MACPLAS INTERNATIONAL

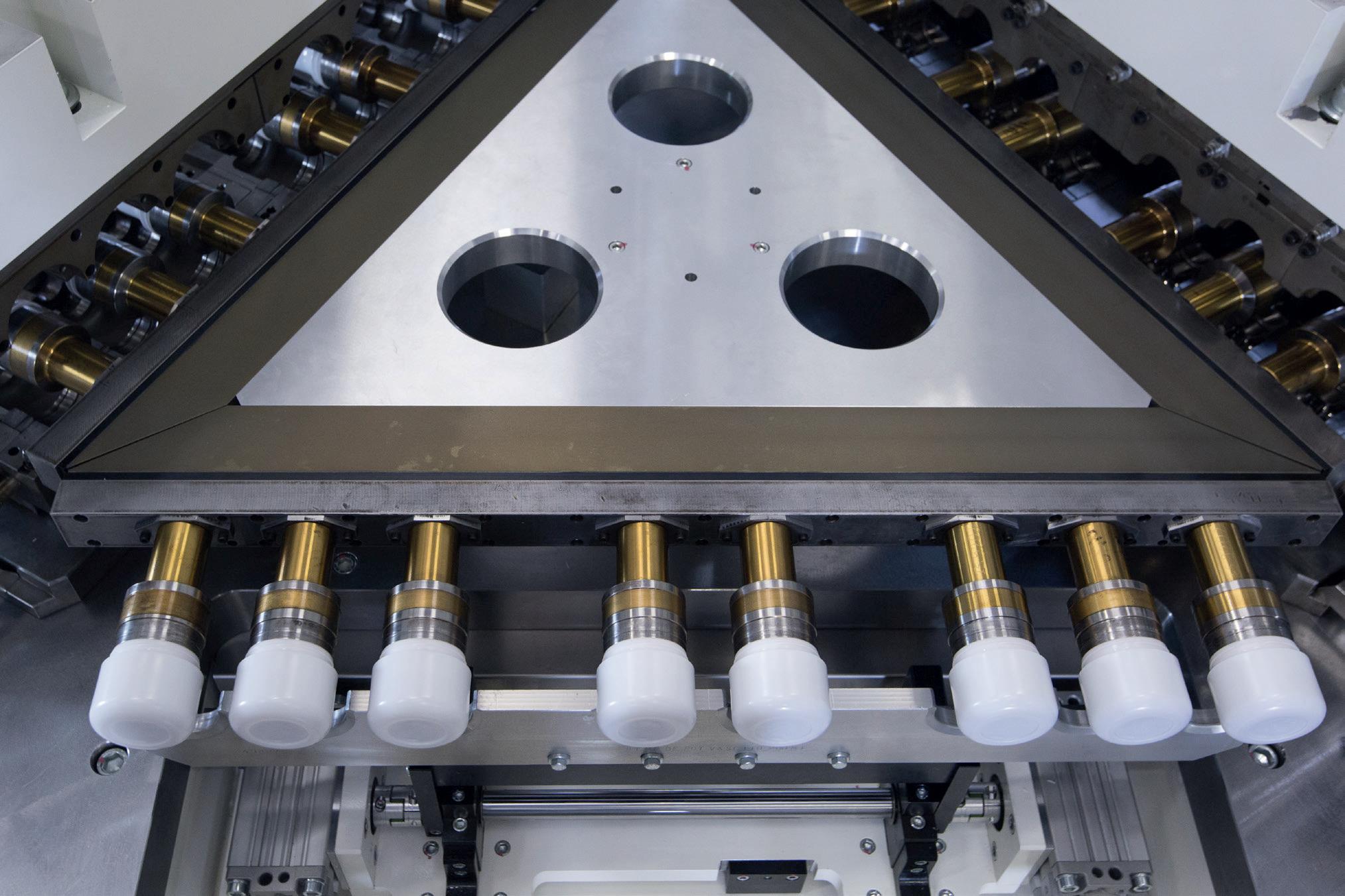

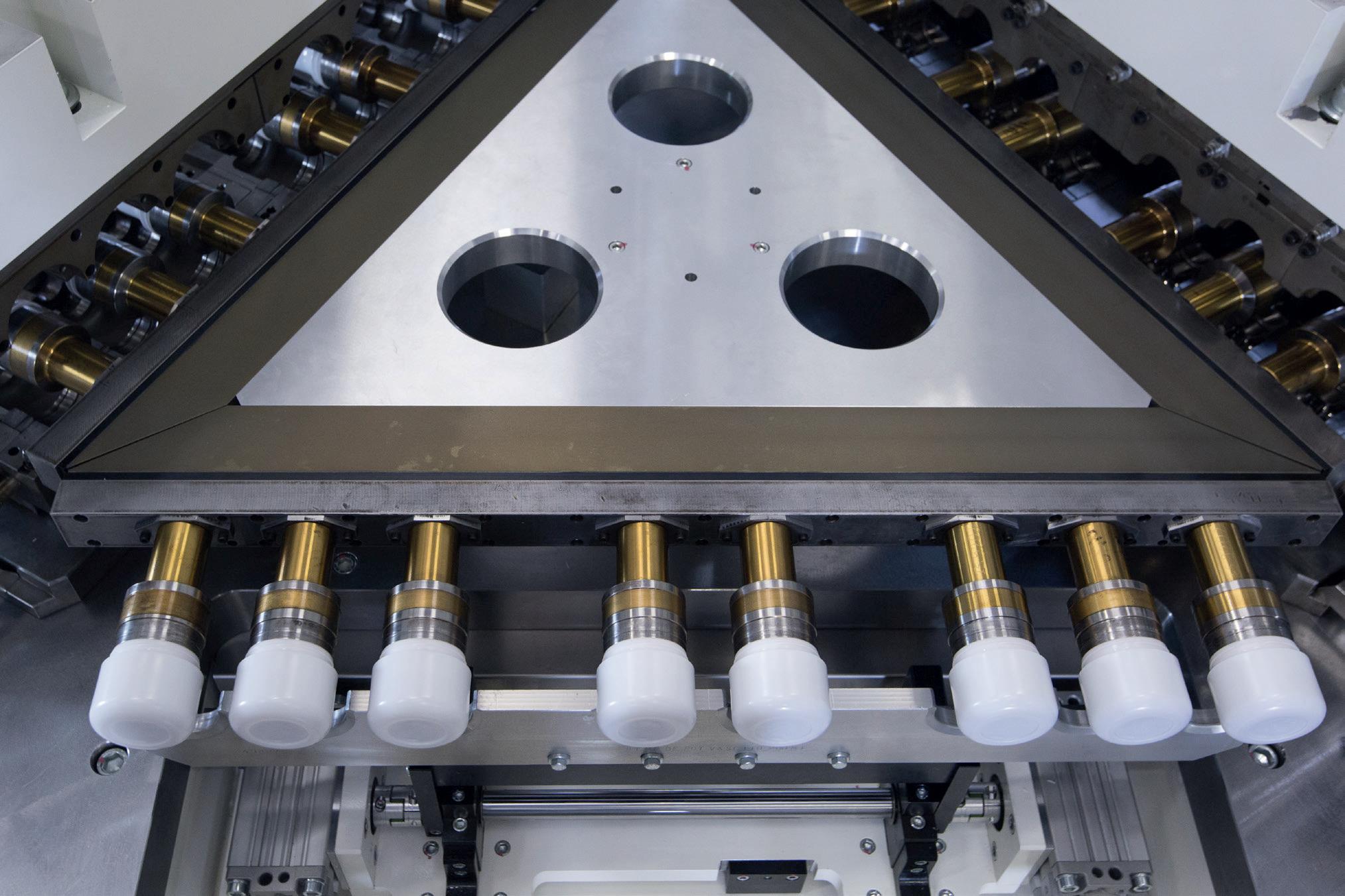

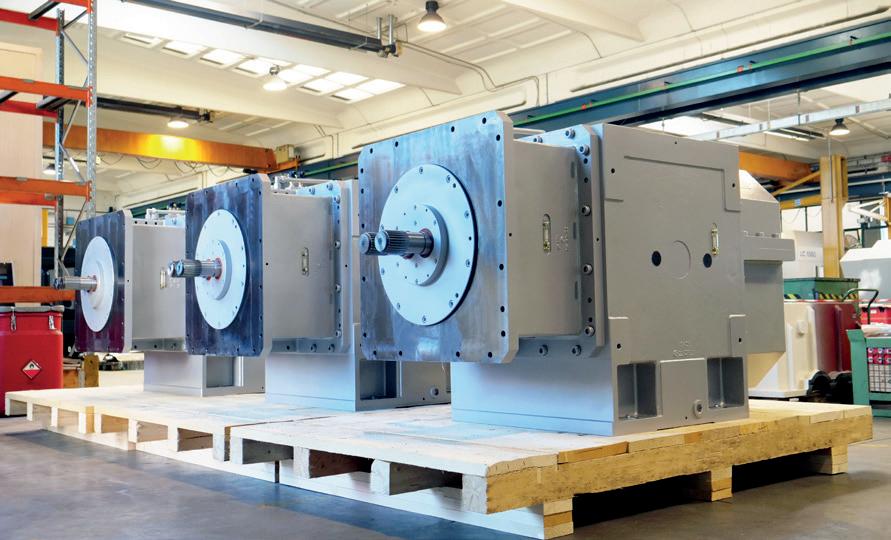

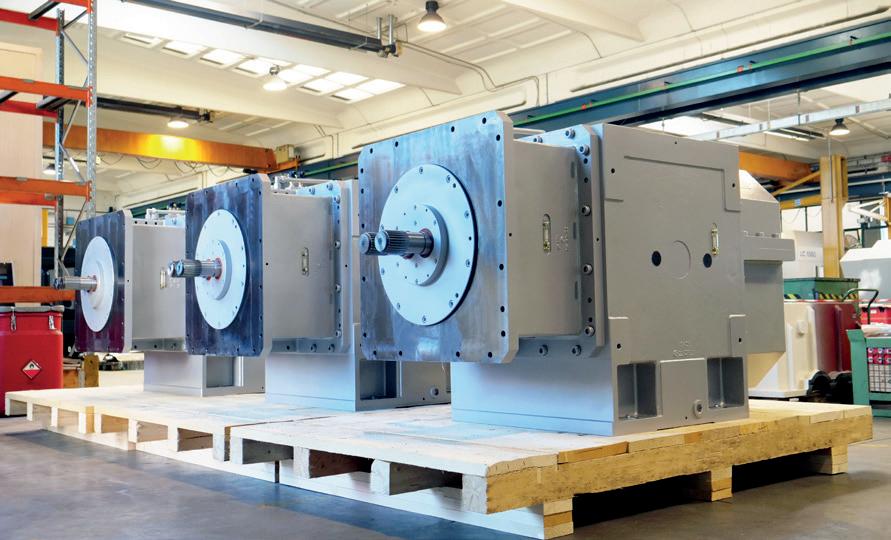

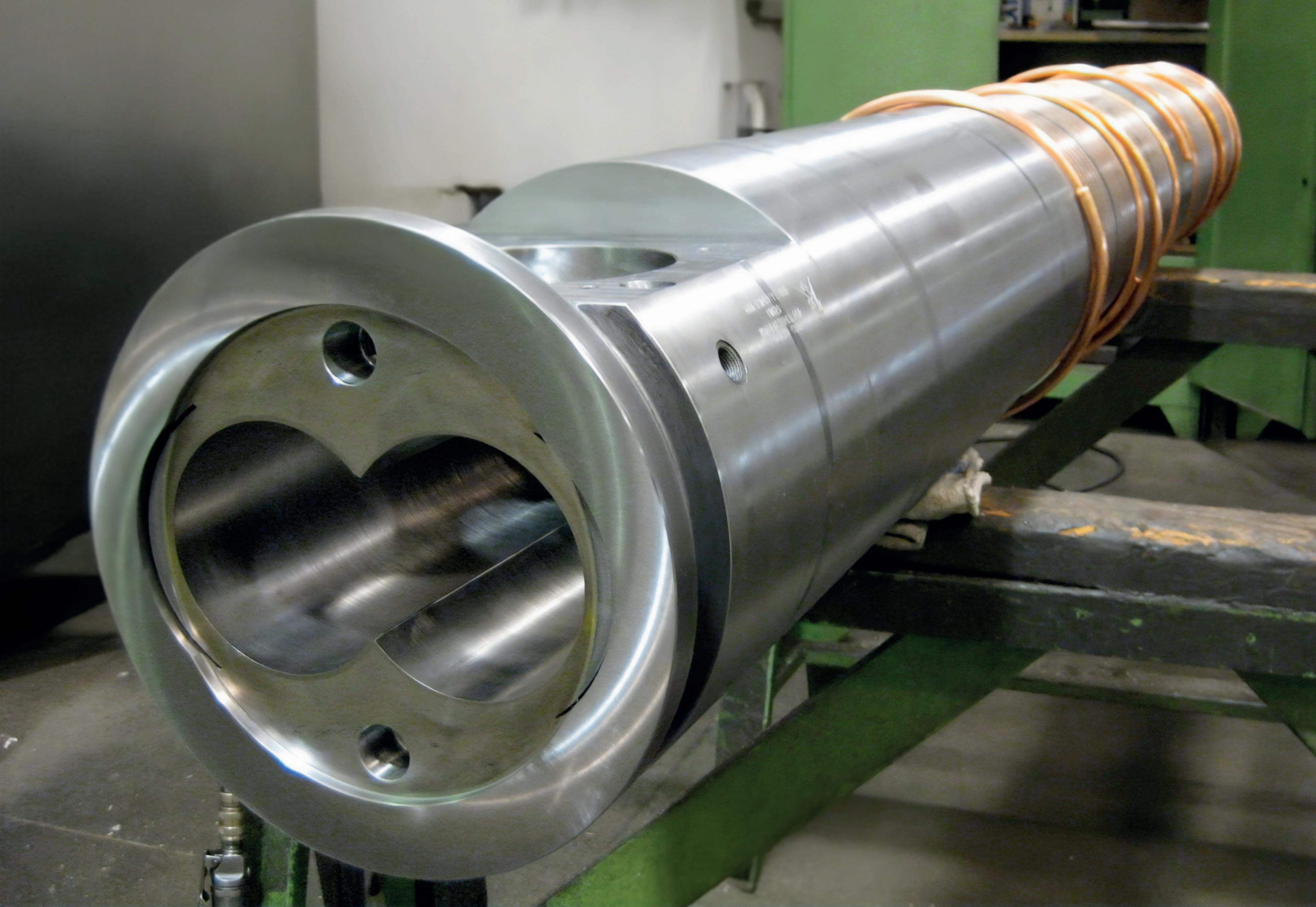

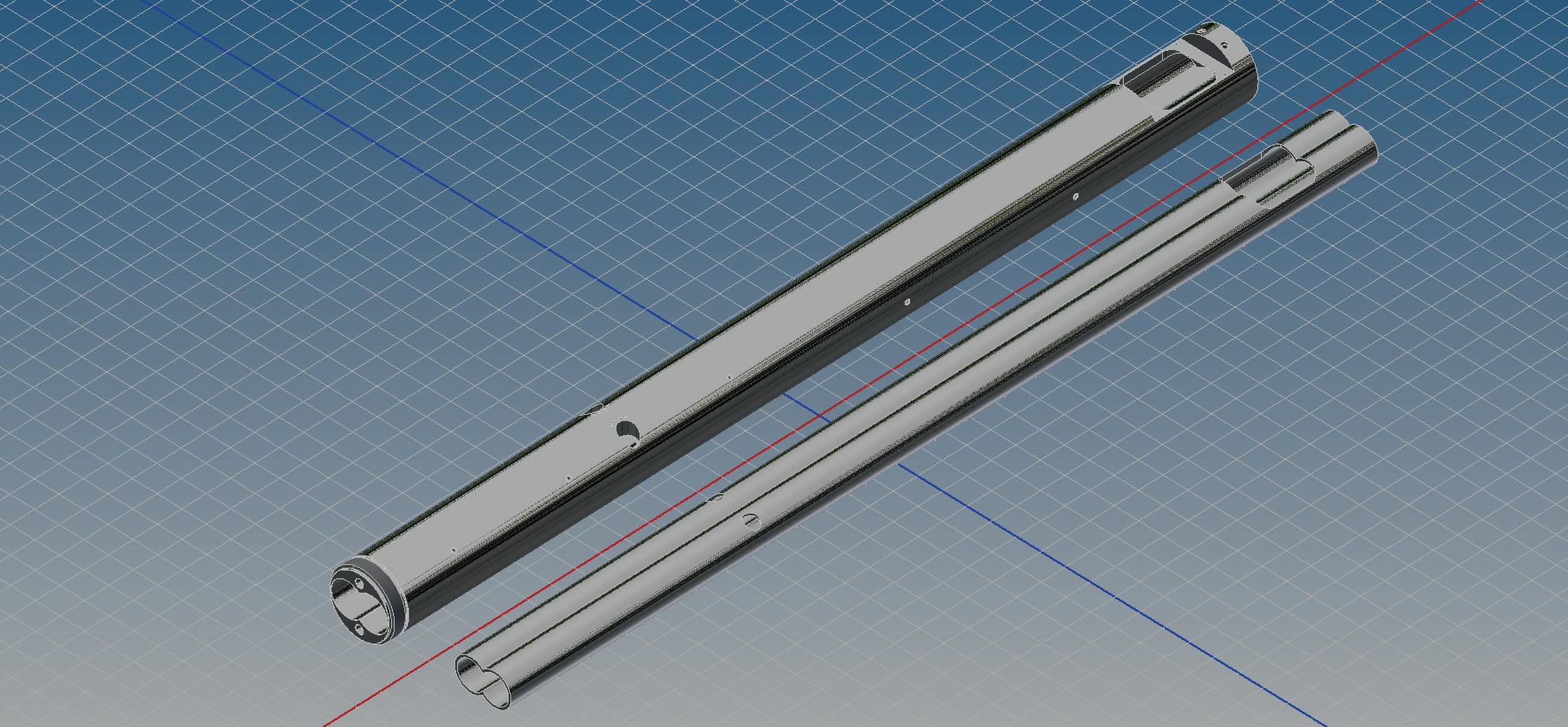

Since 1957, the most advanced extruder gearboxes for single screw, corotating twin screw and counter-rotating twin screw, parallel and conical

