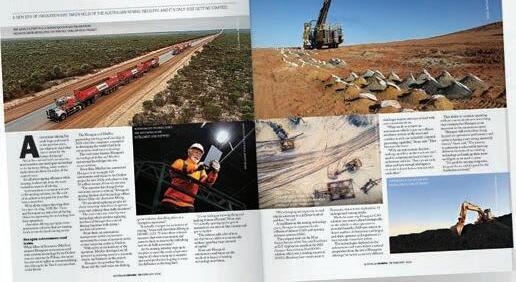

ir quality has long been a defining challenge in the Australian mining industry.

With many operations located in arid or semi-arid regions, dust is an inevitable by-product of mining activity. But dust control is no longer simply an environmental add-on; it has become central to how the industry is judged on its performance, by regulators, communities and employees alike.

The health risks associated with dust exposure are well documented, and Australian mining companies are responding to these realities with renewed focus. While today’s mining is equipped with more advanced dust control technologies than ever before, it is facing growing expectations to protect health, safeguard communities and ensure operations remain sustainable.

Importantly, regulators have set firm benchmarks. From December 1, 2026, Australia will replace the existing Workplace Exposure Standards (WES) with new Workplace Exposure Limits (WEL), creating clearer and more enforceable thresholds for airborne contaminants in the workplace.

This transition signals a tightening of expectations around air quality

JOURNALISTS

JOSEPH MISURACA Tel: (03) 9690 8766

management and reinforces the priority of protecting workers’ health in mining and other high-exposure industries.

Compliance will require investment in improved dust suppression, monitoring and ventilation technologies, but it also positions the resources sector as a leader in workplace health and safety. By staying ahead of regulatory requirements, companies can strengthen their licence to operate, improve workforce wellbeing, and demonstrate a proactive commitment to sustainable mining practices.

Looking ahead, air quality will only grow in importance as mines expand into new regions, commodity demand rises, and communities place greater emphasis on health and liveability. Australian mining will increasingly be measured not only by the tonnes it moves but also by the air it shares with its people and communities. Dust control is more than a regulatory requirement; it is a measure of the industry’s commitment to sustainability and responsibility.

Tom Parker Editor

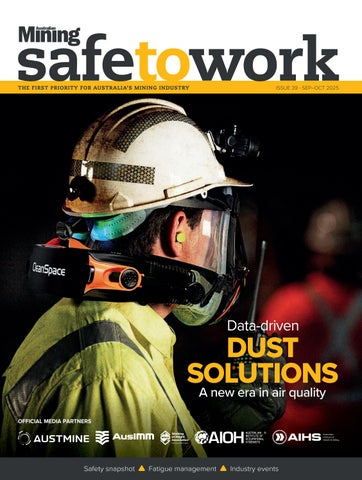

Founded in Australia in 2009, CleanSpace Technology has worked to redefine respiratory protection through its innovative, powered air-purifying respirators (PAPRs). Born from a vision to design lightweight, belt-free and hose-free respiratory gear that combines maximum safety with user comfort, CleanSpace introduced ergonomically crafted respirators engineered to return workers home safely. Its core AirSensit technology dynamically adjusts airflow by responding to the wearer’s breathing, maintaining positive face pressure and ensuring optimal performance.

CEO CHRISTINE CLANCY EDITOR

PARKER

Tel: (03) 9690 8766

Email: tom.parker@primecreative.com.au

ASSISTANT EDITOR

PREALENE KHERA

Tel: (03) 9690 8766

Email: prealene.khera@primecreative.com.au

Email: joseph.misuraca@primecreative.com.au

ENGEL SCHMIDL Tel: (03) 9690 8766

Email: engelbert.schmidl@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

ART DIRECTOR MICHELLE WESTON

New standards and technologies driving safer workplaces and healthier outcomes. 10 Converting dust into data

CleanSpace is redefining respiratory safety with smart, data-driven solutions.

34 Your eyes underground: Monitoring every movement, every shift Nome’s RockMonitor XR system feeds continuous, real-time strata displacement data to centralised smart centres.

PNG Expo 2026 will return with a fresh layout and enhanced networking 8 Redefining air quality

14 Preparing for change

3M experts share key steps to reassess and upgrade respiratory protection for compliance and safety.

38 Healthy minds, safe employees

Safety Mate has joined forces with Black Dog Institute.

46 WA Mining: Driving the future of resources

WA Mining will bring together experts from across the resources sector.

48 Powering up for 2026

RTC5000

POWERED AIR PURIFYING RESPIRATOR COMPLETE SYSTEM

RTC5001

IS YOUR PAPR AUSTRALIAN / NEW ZEALAND STANDARDS CERTIFIED?

PAPR COMPLETE SYSTEM WITH FAST CHARGING EXTENDED BATTERY

RTC5002

RTC5003

PAPR COMPLETE SYSTEM WITH BACKPACK

Australian/New Zealand Standards AS/NZS 1716:2012 Lic. SMK41528

PAPR COMPLETE SYSTEM WITH FAST-CHARGING EXTENDED BATTERY & BACKPACK

Compliance to AS/NZS 1337.1:2010. Compliance to AS/NZS 1801:1997 +Amdt 1-1999

Occupational Protective Helmets

AS THE MINING INDUSTRY

FOR STRONGER

A NUMBER OF ANNOUNCEMENTS AND EVENTS HAVE SHAPED THE SECTOR OVER THE PAST TWO MONTHS. SAFE TO WORK RECAPS SOME OF THE EVENTS THAT MADE AN IMPACT.

From regulatory overhauls and key appointments to critical safety campaigns and nearmiss incidents, July and August delivered another eventful chapter for mine safety across Australia. Here’s a bi-monthly snapshot of the updates that made headlines in that period.

Safe Work Australia and eSafety released new resources to help workplaces recognise and respond to online abuse, offering posters and checklists to address risks emerging from digital communication platforms.

The NSW Resources Regulator issued fresh guidance on preventing electric shocks in the mining industry, urging operators to review their electrical control plans and ensure safeguards were properly aligned to on-site tasks.

Western Australia’s mine safety body officially shifted to the newly created Department of Local Government, Industry Regulation and Safety, following a State Government restructure from July.

Following a Fair Work Commission ruling, more than 2200 labour hire workers at BHP’s Central Queensland coal mines became eligible for annual pay increases of up to $30,000 under Federal ‘ Same Job, Same Pay’ laws.

Janet Schorer was appointed as the inaugural commissioner of SafeWork NSW after its transition to a standalone regulator. She is expected to lead the agency’s efforts in compliance, policy and stakeholder engagement.

Safe Work Australia launched an online hub to help businesses better manage airborne contaminants, offering practical tools to identify risks and understand the long-term health impacts of exposure.

The NSW Resources Regulator released a new technical reference guide to help mine operators and site managers reduce vehicle interaction risks on-site.

SafeWork NSW issued more than 500 compliance notices during its largest enforcement blitz in a decade, targeting businesses across multiple industries to address safety noncompliance.

WorkSafe WA unveiled new educational resources to support mine operators in managing contractor safety and complying with work health and safety (WHS) regulations introduced in 2022.

The NSW Resources Regulator outlined its latest compliance priorities for the second half of 2025, with a

focus on high-risk operational and environmental areas.

Grant Hastie was appointed as executive director of NT WorkSafe, bringing more than 15 years of experience in WHS regulation and chemical safety from his previous roles in Queensland.

A serious near-miss at a coal mine in NSW occurred during excavator maintenance, when a fibre lifting sling snapped and dropped a stick assembly to the ground. A fitter narrowly avoided injury. At another site, a personnel transporter collided with a roof support structure near a portal exit, raising concerns about visibility and safe placement of materials in travel paths.

An investigation into a 2023 incident involving unsafe refuelling practices prompted new guidance on equipment shutdown, cool-down periods, and hazard identification during refuelling.

A worker at a Wollongong coal mine was briefly trapped between ventilation doors during planned works, prompting safety recommendations on exclusion zones and engineered door restraint systems.

AUSTRALIA’S APPROACH TO AIRBORNE HAZARDS IN MINING HAS EVOLVED SIGNIFICANTLY, WITH NEW STANDARDS AND TECHNOLOGIES DRIVING SAFER WORKPLACES AND HEALTHIER OUTCOMES.

It was 30 years ago that Australia took a vital first step in improving air quality by adopting workplace exposure standards for airborne contaminants.

That move in 1995 marked the beginning of a journey to protect workers from harmful substances in the air – dust, gases, fumes and vapours that can go unnoticed but cause serious health problems.

