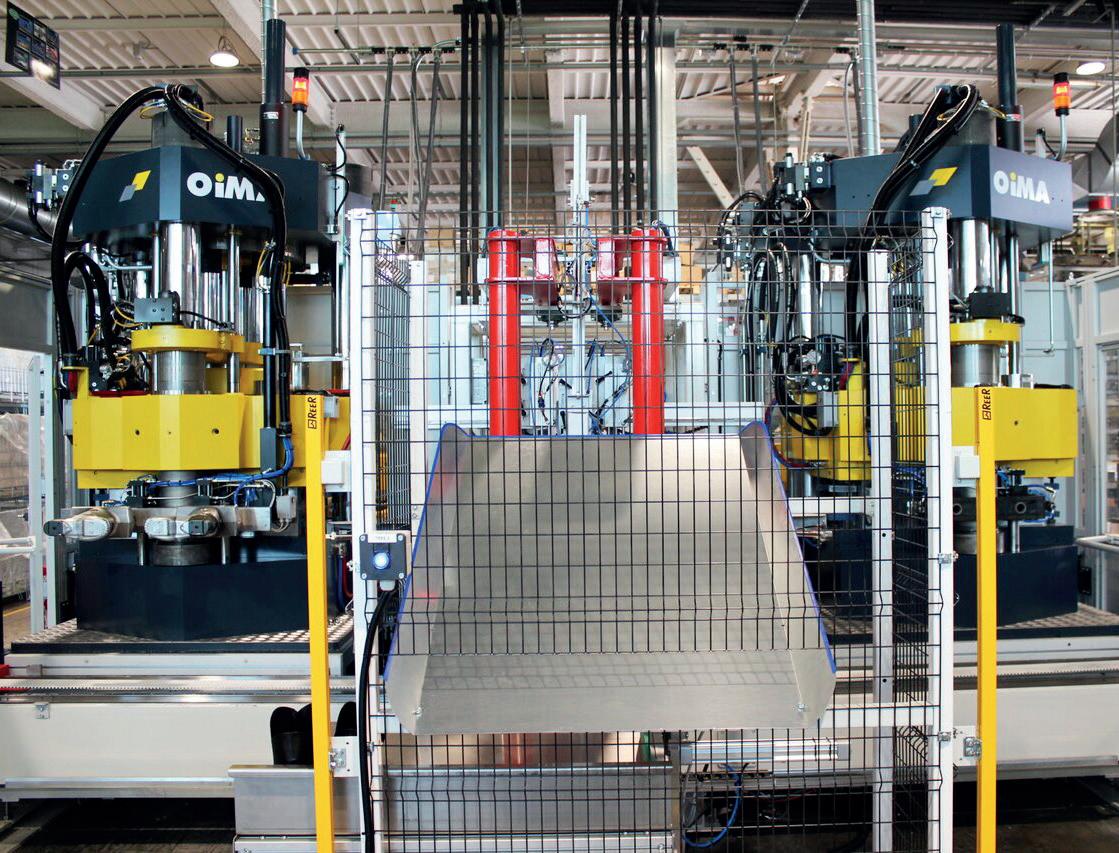

Plastics and rubber technologies ended 2022 with a turnover of 4.35 billion euros, an increase of 8.1% compared to 2021. Previero/Sorema The turnover achieved in 2022 by Italian plastics and rubber machinery manufacturers is the second best ever. OimaThe international stature of the exhibition - taking place five years after the previous edition due to the delay inflicted by the pandemic - is further affirmed by the return of the Chinese and Iranian collectives, and the debut of their French counterpart. There is also a major presence of foreign delegations.

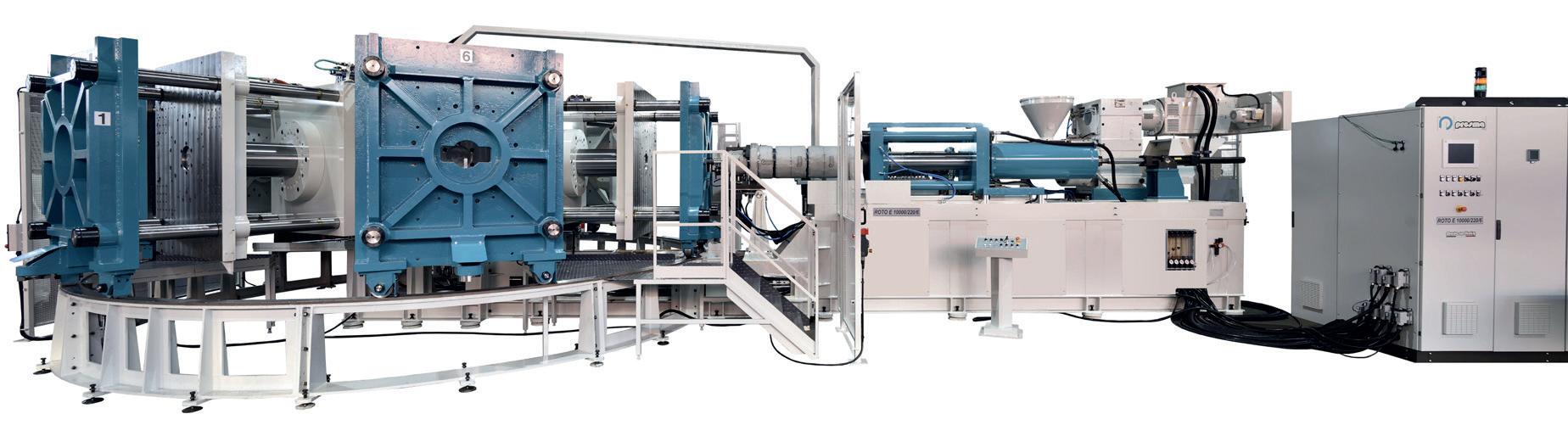

Promaplast has also signed a synergy agreement with Ipack-Ima to boost promotion of Plast among operators in the packaging sector, one with close ties to the plastics industry, with close to 40% of demand coming from the packaging industry.

The three satellite fairs dedicated to three related sectors is hosted again at the 2023 edition of Plast: 3D Plast (focusing on additive manufacturing and associated technologies), Rubber (as the name suggests), and Plast-Mat (dedicated to innovative polymers).

The moments of conviviality that marked Amaplast’s members’ meeting day, held at the Ca’ del Bosco winery in Erbusco (Brescia, Italy), were also useful for participants to meet partners and network.

This year’s fair features a new layout with demo areas outfitted with operational production lines and spaces for company presentations. In parallel, The Innovation Alliance - a partnership between Plast, Ipack-Ima, Print4all, and Intralogistica Italia - proposes a new concept: in response to the upheaval in tradeshow calendars caused by the pandemic, the organizational teams are hard at work on a new interpretation of the initiative, with sub-events focusing on specific issues of current relevance in the various sectors, thus consolidating the message of a harmonious interoperating value chain.

The calendar of side events - conferences, workshops, and exhibitor press conferences - is still in the development phase but the organization team is working to offer visitors many significant novelties.

A moment of the Amaplast assembly during which, in addition to the new president, vice-presidents Barbara Ulcelli (newly elected) and Gabriele Caccia (reappointed) were also chosen.