Since 1957, the most advanced extruder gearboxes for single screw, corotating twin screw and counter-rotating twin screw, parallel and conical

www.zambellogroup.com

www.zambellogroup.com

Since 1957, made in Italy

Since 1957, made in Italy

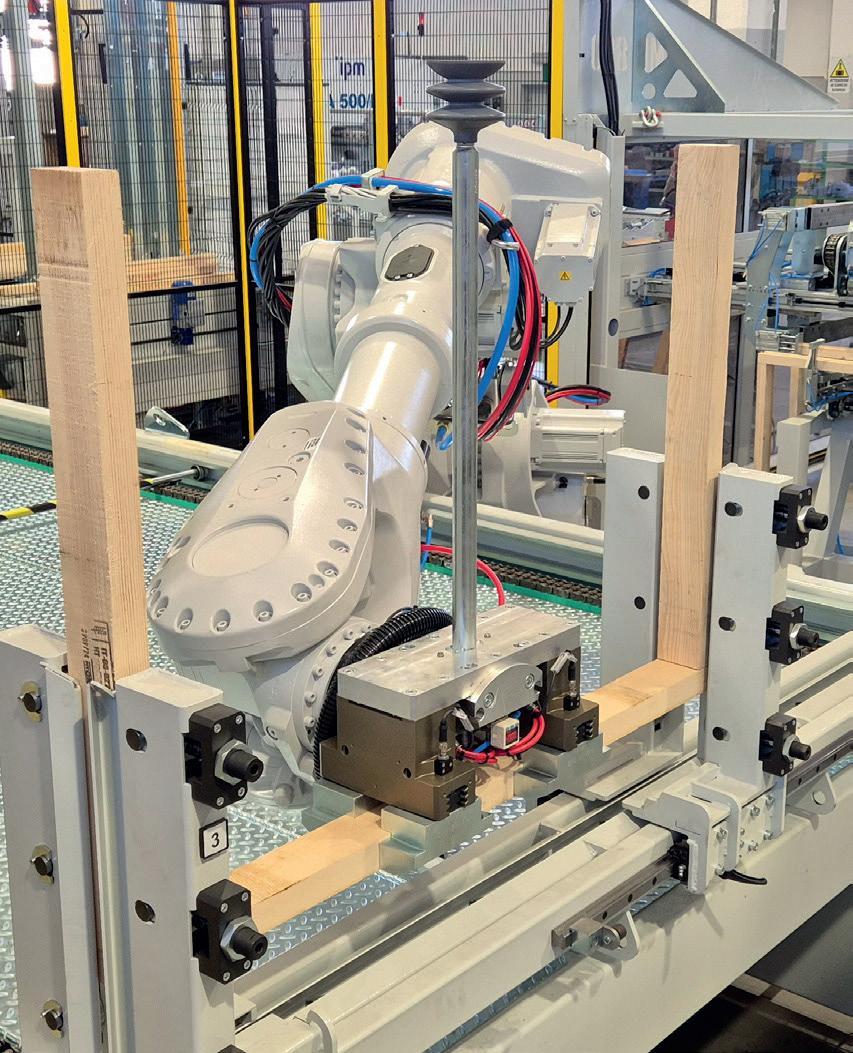

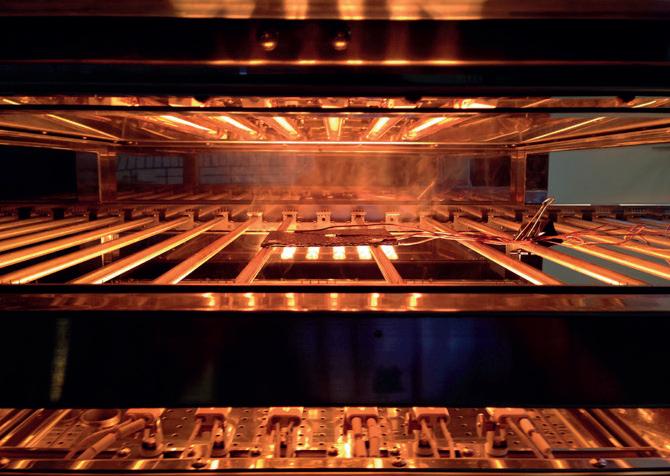

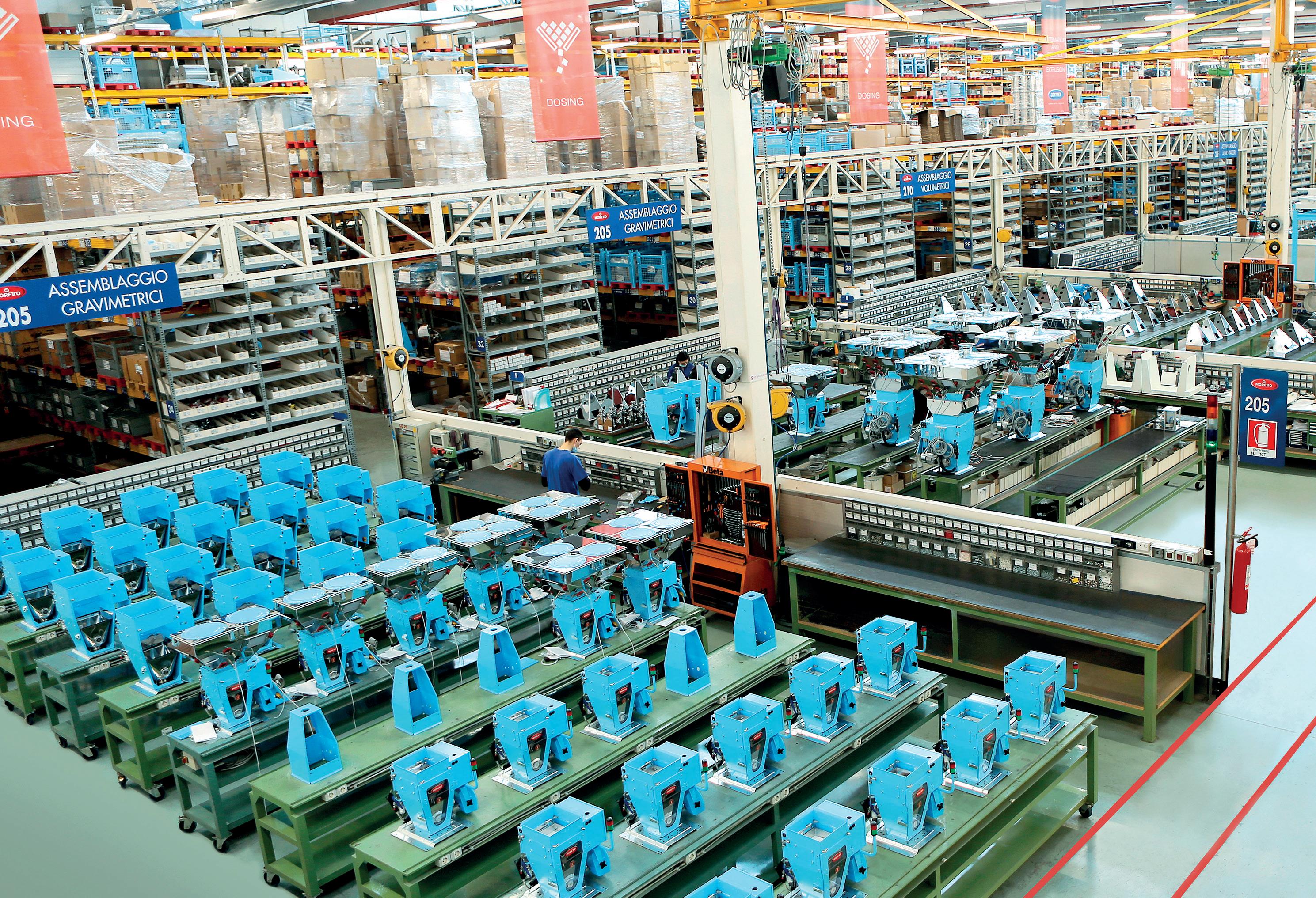

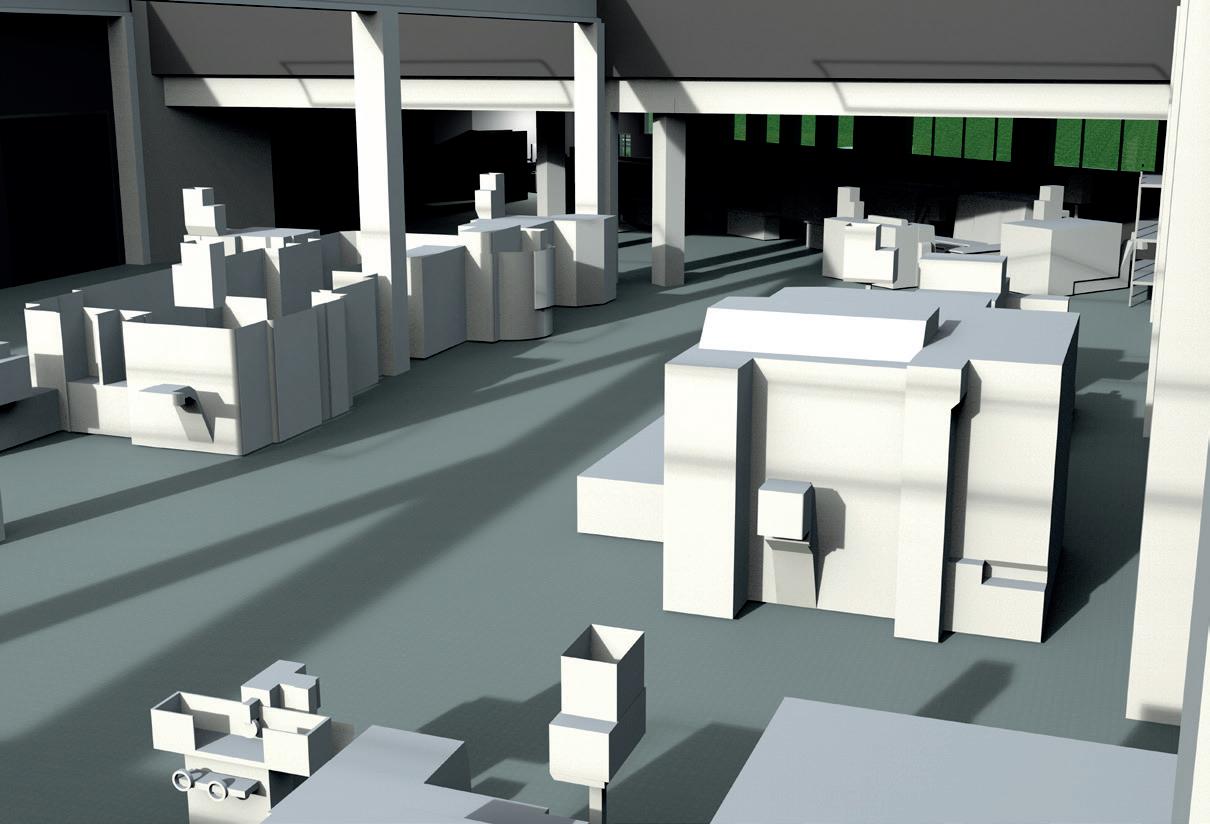

With the state-of-the-art of our new manufacturing plants in Lendinara, we have expanded the automation in all stages of product processing, creating a significant increase in our industrial capacity.

With the state-of-the-art of our new manufacturing plants in Lendinara, we have expanded the automation in all stages of product processing, creating a significant increase in our industrial capacity.

The result of this further investment is greater competitiveness and a significant reduction in delivery times, with the ambition of acquiring new customers in the world of extrusion.

The result of this further investment is greater competitiveness and a significant reduction in delivery times, with the ambition of acquiring new customers in the world of extrusion.

