Enhance fleet management through innovation and sustainability

As a global leader in IoT and connected transportation, Geotab processes and analyses data from over 4 million connected vehicles, generating over 75 billion data points per day. It’s a huge amount of data, and it is most powerful when we have the right tools to securely and efficiently manage it. That’s why we have partnered with Google to leverage Google Cloud’s data analytics and machine learning solutions.

Championing Innovation and Sustainability

Geotab has been awarded two Google Cloud Customer Awards for its achievements in the transportation sector. Recognition in both the Cross Industry and Sustainability categories underscore Geotab’s successful use of Google Cloud’s analytics to innovate and drive sustainable practices in fleet management.

Kirsten Kliphouse, the President of Google Cloud Americas says that the Awards are an opportunity to recognise the most innovative, technically advanced, and transformative cloud deployments across industries globally built on their platform.

In her congratulatory message to Geotab, she acknowledged Geotab’s role in “serving as an innovator for the industry”, which also highlights Geotab’s innovative integration of data to revolutionise the transportation sector, leading to transformative impacts across organisations and customers around the world.

Empowering sustainable transportation

As the world’s premier EV telematics provider, Geotab has demonstrated its commitment to reducing emissions through its Electric Vehicle Self-Assessment (EVSA) tool, which won Google Cloud’s Award for Sustainability.

The tool provides tailored EV recommendations to support businesses and governments in transitioning to electrified fleets. For two consecutive years, Geotab was also identified as a Cross-Industry winner impactful transformation facilitated by Google Cloud. The award also acknowledges the launch of the Intelligent Transportation Systems (ITS) and its flagship transportation analytics platform Altitude.

Altitude has been pivotal in supporting government agencies by offering actionable, privacyconscious data insights for city planning and transportation network enhancements.

Strong synergy of Geotab and Google Cloud show great potential

As a valued partner in the Google Cloud Ready - Sustainability validation program, Geotab plays a crucial role in accelerating sustainability programs and informing strategic decisions for future developments.

Geotab’s collaboration with Google Cloud delivers significant benefits, including real-time improvements in driver safety and behavior, advancement of sustainability goals, enhanced productivity and significant cost savings.

This partnership not only redefines fleet management standards but also illustrates the impactful role of technology in fostering a more sustainable and efficient transportation industry.

An industry-leading solution

Geotab’s partnership with Google demonstrates the company is at the forefront of leveraging data analytics and machine learning to enhance fleet management, drive sustainability and create safer transportation systems worldwide.

By integrating Google Cloud’s advanced analytics with its telematics expertise, Geotab is confident of continuing its lead in the development of sustainable transportation solutions, demonstrating the profound impact that innovative technology can have on the transportation system today.

Delivering for the next generation

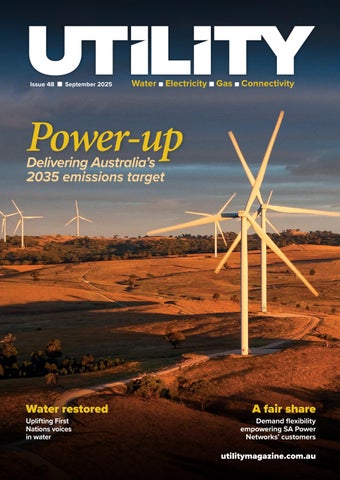

We’re now rmly in the second half of 2025, and 2030 is no longer a distant target, but a deadline looming large. Delivering an almost complete overhaul of our energy system is a colossal undertaking, yet I’m constantly in awe of how far the sector has come.

While Australia powers towards 82 per cent renewables, the AEMC is rolling out new rule changes to ensure that tomorrow’s energy system is one that works for everyone.

Over in the water sector, signi cant updates to the Australian Drinking Water Guidelines have now come into e ect, as have the amendments to the Security of Critical Infrastructure Act 2024, which transferred and upli ed security obligations for telecommunications providers.

Australia’s water, energy and communications sectors are on a path towards a brighter future, but moving forward means navigating increasingly complex challenges and complete unknowns.

In our September 2025 edition Utility, we’re celebrating some of the leaders, innovators and workers who are the champions of this change, and in these pages you’ll nd expert advice and thought-leading content from some of the brightest minds in the sector.

Before we take a look at what’s going on here in Australia, Utility took a trip abroad to Aotearoa New Zealand and caught up with the team at Watercare, who are in the middle of deploying an industry-leading sewer monitoring project.

is evolving energy systems means distribution networks are balancing the need to encourage

electri cation, while keeping prices low and ensuring that the grid remains secure in the face of new demand.

We caught up with SA Power Networks, who took us through the state’s world-leading exible exports program, and shared some valuable learnings as the utility embraces the future of the distribution network and it’s ever-evolving role.

‘An era of unprecedented growth’ has become a bit of a catch phrase, but it really is a time of change and evolution for the sector – and as always, its such a privilege to share the incredible work that utilities from all sectors are doing to build a secure and sustainable future.

While the world is throwing many hurdles at our essential service providers, it is truly encouraging to see them rise to the challenge, and deliver a reliable, a ordable and sustainable future.

Australia as we know it would not be the same without the important work you do – and it’s a privilege to be able to share your knowledge so that utilities from all sectors can learn and grow together.

ART

Katie Livingston, Editor

Drop Katie a line at katherine. livingston@primecreative.com.au or feel free to call on 03 9690 8766 to let us know what you think. Don’t forget to follow Utility on social media – find us on LinkedIn, X and YouTube.

John

PUBLISHER

Sarah Baker

0413 475 078

CLIENT SUCCESS OFFICER

Louisa Stocks

Scan to subscribe to Utility’s weekly newsletter –delivered to your inbox every Thursday morning.

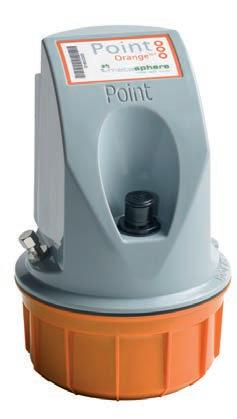

Right-Sized Solutions. Real Problems Solved. Outcomes Delivered.

We go beyond installation to ensure your investment in digital metering translates into measurable outcomes.

OUR FOCUS

Solving real operational challenges, from leak detection to billing accuracy, with right-sized, scalable solutions.

WE MANAGE

The complexity, so you stay focused on your community. Most importantly, we work with you to define success upfront and ensure benefits are realised, not just assumed. From day one to long after rollout, we’re your partner in outcome-driven digital metering.

From waste to opportunity

Australia’s waste streams could power a cleaner future – if policy, infrastructure and investment align to unlock biomethane’s full potential.

is chemically identical to fossil natural gas but renewable in origin. Image: manfredxy/stock.adobe.com

As Australia intensi es its e orts to decarbonise the economy, attention is turning to solutions that can deliver immediate impact without requiring a complete overhaul of existing infrastructure. One such solution is biomethane—a renewable gas derived from organic waste that can be injected directly into the country’s existing gas networks. e 2025 report by Blunomy, commissioned by Energy Networks Australia, outlines the scale of the opportunity biomethane presents, particularly for hard-to-abate sectors such as manufacturing, transport, and heavy industry.

Biomethane is produced through anaerobic digestion, a process that breaks down organic materials like food waste, agricultural residues, and livestock by-products in the absence of oxygen. e result is a gas that is chemically identical to fossil natural gas but renewable in origin. is compatibility with existing gas infrastructure makes biomethane a uniquely practical decarbonisation tool. It can be used in homes, businesses, and industrial facilities without the need for new pipelines or appliances, o ering a seamless transition to cleaner energy.

e report estimates that Australia has the technical potential to produce around 400 petajoules (PJ) of biomethane annually from existing feedstocks. is gure is signi cant, as it represents nearly the entire volume of current fossil gas consumption on the East Coast. Even the more conservative estimate of recoverable potential— between 123 and 308 PJ—would be enough to replace a substantial portion of the gas currently used in industrial and commercial applications. ese feedstocks include food and garden organics, cereal and non-cereal crop residues, sugarcane by-products, and livestock waste, all of which are already present in Australia’s waste streams and do not compete with food production.

One of the most compelling aspects of biomethane is its cost pro le. e report nds that the rst 50 PJ of biomethane could be delivered at a cost ranging from $10 to $27 per gigajoule (GJ), depending on the type of feedstock and the e ciency of recovery practices. ese costs are expected to decline over time as technology improves, supply chains mature, and supportive policy frameworks are introduced. Waste-based feedstocks,

such as food and garden organics, tend to be more coste ective due to their abundance and the lower processing requirements. Agricultural residues, while slightly more complex to manage, also o er strong potential, particularly in regional areas where they are readily available.

