BULK MATERIAL HANDLING

WA MINING CONFERENCE

MINE TECHNOLOGY

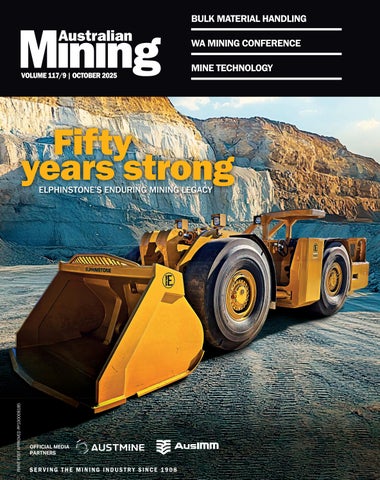

VOLUME 117/9 | OCTOBER 2025

BULK MATERIAL HANDLING

WA MINING CONFERENCE

MINE TECHNOLOGY

VOLUME 117/9 | OCTOBER 2025

ELPHINSTONE’S ENDURING MINING LEGACY

THIS EDITION OF AUSTRALIAN MINING EXPLORES THE INNOVATIONS DRIVING SAFER, SMARTER AND MORE SUSTAINABLE BULK MATERIAL HANDLING.

Bulk material handling sits at the heart of every mining operation. From the moment ore is extracted to the point it leaves site, tonnes of material must be safely and efficiently moved, stockpiled, and processed. It’s a constant flow that relies on precision, durability and innovation, and even small improvements in this space can deliver big gains in productivity and sustainability.

This issue takes a closer look at the equipment and solutions that keep this vital process running smoothly.

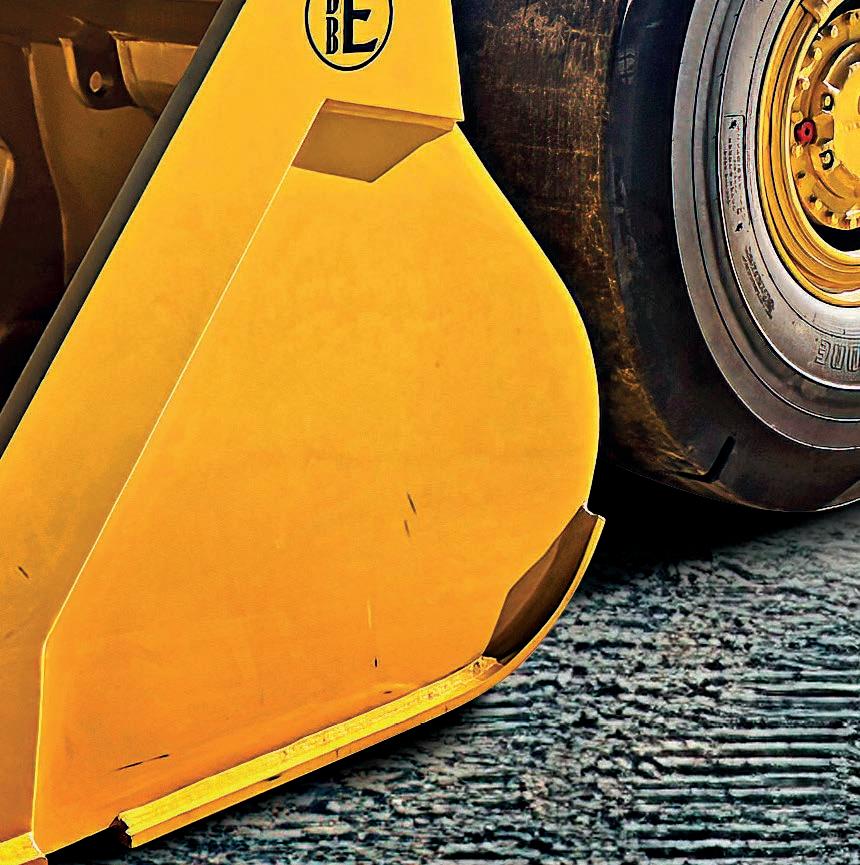

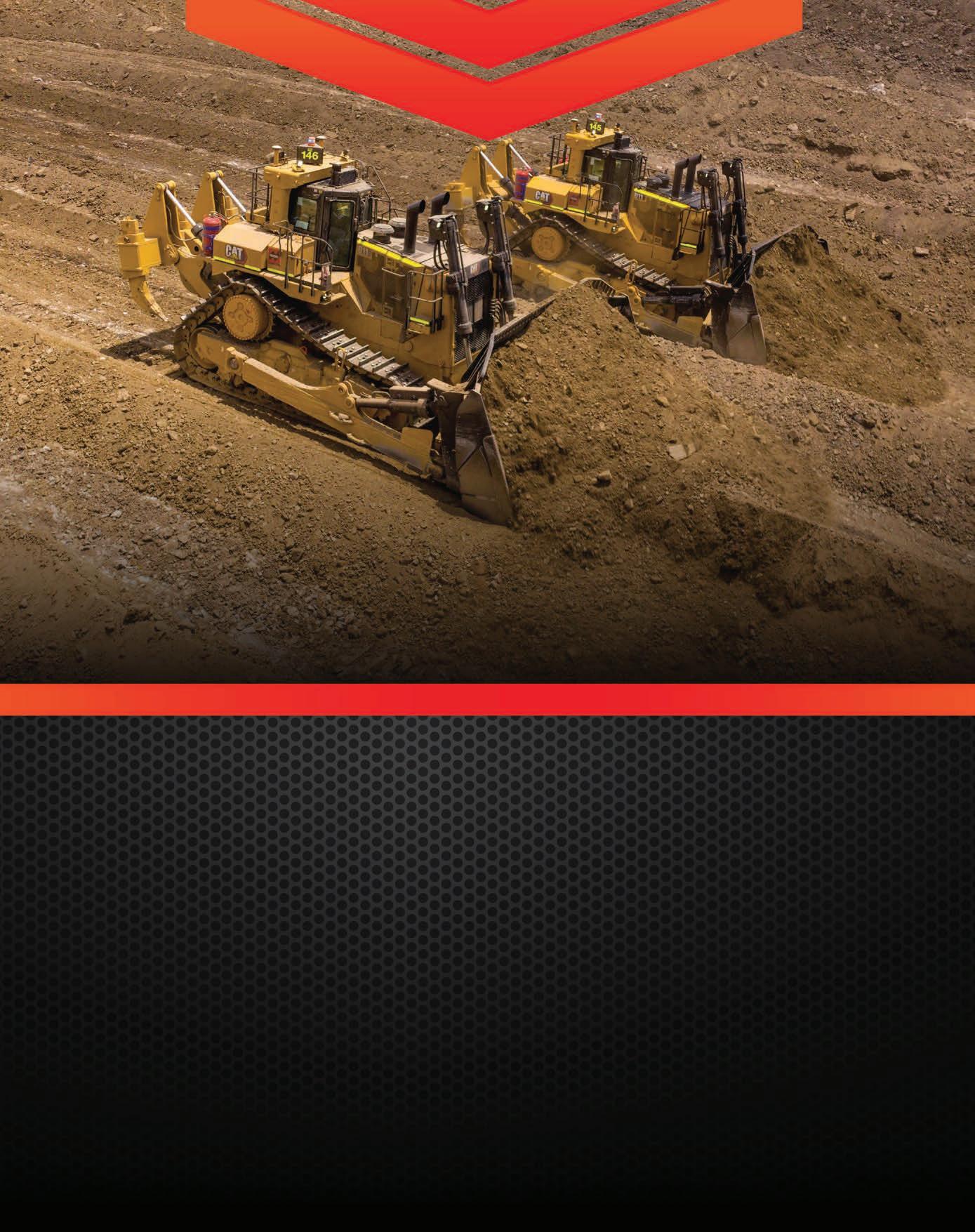

Our cover story profiles Elphinstone, a company with almost 50 years of experience designing equipment for the toughest mining environments. From underground support vehicles to off-highway haul trucks, Elphinstone has become synonymous with quality and reliability. Today, the business continues to grow, adding new capabilities and expanding its presence across the Asia-Pacific region.

We also explore a range of innovations shaping bulk material handling. Fenner Conveyors has teamed up with Tyrecycle to tackle one of the industry’s most stubborn waste streams – used conveyor belts. Their partnership turns these belts into alternative

products, including new conveyor systems, supported by new infrastructure investments in Western Australia.

MAX Plant continues to refine its feeder range, offering customised solutions that give miners greater control over material flow, whether handling iron ore, gold or manganese.

And Bradken highlights the importance of reliability with advanced undercarriage systems designed to extend service life and reduce downtime for hydraulic excavators.

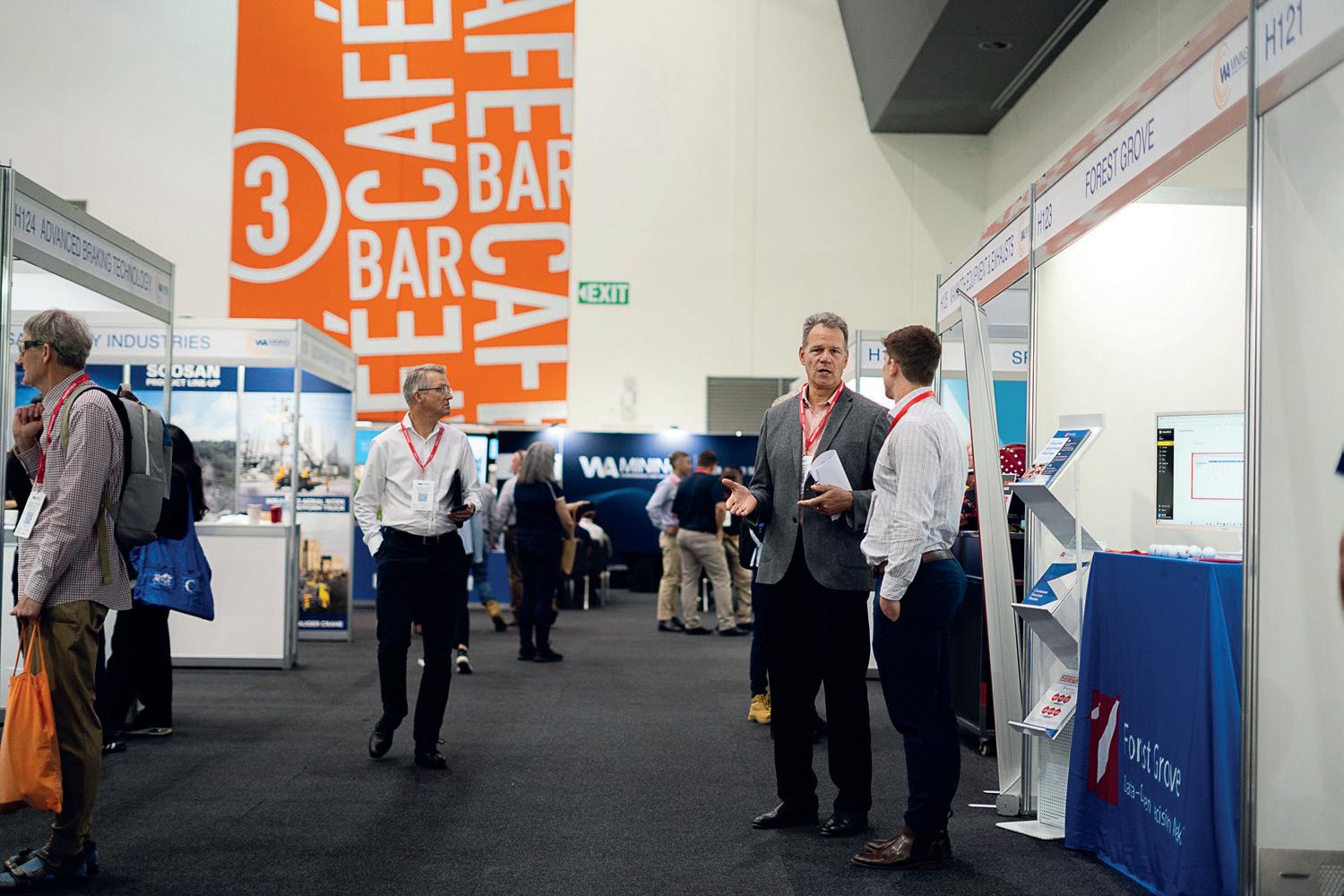

Elsewhere in this edition, we shine a light on the WA Mining Conference and Exhibition and its stellar conference program, featuring slots from the likes of Fortescue, Rio Tinto, Alcoa and Newmont. The event will be held in Perth from October 8–9.

We also spotlight all that’s in store at IMARC 2025, to be held in Sydney from October 21–23.

Tom Parker Editor

CHAIRMAN JOHN MURPHY

CHIEF EXECUTIVE OFFICER

CHRISTINE CLANCY

EDITOR TOM PARKER

Email: tom.parker@primecreative.com.au

ASSISTANT EDITOR

ENGEL SCHMIDL

Email: engelbert.schmidl@primecreative.com.au

JOURNALISTS

DYLAN BROWN

Email: dylan.brown@primecreative.com.au

PAUL HOWELL

Email: paul.howell@primecreative.com.au

BEN CARTWRIGHT

Email: ben.cartwright@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGERS

JAMES PHIPPS

Mob: 0466 005 715

Email: james.phipps@primecreative.com.au

ROB O’BRYAN

Mob: 0411 067 795

Email: robert.obryan@primecreative.com.au

Built on a passion for mining, Elphinstone has been leading machinery innovation for over 50 years. The company designs and manufactures underground mining support vehicles to off-highway extendeddistance haul trucks and mine extraction equipment, serving mining operations across Australia and internationally.

A long-standing Caterpillar OEM Solutions customer, Elphinstone has expanded its capabilities under the Elphinstone Group, acquiring businesses such as Haulmax, SVS, and Southern Prospect. Innovation continues with the development of battery-electric vehicles, the E15 platform, and purpose-built graders. Guided by a peoplefirst philosophy and a commitment to community, Elphinstone delivers solutions that are reliable, adaptable, and customer-focused.