Understanding of these hazards has grown over the ensuing three decades; regulations have tightened and technology has advanced in leaps and bounds.

But airborne contaminants remain one of the most complex health and safety risks in mining. They do not need to be seen or smelled to reach harmful levels, yet their presence can lead to serious and long-term

Processes like drilling, blasting, crushing and transporting materials create air-quality risks in mining.

consequences, including occupational lung diseases, respiratory illnesses and cancers.

Mine sites, among other workplaces, have long relied on standards to guide safe exposure levels. These workplace exposure standards (WES) define the maximum airborne concentration of substances to which most workers can be exposed without adverse health effects. But science does not stand still, and neither does regulation.

New research has emerged since the last major review of the WES in 2003, prompting a nationwide reevaluation of exposure limits and safety practices. A full review of the WES list was undertaken from 2018, with the goal of ensuring the standards reflect the latest health evidence and offer the highest level

of protection for workers. A significant shift is now underway.

From December 1, 2026, workplace exposure standards will become workplace exposure limits (WEL), reflecting a stronger, clearer mandate: these are not recommendations,

reinforces the legal duty of persons conducting a business or undertaking (PCBUs) to prevent exposure wherever possible. If a contaminant cannot be eliminated, its risk must be reduced so far as is reasonably practicable.

To help employers and workers prepare, Safe Work Australia has developed an airborne contaminants hub – a comprehensive, easyto-use online resource designed to support compliance and raise awareness across industries. The hub includes downloadable fact sheets, infographics and a comparison table that outlines how current exposure standards will change under the new WEL framework.

It also offers practical advice on how to assess and manage exposure using the hierarchy of control measures.

With more than 600 substances and mixtures listed, the scale of the challenge is real. But so too is the opportunity.

The hub empowers employers to not only meet regulatory requirements but to lead with

air quality management in mining better than University of Queensland professor David Cliff. With extensive experience at the Minerals Industry Safety and Health Centre and as a safety and health adviser for the Queensland Mining Council, he brings a wealth of industry knowledge and hands-on expertise.

Some of the most significant improvements in recent years, Cliff told Safe to Work, have been the lowering of exposure limits for respirable coal dust and silica, setting new benchmarks that the industry must meet to safeguard worker health. He said the industry’s understanding of dust-related illnesses has broadened considerably.

“[There is] recognition that dust disease goes beyond coal workers pneumoconiosis,” Cliff said.

This shift reflects a more comprehensive approach to worker wellbeing, backed by quality control monitoring of medical assessments and equipment.

Technology is playing a vital role in these advances.

Real-time dust monitoring systems have become essential tools for identifying dust sources and

measuring the effectiveness of control measures. The systems can predict if a worker’s exposure is nearing unsafe levels, triggering timely alerts to prevent overexposure.

These innovations are among the many adopted by leading companies.

“Glencore has started using fixed location real-time sensors as part of their global mine environment monitoring systems, Anglo American has invested heavily in real-time personal monitors, and BMA has sophisticated real-time environmental dust monitoring networks around their open-cut mines,” Cliff said.

“Having airborne contaminant hazard management plans in place also means that the maintenance of dust suppression and exclusion techniques is treated on a systematic and regular basis.”

Looking ahead, Cliff sees promise in developments that prevent dust generation at the source.

“I think the big gains will come from modifying mining methods so that dust is not generated,” he said. “Controls need to be targeted at the type of dust of concern.”

With this approach, the industry can move beyond simply managing risks to preventing harm. It’s a shift that promises safer air, healthier workers and a more sustainable future for mining.

Safety managers across Australia are preparing for a transition that will reshape how airborne risks are managed on-site. By December 2026, Australia will move to a new list of workplace exposure limits (WEL) for airborne contaminants.

The fact mining operations involve the presence of silica dust, gases, vapours and fumes means careful management is required to maintain a safe working environment. Companies and managers play a vital role in addressing these airborne contaminants by implementing controls designed to protect workers’ health.

The transition to the WEL list represents a tightening of those limits and a greater emphasis on compliance. It will require businesses to be more enterprising and transparent in managing exposure.

This evolving regulatory landscape highlights why a proactive, databacked approach to selecting respiratory protection is more important than ever. With the path forward already marked, mining operations now need solutions that align with those fresh priorities.

Offering reliability, ease of use and actionable insights tailored to the realities of mining operations, CleanSpace meets this demand with systems designed to provide effective protection and meaningful information in real-time.

As a specialist in powered airpurifying respirators (PAPRs), CleanSpace recognises that converting dust into data is central to delivering that promise.

Its smart app provides real-time insights into filter life, battery status, fit checks and usage patterns, turning invisible hazards into

visible, manageable information. This empowers workers and safety managers to make informed decisions, ensuring respiratory protection remains uncompromised throughout each shift.

This level of visibility makes a measurable difference on sites where conditions shift quickly and documentation matters.

In the context of the upcoming WEL transition, it also means being able to track and verify protection on a daily basis – building a defensible record of compliance without adding complexity to already demanding operations.

A large operator recently set out to test how CleanSpace’s smart

app could support safety efforts across two of its high-dust work sites. The focus was practical: would it offer meaningful visibility into how respiratory equipment is used day to day, and could that data help teams respond with greater accuracy?

To put that to the test, workers were equipped with CleanSpace CST ULTRA respirators, each paired to the app. Once connected, the units began collecting live data related to fitting, battery life and filter usage. This meant they safety managers could monitor performance immediately, with each session automatically recorded and stored.

After several weeks, the data revealed useful patterns.

Daily wear times typically ranged from 15–37 minutes, depending on the task and level of exposure. The highest uptake aligned with areas of known risk, suggesting workers were using the equipment when it mattered most. Even during moments of lowest protection, the respirators maintained effectiveness above accepted safety standards, providing consistent performance across changing conditions.

Filter usage also followed a predictable rhythm. Most operators required just one filter per shift, and automated reminders helped prompt changes before any issues developed. The few inconsistencies that did appear, such as uneven wear time across teams, pointed to simple training opportunities rather than equipment failures.

What stood out most was the shift in how people interacted with the equipment, with operators appreciating the ability to check their own protection status without needing to ask or guess.

Meanwhile, supervisors found value in something less obvious: a clear record of use. The app showed when equipment was worn and how well it was working.

“It’s not just about wearing a mask anymore, it’s about proving it works every time you use it,” one safety manager on the site said.

What started out as a straightforward equipment trial soon proved to be something far more valuable. Using CleanSpace’s smart app and insights report, the team didn’t just get real-time data but gained a way to turn everyday usage into informed decisions.

With regulation tightening on the horizon, having this kind of clear, actionable information is quickly becoming essential. CleanSpace also supports companies with advanced equipment designed to prepare them for the road ahead. It’s a space where its innovative systems truly come into their own.

The CleanSpace CST ULTRA PAPR offers a powerful combination

of comfort and durability, designed for the realities of mining operations. Its lightweight, ergonomic design helps workers wear it consistently throughout long shifts, while its integration with the CleanSpace smart app ensures protection is optimised.

For sites operating in hazardous environments where explosion risks are a concern, the CleanSpace EX provides intrinsically safe certified, reliable protection without sacrificing ease of use.

Both systems deliver the peace of mind that comes with knowing every breath is safeguarded, and every risk is managed with precision.

It’s this basket of solutions, digital and practical, that could place mining companies ahead of the curve late next year, turning safety on site from an enforced compliance task into a competitive advantage.

And operations don’t need to hold their breath until 2026 for that to happen; CleanSpace is helping make that future a reality today.

EMERGING AS A GAME-CHANGER FOR HIGH-DUST ENVIRONMENTS LIKE MINING AND DRILLING.

In mining and construction, respirable dust exposure isn’t just a health risk – it’s a test of leadership, culture and commitment.

For Eagle Drilling NQ, a company operating in some of Australia’s toughest and dustiest environments, the solution was clear: upgrade respiratory protection across all reverse circulation (RC) drilling operations with the TRIDENT HEXHALE PAPR (powered air-purifying respirator) system. No exceptions, no compromises.

“If we’re doing RC drilling, our people will wear PAPR masks, no matter the site,” Eagle Drilling NQ general manager and ADIA vice president Sally Forgan said.

That simple mandate has placed Eagle Drilling NQ at the forefront of the industry’s dust safety movement; not just monitoring risk but actively neutralising it.