Beyond its role as a clean energy source, biomethane o ers a range of system-wide bene ts. It supports improved waste management by diverting organic material from land lls and wastewater systems, reducing methane emissions and creating value from what would otherwise be discarded. It also enhances Australia’s fuel security by enabling domestic production of renewable gas, reducing reliance on imported fuels. e anaerobic digestion process produces digestate, a nutrient-rich by-product that can be used as a soil conditioner in agriculture, further closing the loop on resource use. Additionally, biomethane production can stimulate regional economies by creating jobs in feedstock collection, processing, and plant operation.

e report also highlights the potential for biomethane to integrate with other emerging technologies. For example, the carbon dioxide captured during biomethane production can be used in Power-to-Liquid systems to create low-carbon fuels for aviation, shipping, and heavy road transport. is synergy between biomethane and other clean energy pathways enhances its strategic value and positions it as a cornerstone of a diversi ed decarbonisation strategy.

Despite its promise, the development of a biomethane industry in Australia faces several challenges. Chief among them is the lack of a clear and supportive policy framework. While other countries have introduced national targets, subsidies, and regulatory incentives to stimulate biomethane production, Australia has yet to implement similar measures. e report calls for biomethane to be included in existing decarbonisation schemes, such as the Hydrogen Headstart Program and the Hydrogen Tax Credit Incentive Scheme. It also recommends the establishment of national production targets, streamlined project approvals, and investment in feedstock recovery infrastructure.

Biomethane

Another key barrier is the competition for feedstocks. Many of the organic materials suitable for biomethane production are also in demand for composting, animal feed, or other bioenergy applications. is competition can drive up costs and limit availability. e report suggests that better coordination across sectors, along with investment in logistics and processing capacity, will be essential to ensure that feedstocks are used e ciently and sustainably.

e logistics of collecting and transporting feedstocks also present a challenge, particularly in remote or sparsely populated regions. Building reliable supply chains will require investment in infrastructure and workforce development, as well as partnerships with local governments, farmers, and waste management companies. Public awareness and acceptance will also play a role, as communities need to understand the bene ts of biomethane and support its integration into local energy systems.

e report emphasises that biomethane is not a silver bullet, but rather a critical piece of the broader decarbonisation puzzle. It is particularly well-suited to sectors that are di cult to electrify, such as hightemperature industrial processes, heavy transport, and

combined heat and power systems. In these contexts, biomethane can provide a low-emissions alternative to fossil gas without compromising performance or reliability.

Looking ahead, the report outlines a vision for a thriving biomethane industry that supports Australia’s net-zero goals while delivering economic, environmental, and social bene ts. is vision includes a mix of small- and large-scale production facilities, integrated with existing gas networks and supported by robust policy and regulatory frameworks. It also includes the development of new markets for biomethane-derived products, such as low-carbon fuels and renewable chemicals.

In conclusion, the Blunomy–ENA report makes a compelling case for biomethane as a ready-to-deploy solution for decarbonising Australian industry. With the right mix of policy support, infrastructure investment, and stakeholder collaboration, biomethane could transform waste into a valuable energy resource, reduce emissions across multiple sectors, and help Australia build a cleaner, more resilient energy future. e opportunity is real, the technology is proven, and the time to act is now. U

The future of recycled water

World-first research has shown purified recycled drinking water use is set to double by 2050.

An Australian-led research project has mapped out the future of puri ed recycled water across the world, with predictions it will be consumed by more than 55 million people over the next 25 years.

e rst of its kind project was led by the Water Services Association of Australia (WSAA) following more than two years of research and consultation with the water sector across the world. It shows that more than 100 cities could be using puri ed recycled water as part of drinking water supplies by 2050, with the number of people consuming it also expected to double.

e ndings come as a number of states and cities across Australia are now exploring future water sources in the face of growing populations, variable rainfall brought on by a changing climate, and the comparative cost of new water sources.

A series of interactive online maps have been developed to chart the global growth of puri ed recycled water systems. Despite the fact that the technology has been proven for decades, puri ed recycled water schemes are only now starting to be rolled out at scale.

ere were a handful of operating systems in use worldwide before the 2000s and that number has steadily increased over the past two decades. More than 35 cities or locations have schemes that are operating and providing clean and safe water to more than 30 million people.

e technology that is used to make puri ed recycled water clean and safe to drink is overseen by numerous

health regulators and water authorities around the world. It uses multiple barrier treatment systems and advanced puri cation technology so the water can be added to drinking water supplies.

Places like California, Texas, and Virginia in the US are already using recycled water to augment their drinking water supplies. While other major cities and regions such as Singapore, Essex in the UK, Barcelona in Spain and Oland in Sweden are also using puri ed recycled water sources.

California and South Africa emerge as two major regions where puri ed recycled water systems are set to substantially increase over the coming decades. However, other major cities and regions are also set to embrace the technology at scale including Florida and Arizona, Bangalore in India, Leon in Mexico and Hampshire in the UK.

Closer to home, Perth has an operating puri ed recycled water scheme supplying groundwater sources, while a scheme in south-east Queensland is available as part of the region’s drought plan.

Sydney has built a demonstration plant as part of a major community education campaign, along with Auckland following a citizen’s assembly which backed puri ed recycled water as its preferred new future water source. e interactive maps chart the use of puri ed recycled water from the early 1960s out to 2050, based on the number, location and types of systems being built and planned. U

Water for life

Water is a shared and precious resource, however, Traditional Owners have rarely been consulted about how water is managed and used. The Victorian Government is now working in partnership with First Nations Australians to involve them in decisions around water management.

Water is not merely a resource to be allocated, consumed, or regulated. It is a living entity, a spiritual force, and a cultural cornerstone.

For Traditional Owners across Victoria, water is inseparable from Country, identity, and law. e

Victorian Government’s Water is Life: Traditional Owner Access to Water Roadmap represents a landmark policy framework that seeks to restore justice, authority, and selfdetermination to Traditional Owners in the realm of water management. Developed through extensive engagement with Traditional Owner Nations, the roadmap outlines a comprehensive strategy to embed cultural values, increase access to water, and transform governance systems that have historically excluded Indigenous voices. e roadmap is structured in two distinct but interrelated sections. e rst articulates the Victorian Government’s commitments and policy directions, while the second presents statements from Traditional Owner Nations, each expressing their unique relationships with water and their aspirations for the future. is dual structure re ects the roadmap’s foundational principle: that water justice must be co-designed, culturally grounded, and responsive to the

diverse needs of Traditional Owners. Participation in the roadmap’s development is not interpreted as endorsement of the colonial water regime, nor is absence from the process taken as a lack of interest. Rather, the roadmap acknowledges the complexity of engagement and the importance of respecting cultural authority and autonomy.

At its core, the roadmap is a response to the enduring impacts of colonisation, which have systematically disrupted Traditional Owners’ relationships with water. ese disruptions are not con ned to historical injustices; they persist in contemporary water policy, planning, and allocation systems that continue to marginalise Indigenous knowledge and rights. e roadmap seeks to address these inequities by establishing pathways for Traditional Owners to hold and manage water, participate in decision-making, and shape the future of water governance in Victoria. e concept of cultural water is central to this vision. Unlike Western paradigms that treat water as a commodity or utility, the cultural water paradigm recognises water as a living entity with intrinsic value and agency. It is not separate from Country—it is part of Country. Traditional Owners hold the cultural authority to speak for water

within their respective Nations, and this authority is grounded in law, lore, and generations of custodial practice. e roadmap a rms this authority and commits to embedding it within the structures and processes of water management.

e bene ts of increasing Traditional Owner access to water are multifaceted and far-reaching. Holding and managing water contributes to improved wellbeing, not only through physical health but also through cultural revitalisation, mental resilience, and community cohesion. It enables the development of cultural economies that are self-determined, sustainable, and rooted in traditional knowledge systems. It enhances ecological outcomes by integrating Indigenous ecological knowledge into waterway management, environmental ows, and catchment planning. And it promotes social equity by addressing systemic barriers and fostering inclusive governance.

e roadmap outlines a series of commitments across short, medium, and long-term horizons. In the immediate term, the government pledges to establish governance structures that enable Traditional Owners to lead water planning and decision-making. is includes providing funding and resources to support capacity-building,

At its core, the roadmap is a response to the enduring impacts of colonisation, which have systematically disrupted Traditional Owners’ relationships with water. “

developing tools and guidelines for integrating cultural values, and ensuring that engagement is meaningful and sustained. Over the medium term, the roadmap envisions increasing water entitlements for Traditional Owners through reallocation, purchase, or new licensing arrangements. It also supports the delivery of cultural ows—water that is allocated speci cally to support cultural practices, ecosystems, and community wellbeing. In the long term, the roadmap aims to transform water governance to re ect shared custodianship, establish enduring cultural water economies, and secure access and rights for future generations.

ese commitments are not static. ey are designed to evolve through ongoing dialogue, co-design, and accountability. e roadmap acknowledges that some

policy options may not be appropriate or acceptable to all Traditional Owners, and it emphasises the importance of exibility, responsiveness, and transparency. It calls for decisions to be led by those with the cultural authority to speak for Country, and it recognises that genuine reform requires more than technical adjustments—it demands a fundamental shi in values, relationships, and power dynamics.

e challenges ahead are signi cant. Existing water regimes are deeply embedded in colonial legal frameworks and market-based allocation systems that o en con ict with Indigenous worldviews. Transforming these systems will require not only legislative and institutional reform but also cultural change within government agencies, water authorities, and the broader community. It will require a willingness to listen, to learn, and to share power. It will require a commitment to justice that is not symbolic but structural.

e roadmap does not o er a one-size- ts-all solution. It respects the diversity of Traditional Owner Nations and their distinct relationships with water. It provides a framework for reform, but it leaves space for adaptation, innovation, and local leadership. It is a living document, intended to be revisited, re ned, and strengthened over time. Its success will depend on the strength of partnerships, the integrity of processes, and the courage to confront uncomfortable truths.