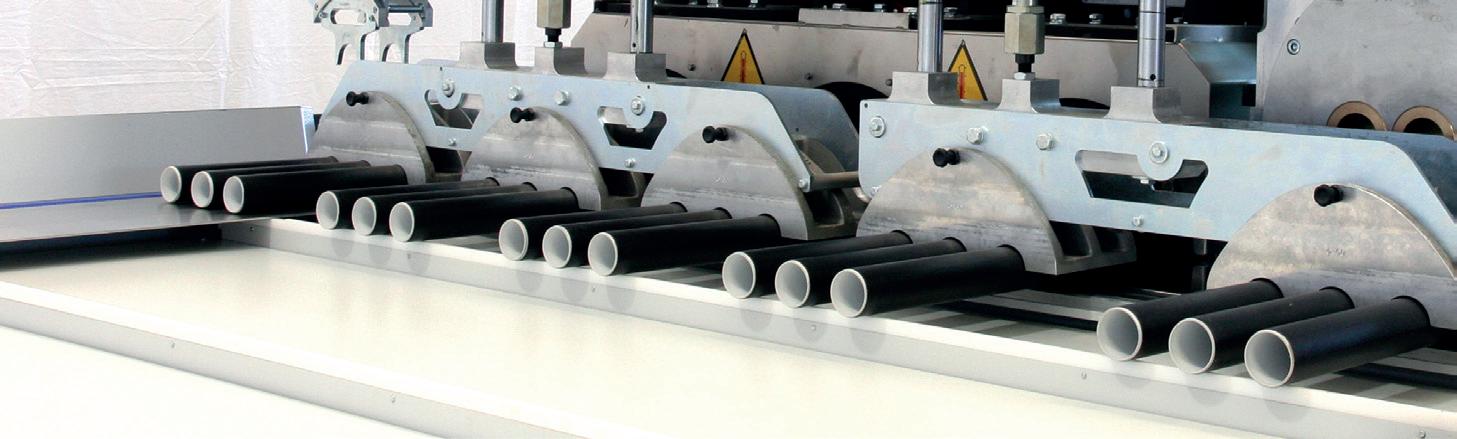

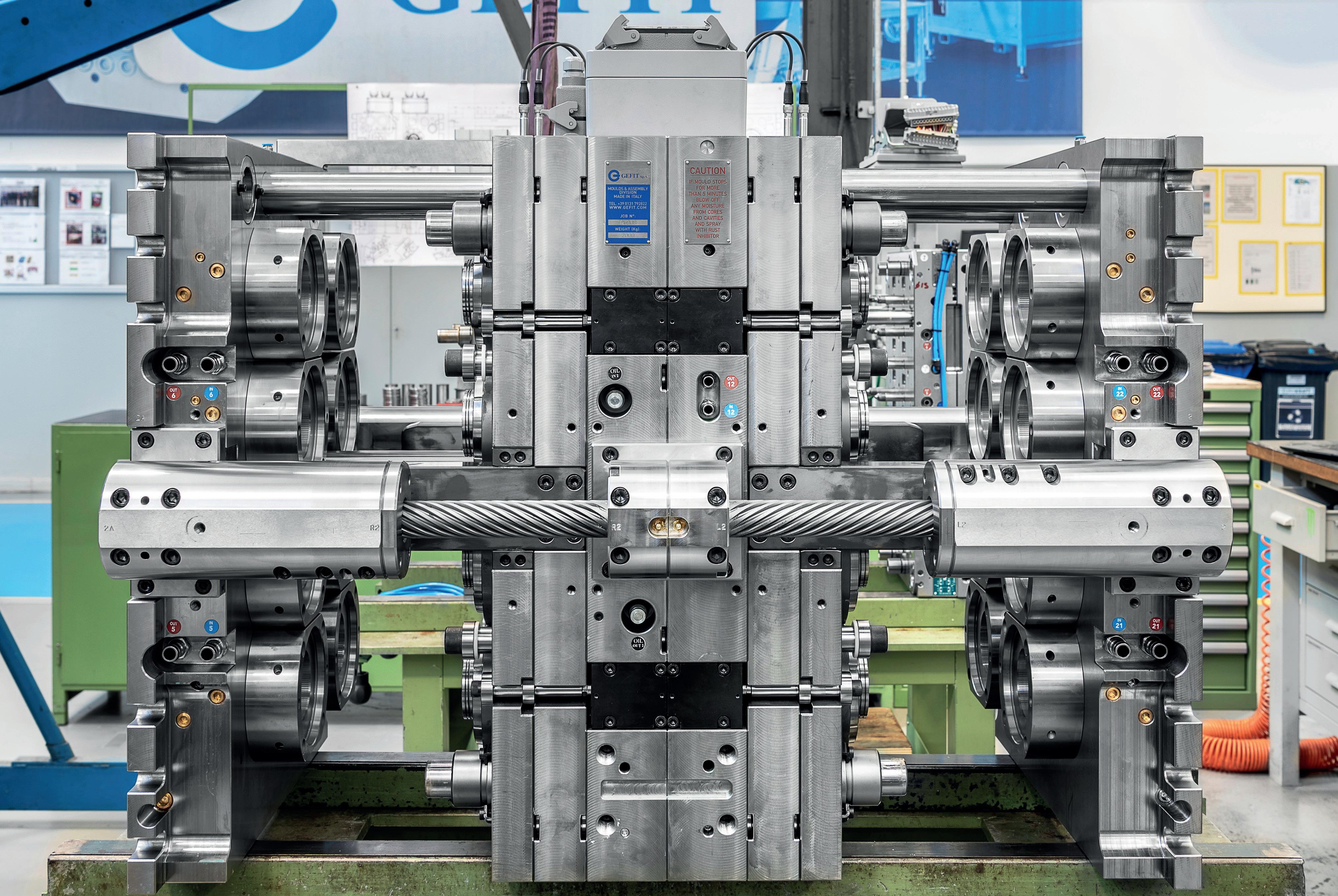

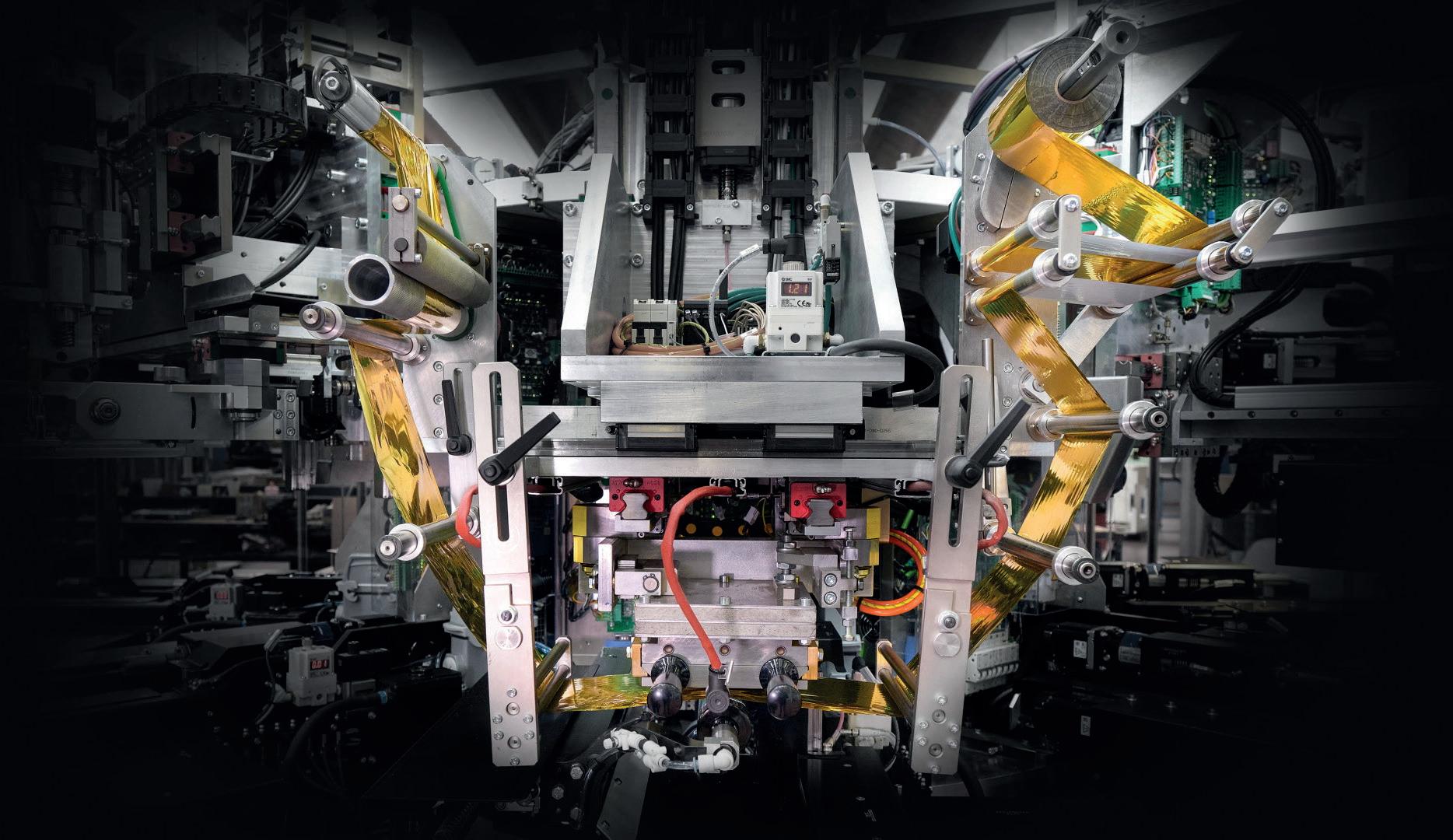

by Comi Group at Plast 2023

by Comi Group at Plast 2023

by Comi Group at Plast 2023

by Comi Group at Plast 2023

HIGHLIGHTS

HIGHLIGHTS

Large-scale 3D printing milling machine for industrial use, revolutionizing additive manufacturing capabilities.

Large-scale 3D printing milling machine for industrial use, revolutionizing additive manufacturing capabilities.

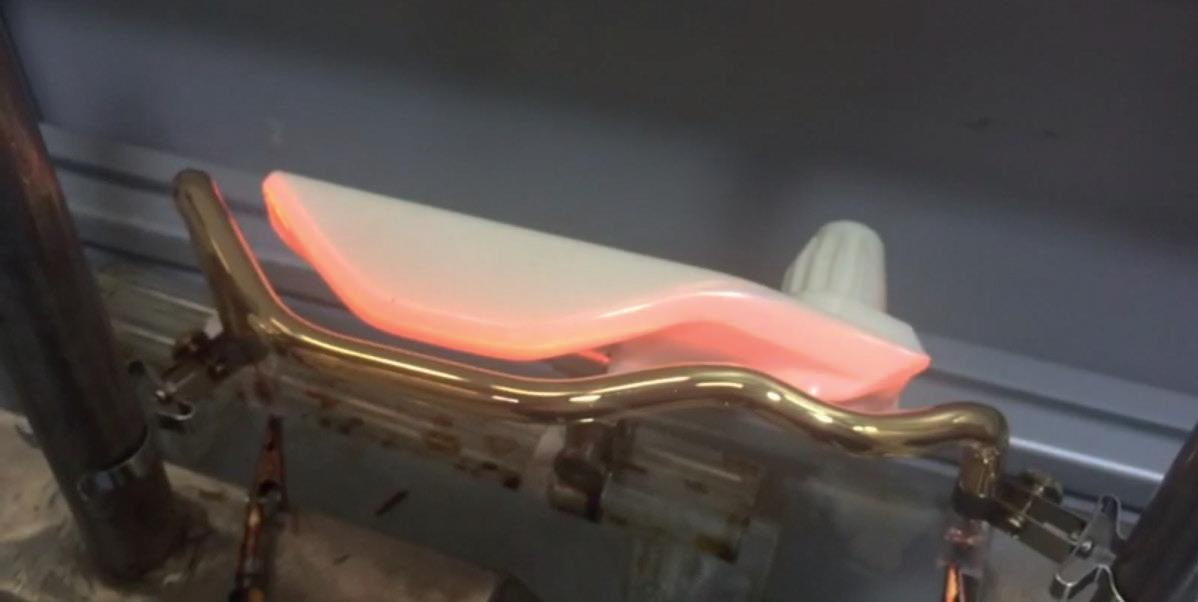

ACF820 thermoforming machine, this state-ofthe-art system boasts four stations, providing unmatched efficiency and versatility for the production of containers, trays, lids, and much more.

ACF820 thermoforming machine, this state-ofthe-art system boasts four stations, providing unmatched efficiency and versatility for the production of containers, trays, lids, and much more.

The keynote presentation of the new president of Amaplast, interviewed immediately after his election. Acknowledgments and news on upcoming commitments and the issues to be addressed in anticipation of an interesting term in an increasingly integrated value chain and, because of this, one capable of generating opportunities and shared values.

BY LUCA MEIDuring the Amaplast annual meeting on June 28, association positions were renewed and Massimo Margaglione, CEO of the mould & assembly division at Gefit, was elected as president of the Italian plastics and rubber processing machinery and moulds manufacturers association for a two-year term. We took this opportunity to ask him some questions about his new role, his agenda and his opinions on the current geopolitical and general economic and industry situation. Let us get right to the new Amaplast president’s answers, which are certainly more interesting than any introduction.

“During his tenure, Dario Previero demonstrated an undeniable ability in running and guiding our association through crises and difficulties that were unprecedented in our recent history. The pandemic, the disruptions in the supply chain, the sharp rise in energy prices, the increase in the cost of raw materials and all the components that are essential for our value chain, inflation that soared to nearly 10% and the increase in interest rates,

these are only the major things that happened during Dario Previero’s term.