As dust regulations tighten and awareness of occupational lung diseases like silicosis grows, PAPRs are gaining ground as a practical and effective upgrade from disposable masks. Yet adoption has been relatively slow, often hindered by cost, comfort or complexity.

That’s where the HEXHALE PAPR system, developed by Industree Group, changes the equation.

Originally designed for tunnelling, the HEXHALE has quickly found its footing in high-dust industries like mining and drilling. Featuring a positive pressure airflow system, it delivers filtered air down the user’s face, creating a clean air barrier that protects without restricting.

With no need for a tight seal, fit testing or clean-shaven compliance, the

The TRIDENT HEXHALE delivers filtered air down the user’s face, creating a clean air barrier.

HEXHALE solves many of the practical challenges faced by field teams.

“What sets it apart is the way it simplifies compliance and improves usability in tough conditions,” Industree regional business development manager Jayden Minto said.

Eagle Drilling’s team trialled multiple units before selecting the TRIDENT HEXHALE RTC5000.

Equipped with long battery life, highefficiency filters and a full-face visor, the unit quickly proved its worth.

“We brought the supplier out with three different units and had 15 of our team members in the room,” Forgan said. “I said, ‘Try them on and tell me what you think’, because I’m not the one who needs to wear them – they are.”

The feedback? Positive across the board. Crews were comfortable, confident and, perhaps most importantly, compliant.

“If they’re not wearing it, they can’t work,” Forgan said. “It’s part of the kit now.”

Behind Eagle Drilling NQ’s success is a strong supply partnership.

Alliance Safety Equipment worked closely with the contractor

and Industree Group to identify the right solution.

“From the start, the collaboration was focused on real-world outcomes,” Alliance general manager Jono Pearson said. “We wanted to balance protection, comfort and budget, and deliver a solution that would actually get used.”

The formula worked. Eagle Drilling NQ now operates every RC rig with HEXHALE units on-board, and the program has caught the attention of regulators and peers alike.

With more than 1000 units already sold, momentum behind the HEXHALE is building. Industree Group continues to invest in improvements, recently launching a headlamp attachment and developing an all-in-one PAPR helmet with an integrated blower unit.

“We don’t just want to sell equipment; we want to be respiratory safety partners,” Minto said.

“When end users, suppliers and manufacturers collaborate, we create real, lasting change.”

As the sector faces a new era of accountability, one thing is clear: the companies that prioritise protection will lead the future. And with TRIDENT HEXHALE, they’ve got the tech to match their intent.

ust and spillage from insufficient transfer point sealing creates multiple problems — respiratory hazards for workers, excessive equipment wear, and regulatory compliance violations. Martin Engineering delivers integrated solutions to control fugitive material and maintain a clean and efficient operation. Martin's modular Transfer Point Kits, combined with ApronSeal™dual-seal skirting, wear liners, and impact cradles, effectively contain dust during material transfer. Airborne particles are collected by Martin's Air Cleaner and returned to the cargo stream. Our Dust Bag option allows positive pressure to escape while filtering particles. Both systems eliminate the complexity of baghouse collectors. Breathe easy. Martin's comprehensive approach to dust control protects worker health, ensures compliance, and maximizes productivity.

Respiratory protection during mining activities is essential to the well-being of workers on site.

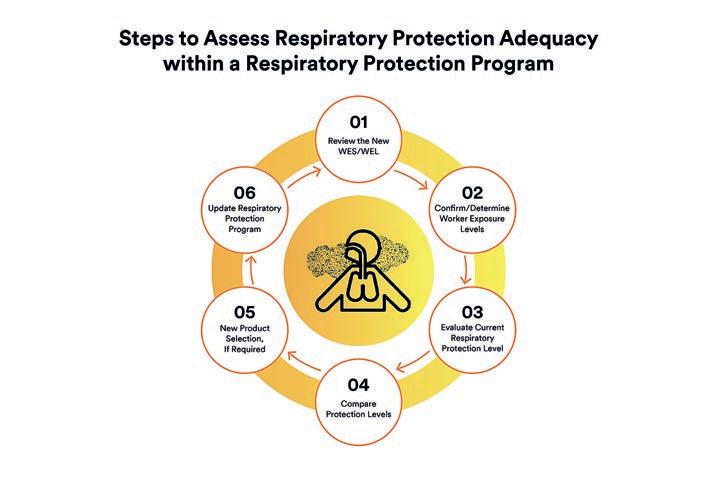

WITH MAJOR CHANGES TO WORKPLACE EXPOSURE LIMITS COMING IN 2026, 3M EXPERTS SHARE KEY STEPS TO REASSESS AND UPGRADE RESPIRATORY PROTECTION FOR COMPLIANCE AND SAFETY.

Several occupational exposure limits (OEL) have undergone revisions in recent years, with many limits being reduced to enhance worker health and safety. With the introduction of new workplace exposure limits (WELs) at the end of 2026, many more are being reduced with this being the first major update since the mid 1990’s.

As these standards and limits evolve, it is crucial for organisations to reassess the adequacy of their current respiratory protection to ensure compliance and safeguard employee health as part of their holistic control review.

Workplace exposure standards (WES)/WELs set the maximum allowable concentration of airborne contaminants to protect workers’ health. While generally acceptable for most, some individuals may still

experience effects below these levels. Employers must reduce before exposure ‘as low as reasonably

practicable’, ideally well below the standard. Lower is always better when it comes to exposure.

Lowering the WES reflects new scientific evidence indicating a need for increasing protection.

An important concept to establish is that respirators do not eliminate exposures, but rather reduce exposures from hazardous levels to acceptable levels when correctly selected, used and maintained.

What is a hazardous level and what is an acceptable level is where the WES/ WEL are utilised in the respirator adequacy assessment process. It is the same concept of respirator reduction and use of WES/WEL for all contaminants. The higher the exposure compared to the WES/WEL, the greater the reduction required of the respirator to bring it below the WES/WEL.

Steps can be taken to assess respiratory protection adequacy:

1. Review the new WES/WEL

Identify the specific substances affected and the new exposure standards/limits relevant to your workplace.

2. Confirm/determine exposure levels

Confirming/determining the concentration levels of hazardous substances that have been reduced in your workplace may involve air monitoring and sampling to obtain accurate data on your current exposure levels.

3. Evaluate current respiratory protection level

Assess the current respiratory protection equipment in use for its assigned protection factor (APF)/required minimum protection factor (RMPF), and its suitability for the specific contaminants present. APF/RMPF are based on the wearer doing all the right things; for example, trained, clean shaven and fit testing (when required). Refer to AS/NZS 1715 for APF/RMPF levels.

3. Compare protection levels

Compare the protection offered by the current respirators against the new exposure standard/limits. Ensure the APF/RMPF of the respirators meets or exceeds the level required to maintain exposure below the revised WES/WEL.

4. New product selection

If required, select new/different respirator with higher protection factors to reduce below the revised WES/WEL.

5. Update respiratory protection program

As necessary, update the respiratory protection program to include new respiratory protective equipment, training, and fit-testing procedures. Ensure that all employees are informed and trained on any changes.

Fine particles of dust pose a serious health risk, especially when fine particles are inhaled. Other safety risks include the increased risk of slips, trips and falls in areas of poor visibility caused by dust.

Dust is a significant operating, environmental and occupational hazard unacceptable to the modern Bulk Materials Handling Industry.

The Quickfit nozzle is part of the ESS Dust Suppression System designed to dramatically reduce the dust emissions generated as part of materials handling processes.

ESS Dust Suppression systems are suitable for most applications where the process will allow for small amounts of added moisture.