Excellence in extruder gearboxes

Excellence in extruder gearboxes

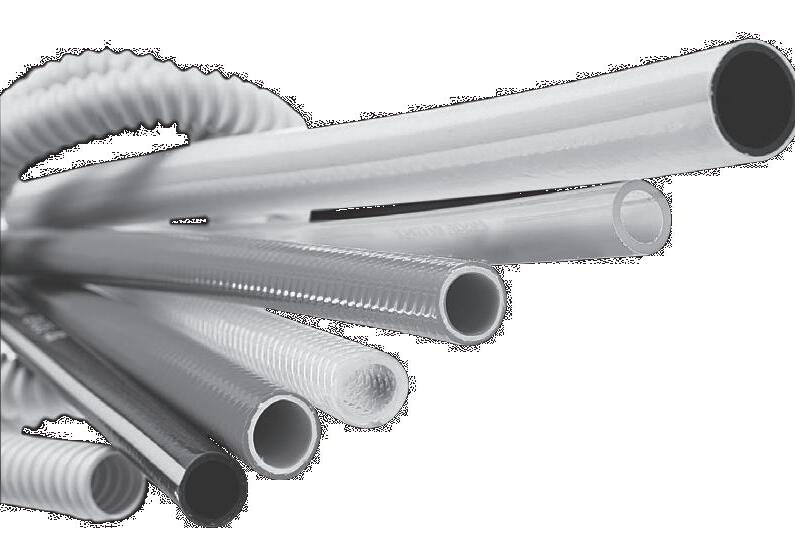

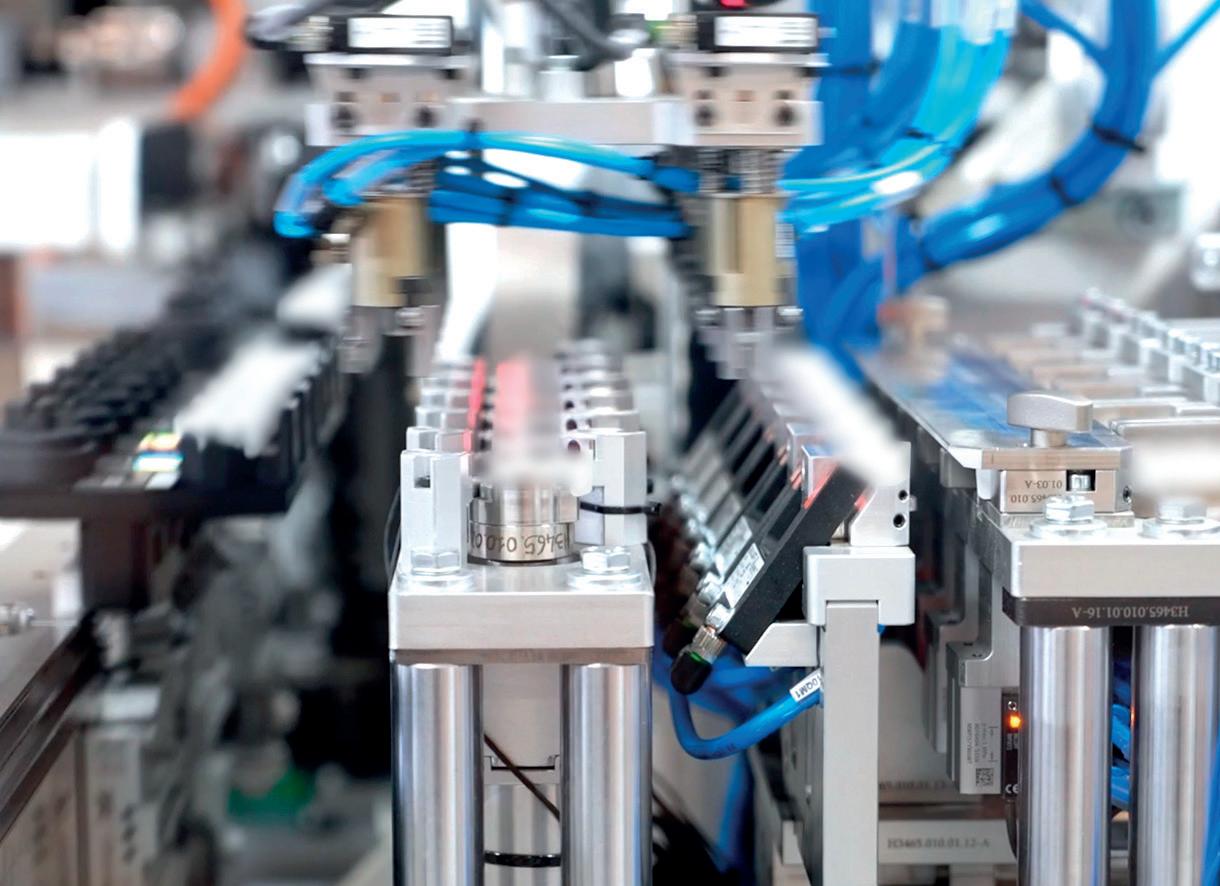

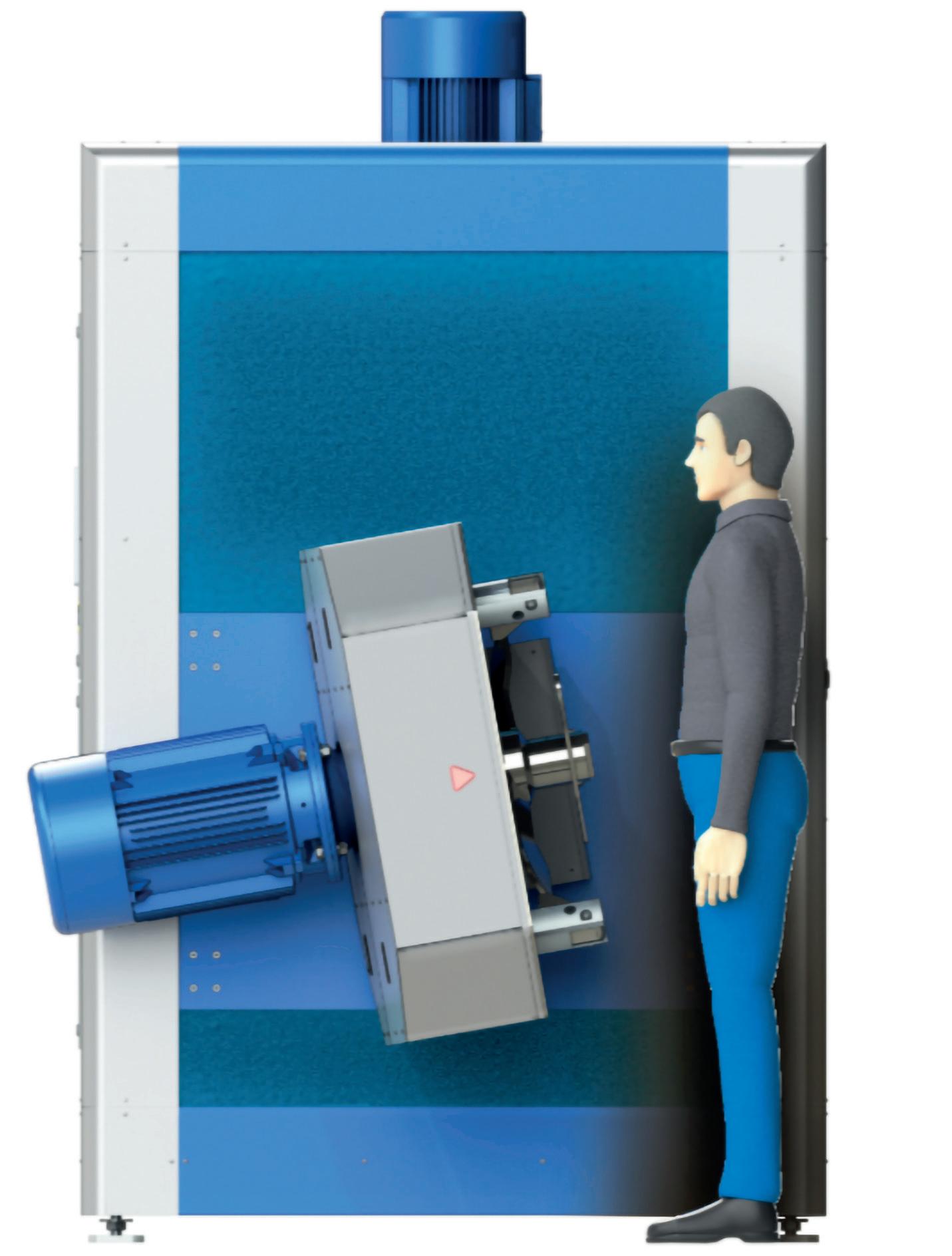

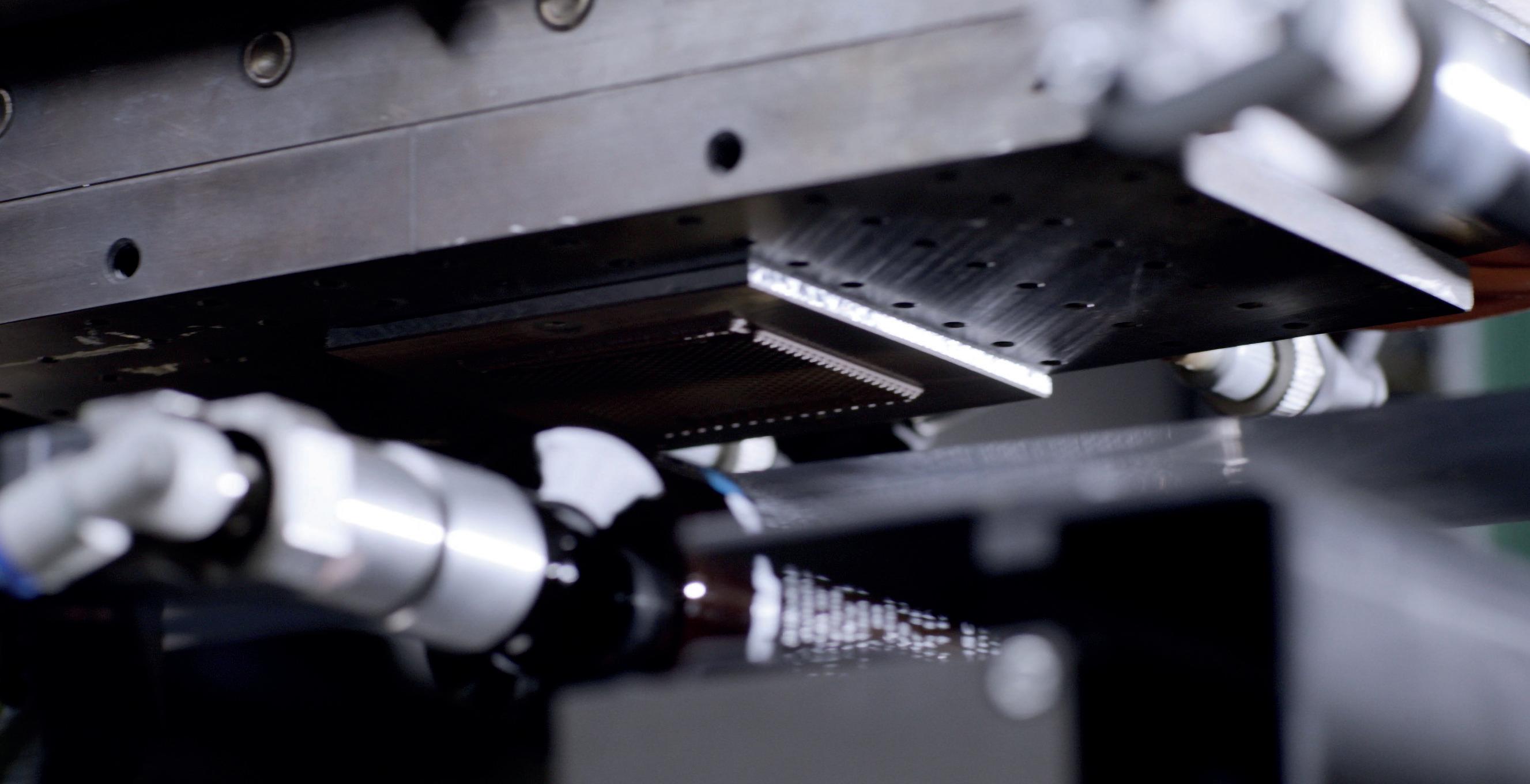

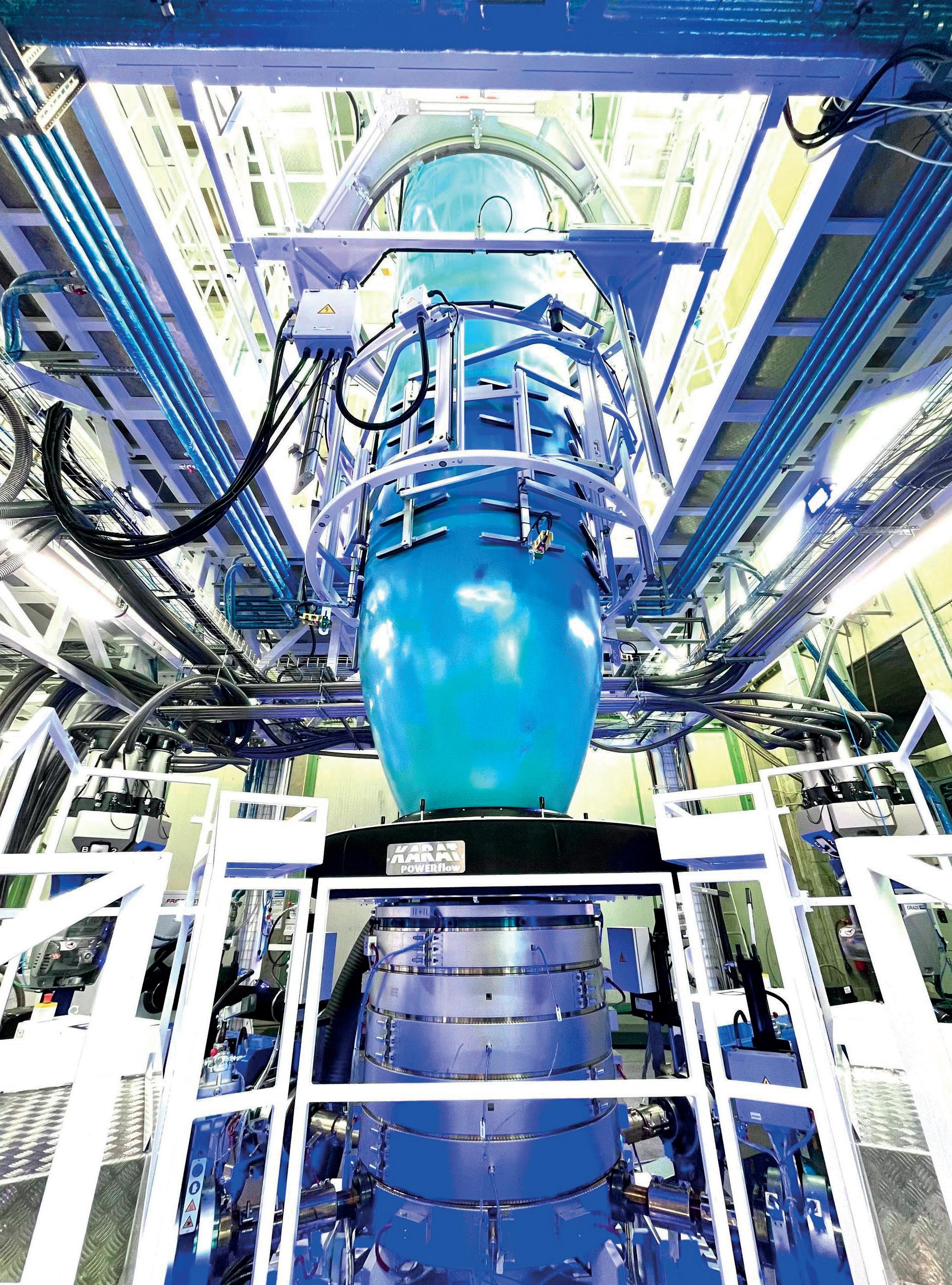

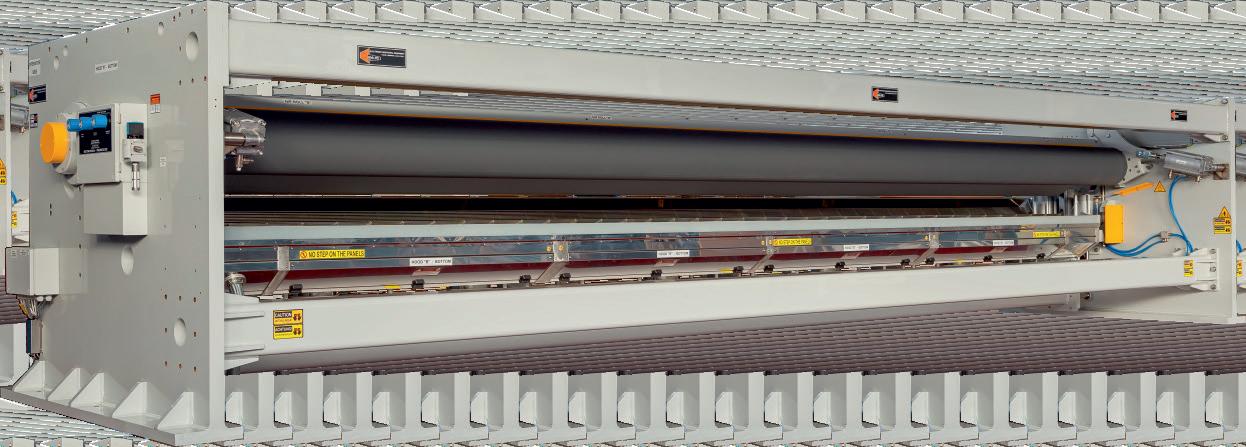

For over 60 years, Sica has transformed imagination into reliable solutions, enabling customers to stay ahead with smart, sustainable, and intuitive technology.