There is no doubt that Dario demonstrated excellent leadership that lead him, among other things, to define and pursue a path of collaboration with two other important industry associations, Acimac and Ucima. From Dario Previero, to whom I express my sincere gratitude for his extraordinary work, I inherit a stronger association that is more dynamic, more present in the supply of qualified services to its members and undoubtedly more accredited with national institutions.

“As the new president of Amaplast, I believe I have to first of all provide continuity to the important initiatives launched by my predecessor and for that I will be committed to promoting, sustaining and implementing that collaborative spirit that has developed between Amaplast and the other two associations I have already mentioned, in order to create a federation that will without question strengthen our position within Confindustria.

I am absolutely convinced that individually, each of us repre-

sents a vigorous force, but I am equally sure that working together we can become an unbreakable strength and be recognised as a qualified and authoritative organization by leading national institutions. Safeguarding the interests of the plastics industry, and the capital goods sector that it serves, is today an undeniable priority and need. We need to work with governments, institutions and national organizations in order to drive favourable policies for our sector and to counter the negative perception of our industry, often and improperly seen as the cause of the environmental scars that surround us.

Apart from this, Amaplast will continue to provide support and assistance in order to inform and often also to train member companies on the delicate and now vital topics such as sustainability and social responsibility of enterprises, ecological transition, circular economy, SUP rules, and modifications to European directives on packaging, and it will continue to be an attentive player and an active support in the maze of regulatory changes and help them, to the extent an association can, to face the market challenges and develop opportunities deriving from the same.”

Since

“In 2000 Acimac, Amaplast and Ucima launched a project of integrated services aimed at improving the quality and scope of the services they offer to their respective members. The project was extremely ambitious from day one and, thanks to the commitment and tenacity of the presidents involved and the fundamental and valuable support from both Mario Maggiani and Giampaolo Crasta, taking centre stage and individualism have been replaced by a collegial and federal spirit which, while preserving the characteristics of the three organizations, has enabled them to work towards common goals. Limiting the path undertaken to solely the integration of services would, however, be reductive, because the vigorous work of advocacy and lobbying the three associations have undertaken and which have enabled us to take on a more impactful role within both Confindustria governance as well as toward stakeholders is clear and undeniable. To cite an example, the important success achieved in regard to the postponement considered under the Milleproroghe Decree, which moved the term for completing investments in 4.0 capital goods from 31 December 2022 to 30 November 2023.

Initial collaboration between Acimac, Amaplast and Ucima was

not only strengthened and consolidated during these three years, but it has also been considered by Confidustria to be a virtuous example of beneficial cooperation. The successes achieved do not, though, represent a finish line but a veritable starting point for creating an industry federation, Confindustria Macchine, the contents and provisions of which were presented during our meeting. In a nutshell, the federal project assumes strategic importance for Amaplast as well as for Acimac and Ucima, and the nascent federation, being open also to other capital machinery and value chain sector organizations, will undeniably become a key “association” for our entire sector, in terms of the provision of services given to member companies as well as the recognition it will without doubt enjoy with Confindustria and the various government institutions.”

2020, there has been a strong connection between Amaplast and the associations Acimac and Ucima, which represent the manufacturers of ceramics machinery and packaging machinery, respectively: what is the initial outcome that you see after three years of working together and, in particular, what are the future prospects?The newly appointed president of Amaplast, Massimo Margaglione, will lead the association for the period 2023-2025.

What can you tell us about current issues such as production sustainability, ecological transition, and corporate digitalization? How should an association like the one you have been called upon to lead and the companies that form its basis approach these issues?

“These are very complex issues, and I don’t pretend to have a comprehensive response in terms of the work that companies and associations should take on in order to be part of the change. In regard to sustainability, I like to think that it is linked to another term that is, in my opinion, more pressing, that gives us an immediate sense of urgency, namely “durability”. Our individual and collective actions must be carried out with the ultimate aim of preserving the world in which we live and making it liveable and lasting for those who come after us. I do not want to philosophize nor delve into inconclusive sophisms, but each of us must play our part to correct the environmental ruin we find ourselves in and without doubt companies are being called upon to act immediately to reduce the negative impact on society and the health of the planet.

The European Directive 95/2014 and the Italian Legislative Decree 254/2016 call for sustainability reporting to be submitted by not only companies listed on the stock market and public bod-

ies but also by large enterprises and this regulatory change will elevate the number of companies involved from a little over 300 to more than 6,000.

Sustainability is often erroneously associated only with purely environmental and climatic issues, but in reality it equally pertains to people and their wellbeing within our companies, the work place, digitalization, research and development, the supply chain, territorial enhancement and, in general, ESG criteria. We find ourselves facing a change that has to represent a real revolution. In this scenario, Amaplast will play a supporting role to member companies wanting to undertake the path of sustainability and, in synergy with the services offered together with Acimac and Ucima, it can help provide highly professional assistance to member companies.

In regard to digitalization, the recent Industry 4.0 national plan and incentives associated with it have encouraged Italian companies to invest in new capital goods, both tangible (machinery) and intangible (software), to improve production and quality processes. Amaplast has sustained and will continue to sustain the digital transition, maintaining relationships with all relevant stakeholders, providing members with assistance, constant and punctual information, webinars, courses, and highly qualified advice. The new frontier of digitalization today is connected to introducing our member companies to artificial intelligence and it is undeniable that sustainability and artificial intelligence will have to work together to improve energy efficiency and use of resources, reducing waste, monitoring production process and more still.”

“The digital and ecological transition represents, as we said, one of the main challenges that our companies have to face, but it also offers great potential for growth. Unfortunately, the international geopolitical panorama does not help companies to tackle the technological changes that are coming.

In addition to the ones you have told us, can you identify other hot topics that are expected to be particularly challenging in the coming months?The newly appointed Amaplast president will lead an association grouping around 170 companies.

The war in Ukraine is still ongoing and inflation, though levelling off, remains very high, at about 6%. Christine Legarde has just announced a further 0.25 point increase in the interest rate (the eighth since July 2022), which raises the base interest rate to 4%. The increases are not over though and at the president of ECB’s own admission, rates will continue to increase “as long as necessary”, meaning until they settle inflation to a rate of about 2%, which is not currently expected to happen until the end of 2025. Undoubtedly, such a rapid rise in rates from zero in early July 2022 to today’s 4% has inevitably had a strong impact on

the real economy: Germany, the driving force of Europe, will record zero growth, if not a recession, but generally the European Commission’s forecasts suggest growth of less than 1% for the entire Eurozone.

Thanks to the drive of tourism, services and PNRR funds, the Italian economy is performing better than its European neighbours and appears to be recording growth of around 1, 1-1.2%. The rise in rates will very probably have a strong impact on household consumption and financial expenses on Italian companies, including our members, and this could create a strong disincentive for new investment and cause stagnation.”

“In actual fact, 2022 figures exceeded expectations and the first months of 2023 saw Italian GDP rise, although the second quarter 2023 opened and is drawing to a close with weak signals, even for Italy, which is recording a slowdown to some extent across all industrial sectors. The Italian economy is resilient, but recent data and the trends of recent months are certainly worrying, with industrial production down. The state of health of our value chain remains positive, but I cannot fail to mention the concern expressed by the Centro Studi Confindustria, which believes it is improbable for the decline in industrial production in the first two quarters to be compensated by the slight recovery forecast for the second half of the year.

In the opinion of Confindustria’s president, Carlo Bonomi, for the sake of the wellbeing of our value chain, we also need to see the application of structural measures to support the industry, like, for example, the permanent extension of fiscal benefits linked to Industry 4.0, as tax and fiscal measures, including permanent ones, to support work, investment and research and development.”

