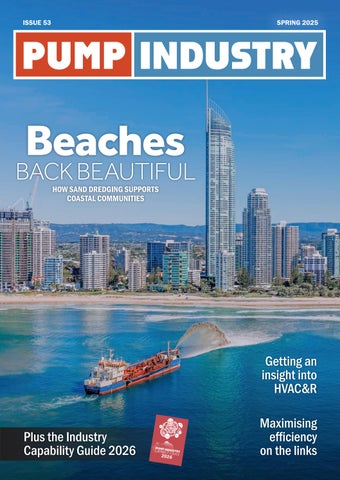

Beaches BACK BEAUTIFUL

Powerful Partnership

Robust,

Engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7.

To find your nearest dealer visit volvopenta.com/industrial

Pump Industry Australia Incorporated

PO Box 527

YARRAWONGA VIC 3730

Phone: +61 493 975 931 secretary@pumps.org.au

www.pumps.org.au

PIA Executive Council 2025

Kylie Kinsella - President Regent Pumps

Joel Neideck – Vice President TDA Pumps

Tracey Guida – Treasurer/Secretary

Alan Rowan – Councillor

Executive O cer – Publications and Training, Life Member

Ken Kugler

Executive O cer – Standards, Life Member

Steve Bosnar – Councillor Franklin Electric/Pioneer Pumps

Michael Woolley – Councillor Tsurumi Pumps

Luke Biermann – Councillor Mechanical Seal Engineering

Tim Yakup – Councillor Regent Pumps

Alex Calodoukas – Councillor Pump Strategy

Keith Bowen – Councillor Xtron Pumps Australia

President’s welcome

Dear PIA Members and Industry Colleagues,

Welcome to the spring edition of Pump Industry.

As we step into the spring season, I’m reminded of the renewed energy and optimism that this time of year brings. In many ways, it mirrors the momentum we’re seeing across the pump industry — a combination of steady progress, evolving technologies, and a growing focus on sustainability and e� ciency.

Over the past year, our industry has shown remarkable resilience. Despite global challenges from economic uncertainty to supply chain disruptions, we’ve continued to adapt, innovate, and lead.

Now, with spring upon us, there is a renewed sense of opportunity. We’re seeing increased investment in infrastructure, water management and energy e� ciency, all areas in which pump technologies play a crucial role.

As professionals in this � eld, we are not just moving � uids; we’re enabling progress. Whether it’s ensuring access to clean water, supporting critical manufacturing, or advancing clean energy solutions, our work has a far-reaching impact.

As advertised in last month’s issue, the PIA held its � rst training session for this year. It was an excellent collaboration with WEG Australia, Drive Systems and our partner, the Cancer Council. We were fortunate to have experts from WEG, who presented an overview of the company

before delivering product training on the latest developments in motor technology, control systems, and gearbox arrangements.

Complimenting the WEG training was the presentation from Drive Systems. We had an insightful product presentation on the history of couplings, where they are now and the best options for all applications. All presenters are to be congratulated on their informative presentations; all participants commented on the high quality of the training they received.

Finally, we heard from the Cancer Council, who reminded us of the importance of not missing our health checks and focusing on bowel cancer. They also encouraged all of us to complete the free bowel test we receive in the mail after the age of 50. You are welcome to donate to this cause through the PIA website or directly on the Cancer Council website. The PIA has donated half of the training proceeds to this valuable cause.

Enjoy the spring edition as I encourage you to take the time to read, re� ect, and engage with this issue. Whether you’re a manufacturer, engineer, distributor, or operator, there’s something here for you.

Thank you for your continued commitment to excellence in all that you do. Here’s to a season of growth, innovation, and shared success.

Kind regards,

Kylie Kinsella PIA, President

Scan to subscribe to Pump Industry’s weekly newsle er –delivered to your inbox every Thursday a ernoon.