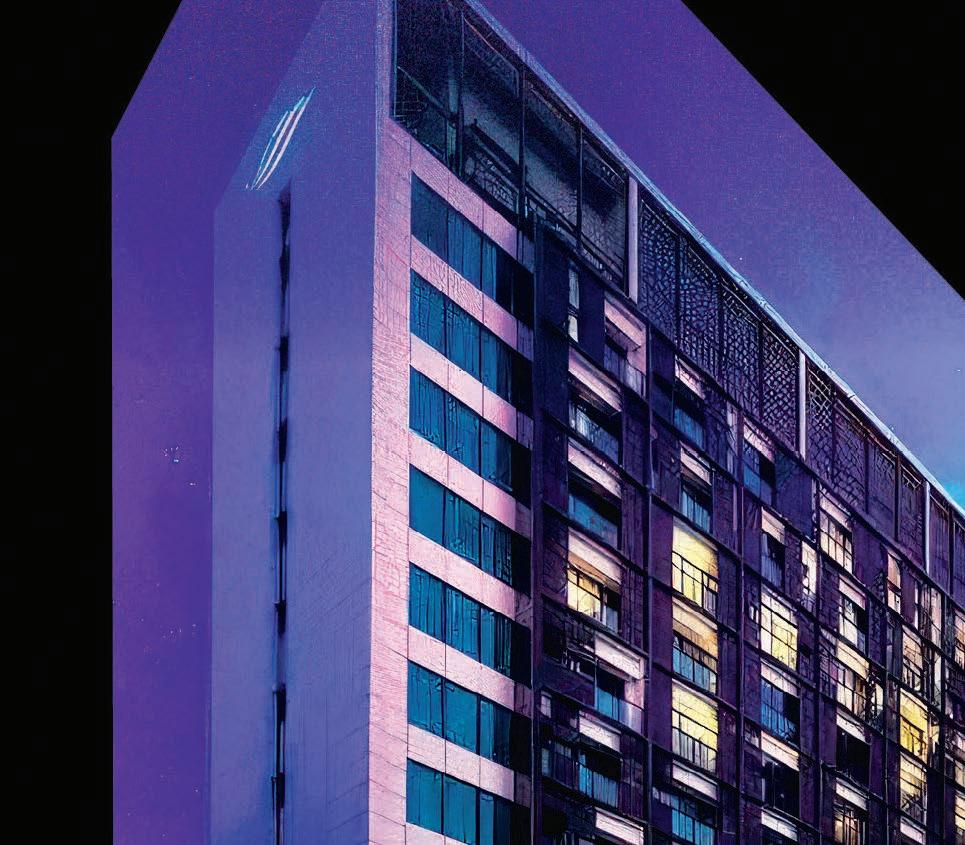

Cover image: Elphinstone

ART DIRECTOR MICHELLE WESTON michelle.weston@primecreative.com.au

SUBSCRIPTION RATES Australia (surface mail) $120.00 (incl GST) Overseas A$149.00 For subscriptions enquiries please contact (03) 9690 8766

8 COMPANY PROFILE

The Big Australian turns 140 BHP remains at the forefront of global mining, leveraging a history of resilience and innovation to lead the industry into a new era.

13 COVER STORY

A cornerstone OEM

Built on a passion for mining, it’s no surprise that Elphinstone has been leading the way in machinery innovation for almost half a century.

16 BULK MATERIAL HANDLING

Transforming mining’s toughest waste Fenner Conveyors and Tyrecycle have teamed up to turn one of mining’s most stubborn waste streams into a closedloop resource.

50 BULK MATERIAL HANDLING

Might and mobility

XCMG’s new mobile crusher range is underpinning faster, more efficient mining operations.

57 INDUSTRY EVENTS

Fresh perspectives at IMARC 2025

IMARC 2025 promises to bring operational expertise and new voices to the table.

79 FUEL MANAGEMENT

Busting mining myths

Veridapt has launched a campaign that proves its fuel tech can survive the toughest mining conditions.

90 PROJECT SPOTLIGHT

Not just another port expansion

With expansion well underway, the planned changes at Lumsden Port are set to transform WA’s export of lithium and copper.

104 MAINTENANCE

Lubrication revolution

TotalEnergies’ lubrication solutions are transforming mining operations with measurable environmental and performance benefits.

107 PROJECT SPOTLIGHT

Queensland’s economic anchor

Bravus Mining and Resources is backing Queensland’s resources future with a bold expansion at its Carmichael mine.

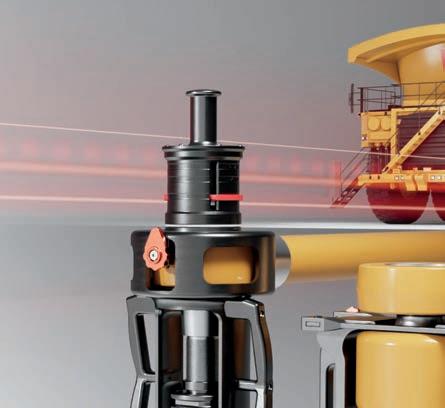

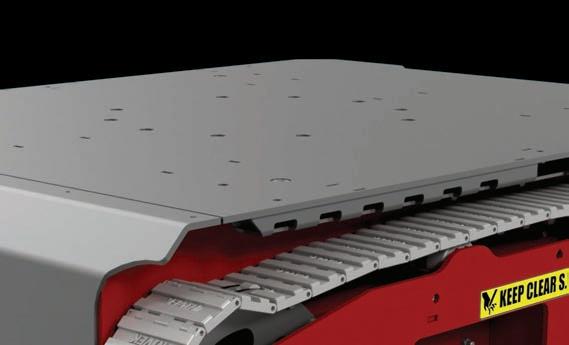

With more than four decades of expertise in delivering innovative undercarriage solutions globally across R9800 and R996 machines, Bradken® has now optimised the R9600 to improve performance for our customers.

From 2007 to 2021, Bradken designed, manufactured, and supplied the majority of the crawler shoes for R9800 and R996 machines to the OEM.

Now, we are delivering improved wear results for our aftermarket crawler shoes, with more than 50% longer wear life compared to competitors’ shoe wear life#.

Bradken® designs and manufactures undercarriage solutions that optimise customer operations, with a focus on critical deliverable areas.

Our products include:

•Crawler Shoes

•Drive Tumblers

•Return Rollers

•Load Rollers

•Idlers

Our innovative design, manufacturing processes, and continuous track improvements deliver longer wear life.

D ELIVE RING AN

SCAN TO LEARN MORE O PT IMISED FUTURE

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING RIO, SACOME, VHM AND WEIR.

Aseries of executive changes has been made at Rio Tinto, with new chief executive Simon Trott wasting no time in reshaping the business.

The company will operate under three core product groups: iron ore; aluminium and lithium; and copper.

Matthew Holcz has been appointed chief executive of iron ore, leading a portfolio that unifies Rio’s Western Australian operations with the Iron Ore Company of Canada and, once complete, the Simandou project in Guinea.

The company said this will combine “proven performance” with future potential, while sharing best practices and technology across the global portfolio.

Lithium will shift into the aluminium group under Jérôme Pécresse, alongside Atlantic and Pacific aluminium operations. Rio said the move strengthens downstream processing and productivity initiatives, including its Safe Production System.

Katie Jackson continues to lead copper, which the company said is well placed for the energy transition, with projects in Mongolia, the US and Chile.

The shake-up also sees the departure of long-serving executives Kellie Parker and Sinead Kaufman.

Trott said the simpler structure will drive “new standards of operational excellence and value creation”, with stronger accountability and disciplined capital use.

The South Australian Chamber of Mines & Energy (SACOME) has welcomed its interim chief executive officer (CEO) Nicola McFarlane.

A mechanical engineer by training, McFarlane has spent more than two decades leading high-impact projects and organisations at the forefront of the global energy transition.

Her experience spans steering largescale hydrogen and decarbonisation initiatives as chief operating officer of the Office of Hydrogen Power in South Australia, and prior to that as director for Hydrogen and New Energies Division for the Western Australian Government.

“As interim CEO, I greatly look forward to leading SACOME in supporting a trusted, forward-looking resources sector that attracts increased investment, strengthens community confidence and powers South Australia’s prosperity,” she said.

“My background enables me to effectively champion our members’ interests, build collaborative government and stakeholder relationships and keep our industry competitive.

McFarlane replaces the former CEO Rebecca Knol, who resigned in August.

Knol first joined SACOME as CEO in November 2016. In her role, she positioned the industry association at the forefront of policy and advocacy leadership in the state.

Knol has now stepped down as CEO after almost nine years to explore new opportunities.

VHM recently made two major appointments. As part of Goschen’s next development phase, VHM has appointed Andrew King as its new CEO and Benjamin McCormick as its new chief financial officer (CFO).

Both of the new roles will officially take effect from October 1.

A founding principal and director of Tanarra Capital, King brings more than 30 years of senior executive and board experience across the private equity, maritime and logistics, resources, infrastructure, and international trade sectors.

Trained as a certified practising accountant, McCormick has more than 25 years of experience in the mining industry, specifically in capital markets, mergers and acquisitions, corporate restructuring, funding strategies, and governance.

McCormick previously held senior finance leadership roles at REX Minerals, Federation Mining, Andean Precious Metals, Rincon Mining, and Newcrest Mining.

Current CEO Ron Douglas will remain with the company in a non-executive position capacity and current CFO Cameron Knox will step down from his role, both of which will also take effect on October 1.

At Weir, Mick Henderson has been appointed as the regional managing director for its minerals division in the Asia-Pacific (APAC) region.

Henderson brings a wealth of experience and a proven track record of delivering results across eastern Australia and the Pacific Islands.

His considerable regional insight and customer-first mindset underscore Weir’s commitment to supporting mining and resources customers with innovative solutions, responsive service and operational excellence.

Since joining Weir in 2017, Henderson has led teams across Queensland, New South Wales, Papua New Guinea, and the Pacific Islands. Most recently, as Weir director – eastern Australia, he focused on delivering value to mining and resource customers in the region through tailored service and support.

In his new role, Henderson emphasised the fact he will focus on expanding Weir’s regional presence, strengthening customer partnerships, and ensuring consistent delivery of highperformance solutions across the full product portfolio.

“I am dedicated to driving Weir’s mission by working collaboratively to deliver innovative, sustainable solutions and superior service,” Henderson said.

“With our talented team, I am inspired to build on our strong foundation and reach new heights together.”

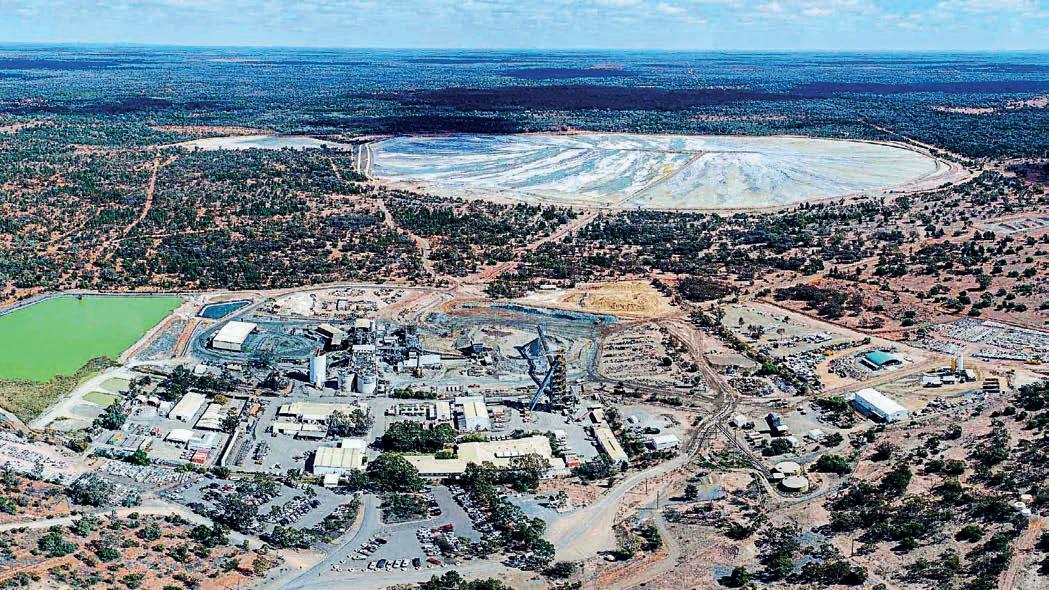

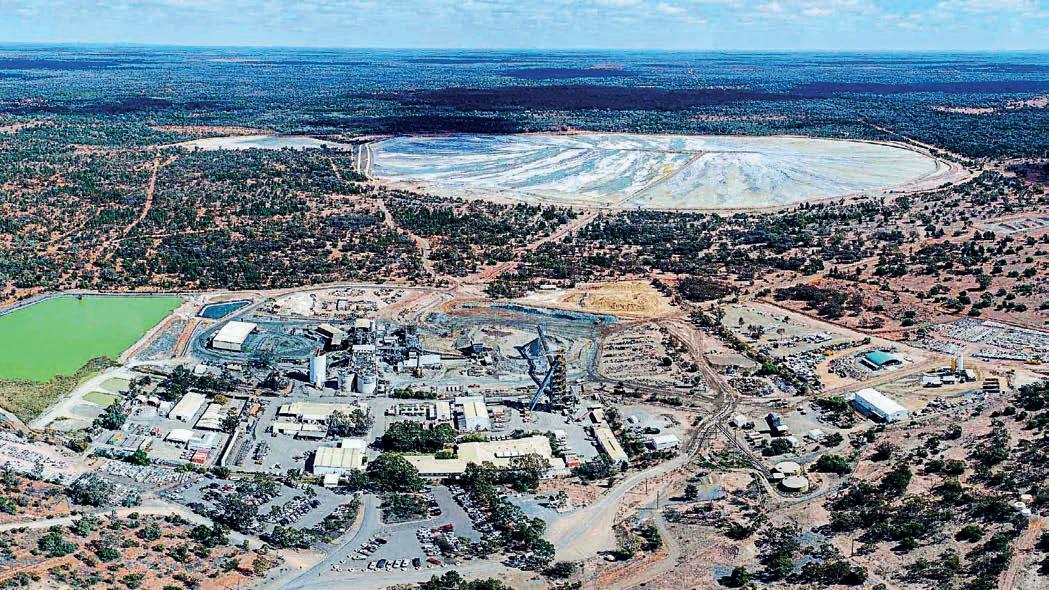

BHP REMAINS AT THE FOREFRONT OF GLOBAL MINING, LEVERAGING A HISTORY OF RESILIENCE AND INNOVATION TO LEAD THE INDUSTRY INTO A NEW ERA.

Charles Rasp could scarcely have imagined that in 2025 the company he founded 140 years earlier would be represented in the White House, with its chief executive meeting the US President to discuss global critical minerals supply chains, and why companies like BHP are crucial to winning the artificial intelligence (AI) race.

The White House meeting on August 19 between President Donald Trump, US Interior Secretary Doug Burgum, BHP chief executive Mike Henry, and his Rio Tinto counterparts was convened to specifically discuss the Resolution Copper mine, recognised as one of the largest and best undeveloped copper deposits in the US.