For Traditional Owners, the roadmap o ers a platform to reclaim custodianship, restore cultural practices, and shape the future of water in Victoria. It a rms their rights, recognises their knowledge, and supports their aspirations. For government and water sector agencies, it provides a blueprint for reform, collaboration, and accountability. It sets out clear expectations and measurable outcomes, and it establishes mechanisms for monitoring progress and ensuring transparency. For the broader community, the roadmap is an invitation to reimagine our relationship with water—not as users or owners, but as stewards and allies.

Water is Life is more than a policy framework. It is a call to action. It challenges us to move beyond tokenistic engagement and towards genuine partnership. It asks us to confront the legacies of colonisation and to build new systems rooted in equity, respect, and reciprocity. It reminds us that water is not just managed—it is honoured. In the words of many Traditional Owners, water carries memory, meaning, and movement. It is part of us, and we are part of it. e roadmap recognises this truth and seeks to embed it into the fabric of Victoria’s water systems. As it unfolds, its impact will be measured not only in entitlements and allocations but in relationships— between people and Country, between governments and communities, and between past and future.

Water is life. And life, when honoured, ows freely. U

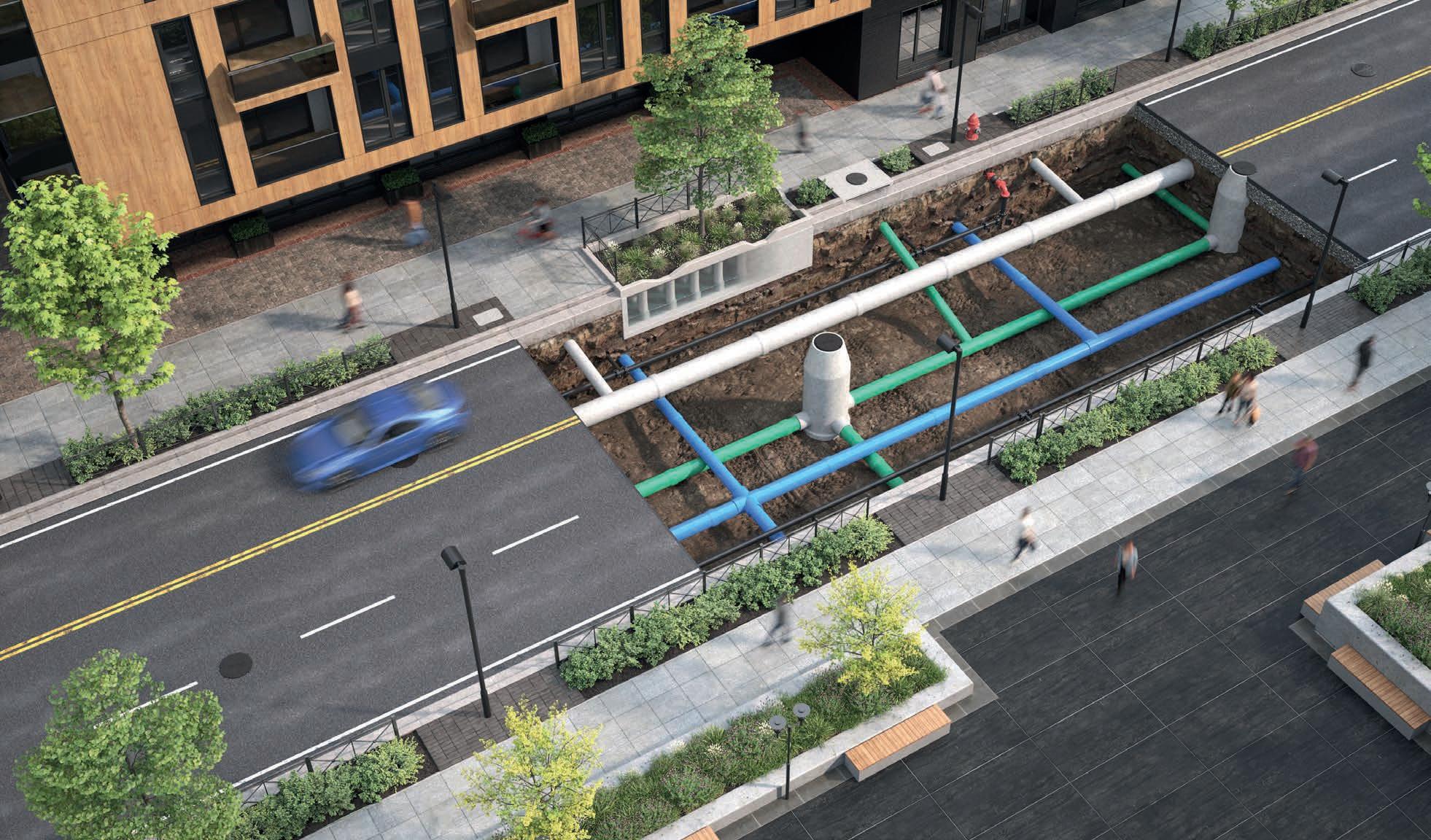

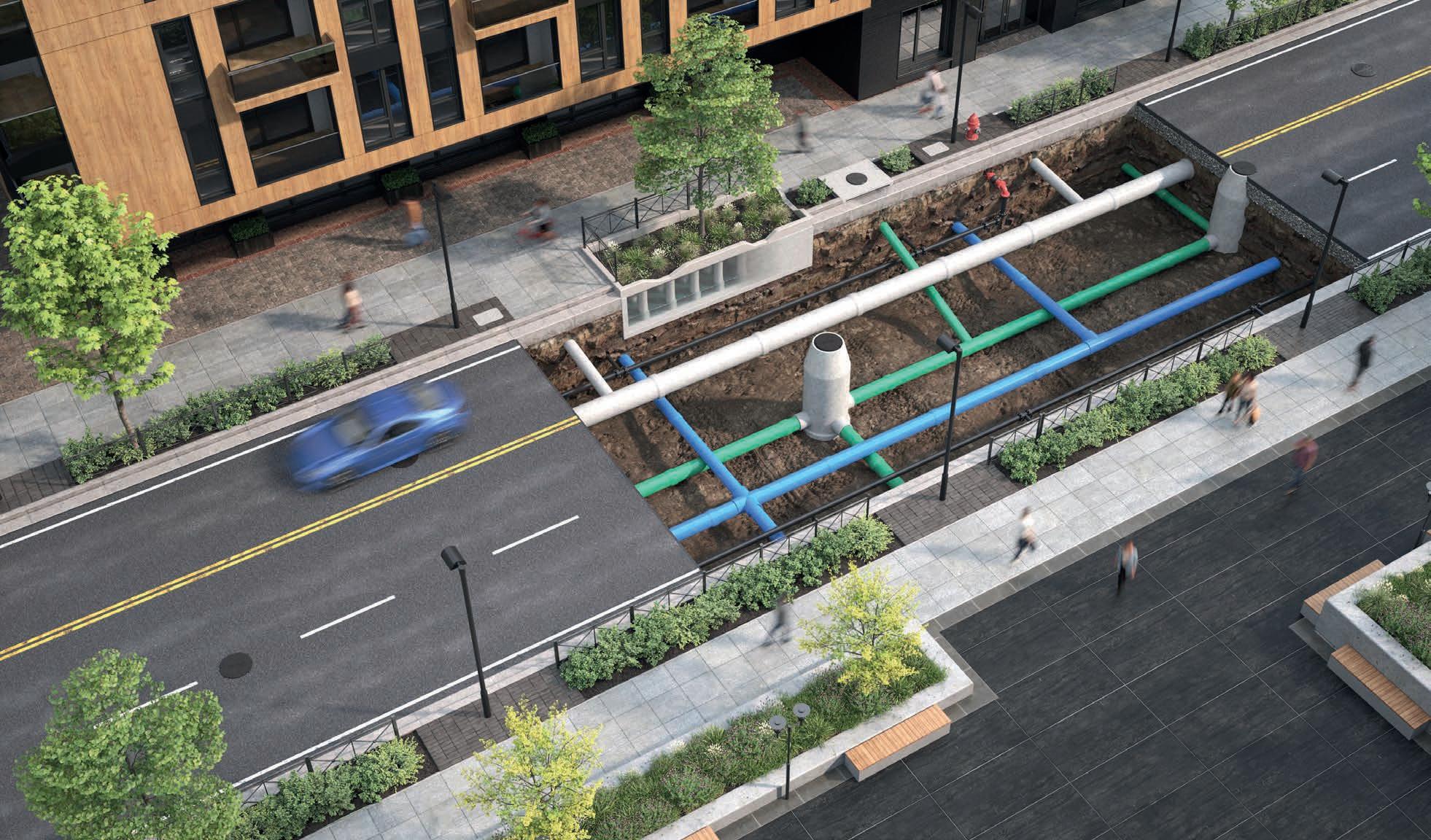

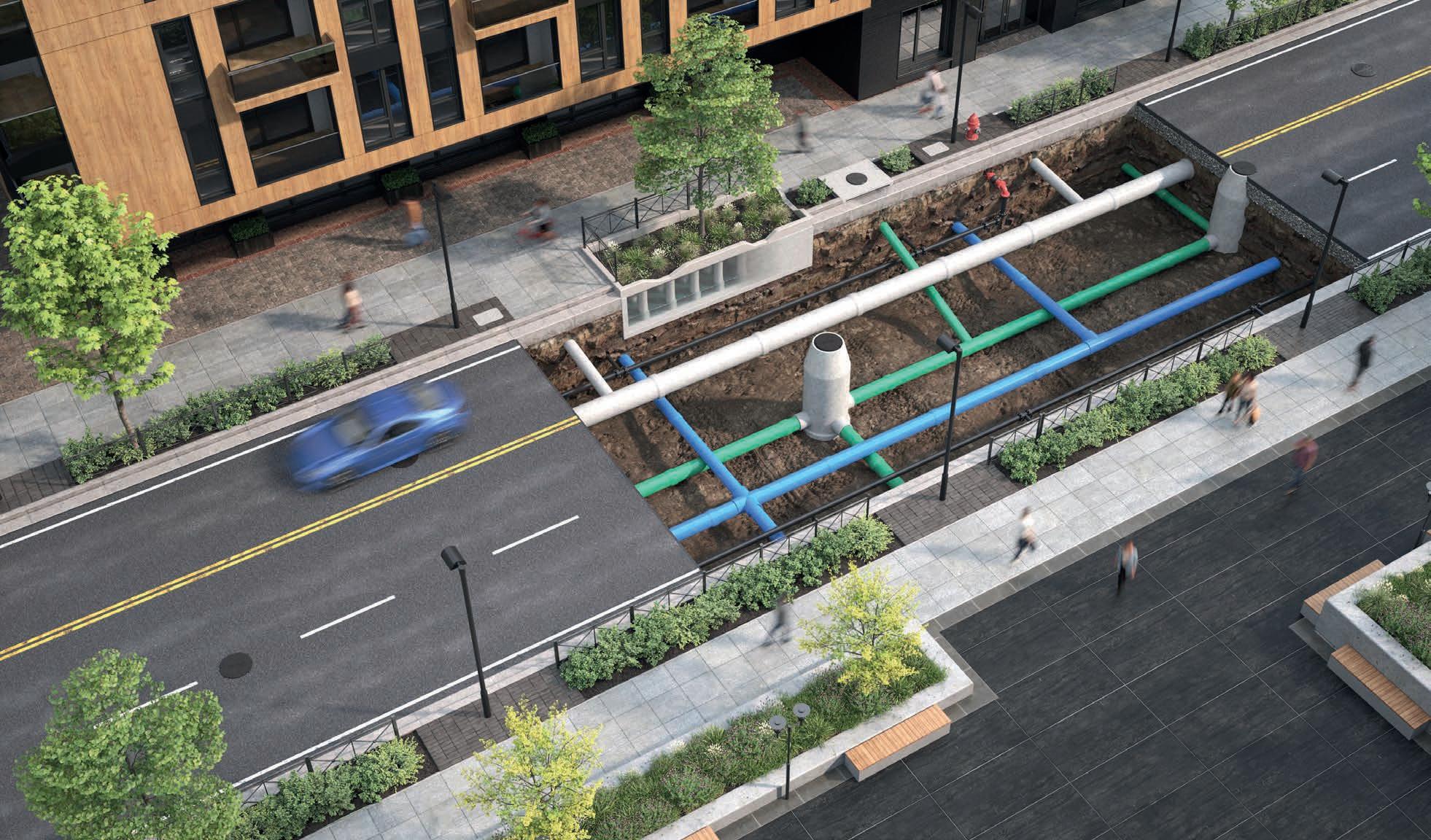

As pressure rises on Australian water infrastructure, compounded by climate change, ageing assets, population growth, rising costs and increasing expectations, the way forward must be innovative, e cient, and sustainable. For

In Australian water we have reached, and in some ways surpassed, a critical in ection point. Increasing extreme weather events brought on by climate change are pushing our systems beyond their current limits. Urban sprawl and higher density inner city living are similarly putting intense strain on assets that are o en operating near the end of their lifespans.

Inter ow Innovation Manager and civil engineer, Joseph Curkovic, agrees the asset and engineering challenges the sector faces are immense.

“We’re acutely aware of the mega, macro and micro challenges facing water authorities,” Mr Curkovic said.

Innovative engineering solutions play a critical role in resolving many of these complex problems, including wellestablished trenchless technologies that help asset owners to address challenges in rehabilitating and renewing existing pipelines.”

“ ese techniques minimise excavations and result in minimal surface disruption, faster construction times at a lower cost, and signi cantly reduce the environmental footprint associated with building new pipelines, o en using open trench methods.”

As constraints tighten, Mr Curkovic said expectations rise and seemingly con icting demands increase, new technologies and methodologies are paramount to meet the future needs of our customers.

“What will be required is greater, more open dialogue and collaboration across the entire value chain and asset lifecycle between asset owners and delivery partners like Inter ow, who are leaders in trenchless technologies. It will demand increased collaboration, and ultimately, joint investments in new technologies.”

Only then, he says, will we be able to improve outcomes for the environment, and for communities that depend on our water and wastewater networks.

The net-zero challenge

More broadly, the path to sustainability and achieving net-zero carbon emissions remains challenging, according to Inter ow Sustainability and Environment Manager, Pam Johnson.

“It’s not that solutions don’t exist – many of them do. e challenge lies in rolling them out consistently across an entire sector, across businesses of all sizes and at all stages of their sustainability journey.”