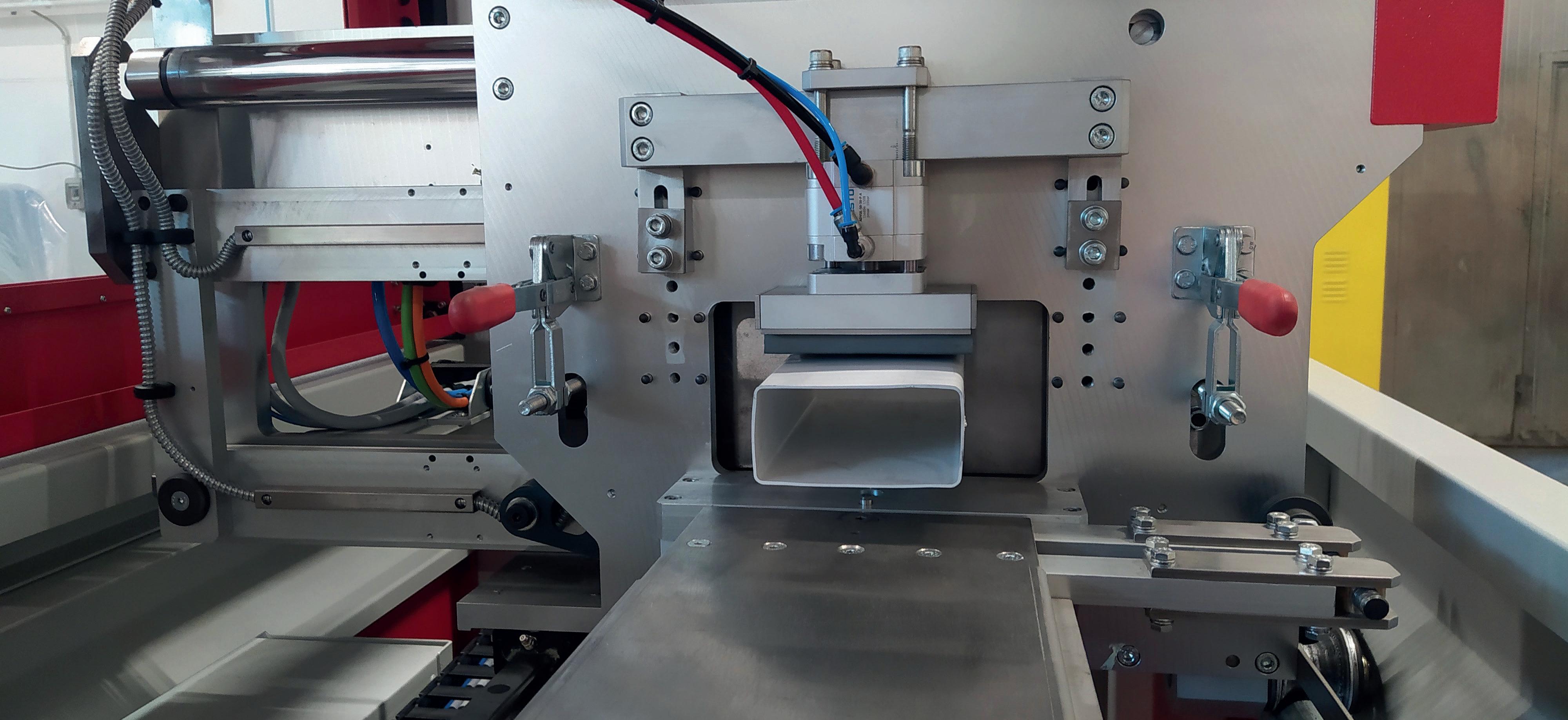

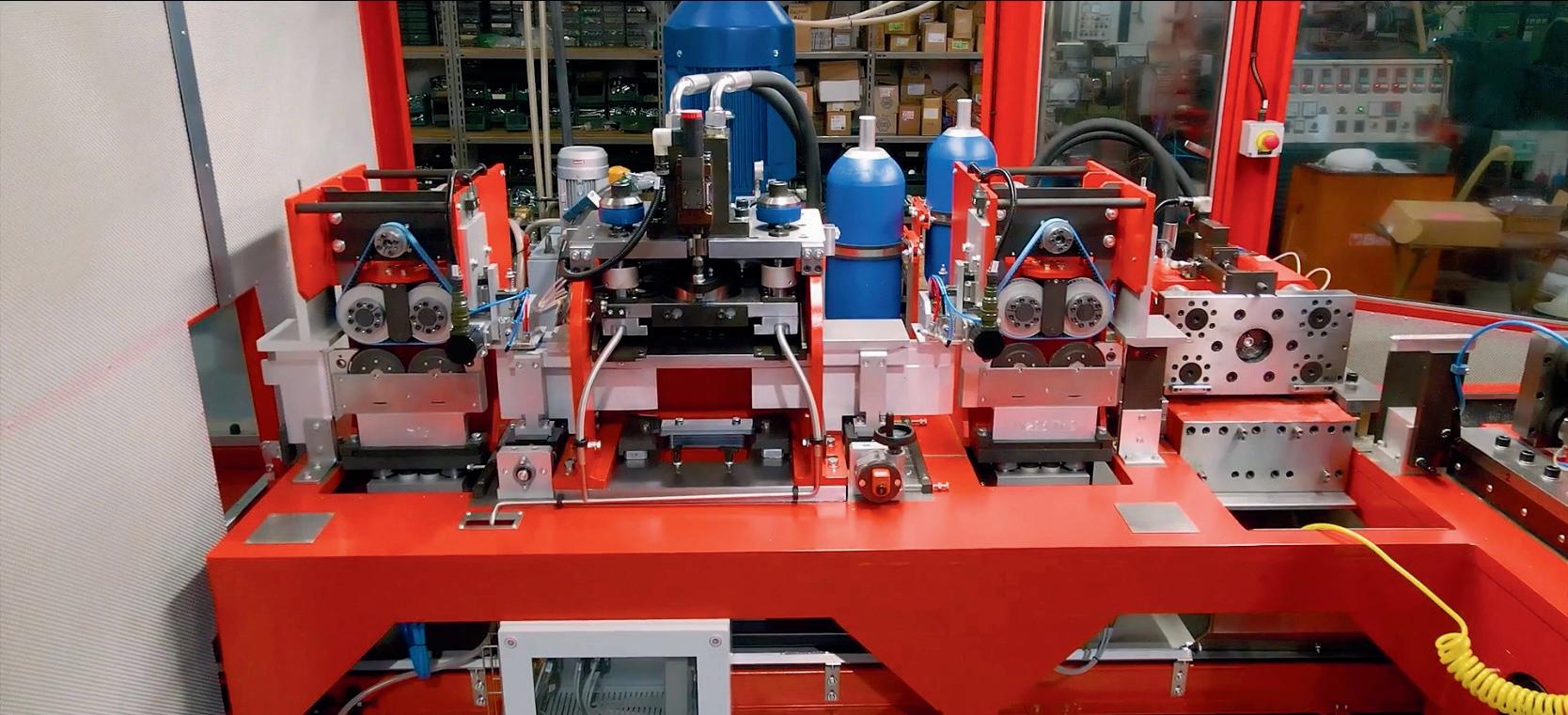

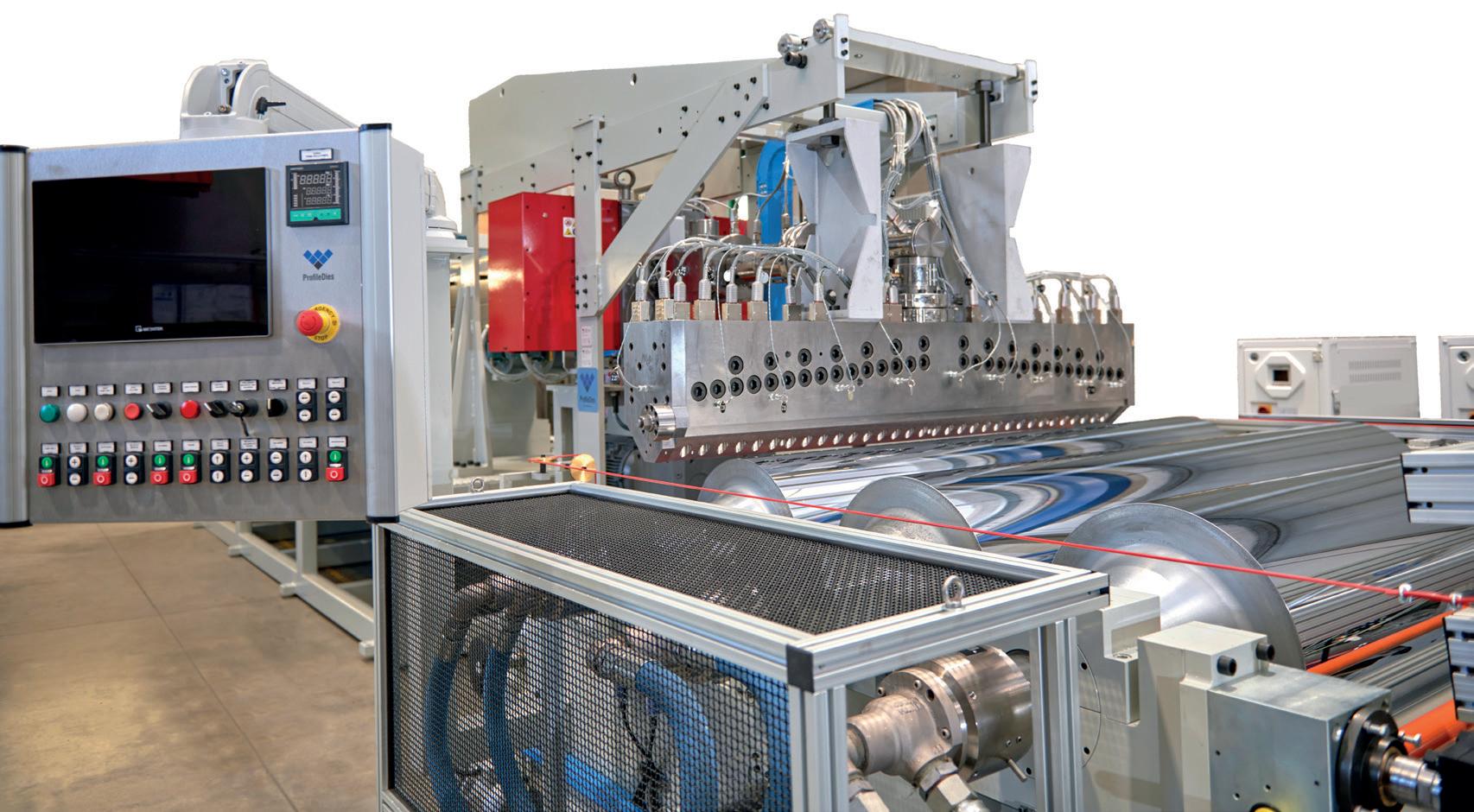

From haul-offs and cutting machines to belling units, coilers, packaging systems, and auxiliary equipment, the company offers a comprehensive range of solutions for plastic pipe production. What sets Sica apart is not only the machinery itself, but the thinking behind it. Every product is engineered to integrate seamlessly, reduce complexity, and enhance performance across all pipe types.

Innovation is the driving force behind Sica’s development. With 32 active patents and a dedicated R&D team, the company continues to reimagine downstream technology to be smarter, more sustainable, and increasingly userfriendly. A clear example is its new Human Machine Interface (HMI): intuitive, responsive, and designed to simplify operation while improving efficiency.

At the heart of Sica’s approach is a strong customer focus – including a firm commitment to sustainability. Each machine is designed to help customers reduce energy consumption, minimise waste, and achieve their environmental objectives without compromising on performance. In today’s industrial landscape, sustainability is not merely a choice but a shared responsibility – one that Sica fully embraces to better support its partners. Every component, every design, every upgrade serves a single purpose: helping customers succeed, sustainably.

Excellence at Sica extends beyond machinery. Its after-sales support is fast, reliable, and continuously evolving. The company is currently developing a 24/7 assistance platform to ensure expert support is always accessible, reinforcing its dedication to operational continuity and customer care. With two international branches – a commercial and service site in the U.S. (Sica America Corporation) and a production and commercial site in India (SPM – Sica Plastic Machinery) – the company maintains a strong global presence and proximity to customers wherever they operate. Choosing Sica means selecting a partner that goes beyond performance – a company that builds not only for today, but for the future. It is a team that places the customer experience at the centre of every technical decision. Because at Sica, the future is built with one clear goal: making its customers’ work easier, faster, more efficient, and more rewarding.

www.sica-italy.com

It’s spelt “K” but pronounced “Plast”!

14 Italian manufacturers: better-than-expected

Milan becomes an international hub for plastics sustainability

Federazione Gomma Plastica: Luca Iazzolino appointed new President

The future of plastics: circular and competitive

Looking to the future with optimism and determination

Over 1.7 billion euros revenue

New subsidiary in Spain and new technology centre in Switzerland

Increase production capacity to over 6.6 million tonnes

Plan for stronger EU chemical industry

Miriam Olivi new General Manager

A new CEO with extended responsibility

Acquisition completed

Long-term global collaboration agreement 38 Two plants in Germany and one in the United Kingdom 38 Songwon appointed new CFO