The meeting underlined the crucial role mining plays in a modern, technologically driven global economy, and in securing global supply chains.

Located near Superior, Arizona, the BHP–Rio Tinto joint venture Resolution Copper project has been bogged down in red tape and legal wrangling for the past 20 years.

Following the White House meeting, Henry expressed optimism that the project could finally move forward.

In a LinkedIn post, Henry wrote that BHP appreciated the US Government’s efforts to boost mining and open new possibilities for development, especially for critical minerals such as copper and potash, two key areas of interest to BHP.

“Resolution Copper is one of the largest untapped, high-grade copper resources in the US today,” Henry wrote.

“Copper is essential to everyday life as a critical component in powerlines, smartphones, medical equipment, cars, and data centres. Demand for copper is growing strongly.

“The world needs more mining to build the future.”

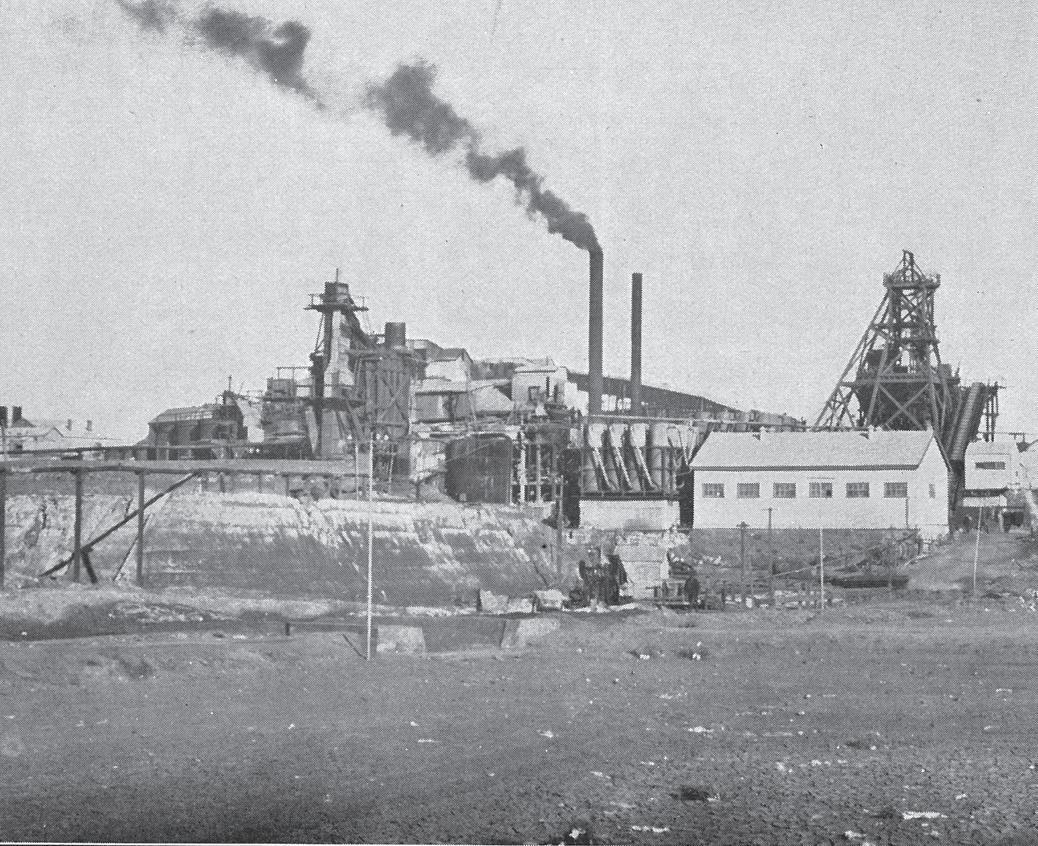

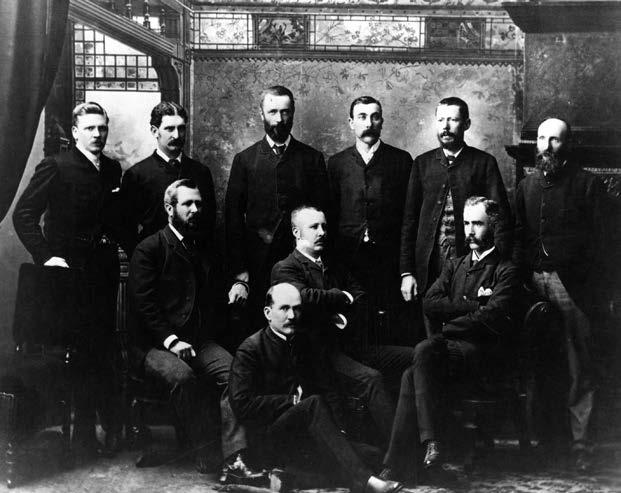

BHP DIRECTORS BACK L–R: WR WILSON; WILLIAM KNOX; BOWES KELLY; DE MCBRYDE; JB REID; WALTER SULLY. FRONT L–R: GEORGE MCCULLOCH; WP MCGREGOR; KE BRODRIBB. SEATED: SR WILSON (GENERAL MANAGER)

Along with Resolution, BHP’s global copper operations include several mines in South America, including Escondida in Chile the world’s largest producer of copper concentrates and cathodes, and Pampa Norte, which produces highquality copper cathode.

In Chile, BHP has a strong pipeline of organic growth options with attractive returns across its main assets, with forecast copper production to average around 1.4 million tonnes per annum (Mtpa) through the 2030s. It also has a non-operating partnership in Antamina,

a large, low-cost copper and zinc mine in Peru.

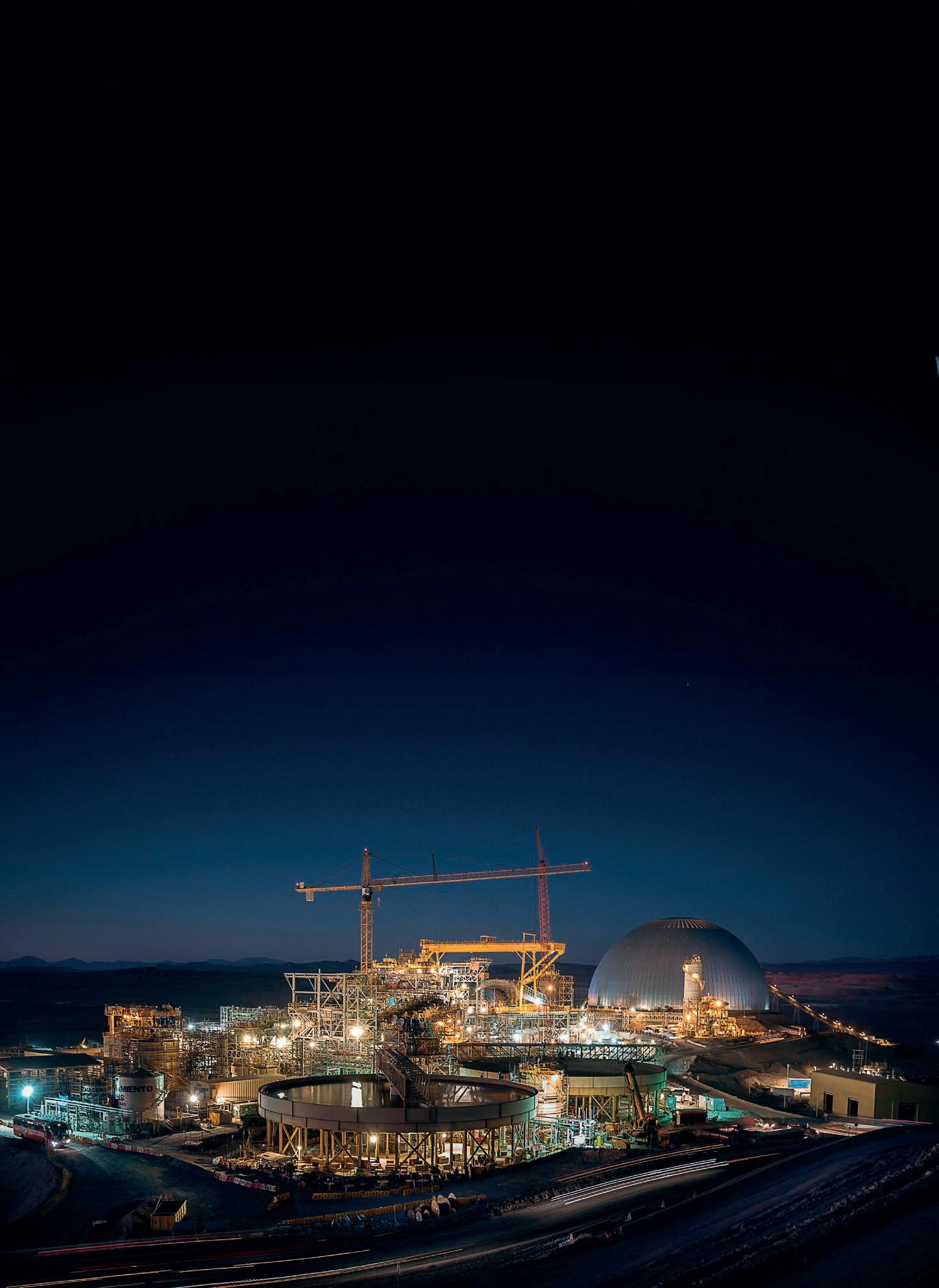

In Australia,BHP’s wholly owned Copper South Australia project comprises the Olympic Dam, Carrapateena and Prominent Hill underground and surface operations, as well as the Oak Dam exploration project. These are located within SA’s Gawler Craton, one of the world’s most significant copper, gold, silver and uranium oxide basins.

The company noted in its 2025 annual report that it was assessing a pathway to deliver more than 500 kilotonnes per annum (ktpa) of copper production, with a strategy to scale up to 650 ktpa from Copper South Australia.