“While managing our operational emissions remain challenging, it’s achievable, especially with Inter ow’s strong purpose: to improve lives, communities and the environment,” she said.

“But when it comes to what we buy and how it’s made – essentially, how other businesses operate – systemwide progress will take deep collaboration, not just with suppliers but across the whole industry.”

As major water authorities begin shi ing their procurement focus to include decisions around more sustainable and performance-based outcomes, it opens the door to new ways of working that challenge wellestablished and accepted engineering practices.

“ at gives us permission to push ahead with our innovation programs and bring our purpose to life,”

Ms Johnson said.

“Without those shi s in customer expectations, some sustainable alternatives might never gain traction.”

Ms Johnson said the myriad of pressures on water in Australia mean success is no longer de ned solely by technical outcomes. It is also about ensuring long-term water security, building stronger communities, respecting cultural heritage, embedding climate resilience and enhancing biodiversity.

“We must partner strategically to get where we want to go, and to make sure we’re all on the same journey.” U

We’re Creating the Future of Water for people, communities and the environment

Collaboration is the key to eliminating challenges, so the team at Lanco group work closely with contractors and water authorities to overcome issues as they arise. Image: Adwo/stock.adobe.com

Built for centuries

It’s an era of expansion for the water sector, but new infrastructure doesn’t just need to meet our needs today, it needs to be built for tomorrow.

Australia’s water networks are under more strain than ever. As the population grows, climate patterns shi , and demand becomes more complex, legacy infrastructure is struggling to keep up.

ese ageing systems need to be upgraded to meet new standards and rising community expectations, while at the same time water networks need to expand to accommodate populations growth and support the new green eld developments cropping up all over Australia.

Both existing and new assets also need to be resilience to increasing extreme storm, heat and ooding events, and equipped to meet future needs.

And utilities need to deliver all this without placing extra burden on consumers.

For Lanco Group Senior Design Engineer, Anthony Drossinis, success starts at the design phase.

From design to delivery

Maximising the lifespan of an asset means better return on investment, and ultimately means customers won’t be funding frequent upgrades or replacements down the track. Mr Drossinis explained that to do this, water and sewer assets need to be engineered to last a design life of at least 100 years.

“ e two main factors that contribute to the longevity and resilience of utility infrastructure is the pipe type and workmanship of pipeline installation,” he said

“I design based on the latest materials using mostly PE and the newer pipe ECOPUR for contaminated areas, this will ensure that the water infrastructure will last longer.

“However, it also depends on contractor’s workmanship, as this may have an impact on pipe integrity.”

Collaboration is the key to eliminating challenges, which why the team at Lanco group work closely with contractors and water authorities to overcome issues as they arise.

“I am in communication with the water contractor throughout the project to ensure that piping is laid as per current standards to last a lifetime,” Mr Drossinis said.

“As part of our QA construction auditing process we would audit the contractor on site and monitor if they are installing pipe as per the MRWA water code. [We’d also check] on the quality of the pipe delivered to site to see if there are any defects, and ensure that the contractor providing the joining of pipes is completing this as per the MRWA water standards.”