A difficult start for European chemistry in 2025 39 New President for BPF

42 Illegality, unfair competition and dumping hinder recovery

The use of biomass as a feedstock for bioplastics

Industrial-scale regeneration of carbon fibre

PFAS polymers: restrictions and bans under consideration

Rigid polyolefins recycling market hits standstill

Guidelines for certifying recycled plasics for food contact

EU vehicles: more recycled plastic and better recyclability

Driving digital transformation in plastic recycling and extrusion

Cybersecurity – a new challenge facing the European manufacturing industry

pulsating technological heart in industrial automation

A history of expertise, passion and vision

years of service to manufacturing

solutions shaping the future of beverage

and innovation looking to the future

80 Integrated robotics and an expanded offering

84 Serving global industrial innovation

86 A new facility at the heart of the 2026 programme

90 Towards an increasingly innovative future

94 All in a name

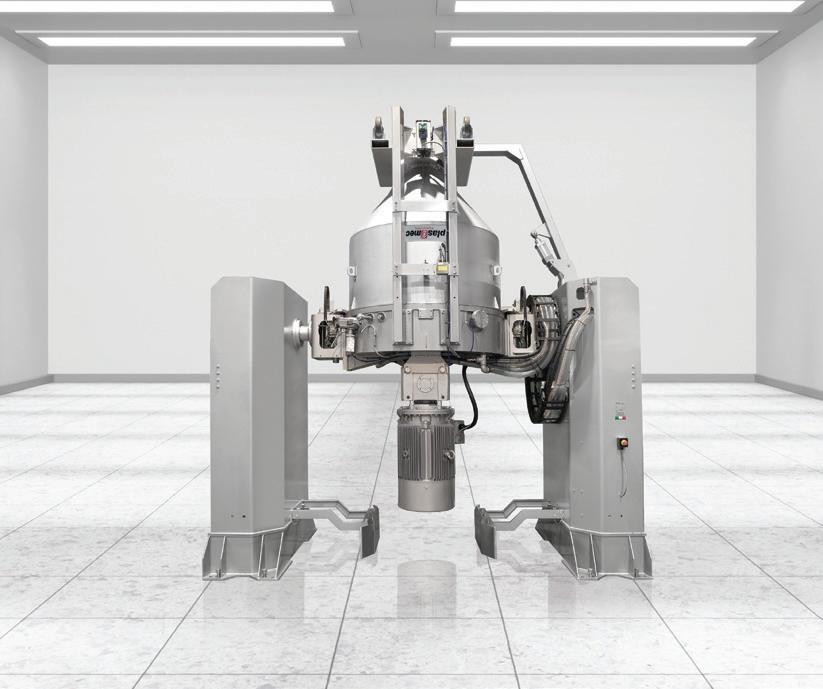

98 The mixing of the future comes from tradition

100 Complete, automated and controlled mixing plants

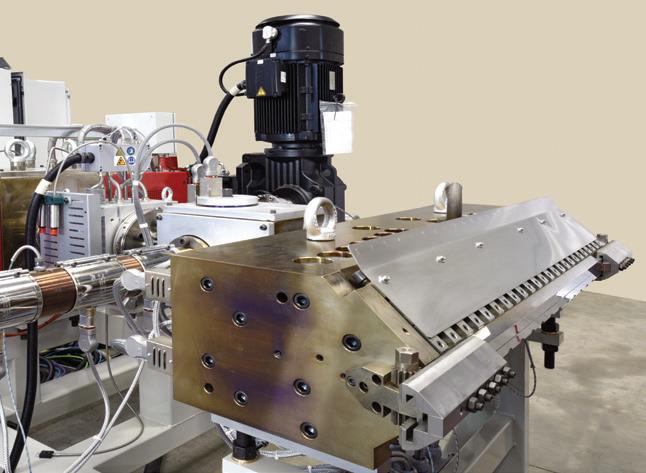

102 Tailor-made plasticising between innovation, sustainability and new challenges

104 The evolution in direct printing on plastic packaging

106 Unlocking new potential in filtration and extrusion

108 Redefining plastics recycling

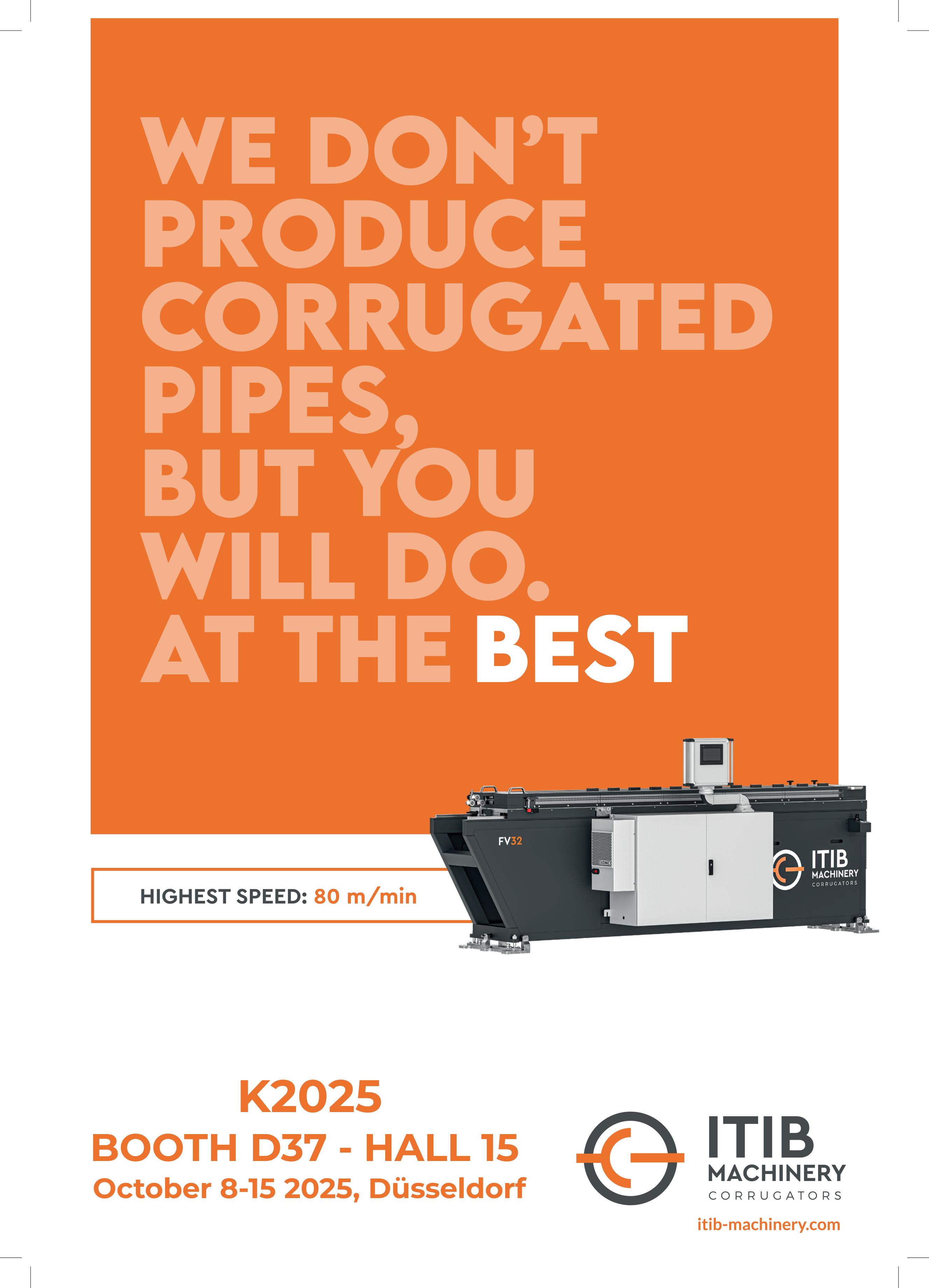

110 Efficient, flexible and therefore cost-effective PP pipe extrusion

111 A new suite for extrusion

112 Commitment and quality

113 Electric blow moulding between innovaton and redesign

114 Extruders for sepecialised, strictly regulated applications

115 Three green automation islands

116 New smart line and enhanced tandem smart solutions

117 Efficient, consistent and fast

118 Thermoforming machine and machining centres

119 First time

119 Precision, Efficiency, Durability

120 A combination of performance and aesthetics

121 Supporting plastic circularity in the Philippines

121 De-inking of flexible and ridig packaging

122 Agricultural irrigation pipes and sheets of optical quality

123 Fifty years of printing expertise on display

125 Sustainable innovation and global leadership in engineering polymers

126 New President Giuseppe Rinaldi looks to the future

130 Discover the journey

132 A new divison for electrical-electronic sector

133 Colour variety for biodegradable plastics

134 High-performance fillers

135 A journey towards circular materials and advanced recycling

136 Ski mask made of up to 70% bio-based TPU

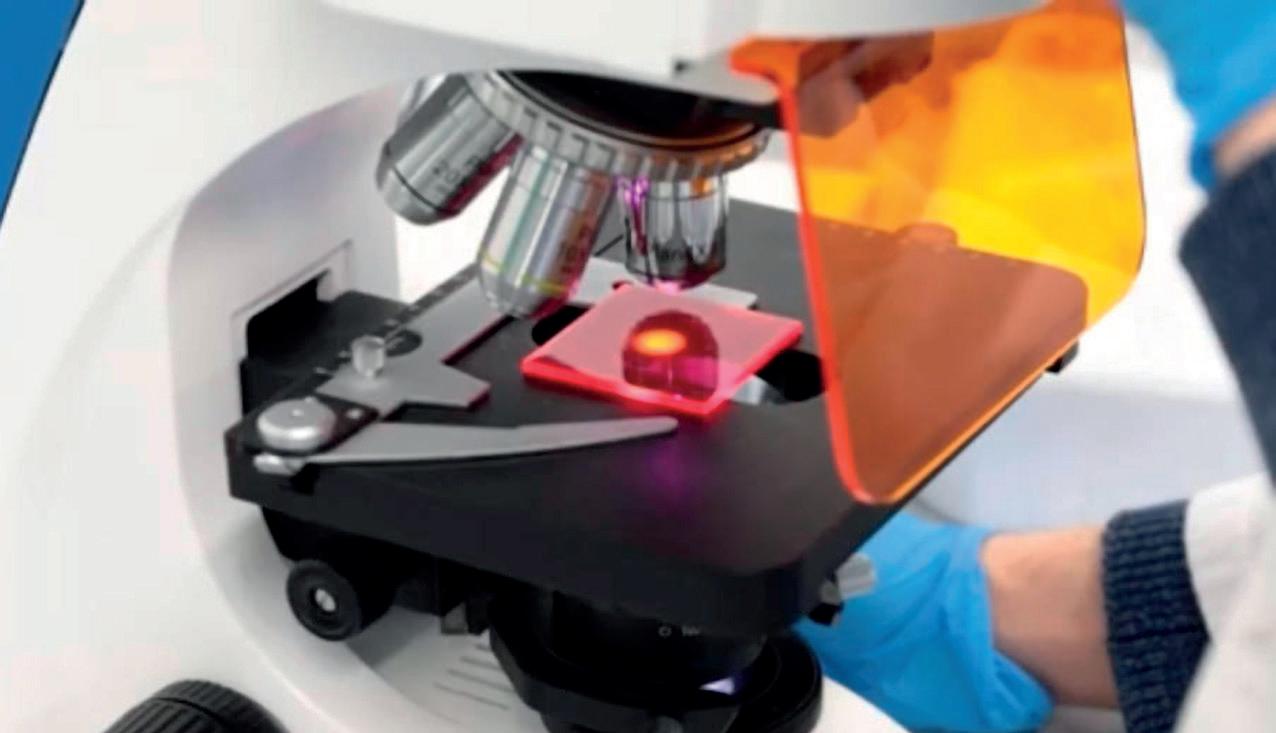

137 Accreditation for materials and SLS technology

138 Solar panels made from recycled plastic

138 At K 2025 reusable cups in recycled PP

139 For three years towards a more sustainable and circular chemistry

140 Plant-based additives to enhance PE and PP polymerisation

140 New food-contact and flame-retardant compounds

142 Ready to tackle the challenges of the third millennium

145 K, Interpack and Drupa in Saudi Arabia

October 2025

Managing director Mario Maggiani

Editor in chief Luca Mei

Editor Giampiero Zazzaro

Editorial assistant Alice Polimeno

Sales manager

Roberta Pagan (Italy)

Martina Lerner (Europe)

Administration Elisa Belloni

Editorial committee

Massimo Margaglione, Gabriele Caccia, Barbara Ulcelli

Contributors to this issue

Stefania Arioli, Stefano Bertacchi, Stefano Lugli, Stefano Nicolussi

Published by

Centro Direzionale Milanofiori - Palazzo F/3

20057 Assago (Milano, Italy)

Tel.: +39 02 82283735

Fax: +39 02 57512490

e-mail: macplas@macplas.it www.macplas.it

Registration at the Court of Milan n. 68, 13/02/1976

Registration at the National Press Office n. 4620, 24/05/1994

Layout and prepress

Faenza Printing SpA

Printed by

Faenza Printing SpA

Postal delivery: IFS Italy

ISSUE PRICE: 8 euro if not sent with mother magazine

The managing direction of the magazine declines any responsibility for possible unreliability of editorial articles and notes coming from various sources

ASSOCIATED TO:

83 AMUT www.amut.it

120 BARUFFALDI www.baruffaldi.eu

92 BAUSANO www.bausano.com

52 BFM www.bfm.it

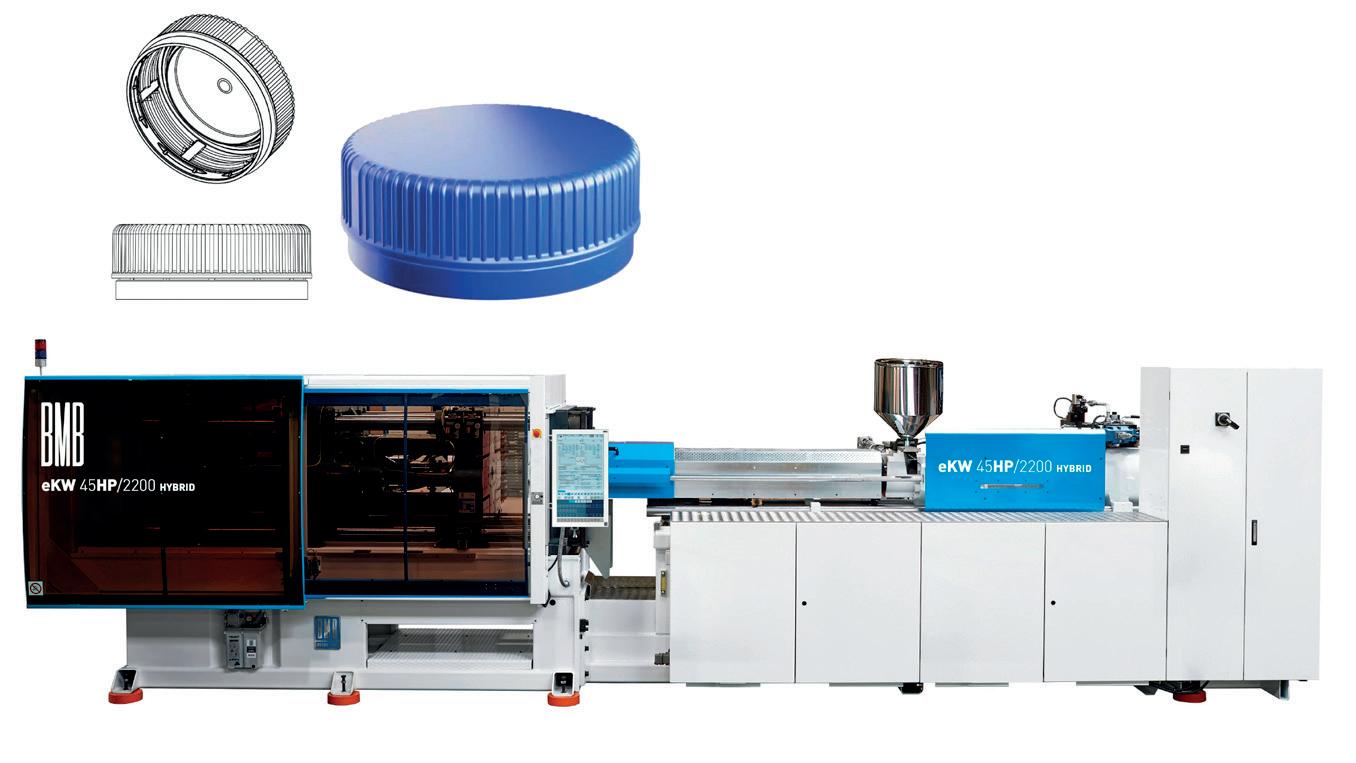

Back cover BMB www.bmb-spa.com

135 CALDARA PLAST www.caldara.it

144 CHINAPLAS 2026 www.chinaplasonline.com

88 CMS www.cms.it

63 COLINES www.colines.it

122 COMERIO ERCOLE www.comercole.it

5 EUROVITI www.euroviti.com

124 GAMMA MECCANICA www.gamma-meccanica.it

72 GEFIT www.gefit.com

118 GEFRAN www.gefran.it

123 GIBITRE www.gibitre.it

30 GIURGOLA www.giurgola.it

139 GRAFE www.grafe.com

41 HELIOS QUARTZ www.heliosquartz.com

13 ICMA www.icmasg.com

Inside back cover IMG www.imgmacchine.it

3 IPM www.ipm-italy.it

11 ITIB www.itib-machinery.com

27 MARIS www.mariscorp.com

137 MAST www.mastsrl.it

Inside front cover MECCANOPLASTICA www.meccanoplastica-group.com

145 ME.RO www.mero.it

96 MIXACO www.mixaco.com

40 MIXRON www.mixron.it

82 MORETTO www.moretto.com

26 NEGRI BOSSI www.negribossi.com

67 OMSO www.omso.it

146 PACKAGING SPEAKS www.packagingspeaksgreen.com

GREEN

22 PET SOLUTIONS www.petsolutions.it

62 PLAS MEC www.plasmec.it

141 PLAST 2026 www.plastonline.org

71 PLASTIBLOW www.plastiblow.it

93 PLASTORE www.plastore.it

9 PRESMA www.presma.it

23 PREVIERO www.previero.it – www.sorema.it

136 PROFILE DIES www.profiledies.it

125 RADICIGROUP www.radicigroup.com

105 ROBOLINE SYTRAMA www.sytrama.com

Cover SICA www.sica-italy.com

53 SIEMENS www.siemens.com

51 TECHNO BINS www.technobins.it

7 TECNO SYSTEM www.tecnosystemfe.it

ASSOCIAZIONE NAZIONALE EDITORIA DI SETTORE

INSTITUTIONAL SPONSORS

AMAPLAST

ITALIAN PLASTICS AND RUBBER PROCESSING MACHINERY AND MOULDS MANUFACTURERS’ ASSOCIATION

AIPE

ITALIAN ASSOCIATION OF EXPANDED POLYSTYRENE

ASSOGOMMA

ITALIAN RUBBER, CABLES, WIRES AND SIMILAR MANUFACTURERS’ ASSOCIATION

ASSORIMAP

44 TECNOMATIC www.tecnomaticsrl.net

89 TECNOVA www.tecnovarecycling.it

4 ULTRA SYSTEM www.ultrasystem.ch

97 UNITECHEM www.unitechem.eu

Front flap ZAMBELLO www.zambello.it

ASSOCIATION OF ITALIAN PLASTICS RECYCLING AND RECLAIMING COMPANIES

CIPAD

COUNCIL OF INTERNATIONAL PLASTICS ASSOCIATIONS DIRECTORS

IIP

ITALIAN PLASTICS INSTITUTE

SPE ITALIA SOCIETY OF PLASTICS ENGINEERS

UNIONPLAST

ASSOCIATION OF ITALIAN PLASTICS PROCESSING COMPANIES

UNIPLAST

ITALIAN STANDARDISATION BODY FOR PLASTICS

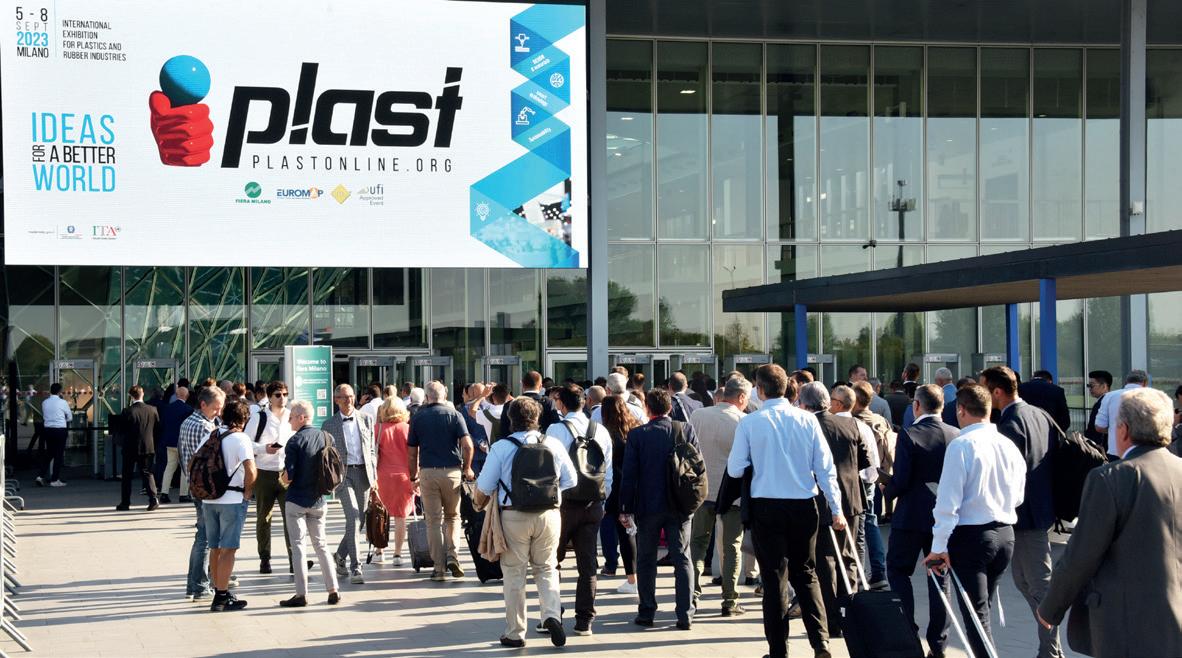

Heaven forbid I should draw comparisons between K and Plast. I certainly don’t want to spark controversy or, worse still, lay myself open to criticism for daring to compare Plast – our Italian trade fair which, after all, remains the second most important in Europe – with the K show. The German event is still widely considered the leading global fair, even though we know that, at least in purely numerical terms – whether in total net area or, more significantly, visitor numbers – Chinaplas is now by far the largest.

What I really wanted to point out in this ideal “excursus” is that, following the major event in Düsseldorf, the highlight of next year’s exhibition calendar in Europe will undoubtedly be Plast.

Let us not forget that the Italian plastics and rubber processing industry ranks second only to Germany’s. The same holds true for manufacturers of machinery, equipment, and moulds. And – allow me to say it with a touch of pride – despite the numerous political and economic challenges, this particular sector has performed, and continues to perform, exceptionally well, especially when comparing Italian figures with their German counterparts. I won’t repeat the statistics already widely covered in the pages of our magazine, but suffice it to say that in 2024, Italy’s sector turnover grew by 1.4% (a positive sign!), while Germany’s fell by 19%, clearly weighed down by the automotive market crisis.

It is therefore only natural to see Plast as the continuation of the technological development we will surely witness at K. Italy also serves as a natural bridge between Africa and Europe, with the Mediterranean basin becoming a key source of visitors eager for technology and innovation.

The organisational effort is significant: we are well aware that putting on a trade fair today is far more complex than it was twenty years ago. While exhibitors remain fairly loyal (though they tend to reduce the space booked), visitor numbers are declining across the board – at K, for example, attendance has dropped from over 230,000 to around 176,000 over the past three editions.

That’s why we’ve strengthened the Plast team with a new head of exhibitions and enhanced our communications department, with a particular focus on social media channels. As always, our commitment is absolute. It’s no coincidence that we’ve also established a synergy with Xylexpo (the exhibition for woodworking machinery and equipment), which will be held on the same dates as Plast. There will be a single admission ticket, the halls will be adjacent, and visitors will experience what feels like a single, integrated event.

Beyond this perception, it truly is a shared project – one that has been deliberately given a clearly defined name: MaTec – Materials and Technologies. It brings together not only Plast and Xylexpo, but also a brand-new exhibition and conference, making its debut: Composites Future, dedicated to composite materials. It acts as a natural link between related technologies for materials that may seem unrelated at first glance, but which, in many cases, share common ground in terms of processing and applications.

In short, as always, we are looking ahead – helping companies grow, and helping the sector progress, so they can face a future that remains highly competitive.

The 2024 financial year for plastics and rubber machinery manufacturers closed with a 1.4% increase in turnover. This performance marks an upward revision of the provisional figures released in March, reflecting greater resilience than initially anticipated. The sector’s stability was largely sustained by strong export performance, which offset the relative weakness in domestic demand and import activity. Massimo Margaglione has been confirmed for another term as President of the association, underlining continuity in leadership. Following the success of GreenPlast, industry stakeholders are now focusing their efforts on the next major milestone: Plast 2026.

By Stefania Arioli

During the last annual general assembly of Amaplast – Italy’s national trade association representing some 170 manufacturers of machinery, equipment, and moulds for plastics and rubber processing, and member of Confindustria – Massimo Margaglione was confirmed as President for the 2025-2027 term, alongside Gabriele Caccia and Barbara Ulcelli, who were appointed Vice Presidents.