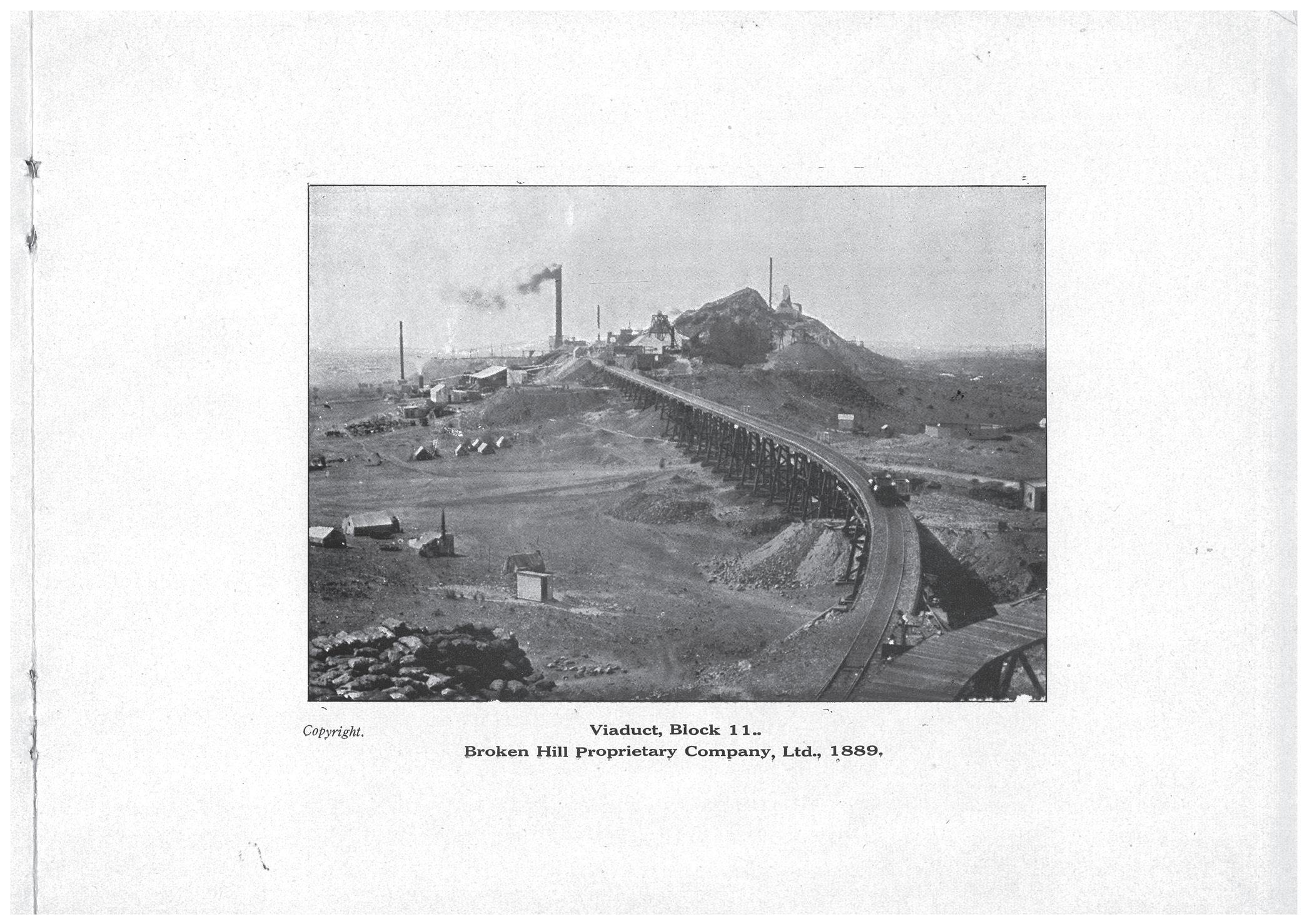

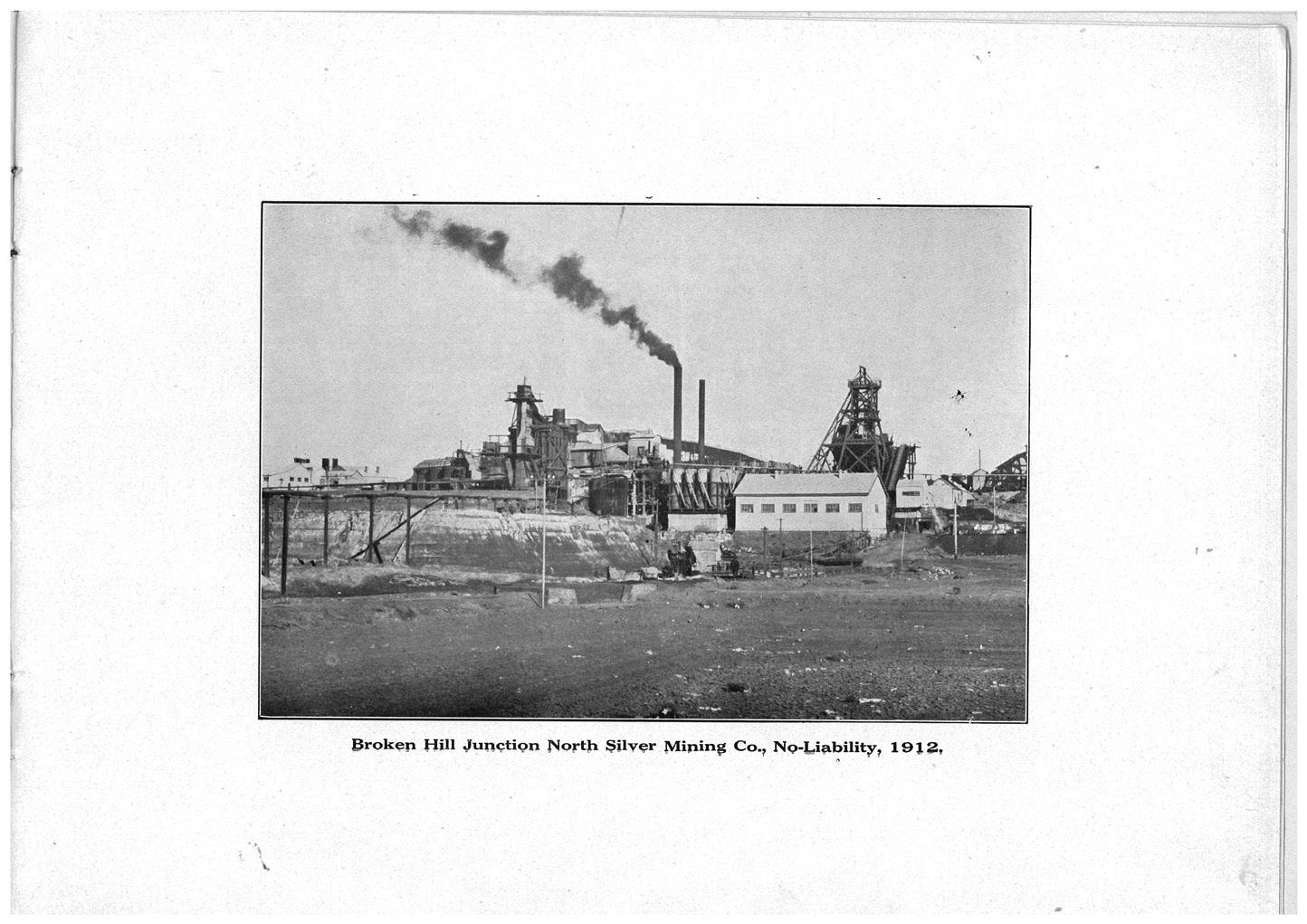

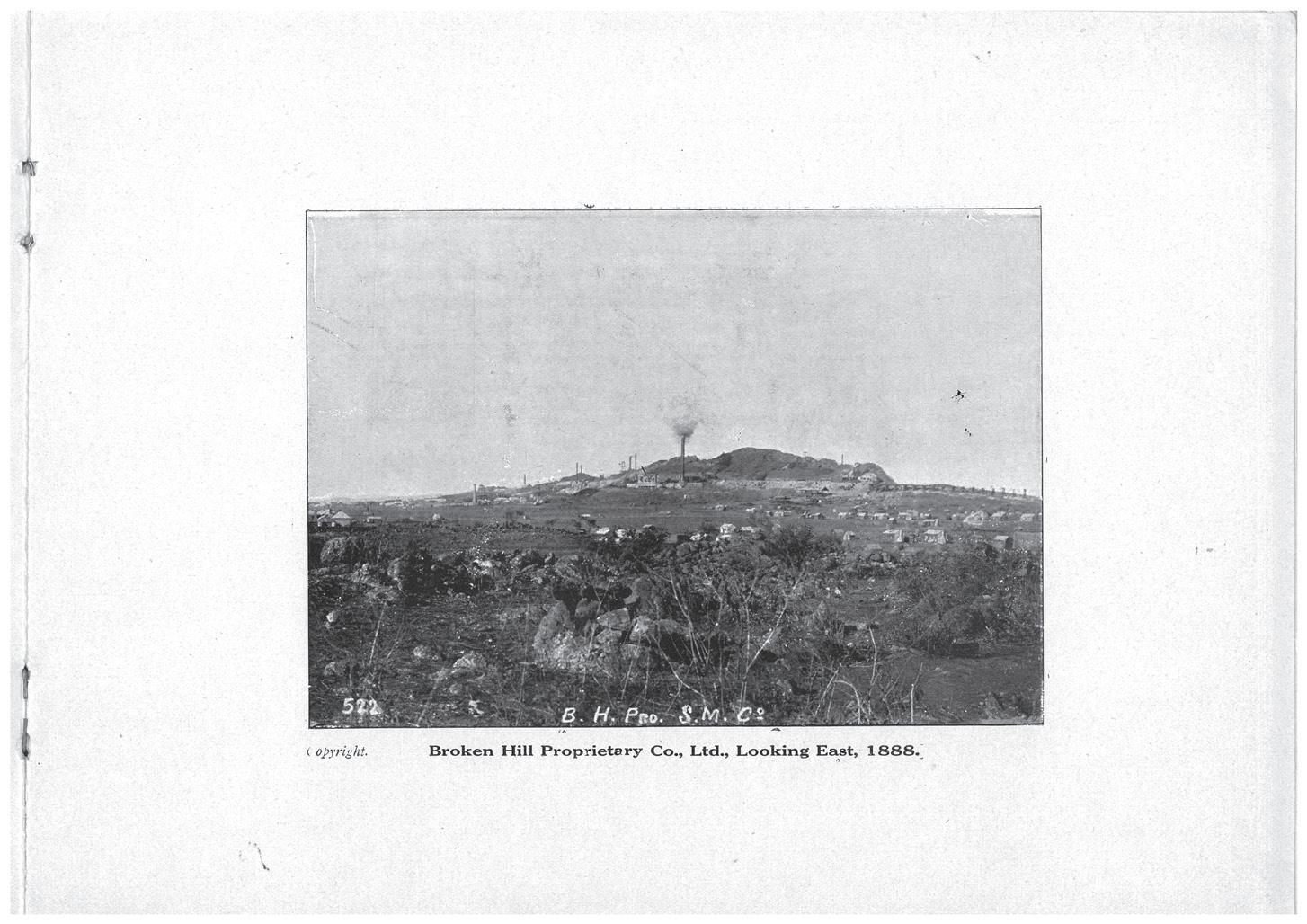

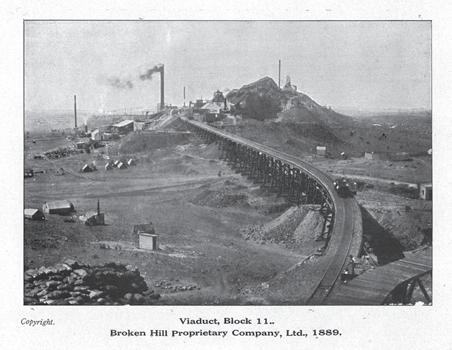

The BHP story began in 1883, when Charles Rasp, a boundary rider on a remote sheep station in the Barrier Ranges of New South Wales, discovered silver and lead on a rocky outcrop known as Broken Hill. Rasp paid the NSW Government the annual rent of five shillings an acre on two miles of mining lease, thought to be the largest single lease taken out on a payable orebody in Australia at that time.

The Broken Hill Proprietary Company Ltd was floated on the stock exchange in 1885, with its head office in Melbourne, where it remains in 2025.

The company soon became known simply as BHP.

Australian historian Professor Geoffrey Blainey, writing on BHP’s early years, noted that, apart from one, none of the seven directors were trained miners.

“The seven directors were wool men, and with one exception their expertise was not in the mining industry,” Blainey wrote.

“Fortunately, they made one of the wisest decisions in Australia’s industrial history: they decided that they would search overseas for the best engineers whom money could buy.”

That decision set the stage for two of the company’s defining characteristics: its willingness to embrace the

Impressed by his academic writings and his work on mines in Spain (where he had helped resurrect ancient Roman silver mines), as well as in Mexico and the US, BHP persuaded Delprat to move to the Australian colonies in 1898 first to Broken Hill and then to Adelaide.

Starting as the assistant general manager, he succeeded another esteemed early Australian mining figure, Sir Alexander Anderson Stewart, as general manager in 1899.

In the early 1900s, Delprat was central in developing the Potter–Delprat flotation process, a pivotal innovation in mining history.

The process separated ore from crushed rock by using bubbles to float the ore to the surface, enabling the extraction of vast tonnages of zinc that had previously been uneconomic.

Speaking at the IMARC gala dinner in 2016, Henry, then president of BHP’s Minerals Australia business, said Delprat’s legacy embodied the

century ago to the drone technology, driverless trucks and automated drills of today, our industry has never shied away from the challenges or opportunities that pave the way for innovation,” Henry said.

Over the next eight decades, BHP flourished as Australia grew.

The nation’s demand for mineral resources fuelled the company’s expansion, with milestone moments including the opening of the Newcastle Steelworks in 1915; support for WWII defence efforts; the creation of its Central Research Laboratories in Newcastle in the 1950s; and the discovery of rich iron ore deposits at Mt Newman in the Pilbara in the late 1960s.

The company’s operational excellence, married to commercial acumen, resulted in BHP becoming an Australian mining giant, and one of the country’s best-recognised brands.

billion acquisition of Utah International,

That acquisition turned BHP into a major coal exporter, and it expanded operations into the US, Brazil, Canada and Chile.

Now a global business, iconic TV ads in the 1980s further cemented its reputation at home as the ‘Big Australian’.

BHP hurtled towards the new millennium. Its controlling interest in the Escondida mine in Chile made the company one of the world’s leading copper miners, while the establishment of the EKATI diamond mine in Canada broadened its minerals suite.

Its chief businesses at the time were steel, copper, iron ore, coal, natural gas, oil and petroleum. Then BHP chief executive John Prescott even floated the idea of moving into construction and transport.

New millennium, new challenges

However, not everything BHP touched turned to gold.

Its $3.2 billion Magma Copper Mines acquisition in 1996 did not go as planned, and the Ok Tedi copper mine in Papua New Guinea was embroiled in controversy. The late 1990s were a relatively difficult period for the miner as its share price took a hit.

In 1999, the company made the momentous call to close its Newcastle steelworks, which marked the start of its exit from steelmaking. In 2001, it merged with Anglo-Dutch metals and minerals company Billiton to become BHP Billiton. The next year saw the demerger of BHP Steel.

Rapid growth was soon tempered by a return to its traditional core of mining businesses.

Meanwhile, China had begun its meteoric industrialisation, with average annual growth rates of 9–10 per cent during the 1990s and beyond.

The country’s massive demand for minerals proved serendipitous for BHP and the entire Australian mining

industry. By the end of 2015, BHP had shipped more than one billion tonnes of iron ore to China.

One hundred and forty years from its founding, BHP is active around the world, with major operations in Australia, Chile, the US, Brazil, Canada and Peru. Its global headquarters remain in Melbourne, where it opened its first office.

“BHP, like many companies that became notable, made the most of adversity,” Blainey wrote.

Other companies talk about resilience, but BHP lives it.

Even after 20 years of relative frustrations, it is easy to get the sense that the Big Australian has more than enough resolve to make Resolution Copper work.

In the 2025 annual report, Henry did not shy away from BHP’s sizeable investment in copper mining.

“We’re seeing an increasing focus on critical minerals supply and supply chain security across the globe,” he said. “This is happening against a backdrop of growing geopolitical and trade tensions, and reflects a growing understanding and acceptance of the critical role mining will play in supporting national security, energy transitions and technology development.

“We’ve reshaped our portfolio in anticipation of the megatrends playing out around us, including our position in copper. A much greater proportion of our EBITDA [earnings before interest, taxes, depreciation and amortisation] – 45 per cent in FY2025 – now comes from copper.”

On its 140th birthday, the world’s biggest miner, which Henry also describes as the world’s best, is in prime position to continue its remarkable story of growth, resilience and innovation as it leads the way on critical minerals production into the future. AM

FACTS AND FIGURES

•BHP ACHIEVED OVER TWO MILLION TONNES OF COPPER PRODUCTION FOR THE FIRST TIME IN FY25, LIFTING PRODUCTION BY 28 PER CENT SINCE FY22

•A TOTAL OF 91,304 EMPLOYEES AND CONTRACTORS GLOBALLY •FY25 TOTAL REVENUE $US51.3 BILLION ($78.56 BILLION)

• UNDERLYING EARNINGS BEFORE INTEREST, TAX, DEPRECIATION AND AMORTISATION $US26 BILLION ($39.8 BILLION)

• NO FATALITIES ON THE JOB IN FY25, AND HIGH POTENTIAL INJURY FREQUENCY DECLINED 18 PER CENT ON THE PREVIOUS YEAR

We are now better equipped than ever to help you to optimise your comminution and material handling operations for maximum performance, safety and efficiency. Our industry leading expertise in crushing, screening, feeding, loading and wear protection allows us to bring you an unrivalled equipment line-up. We underpin this unique offering with our expert process knowledge, full range of digital tools, high quality OEM spare parts, consumables and life-cycle services.

Scan the QR code to discover why we are the industry’s partner in eco-efficient mineral processing.