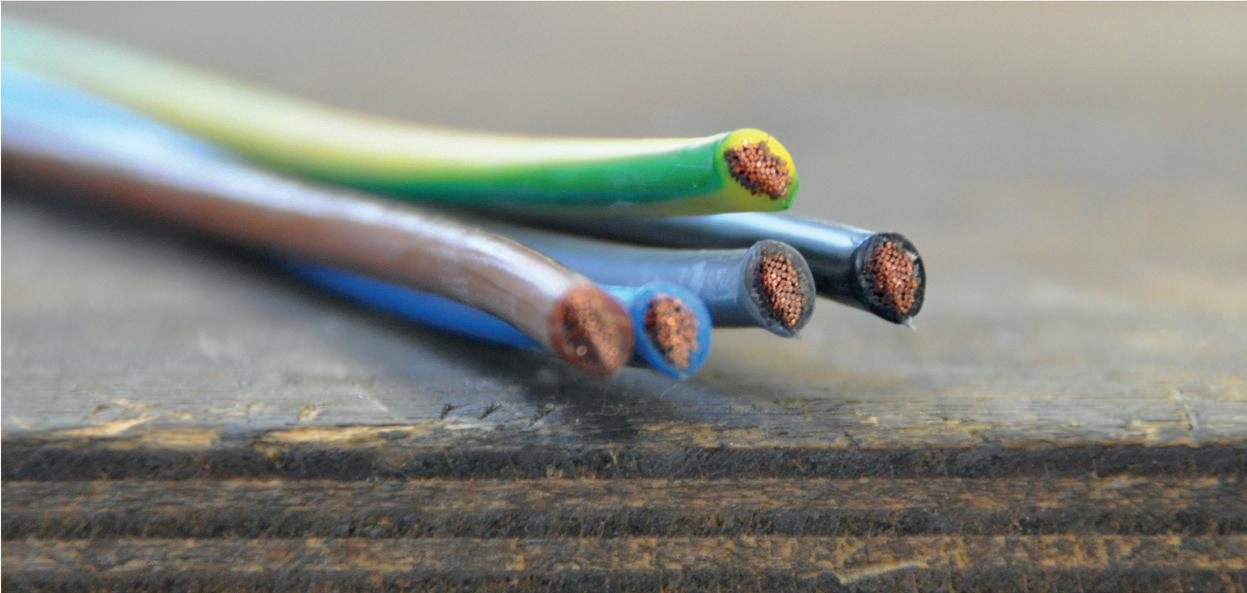

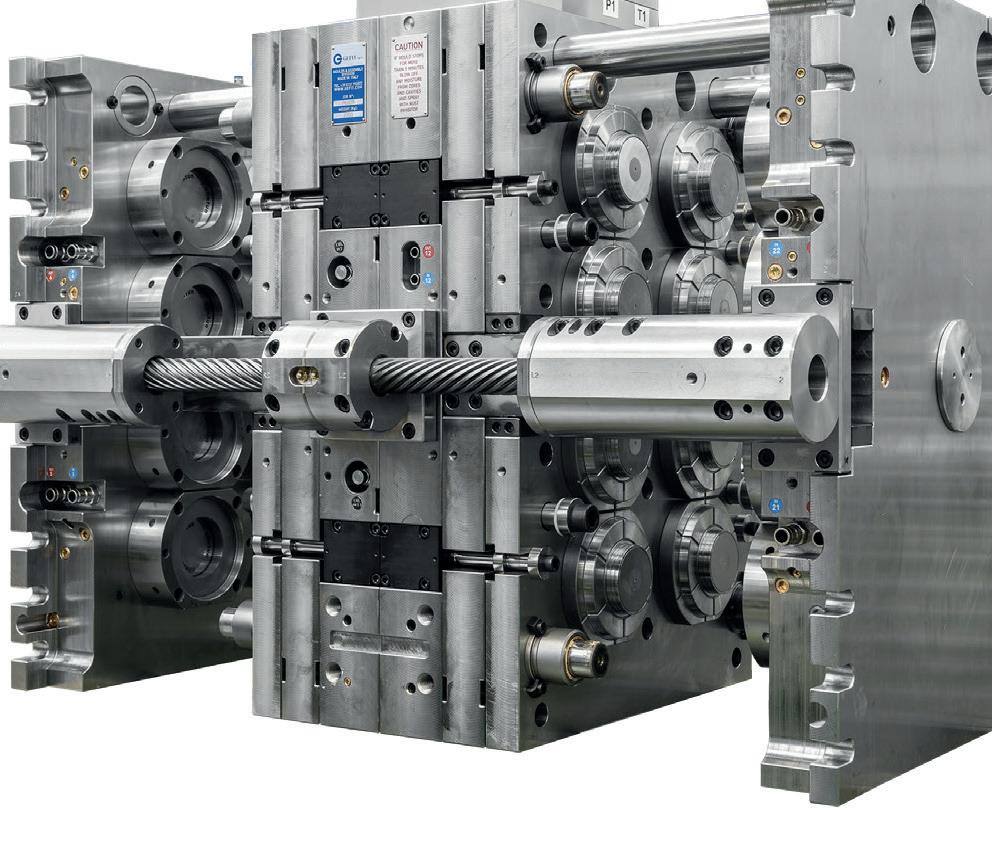

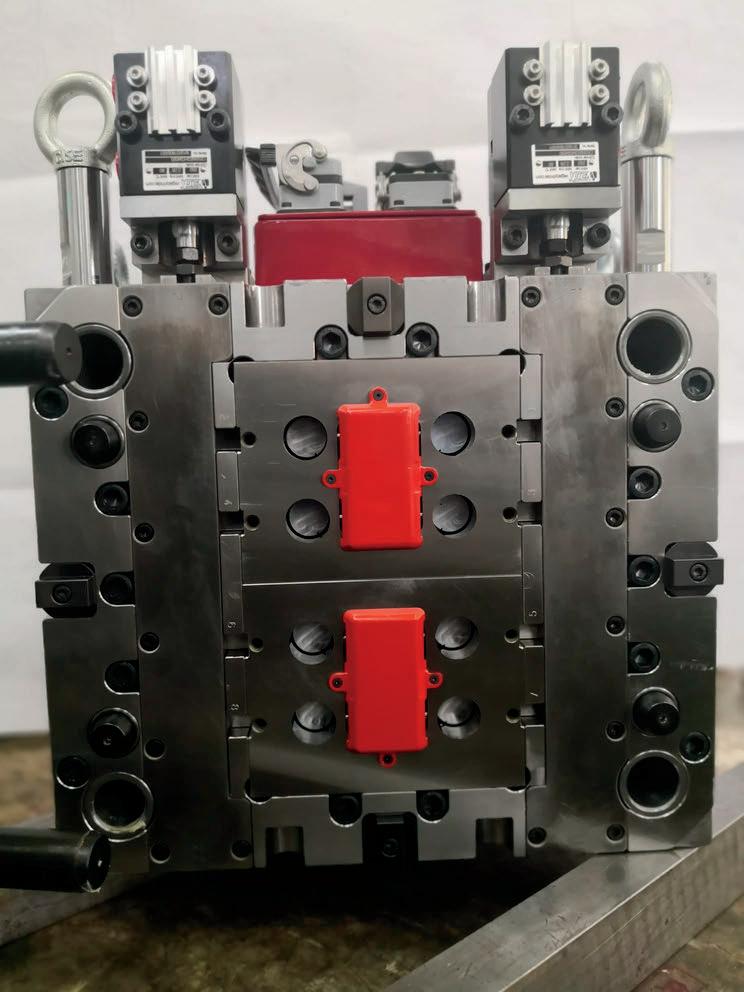

A mould for test tubes. Massimo Margaglione is CEO of Gefit’s Mould&Assembly division - in the opening photo a stack mould, above an assembly system for the food industry. GefitPolynt confirms its leadership in Special Purpose Plasticizers by extending its product range with an innovative polymeric Plasticizer formulated with 100% renewable raw materials. The new Plasticizer, identified by the brand Polimix RNew, allows 50% Carbon Footprint reduction compared to the functionally equivalent fossil-based Plasticizer.

Polimix RNew, being already listed in the main global Inventories, can be commercialized in any regional market interested in its innovative properties.

Polimix RNew can be utilized without any change in manufacturing technologies, from compounding to the other typical PVC transformation processes.

Polimix RNew inherent efficiency in manufacturing process combined with its ability to maintain adequate flexibility in a wide range of operating temperatures and good solvent resistance, makes it suitable for use in the Automotive and Construction sectors and PVC articles that come into contact with foodstuffs.

Exports:

There is an export potential of 16 billion euros for Italian capital goods incorporating automation, creativity and technology. The possibility of expanding the exports of highly sophisticated machinery is equally distributed between more developed countries and emerging countries, approximately eight billion in each area, suggesting Italian enterprises to increase their market shares in both of them.

These figures are part of the first Ingenium study “Il potenziale dei beni strumentali italiani nel panorama internazionale (The potential of Italian capital goods on the international scenario)” conducted by Centro Studi Confindustria, the main Italian organisation representing industrial manufacturing and service enterprises, with the financial support of Federmacchine, the trade association that brings together Amaplast, Acimac and Ucima, among others, and the contribution of Sace above all for its focus on ASEAN countries, in particular Vietnam, the Philippines and Thailand, whose markets offer a great deal of opportunities for Italian manufacturers.

The machines included in the study are defined through three distinctive elements: automation, creativity and technology. Hence the acronym ACT that covers 202 product categories on which Italy can rely to face the international challenges. These machines feature high accuracy, increasingly pervasive use of electronics compared to mechanics, agility in adopting tailor-made solutions and a growing content of services included in the supply scope. In many categories of goods, Italy boasts a competitive edge in terms of prices and, at the same price, of the higher volumes of units sold. As a result, it is not surprising that

the country is world leader in the production of many categories of machines.

“In relation to the absolutely important role that “made in Italy” assumes in the global and the Italian domestic economy as a fundamental asset for growth, capital goods are the robust backbone of Italian excellence exported abroad. Without them, many of the consumer goods which in our imagination represent Italy in the world, such as fashion, furniture and food, would be simply unfeasible,” said Barbara Beltrame Giacomello, vice president for internationalisation at Confindustria. “Machines always occupy a top position among the Italian goods sold abroad and represent a significant share of our exports. The latest export figures show signs of a slowdown after the record levels reached in recent years, which supported the competitiveness of Italian industry in an extremely challenging and uncertain international context - one more reason to continue betting on “made in Italy” and commit ourselves to strengthening it fearlessly. Also because, as shown by these figures, there is a great potential that we must be able to tap through a real system policy aimed at supporting enterprises on international markets, especially the small and medium-sized ones.”

“Widely recognised for its excellent performance, the Italian machinery industry has always made a decisive contribution to the trade balance of the country. In fact, this sector, that also includes the members of Federmacchine, records the largest trade surplus. Now, thanks to the Ingenium report, enterprises operating in the sector have at their disposal an additional tool to understand how and where to direct their products, taking into account the markets with the greatest potential as well as some strategic suggestions in order to better cover the outlet areas”, said Alfredo Mariotti, secretary general of Federmacchine.

Italy world leader in machinery, 16 billion potential. Barbara Beltrame Giacomello, Confindustria: “A system policy that supports enterprises on international markets is necessary”. Barbara Beltrame Giacomello, vice-president for internationalisation, Confindustria. ConfindustriaThe Ingenium report shows that among the more developed markets, those that offer the greatest potential are the USA (with an additional export potential estimated at about 1.7 billion euros), France and Germany on equal merit (600 million euros) followed by Austria and Canada. The additional potential in emerging markets is driven by China, where 52% of the total export potential is still available, for an amount of around two billion euros. This potential in China is largely due to the size of the market. China is followed by Turkey (700 million) and India (600 million), then Mexico and Brazil.

Italy is also among the top exporters in terms of market share and competitiveness among international suppliers of ACTs. In 2020, our country ranked fifth, behind China, the United Kingdom, Germany and Austria. The main importers of ACT machinery from Italy are the United States, followed by Germany and China.

ACT exports are worth almost 28 billion euros. The value of Italian ACT machinery exports to the world can be broken down by destination markets. The greatest share is taken by the more developed markets, which together are worth over 18 billion euros.

The value of exports to emerging markets, on the other hand, is more limited, accounting for just over nine billion euros. The exports of ACTs grew above all in America, as well as in the European continent: these markets recorded the greatest growth during 2022 compared to the previous three years.

Finally, the report also indicates the way to activate this potential, suggesting initiatives in various areas for increasing the competitiveness of enterprises, such as servitisation (i.e. the provision of additional after-sale services), adopting more sustainable behaviours, favouring international treaties, stimulating innovation.