Mr Drossinis said that having clear, open communication with stakeholders helped him overcome challenges with two complex major water main relocations: one on Mickleham Road in Greenvale for Service Stream; and another on Clyde Road in Berwick in collaboration with Downer.

“Both these projects involved a number of stakeholders that were a ected by the relocation of a number for water mains for a road upgrade,” he said.

“Meetings were scheduled weekly and most meetings were organised to discuss updates on the project, design alternatives and other issues that stakeholders raised.”

For the Mickleham Road project, Mr Drossinis said he coordinated with Service Stream to source exact size ttings for the bigger pipe and con rm the new water main alignment.

“E ective communication between stakeholders was important for the project to run smoothly and completed on time,” he said.

While it presented new challenges, Mr Drossinis said that the Clyde Road water relocation project was one of the most rewarding – and from it he was able to improve his design process and the way he communicated with other stakeholders, such as Vicroads.

“From this project I have learnt to deal with con ict in design and has shaped me to tackle harder and di cult projects going forward,” he said. ese skills are especially important in situations where one project’s construction schedule clashes with another’s.

“In some cases there may be clashes when commencing construction on site at the same time as another authority is constructing their service,”

Mr Drossinis said.

As the population grows, legacy infrastructure is struggling to keep up and our water networks need to expand. Image: FiledIMAGE/ stock.adobe.com

e two main factors that contribute to the longevity and resilience of utility infrastructure is the pipe type and workmanship of pipeline installation “

“For example, I have recently been working on a project in South Melbourne in which we were scheduled to commence sewer works on a speci c date.

“However, Citipower advised they were completing their works for the site in the same area as our sewer works, [which] required us to reschedule our works to another date.”

Today’s challenges demand smart urban planning and engineering expertise, particularly in places like Melbourne where a large number of sites are heritage listed.

“We have completed many projects in which the land of the site may be classi ed as heritage listed or even may have cultural heritage artifacts within the site,” Mr Drossinis said.

If an artifact is found on site during construction, then this would hinder the project delivery because crews are not allowed to work on the site – so it’s essential that Lanco Group has all the information to help utilities plan ahead.

“ e rst thing the team do is conduct a property report search on the lot to see if it’s within an Aboriginal cultural heritage area.

“If the site is found to be within an Aboriginal cultural heritage area, then we would normally complete an Aboriginal Cultural Heritage Assessment to determine if a Cultural Heritage Management Plan is necessary for the site,” Mr Drossinis said

With more than 27 years of experience in the water sector, Lanco Group is a trusted partner to utilities, councils, and developers across Victoria and as well as a growing number in other parts of Australia.

e company specialises in civil infrastructure design, hydraulic and drainage services, project management, contract administration, construction auditing, and technical dra ing – but what really sets it apart is its people.

Mr Drossinis explained that the team take a tailored, collaborative approach to align with each client’s unique needs and solve problems as they arise.

“I’m always learning something new every day,” he said.

“I like the challenges of complex projects, [and I enjoy] helping clients. [I’m proud to help] enable Melbourne’s water and sewer infrastructure to grow for future generations.”

U

For

more information, visit www.lancogroup.com.au

Celebrating excellence

The 2025 NSW Water Industry Operations Conference and Exhibition was a celebration of innovation, resilience and the people who keep Australia’s water flowing.

Held over two days at the Newcastle Racecourse, the 2025 NSW Water Industry Operations Conference and Exhibition brought together operators, engineers, suppliers, and industry leaders from across the state and beyond. With its coastal charm, vibrant arts scene, and proud industrial heritage, Newcastle provided a tting backdrop for a conference that honoured both tradition and transformation in the water sector.

e conference o cially began with the Chairman’s Reception, an invite-only evening that recognised the contributions of sponsors, committee members, and volunteers.

Hosted by WIOA Chair Mat Greskie and Board Director Robert Scott, the reception included a special presentation to Sally Shepherd, acknowledging her achievements and service as an outgoing Board Director. is spirit of recognition and gratitude carried through the entire event, setting the tone for two days of learning, networking, and celebration.

A standout moment of the conference was the Women of Water Breakfast, which marked the continued national rollout of the Women in Water Operations (WiWO) initiative. is breakfast provided a welcoming space for women in the industry to connect, share experiences, and build community.

It also highlighted the growing momentum behind gender equity in water operations, with WiWO o ering a platform for mentorship, advocacy, and professional development.

e technical program was equally impressive, featuring 22 paper presentations from passionate operators and industry experts. Topics ranged from ood response and PFAS management to water quality improvements and climate adaptation strategies.

Keynote speakers included Sydney Water’s Sally Rewell and Daniel Leach, who spoke about modernising operations training, and Brendan Guiney from the Water Directorate, who shared insights on supporting regional operators. ese sessions underscored the depth of expertise within the sector and the importance of continuous learning in an era of rapid change.

Beyond the conference hall, the exhibition showcased products and services from over 120 leading companies. Attendees explored interactive displays, discovered new technologies, and forged valuable business connections.

Our operators work long and hard to deliver high-quality water. It’s not my award, it’s their award

e Meet the Exhibitor Dinner provided a relaxed setting for further networking, with canapés, drinks, and light entertainment overlooking the racecourse.

During this event, NSW Advisory Committee Chair, Alan Butler, was honoured with induction into the IDIOTS – Delegates of the Inextricably Obstructed Tap Society – a tongue-in-cheek recognition of long-standing service and commitment to WIOA’s mission.

Competitions added a lively dimension to the event, with the Reece Civil + Viadux Main Tapping Competition drawing enthusiastic crowds.

e 2025 NSW nals saw Orange City Council and MidCoast Council go head-to-head, with MidCoast Council’s team of Dean and Mark clinching victory by a mere few seconds. eir winning cheque of $1,000 was donated to GIVIT, a charity that connects Australians in need with essential goods and services. is act of generosity re ected the community spirit that runs deep in the water industry.

Another highlight was the IXOM Best Tasting Tap Water Competition, which crowned Richmond Valley Council as the 2025 NSW/ACT champion. e contest, held on the rst day of the conference, brought together samples from water treatment facilities across the region. A er rigorous judging based on clarity, odour, and taste, Richmond Valley Council’s Casino Water Treatment Plant emerged victorious by a single vote, edging out strong contenders from Sydney Water and Central Coast Council.

is win marked a triumphant return for Richmond Valley Council, whose Casino WTP previously claimed the national title in 2021.

Upon accepting the award, Richmond Valley Council Water Operations Team Leader, Allison Hawthorn, said this win belongs to the operators.

“We face a few challenges with our treatment – the water starts all pristine up on the hills of the Queensland–New South Wales Border, but as it cracks down [the Richmond River] into Casino it’s not always the best quality water at that point and sometimes there’s a rapid rise in the turbidity and it can be quite clean at other times,” she said.

“ e sample today was taken from our works depot, and our operators work long and hard [to deliver high-quality water] – they really do. It’s not my award, it’s their award.”

eir dedication, skill, and attention to detail were on full display in the winning sample, which will now represent NSW/ACT in the national nals later this year.

e conference concluded with the NSW Awards Night Celebration, which recognised excellence in operations, innovation, and leadership.

Lindsay Walsh received the New Life Member Recognition for his 19 years of service, including his role as a founding member of the NSW Advisory Committee. Known for his wisdom, humility, and regular contributions as a presenter and MC, Walsh’s recognition was met with heartfelt applause.

Veolia operator Andrea Coleman was named the 2025 NSW Young Operator of the Year. Starting her career as a laboratory assistant, Ms Coleman quickly advanced into operations, demonstrating a strong work ethic and a passion for digitisation and system modernisation. Her contributions to the Illawarra Water Filtration Plant have made her an invaluable team member and a rising star in the industry.

MidCoast Council’s Craig Stone was awarded the 2025 NSW Operator of the Year for his technical expertise and commitment to water quality. Mr Stone played a pivotal role in ensuring the Bootawa Water Treatment Plant maintained 100 per cent compliance with Australian Drinking Water Guidelines for four consecutive years. His leadership during the 2025 Manning oods, when he camped at the plant for three days to maintain operations, exempli ed his dedication and resilience.

Other awards included Best Paper by an Operator, won by Veolia Wastewater Supervisor, Scott Collis, for his presentation on navigating capital upgrades, and Best Paper Overall, awarded to Shane Dyson and Steve Buck from Icon Water for their work on mitigating water hammer in dissolved air otation systems.

Chris Yeats from PYROCAL received Best Poster Presentation for his insights on biosolids management, while Control Components won the Ron Bergmeier Award for Best Exhibition Site, recognised for their engaging and innovative booth.

e conference showcased the technical excellence, collaborative spirit, and deep sense of purpose that de ne the New South Wales water industry. From the operators who ensure safe drinking water every day to the innovators pushing the boundaries of what’s possible, the event celebrated the people who make water work.

It’s not just about infrastructure or compliance – it’s about the individuals who rise to the challenge, adapt to changing conditions, and deliver essential services with pride and professionalism – and the 2025 conference was it was a celebration of community, excellence and the shared commitment to securing Australia’s water future. U

Saving Water... by detecting leaks

Two-way street

What happens to our distribution networks when the primary consumers of electricity become the grid’s largest supplier too? This is on the cards for most of Australia, but for SA Power Networks it’s a lived reality.