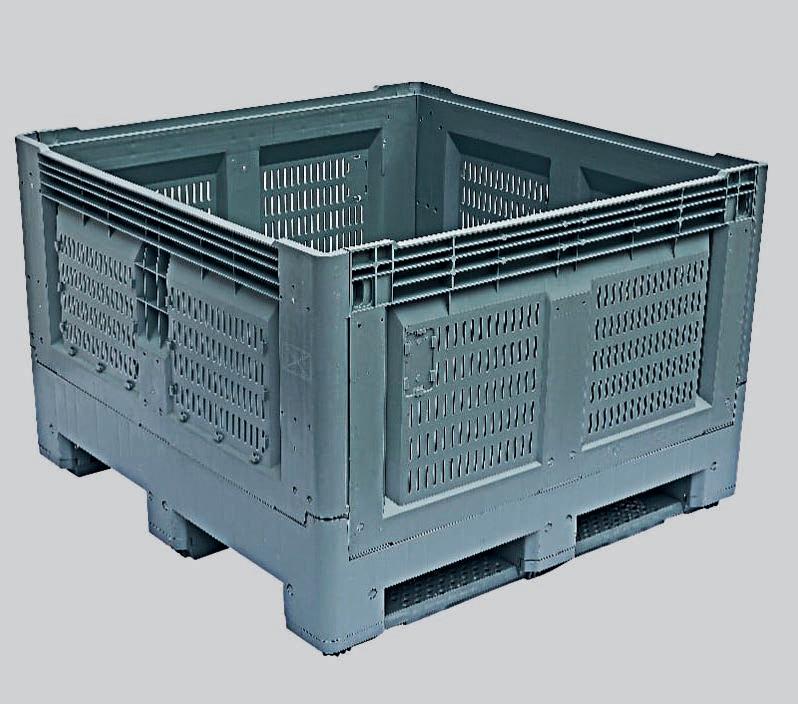

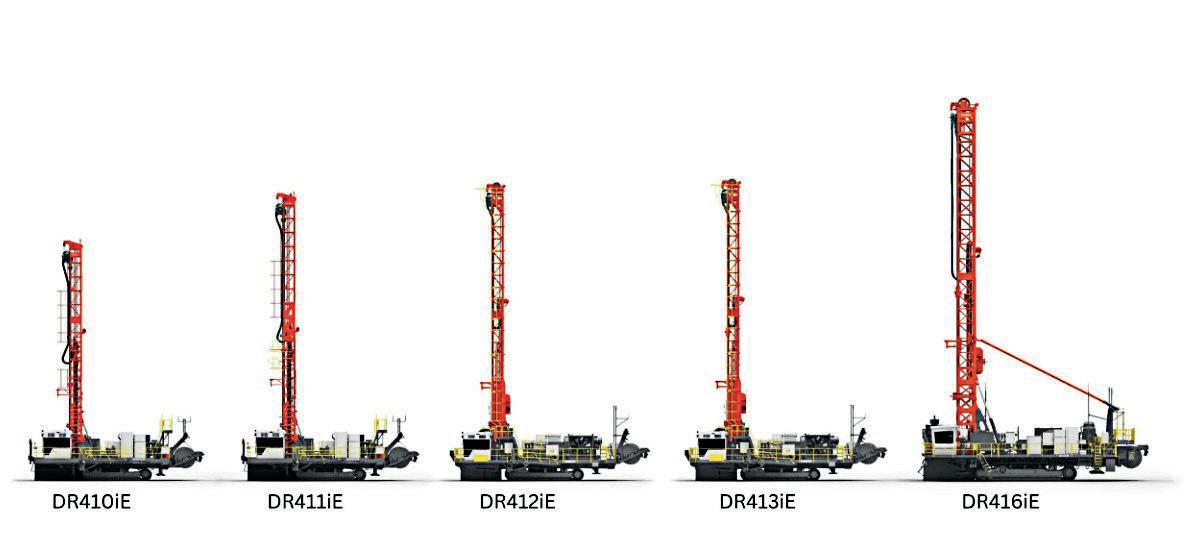

BUILT ON A PASSION FOR MINING, IT’S NO SURPRISE ELPHINSTONE HAS BEEN LEADING THE WAY IN MACHINERY INNOVATION FOR ALMOST HALF A CENTURY.

Elphinstone has become a name synonymous with the mining industry, manufacturing specialised equipment for underground and surface sectors for 50 years.

From underground mining support vehicles to off-highway extendeddistance haul trucks and mine extraction equipment, the company is also a wellestablished Caterpillar (Cat) OEM Solutions customer.

Elphinstone Group banner throughout Asia Pacific, the brand continues to strengthen its capabilities and expand its presence across multiple heavyindustry sectors.

After completing his trade qualifications, Dale’s employment began as a field service mechanic across Tasmanian and King Island mine sites.

Two years later, he travelled overseas and commenced work with Canadian Cat dealer, Finning, in 1973.

It was in 1975 – when Dale was modifying Cat surface mining equipment for underground mining applications out of his father’s shed on their farm in Burnie, Tasmania

and AD17, entered the market during the early 1980s.

Innovation and support for the mining industry didn’t stop there. Following an economic downturn in the mid 1980s, mining companies wanted to reduce their tunnel size which required smaller machines with equal capacity.

In 1986, Elphinstone accepted the

and manufactured load haul dump loader (LHD), the R1500.

The following year, Elphinstone sold its first R1500 overseas to Freeport McMoRan’s Henderson mine in the US.

Dale recalls negotiating with the purchasing team at Henderson mine.

“Someone said to me, ‘You realise that your machine price is double your

THE ELPHINSTONE NAME HAS BEEN ASSOCIATED WITH MINING SINCE THE 1960S.

competition was, because we sell the value of our product and what it will do for you’,” he said.

Elphinstone replaced 36 of the competitions’ loaders at Henderson with ten Elphinstone R1500 LHD loaders. Innovation, growth, philanthropy

By 1988, Elphinstone was going from strength to strength, developing and selling several new machines – including the R2800 LHD – the first of which is still operational today.

New developments followed in 1991 including the R1700 LHD and AD40 dump truck, designed to complement the larger LHDs.

The first R2900 was developed and sold in 1994, and by the end of that year, Elphinstone had delivered more than 200 LHDs globally.

The company’s success drew the attention of Caterpillar, and the two parties established a 50/50 joint venture in 1995, creating the business known as Caterpillar Elphinstone Pty Ltd.

At the turn of the millennium, Caterpillar exercised its option to purchase the remaining 50 per cent of the business replacing the Elphinstone name with the Caterpillar trademark.

As the group further diversified and expanded its mining machinery portfolio, including the purchase and relocation of Haulmax (Aust) Pty Ltd to Tasmania, commercial acquisitions continued to expand Elphinstone’s footprint across Australia and overseas.

After the sale of its underground mining business to Caterpillar,

the family partnering with the State Government to establish a state-of-theart, regional cancer treatment facility and provide university scholarships to local budding radiographers.

The Elphinstone Group’s commitment to giving back to their local communities also extends to the sponsorship of local sporting events, clubs and organisations.

“It is incredibly important for us to give back to the community that has supported us for over the last 50 years,” Cheryl Elphinstone said.

of skilled employees and maintain the well-established, local supply chain, Elphinstone worked with Caterpillar to “buy back” its brand and proceeded to consolidate the existing Haulmax business with newly acquired businesses, Specialised Vehicle Solutions (SVS) and Southern Prospect.

In 2016, Elphinstone spent $11 million refurbishing the previously leased Caterpillar manufacturing facilities and re-established themselves in the underground mining industry, launching a new range of specialised underground hard rock support vehicles.

market in 2016, Elphinstone has designed and developed more than 20 underground

three-person cabs hosting a number of utilities, such as concrete agitators, delivery trucks, scissor lifts, water cannons and tilt trays.

Additionally, the company continues to invest in electrification projects to provide alternative sustainable solutions for the future.

“The E15 powertrain will include multiple options – both diesel and electric – in the future depending on customer applications, requirements and appetite for decarbonisation,” Elphinstone global sales and marketing manager Tim Mitchell told Australian Mining.

In 2019, Dale Elphinstone received an Order of Australia Medal for his contribution to business and philanthropic work.

At the Austmine Conference in 2023, Elphinstone received the Champion of Innovation Award in recognition of his contribution to innovation in underground mining and manufacturing in Australia.

More recently in 2024, Dale was honoured to become the first person outside of the US to be inducted into the prestigious National Mining Hall of Fame in Denver, Colorado, and in October 2025, Dale will be presented with the prestigious AusIMM Institute Award, celebrating the company’s dedication, leadership and commitment to excellence.

In his own words, Dale would say “one person doesn’t do very much” and attributes the company’s 50-year success to its valued team of people.

“We’ve done a lot of things because we didn’t know we couldn’t and because we have a great team of people with a lot of yagottawanna,” he said.

To this day, the Elphinstone brand is recognised as a pioneer of underground mining heavy vehicle solutions. AM

SMARTER DESIGN. PROVEN QUALITY. RAPID RESPONSE.

Our focus is simple: to help you get the most from your equipment. That’s why MASPRO combines advanced technology, deep industry knowledge, and a commitment to continuous improvement to produce parts you can count on. From design to delivery, everything we do is about faster turnaround, longer service life, and confidence in your mining operations. The result? Parts that keep your site moving, shift after shift.

Follow us on:

FENNER CONVEYORS AND TYRECYCLE HAVE TEAMED UP TO TURN ONE OF MINING’S MOST STUBBORN WASTE STREAMS INTO A CLOSED-LOOP RESOURCE.

Mining is an industry built on movement, with conveyor belts providing the basis for ore transportation from one cog in the value chain to the next.

When belts reach the end of their service life, the question of what to do with them has, until now, been met with few viable answers.

This is changing thanks to a new partnership between Fenner Conveyors and Tyrecycle.

The two companies are combining technical expertise, specialised equipment and national reach to recycle used conveyor belts for alternative product streams including new conveyor belts.

Years in the making, the initiative takes advantage of significant new local infrastructure investments by both businesses in Western Australia.

Fenner’s soon-to-be-commissioned rubber mixing facility at its Kwinana manufacturing hub, paired with Tyrecycle’s East Rockingham processing plant, creates a powerful co-located recycling ecosystem.

Under the program, Fenner’s service teams remove old conveyor belts during scheduled changeouts or from existing storage areas, utilising in-house belt handling equipment developed specifically for harsh mining conditions.

These are then transported directly to Tyrecycle’s facilities in either Port Hedland or East Rockingham..

Tyrecycle processes the belts using high-powered Danish-designed equipment, capable of handling the largest steel-cord belts that have historically been too difficult to recycle.

The recovered rubber polymers and steel can be sold to domestic and international markets or, in a first for Australia, be returned to Fenner’s new rubber mixing plant to be reintroduced into the manufacturing of new conveyor belt.

“This is a really important strategic partnership involving a belt specialist with highly specialised equipment and reach into the mining sector,” Tyrecycle chief executive officer Jim Fairweather told Australian Mining

“Once the end-of-life belt comes to us, we can process it and return it to Fenner’s manufacturing facilities where it is incorporated into new belting products.”

This is no pilot project waiting on future breakthroughs, with more than 1000 tonnes of conveyor belt having already been recycled in trials and accepted by downstream trading partners.

The closed-loop element, which sees recovered rubber sent back into Fenner’s manufacturing stream, is now within reach.

“For years, solutions such as this were always seen as something down the track,” Fenner Conveyors managing director Jen Green told Australian Mining

“Conveyor belt recycling is here now, on our doorstep and that’s why it’s an exciting partnership.”

Fairweather said while passenger tyres are recycled at a rate of 98 per cent in Australia, mining tyres sit at just one per cent and conveyor belts at close to zero.

“The mining sector has been looking for a solution,” he said. “Our partnership with Fenner means we’re uniquely positioned to meet that unmet demand.”

Central to the partnership is Fenner’s investment in its Kwinana rubber mixing facility.

“Mixing rubber compounds locally allows us to bring raw ingredients together and tailor compounds to different applications, with new mixes tested by our local R&D (research and development) centre,” Green said.

“This partnership enables us to incorporate recycled polymer composites from Tyrecycle, accelerate innovation and new product development, protect IP, and keep manufacturing local in Australia.”

For Tyrecycle, the East Rockingham facility, located just a few kilometres from Fenner’s Kwinana manufacturing plant, was intentionally designed with the capability to process conveyor belts.

“When the plant was built, we knew it would one day process conveyor material,” Fairweather said. “The equipment was specifically designed to handle it from day one.”

For mining companies, the benefits go beyond logistics. Diverting used belts from landfill or long-term storage will limit waste volumes, reduce emissions and contribute to decarbonisation targets.

“Companies all around the world are looking to reduce their waste footprint and increase circularity,” Green said. “Mining clients now have a solution for a waste stream that previously wasn’t available.”

Clients can engage through either Fenner or Tyrecycle, with joint engagement and site visits already underway with some mining customers. While the partnership’s immediate focus is on Western Australia, where both companies have invested heavily and operate in close proximity, the model is designed for scalability.

Fenner’s national footprint and Tyrecycle’s growing facilities across Australia create a platform for expansion once the WA operation is optimised.

“These are two established businesses with existing infrastructure, so the scalability opportunity is real,” Fenner Conveyors executive general manager –sales and marketing Trevor Svenson said.

“But first we want to push the limits of what’s possible in WA.”

The partnership’s origin stretches back years. Following recent capital investments and the pairing of Fenner’s Kwinana facility and Tyrecycle’s East Rockingham plant, everything has now fallen into place.

“Fenner and Tyrecycle have always shared similar values and outlooks,” Green said. “With these last pieces in place, the time is right to bring it to our customers.

“The exciting part is we’re not just talking about what could be done, we’re actually doing it.”

For a mining industry seeking credible, immediate steps to achieve sustainability, this partnership could make all the difference. AM

At Australian Power Equipment (APE), we deliver more than high-voltage power solutions – we deliver peace of mind. From brand-new transformers to expertly refurbished equipment, we help industries stay switched on with smarter, faster, and more sustainable options.

Our circular economy model means we don’t just supply power—we give old equipment new life. By refurbishing quality assets from decommissioned sites, we minimise waste, reduce lead times, and keep urgent projects moving. It’s better for business and better for the planet.

But our commitment doesn’t stop there. We actively support wildlife conservation and rewilding efforts across Australia –because powering progress should never come at the cost of our environment.

With a nationwide network and a lean, responsive team, APE sources and delivers critical equipment when and where it’s needed most. Whether it’s mining, infrastructure, or renewables, our clients trust us to keep operations running and downtime to a minimum.

Backed by decades of experience and a clear vision for the future, we’re proud to be shaping a more sustainable tomorrow.