Ambienta SGR, one of Europe’s largest asset managers entirely focused on environmental sustainability, acquired the majority stake in Previero. The company, which is currently led by the third generation of the founding family, will still benefit from Previero’s distinctive experience in the recycling arena going-forward as they will retain a significant stake in the business. Founded in 1922 and based in Anzano del Parco (Como, Italy), Previero is the pioneer in the plastic mechanical recycling space, driving market innovation and delivering benchmarking quality standards. As of today, the company is among the few players capable of offering turnkey

recycling solutions covering the entire preprocessing phase and addressing all types of feedstocks. With a workforce of 110 employees approximately, Previero focuses on R&D, engineering, and assembling/testing activities, which over the years led to a differentiated and integrated value proposition, matching the increasing need of global recyclers to identify technological partners capable of supporting them in the design and commissioning of the full recycling line. Previero solutions represent a key enabler of the transition towards plastic circularity, a process which is still in its early days as only 15% of plastic waste generated worldwide is actually recycled - ratio which is expected to almost double by 2040 driven by tightening regulations and brand commitments. This makes Previero an ideal fit to Ambienta’s investment strategy, representing both a Pollution Control and a Resource Efficiency investment. Previero’s turnkey recycling solutions turn post-consumer and post-industrial waste into high quality flakes, with positive impacts on: materials recycled, CO2 emissions reduced, energy saved and landfill saved. Technological and regulatory advancements, the already

Versalis - Eni’s chemical company and a shareholder of Novamont (36%)and Mater-Bi - a company controlled by Investitori Associati II and NB

Renaissance - recently announced the signing of an agreement for Versalis to acquire the remaining 64% of Novamont’s shares currently held by Mater-Bi. Next steps and the timing of closing are subject to approval by the competent authorities.

Versalis is the largest Italian chemical company and leader at an international level, whose strategy hinges on its product portfolio specialization, including the chemistry from renewables. Novamont is a B Corp-certified

Benefit company and a leading player in the circular bioeconomy sector, as well as a leader in the market for biodegradable and compostable bioplastics and biochemicals. Its acquisition represents a great opportunity for Versalis to accelerate its strategy through the integration of a technological platform which is both unique and complementary. This will significantly contribute to the decarbonization of Versalis’ product portfolio.

The deal will strengthen the Novamont platform by accelerating the growth of high value-added, multi-product supply chains and local projects. The goal is decoupling the use of natural

visible acceleration of the investment in additional recycling capacity worldwide and increasing demand for high-end solutions delivering foodgrade recycled quality, all represent significant opportunities for Previero.

Ambienta aims to support the company in seizing these opportunities, providing financial and managerial resources, promoting further investments in fixed and human capital, and more broadly partnering with the three Previero brothers in making the company an even stronger player in the global market.

Previero is the first platform investment from Ambienta’s most recent fund, Ambienta IV. Hitting its hard cap of 1.55 bilion euros, Ambienta IV is the largest European Private Equity fund ever raised solely focused on companies that enable positive environmental change in their respective sectors.

“In Ambienta we found a partner capable of understanding the history and the potential of the company, whom we believe will provide complementary industrial and international expertise that will enable us to capture the many opportunities we see ahead more quickly and effectively”, Flavio Previero, chairman of Previero, commented.

resources from economic growth so as to keep doing more with less.

CUSTOMISED TURN-KEY SOLUTIONS FOR THE EXTRUSION OF PLASTIC PROFILES

The extrusion lines for profiles aim to satisfy a wide range of purposes in the fields of extruded profiles, such as technical profiles and window profiles for the building sector, thermal break profiles with fiberglass and cable ducts, by using a great variety of raw materials.

speeds) and allow to produce different diameters (even micro-tubes) with a wide variety of medical grade materials.

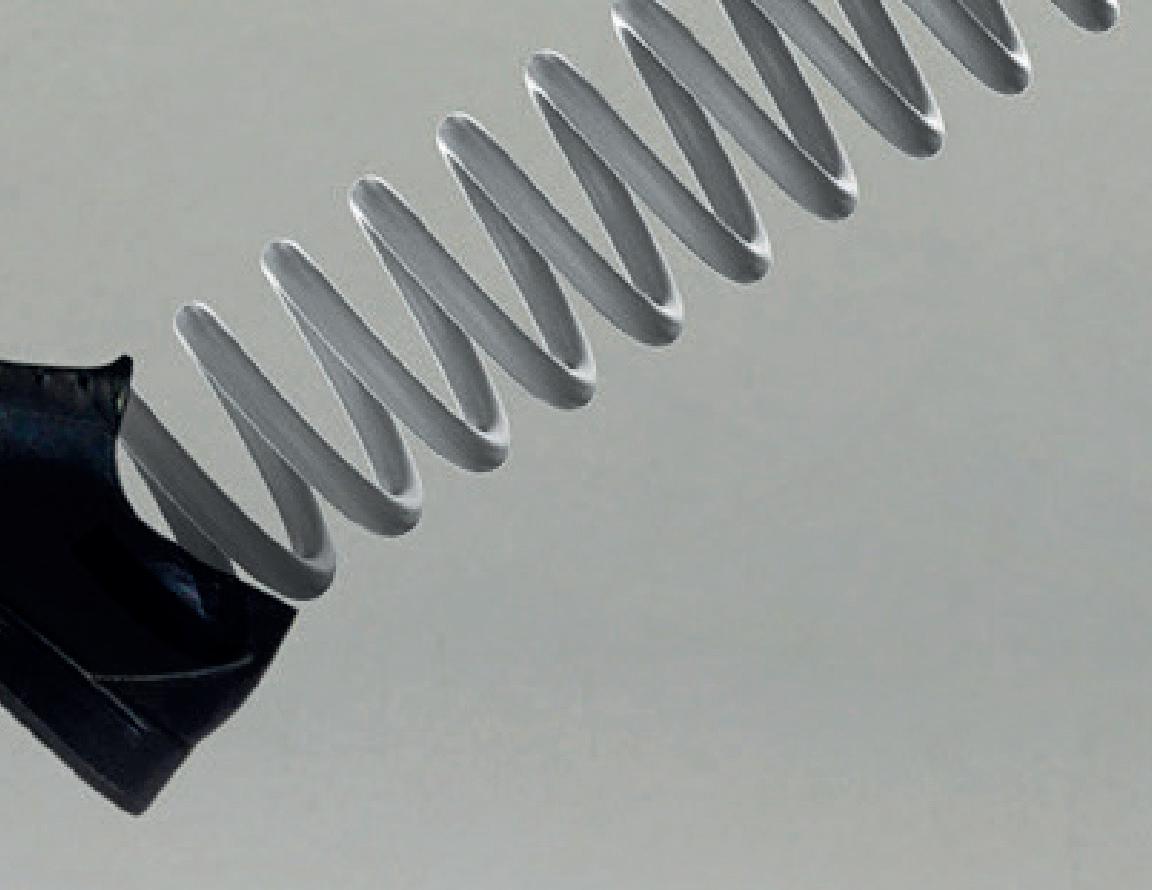

extrusion lines for spiral smoothbore medical pipes

A broad and interesting all-round scrutiny of what is currently a very pressing issue, sustainability, laid out in one of the most sensitive contexts in terms of public opinion as well as market, meaning enterprises, having become for the latter an added value for improving investment, economic performance and the perception of operations on a social level. With a closer look at the situation in Italy.

BY GIROLAMO DAGOSTINOThere is a well-established need for sustainability today on the economic and production panorama, and it influences the way enterprises are operating. Particularly after the so-called “circular economy package” published by the European Commission in 2018, the arm of lawmakers on the entrepreneurial panorama is predominant and imposes an about turn in the modus operandi of enterprises or, even more so, it requires an adjustment in their regular daily work, including sustainability in their development plans. Environment and sustainability are always considered very “high” concepts, the prerogative of policy makers far removed from business operators. At the beginning of the third millennium, corporate sustainability remains a stimulus for actions most often voluntary, without

substantially conditioning production. Even from a legal standpoint, the right to the environment has a unique configuration. There is no effective basis for environmental protection to weigh directly on business activity. The right to the environment, in fact, is among the so-called “widespread interests” and it is defined from a legal standpoint as being those interests not belonging to a particular entity, latent in the community, as being common to all the individuals in a social group and not identifiable as a particular interest. The legal doctrine subsequently made a small step forward, transforming widespread interest in “common interest”, namely belonging to a representative body of a not casual group, interest that is common to all parties who are part of the community, which, being common, become subjective to the same

body. From here it follows that this interest does not constitute a subjective individual position, but rather the actual position of the exponent body, as written in the TAR Lazio, section II, sentence no. 6861 of 30 May 2019. This suggests that only bodies or subjects representing the community, namely those which are recognized by national regulations, such as those appointed on an institutional level to protect it (environmental associations, public bodies, institutions), and not the individual citizen, can hold up in court the right to the environment and they can only do this in the event of environmental damage, therefore after the fact. To instil sustainability in the production world and create an effective balance between business activity and the environment, avoiding environmental damage to the greatest

One of the actions for companies for reducing their environmental impact relates to the efficient and sustainable management of energy and transportation, thanks also to the incentives policies of Renewable Energy Sources (RES) and energy efficiency pursued in Italy in recent years.

The implementation of practices aimed at developing social and environmental sustainability among businesses could also potentially drive growth and economic performance.

extent possible, something was needed that would translate into the practice the “precautionary principle”, identified by European lawmakers as being one of the pillars of policies aimed at protecting the environment.

Clambering through the intricacies of legal sciences that risk getting bogged down in the configuration of a law that still presides today only over collectives, the EU lawmakers decided at some point to impose behaviour that had the objective of redirecting flows of capital to sustainable investment, in order to create sustainable and inclusive growth, manage financial risks from climate change, resource depletion, environmental decline and social questions as well as promoting long-term transparency and vision in economic-financial activities.

Communication, by some categories of business, of pertinent, comparative and reliable information on sustainability becomes a preliminary condition for achieving these objectives.

Production activity must be “sustainable”. A series of political orientations were adopted then transformed into European laws that have elevated care for the environment and sustainability to be an element that carries weight when doing business, and conditions business and financial relationships between private individuals. The attention to aspects linked to corporate sustainability becomes an element that sets bodies apart and contributes to better management of

corporate risk and provides a guarantee to stakeholders and protects the integrity of the resources involved in relationships with third parties. For this reason, the attention to sustainability must be clearly laid out, at least for those categories of economic subjects that currently are identified by law.