ESS Dust Suppression System utilising Quickfit Nozzles are

•Easy to Install and maintain – with service occurring outside the structure

•Low Maintenance – by using filters to reduce blockages

•Low Water Consumption Units – using 2 litres of water a minute over a range of pressures. Making it suitable for drier environments

•Designed in Kit Forms – available in kits of 2, 4 or 6

•Tailored to suit your sites needs

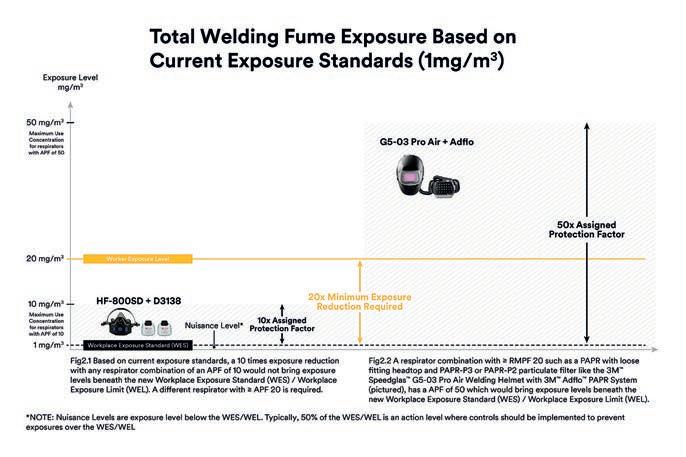

In recent years, the total welding fume WES was reduced from 5mg/ m3 to 1mg/m3, a significant reduction. This can be used as an example of assessing the adequacy of a half facepiece respirator with P2 particulate filters for the previous exposure standard to the new one. •Previous exposure standard (5mg/ m3 TWA WES)

• APF/RMPF of 10 for a half facepiece respirator with P2 filter. This means this respirator/filter combination is adequate for exposures of up to 10 times the WES (5mg/m3), which would be 50mg/m3

• Adequate combination protection for this as 20mg/m3 TWA is below the maximum use concentration (MUC) of 50mg/m3 TWA

• New/current exposure standard (1mg/m3 TWA WES)

•APF/RMPF of 10 for a half facepiece respirator with P2 filter. This means this respirator/ filter combination is adequate for exposures of to 10 times the WES (1mg/m³ TWA), which would be 10mg/m3 TWA

• Inadequate respirator combination protection for this exposure as 20mg/m3 is above the maximum use concentration (MUC) of 10mg/m3

• A different respirator combination must be selected that has an APF/RMPF greater than 20, so the respirator reduction is below (ideally well below) the new exposures standard of 1mg/m3

• An example respirator combination that has an APF/ RMPF greater than 20 and would be adequate could be a full face with P2 particulate filter (50 APF/RMPF)/P3 particulate filter (100 APF/RMPF) or a powered air purifying respirator (PAPR) with loose fitting headtop and PAPR-P2 or PAPR-P3 particulate filter (APF/RMPF 50). Refer to AS/ NZS 1715 for full table of respirator combinations and APF/RMPF.

This is a simple example of reassessing the adequacy of a respirator combination in use and if it is still adequate with a new exposure standard.

There are also many other suitability considerations in addition to the above such as personal protective equipment (PPE) compatibility, comfort, fit/ fit testing, facial hair compatibility, communication needs, thermal impact, maintenance, wear time, physical characteristics of the work

area, demands of the work, and worker acceptance, to name just a few.

With the introduction of new WELs by the end of 2026, adopting a proactive approach is especially prudent. Stay informed about regulatory developments and emerging research related to occupational exposure. Companies should consider investing in adaptable respiratory protection solutions that can accommodate future changes in standards.

Improve Hydration Efficiency

Boosts Daily Energy Levels

Enhance Mental Clarity

Muscle Function & Recovery

FINE DUST AT MINE SITES IS NO LONGER JUST A CLEANING ISSUE, IT’S A POTENTIAL HEALTH RISK AND A COMPLIANCE PRIORITY, AND TENNANT’S ADVANCED SWEEPING TECHNOLOGIES ARE MEETING THAT CHALLENGE HEAD-ON.

As the mining industry continues to grow and evolve, expectations around air quality and dust control management are rising nationally.

Driven by a commitment to worker health and the growing demands of regulatory compliance, operations are rethinking how they manage fine dust, and how they clean. Many

for equipment that’s not just faster, but smarter.

Modern machines like Tennant’s HEPA (high-efficiency particulate air)-quipped industrial sweepers are helping mining and processing companies clean more effectively, stay in line with regulations, and create safer environments for their teams.

As a global leader in cleaning

provides industrial solutions that support silica exposure control plans, helping to create safer, healthier, and more productive work environments, while working toward Occupational Safety and Health Australia (OSHA) compliance.

Tennant’s industrial floorcare equipment is designed with a clear understanding of the risks

silica dust – and the need for a comprehensive, effective response.

Across industries, silica dust is recognised as a serious on-site hazard that impacts worker health and safety. Generated through activities such as cutting, sawing, grinding, drilling, and crushing materials like brick, sand, and concrete. It presents significant health, safety and compliance concerns in sectors including construction, mining, and manufacturing. Addressing this hazard requires tailored exposure control plans that combine engineering with proven cleaning practices.

Because no two sites are the same, Tennant Australia offers three core methods to manage silica dust, each suited to different operational demands:

Wet sweeping, which is effective in most applications, uses several models of Tennant Australia industrial sweepers designed to suppress dust with moisture. In select scenarios, water flooding via Tennant scrubbers – walk-behind and ride-on machines – can also control silica dust at the source.

Where wet methods are not feasible, Tennant Australia’s industrial sweepers equipped with optional HEPA filtration systems provide dry sweeping as an effective alternative.

Supplier-tested and certified, the High Efficiency Particulate Air (HEPA) Filters capture fine particles as small as 0.3 microns at 99.97% efficiency that would otherwise remain airborne. For added operator protection, select models such as the S30 Ride On Sweeper can be fitted with HEPApressurised cabs with magnehelic pressure gauges, as well as external dual brush dust suppression skirts.

Using this suite of tools and technologies, Tennant Australia helps businesses tackle three critical objectives: maintaining air quality by managing respirable dust, ensuring compliance with workplace health and safety regulations, and creating safe, healthy and productive environments for employees.

One industrial site demonstrating the impact of Tennant’s advanced dust

control technology operates within an 180,000-square-foot facility, where airborne dust is a constant concern.

Facing the challenge of managing respirable particles in a high-volume production environment, the company partnered with Tennant to test the S30 ride-on sweeper equipped with a HEPA filtration system.

The machine’s four-stage filtration –including Tennant’s proprietary PermaFilter, SweepMax Plus Cyclonics, a canister nanofibre filter, and an optional HEPA dust filter – proved effective, capturing over nine tonnes of dust and debris in just 60 days.

“The impressive thing is that the primary filter system is so effective that the HEPA filter has only gained a half a kilogram of debris within that timeframe,” Tennant product engineer for sustainability Mat Segar said.

This type of efficiency helps to support a long service life for the HEPA filter system, which is expected to last six months or more with proper maintenance.

Results were evident not only in reduced airborne dust but in the overall cleanliness of the site.

“It’s a lot cleaner than just a broom and a dustpan,” the site’s safety manager said. “It contains the dust within the filters, so you don’t have it floating in the air and people breathing it in.”

Beyond health improvements, the Tennant solution delivered measurable gains in efficiency. Manual sweeping that once took more than 10 hours could now be completed in under two, freeing personnel for higher-value tasks.

“This will allow you to have one operator do the same amount of cleaning in a very short period of time,” Segar said.

Managing silica dust ultimately goes beyond compliance, it’s about building a workplace where health, safety, and productivity go handin-hand. That’s why Tennant backs every machine with expert service and support.

All Tennant field technicians are company-trained and carry the parts needed on board to minimise delays. They don’t just know how to service or repair every Tennant machine, they know how to operate them too. This ensures they can quickly diagnose issues, optimise performance, and get equipment back to work faster.

Because when it comes to silica dust control, there’s simply no room for downtime.

By choosing Tennant’s HEPAequipped sweepers, supported by expert service, businesses can strengthen compliance, protect worker health, and maintain cleaner, safer worksites.

Dust has always been part of mining life, but today’s industry understands the risks it brings more than ever.

From respirable crystalline silica to diesel particulate matter, exposure to airborne hazards is one of the most pressing workplace health and safety challenges facing mining operations in Australia.

According to Safe Work Australia, around 600,000 workers are exposed to silica dust each year, with mining and construction workers most at risk. Prolonged exposure can lead to chronic conditions such as silicosis, chronic obstructive pulmonary disease (COPD), and even lung cancer. Beyond health, poor dust management can result in site shutdowns, reputational damage, and increased scrutiny from regulators.

While mining bears the brunt of dust-related health risks, the problem isn’t isolated to the resources sector.

Manufacturing plants face exposure to welding fumes and particulates,

while agriculture deals with grain dust and allergens.

The lesson is clear: no industry is immune to air quality challenges and solutions must be robust and adaptable.