AGENTS FOR

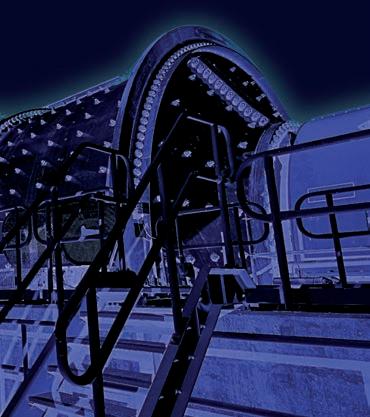

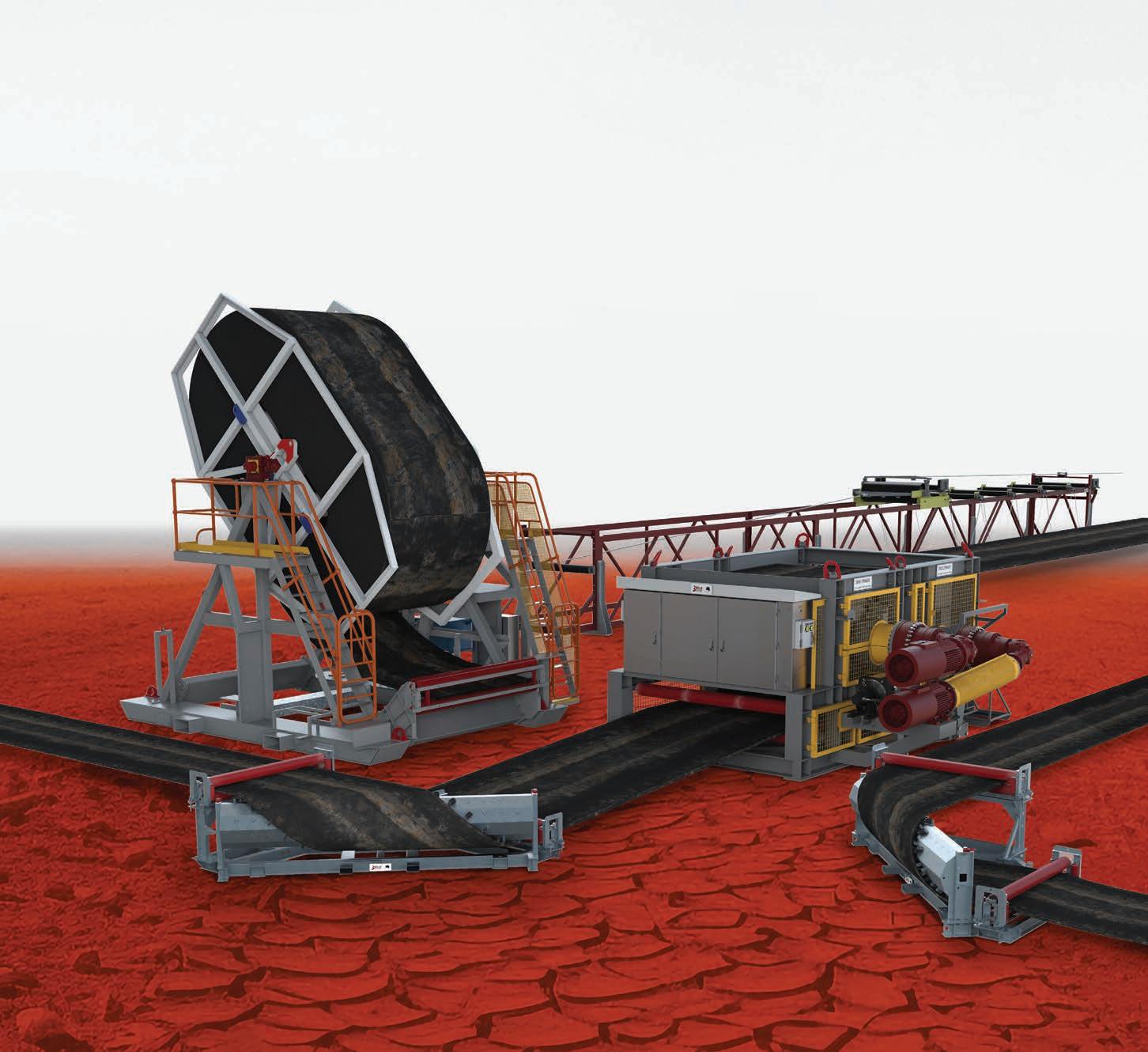

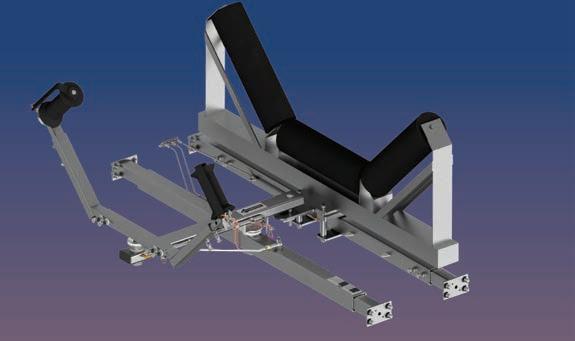

THE THOR LOPRO TELESCOPIC RADIAL CONVEYOR COMBINES PROVEN ENGINEERING WITH AN INNOVATIVE

It takes some heavy machinery to move mountains, but weight can also negatively affect the ground bearing pressure that equipment generates. Too light and the machine can’t do its job; too heavy, and the foundation material below is negatively impacted.

This is the perennial problem that Canada-based manufacturer Thor Global sought to resolve with its telescopic radial conveyor.

Developed in response to stricter requirements for in-spec material supply, the conveyor enables operators to build larger and more consistent stockpiles. With a much longer horizontal reach than traditional conveyors, operators can layer material concentrically, in multiple windrows, effectively minimising segregation.

Thor designed and introduced the first telescopic radial conveyor in 1992, and the innovation quickly gained traction across the global mining industry. Thor then pivoted its primary focus towards these systems in response, and the manufacturer now produces one of the widest ranges of these tools, catering to the full spectrum of remote site mining conditions around the world.

Lincom Group is the exclusive dealer of Thor Global equipment in Australia, and there’s no doubting the company’s enthusiasm for the range. Lincom’s product manager Alan Dunbar said the brand was the original

and best manufacturer of telescopic radial conveyors.

“With Thor’s load equalisation system, the machines are strong, but lightweight where it counts,” he said. “The range is versatile and well suited to Australia’s diverse mining conditions.”

The latest incarnation of the Thor radial conveyor is the LoPro. As the name suggests, this offers the lowest feed height in the industry, and the patented hinge point enables the feed angle to remain constant, thus eliminating spillage, while a robust truss structure ensures strength and stability.

The Thor LoPro is designed to be more mobile, and is available in two standard lengths of 40m and 46m. Each is capable of handling up to 1500 tonnes per hour, with a feed height of just 1.5m at a fixed hopper angle.

This compact profile brings a host of advantages to the operating mine. In particular, the static hopper design removes the need for an increased drop height when feeding the conveyor. This reduces the impact and wear on the hopper as well as its belts and tail undercarriage.

“Allowing the conveyor to be fed from a constant, lower angle eliminates spillage and streamlines operations,” Dunbar said. “This lower feeding height contributes to maximum versatility for different material types and processing machinery without requiring additional equipment.”

The exclusive partnership between Lincom and Thor Global has been built on more than three decades of field-tested reliability across Australia’s demanding mining conditions.

“Thor equipment is engineered for longevity in the harshest environments,” Dunbar explained. “The build quality speaks for itself and when you’re investing in equipment for a remote mine site, you need absolute confidence it will perform day after day.”

The LoPro exemplifies this philosophy, delivering the durability and innovation that has made Thor the industry benchmark for telescopic radial conveyors.

While Thor Global provides world-class equipment, Lincom’s value proposition extends far beyond being simply a supplier of those machines.

Lincom positions itself as a partner who can offer support across the breadth of operations, enabling customers to focus on results. This comprehensive approach means the company is on-hand for the entire equipment lifecycle, from spare parts and service to machine rebuilds.

Lincom provides complete customer satisfaction with service and support provided in throughout Australia 365 days per year. The company’s service offerings span the full spectrum, from preventative maintenance through

to emergency breakdown repairs and scheduled refurbishments, with expert technicians available to assist customers whenever needed.

“We understand that downtime is lost revenue,” Dunbar said. “Our goal is to keep equipment running at peak performance, whether that’s through regular maintenance schedules or rapid responses if something goes wrong.”

Lincom firmly believes that the initial sale is just the beginning of its commercial responsibilities, focusing on long-term partnerships rather than transactional dealings. The company provides diagnostic and reporting services, offering practical recommendations and action plans to ensure equipment runs smoothly.

This includes access to original stock and locally-sourced spare parts, understanding the critical need for equipment reliability and peak performance capacity every single day.

For Australian mining operations seeking reliable bulk material handling solutions, the Thor LoPro represents the convergence of proven engineering and local expertise.

Through Lincom’s partnership with Thor Global, operators gain access to industry-leading equipment backed by comprehensive support – ensuring maximum uptime and operational efficiency in Australia’s challenging mining environments. AM

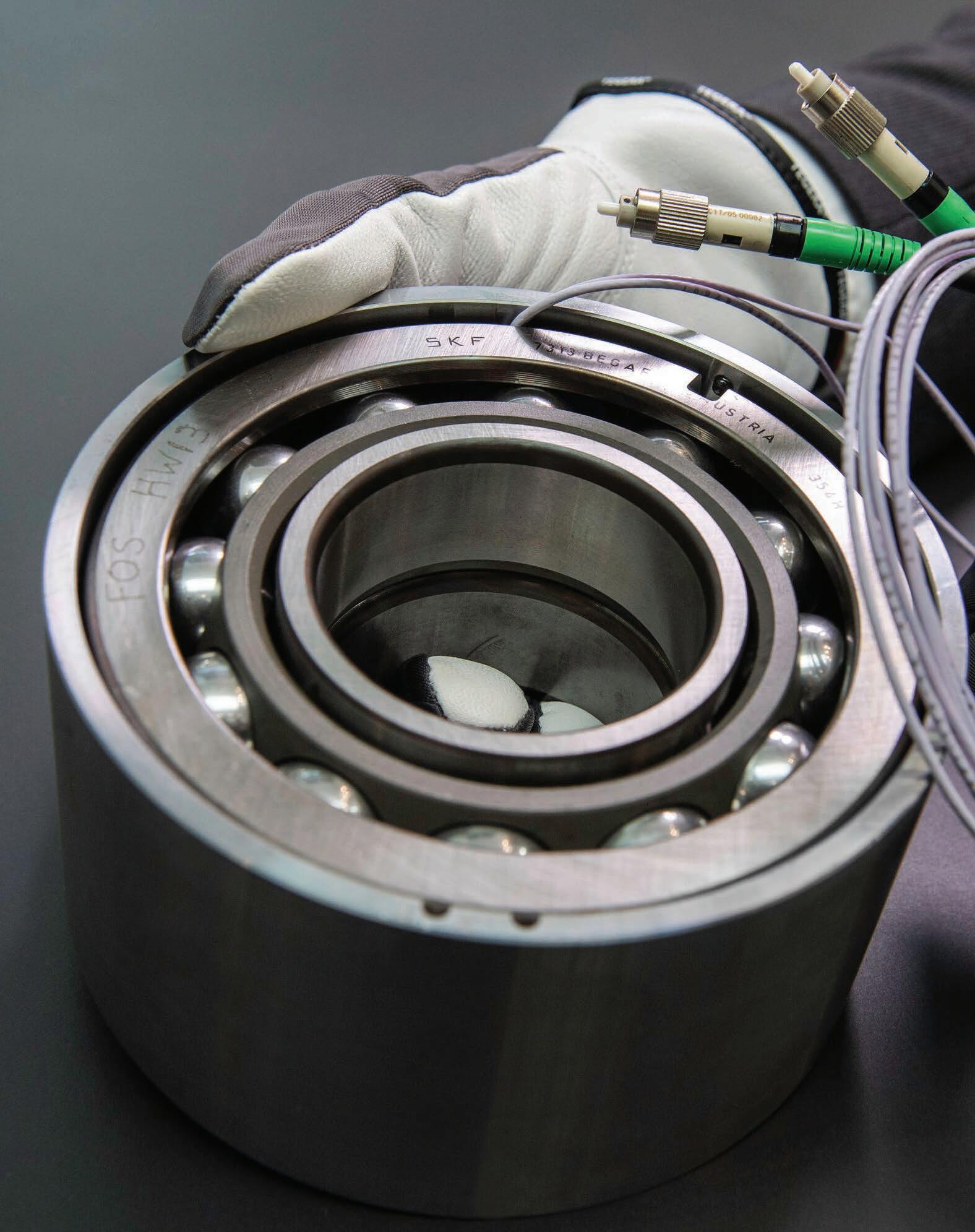

With a proud history of being a leading specialist in undercarriage solutions for mining equipment, Bradken continues to innovate to meet customers’ needs.

The company has been at the forefront of undercarriage design and manufacture for more than 40 years, and has supported customers in some of the most demanding conditions across the globe.

Today, Bradken’s work on the R9600 hydraulic excavator undercarriage highlights its continued commitment to providing customers with longer service life, lower total cost of ownership and confidence in the field.

From its early days of manufacturing crawler shoes for hydraulic excavators through to its most recent advances, Bradken has demonstrated the power of sustained innovation.

Between 2007 and 2021, the company designed, manufactured and supplied the majority of sets of crawler shoes for R9800 and R996 excavators to the original equipment manufacturer (OEM).

That track record has established a foundation of trust with OEMs and end users, who have seen first-hand

the gains delivered through Bradken’s metallurgical expertise, rigorous design processes and state-of-the-art manufacturing facilities.

“We partnered with Liebherr in the design of the crawler shoe and drive tumblers for their 996B and 9800 excavators,” the company said. “And, for over 15 years, Bradken was the supplier of choice for R996B and R9800 crawler shoes and drive tumblers to the OEM.”

Since 2021, Bradken has been free to sell direct to the market and has been supplying customers worldwide with leading undercarriages for R996B and R9800 machines.

Leveraging decades of manufacturing expertise, Bradken’s recent design and material enhancements deliver reduced costs, improved performance, and enhanced safety in the toughest environments on earth.

Mining operations are facing pressure to reduce downtime and extract maximum productivity from their machines.

Bradken’s approach is squarely aimed at meeting those challenges, and that commitment is perhaps most visible in the company’s undercarriage offerings.

Following case study research into R9800 and R996 track shoe comparison of Bradken and competitor track shoe wear rates, Bradken’s crawler shoes have been shown to deliver more than 50 per cent greater wear life compared with competitor products.

In practical terms, that means fewer change-outs, lower maintenance costs and more machine availability – these metrics can make a significant difference to a mine’s bottom line.

Scale is another factor that helps to set Bradken apart. As one of the largest manufacturers of undercarriages for mining machines over 200 tonnes, the company has supplied more than 250,000 crawler shoes to mining customers worldwide in the past quarter-century.

This scale is matched by a customerfocused approach that recognises the diverse conditions in which mining operations take place. By tailoring solutions to site-specific requirements, Bradken works to ensure its components deliver superior performance while minimising downtime.

Technology enhancements

Technology has also become an increasingly important element of the company’s offering.