In his talk, Massimo Margaglione illustrated the performance of the Italian plastics and rubber processing machinery industry, commenting on the results of the fifth edition of the National Statistical Survey carried out by the MECS-Amaplast Statistical Studies Centre. The survey focused on approximately 430 manufacturers (representing over 15.000 employees), who generated revenues exceeding 4.82 billion euros (+1.4%), with exports accounting for more than 74% of the total sum. This performance is particularly reassuring considering the multiple ongoing geopolitical tensions, the complex legislative

framework, and the occasionally disadvantageous decisions imposed by European institutions.

Vice President Barbara Ulcelli commented on the survey results concerning the structure of the association and, more broadly, the structure of the Italian plastics and rubber processing machinery industry, covering aspects such as geographical position, company size, and workforce. She also provided an update on ongoing negotiations for the renewal of the National Collective Labour Agreement (CCNL), represented by Federmeccanica, of which she is a General Council member.

Vice President Gabriele Caccia focused on topics concerning his field of work, including Amaplast’s participation in industry fairs over the past year, the results of GreenPlast 2025, and the preparations for Plast 2026.

The guest of honor at the assembly was Professor Carlo Cottarelli – Italian economist, former senator and special commissioner for the spending review, essayist and university lecturer – who delivered a lecture on the current global economy

and its potential future developments with a special emphasis on Italy.

According to the findings of the fifth edition of the National Statistical Survey by the MECS-Amaplast Statistical Centre, the Italian plastics and rubber processing machinery industry closed 2024 with a 1.4% increase in turnover, reaching over 4.82 billion euros. This result surpasses the preliminary forecast published in March, which had anticipated a slight contraction in production.

The stability of the sector can largely be attributed to the strong performance of exports, which increased for the fourth consecutive year. According to Istat data, exports increased by 1.5% compared to 2023, reaching a total value of 3.62 billion euros. Exports, accounting for three quarters of total pro-

duction, peaked in the final quarter of the year, particularly in December.

While more established markets such as the European Union and North America registered modest growth, other regions –despite accounting for smaller shares – proved to be more dynamic. Significant increases in demand were observed in the Far Est – especially in China and India – as well as in non-EU European countries (Turkey), Sub-Saharan Africa, and the Middle East.

Conversely, imports declined by 7% over the course of the year, ending just above one billion euros.

The macro-level data emerging from the latest National Statistical Survey outline an industry composed of approximately 430 manufacturers of plastics and rubber processing machinery, equipment, and moulds, collectively employing over 15,000 people.

Most of the companies are located in Lombardy (53% of production facilities), followed by Veneto and Emilia Romagna (each with 14%), and Piedmont (nearly 9%).

Moreover, a direct relationship between company size and revenue-generating capacity can be observed. While most companies fall into the three smallest turnover brackets (up to 10 million euros), employing 72% of the sector’s workforce, it is the larger enterprises that account for the majority (78%) of total industry turnover. As a result, as company size increases, so does average revenue per employee and focus on exports.

Vice President Barbara Ulcelli emphasized that the average revenue per employee in the sector stands at approximately 320,000 euros, significantly higher than the national industrial average. This figure rises even further within Amaplast companies, approaching 330,000 euros.

As far as end markets are concerned, the largest share of revenue comes from the packaging sector (roughly 29% food-related and 17% non-food). The packaging sector is followed by the automotive industry (nearly 16%), construction (12%), and medical applications (5%).

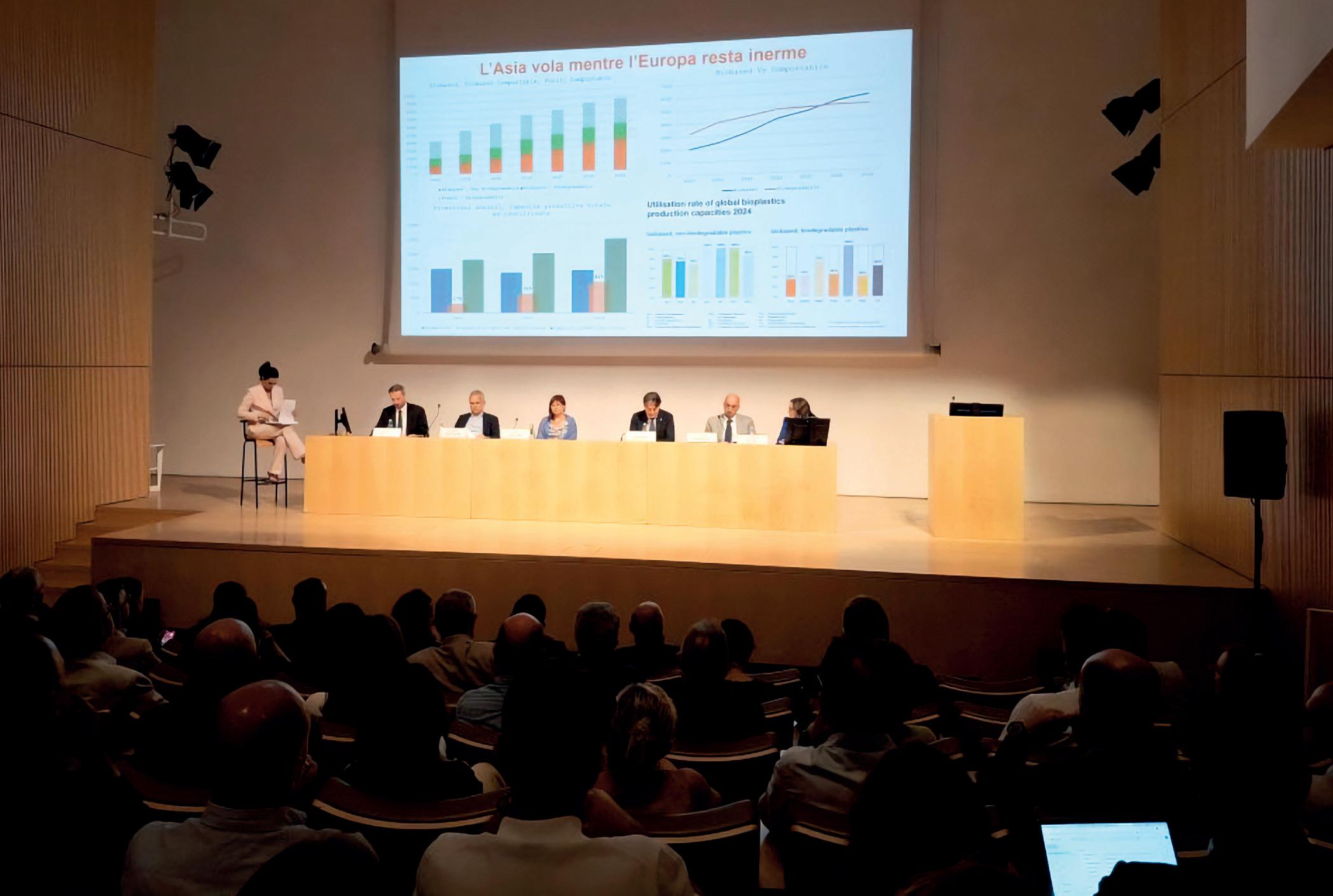

In addition to information on the numerous international trade fairs Amaplast took part in over the past year, Vice President Caccia presented the outcomes of the second edition of GreenPlast – the international exhibition-conference organized by the association’s service company, Promaplast. The event centred around materials, technologies, and processing innovations within the plastics and rubber sector, with a strong emphasis on environmental sustainability and energy efficiency.

The 2025 edition – held from 27 to 30 May as part of The Innovation Alliance alongside trade fairs such as Ipacklma, Print4All, and Intralogistica Italia – welcomed 200 exhibitors (75% domestic and 25% from 19 foreign countries) across 5,500 square metres. The event registered nearly 17,400 attendees, based on pre-registration and shared visitor tracking data across all fairs, all accessible with a single entry ticket. Positive feedback was also received for the conference “Shaping a sustainable future for plastics”, organised in collaboration with AMI-Applied Marked Information, a global leader in consultancy and event planning for the plastics industry. The event brought together experts from across the entire plastics supply chain to discuss the challenges and opportunities of ecological transition.

The next edition of GreenPlast is scheduled to take place from 29 May to 1 June 2028, once again in conjunction with Ipack-lma and Intralogistica Italia.

With regard to upcoming fairs, Vice President Caccia noted that preparations for Plast, the historic trade show organised by Amaplast-Promaplast, have already begun. The twentieth edition will once again take place at Fiera Milano in Rho-Pero (Milan), from 9 to 12 June 2026. The association joined forces with Acimall (which represents woodworking machinery manufacturers and is a promoter of Xylexpo) to launch a new joint exhibition project called MATEC (MATerials and TECnologies) combining both shows. In collaboration with Assocompositi, it will also feature the first edition of Composites Future, a conference-exhibition dedicated to composite materials – a natural bridge between the plastics and woodworking sectors.

In his speech, Professor Carlo Cottarelli provided an overview of the global economy – projected to grow by 2.8% in 2025, barring any additional shocks that may further exacerbate the uncertainty many businesses already fear. The US and China are expected to be the main drivers of this growth.

He then studied the trajectory of the performance of the Italian economy over the past few decades and pointed out the factors hindering its growth, including, first and foremost, the heavy tax burden, excessive bureaucracy, high energy cost, the sluggishness of the justice system, and the increasingly alarming demographic decline.

L’export di macchine a confronto (000 euro)

Machinery exports in comparison (000 euros)

8,000,000 6,000,000 4,000,000 2,000,000

0

Source Istat

With 200 exhibitors from 19 countries, over 17,000 visitors and a high-profile international conference, GreenPlast 2025 reaffirmed its status as the leading Italian event entirely dedicated to energy efficiency, recovery and recycling in the plastics sector. A significant achievement during a critical phase for the industry, navigating rapidly evolving EU regulations – first and foremost the Packaging and Packaging Waste Regulation (PPWR) – and a slowing domestic market, counterbalanced by robust exports, the true engine of Italy’s machinery manufacturing sector.

By Giampiero Zazzaro

From 27 to 30 May, the halls of Fiera Milano Rho hosted the second edition of GreenPlast, the exhibition-conference organised by Promaplast and part of The Innovation Alliance. The strength of the event lies in its

ability to bring together technology, materials, recycling and reuse under one roof, combining a technical exhibition with a rich programme of conferences. A format still relatively uncommon in Italy, but increasingly recognised and appreciated internationally.

The 2025 edition welcomed 17,373 visitors and 200 exhibitors – 25% of whom came from abroad – across 5,500 sqm of exhibition space.

Mario Maggiani, CEO of Promaplast, underlined the strategic value of the format: “Despite a challenging economic context, we exceeded the numbers of the first edition – proof that the industry remains eager to innovate”.

GreenPlast was held alongside Ipack-Ima, Print4All and Intralogistica Italia, as part of The Innovation Alliance, Europe’s only integrated trade fair platform, which in 2025 welcomed 108,458 professionals from 143 countries and 1,857 exhibitors from 38 nations. The next GreenPlast edition is scheduled from 29 May to 1 June 2028.

Exhibitors emphasised the “quality of contacts” over mere visitor numbers, thanks in part to targeted matchmaking involving more than 100 international buyers selected in cooperation with the Italian Trade Agency (ICE).

GreenPlast took place within The Innovation Alliance, the exhibition platform that brings together GreenPlast, Ipack-IMA, Print4All and Intralogistica Italia. In its 2025 edition, the alliance welcomed 108,458 professional visitors from 143 countries and 1,857 exhibitors from 38 nations – a unique context in Europe designed to strengthen connections between different industrial sectors, promoting innovation, digitalisation and sustainability.

The synergistic aggregation of related supply chains multiplies networking opportunities across converging industries and encourages a holistic view of manufacturing. The sectors represented within The Innovation Alliance generate a combined turnover of over 25 billion euros, with around 90,000 employees and an average export rate of 64%.

GreenPlast will return from 28 May to 1 June 2028 at Fiera Milano, maintaining its triennial schedule, while the other exhibitions will follow individual calendars tailored to their market needs and positioning within the international trade fair landscape.

This strategic decision aims to enhance the individual value of each show while preserving a shared identity and cross-cutting vision.

The Innovation Alliance will continue to thrive through collaborative initiatives, thematic synergies and shared industry plat-

forms — an evolving ecosystem aligned with the needs of the manufacturing sector. This development underscores the maturity of the project and its ability to evolve without compromising coherence, further strengthening cooperation across the represented industries beyond the context of the fair itself.

Curated by AMI – Applied Market Information, a recognised leader in plastics industry consultancy and event organisation, the conference featured around 40 technical presentations and several round tables. It offered a stage for pioneering ideas and pressing sustainability challenges, attracting industry leaders, innovators and stakeholders from around the globe. With Europe leading the way in adopting sustainable practices and regulations in constant flux, the conference served as an ideal platform for exchanging ideas and establishing international partnerships.

Together with Promaplast, AMI developed a programme divided into thematic sessions covering key topics such as plastics waste management, chemical and mechanical recycling, energy efficiency, bioplastics, eco-design, EU regulatory developments, recyclability targets and recycled content quotas, automation in polymer sorting and the use of AI to reduce environmental impact.

This multidisciplinary forum shed light on both the challenges and opportunities of a sustainable transition for the plastics value chain. Panels sparked debate around the implications of emerging EU policies, such as the PPWR, which will significantly influence industrial decisions in the coming years.

During the recent Amaplast General Assembly, President Mas-

The conference featured a structured programme of thematic sessions covering key topics across the plastics value chain from waste management and mechanical/chemical recycling to energy efficiency, bioplastics, eco-design, regulatory evolution and polymer sorting automation.

With 200 exhibitors from 19 countries, over 17,000 visitors and a high-profile international conference, GreenPlast 2025 confirmed its position as Italy’s leading event on energy efficiency, recovery and recycling in the plastics sector.

According to Promaplast CEO Mario Maggiani, GreenPlast is carving out a growing role on the international exhibition calendar, thanks to results that exceeded expectations in this second edition.

simo Margaglione stated: “The Green Deal, the Fit for 55 package, the SUP Directive and the PPWR – due to come into effect on 12 August 2026 – are already redefining the playing field for all those who design, convert or use plastics in their processes. Businesses will have to face significant investment requirements due to regulations that are still unclear. If international competitors are allowed to operate under different rules, our competitiveness could suffer”.

He continued: “Together with Amaplast Director Mario Maggiani, our partner Bistoncini Partners, and the other founders of the Confindustria Machinery Federation (Acimac, Acimall and Ucima), we are working to ensure our voice is heard. While we do not aim to rewrite the PPWR, we are committed to reshaping its obligations to make them more workable. Around 50 secondary regulations are still needed for the PPWR to be fully operational, and several of these could have a significant impact on our industry. I am not opposed to the Green Deal – on the contrary, it could be a major opportunity for Europe – but only if accompanied by coherent economic policies that avoid deindustrialisation and protect industrial competitiveness. It would be shortsighted to think that sustainability and decarbonisation efforts should fall solely on businesses”.

This reflects the ongoing commitment of the machinery sector to finding a balance between regulatory requirements and industrial sustainability.

According to research by the MECS-Amaplast Study Centre, the Italian plastics and rubber machinery sector – made up of around 430 manufacturers and over 15,000 employees – closed 2024 with a 1.4% increase in turnover, reaching over 4.82 billion euros.

This stability is largely due to strong export performance, which grew for the fourth consecutive year. Istat data show a 1.5% increase in exports compared to 2023, totalling 3.62 billion euros.

Exports – accounting for three-quarters of production –peaked in Q4, particularly in December. While mature markets such as the EU and North America showed slower growth,

more dynamic destinations included the Far East (especially China and India), non-EU Europe (notably Turkey), sub-Saharan Africa and the Middle East. Conversely, imports remained weak throughout the year, with a 7% decline and a final value just above 1 billion euros. The geographic distribution of companies remains largely unchanged: Lombardy leads with 53% of production sites, followed by Veneto and Emilia-Romagna (14% each), and Piedmont (9%).

A breakdown by company size reveals a direct correlation between size and revenue generation. While the majority of firms fall into the lower turnover brackets (up to 10 million euros), accounting for 72% of sector employment, the larger companies generate 78% of total industry revenue. Larger size also correlates with higher average revenue per employee and stronger export orientation.

The attendance figures, high-quality audience and vibrant mix of technological and cultural content confirm GreenPlast 2025 as a key event for a plastics and rubber industry committed to sustainability.

As companies face geopolitical instability, raw material shortages and rising energy costs, events like GreenPlast play a vital role in creating value through innovation and networks. The event not only fosters targeted matchmaking but also encourages collaboration among start-ups, SMEs and large industrial players.

Its role as an enabler for industrial sustainability is now well established, supporting the sector in its ecological transition. Looking ahead, GreenPlast is set to further solidify its role as a hub for dialogue between industry, institutions and research. Its strategic placement in the trade fair calendar and link with The Innovation Alliance enhance its international relevance, positioning it as a reference point for circular economy policies.

The next edition is eagerly awaited by a supply chain increasingly called upon to deliver tangible solutions to today’s environmental and regulatory challenges. GreenPlast will continue

to be the place where plastics evolve into a sustainable future –driven by environmental responsibility, innovation and industrial competitiveness, both in Italy and abroad.

At GreenPlast, sustainability is not only about technology and industrial processes – it is also a matter of culture and expression. The Art & Plastics area provided a powerful bridge between the world of manufacturing and artistic language. Works by artists such as LadyBe, Pina Inferrera (Plastica d’Artista), topylabrys (Arte da mangiare mangiare Arte and Museo Acqua Franca), and the MAP – Museo Arte Plastica in Castiglione Olona gave new life and meaning to plastic materials. Through installations, performances and sculptures, plastics were transformed into metaphors for change – tools for reflecting on the role of materials in today’s society. A powerful and accessible visual language capable of raising professional awareness of ethical, environmental and social issues, and of telling new stories of circularity.