At this year’s Workplace Health & Safety Show Sydney, to be held at Sydney Showground from 22–23 October, exhibitors will showcase technologies designed to keep workers safer in high-risk environments like mining:

• All Preparation Equipment –H-class vacuums, air cleaners and surface prep tools to manage silica and keep your crew safe

• Active Environmental Solutions (AES) – real-time dust, silica and gas monitoring technologies, including wearable devices and calibration services

• A-SAFE – semi-elastic, flexible workplace barriers that serve as protective signage and site safety demarcations

• AMCS EHS Solution – a modular, cloud-based platform to centralise OH&S, streamline risk management, and support compliance

• Apex Welding Safety –specialists in fume control and welding-related dust safety, offering whitepapers and training to reduce exposure risks

• Bastion Pacific – suppliers of heavy-duty, cut-resistant gloves and personal -protective equipment (PPE) built for dusty, high-heat environments

These brands represent the frontline of dust control and air quality innovation, giving mining operators direct access to proven systems that can protect their people and keep operations compliant.

Workplace Health & Safety Show portfolio director Stephen Blackie describes airborne hazards as “one of the most common but underestimated risks in mining”.

“From silica dust to diesel particulates, these exposures affect thousands of workers every year,” he said.

“The Workplace Health & Safety Show brings together the leading names in protection and monitoring so that mining companies can find practical, effective solutions to safeguard their workforce.”

The mining industry is under increasing pressure from regulators, communities and workers themselves to address air quality risks. Dust suppression, filtration and respiratory protection are no longer optional addons: they are core to operational safety and sustainability.

The Workplace Health & Safety Show will be held at be held at Sydney Showground from 22–23 October. Visit whsshow.com.au/sydney for more information.

SAFETY MATE OFFER THEIR BLACK DOG PRODUCT RANGE TO SUPPORT THE WORK OF BLACK DOG INSTITUTE

Black Dog Institute are the only medical research institute in Australia that investigates mental health across the lifespan—from childhood to adulthood. They conduct translational research, connecting the dots between research studies, education programs, expert knowledge, digital tools, and lived experience. By translating research into practical, evidence-based solutions, Black Dog Institute aim to create real-world change that improves mental health outcomes for all Australians.

Mental health is becoming widely acknowledged as an important component in business stability, workforce and even productivity. 20% of Australians will experience symptoms of mental illness each year. Better drives everything at Black Dog Institute, the power of better can help prevent suicide, and it can be the beginning of new hope. At the core of their mission, Black Dog Institute want better mental health for all.

BLACK DOG CUT D GLOVE

• Lightweight cut level D

• Touchscreen compatible

• Comfortable and durable

• $1 per pair donated to Black Dog Institute

BLACK DOG IMPACT CUT F

• Lightweight cut level F

• Excellent fit, breathability and comfort

MENTAL HEALTH TOOLS AND RESOURCES AVAILABLE WITH EVERY PAIR OF BLACK DOG GLOVES

• Touchscreen compatible

• Soft and flexible TPR impact protection

• Durable and breathable nitrile coating

• $1 per pair donated to Black Dog Institute

BLACK DOG STREAM EVO

• Maximum comfort and protection

• Tecton 400™ Anti-scratch and Anti-fog

• Soft, adjustable, anti-slip nose bridge

• 50c per pair donated to Black Dog Institute

SKYTEC 3030V

• Market first and only full foam face seal – ensuring excellent face fit testing results, and comfort

• Four point headstrap adjustment

• Low breathing resistance valve

• Also available in smaller size (3030V-S)

• 50c per mask donated to Black Dog Institute

Wheretofindhelp?

Ifyouorsomeoneyouknowissufferingextremedistressandneeds urgentassistance,call000orLifelineon131114orgotoahospital emergencyDepartment. YourGPcanbeagoodstartingpointbutifyoudon’tfeeltheyare helpingdon’tbeafraidtochangehealthprofessionals. Forinformation,factsheets,self-helptools,andself-tests,visitour websiteatwww.blackdoginstitute.org.au

Astheonlymedicalresearchinstitutein

science,compassionandaction

Ask:besupportiveandask,“areyouOK?”

2. Listen:takewhattheysayseriouslyletthemknowyoucare.

3. Respect:theirpointofview.Letthemknowhelpisavailable.

4. Encourage:suggesttheytalktoaGP,friendorrelative.

5. Followup:makeatimetocheckinonthem.

6. Takecareofyourself:helping someonecanbedemanding.

Whennegativethoughtsandfeelingstakeover,we canfeeloverwhelmed,losesleep,feelexhausted,and starttoavoidthingswenormallyenjoy.myCompass canhelpyoubetter manageyourmentalhealth. myCompassisfree evidence-based programthatfeatures effectivestrategies tohelpyounavigate

DMany regulated particulates, such as respirable crystalline silica (RCS), are invisible to the naked eye, so workers near a conveyor system often do not realise the danger or their level of exposure.

Some operators can easily identify the source of dust, but certain solutions are more complex to address than others. Modern conveyor equipment designs consider dust and provide solutions that are easier to maintain and help support workplace safety compliance.

Inspectors from provincial agencies can equip trained workers with personal dust monitors that they wear throughout their shifts.

The small machines collect particulates from the air to measure RCS, heavy metals and other regulated substances. The filters capture particulate matter (PM) smaller than 10 microns (µm) in size.

eight-hour time-weighted average (TWA), ie a single shift.

For perspective, PM smaller than 200µm, roughly the size of sand dust, is light enough to remain airborne on ambient air currents. When PM reaches 100µm – approximately the size of a cross section of a human hair – it becomes invisible to the naked eye. At 10µm or smaller, the particulate is considered “respirable”, meaning it can surpass the body’s natural defenses and enter deep into the lung causing serious damage and health issues. Once measured, inspectors usually order violators to address air quality. Personal protective equipment (PPE) such as respirators can be the answer in the short term, but for the long term regulators recommend that operators address the problem using “engineering controls”.

These are equipment solutions that prevent emissions, reducing or eliminating the need for PPE.

The volume of conveyor dust emissions is dependent on the

conditions and the application. Operators and designers should first know the material characteristics and how they change as they pass through the processing and conveying system.

Year-round weather conditions can cause dust, especially during dry seasons, which pull humidity out of the air, increasing emissions. Prevailing winds or changes in wind patterns can suddenly shift a dust-free operation into one with several violations.

Conveyor dust emissions are also derived from many sources, including transition points, material impact, and cargo disruption:

• Dust at the transition happens when material falls to the belt, hitting the sides of the chute or rock boxes on the way down. As it falls, material not contained by a drop chute (such as onto a stockpile) separates, exposing the entire stream to ambient air currents allowing emissions.

• Dust on impact happens when material lands on the belt with no controls. Depending on the height, weight and density of the material, the impact on the belt causes air turbulence and shifting, leading to airborne emissions.

• Dust from disruption happens along the conveyor path, often between idlers where the belt slumps. This causes the cargo to shift and bounce slightly along the belt path, disrupting material and causing dust emissions.

Loading zone design has shifted over the past decade in response to the need for dust reduction and greater efficiency and is an excellent example of an engineering control.

Rather than transitions from conveyor to conveyor or storage container to conveyor, which are straight drops from heights, chutes direct and control material flow using spoon designs. These designs help to ensure material is loaded in the centre

of the belt with little impact. This reduces dust, spillage, mistracking and belt damage commonly associated with conveyor transitions.

The impact of material on the belt can cause splashing and produce air turbulence that seeks exit points from the chute through gaps between the skirt and the belt created by the slump between impact idlers. These rollers also tend to break under long-term pressure, causing them to seize.

So another innovation replaces impact idlers with bed of steel angles lined by energy-absorbing impact bars with a top layer of low friction, ultra-high molecular weight (UHMW) polymer or polyurethane. The bar design helps the skirtboard sealing systems consisting of a wear liner and skirting to retain a consistent seal at the loading point to reduce spillage and dust emissions.

Eliminating moving parts and the requisite lubrication of rolling components drastically reduces the

amount of maintenance and improves safety by promoting a tight seal between the skirting and the bar.

After cargo has been loaded, the stilling and settling zones of the transfer enclosure should be properly designed to have a sealed environment that controls airflow with negligible dust emissions. This design should include closely set idlers or idlers that transition between cradles.

Another important element is continuous external skirting in single strips that run the length of the enclosure on either side. Strategically placed dust curtains inside the enclosure slow airflow enough for particulates to settle back into the cargo stream. Dust bags and compact mechanical air cleaners, when installed on the enclosure, will also capture dust and ensure a dust-free exit from the enclosure.

Wind can be an issue once the material has left the enclosure, so many operators cover exposed conveyors. However, this does not control dust from material shifting, disruption over idlers or mistracking. These actions can cause spillage and dust to fall along the length of the conveyor. Installing tracking devices along the belt path helps reduce spillage from mistracking even if cargo shifts.