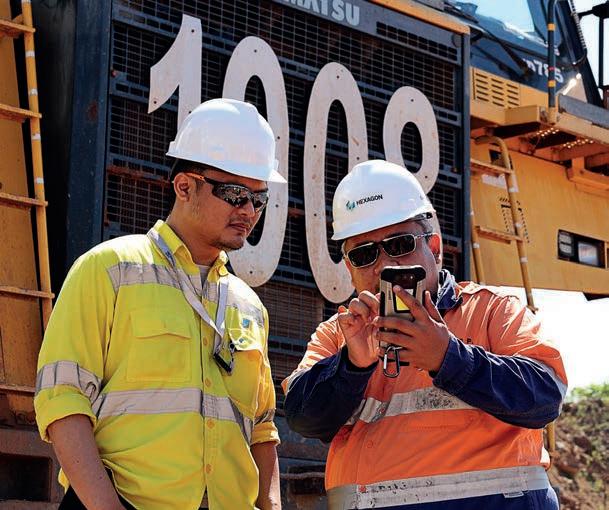

Through the company’s dedicated Bradken Inspect app, inspections can be conducted more efficiently with detailed condition assessments of undercarriage components provided.

The resulting reports provide a clearer understanding of wear patterns and performance rates to enable maintenance planning. This wear monitoring and reporting service provides the basis for predictive analysis, refurbishment recommendations and design improvements that help extend the life of critical components.

For mine operators, the ability to accurately track wear and plan maintenance translates into greater predictability, reduced unplanned downtime, and ultimately a lower total cost of ownership.

The optimisation of the R9600 excavator undercarriage is the latest step in Bradken’s journey of continual improvement.

Years of investment in research and development have gone into refining the R9800, R996 and now the R9600 ranges, ensuring that Bradken’s customers benefit from components that are not just robust but also smarter in the way they are designed and manufactured. AM

You commute to the far ends of the earth. Your workplaces are in the most challenging environments on the planet. The unrelenting pressure you face to cut costs while being safer, more sustainable and more productive demands more than partial solutions or occasional transactions. It demands a trusted partner, committed to meaningful support, data-driven insights and solutions that connect all parts of a mine. We’re Hexagon. One partner. For the life of your mine.

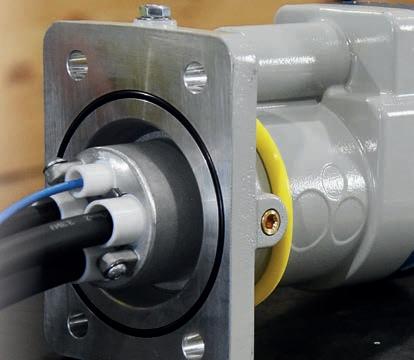

THEJO HIGHLIGHTS HOW MODERN DUAL-PISTON SYSTEMS ARE REDEFINING CLEANING PERFORMANCE IN THE HARSHEST OPERATING CONDITIONS.

In the demanding landscapes of Australian bulk material handling sector, uninterrupted material flow is the foundation of efficiency. Yet persistent build-up in hoppers, silos, kilns and chutes continues to disrupt operations. These blockages trigger production delays, drive up maintenance costs, and introduce serious safety risks.

Air blasters – compressed-air devices designed to dislodge adhered material – are frontline tools in preventing these issues. Too often, however, their selection can be driven by short-term thinking rather than sustained performance. Experience across heavy industries has shown that prioritising performance is the best way to ensure lasting reliability, safety and operational excellence.

Material build-up is rarely caused by a single factor. Moisture, particle cohesion, variable feed rates and temperature swings can all contribute to accumulations.

Sticky ores, coal dust and clinker are especially problematic.

In chutes and silos, where airflow stagnates, these materials harden quickly and cling to surfaces, resisting flow even under high loads.

The consequences of this situation are costly and extend beyond production losses:

• Frequent stoppages for cleaning and de-choking silos and hoppers

• Lost production time, sometimes running into hundreds of thousands of dollars per incident

• Potential equipment damage from manual hammering or forced clearing

• Safety risks when personnel must enter confined spaces or handle hazardous dust

• Higher labour costs due to manual intervention

Unchecked build-up is one of the most expensive hidden drains on plant performance. It erodes output, consumes additional energy, and places unnecessary strain on workers and equipment alike.

While air blasters are designed to fight material build-up, conventional designs introduce their own hidden costs; they often appear inexpensive at the time of purchase, but their inefficiencies compound rapidly in daily operations.

Some of the biggest drawbacks include low blast force that struggles with compacted material, longer fill times, higher air consumption per effective blast, frequent firing cycles, and shorter lifespan.

What looks like a simple solution often becomes higher total cost of ownership due to downtime, wasted energy, and increased servicing.

Conventional units often have difficulty keeping up with the demands of modern heavy industry, resulting in higher air bills, strain on compressors, and recurring blockages.

Modern air blasters like Bazooka can overcome these challenges with dual-piston valve technology, a design that unlocks greater power and efficiency. Unlike single-piston systems, which release compressed air through a series of restricted passages, the dual-piston design opens inlet and outlet valves simultaneously, allowing compressed air to escape in a single, instantaneous burst, maximising impact at the point of discharge. Potential benefits include up to 30 per cent more force than conventional units, less wait time between blasts, fewer cycles needed to achieve full clearance, and stronger, faster blasts that clear stubborn deposits.

In simple terms, dual-piston systems deliver more cleaning power with less

energy, less downtime and less wear. This performance leap can mean the difference between continuous operation and costly interruptions.

Controlled load-cell testing by Thejo has confirmed Bazooka’s performance advantage.

In repeated trials, it consistently reached peak blast forces of around 1280kN in 0.3 seconds.

IN SIMPLE TERMS, DUAL-PISTON SYSTEMS DELIVER MORE CLEANING POWER WITH LESS ENERGY, LESS DOWNTIME AND LESS WEAR.”

For industries where every hour of uptime counts, performance-driven blasters deliver measurable results.

Beyond the obvious savings in downtime, they also:

• reduce compressed air usage per tonne of material handled

• extend the lifespan of blasters and the equipment they protect

• improve operational safety by reducing reliance on manual intervention

• provide predictable, consistent performance even in extreme temperature or moisture conditions.

This combination of benefits goes beyond operational convenience. It forms a strategic shield against rising costs, equipment failures and unplanned shutdowns. In harsh environments like Australian mines, where reliability is nonnegotiable, high-performance systems are the only viable choice.

Procurement in today’s industrial environment should go beyond short-term fixes. The priority should be equipment that delivers consistent performance, protects worker safety, and ensures longterm reliability. A procurement strategy that emphasises durability, efficiency and validated performance is not just prudent; it is essential.

Adopting performance-first procurement, anchored in proven dual-piston designs, offers a sustainable path forward. Choosing highperformance air blasters is an investment in productivity, safety and long-term operational excellence, helping to ensure resilience in the toughest operating conditions.

In an environment where material build-up is inevitable but stoppages are not, performance must take precedence. For Thejo, the choice is clear: embrace modern dual-piston solutions that secure lasting reliability and operational success. AM

Belt conveyor operators in high-volume bulk handling industries often discuss the efficiency “sweet spot”, which refers to the balance between the amount of spillage beneath the system and dust emissions above, relative to the volume of material being transported and the total uptime. To put it bluntly, this balance is a myth.

There is no trade-off between maintaining a clean operation and ensuring productivity. In fact, installing the correct material discharge and belt cleaning configuration can effectively address both concerns, along with a variety of other issues throughout the entire conveyor system.

Quality and construction of belt cleaners are crucial for achieving optimal results. Two cleaners from different manufacturers, both made of polyurethane, may appear quite similar. But once they are installed and tensioned, operators will notice significant differences.

Typically, a lower-quality cleaner allows more material to carryback, requires more maintenance labour, needs to be replaced more frequently, may not be suitable for the application’s volume or properties, and could damage the belt,

Carryback refers to material that is not discharged, bypasses cleaners, and

This is caused by carryback. After passing through the cleaner(s), material drops at the snub pulley and/or the take-up pulley. It typically does not

cleanliness and safety.

Solution: A primary cleaner blade endures the stress of heavy bulk material, so it is important to ensure it is properly graded. When selecting a primary belt cleaner, consider the pulley diameter, belt speed, production volume, and material properties. Wet, viscous, acidic/alkaline, and sharp/ abrasive materials may require blades made from specialised polyurethane or material blend.

Many conveyors come with a “tracking” system that is intended (ineffectively, in many cases) to keep the belt from coming into contact with the stringer and shredding the edges. Some operators who experience mistracking on the return install a “crown” roller design, which is thicker in the middle. If the belt drifts slightly, this design uses its weight to realign it back to the centre.

When these return rollers are fouled by carryback, they no longer realign the belt. If the belt is not centred on the tail pulley, the cargo is likely to be loaded off centre. This can result in the belt drifting further off centre, spilling cargo from a full belt and potentially damaging the entire system.

Solution: Modern belt alignment systems like the Martin Tracker HD can remedy misalignment more effectively

than installing crown rollers. Designed for either the return or carrying side of the belt, these devices use sensing arms to detect slight variations in the belt path and immediately correct them by turning a roller or idler in the opposite direction.

Trackers are recommended for all systems because many factors can cause mistracking, not just carryback and broken equipment. However, mistracking results from carryback, so the underlying cause should be addressed first. Belt tracking on the return is also advised, regardless of issues stemming from carryback. With longer gaps between rollers on the return side than the upper carrying side has between idlers, the return side is susceptible to wind, belt camber, and other elements that can lead to drift.

Running a system to failure due to an overstretched workforce will lead to more expensive and prolonged downtime. Inspection and maintenance of a conveyor system should be routine and performed regularly to prevent unscheduled downtime. This is easier said than done, since belt cleaner tensioning is a continuous challenge for many operators.

Under-tensioning leads to carryback and expedites the blade wear. In contrast, over-tensioning results in higher power costs and increased heat from friction, runs a higher risk of pullthrough, and accelerates blade wear.

After lock-out, tag-out (LOTO) procedures, changing cleaners can be an ergonomically awkward task performed beneath a conveyor or inside the drop chute, often requiring two or more people and/or a confined space entry certification.

Solution: Carrying out maintenance during a scheduled shutdown, when staff can focus on specific tasks in a controlled environment, is optimal. Many innovations to minimise maintenance time have been introduced in recent years. For example, Martin Engineering’s N2 Position Indicator (PI) helps determine scheduled downtime by providing data on the wear status of belt cleaners. Delivered via mobile app, the N2 PI not only alerts users if an incident occurs, but the data it provides also helps operators understand wear times. This informs managers and aids them in coordinating maintenance schedules for greater efficiency.

Carryback increases safety risk and operational costs. Although it is strongly discouraged, operators continue to assign workers to clear spillage from around the system while the belt is running, shovelling the spillage back onto the moving conveyor, or into a skip or barrow – all of which drives up labour costs. If a worker comes into contact with the belt, risk of an injury or fatality is high. Working on or near moving conveyors remains a leading cause of workplace injuries and deaths. Beyond the devastating price paid by a worker’s family and colleagues in such circumstances, these incidents always result in costly

fines, unscheduled downtime, and increased insurance premiums.

Solution: Avoid safety issues and labour costs associated with cleaning by eliminating the cause, carryback. Always follow the LOTO procedure and never allow any worker to perform maintenance on or around a working conveyor. One innovation that enhances servicing and safety is the Safe to Service Martin QC1+ Primary Cleaner or Safe to Service SQC2S Secondary Cleaner. Instead of confined space entry or crawling under the system, these designs enable equipment to be pulled away from the mainframe and serviced quickly and ergonomically by a single worker from outside the chute. AM

When Emesent Hovermap is mounted on a drone or robot, world-leading autonomy enables it to execute missions with little to no human intervention. Emesent technology takes control, making intelligent decisions so users don’t have to, all the while mapping dangerous and inaccessible environments and providing fast and accurate data that keeps teams out of harm’s way.

FROM MANGANESE TO IRON ORE AND GOLD, MAX PLANT’S FEEDERS GIVE MINERS

For decades, MAX Plant has been a go-to mineral processing partner in the Australian mining industry, delivering tailored solutions to solve the most pressing operational conundrums.

Core fixtures in MAX Plant’s portfolio, the feeder stacker (FS) and belt feeder (BF) ranges have proven their worth in the harshest mining environments, serving as key cogs in bulk material handling value chains.

But MAX Plant doesn’t deploy a solution without ensuring it’s siteready first.

“We offer customisations to suit the client’s specific requirements,” MAX Plant business development manager Neil McKenna told Australian Mining “From how they’re powered to whether they’re mobile or skid-mounted, we adapt our feeders to best suit customer needs.”

MAX Plant’s expertise goes beyond product customisation, with support available throughout a machine’s lifecycle. This helps the company stand out from the rest.

“We don’t just supply equipment, we also install and maintain it for our clients,” McKenna said. “And when we mobilise, we train operators on everything they need to know about the machinery.”

The versatile feeder stacker Available in both track-mounted and skid-mounted variations, MAX Plant’s feeder stackers are specifically designed for production rates up to 800 tonnes per hour. This range includes the FS1200, FS1000 and FS800, with options to suit a range of applications and requirements.

“The feeder stacker units are used for what we call surge capacity, which allows you to control the feed and flow of the material through the crushing plant,” McKenna said.

“We can speed up or slow down the feed coming from the stacker to the rest of the plant. This gives us greater feed control without having surges of material coming through spasmodically.”

So what does a customised feeder stacker look like?

“We might provide extra options to support the machine, like static grizzlies over the feeder hopper, or we could boost hopper capacity,” McKenna said. “We can also adapt the length of the conveyor boom or even remove elements of the feeder stacker completely.

“We want to give our clients something that works for them.”

MAX Plant’s feeder stackers can be either diesel or electric powered, providing up to 185 kilowatts of power.

So how is the feeder stacker currently being used in the Australian mining industry?

“A manganese mining client had more than 100,000 tonnes of oversized material after the crushing and screening process – which is a significant amount,” McKenna said.

“The client used a MAX Plant feeder stacker to feed the material back into their existing primary jaw crusher to be recirculated through the plant. The client wanted a fully mobile unit so they could easily move the machine and feed the jaw from different locations.”

McKenna also explained a popular iron ore application.

“Iron ore miners are using MAX Plant’s feeder stacker for loading trucks and train carriages,” he said. “Once iron ore has been crushed and stockpiled at the mine, clients will feed product from existing stockpiles into the feeder stacker for it then to be fed into truck bodies or train carriages for transportation off-site.”