Every year since 2019, roo op solar has been the largest single category of new renewable energy generating capacity added in Australia.

It now equates to 25GW of installed capacity – more than black and brown coal combined – and accounted for 31 per cent of all renewable energy generated across the country in 2024 .

While uptake of this technology has increased across the board, South Australia has the rst power system in the world where roo op solar can at times exceed the entire state’s electricity demand.

SA Power Networks Senior Manager Enterprise Innovation, James Brown, explained that 45 per cent of the state’s residential customers have a solar system installed on their home.

“If you add it all together, that’s 3GW of installed capacity. at’s three times bigger than any other central generator in the system – the biggest gas- red power station we have still in South Australia is B Station at Torrens Island at 800MW,” he said.

“ ere are now times where the entire demand of South Australia is supplied just by roo op solar during the middle of the day.”

South Australia o ers some of the most a ordable household solar installations in the country . Over last decade the State and Federal Government introduced several schemes to incentivise uptake of this technology and, as demand for installations grew, the market became more competitive, driving prices down further. ese low prices, in turn, encourage further installations, which is fantastic for meeting the state’s target of net 100 per cent renewable generation by 2027, but what does it mean for distribution network operators?

“ ere are two challenges that come with integrating really high levels of solar,” Mr Brown said.

“ e rst is network congestion. e distribution system was built for the one-way ow of energy from big, centralised generators down to end consumers. Now customers are feeding energy back into the grid, which is overloading poles, wires and substations in the reverse direction.

“ ere’s no diversity in solar: if the sun is shining, solar panels are putting out power and pushing it back onto the grid.

“When we design the network around demand, not everyone’s turning on their kettle and their air conditioner and their electric stove at the same time, but with solar, as soon as the sun is out then solar is feeding in to the network, and by the middle of the day much of the network is operating at or above full capacity.”

en there’s also the issue of system security.

“When the state is completely supplied by roo op solar, there are some challenges that come with keeping the system stable,” Mr Brown said.

“It’s really a challenge for the Australian Energy Market

Operator (AEMO), but distribution networks increasingly have a role in supporting them to maintain power system security.

“Complicating things further is the fact we expect a lot of customers will electrify their homes, their vehicles, their businesses in the coming years. And some forecasts see demand doubling in the future, if it’s not well managed.”

But just as there are challenges, Mr Brown said that this also presents a major opportunity.

“If we can integrate these resources through demand exibility, so they can be responsive to the needs of the network and broader energy system at certain times, this could save billions of dollars across the National Energy Market (NEM) in the energy transition,” he said.

The best of both worlds

e AEMO’s Integrated System Plan (ISP) outlines the sector’s roadmap to net zero, and it primarily focuses on the transmission system and large-scale centralised generation and storage, but Mr Brown said that there’s an opportunity to for consumer energy resources to play a major role.

“ e ISP considers what consumers are going to do with their resources as an input, but to be truly a least-cost plan, it needs to look at the demand-side and consumer energy resources (CER) as an output, not just an input,” he said.

“We know that consumers are willing to invest in all this new technology, but we know that there are still empty roo ops and huge potential for home batteries and V2G technology - which the distribution network could accommodate much more of, at little or no extra cost.”

“ is could be a low-cost way to meet demand with technology that we know can be deployed rapidly at scale” Mr Brown said there’s room in the ISP to include recommendations around how Australia can invest more in that part of the system too.

“It’s not about transmission versus distribution. ere’s so much to be done in the energy transition that we just need to everything at this point,” he said.

“If we can get the optimal mix of resources at the distribution level, we can signi cantly improve long-term outcomes for customers... [and] demand exibility is the key to integrating these resources into the grid.”

Any way the power flows

A study from the Australian Renewable Energy Agency (ARENA) found exible demand could save between $3 billion and $18 billion in generation and storage costs3 –and especially in a cost-of-living crisis this is by no means insigni cant.

“ e size of the prize is huge. So, we need to have a crack at making it happen,” Mr Brown said.

Traditionally, whenever demand on the system increased, the network operator would then build bigger substations or upgrade the poles and wires. But, exible

demand incentivises customers to use digital technology to shi the use of their assets to outside peak demand times – meaning more assets can be accommodated by existing networks.

Mr Brown played a key role in developing and implementing SA Power Network’s rst real demand exibility o er – Flexible Exports.

e rst trials kicked o in 2021, and now Mr Brown said the team are looking at what they can build upon from there.

“In around 2015–16, we started to see the network become congested due to all the solar that was out there, which manifested in the voltage going higher and

customers inverters tripping o ,” he said.

“We were getting increasing numbers of customers contacting our call centre to understand what was happening to their system. And so we were faced with the challenge of guring out how we can support solar at scale.

“We could spend what we forecast to be hundreds of millions of dollars in upgrading the network to support all this excess solar, the cost of which would be passed through to all customers, so even those who don’t have solar would have increased electricity bills.

“We could also limit solar exports all the time, and tell customers they’re going to be xed at a really low level of

Image: SA Power Networks

grid export all throughout the year, which means they get less value from their solar, which impacts their return on investment. It would’ve also meant potentially wasting all of this cheap renewable energy that’s been generated on our roo ops.”

However, Mr Brown explained that when SA Power Networks did the modelling, it was actually only a handful of days per year where the grid was becoming congested.

“So, we thought rather than building a network to support this all the time or restricting customers all the time, why don’t we build a system that allows customers to export more outside of those peak times and reduce exports at times only when the grid is actually congested,” he said.

South Australia is the rst, and currently the only, state to o er all customers a exible export limit – and from July 2025 all solar customers can now choose to have a grid export limit of 1.5kW per phase, or a exible limit that varies up to 10kW per phase, depending on the grid conditions.

But blazing that trail didn’t happen in a day.

“It was a long journey, because we had to do a range of things behind the scenes to make that happen,” Mr Brown said.

“We needed to develop standards to communicate with customer inverters, to tell them what their export limit is at a point in time, which hadn’t been done before.

“We went on a search and looked at international standards, and we found the Common Smart Inverter Pro le (CSIP) from California, but it didn’t really t the context. So, we took that, we came together in a working group with like-minded stakeholders across the country and developed a local adaptation, which has recently been aformalised by Standards Australia, aptly named CSIPAUS.”

SA Power Networks then had to work with all of the manufacturers of solar inverters across the globe to build that capability into their inverters.

“South Australia is a small jurisdiction, so you might think ‘why are all these global manufacturers going to focus in on South Australia and build this capability?’

“And I think we were able to sell them on the vision that this is going to become the standard for Australia and then everywhere else in the world. We’re at the forefront of the transition when it comes to roo op solar, and if they come on the journey with us, they’ll be set up for when this becomes a requirement elsewhere,” Mr Brown said.

“We also worked really closely with the South Australian Government who developed requirements that meant any solar that was sold in the state had to have these new capabilities, because we thought it was an essential requirement going into the future.”

To ensure that solar installers had the tools they needed to get these systems up and running correctly, SA Power Networks also engaged with the solar industry over a long

period of time. It completely revamped its whole solar connections process and ew in equipment manufacturers from across the country to conduct in-person training with installers.

We’re all part of the solution

With Flexible Export rolled out across South Australia, Mr Brown and his team are now supporting other systems to implement the same capabilities – and he said engagement is central to success.

“Codesign solutions if possible. Involve customers early. Involve industry early. If you make them part of the solution and equip them with the tools and processes to be successful, then they’ll be your biggest advocates,” he said.

In developing this new norm, SA Power Networks treated exible exports as a ‘product o ering;’ rather than an engineering solution – which Mr Brown said means the design is customer- rst and the systems and tech are an enabler.

“Just shy of 90 per cent of customers are choosing to opt into the exible limit.

“And there’s a lot of talk about consumer trust in the transition which is critical. We think that in practice, if you get the deal right and you engage with customers and are transparent about what you’re o ering, then they’re willing to make that trade o .

“And we’ve seen that play out in reality, with more than 26,000 solar customers signed up to Flexible Exports.”

For SA Power Networks, engagement with the solar industry was again crucial to making sure the roll-out of the o er was successful.

“Customers tend to not have a lot of direct engagement with their distribution network outside of when they want to get a connection or when the power’s out and they want to get it restored,” Mr Brown said.

“And the key for us was we recognised that the solar industry was really the conduit to the customer.

“So, we tried to train and equip the industry with the things that they needed to be able to put this o er in front of customers.”

At rst, SA Power Network’s approach was to give the installers all the information they could and let them gure out how to pitch it to customers. But Mr Brown said they found that the best solution was a surprisingly simple one.

“In the end, they just wanted some simple o cial documentation from us that they could just put in front of the customer and say: ‘this is from SA Power Networks, this is what Flexible Exports is, and this is how it works’,” he said

“And that’s been really key to helping support trust, because they trust the person who’s installing a solar system to help them get some energy independence and save them money on their bills.”

e other core element to building trust consumer trust is transparency with information.