Cover image: City of Gold Coast

Published by

Chairman John Murphy

Chief Executive O� cer

Christine Clancy

Editor Chris Edwards

Design

Jacqueline Buckmaster

Head of Design

Blake Storey

Business Development Manager

Rima Munafo

rima.munafo@primecreative.com.au +61 413 475 078

Client Success Manager

Louisa Stocks

Head O� ce

Prime Creative Media

379 Docklands Drive

Docklands Victoria 3008

P: +61 3 9690 8766

info@primecreative.com.au pumpindustry.com.au

Subscriptions

P: +61 3 9690 8766

subscriptions@primecreative.com.au

Pump Industry is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

6 Planning for shifting sands HVAC&R 10 Liquid cooling takes the lead 12 Innovation in every degree PIA MEMBER NEWS

14 Future-ready with hose-diaphragm pumps

16 Building the next generation

19 A smarter alternative to traditional packaging

20The case for OEM parts

23 Precise and protective pump power

MINING

24 Making space for precision

26 Engineered pump solutions at WA Mining

28 Supporting mining with ROTO EFFICIENCY

Contents Regulars

PIA WELCOME

3 President’s welcome PUMP CURVES

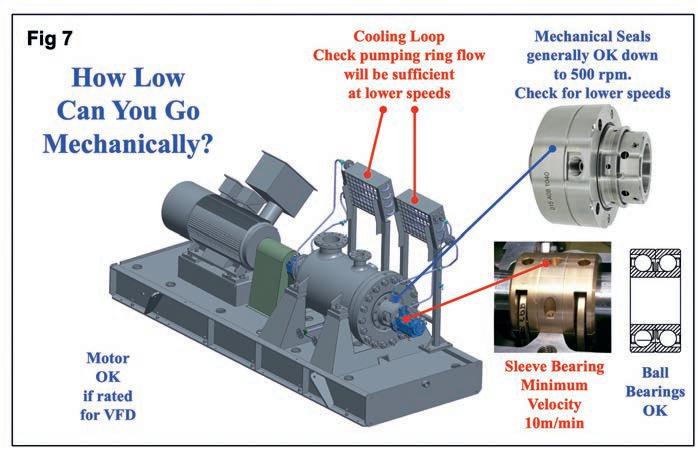

43 #16: How low can you go?

31 Performance where it counts

32 Powering e� ciency at Yarra Yarra

FOOD AND BEVERAGE

34 Milking more from every pump MOTORS

37 Gearboxes powering pump performance

38 Super premium motor upgrade

INDUSTRY ADVOCATES

41 Australian Refrigeration Council ICG

51 Pump Industry Capability Guide 2026

PUMP HANDBOOK

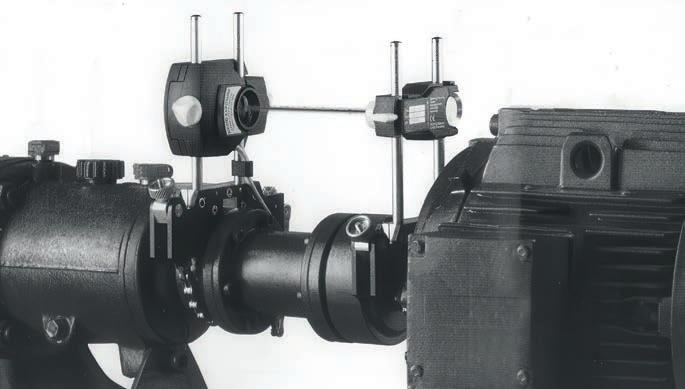

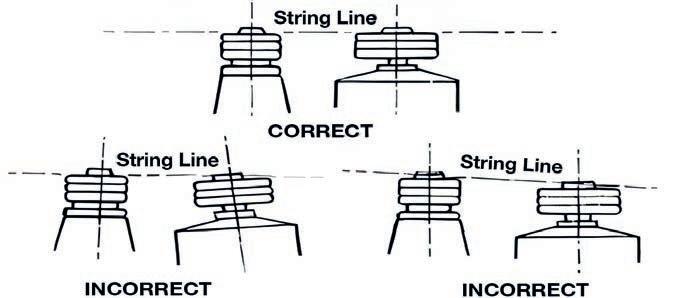

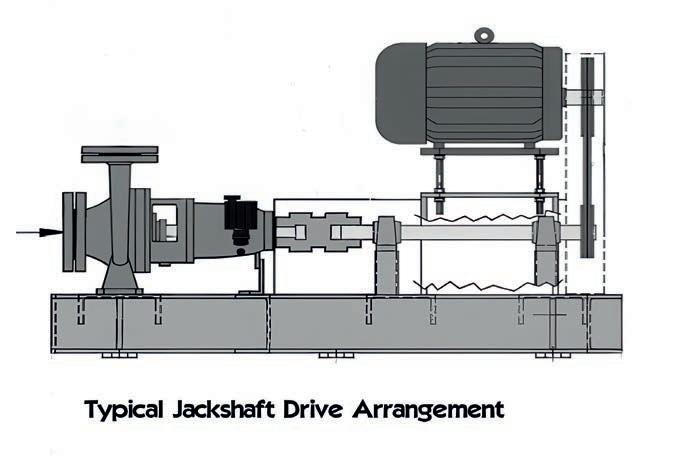

46 The right alignment

This magazine is published by Prime Creative Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