One of the core topics addressed was the role of chemical recycling in transforming plastics waste into valuable resources, with insights into cutting-edge technologies and sustainability projects focused on packaging reuse.

The “Art & Plastics” initiative portrayed the journey towards more responsible use of plastics through artistic expression.

Roberto Forresu elected President of Assogomma (the association of Italian rubber converters), and Massimo Centonze, elected President of Unionplast (the association of Italian plastics converters), have been appointed Vice-Presidents of the Federation under which the two member associations are grouped. Alongside them, Dario Baessato, Marco Bergaglio, and Edith Leoncavallo Bonizzoni – nominated by the newly appointed President – will serve as Vice-Presidents, forming the new Presidential Council for the next four years.

During the most recent General Assembly of the Federazione Gomma Plastica, Luca Iazzolino was elected President for the 2025–2029 term, thus assuming leadership of a sector that constitutes one of the cornerstones of Italian manufacturing, employing over 160,000

people across nearly 3,800 companies. Chief Executive Officer of Plastotecnica – a leading company based in Padua (Italy) specialising in flexible polyethylene packaging – Luca Iazzolino also serves on the Board of Directors of Corepla and is a member of the General Council of Confindustria Veneto Est. He is actively involved in issues related to recycling and the circular economy. He succeeds Marco Do, who led the Federation over the past four years.

Alongside the election of the President, the new executive team of the Federation was appointed for the 2025–2029 term. Roberto Forresu (Global Head of Industrial Relations & Employment Governance at Pirelli), elected President of Assogomma (the association of Italian rubber converters), and Massimo Centonze (CEO of ITP), elected President of Unionplast (the association of Italia plastics converters), automatically assume the role of Vice-Presidents of the Federation by virtue of their positions.

Luca Iazzolino, newly appointed President of Federazione Gomma Plastica for the 2025–2029 term.

They are joined by three additional Vice-Presidents appointed by President Iazzolino: Dario Baessato (General Manager of IVG Colbachini), Marco Bergaglio (entrepreneur at Pibergroup), and Edith Leoncavallo Bonizzoni (Europe Industrial Relations Director at Prysmian).

A team selected in the spirit of continuity and expertise, appointed by the member companies at a pivotal moment for the two industries represented by the Federation. These sectors are now called upon to navigate a series of complex challenges arising from an increasingly strained geopolitical landscape and an unfavourable regulatory framework, in addition to the upcoming renewal of the national collective labour agreement, which is set to expire at the end of 2025.

“The rubber and plastics sector is facing a period that is – and will continue to be – truly challenging,” stated the newly elected President, Luca Iazzolino. “The economic and geopolitical situation is highly uncertain, and the significant impact – both current and anticipated – of adverse regulations, primarily originating from the European level, is further undermining the competitiveness of businesses in both the rubber and plastics industries. This raises the risk of severe deindustrialisation.

The Federation aims to be a firm point of reference, providing unified representation for two sectors that are vital to Italy. It is committed to safeguarding and strengthening their future –both for the companies and the workers who are part of them.”

The rubber and plastics industries constitute a strategic value chain for the Italian economy — not only in their own right, but also as essential enablers for key industrial sectors such as food, automotive, construction, pharmaceuticals, and mechanical engineering. They play a decisive role in sustaining and enhancing the competitiveness of both the national and European manufacturing systems. Approximately 40% of total output is destined for export, underscoring the international relevance of the value chain, in which Italy ranks among the top three producers in Europe for both industries.

According to the latest data available for 2024, a total of 3,797 companies apply the National Collective Labour Agreement for the rubber and plastics sector, employing 164,317 workers. Of these, 29% are women and 71% are men. Geographically, there is a clear concentration in Northern Italy, which accounts for over 70% of both enterprises and employment in the sector. Lombardy remains the leading region, with more than 900 active companies. Central Italy accounts for approximately 17% of the sector’s workforce, while Southern Italy and the Islands represent the remaining 13%. The sector continues to play a pivotal role in several key industrial value chains, including food, automotive, construction, pharmaceuticals, and electronics, to name but a few. It also holds a crucial position in terms of Italy’s export performance.

Established in 2005 through the merger of Assogomma and Unionplast, Federazione Gomma Plastica is the employers’ association within the Confindustria system that advocates for the interests of the rubber industry, electric cable manufacturers, and the plastics and related materials converting industries—a sector that employs around 140,000 people in Italy. Through its two core components, Assogomma and Unionplast, the Federation draws on over 70 years of experience in promoting and safeguarding the industries it represents. Today, it brings together 499 member companies from the two sectors, employing more than 47,000 workers.

The primary objective of the Federation and its member associations is to meet the needs of affiliated companies by providing consultancy services, information, and publications, as well as by organising events, initiatives, and supporting strategic projects. The Federation is committed to promoting the growth and advancement of the sector, including through legislative engagement and the active monitoring of key industrial issues. In this regard, the Federation and its member associations serve as a key point of reference within the Confindustria system in their relations with European, national, and local institutions. The Federation also represents the sector in the negotiation and drafting of the National Collective Labour Agreement for the rubber and plastics industries. In terms of the number of employees represented, it ranks among the most significant sectoral federations within Confindustria.

Precision • Efficiency

The NOVA 5eT features the new TACT 5 control system, built for smart factories and designed to deliver a seamless user experience.

What sets it apart:

• EtherCAT architecture for faster, more responsive performance.

• Standardized EUROMAP 77/83 connectivity via OPC-UA.

• Precision control through advanced digital servo drives.

• Sleek and intuitive 15” LCD interface.

• Ultra-durable industrial-grade touch panel.

Find out more: www.negribossi.com

Protagonists in the compounding field and specialized in the production of co-rotating twin-screw extruders since 1962.

A report on the annual conference of the European Plastics Converters (EuPC). An opportunity to address the pressing issues currently facing the European plastics industry and to outline future strategies for action. The event also marked a renewed push for the association, now under new leadership.

By Luca Mei

The European Plastics Converters (EuPC) recently successfully concluded its Annual Conference gathering over 150 participants, including industry leaders, EU policymakers, investors, and key stakeholders across the plastics value chain. The conference served as a pivotal forum to discuss the future of plastics, balancing sustainability, competitiveness, and circularity.

A major highlight of the event was the official introduction of Federica Gallicchio as the new Director General of EuPC. Federica Gallicchio, who brings significant expertise in European policymaking and advocacy, was warmly welcomed by members.

“Federica brings invaluable expertise, having worked closely with EuPC members for many years. Her deep understanding of both the regulatory landscape and industry needs makes her the ideal person to lead EuPC into its next chapter,” stated Benoît Hennaut, EuPC President.

Under this year’s theme, the circular and competitive future of plastics, the discussions explored regulatory shifts, market chal-

lenges, and investment strategies shaping the industry evolution in Europe.

Head of Unit for Sustainable Products at DG GROW, Stefano Soro, outlined the EU’s strategic framework for competitiveness, presenting the EU’s strategy for a Clean Industrial Deal, emphasising circularity, access to raw materials, and the proposed Circular Economy Act to harmonize EU waste and recycling markets.

Executive Director of Repsol, Jaime Martín Juez, presented the company’s roadmap towards net-zero emissions by 2050, highlighting key investment projects in circular and bio-circular polymers and reinforcing Repsol commitment to the entire plastics value chain.

Head of Unit for Industry, Good, Energy, Customs and Origin at the European Commission’s Directorate General for Trade, Pauline Weinzierl, highlighted the industry’s need for clear and consistent regulation to support long-term innovation and investment, reinforcing the importance of a practical policy framework in achieving sustainability goals.

External Affairs Director of Amcor, Mike Baxter, addressed the economic realities of plastic film recycling, pointing out that while technologies exist, cost barriers and import competition hinder progress. He emphasized the need for verifiable souring of recycled materials to support the EU recycling sector.

Chair of Foundation Central Packaging, Gunda Rachut, stressed the urgency of harmonising EPR schemes and the benefits of a standardized, digital compliance system across the EU, enabling smoother market access and reduced reporting burdens.

The EuPC also launched the European Plastic Films (EuPF) sector group, bringingtogether companies from the flexible

packaging and films segment to strengthen policy engagement and innovation.

At its inaugural session, Renato Zelcher, CEO of Crocco and former EuPC President, was appointed as the first President of EuPF, declaring that “our goal is to actively contribute to the ongoing policy dialogue, promote circular solutions, and drive technological progress in line with the EU’s Green Deal objectives”.

During an exclusive gala dinner held as part of the EuPC Annual Event 2025, the Polymers for Europe Alliance proudly unveiled the winners of the 2024 Polymer Producers Awards. The ceremony honored the top-performing polymer suppliers who have demonstrated exceptional service and long-term commitment to the European plastics converting industry.

This year’s edition featured awards across more than 10 polymer categories, with winners selected through an independent customer satisfaction survey conducted among European polymer converters.

A special mention went to Vynova, who is the Overall Winner 2024, achieving an outstanding 96% satisfaction score, and to Repsol, awarded as Supplier of the Decade, recognizing its consistent excellence in quality, reliability, and its strong engagement with the European market since the inception of the initiative in 2015.

A joint meeting with Plastics Europe highlighted a renewed commitment to presenting a cohesive industry position and working collectively with institutional and societal stakeholders to advance shared goals for 2025 and beyond.

The success of the 2025 Annual Conference reaffirmed EuPC’s strategic role in tackling systemic challenges, fostering collaboration, and advancing the European plastics industry’s transformation. EuPC remains committed to advocating smart policies and circular solutions to secure a competitive, resilient future.

Federica Gallicchio

European Plastics Converters (EuPC) appointed Federica Gallicchio as new Managing Director. Federica Gallicchio joined EuPC in 2019 and has since built an impressive track record within the organisation. Initially working within the Packaging Division, she soon took on a leadership role in the Automotive Division, while also promoting innovation across the European plastics value chain through her involvement in several EU-funded initiatives in close cooperation with the major European R&D centres active in the plastics and composites sectors. With a strong background in advocacy,

Federica Gallicchio brings deep knowledge of European policymaking, having previously worked for a Member of the European Parliament active in the ENVI Committee. Her combined experience in public affairs and industry leadership makes her well-placed to guide EuPC at a time of unprecedented regulatory and technological change.

As Managing Director, Federica Gallicchio will focus on strengthening EuPC’s role as a key voice for European plastics converters, driving forward the organisation’s sustainability goals and reinforcing its advocacy efforts at the EU level.

“I am honoured to take on this role and to continue working with our members, partners, and stakeholders to help shape a more innovative, sustainable, and competitive plastics industry in Europe. The coming years will be critical for our sector, and I am fully committed to supporting EuPC in addressing both challenges and opportunities ahead,” commented Federica Gallicchio after her official appointment.

The 2024 consolidated financial statements approved by the Camozzi Group closed with revenue of 592 million euros, 81% of which were generated abroad and 19% in Italy. At an overall level, the breakdown of revenues by geographical area saw EMEA accounting for 51%, the Americas 16%, and APAC 14%. Ebitda, net profit and cash flow reached 102, 30.3 and 95 million euros respectively, while investments totalled 45 million euros. “In an economic and geopolitical context among the most complex in recent decades, we are proud to have closed 2024 with an overall positive result, which confirms the solidity of our strategic model. This model is based on broad sectoral and geographical diversification, the resilience of our people, and our ability to continue creating value even in challenging scenarios,” said Lodovico Camozzi, Chairman and CEO of the Group. “We look to the future with optimism and determination, continuing to invest in research and development, adopting and experimenting with cuttingedge technologies, and, above all, strengthening our direct presence in key global markets by placing human resources and local supply chains at the centre.”

Throughout 2024, Gruppo Camozzi continued to strengthen its “local to local” model through a direct, productive, and commercial presence in the world’s major economies (Europe, the United States, China, and India). This approach supports operational resilience by reinforcing relationships with both customers and local partners. The Group operates directly in 78 countries, with 25 production plants across Europe, the US, China, and India, and 39 subsidiaries or service centres. In recent years, industrial investments have been significantly increased to reinforce direct presence in the United States and major Asian economies. In particular,

Gruppo Camozzi consolidated its presence in India through a series of investments aimed at strengthening the local supply chain and expanding production capacity in the country. Among the most notable developments was the opening, in October 2024, of a new manufacturing plant, the launch of a training centre, and the progressive establishment of a local R&D hub for its subsidiary, Camozzi Automation.

The Group’s stability is further enhanced by its ability to diversify across a wide range of industrial sectors. Its portfolio ranges from the production of extremely large machinery to highly miniaturised, interconnected components, as well as advanced software and algorithms. Recently, through the work of Camozzi Digital & Mechatronics, the Group has developed a cognitive platform using generative artificial intelligence. This platform integrates certified production data and autonomously executes industrial processes, supporting operators and managers through natural language interaction.

Driven by the Camozzi Research Center (CRC), R&D investments amount to 3% of turnover and are focused on constantly identifying and testing key technological megatrends, with the aim of rapidly translating them into industrial solutions. Equally important is the centre’s ability to foster collaboration and synergies with universities and technology partners, including through participation in extended partnerships. Today, the Group is involved in four such partnerships, including MICS – Made in Italy Circular and Sustainable. This includes projects focused on advanced materials for additive manufacturing, robotic solutions aimed at maximising operator safety and wellbeing, and integrated electronic and mechatronic technologies.

Gruppo Camozzi is a leading Italian multinational company active in industrial automation, additive and subtractive manufacturing and the development of mechatronic solutions for the advanced factory.

Sacmi closes 2024 with sales revenues of 1.728 billion euros. Despite the complex international economic and geopolitical backdrop, the company’s economic and financial fundamentals proved to be sound. For the first time, net equity exceeded one billion euros (1.055 billion, +172 million compared to 2023) while Ebitda settled at over 323 million euros and Ebit at 236 million. Net profit exceeded 200 million euros. This is what emerges from the 2024 consolidated financial statements approved by the company. “2024 was a solid year that went beyond expectations”, pointed out the president of Sacmi, Paolo Mongardi. “Sacmi’s forward-thinking strategy rests on solid foundations and fully embraces the global drivers of digitalization and sustainability”.

The year saw a continued focus on the core businesses, confirming the sterling reputation and customers’ confidence in Sacmi products across all sectors. In parallel with the tobe-expected slowdown in the ceramic sector – the result of international tensions and the sluggish global construction market – the Rigid Packaging, Advanced Technologies, Packaging & Chocolate sectors all performed excellently, driven by highly dynamic markets receptive to innovation. Investment remained consistently high in 2024 at 71 million euros, in line with the previous year, with a strong focus on innovation (276 new patent applications in 2024 alone, over 6,200 in the group’s history) and training (over 94,000 hours). In parallel, Sacmi confirms its role as a key player in the manufacturing industry’s ecological transition: during the year it presented innovative firing processes (e.g.

electric), new process control solutions (thanks also to the acquisition of a majority share in Italvision in 2024), plus new eco-compatible standards, processes and materials in the packaging sector.

“Sustainability is the key to future competitiveness”, explained Paolo Mongardi. “We continue to invest in people by focusing on our values, which have consistently guided Sacmi to worldwide success”. The green commitment is also evident at governance level: the obligations of the new European CSRD (Corporate Sustainability Reporting Directive) were brought forward to 2024 and the first Group Sustainability Plan – an ambitious project that details actions and goals along the entire value chain, from suppliers to local communities – was drawn up.

In the ESG sphere, Sacmi has strengthened monitoring of indirect emissions linked to the use of its products and plants: this is part of an approach that centres on ecodesign and the entire product life cycle to ensure processes are truly circular and impacts are minimized. The share of self-produced renewable energy is also growing (2.6 million kWh), the goal being to progressively decarbonize production facilities. On the employment front, the Group had a total of 4,756 employees at the end of 2024. Close collaboration with universities and research facilities also continued, while ties with local communities became even stronger in 2024, with 90% of procurement networks consisting of local suppliers. Over the three-year period, the company also donated 2.4 million euros to healthcare, educational, safety, inclusion, sports and cultural projects.

Injection moulding machine manufacturer Engel is continuing to advance its internationalisation strategy and, as of 1 April 2026, will acquire its long-standing sales partner Roegele in Spain. This move strengthens Engel’s presence in the southwestern European market and marks the establishment of a new subsidiary: Engel Spain.

Spain is one of Europe’s most important plastics markets –both in terms of volume and revenue. Engel has a particularly strong presence in the automotive sector and ranks among the market leaders. Other sectors, such as packaging, medical, and technical moulding, also offer significant growth potential. Engel Spain will be integrated into the global Engel Group as an independent subsidiary. All Roegele employees will be retained. This integration fits seamlessly into Engel’s strategic focus: our customers’ needs are our top priority –which is why Engel continues to invest in customer-centric structures worldwide. Strengthening the local service and application technology teams will enable Engel to deliver targeted added value.

The site in Barcelona – Roegele’s current headquarters – will be upgraded and, thanks to its generous size, offers excellent conditions for future development. The approximately 600 sqm production area offers a wide range of potential uses. With the establishment of Engel Spain, Engel is now represented by its own subsidiaries in all major markets in southern and western Europe. Direct proximity to customers, local expertise, and close integration with Engel’s European network will enable even more focused support and

continued development of the market.