More often than not, the conveyor discharges down an open shaft with a dead drop into the transfer chute leading to another conveyor into a hopper or silo, or onto a storage pile. The material separates when it leaves the belt, exposing the entire stream and allowing smaller particulates to become airborne. Stacker conveyors and tripper conveyors are especially prone to this and often utilise a misting ring or specially designed sock to control the stream.

However, material often hits the back of the transfer chute or impacts on rock boxes, which can result in dust blowing back up the chute. Enclosing the discharge zone and controlling the impact of material using a spoon design will mitigate blowback. In addition, adding air cannons helps direct cargo and airflow, and prevent

unscheduled downtime from build-up and blockages within the chute.

Conveyor belts across all bulk handling sectors take a tremendous amount of punishment, and the single most expensive piece of equipment on the conveyor system is the belting. No matter how careful the upkeep, the belt will eventually start to show divots and cracks.

The weight of the cargo can cause dry material to stick to the surface and dust and fines collect in the flaws. If not properly cleaned, the adhered material will not be discharged with the cargo flow and remain on the belt as carryback, spilling fines and emitting dust along the return path of the system.

Primary cleaners remove the most abrasive and hardest material left on the belt after discharge. Mounted at the head pulley on a tensioned assembly and the engineered polyurethane construction, many blades are in a curved configuration that allows the blade tip to fit snuggly against the belt and wear evenly throughout the blade’s life with only minor adjustments to the tensioner.

One innovative primary cleaner design requires no tensioning at all after initial installation. It features a matrix of tungsten carbide scrapers installed diagonally to form a three-dimensional curve around the head pulley and

typically delivers up to four times the service life of urethane cleaners without ever needing re-tensioning.

Secondary and tertiary cleaners are located immediately after the belt leaves the head pulley to address dust and fines that escape the primary cleaner. Generally equipped with spring or air tensioners that easily adjust to fluctuations in the belt, secondary and tertiary cleaners dislodge dusty carryback, adding it back into the cargo flow.

The prevailing impression that bulk handling is inherently dusty is an old idea that regulators are trying to reverse. By identifying causes of dust and retrofitting modern equipment, operators find they can control emissions at the source and increase efficiency.

SentineX’s rugged sensors, housed in tough cases, measure vibrations from multiple directions and detect overpressure in

without the stress of wondering what might be missed.

the air.

SENTINEX IS DESIGNED TO ENSURE MINE SITES ALWAYS STAY ONE STEP AHEAD BY REDEFINING ENVIRONMENTAL MONITORING.

In a complex sector like mining, every site needs a sentinel –something steady and watchful that never blinks or misses a sign.

In the swirl of dust, noise and vibration that comes with heavy industry, small problems can quickly grow if they go unnoticed. But when environmental limits are tight and scrutiny is high, even a moment’s delay can mean a breach, a complaint, or a halt in work.

Compliance demands more than routine checks and reactive fixes; it requires constant awareness and

the ability to respond the moment conditions change.

And that is exactly what Novecom’s SentineX – a platform designed for continuous remote environmental monitoring – brings to the table.

Rather than just a monitoring tool, SentineX feels more like a steady guardian watching over mining sites and heavy industry operations, providing a steady flow of real-time data and instant alerts. This gives teams not only the clarity they need but also the confidence to act swiftly and keep everything running smoothly

Take dust monitoring, for instance. In the past, tracking dust often meant occasional spot checks or scrambling to respond only after emissions had already risen.

SentineX flips that script.

Combining rugged, weatherproof hardware with sharp software driven analytics, it continuously watches the air with precision. Its fixed dust monitors meet Australian standards, measuring fine particles like PM10 and PM2.5, while portable monitors use light scattering and particle counting to help operators investigate dust sources.

The system’s hardware also seamlessly adapts to site needs, whether mounted high on a pole powered by mains electricity or attached to mobile trailers running on solar energy. It is designed to fit into existing air quality and weather stations, giving operators a full picture of environmental conditions.

Around-the-clock monitoring keeps teams informed every minute, with instant alerts when dust levels climb. Some of those key insights are pulled together in monthly reports, easing compliance burdens and freeing teams from tedious manual work.

Noise monitoring is another vital piece of this environmental puzzle.

SentineX listens constantly, either through a single microphone that captures sound from all directions or a more sophisticated array of four mics that can identify where noise is coming from and how loud it is.

Artificial intelligence (AI) also steps in here, separating industrial noise from environmental noise to cut false alarms and speed up response. SentineX ‘AiCoustics’ automatically classifies noise by comparing it with a huge database of known noise sources, cutting out the timeconsuming and costly manual process.

In a situation where, for example, the buzz of a mine’s overnight haulage suddenly edges closer to noise limits, SentineX’s live monitoring and automatic alerts mean the team can

quickly check the dashboard, review recent patterns, and act fast.

Managers can then change truck routes and set up sound barriers, keeping noise in check and community concerns at bay, resulting in a win born from staying ahead rather than chasing problems.

Completing this vigilant watch is blast vibration monitoring. Blasting sends shockwaves through the ground and air, and managing those vibrations is crucial to prevent damage and disturbance. SentineX’s rugged sensors, housed in tough cases, measure vibrations from multiple directions and detect overpressure in the air.

Tracking data like peak particle velocity and vibration profiles in realtime means teams can gain a detailed understanding of blast impacts.

With these insights, operators can foresee hotspots and adjust blasting plans accordingly.

In sensitive areas like underground mines near critical infrastructure, this proactive monitoring keeps vibration within safe limits. Automated reports then offer clear, reliable evidence to regulators and neighbours alike, helping build confidence and reduce risk.

These capabilities are all united by SentineX’s intuitive interface and solid support.

reporting, SentineX does more than tick boxes. It helps teams get ahead of problems, protect health, respect communities, and keep operations moving without interruption.

In an industry where every moment counts, SentineX is more than a system; it is the watchful presence on which operators can rely quietly working behind the scenes to keep things safe, steady and ahead of the curve. It’s always there – and it’s always alert.

WORK ENVIRONMENTS.

“What you can’t see can hurt you, and there’s a lot you can’t see.”

This tagline is not an empty caution, rather it’s a call to action on Sy-Klone’s website – a reminder of the progress the industry is making in addressing invisible risks like airborne dust and silica.

The company, a global leader in clean air solutions, focuses on protecting machine operators by delivering advanced powered precleaning, filtration and pressurisation systems that make in-cab environments safer and fully compliant with evolving air quality standards.

As the mining sector continues to raise the bar on worker protection, air quality has become a defining frontier. New research, technologies, and standards are changing how the industry thinks about airborne risk. Nowhere is this progress more evident than inside the operator cab. It is here that exposure to respirable crystalline silica, or RCS, can reach harmful levels. But it is also here where some of the most effective solutions are taking hold.

A cab air quality system works in three key ways: precleaning the

air, which removes 90 per cent of contaminates before the filter, filtering the precleaned air to remove fine dust and harmfulmicroscopic particles, maintain positive pressure to keep fine particles out of the cab, and filter recirculated air already inside the cab.

Sy-Klone’s RESPA Cab Air Quality System brings all these elements together in a single, integrated solution. Outside air is pulled through a precleaner and HEPA filter, then delivered to the HVAC, helping to create a steady, clean airflow. At the same time, a recirculation filter captures dust that may already be in the cab, reducing build-up and keeping surfaces clean. A monitoring system tracks air quality and filter performance, alerting operators when action is needed. With these three components working in tandem the system creates a protective environment that is both measurable and reliable.

The release of AS/NZS ISO 23875 on safe cab environments set clear cab air quality performance targets, including the ability to maintain dust concentrations below 25 ug/m3. This gives mine operators: auditable goals that help turn compliance into action.

Sy-Klone sad its technology sets the standard with a system that is 100 per cent effective in reducing operator exposures when properly installed. That means fewer risks, greater peace of mind, and a work environment that actively supports long-term health.

With its RESPA Advisor+ 2.0, SyKlone adds a layer of intelligence to cab safety to meet current and future compliance. The system continuously monitors key indicators such as dust concentration, carbon dioxide levels, and filter life, giving site managers and operators real-time data they can act on.

“As a mine operator, there’s no more important asset than your people,” Sy-Klone executive vice president of standards and regulations Jeff Moredock said. “And as mining continues to face a growing labour shortage, going above and beyond for workers is key to attracting and retaining the industry’s best talent. While government-driven regulations can certainly help foster safe work environments, safety is important to every mine operation – with or without compliance requirements.”