Demonstrated commitment in regard to the concepts of sustainability becomes an “added value”, a passkey to access dedicated credit facilities, a lever to building brand reputation, which makes doing business with an economic player more appetizing. The need for sustainability is driven, therefore, on the one hand by law, which in this case anticipates the market dynamics and inverts a mechanism that generally sees the relationship between supply and demand as a factor that regulates the markets, and on the other hand, the market itself, which must make a virtue of necessity and ultimately considers caring for environmental aspects and sustainability to be an added value. Implementing corporate sustainability leads to new practices, potentially ones that combine growth and economic performance, social and environmental sustainability. In this context, economic-financial aspects are set into a broader framework, which considers the dimension of sustainability set out in measurable corporate behaviours and practices: it therefore becomes increasingly important to verify advances in ESG criteria (Environmental, Social, Governance), assumed as the legal basis for investment sustainability. Measuring sustainability becomes a challenge also for sectorial analysis because on a company level measuring statistics is not yet primarily oriented to monitoring strictly economic performance. Sustainability indicators (KPI) multiply and today number more than 500, organized into environmental, social, and governance aspects.

Although sustainability indicators measure the performance of enterprises and the way they implement their plans, it becomes important to select the right

parameters, which are closely connected to the proposed objectives and relevant to the particular entity in terms of how results are intended to be measured in terms of the achievabilty of the sustainability objectives. It is clear how vital it is to identify sets of indicators that can provide key information to adequately measure sustainability in each sector. Otherwise, much of their effectiveness is lost. Because the application of these indicators is voluntary, there is nothing to say that an enterprise cannot come up with its own package of indicators.

The virtuous mechanism by which the market rewards those enterprises that demonstrate care for the environment and sustainability are beginning to take on a precise profile. According to surveys on the Italian manufacturing industry, in 2018 about seven companies out of 10 adopted sustainable behaviour. The latest Istat findings show that out of a representative sample of Italian enterprises, 712,000 (68.9% of businesses with three or more employees) claim they engage in activities aimed to improve well-being in the workplace for their employees; 688,000 (66.6%) undertake actions that reduce the environmental impact of their operations; 670,000 (64.8%) have taken measures to improve the level of safety within their premises or the area where they have operations. On the whole, 84.3% of enterprises have completed at least one socially sustainable action and 75.8% have performed at least one environmentally sustainable action. However, detailed analysis of the number of actions reveals that businesses pay more attention to environmental sustainability: 10.3% have performed more than 10 environmentally sustainable actions, 2.7% have performed more than 10 and 50.4% just one.

The commitment to reducing the environmental impact is more marked in in-

Gerd Altmann by Pixabay

Gerd Altmann by Pixabay

dustrial enterprises in the strictest sense (71.6%) and construction (71.1%) compared to service providers (64.5%), those most active in the health and social assistance sector demonstrate the highest levels (73.1%). Detailed business activity reveals a commitment to improving well-being in the workplace among companies operating in health and social assistance (77.1%) and education (76.1%). Focus paid to safety within a company or in the area where it operates (which is part of the social aspects of sustainability) is greater among industrial enterprises (74.0%) compared to service providers (61.0%). Sustainable behaviours rise in line with the size of enterprises. Large enterprises (250 or more employees) are more than 10-20 percentage points higher than the national average in all macro areas: +24 points in safety, while for the initiatives implemented in the area, the percentage was 25% higher for common interest initiatives and 20% higher for those involved in the fabric of local production. The differences in reducing the environmental impact (+18%) and for initiatives aimed at wellness in the workplace (+13%) were also significant.

In the Istat survey, the morphology of sustainability presented other dimensional differences: micro enterprises (3-9 employees) showed a more marked orientation to improving well-being in the workplace while companies with 500 and up employees were more attentive to safety and reducing the environmental impact. Another important aspect driving enterprises to implement actions targeting sustainability is reputation. In fact, improving reputation among customers and suppliers is the leading motivation for reducing environmental impact for 32.1% of enterprises.

In terms of social sustainability initiatives, the data shows that two thirds of enterprises are involved in operations to improve well-being in the workplace and professional development. The majority of enterprises who have stated that they have implemented measures to improve well-being in the workplace (712,000, 68.9% of participating companies) undertake this commitment mainly by adopting more flexible working hours (coming in, leaving, breaks, and so on)

or good practices associated with professional development (measures for economic progress, formative growth, changing positions, and so on). Between 2016 and 2018, these measures were implemented by between 68.6 and 65.6% of enterprises.

More limited, but still significant, has been the adoption of good practices associated with protecting equal opportunities for employees (61.9%), as well as involvement in defining company objectives (59.4%). An additional element garnering attention in company policy aimed at well-being in the workplace is maintaining high levels of staffing even if it means lowering profits (52.4%).

Istat data from the period prior to Covid shows that smart working and working from home was only practiced by 10.3% and 3.7% of enterprises (118,000 in absolute value, taking into account one of the two or both forms of work). The pandemic then drove a strong acceleration in the adoption of these measures. In general, smart working or working from home were closely linked to the size of the company and the business sector where companies operate while no substantial dif-

Materialsaving, reuse of raw material and the use of recycled raw materials are good established practices among manufacturing companies to limit consumption and exhaustion of resources.

Quadro d’insieme

ferences on a territorial level emerged. Identifying the number of enterprises who have adopted these tools out of the total number of enterprises surveyed, there was a decline of about 10 percentage points between large (24% smart work and 15% working from home) and medium (13.3% and 8.4%), small enterprises (10.2% and 4.9%) and micro enterprises (10.2% and 3.2%). This figures are common to all economic macrosectors. On an industry level, the difference is also seen within the same segments, confirming how the possibility of using flexible workforce practices is connected to the product/service offered or the production process followed.

chose thermal insulation of buildings and/or the construction of low energy use buildings and almost 10 out of 100 incurred the expense without receiving incentives. In Italy, the management of water resources presents various critical factors, especially in some more vulnerable areas, to a large extent linked to the growing pressures in demand compared to natural availability, inefficiency in the water distribution network and the relevance of pollutant loads deriving from anthropic activity.

An environmental and sustainability advising service provided in an associative context draws on the advantage, compared to the sea of advising services proposed, of knowledge of the sector and representation, promotion and protection of its members by the assocation.

the water supply business, management of waste and reclamation (45.9%). Even manufacturers stand out with above average levels: 35.6% have used recycled raw material, while 67.3% have adopted measures to limit the use of production materials, with limited differences linked to the area and size of enterprises.

Although communication plays a fundamental role for underscoring a companyʼs commitment to implementing actions aimed at sustainability, in Istatʼs 2018 findings, sustainability statements and/or reports were limited.

Comportamenti “sostenibili” per sette imprese su 10 Nel 2018, 712 mila imprese (68,9% delle imprese con 3 e più addetti) dichiarano di essere impegnate in azioni volte a migliorare il benessere lavorativo del proprio personale; 688 mila (66,6%) svolgono azioni per ridurre l’impatto ambientale delle proprie attività; 670 mila (64,8%) si sono attivate per migliorare il livello di sicurezza all’interno della propria impresa o nel territorio in cui opera no.

Rispetto al rapporto con altri soggetti e c on il territorio, quasi un terzo (31,3%, ossia 323 mila imprese in valore assoluto) sostiene o realizza iniziative di interesse collettivo esterne all’impresa ; una quota analoga di imprese supporta o realizza iniziative a beneficio del tessuto produttivo d el territorio in cui opera (303 mila imprese, pari al 29,4%)

L’attenzione alla sostenibilità sociale (che include le azioni realizzate per il benessere lavorativo e la sicurezza) e ambientale (azioni per ridurre l’impatto ambientale delle proprie attivit à) assume intensità diverse osservando il numero di azioni realizzate tra il 2016 e il 2018 (Figura 1)

Nel complesso, l’84,3% delle imprese ha portato a termine almeno una azione di sostenibilità sociale e il 75,8% ha realizzato almeno una azione di sost enibilità ambientale Tuttavia, analizzando il dettaglio per numero di azioni, le imprese dedicano maggiore attenzione alla sostenibilità ambiental e: il 10,3% ha realizzato più di 10 azioni di sostenibilità ambientale, il 2,7% ne ha compiute più di 10 e il 50,4% solo una.

One of the areas of intervention for companies for reducing their environmental impact relates to the efficient and sustainable management of energy and transportation, seeing strong growth thanks also to the incentives policies of Renewable Energy Sources (RES), and energy efficiency pursued in Italy in recent years. To reduce energy consumption, 40.1% of enterprises have installed efficient machinery, plant and/or equipment; 32.2% did this without drawing on incentives. Of the investments targeting energy saving, 13 companies out of 100

Valori percentuali sul totale imprese con tre e più addetti. Anno 2018

Italian enterprises have placed in the forefront measures to curb water withdrawal and consumption, implemented by six companies out of 10 in the three-year period from 2016-2018. Next come wastewater treatments to control pollutants, possibly only in the context of some manufacturing enterprises, implemented by a fifth of enterprises, and that of reusing and recycling water (8% of enterprises). Production sustainability also manifests in saving materials used in production processes, relevant for 52.8% of enterprises, and in using raw material seconds (waste that is recovered and reenters production), implemented by 21.3%). Saving materials and reusing raw materials is higher than average in the extraction sector (56.1% and 40.6% of enterprises) and, with reference only to the containment of production materials, in

E SOCIALE

Low (1-4 actions) Medium-low (5-9 actions) Medium-high (10-14 actions) High (15-18 actions)

The recent publication of the Directive 2022/2464/EU which governs the obligation for certain categories of enterprises to draw sustainability reports has placed a greater focus on evaluating and communicating environmental performance. Companies have gained a greater awareness of these instruments that are an important checkpoint for the verification and consolidation of the companyʼs reputation, even for strategic programming that is more attentive to the effective risks and environmental impacts. Moreover, the market increasingly requires the clarification of risks linked to shortfalls of an environmental and social nature that influence the possibility of establishing lasting business relationships.

In the three-year period 2016-2018, 12.4% of enterprises have obtained voluntary environmental certification for products or processes. It is a much more widespread practice among large enterprises (57%), in some cases subject to regulatory obligations, and medium (39.1%), as well as small enterprises (19.0%) or micro enterprises (9.7%).

L’impegno verso una riduzione dell’impatto ambientale è più accentuato tra le imprese dell’industria in senso stretto (71,6%) e in quelle delle costruzioni (71,1%) rispetto alle imprese dei servizi (64,5%) tra le quali quelle attive nel settore della Sanità e assistenza sociale mostrano percentuali elevate (73,1%).