Engel recently has also opened a new Tech Centre at its site in Frauenfeld (Switzerland). With this new technology centre, the Austrian injection moulding machine manufacturer is making a targeted investment in customer support, training and further education, as well as technological development –particularly in the highly regulated medical technology sector. The new Tech Centre includes modern training and office facilities as well as a hands-on application centre. At the heart of the installation are two Engel injection moulding machines: a tie-bar-less victory electric in medical configuration with a clamping force of 500 kN and a fully electric e-mac with 1,000 kN, equipped with an easix articulated robot. Both machines are fitted with the full range of digital assistance systems from the Engel iQ product family. These smart solutions help processors increase process stability and efficiency while significantly reducing production costs. With the new Tech Centre, Engel is pursuing several goals. Customers can explore new technologies under realistic conditions, test their own applications, and develop tailored production solutions. At the same time, the Tech Centre serves as Engel’s first medical competence centre outside of its production plants – a testament to the company’s strong commitment to the expertise of its subsidiaries. Another key focus is the newly designed training centre. Engel offers both a comprehensive training programme and customised advanced training sessions, including productionaccompanying instruction.

Roegele, in the large picture, will become Engel Spain from 1 April 2026; in the box Engel Switzerland, where the new Tech Centre was opened.

Petrochemicals and polyolefins producer Borouge has announced a series of strategic expansion projects that will increase its capacity by more than 200,000 tonnes per year and generate an Ebitda between 165 and 200 million dollars. The company has awarded two major contracts aimed at boosting the nameplate capacity of its second ethane cracker (EU2) and the fourth and fifth polyethylene units (PE4 and PE5).

Linde Engineering has been awarded a contract for FrontEnd Engineering Design (FEED) services to upgrade Borouge’s second ethane unit (EU2) with an additional capacity of 230,000 tonnes per annum. This strategic project is expected to increase the EU2 cracker’s capacity by 15%, delivering significant financial gains upon completion in the fourth quarter of 2028. The ethane used as feedstock for the EU2 cracker is supplied by Adnoc Gas and Adnoc Refining, ensuring an integrated and reliable supply chain.

Target Engineering Construction Company has been awarded an engineering, procurement, and construction (EPC) contract for the expansion and refurbishment of its PE4 and PE5 production units, following a competitive bidding process. This enhancement will increase their nameplate capacity from 540,000 to 700,000 tonnes per annum each. Leveraging Borealis Borstar polyethylene technology, the project is scheduled to be ready for start-up in the first quarter of 2027.

“By increasing production at our EU2, PE4 and PE5 units, as well as delivering the Borouge 4 mega project, we are strategically positioned for accelerated growth. The expansions of our ethylene and polyethylene capabilities will enable Borouge to meet growing market demands, unlock new

revenue streams, and further strengthen our global market position”, Hazeem Sultan Al Suwaidi, CEO of Borouge, said. Since 2001, Borouge has increased its annual production capacity tenfold, reaching 5 million tonnes per annum and positioning itself among the top five polyolefin producers in the Middle East and Asia Pacific. Together with the Borouge 4 mega project, these expansion projects, once fully ramped up, will increase the company’s annual total polyolefins production capacity to over 6.6 million tonnes per annum by 2028. These projects are driving significant value to the UAE’s economy through Adnoc’s In-Country Value (ICV) program, supporting economic and industrial growth.

The Company’s major shareholders, Adnoc and OMV have proposed the combination of Borouge and Borealis, along with the acquisition of Nova Chemicals, to create Borouge Group International. These transformational deals will create the world’s fourth largest polyolefin company, a 60 billion dollars global polyolefins leader with a substantial capacity of 13.6 million tonnes across 62 plants spanning North America, Europe and the Middle East – more than doubling Borouge’s current capacity. Borouge Group International represents a new era of scale, growth, innovation and shareholder value. The new entity intends to offer an attractive estimated total dividend of 2.2 billion dollars post-closing of the transaction, equivalent to a minimum of 16.2 fils per share dividend, annually from 2026 to 2030.

These Borouge projects add value to the UAE economy through Adnoc’s In-Country Value (ICV) programme, supporting the country’s economic and industrial growth.

The European Commission recently presented an Action Plan for the Chemicals Industry to strengthen the competitiveness and modernisation of the EU chemical sector. The Action Plan addresses key challenges, namely high energy costs, unfair global competition, and weak demand, while promoting investment in innovation and sustainability. The Action Plan is accompanied by a simplification omnibus on chemicals – the sixth that the Commission has presented in this mandate so far, the so called Sixth Omnibus – to further streamline and simplify key EU chemicals legislation, alongside a proposal to strengthen the governance and financial sustainability of the European Chemicals Agency (ECHA).

The Action Plan proposes four measures. As for resilience and level playing field, the Commission will establish together with Member States and stakeholders a Critical Chemical Alliance to address the risks of capacity closures in the sector. The Alliance will identify critical production sites needing policy support and tackle trade issues like supply chain dependencies and distortions. The Commission will also swiftly apply trade defence measures to ensure fair competition, while expanding chemical import monitoring through the existing Import Surveillance Task Force. The Alliance will align investment priorities, coordinate EU and national projects, including Important Projects of Common European Interest (IPCEIs) and support EU critical production sites to boost innovation and regional growth.

On the subject of affordable energy and decarbonization, the Commission will implement at full speed the Affordable Energy Action Plan to help reduce high energy and feedstock costs. It has introduced clear rules for low-carbon hydrogen and will update state aid to lower electricity costs for more chemical producers by the end of the year. The plan also encourages

using clean carbon sources like carbon capture, biomass, and waste, alongside support for renewables. A public consultation on improving chemical recycling has also been launched. Concerning lead markets and innovation, the Action Plan highlights fiscal incentives and tax measures to boost demand for clean chemicals. The upcoming Industry Decarbonisation Accelerator Act will set EU content and sustainability rules to support market growth and clean technology investment. The upcoming Bioeconomy Strategy and Circular Economy Act will boost the EU’s resource efficiency, chemicals recycling, and strengthen the market for bio-based and recycled alternatives to fossil-based inputs. The Commission will also launch EU Innovation and Substitution Hubs and mobilise EU funding under Horizon Europe (2025–2027) to accelerate the development of safer, more sustainable chemical substitutes. Finally, the plan provides for interventions on per- and polyfluoroalkyl substances (PFAS), reaffirming the Commission’s commitment to minimise PFAS emissions through a robust, science-based restriction, while ensuring continued use in critical applications under strict conditions where no alternatives are available which will be proposed swiftly after ECHA’s opinion. The Commission will also invest in innovation, promote remediation based on the polluter pay principle, and prioritise the development of safer alternatives.

The EU chemical industry is the fourth largest manufacturing sector, with 29 000 companies providing 1.2 million direct jobs and supporting 19 million across supply chains. The European chemicals industry action plan builds on the Competitiveness Compass and Clean Industrial Deal, while the simplification package delivers on President Ursula von der Leyen’s commitment to simplify EU laws and cut administrative burdens, helping businesses innovate and grow.

Resilience and level playing field; affordable energy and decarbonisation; lead markets and innovation; taking action on per- and polyfluoroalkyl substances (PFAS): these are the measures proposed by the European Commission to strengthen the competitiveness and modernisation of this sector.

Miriam Olivi was appointed general manager of Frigosystem Corema, a manufacturer of industrial chillers and temperature controllers, after 18 years in sales at the company, during which time she made a decisive contribution to spreading the brand globally and building an international sales network. The general manager is already active in her new role and is flanked by a team of new employees. Together, they aim to structure the company in the best possible way and guide it towards a new course of technological and commercial growth and development. Miriam Olivi has also been president of the newly founded association Women in Plastics Italy for some months now.

After a long experience in sales and commercial management,

was appointed General Manager of Frigosystem Corema.

The Board of Directors of IMS Technologies, a company based in Calcinate (Bergamo, Italy) and part of the Coeclerici Group, active in the design and manufacture of machinery for packaging and converting through its subsidiaries Goebel IMS, Leam IMS and Rotomac, has appointed Ivo Conti as the new Chief Executive Officer, with extended responsibility across all group companies. This appointment marks the beginning of a new chapter

for the Group, which is strengthening its industrial strategy by placing a renewed focus on managerial expertise, innovation, and global market presence.

Born in Brescia in 1971, Ivo Conti holds a degree in Economics and Business and brings with him an extensive professional background across international industrial and financial sectors. Since 2008, he has served as CEO of Nemas Holding and

has held senior executive positions in companies such as CGA Technologies, Officine Tecnosider, Evraz Palini e Bertoli, Trasteel International, and the Riello Group, operating in Italy, the United Kingdom, and Switzerland. A specialist in turnaround scenarios and sustainable growth, the new Chief Executive Officer has proven expertise in managing industrial plans, building high-performance teams, and engaging effectively with stakeholders.

Maag Group announced the completion of the Sikora acquisition. The aim of the partnership is to leverage joint synergies in a targeted manner and to strengthen the position of both companies in the long term. With the completion of the transaction, Maag and Sikora will now combine their expertise to leverage new technological and geographical synergies, aiming at offering innovative solutions while providing expanded global support to customers.

“We are very pleased about this partnership. By combining our strengths and expertise, we are ideally positioned to create additional value for our customers, drive innovation in a targeted manner, and promote the long-term growth of both companies”, Ueli Thuerig, President of Maag Group, explained.

Haitian and Haier

“We are proud to be officially part of the Maag family now. This partnership goes far beyond standard cooperation – it is based on a shared commitment to innovation, entrepreneurial spirit, and sustainable action, which form the foundation for long-term success. It marks an important step in our

shared future, opens up a wide range of opportunities, and strengthens our ability to develop innovative solutions. We look forward to working with Maag to continue our success and growth in a sustainable way”, Christian Frank, CEO of Sikora, commented on the closing.

Haitian Group and Haier Smart Home recently signed a global strategic cooperation agreement. This event marks a new milestone in their 30-year partnership, expanding into a broader global strategic collaboration. Haitian and Haier will deepen their integration of advanced technologies such as intelligent manufacturing, big data, and artificial intelligence. The partnership aims to explore customized services that meet full-scenario user demands and to jointly build a co-creative and mutually beneficial ecosystem.

Haitian will provide Haier with worldclass technical support and efficient supply chain services, leveraging its global network to support Haier’s localized smart manufacturing and agile response in overseas markets. Additionally, the two parties will cooperate on talent development, jointly cultivating skilled professionals in intelligent manufacturing to accelerate the implementation of ecosystem capabilities. Since Haier purchased its first Haitian

Haitian and Haier have enjoyed a partnership spanning more than 30 years, during which time Haitian has supplied Haier with over 500 injection moulding machines; this agreement extends the partnership in the long term.

injection moulding machine in 1995, Haitian has delivered over 500 highperformance machines to Haier. Haitian will continue to support Haier in building intelligent and connected factories, and in establishing a digitalized and intelligent production

system. This upgraded strategic collaboration will further integrate the global resources of both parties and lay a solid foundation for jointly building a one-stop intelligent manufacturing service chain in international markets.

DOW announced that, as a follow-up to the European asset actions first announced in April 2025, its Board of

Directors has approved the shutdown of three upstream assets in Europe, in addition to certain corporate and other assets across the Company’s global asset footprint: ethylene cracker in Böhlen, Germany; in the fourth quarter 2027, chlor-alkali and vinyl (CAV) assets in Schkopau, Germany; in fourth quarter 2027, and basics siloxanes plant in Barry, United Kingdom in mid-year 2026. The shutdown of upstream assets in Europe will right-size regional capacity, reduce merchant sale exposure, and remove higher-cost, energy-intensive portions of Dow’s portfolio in the region. This will improve the company ability to supply profitable derivative demand and optimize margins. In April 2025, the Company announced it had identified three assets in Europe for action across all of its operating segments. On June 30, 2025, Dow’s Board of Directors approved

Songwon recently completed its planned CFO succession. Hans-Peter

Wüest, with Songwon for 19 years and CFO of Songwon Industrial Group for

restructuring actions to rationalize the Company’s global asset footprint, including these three assets as part of its European review, and certain corporate and other assets.

Dow’s actions to shut down these assets will result in an operating Ebitda upliftbeginning in 2026, ramping to 50% of the approximate 200 million dollars target by year-end 2027 with full delivery by 2029, with a cash outlay of approximately 500 million dollars over four years. The shutdown of the assets is expected to begin in mid-2026 and is estimated to be complete by the end of 2027, with potential decommissioning and demolition to continue into 2029 as needed. Approximately 800 Dow roles will be impacted as a result of these actions, which will be in addition to the planned reduction of 1,500 positions globally.

14 years, has been a key contributor to Songwon’s growth and global expansion. He stepped down from his role as CFO on 1 April 2025, as Songwon’s succession planning process concluded. He has also stepped away from the Executive Committee but will continue to support the organization as a valued member of Songwon’s Board of Directors.

Johannes Honegger, with Songwon since 2013 and closely involved in executing its financial strategy with Hans-Peter Wüest, succeeds him as CFO and member of Songwon’s Executive Committee, reporting directly to the Group CEO. Drawing on his solid expertise and extensive knowledge of Songwon’s operations, he ensures a seamless transition, maintaining strategic continuity and continuing to build on the company’s solid financial foundation.

Johannes Honegger

The competitiveness of the European chemical industry continues to be under serious pressure, with no sign of improvement early in 2025, neither on the cost side, nor on the demand side. This was according to the report of Cefic, the European Chemical Industry Council, on the first three months of 2025.

Looking at the first quarter of 2025, the EU27 chemicals capacity utilisation stands at 74%, significantly below the EU’s long-term average and trailing the United Sates average since third quarter of 2022. Weak demand and declining business confidence continue to challenge the EU27 chemical industry.

Additionally, gas prices remain 3.3 times higher than in the United States, rendering them uncompetitive on a global scale.

While a significant increase in trade surplus was observed in 2024 in comparison to 2023, driven by lower import rates due to lower domestic demand, this trend risks reversing. This is based on data from first two months of 2025, as the European Union chemicals trade surplus decreased by 25% due to increasing imports.

Recovery remains distant, with demand growth constrained by weak economic conditions in Germany and the USA. The business trade environment for

At its recent 90th annual general meeting, British Plastic Federation’s (BPF) elected Martin Hitchin (Chief Executive of Rehau UK, Ireland and Scandinavia) as the new president of the trade association. He follows the outgoing president, Nigel Flowers (Sumitomo (SHI) Demag), who has served for the past two years. BPF General Director Philip Law thanked Nigel Flowers for his valuable contribution during his tenure, especially his contribution to the work done on improving productivity within the UK plastics industry. Law stated: “Nigel has been a strong supporter of the BPF and a fountain of knowledge, especially in the area of productivity, where he has done an outstanding job. His advice and insights have been very helpful to us, and I am also grateful for the time he has taken to chair several of our events in fields related to his expertise”.

Nigel Flowers started his plastics career at Hozelock before joining Sumitomo (SHI) Demag in 1985, ultimately becoming its managing director in 2006. He has been a member of the BPF’s Education & Skills Committee for many years and also chairs the

BPF’s Productivity Committee. Flowers declared: “I have enjoyed immensely my time as president of the BPF and I would like to take this opportunity to warmly welcome Martin Hitchin into the role. He has experience in many areas of plastic processing as well as a background working with windows, pipes, the automotive sector – and also for recyclers. His diverse background means he brings a wealth of knowledge that reflects the breadth of the BPF itself”.

Martin Hitchin has worked in the manufacturing and construction sector for 35 years. He joined Rehau in 1988 and worked his way up, being appointed CEO in 2007. He is also the vice Chair of New Model Institute for Technology and Engineering (NMITE), a start-up engineering university in Hereford.

Newly elected BPF President Martin Hitchin said: “I have been involved with the BPF for many years and am aware of the numerous strands of work it does to support our industry. Input from the BPF Council helps to shape priorities of the organisation and ensure they reflect the various requirements of the wider industry. I am honoured to have been voted in as president and look forward to working with the BPF to deliver more

European chemical companies faces high risks due to the unprecedented, global trade disruptions caused by US tariffs. Consequently, EU27 chemicals output is projected to grow from 2.5% in 2024, to probably less than 0.5% in 2025. For the European chemical industry council urgent and concrete actions are required to create a business environment that allows business to leverage their strengths and enables Europe to achieve its objectives.

The European chemical industry has faced a challenging start to 2025. The competitiveness of the European chemical industry continues to be under serious pressure, with no sign of improvement early in 2025.

successes as we face the challenges ahead”.

Law added: “I am extremely pleased to have Martin Hitchin as the new president of the British Plastics Federation. He has had a distinguished career and is an invaluable member of the BPF Council. I am sure that he will play a key role in ensuring the BPF continues to provide value to its members while supporting the wider industry”.

In 2024, BPF welcomed 54 new members, taking membership comfortably over 600 companies from across the entire UK plastics supply chain.

Thermoforming of plastic parts Deburring of stamped part EMBOSSING PROCESS DRYING OF PLASTIC PELLETS

Crystallization and drying of PET, PPS, PLA Curing of paints on plastic

Softening process Forming process Bending process Vulcanization processed in rubber industry

Drawing of plastic tubes SEALING PROCESS GLUING PROCESS

www.heliosquartz.com

Helios Quartz Group SA

Via Roncaglia 20 6883 Novazzano - Switzerland

Tel. +41 ( 0 ) 919233555/6 Fax +41 ( 0 ) 919233557

swiss@heliosquartz.com

Helios Italquartz S.r.l. Via delle Industrie 103/A 20040 Cambiago - Milano - Italy

Tel. +39 02 95 34 93 18 Fax +39 02 95 34 50 85 italy@heliosquartz.com

th Annual Report of Assobioplastiche