It is a standard that the industry is not only reaching, but exceeding, and companies like Sy-Klone are helping lead the way.

That’s why you can depend on Winc to deliver what you need, when you need it.

Our Health & Safety Essentials are:

• From the world’s most trusted brands

• Compliant with Australian standards

• Made to last

• Ethically sourced

• Delivered next business day*

Our in-house team of Health, Hygiene & Safety Specialists are on standby to support with safety audits, product advice as well as sustainable and First Nations solutions to meet your organisation’s unique Health & Safety requirements.

INSIDE THE COMPLEX WORLD OF MINING DUST, RWDI USES EXPERTISE AND INNOVATIVE TOOLS TO HELP OPERATORS UNDERSTAND, MANAGE AND REDUCE ITS BROADER IMPACT.

Dust is where Brian Sulley spends much of his time.

Not the kind of dust you wipe off a shelf, but the kind that lifts off roads, settles on equipment and lingers in the air after a blast or a truck rolls by on a mine site.

Sulley is the technical director at RWDI, an environmental consulting firm specialising in air quality, wind and climate studies.

At RWDI, dust demands understanding – how it moves, where it settles and what it means for workers on-site and residents down the road.

That focus on dust and its impact has shaped much of the company’s work in mining. It supports some of

the industry’s biggest players, but the work always starts with a simple, onthe-ground approach.

“We walk through their facilities, identify emission points, then figure out where those contaminants travel in the environment,” Sulley told Safe to Work.

Armed with that insight, operators can act early to keep air quality issues from reaching nearby communities.

Sometimes, the call to act comes from data. Other times, it’s a complaint, such as dust drifting into communities bear the site or haze near a fence line. Either way, RWDI’s role is consistent: track the source, model the dust’s path, recommend practical solutions.

That might mean tweaking watering schedules, installing wind fences, planting vegetation or applying targeted suppressants. Every site is unique, but the goal remains the same – to reduce impact before it strains relationships with local stakeholders.

Much of RWDI’s mining work focuses beyond the fence line, where objections usually arise, but they also help manage dust within the site itself.

It can be about worker safety, and it can also be about protecting assets and maintaining clear visibility.

“One project we’re doing for a [Tier 1 mining company] involves addressing dust that’s affecting worker lunchrooms and rest areas,”

Sulley said. “And, in some cases, mitigating its effects on equipment.”

When health concerns arise, RWDI can also support testing for airborne hazards like crystalline silica.

“We’re often called in because we’re already on-site doing air-quality work,” Sulley said.

“We collaborate with industrial hygienists to assess exposures, then figure out where to spray or install controls like wind screens.”

This integrated approach, from measurement to mitigation, helps operators stay ahead of compliance requirements and community expectations. Sulley also highlighted RWDI’s role in setting up monitoring and reporting systems, especially when transparency is key.

“In some cases, we even operate the monitors ourselves,” he said.

“Sometimes the data’s just for internal use, but either way, it gives clients a way to spot problems early.”

In a long-term project, RWDI supported a major mining client managing air quality across multiple operations. The team modelled emissions from pellet-making furnaces and explored pollution reduction at the stack level. It also assessed impacts from a new pit, using detailed operational data to create realistic scenarios of how dust might move through the surrounding environment.

Field visits, monitoring, and close collaboration with regulators helped shape a plan balancing operational needs with environmental responsibilities.

RWDI has been doing this kind of work for decades, and Sulley has been part of it for 24 years.

“I’ve learned from colleagues who’ve been at this since the 1980s,” he said. “And I can pull up every file we’ve worked on going back to 1972.”

That institutional memory means anyone in the team rarely has to guess;

they’ve often seen a version of the problem before. As a result, they’ve built tools to test ideas and replicate site conditions in controlled environments.

That capability makes all the difference when conditions change, or decisions need to be made quickly.

Sulley spends so much time focused on dust because it’s a complex part of mining, one that affects everything from worker safety to community health. His job is to decode how dust behaves, helping mines understand what’s in the air and figure out the best ways to manage it.

That’s what sets RWDI apart. They don’t just track dust, they use decades of experience and specialised tools to predict problems before they start.

For Sulley and his colleagues, managing dust isn’t just about control, it’s about helping mines operate responsibly and keep everyone safe.

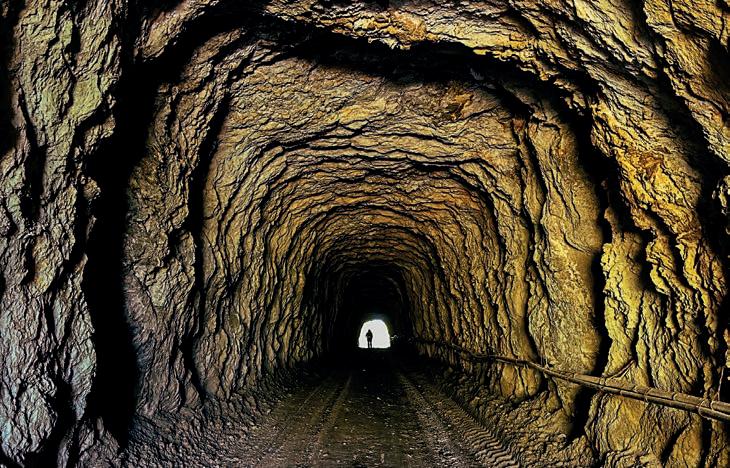

Confined mine spaces pose higher dust risk for miners due to poor ventilation and limited access.

THE CONFINED SPACES OF AN OPERATION REPRESENT A UNIQUE AIR-QUALITY CHALLENGE DUE TO THE NATURE OF THE MATERIALS AND PROCESSES.

Confined space entry remains one of the most hazardous activities in mining operations.

Whether accessing tanks, hoppers, sumps or process vessels, workers face a high-risk environment where dust, toxic gases and oxygendeficient atmospheres can accumulate quickly and unpredictably, posing an often-underestimated threat to worker health.

A best-practice approach means more than minimum compliance; it requires safety professionals to embed dust suppression and respiratory protection into a broader risk management framework, one that integrates planning, engineering, monitoring and emergency readiness that aligns with access and egress methodologies.

In a mining environment, confined spaces are uniquely challenging due to the nature of the materials and processes involved. Dust generated through cutting, grinding, maintenance or simply disturbing residual buildup can linger in still air, potentially exposing workers to hazardous particles that damage lungs and increase the risk of long-term illness. Confined spaces, with limited access, poor natural ventilation, and potential for rapid atmospheric change, magnify the risk. The presence of oxygendeficient air, flammable vapours or toxic gases like hydrogen sulphide or carbon monoxide pose further risks.

This complex environment demands a multi-layered control strategy, one built on strong risk assessment, robust planning and a commitment to continuous monitoring and response.

Best practice starts with treating confined space hazards as a highconsequence risk, requiring controls that are proactive and resilient. While standards such as AS 2865 (Confined Spaces), AS/NZS 1715 (Respiratory Protection), and the Model WHS Regulations provide a framework, they must be applied with context-specific insight and a willingness to go further when risk justifies it.

In mining, best practice means looking beyond administrative controls and personal protective equipment (PPE) to engineer risk out of the task such as whether a dusty process can be performed outside the space, or substituted with a safer alternative. Where entry is unavoidable, the focus shifts to controlling the environment and equipping workers with the knowledge, tools and support to manage respiratory risks.

Reducing airborne hazards through physical control of dust at the source, such as integrating water-based suppression systems, can significantly reduce the release of fine particles into the air.

Vacuum extraction also plays a critical role. High-efficiency particulate air (HEPA) filtration, combined with explosion-proof equipment, allows for safe removal of dust without the risks associated with compressed air blowdowns, which often spread contaminants rather than remove them.

Tailored ventilation in mining must be planned, not improvised. Applying forced air, either as extraction to create negative pressure or as clean air supply, ensures continuous airflow and prevents stagnation.

Where residual risk remains, respiratory protective equipment (RPE) becomes essential with selected equipment that matches the hazard, fits the worker, compliments other PPE without compromising performance.

Properly fitted P2 or P3 filters are the minimum requirement for most dust hazards, but higher-risk environments may demand powered air-purifying respirators (PAPRs), while supplied-air respirators (SARs) or selfcontained breathing apparatus (SCBA) are mandatory in oxygen-deficient or unknown atmospheres.

Crucially, all RPE use must be supported by a formal respiratory protection program. That means conducting fit-testing, training workers, maintaining equipment, and regularly reviewing performance.