“We’ve tried to be as transparent as we can about how o en solar is going to get turned down or export will be increased,” Mr Brown said.

“We can never provide guarantees for future performance, but we do provide the last 12 months of data on our website so that when you’re going through the process, the installer can bring you to that web page, type in your address and say, ‘Look, this is what it was like last year.

“But trust is built up by being transparent and doing the right thing over an extended period of time. You can’t win it overnight.

“If we can continue to show that this is something that consumers can trust, then we’re hoping that that builds a solid foundation for the next phase that we’re looking to do in this space.”

The next phase

As more CER come online, Mr Brown said SA Power Networks is transitioning to a new function: from an asset owner to distribution system operator.

“We need to enable and coordinate the resources on the distribution network so that they result in the best long-term outcomes for all customers, not just those that can invest in the technology,” he said.

According to Mr Brown, there are three steps on that journey.

e rst is exible connections, which involves rewarding customers for signing up to make their CER and smart appliances able to respond to signals based on the grid conditions.

“Flexible Exports is our rst foray into this for solar, and we’re now testing exibility on the demand side – so with smart appliances such as EVs, hot water systems, and other technologies,” Mr Brown said.

Increased electri cation could potentially double network demand by 2050, and SA Power Networks is looking to support as much of that added demand within its existing network at possible.

If the network doesn’t need to be upgraded, then those expenses won’t be re ected in customer’s bills.

Mr Brown explained that there will still be some places that need to be upgraded, but SA Power Networks’ vision is to minimise that as much as it can – and right now this is being tested with its Energy Masters pilot.

Delivered in collaboration with the South Australian Government, electricity retailers and technology providers, the program gives 500 households subsidies to install electric appliances (for example, split-system air-conditioners, heat pump hot water systems or EV chargers) at their home as well as a home energy management system (HEMS) to manage their use.

ose customers are then being rewarded for the exible use of those appliances.

“ e home energy management system will rst optimise for the best use of the customer behind the meter. So, for example, if they’re on a time of use tari the HEMS will schedule appliances, and charge and discharge any battery at the home to minimise the customer’s electricity bill,” Mr Brown said.

“ ey also consent to a exible connection with us, where we will send them a signal from the grid and say, if you allow your exible appliances to respond at these times and keep their usage within the limits of the grid, we’ll pay you a rebate on your distribution charges on your electricity bill.

“ en the retailers in the program are saying, ‘well, if you’re willing to go even further and enable us to manage your resources based on the wholesale price of electricity, then we’ll give you more nancial rewards.”

According to Mr Brown, interoperability is going to play a key role to this initiative’s success – meaning the technologies that customer purchase need to be able to work together communicating consistently with each other and the grid.

“Standards don’t sound like a shiny thing, but they’re super important for enabling consumers to get the most out of the resources that they’re purchasing,” he said.

e message SA Power Networks is hearing from most consumers is that energy need to be simple and easy – so demand exibility o ers can’t be too complex either.

To get this right, Mr Brown said there will need to be tight collaboration between networks, retailers, and tech companies to build simple o ers that are ‘set and forget’ to avoid burdening the customer.

Image: SA Power Networks

On the bright side, customer interest in the Energy Masters pilot exceeded SA Power Network’s expectations.

“We had 500 spots in the program, and we had more than 2000 people apply. So, there’s consumer interest in doing this – and I think that helping to contribute to the broader system and reduce costs for everyone is something that some consumers are keen to do – if the rewards and trade-o s are transparent,” Mr Brown said.

Charging ahead

e next is phase is what SA Power Networks calls exibility services.

Even with exible connections in place, Mr Brown said that there will still be network constraints – and again, instead of investing in poles and wires, SA Power Networks thinks that solar, batteries and EVs can be part of the solution.

“First, we’re looking to trial a marketplace where we can we publish our network constraints and aggregators, VPP operators and large battery customers (or people acting on their behalf) can say ‘I’ve got capacity in that area. I can reduce demand by discharging my battery or turning o my EV chargers during that time,’ and then we will pay them for doing so,” he said.

“ is is an e cient way for us to procure non-network solutions. is has been done at scale in the UK and it’s something that we’re looking to bring to Australia.

“Our context is a bit di erent to the UK model – over there it’s mostly about larger resources – but we think that it’s possible with smaller resources connected deep in the distribution network.

“CitiPower, Powercor and United Energy are doing a trial of this at the moment and we’re hoping to start our own trial from next year.”

e third and nal stage on SA Power Networks’ journey is ensuring that these resources are considered as part of energy system planning and can be integrated into the wholesale energy market.

“It’s our role to help facilitate those resources that are participating in the wholesale market or doing other things with retailers, and also maintain overall reliability and system security,” Mr Brown said.

“It all sounds complex, especially in a world where consumers are telling us that energy needs to be simple, but what we’re nding is that in collaboration with retailers and technology companies we can o er this in a way that’s simple for the end consumer.

“We could see a world where an electricity plan looks like a mobile plan; where if you install all these resources, your bill will be X dollars a month, or if you are willing to be exible and respond to the grid, it’ll be a much cheaper cost, and customers decide to opt in get the nancial bene t.”

Leaving no-one behind

By now, the entire sector knows the importance of consumer participation in the energy transition, but for customers to be a part of this shi to renewable, exible energy they need to purchase and install new technology in their homes – so, what about consumers that don’t have the opportunity to do that?

For SA Power Networks, its role is to enable customers to install the technology they wish to, but Mr Brown said that shouldn’t come at the cost of its core purpose: to deliver reliable and a ordable power for all customers. ere are many varied reasons why customers can’t access modern technology, but one of the core barriers is nancial vulnerability.

For those without the means to purchase solar systems, batteries or EVs, Mr Brown said there needs to be electricity tari s that are simple, predictable and make the most of the technology that others are installing so that people who are nancially disadvantaged can still save money on their electricity bills. ere are also people who have limited access to CER as a result of their living circumstance, like renters or apartment dwellers.

Renters can’t make modi cations to their property without the landlord’s consent, and there’s o en no incentive for the landlord to make those improvements. Similarly, it’s di cult to put a solar system on an apartment building – and residents may not be able to get an EV (or get the best charging rates) if there are no charging facilities in their complex.

“We need models that open the door for everyone.

“ at’s things like having shared solar or community batteries that customers can receive bene ts from, even if they don’t have the physical means to install it on their property,” Mr Brown said.

“ en there’s the wicked problem of getting the right incentives in place, so that landlords and/or renters can invest in technology.”

Both the energy system, and the utility sector as whole are undergoing a major shi . For many regulated utility businesses like SA Power Networks, Mr Brown said that developing new exibility o erings is bringing them closer to customers that ever before.

“We need to have a product mindset, which we kind of never have had as a sector before – we’re developing things that we want consumers to take up, whereas before, we’ve had a monopoly mindset where consumers have just had to take what we’re o ering,” he said.

“So, when we’re developing these new o erings and services, we need to think about them from the consumer lens and ask them what they want.”

Autodesk Water Infrastructure Solutions

Water may be finite. Human ingenuity isn’t.

Water shapes our lives and landscapes. However, extreme weather and rising demand pose challenges to both that must be answered. From storm and drought resilience to safe drinking water, whole ecosystems and communities rely on the effectiveness of infrastructure and the work of its designers, engineers, builders, and operators.

Water distribution: Maximise water quality and efficiency while minimising leaks with intelligent network design capabilities, accurate hydraulic modelling, and predictive network monitoring and analytics.

Storm and flood: Combine hydraulic simulations and predictive monitoring to forecast how your system will respond to varying conditions and inform decision-making around capacity fluctuations, system expansions, site-design, and emergency planning.

Treatment plants: Efficiently design treatment plants and create digital twins that streamline operational and compliance challenges at scale. Use sensor data to optimise plant performance and inform decision making.

Wastewater collection: Evaluate risk, improve precision in catchment design, and simulate hydraulic dynamics for urban planning—so you can justify capital spend in areas like capacity improvement.

Operation and maintenance: Extract actionable insights from SCADA and IoT data. Visualise them and disperse them to relevant stakeholders quickly and efficiently, enhancing efficiency and compliance outcomes for your water infrastructure.

At Autodesk, we equip the water industry with the solutions needed to make the best decisions possible at every stage of a water asset’s lifecycle.

Strengthening Victoria’s energy system

Construction of the Melbourne Renewable Energy Hub is well underway – and it’s set to play a key part in securing the state’s electricity grid as coal-fired power stations retire.

Australia’s energy system is in the midst of a profound transformation – and the sector must not only deliver enough new clean energy infrastructure to meet our net-zero goals, but in doing so ensure a reliable, a ordable electricity supply.