Designed for use as a primary or surge feeder in plants, MAX Plant’s belt feeder range provides the same level of customisation – and can be used alongside wheel loaders up to a Caterpillar 988 size.

McKenna said a niche market for MAX Plant’s belt feeders has been to support paste plants.

“Like our FS feeder, the BF feeder has a very wide hopper, which allows it to be fed with very large wheel loaders.

This makes it perfect for feeding sand and aggregate into paste plants, which pump concrete material underground to fill mine voids.

“We’ve also supplied BF feeders into gold mines, where clients have used them to feed secondary crushed material into a processing plant. In this case, the feeder would usually be fed by an articulated dump truck.

“The BF feeder is a versatile bit of kit for feeding material into existing operations.”

MAX Plant’s feeder stacker and belt feeder, which have become soughtafter solutions in the Australian mining industry, are being further advanced with the advent of remote monitoring.

“We’re integrating PLC (programmable logic controller) controls with our BF and FS systems,” McKenna said.

“This enables a unit to communicate with the main plant control system, which gives site operations greater control of their process plant. The PLC system might tell the feeder to speed up or slow down depending on the desired feed.”

Giving operators greater control over their equipment delivers a better client experience, McKenna said.

“We’re also integrating a control system that monitors feeder performance and provides real-time warnings of anything that’s going wrong. That can be monitored 24–7 by operators or by our service technicians in Perth.” AM

WITH OVER 150 INSTALLATIONS ACROSS AUSTRALIAN MINING OPERATIONS, AUMUND GROUP IS A HOUSEHOLD NAME IN BULK MATERIAL HANDLING.

SCHADE’s 145-year engineering heritage has established the AUMUND Group company as one of the world’s premier suppliers of mining stockyard equipment, with more than 800 stackers and reclaimers operating globally across the most demanding mining environments. This kind of worldwide experience directly benefits Australia’s mining sector through proven, battle-tested technology.

SCHADE’s scraper chain technology, refined over 70 years, delivers reliability in mining applications. SCHADE’s robust design offers superior performance in Australia’s harsh conditions, with simplified automation and reduced maintenance requirements – critical factors for remote mining operations.

The company’s mining portfolio includes complete stockyard solutions for iron ore, coal, copper concentrates, and battery minerals. SCHADE’s longitudinal and circular stockyard configurations are designed to maximise storage capacity while enabling efficient blending operations essential for consistent ore quality.

From Brazilian iron ore operations to Australian coal terminals, SCHADE’s worldwide mining installations demonstrate consistent performance across diverse materials and climates.

The company’s largest twin-boom scraper reclaimer, a testament to engineering innovation, handles massive throughput rates while maintaining precise blending capabilities.

SCHADE’s wagon dumper technology serves major mining railways worldwide, with unit train and pivot frame designs optimised for high-capacity mineral transport. This global experience ensures Australian mining operations have access to proven solutions adapted to local requirements.

SAMSON specialises in mobile equipment ideally suited for mining’s dynamic operational requirements. The company’s global mining installations demonstrate versatility across diverse applications, from remote mine sites to major export terminals.

SAMSON’s mobile material feeders excel in mining applications, receiving materials from dump trucks, loading shovels, and excavators while providing consistent feed rates to downstream processing. The STORMAJOR and BOOMFEEDER ranges combine material feeders with boom conveyors to support emergency feed and crusher interface applications, as well as stockpiling operations.

Available on grouser tracks for mining terrain, this equipment offers exceptional mobility for temporary installations and changing mine layouts.

The Eco Hopper addresses critical dust control challenges in mining applications. This dustfree system handles grab unloading operations while adhering to the mining sector’s increasingly stringent dust control regulations.

With nearly 150 years of mining experience, AUMUND has handled every conceivable bulk material from copper concentrates to iron ore pellets, coal, manganese ore, and beyond.

This global mining experience, supported by the company’s in-house material testing facility, helps to ensure optimal equipment selection for specific mining applications.

AUMUND’s apron feeders support primary crusher applications, where reliability is paramount. With thousands of installations in process-critical mining applications, AUMUND feeders consistently exceed performance expectations in the world’s most demanding mining environments.

The company’s bucket elevators serve mining operations globally, handling materials from fine concentrates to coarse ores with unmatched reliability.

AUMUND delivers complete pitto-port mining solutions, from primary crushing feed systems through to

port-loading facilities. This capability helps to provide Australian miners with single-source supply chain efficiency and integrated system optimisation.

The AUMUND Group’s global experience translates directly into Australian solutions.

With more than 150 installations across Australian mining operations spanning five decades, the group understands local operational challenges while applying international mining expertise.

From Pilbara iron ore operations to Queensland coal terminals, AUMUND Group equipment handles Australia’s diverse mining materials with proven reliability.

The combination of SCHADE’s stockyard expertise, SAMSON’s mobile solutions, and AUMUND’s proven feeding technology supports comprehensive mining solutions backed by global experience and local support through established partnerships with WDT Engineers (Brisbane) and Ammermann (Sydney).

As the Australian mining industry expands into new commodities and remote locations, AUMUND Group leverages its global reputation to provide reliable, efficient solutions for the sector’s evolving challenges. AM

ESS ENGINEERING, A LEADER IN CONVEYOR BELT CLEANING TECHNOLOGY, HAS UNVEILED AN AUTONOMOUS TENSIONER TO OPTIMISE CLEANER PERFORMANCE.

As mining operations scale to meet global demand, conveyor systems are under increasing pressure. Faster, wider and more heavily loaded belts are now the norm, making efficient carryback control more critical than ever.

Australian mine sites present unique logistical challenges.

Many mining operations are located remotely and are largely staffed by the fly-in, fly-out (FIFO) community, which means regular site visits to inspect and maintain belt cleaners and other conveyor belt accessories are often limited to scheduled shutdowns.

Conveyor belt cleaners are essential for removing material fines from the return side of the belt. Without effective cleaning, these material fines or carryback can lead to conveyor belt mistracking, increased spillage, accelerated wear, more safety hazards, and increased potential downtime.

Maintaining correct blade-to-belt contact historically required regular adjustment by trained local technicians to control carryback.

Spring and air tensioning devices were introduced as the labour market was squeezed and site access was reduced for

security and safety. This meant more time could elapse between opportunities for maintenance; however, inconsistent tensioning had resulted in uneven blade wear and reduced cleaning efficiency.

“Belt cleaner blades are designed to wear over time, but as they do the spring within the cleaner assembly extends and applies less force, causing less contact pressure with the belt,” ESS Engineering mechanical engineer Mitch Stone told Australian Mining

During inspection and maintenance periods, trained staff recognise the issue and manually adjust the tensioning device – a reactive approach to maintenance.

The reality, as Stone said, is that “cleaners aren’t adjusted or monitored as frequently as they should be”, which frequently results in premature or uneven blade wear.

“The autonomous tensioner removes the need to adjust the belt cleaner’s blades manually, saving time and resources, especially in remote or hazardous areas,” Stone said.

ESS’ autonomous tensioner can be retrofitted to existing belt cleaner systems, connecting directly to the mainframe spring. Using intelligent control systems, the cleaner blade tension is automatically

adjusted as it wears, maintaining consistent cleaning pressure and prolonging the cleaner blade’s lifespan.

The autonomous tensioner reduces much of the manual re-tensioning and monitoring with an onboard sensor and actuator package.

Sensors measure the force exerted by the cleaner arm, while a motorised mechanism automatically re-tensions the mainframe spring to restore a force predetermined through the applicationspecific wear rate. This closed-loop system ensures the blades wear at a consistent, linear rate, extending service life and preventing end-of-cycle acceleration that prematurely destroys blade edges.

All tension and wear data is relayed in real time via an in-built 5G antenna to a secure desktop interface.

Operators can enter wear data through a human–machine interface (HMI), inputting specific blade-wear targets into the system – for example, “typical blade life is six months” – and the tensioner will adjust the force over the life of the blade accordingly.

Adjustments can be made from a control room or any internet-connected

device. In addition, a stainless-steel enclosure houses a screen that allows you to set up and adjust the autonomous tensioner at the conveyor.

Beyond safety and labour savings, the system delivers proactive maintenance intelligence.

“With the autonomous tensioner, you can monitor and operate the belt cleaner at the same time, which means you have a clear view not only of how your cleaner is wearing but also how it is performing,” Stone said.

This level of visibility helps to prevent unplanned shutdowns and optimise conveyor maintenance.

The autonomous tensioner is currently in the trial phase.

“It’s been operating for a while now at a test site, and the feedback from the client has been overwhelmingly positive,” Stone said.

As Stone attests, autonomous tensioners strongly complement ESS’ belt cleaner portfolio.

“We’re looking at this as an extension of the work we already do around operational safety,” he said. “We have a long history of providing conveyor belt cleaners – our core product – so this helps improve functions and bring our technology into the world of automation.” AM

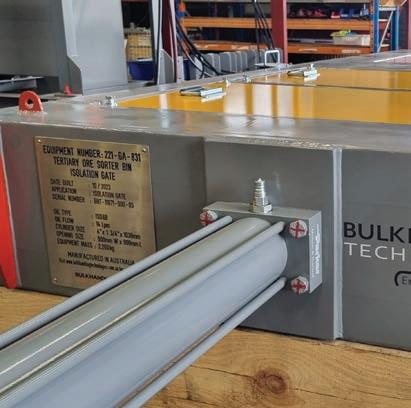

A CUSTOM-BUILT LITHIUM ORE HOPPER GETS TO WORK.

BULK HANDLING TECHNOLOGIES’ COMPREHENSIVE DESIGN-AND-BUILD APPROACH IS HELPING MINING OPERATIONS ACHIEVE OPTIMAL PRODUCTION CAPACITY.

Bulk material handling is a core task of any mining operation. It takes an extensive fleet of machines to move, store and process extracted materials, with feeders, crushers, screens, stackers and more all having to work together for the best results.

With so many moving parts, reliability and durability become vital characteristics for each link in the chain. If one machine goes down, or even just slows down, the whole operation is impacted.

For Bulk Handling Technologies (BHT), it’s this all-too-common situation that drives its team forward.

The Perth-based company supplies custom designed-and-built equipment all over Australia and internationally, and prides itself on supplying machines that are built to last.

BHT engineering manager Paul Ingleson believes this approach gives the company’s mining clients important peace of mind.

“Standardised, off-the-shelf equipment is often engineered down to a price,” he told Australian Mining “There are often compromises in quality, and there are definitely compromises in durability and reliability.

“Our ideal customer is someone who focuses on minimising downtime and optimising maintainability. If that’s important to them, we know they’ll appreciate the work we put into making every machine reliable and fit for purpose.”

Creating a bespoke product that suits each customer’s specific needs and circumstances involves a range of teams all working together.

For Bulk Handling Technologies, the promise is for a full research, design and custom build service, as well as delivery and set up.

“We’ve got a library of resources and skills for designing and building bulk materials handling equipment,” Ingleson said. “When we get an enquiry from a customer about a particular requirement, it’s often something that can’t be done reliably using standard, offthe-shelf equipment.

“We of course have standardised components and some standard designs, but everything we do, almost without exception, is customised in some way. Almost nothing is identical to what we’ve done before.”

A customer’s requirements could be around capacity or feed rates, or they

could be about meeting the unique specifications of the local mine site.

BHT customers operate internationally and across Australia. The company has been handling custom equipment for several African-based mining and infrastructure projects in recent years.

A recent project for a lithium operation in Western Australia perfectly illustrated BHT’s bespoke approach. The mine had been struggling with an off-the-shelf hopper and belt feeder system that wasn’t meeting the task of handling the client’s specific operational requirements.

“They were experiencing regular hang-ups and bridging issues that were causing expensive downtime,” Ingleson said.

“They needed a system that could reliably accept feed from their Komatsu WA700 loader without constant interruptions.”

BHT began with a comprehensive site audit and a review of material testing data to understand exactly what the client was dealing with. The lithium ore’s flow properties varied significantly with moisture content, and the client needed a 6m hopper that could ensure uniform drawdown across its entire length.

“Long hoppers present unique engineering challenges,” Ingleson said. “Without proper design, they can preferentially feed from one end, causing reloading delays and premature belt wear.

“Our solution incorporated 70° wall angles, polished Arcoplate liners, and a carefully positioned offset baffle.”

The resulting 225-tonne-per-hour system, featuring a 19m belt feeder, was assembled and tested in BHT’s Perth workshop before shipping. This approach eliminated on-site commissioning problems and ensured the client could achieve full production capacity from day one.

For mining operations where downtime costs thousands, if not millions, per hour, the choice between standard and custom equipment becomes a strategic business decision.

BHT’s approach of comprehensive testing, bespoke design and complete workshop assembly and testing helps to ensure clients receive engineered systems rather than more generic solutions.

As Ingleson put it, BHT’s customers understand that investing in maintainability and reliability from the outset delivers far greater value than accepting the compromises that can potentially come with noncustomised alternatives. AM

Fabric shelters have become synonymous with the mining industry because of their highquality protection and manoeuvrability – with one company going above and beyond to stay at the vanguard of innovation.

DomeShelter Australia has been delivering engineered fabric shelters for more than three decades, with almost 9000 shelters installed in more than 50 different countries, including in some of the world’s harshest environments.

“We have a major focus on design and engineering, which puts us at the forefront of industry conversation because of the mining sector’s strict regulations,” DomeShelter Australia technical solutions principal Bobby Fawkes told Australian Mining

“Our capabilities are all in-house, which positions us as a real expert in this field. We design bespoke solutions to address specific problems mining companies are facing everyday.”

DomeShelter solutions, which come with a 10-year warranty, have a range of benefits. They’re durable, easy to install, and are proven in the toughest of conditions, including cyclones.

The shelters come in a variety of different designs to help ensure each one is fit-for-purpose. Container, concrete wall and post-mounted options support bulk storage facilities wherever they’re needed, with combination options allowing for even greater flexibility.

develop an understanding of the client’s key challenges and what success looks like for them,” Fawkes said.

“Our experts are on hand to assess viability and come up with ways of seamlessly integrating shelters to enhance efficiencies across mining operations.

“We want to get to the bottom of what clients are trying to achieve – fully understanding what they’re working with, the product they’re storing, the length of time it is to be stored for, and what machinery they’re using.

“The client then has the opportunity to review a range of options and, along with our recommendations, consider what will provide the best return for their operation.”

Fabric shelters can not only be used for protecting people, machinery and creating workshop space but they can also be used for bulk storage.

Concrete wall-mounted fabric shelters are one such solution, having been described as a “rugged workhorse” in the most challenging of environments.