Rispetto al miglioramento del benessere lavorativo non si evidenziano significative differenz e tra macro settori di attività economica (70,0%, 70,4% e 68,4% rispettivamente le quote nell’industria in senso stretto , nelle costruzioni e nei servizi) Osservando i dettagli per attività economica, si rileva un impegno nel miglioramento del benessere lavorativo tra le imprese che operano nella Sanità e assistenza sociale

Fewer than 4% of enterprises report drawing environmental and sustainability statements and/or reports, but the figure rises to 30.8% among large enterprises. The evaluation of environmental sustainability initiatives is, on the other

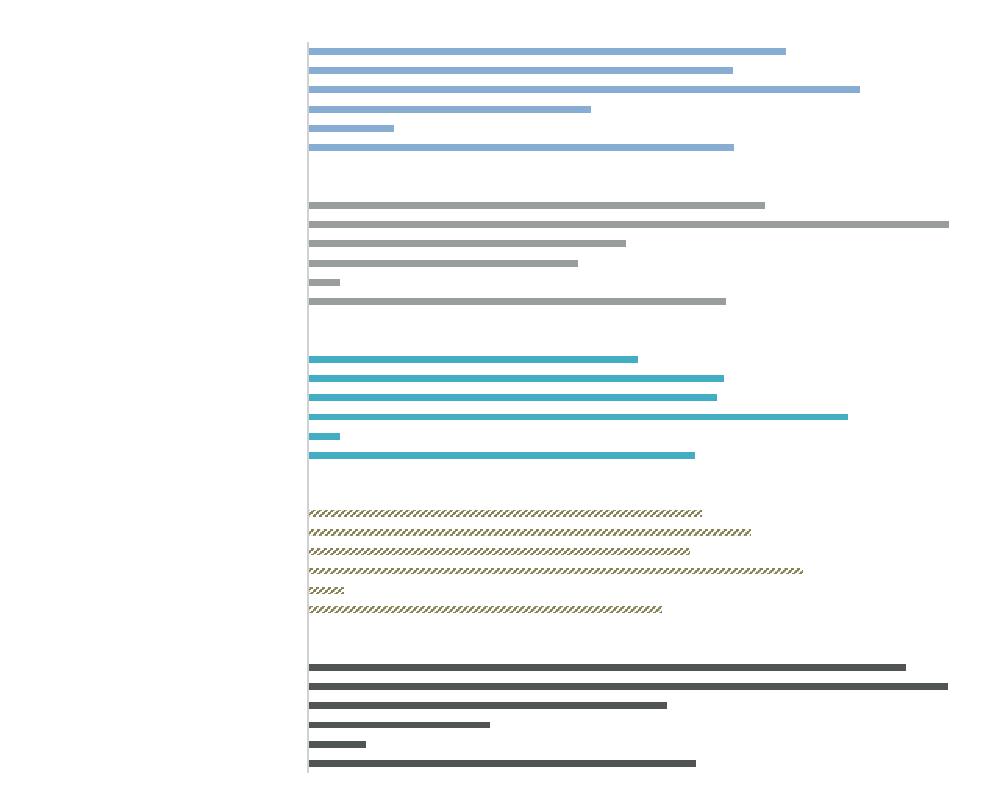

Enterprises based on the number of environmental and social sustainability actions (percentage of all enterprises with three or more employees - source: Istat).

FIGURA 1 IMPRESE IN BASE AL NUMERO DI AZIONI REALIZZATE PER LA SOSTENIBILITÀ AMBIENTALE

Enterprises based on the number of environmental and social sustainability actions (percentage of all enterprises with three or more employees - source: Istat).

FIGURA 1 IMPRESE IN BASE AL NUMERO DI AZIONI REALIZZATE PER LA SOSTENIBILITÀ AMBIENTALE

hand, practised by 13% of enterprises (almost 50% of large enterprises).

Increasingly, companies require sustainability advising services. As a result, the market has become populated with the most diverse proposals based on the fact that attending to certain aspects linked to sustainability is today a commercial and strategic driver.

Measuring a companyʼs sustainability often involves algorithms that pay little consideration to the specific requirements of the governing organization and even more often, the economic needs of the proposal, regardless of the unique features of the activity sector. The result sometimes shows a certain uniformity and standardization in the proposal and a depersonalization of the analysis. What differentiates the proposal and performance of an environmental and sustainability advising service in an associative context from the vast sea of advising proposals can be inferred: knowledge of the sector of which the association historically provides representation, promotion and protection for its members.

Knowledge of company specifics is certainly a useful element for identifying the right path for ecological transition or identifying the most appropriate tool for implementing sustainability within a company. A vital element is the trust that the member has for the association and the loyalty that the latter must necessarily establish with the member for a long-term relationship of reciprocal convenience.

It is true that the “Big Four”, namely the biggest general auditing companies carry a certain weight on the market, which is where this appellation comes from, but the strict relationship between association and member, at the base of which obviously needs to be key skills and professionalism, can deliver a tailored result not so easily available from other sources.

Valori

(*

* Il quesito permetteva risposte multiple.

Is coherent with the business operations

Is part of the strategy and/or mission

Improves the client/supplierʼs reputation

Consolidates links with the local community

Previsti in crescita g

Is advantageous for specific taxation/subsidies

Other reasons

Ridurre l'impatto ambientale

a sostenibilità n trova un riscontro negli investimenti per responsabilità ambientali e soc

Migliorare il benessere lavorativo

T e 4.1, 4.2 e 4.3 dell’appendice statistica) Il24,4%% delle imprese ha pianificato investimenti

L iali (T in questo ambito n 2021)

Is coherent with the business operations

Is part of the strategy and/or mission

Improves the client/supplierʼs reputation

Consolidates links with the local community

-2018, quota che sale al 29,0% nelle previsioni del triennio successivo (2019% delle imprese con 500 addetti e oltre ma solo dal 20,9% delle micro (3-9 addetti).

La dimensione aziendale gioca ancora una volta un ruolo importante: tali investimenti sono stati infatti realizzati dal

Is advantageous for specific taxation/subsidies

Other reasons

Sostenere o realizzare iniziative di interesse collettivo

Supporting or implementing initiatives of collective interest

Is coherent with the business operations

Is part of the strategy and/or mission

A livello territoriale 2018 non fanno registrare differenze rilevanti: del Nord le imprese del Mezzogiorno e del Nord

gli investimenti in sostenibilità ambientale e so ciale effettuati nel periodo 201625,3% di quelle est Per il triennio successivo si prevede un aumento più accentuato tra est (rispettivamente 29,9% e 29,8%)

Improves the client/supplierʼs reputation

Consolidates links with the local community Is advantageous for specific taxation/subsidies

Other reasons

%

o, il Farmaceutico, la Raccolta, trattamento e smaltimento dei rifiuti, il Recupero dei materiali,

Is coherent with the business operations

Is part of the strategy and/or mission

Improves the client/supplierʼs reputation

Consolidates links with the local community Is advantageous for specific taxation/subsidies

Other reasons

Is coherent with the business operations

Is part of the strategy and/or mission

Improves the client/supplierʼs reputation

Supporting or implementing initiatives of economic development

Sostenere o realizzare iniziative di sviluppo economico

Increasing safety levels

Incrementare livelli di sicurezza

le più scelte da imprese del Mezzogiorno e del Centro per obiettivi di sostenibilità strumenti, finanziari e non, utilizzatiperperseguire obiettivi di sostenibilità nel 2018 il 13,8% delle imprese ha fatto ricorso ad attività interne svolte

% si è avvalso di finanziamenti economici di progetti o iniziative, il 9,7%

I settori economici che investono maggiormente in queste attività, con oltre delle imprese, sono il C le A A Considerando ambientale e sociale a titolo gratuito o agevolato dal personale ha impiegato uso gratuito o agevolato di beni dell’impresa (macchinari, tecnologie, immobili, ecc.).

Consolidates links with the local community Is advantageous for specific taxation/subsidies

Other reasons

Un fattore discriminante nell’adozione di misure per il benessere lavorativo e per la conciliazione dei tempi di vita-lavoro è la dimensione aziendale: la loro implementazione aumenta al crescere del numero di addetti in quasi tutti i tipi analizzati. In particolare, un maggiore scarto è osservabile nell’offerta di un asilo aziendale gratuito o a condizioni agevolate, negli strumenti di sostegno economico e nelle estensioni della durata dei congedi parentali o per gravi motivi.

Per gli obiettivi di sostenibilità, le imprese del Mezzogiorno e del Centro hanno optato per attività interne a titolo gratuito utilizzando personale dell’impresa (rispettivamente 14,2% e 14,1%) mentre quelle del Nord-est e del Nord-ovest si sono orientate maggiormente verso finanziamenti di tipo economico di progetti/iniziative (12,6% e 11,3%) (Tavola 6 dell’appendice statistica).

Verso infrastruttu

Well-being in the workplace

La s hanno scelto i finanziamenti economici per le iniziative le microimprese ha fatto ricorso ad

Flexible working hours

Good professional development practices

Good equal opportunity practices

Involvement in defining business objectives

Uno degli ambiti di intervento per la riduzione degli impatti sull’ambiente attiene alla gestione efficiente e sostenibile dell’energia e dei trasporti, in forte sviluppo grazie anche alle politiche di incentivazione (FER) e dell’efficienza energetica portate avanti dal nostro Paese negli ultimi anni

High employment levels

Authorization/leave/part time for maternity/paternity (beyond legal requirements)

Per i in modo autonomo, in congiunzione con soggetti misti (pubblico, privato, terzo sett con soggetti del terzo settore (Tavola Infine, il mentre il 7,8%

Authorization to enrol children in nursery school

Internal communication on rights of parents

Per ridurre i consumi energetici e macchinari, impianti e/o apparecchi efficienti li investimenti finalizzati al risparmio realizzazione di edifici a basso consumo energetico

Extension of the length of leave for serious reasons

Smart working

Extension of the length of maternity/paternity leave

5 to caso si è indagato il tipo di finanziamento economico utilizzato per gli investimenti in termini di ripa

P nella produzione di energia da fonte rinnovabile elettrica (7,2%) o termica (4,4%) e 7 (2,8%). Per queste iniziative, circa la metà degli investimenti ll’erogazione di incentivi.

Economic support for workers and families

Acquisition of disadvantaged people (beyond legal requirements) Working from home

Subsidized or free company nursery

Ancora poco diffuse imprese su 100 hanno acquistato automezzi elettrici o ibridi.

Measures for well-being in the workplace and reconciliation of work life balance between 2016 and 2018 (percentages of all enterprises with three or more employees - source: Istat).