Effective risk management continues through real-time monitoring, clear communication and embedded emergency capability.

Atmospheric testing must be performed before and during entry, not just for dust but for oxygen levels and toxic gases.

Permits should reflect a deep understanding of the task, space and risk controls. They should require validation of controls, confirmation of ventilation effectiveness, and assurance that rescue capability is in place and ready to respond.

Emergency planning, especially in mining, must factor in respiratory protection for rescuers as well.

The Working at Heights Association of Australia’s (WAHA) position underscores the importance of integrating respiratory controls into confined space rescue planning, not as an afterthought but as a core design element.

Best practice is about culture, and a strong safety culture in mining recognises that confined space work is a unique event that demands planning, engagement and technical control.

That culture is supported by investment in training, by empowering supervisors to challenge unsafe plans, and by giving teams the time and tools to do the job right.

By embedding best practice into confined space entry, particularly in the areas of dust suppression and respiratory protection, mining organisations not only protect workers from harm but also build resilience into their operations, reduce downtime and improve compliance confidence.

Managing dust and respiratory hazards in confined spaces isn’t simply a compliance exercise; it’s a test of an organisation’s safety maturity. In mining, where the risks are amplified and the consequences are severe, adopting best practice approaches is both a duty of care and a business imperative.

WAHA’s guidance, coupled with existing standards, offers a pathway toward safer, smarter confined space work. By applying the hierarchy of controls with intent, investing in engineering solutions, and embedding respiratory protection into the broader system of work, safety professionals can lead a transformation in how confined space hazards are addressed, one that places prevention at the centre and people at the forefront.

In

NOME’S ROCKMONITOR XR SYSTEM FEEDS CONTINUOUS, REAL-TIME STRATA DISPLACEMENT DATA TO CENTRALISED SMART CENTRES, ENABLING SAFER DECISION-MAKING FROM A SECURE, REMOTE LOCATION.

Nome’s strata monitoring product suite is built on a simple yet impactful idea: Save Lives, Revolutionise Industries.

By harnessing digitalisation and automation, the company’s technology delivers real-time insights that reduce reliance on manual checks and help to ensure faster, data-driven responses, and significantly improve underground safety.

This type of monitoring has traditionally relied on manual inspections and isolated instruments, which often only provide snapshots

Nome’s RockMonitor system has been developed to ensure miners remain unharmed in underground environments.

supported safety efforts, they can be limited in their ability to detect subtle trends or deliver continuous real-time insight. Automated alerts and continuous digital monitoring mean risks can be identified and addressed before they escalate, creating a safer, more predictable underground environment.

That’s where Nome’s RockMonitor XR comes to the fore, offering a smarter, safer approach to ground stability. Designed to meet the need for continuous, reliable strata displacement data, the RockMonitor XR package consists of telltales – a fail-safe device used

directly into mine roofs, backs or sidewalls.

Each telltale features two or four anchor points, allowing it to detect movement across multiple layers of rock. These sensors connect to an underground controller that transmits data in real-time to a central server, giving decision-makers instant visibility via real-time alerts, without the need for manual checks.

The system also integrates seamlessly with a mine’s own smart centres, allowing teams to monitor strata conditions alongside other critical mine data – all from a single control room.

This capability is an essential part of RockMonitor XR because it removes the need to send personnel underground for routine checks, reducing exposure to risk while ensuring potential hazards are identified as early as possible. It also delivers clear operation benefits in that reducing reliance on manual checks helps to improve production efficiency and minimise downtime.

This continuous flow of information is enabled by Nome’s Core Applications software, which provides a seamless connection between the underground controller and surface systems, allowing for the real-time transmission of strata displacement data.

The system logs all activity and triggers alarms when movement exceeds pre-set thresholds, ensuring timely responses to emerging risks.

Live and historical data can also be accessed from a single platform, with detailed graphing tools that give operators deep insight into ground behaviour.

The impact of Nome’s RockMonitor XR becomes even clearer when seen in action.

Workers at a Tier 1 underground mine where the system was deployed were sometimes put at risk due to the safety teams’ reliance on manual inspections, which also often led to missing early signs of danger.

When the mine installed Nome’s real-time system to counter the issue, it began receiving automated rock movement alerts at its surface control room. One such alert prompted the evacuation of an area that later experienced a significant roof collapse.

If traditional methods were still being utilised in this instance, it’s likely personnel injuries or even fatalities could have occurred.

This example, just one of many, serves to highlight the critical role advanced monitoring technologies play in modern mining operations.

Nome’s RockMonitor XR enables mines to move from reactive safety measures to proactive risk management, protecting personnel and production.

8-9

EFFECTIVE HAND PROTECTION STARTS WITH THE RIGHT GLOVES, AND NINJA GLOVES ARE HELPING TO SET A NEW STANDARD FOR SAFETY AND PERFORMANCE ON MINE SITES.

In high-risk industries like mining, hand injuries remain one of the most common on-site safety issues, making effective protective gloves an invaluable tool.

Workers are frequently required to use their hands to operate heavy machinery, handle tools and manage materials. These daily tasks expose them to a range of injury risks, particularly cuts, crush injuries, and impact trauma.

According to Safe Work Australia, the wrist and hand are the most frequently injured body parts in the workplace, accounting for 38 per cent of all work-related hospitalisations,

with fingers and thumbs making up 24 per cent of that number.

To reduce these incidents, it’s essential to pair effective training and hazard awareness with the right personal protective equipment (PPE). Among the most critical of these are protective gloves, and recent innovations in glove design are making a real difference.

A standout example is the Ninja Slash-Tec FA-6 Cut F Impact Glove.

Built with fine 18-gauge Kevlar liners, the glove offers a close fit that allows for dexterity while still providing high-level cut resistance. It includes a foam coating that improves grip and

abrasion resistance, making it suitable for wet and dry environments.

While its cut resistance and grip are essential, the glove also addresses more severe threats. Crush injuries, in particular, represent a serious risk. These most commonly happen when a hand becomes trapped between two objects, leading to bruising, broken bones, nerve damage, or even amputation.

Alongside crush injuries, impact trauma is another significant concern. Whether from a direct blow or the repetitive use of heavy tools, these injuries can cause deep tissue damage, fractures, and even long-term conditions like carpal tunnel syndrome.

A recent report on safety performance in Western Australia’s mineral industry showed that 16 per cent of all serious injuries were handrelated, with 56 per cent of those caused by crush and impact.

To combat these risks, the Ninja Slash-Tec FA-6 incorporates a highperformance rubberised impact protection system that absorbs and deflects forceful blows – providing crucial protection in high-risk tasks.

This Slash-Tec FA-6 Cut F Impact Glove is part of Ninja’s wider focus on developing high-performance hand protection that doesn’t compromise on comfort or flexibility.

As a global leader in the PPE space, the company continues to combine innovation with realworld application.

For mine operators this directly translates to more than just a handful of benefits. By investing in welldesigned protection tailored to tough conditions, employers can help ensure workers return home safely, with their most valuable tools intact.

MENTAL HEALTH IN THE WORKPLACE IS INTEGRAL TO SAFETY, AND THAT’S WHY SAFETY MATE HAS JOINED FORCES WITH BLACK DOG INSTITUTE.

In high-risk industries like mining and construction, much of the safety focus has traditionally been on the physical side of the ledger.

But protective person equipment (PPE) supplier Safety Mate is aiming to change that as it aligns physical safety with mental health advocacy through its ongoing partnership with Black Dog Institute.

Together, these organisations are proving that safety goes beyond gloves, glasses and respirators, and includes the wellbeing of the people wearing them.

Since 2021, Safety Mate has partnered with the Black Dog Institute – a not-for-profit facility for diagnosis, treatment and prevention of mood disorders – to bring mental health to the forefront of the workplace.

This collaboration, according to Safety Mate, “extends beyond donations or awareness campaigns”. Through expert-led mental health training, Safety Mate empowers its staff and, by extension, its customers, to recognise, manage and support personal and professional mental health challenges.

Its involvement with Black Dog Institute has allowed Safety Mate to see the positive shift in its internal culture first-hand.

The training has helped its team foster open conversations and extend that support to the industries it serves.

This training is especially valuable in sectors where mental ill-health is a recognised risk. By building knowledge and empathy, Safety Mate is helping to create safer, more supportive workplaces across Australia.

A standout result of this partnership is the Black Dog product range, an innovative line of safety gear that champions mental health while maintaining exceptional safety standards.