While the Federal Government has pledged to generate 82 per cent of the country’s electricity from renewable sources by 2030, Victoria and set its own target of 95 per cent by 2035. To accelerate this transition to clean energy, the newly reformed State Electricity Commission (SEC) has partnered with Equis to deliver one of the world’s biggest batteries –the Melbourne Renewable Energy Hub (MREH).

e rst phase of the MREH project comprises the connection of a 600MW and 1.6GWh battery energy storage system (BESS) into the existing Sydenham Terminal Station through a new 500kV underground cable circuit. At the completion of this phase, the MREH will have su cient battery storage to power 200,000 homes during the evening peak period. e system will soak up surplus roo op solar and energy from the grid, charge the batteries when renewable energy is most abundant, and discharge when supplies tighten.

As Victoria’s ageing coal- red power stations retire, this development in Melbourne’s west is set to strengthen the electricity network and safeguard the state’s power supply.

e MREH will also unlock capacity for more renewable energy to help Victoria hit its 95 per cent renewable electricity target.

Equis has engaged Transgrid to develop the transmission infrastructure required for the 500kV connection to the Victorian grid including the establishment of new Plumpton Renewable Terminal Station (PRTS) and a 500kV underground cable system between PRTS and AusNet’s Sydenham Terminal Station (SYTS). Daly’s Constructions was engaged via Taihan Electric for the delivery of this 500kV underground cable system.

A landmark power project

e 1875m-long underground cable system connecting PRTS to SYTS is the rst 500kV underground AC cable system constructed in Australia. Not only does the MREH represent a groundbreaking achievement for the country as a whole, but in delivering the rst cable installation of this type in Australia – and what is also believed to be the third ever in the entire southern hemisphere – Daly’s Constructions has set a new industry benchmark.

According to the team, Daly’s Constructions is also the only construction partner in Australia to deliver high-voltage (HV) and extra-high-voltage (EHV) cable installations in Australia, spanning 11kV through to 500kV – including 22kV, 33kV, 66kV, 110kV, 132kV, 220kV, 275kV, 330kV, and 400kV.

As the principal contractor for underground cable works within AusNet’s SYTS and the parcel of land next to the terminal station, the Daly’s team took great care to ensure that this landmark project was not only delivered on time, but in a way that ensured the safety of everyone on-site and protected the local environment.

In addition to trenching, conduit installation and installing cables, Daly’s was responsible for the construction of the joint bays, erecting the cables onto structures, producing a detailed design of termination structure foundations within SYTS and facilitated the installation of joint and terminations.

e team also conducted site investigations – including thermal resistivity survey and Geotechnical testing along the route – implemented environment and sediment controls along the cable easement, and handled the temporary works design and construction of two weatherproof sca olds to facilitate termination works.

As the SYTS is a live 500kV terminal station, successful delivery of the works within the 500kV terminal station required Daly’s ongoing coordination with everyone involved and strict adherence to safety protocols.

Once complete, the MREH will be the largest BESS in the Southern Hemisphere, but it also includes the fi rst 500kV cable and the fi rst 500kV battery connection in Australia.

Images: Daly’s Constructions

To facilitate the large-diameter cable required for this project, Daly’s had to take a specialised approach, including designing and manufacturing a new hydraulic drum stand.

Breaking down barriers

Trenching works kicked o in July 2024, but a signi cant amount of rock in ground presented a schedule risk for the project, and it was estimated that around 60–75 per cent of the excavation works included rock breaking in hard basalt.

To tackle these very hard ground conditions, Daly’s employed its eet of 23t and 13t excavators and assisted with the development of an accelerated program to minimise the impact on the project’s timeline.

Daly’s deployed multiple crews to complete concurrent work fronts within the cable easement, the PRTS and the SYTS.

e trenching works were completed in January 2025, and the team wasted no time in kicking o the installation of the power, optical bre and earthing cables.

Rising to the challenge

To meet the desired ratings, the cables were installed within conduits in a at spaced arrangement, which were back lled with thermally rated materials in accordance with the design.

A total of six drums of 154mm-diameter cable, each 5.3m wide and weighing 31t were needed for this landmark project, which called for a specialised approach. Daly’s designed and manufactured a new hydraulic drum stand that can handle cable drums ranging from 2.4m wide to 8m wide, 3.0–4.4m in diameter and up to 70t in total weight, with a gearbox and motor designed to hold or recover cable up to 10t. ese cable drums were transported from South Korea to Daly’s Laverton yard for storage, then the Daly’s team managed the transportation from Laverton to the

project’s site – which required specialised transport with pilots vehicles, as well as oversize and overmass (OSOM) permits.

Specialised cranage had to be used to load and unload the cable drums, which required Daly’s to develop li plans and perform geotechnical testing to establish ground bearing pressure. e Daly’s team even had to modify its caterpillars for this project to take the larger cable and as well as its ramp roller to cater for the increased width and height of drums.

e installation works wrapped up in February 2025, and Daly’s began works to construct two 30t precast joint bays – which included the installation of enclosures and ancillary pits for the cable jointing works.

While two joint bays were constructed, the cables were jointed at just one, with the second joint bay to be used for future extension of the circuit to a new terminating point.

Daly’s installed two 20m-long sca olds, which were covered with weatherproof shrink wraps to ensure the termination works were not impacted by dust and moisture. ese sca olds stood at 5m deep and 11m high with four working decks and were fully equipped with power supplies and air-conditioning.

By the end of April 2025, the cable system was ready for pre-commissioning to meet the accelerated program, marking a major milestone in the delivery of this complex transmission project.

Building positive outcomes

Daly’s strong commitment to both worksite safety and cultural and environmental responsibility was put into practise at every stage of this project, which resulted in highly positive outcomes.

Not only was it completed without a single environmental breach or incident, but the team’s collaborative e orts and proactive risk management meant that there were zero losttime incidents, and just one medically treated incident. e team’s dedication to health and safety was evident throughout the project duration, and regular inspections, frequent joint walk-throughs, and ongoing engagement through daily, weekly and monthly meetings allowed Daly’s to foster a culture of continuous improvement and accountability.

External safety audits conducted identi ed no nonconformances, reinforcing the project’s high standards of compliance and performance. e integration of all stakeholders in planning, review processes, and site activities ensured alignment, transparency and shared ownership of success.

Construction works were carried out to comply with Cultural Heritage Management Plan (CHMP) conditions and a strict environmental management framework was set out to ful ll the planning permit requirements. ese controls included mandatory CHMP induction,

regular Registered Aboriginal Party (RAP) inspections, dust and noise control, establishment of a no-go zone along the cable easement and sediment control. Daly’s also established speci c measures to protect the habitat of the endangered growling grass frog.

All the construction activity along the cable route was strictly con ned to established easement and beyond that was a no-go zone, which was delineated with approximately 4km of temporary fencing. A 1.5km-long sediment fence was also constructed along the cable easement on identi ed locations, and another speci c fence was constructed around the growling grass frog habitat near the land adjacent to SYTS to prevent the frogs from entering the construction area.

Pre-commissioning tests were completed in May 2025, and Daly’s Constructions Director, Mark Daly, credited the project’s success to strong teamwork with stakeholders, solid planning, and the dedication of an experienced construction crew.

Regular progress meetings and open lines of communication helped keep everyone aligned and ensured smooth coordination across key work areas –leading to a well-executed delivery of this vital piece of renewable energy infrastructure.

As Victoria’s energy transition powers ahead, the success of this groundbreaking project reinforces both the state’s future, and Daly’s position as a trusted partner in delivering critical energy projects across Australia. U

This complex project was completed safely, underscoring Daly’s commitment to cultural and environmental responsibility.

To prevent delays due to the hard ground conditions, Daly’s crews worked across di erent work fronts concurrently.

Daly’s Installed weatherproof sca olds equipped with power supply and air conditioning to facilitate the installation of cable terminations.

If you’re seeking a reliable, scalable solution for managing your trade fleet needs, Enviroline is your partner in delivery.

We help fleet managers minimise complexity, improve rollout timelines, and ensure every vehicle meets your standards for performance and presentation.

Powering change

The Federal Government has unveiled an ambitious national emissions target that can only be achieved by successfully transitioning the grid to renewable energy. There’s a lot resting on utilities’ shoulders at the moment, but are we actually on track for 2030?

On ursday 18 September 2025, the Federal Government announced that it has accepted the Climate Change Authority’s independent advice, and set a national target to reduce Australia’s carbon emissions to 62–70 per cent below 2005 levels by 2035

According to the Federal Government, this is an ambitious but achievable target that responds to the science and is delivered with a practical plan.

A risk we can’t ignore

Australia’s rst National Climate Risk Assessment (NCRA) paints a sobering picture: climate risks will be cascading, compounding and concurrent – and no Australian community will be immune. is comprehensive assessment was developed by the Australian Climate Service, drawing on data from the Bureau of Meteorology, CSIRO, the ABS and Geoscience Australia to outline the risks posed by climate change across the country.

By 2050, up to 70 per cent of native plant species could face conditions outside their current climate range. Sea level rise could put 1.5 million more people in highrisk coastal areas. Heatwaves could claim lives and threaten the security of our water supplies – especially in northern Australia. And the economic toll from reduced productivity and disrupted supply chains will be felt across every sector

While it nds that climate hazards will worsen under all plausible futures, the di erence between 2°C and 3°C of global warming is signi cant and early action can reduce long-term costs and protect what we value most.