Per smart work e telelavoro incide molto la dimensione aziendale

Al momento del censimento, lo smart working e il telelavoro risultavano utilizzati solo dal 10,3% e dal 3,7% (Prospetto 1) delle imprese (118 mila in valore assoluto, considerando una delle due forme di lavoro o entrambe). La diffusione della pandemia da Covid-19 ha poi impresso una forte accelerazione nell’adozione di queste misure

Il ricorso allo smart working o al telelavoro risulta fortemente legato alla dimensione aziendale e al settore di attività economica in cui le imprese operano mentre non emergono sostanziali differenze a livello territoriale Rapportando il numero delle imprese che hanno adottato tali strumenti al totale delle imprese censite si registra uno scarto di circa 10 punti percentuali tra grandi imprese (24,0% smart work e 15,0% telelavoro) e medie (13,3% e 8,4%), piccole (10,2% e 4,9%) e microimprese (10,2% e 3,2%). Tale dinamica è comune a tutti i macro settori economici (Prospetto 1).

A livello settoriale le differenze si ravvisano anche all’interno degli stessi comparti, a conferma di quanto la possibilità di utilizzo del lavoro agile sia correlata al prodotto/servizio offerto o al processo produttivo seguito.

In particolare, sono i settori dei Servizi di informazione e comunicazione, soprattutto quello della Produzione di software e della consulenza informatica, delle Telecomunicazioni e delle Attività di produzione cinematografica, televisiva e musicale a distinguersi per il maggiore utilizzo: tra il 2016 e il 2018 il 26,8% delle imprese attive in questi settori ha adottato lo smart working e il 20,8% il telelavoro (Figura 7).

Il ricorso allo smart work è significativo anche nel settore dell’Istruzione (19,7% delle imprese, con una incidenza più elevata per corsi post universitari, ricreativi o di formazione), nelle Attività professionali, scientifiche e tecniche (18,2%, in particolare quelle impegnate nella ricerca e sviluppo, pubblicità e ricerche di mercato, design e interpretariato), nel settore della Fornitura di energia elettrica, gas, vapore e aria condizionata (15,5%) e nelle attività di Servizi alle imprese (14,1%, con valori particolarmente elevati per le agenzie di selezione e ricerca del personale). Le Attività pro fessionali, scientifiche e tecniche, così come il settore delle Utilities, presentano valori superiori alla media nazionale anche per il telelavoro

Companies who have made investments in the sustainable management of energy and transportation between 2016 and 2018, by type of investment and presence or lack of incentives (percentage of total companies who have implemented actions to reduce the environmental impact of their operations - source: Istat).

energetica hanno dato luogo, tra il 2011 e il 2018, a risparmi ener getici pari al 54%, dell’obiettivo nazionale al 2020 previsto dal Piano nazionale di Azione per l’Efficienza Energetica nel settore industriale, al 42% nel settore trasporti e al 26% nel terziario (Cfr. ENEA, “Rapporto Annuale Efficienza energetica” 2019). Nel corso del 2019 il Gestore dei Servizi Energetici ha riconosciuto alle imprese incentivi per oltre 10 miliardi di euro destinati principalmente al sostegno delle fonti rinnovabili ne, settore elettrico; tali interventi hanno generato un risparmio di emissioni di CO 2 in atmosfera stimato in circa 31 milioni di tonnellate (fonte GSE).

7 Gli impianti di cogenerazione sono finalizzati alla produzione combinata di energia elettrica e calore, quelli di trigenerazione alla

The VinylPlus Sustainability Forum 2023 was recently held in the city of Dante, where the Progress Report 2023, taking stock of the European PVC industry, was presented. The event was attended by over 160 delegates from 21 countries.

On May 11, Florence provided the venue for the eleventh VinylPlus Sustainability Forum, organised by VinylPlus. The event saw the presentation of the Progress Report 2023, listing the main achievements and progress achieved by the European PVC industry in 2022, which Karl-Martin Schellerer, President of VinylPlus, summarized in his opening address. Two years after the launch of the VinylPlus 2030 Commitment, the annual forum, this year entitled “Making the EU Green Deal Happen”, attracted more than 160 delegates from 21 countries to the Tuscan capital to discuss sustainable ways to promote carbon neutrality, circularity in the building and construction sector, developments in green procurement and certification of sustainable products.

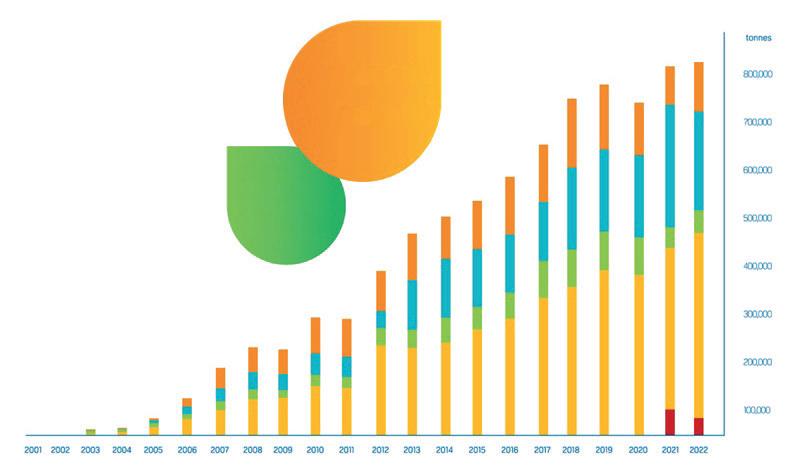

In terms of circularity, 813,266 tonnes of PVC waste were recycled within the VinylPlus framework in 2022, representing around 27% of the total PVC waste generated during the year in the EU-27, Norway, Switzerland and the UK. Since 2000, 8.1 million tonnes of PVC have been recycled and reused in new prod-

ucts, preventing the release of 16.2 million tonnes of CO2 into the atmosphere. Heavy investments have been made in research and development projects aimed at removing legacy additives from waste and increasing chemical recycling of PVC waste that cannot be mechanically recycled in an eco-efficient manner. In addressing the issue of legacy additives, the industry is also looking to future-proof additives used today: a key tool to achieve this is the Additive Sustainability Footprint methodology, which enables companies to proactively assess and promote the sustainable production and use of PVC additives throughout the entire product lifecycles. The methodology was shared with European PVC converters and presented at several events in Europe and abroad. VinylPlus’ vision is to broaden the use of the Additive Sustainability Footprint. Throughout 2022, VinylPlus also launched a series of initiatives aimed at supporting member companies’ efforts in reducing water and energy consumption, increasing the use of renewable energy and raw material, and minimising any accidental spillage of PVC into water and the environment.

As for the VinylPlus Product Label, the sustainability certification for PVC products for the Building and Construction sector, was updated and included in the Italian GPP CAM (minimum environmental criteria). The Label’s criteria are currently under assessment by the Swiss organisation Ecobau. In addition, the first five companies have obtained the VinylPlus Supplier Certificates, the sustainability certifications for additives suppliers and compounders.

Moderated by Frédéric Simon, Senior Editor of EurActiv, the first session of VinylPlus Sustainability Forum 2023 focused on the upcoming European policy initiatives on plastics and PVC and the regulatory challenges of the EU legislative framework. Significant contributions to the debate, and inspiring perspectives, were provided by Francesco Virtuani, Circular Economy and Sus-

tainable Development Division of the Ministry of Enterprises and Made in Italy; Paola Migliorini, Deputy Head of Unit, European Commission DG Environment; and Simone Doyle, Head of Risk Management Unit at the European Chemicals Agency (ECHA).

“The European Chemicals Agency’s objective – observed Simone Doyle – is to implement legislation to ensure the protection of human health and the environment and we look at chemicals more holistically, across lifecycles in a less fragmented way, also considering sustainability. The current investigation work on PVC and PVC additives, requested of ECHA by the EU Commission, gives us the opportunity to develop a framework to compare circular economy aspects of PVC and alternatives and their wider environmental impacts throughout the lifecycle. We hope this approach for PVC can be used in other impact assessments in the future.”

“VinylPlus is fully committed to supporting a rigorous, comprehensive, and science-based investigation process – commented Brigitte Dero, Managing Director of VinylPlus – to ensure the European PVC value chain a fair transition to a sustainable future. Our Forum 2023 shows that the European PVC industry can work jointly with policymakers and industry partners to address sustainability challenges. The recent publication of the REACH restriction on lead in PVC, for example, is the result of fruitful discussions between regulators, industry, and other stakeholders and builds upon the industry’s efforts to reduce the use of hazardous substances in PVC products and further enhance the circularity of the PVC industry. This regulatory measure will restrict the import of lead-containing PVC products from third countries where lead is still used as a stabiliser and will enable the PVC industry to meet its ambitious recycling targets in a way that is safe for human health and the environment.”

The event’s second session focused on accelerating circularity in the building and construction sector. Discussions revolved around the Construction Product Regulation, currently under revision, and to the implementation of the Eco-Design for Sustainable Products Regulation, as well as architects’ and industry’s perspectives on how circularity in construction can be achieved.

In the last session of the Forum, speakers analysed the path towards sustainable development through certified and traceable products and the future of Green Public Procurement (GPP) in

Europe. The contribution to more sustainable products for GPP provided by the VinylPlus Product Label for PVC converters and the VinylPlus Supplier Certificates for PVC additives suppliers and compounders is increasingly recognised by stakeholders. An award ceremony was dedicated to the companies that were certified in 2022: Akdeniz Chemson, Baerlocher, IKA, Polymer-Chemie, Reagens, Salamander and Sattler.

Closing the forum, Karl-Martin Schellerer commented “I am very proud to announce that the PVC industry is on track to deliver the first targets of VinylPlus 2030. We are continuously working to improve our sustainability performance. Still, a clear and supportive regulatory framework is essential to set even more ambitious targets and continue to play a significant role in enabling the EU Green Deal. To this end, we are ready to work collaboratively and constructively with regulators in line with a scienceand evidence-based approach. I am sure that the enthusiasm and the engagement of our partners seen during the Forum will continue to contribute to the achievement of VinylPlus 2030 targets and to make the EU Green Deal happen.”

813,266 tonnes in 2022

8.1 M tonnes since 2000

Recycled PVC, in tonnes, 2022

Since 1982 we have been reliability, competence, innovation, research

We produce extrusion systems for regeneration of post-consumer/ post industrial waste

• high energy efficiency

• quick installation • user friendly

easy maintenance A new range of machines is borning.