Pumps Industry acknowledges Aboriginal Traditional Owners of Country throughout Australia and pays respect to their cultures and Elders past, present and emerging.

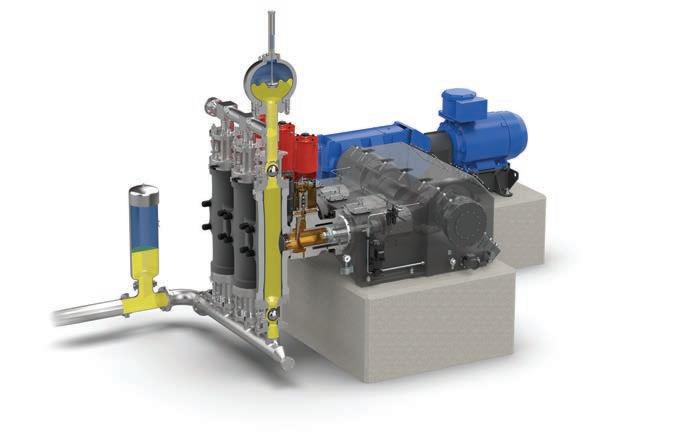

MULTISAFE® DOUBLE HOSE-DIAPHRAGM PUMPS

Precision-engineered for the most demanding applications, FELUWA’s MULTISAFE® technology ensures safe and efficient handling of abrasive, aggressive and toxic media – even under extreme operating conditions.

Our pumps are designed for high-pressure and high-performance requirements, delivering:

Flow rates up to 1,000 m³/h

Pressures up to 350 bar

YOUR SOLUTION FOR:

Reactor, autoclave and gasifier feeding

Concentrate and tailings transfer

Fly and bottom ash disposal

Wet oxidation

Mine dewatering

Planning for shifting sands

As coastlines retreat and storm events intensify, the importance of long-term sand management has never been more urgent.

In March 2025, Tropical Cyclone Alfred stalled ominously o� the Queensland coast. The system didn’t strike with the speed of a traditional cyclone. It lingered, dragging out its destructive presence over a harrowing twelve-day period. During that time, the storm unleashed sustained high-energy wave conditions across southeast Queensland and northern New South Wales, coinciding with seasonal king tides and already vulnerable dune systems. Entire sections of shoreline were overtopped or sheared away. By the time the cyclone � nally cleared, beach widths had shrunk by up to 50 metres in some locations, and o� shore sand bars had reformed in unpredictable patterns.

For engineers, planners, and councils, the aftermath was not just a test of seawalls or sediment management strategies. It was a stress test for decades of planning and sand pumping infrastructure investment. Those with pre-installed slurry pipelines, booster pump capacity and pre-approved nourishment zones were able to act swiftly. Others were forced to wait weeks, in some cases, to secure the necessary approvals. Some shorelines recovered quickly. Others were left exposed and continued to erode further. The contrast o� ered a clear message: resilient coasts need not only forecasting tools, but the physical ability to move sand when and where it matters most.

Sand moved faster than approval cycles

The City of Gold Coast’s Matt Moore did not understate the event’s impact.

“We had beach width losses of up to 50 metres and six-metre-high scarps,” Moore said. “Approximately four million cubic metres of sand were taken from the upper beach and deposited in o� shore bars.”

The cyclone produced the highest monthly wave energy on record since the city began tracking it in 1992. What made Tropical Cyclone Alfred particularly destructive was its duration.

“We had about 12 days of high-energy wave events from a single crossing,” Moore said. “It a� ected the entire 32 kilometres of urban beaches.”

Had the city not invested heavily in sand pumping infrastructure, the damage would have been far more extensive. Gold Coast’s shoreline management relies on a multi-tiered system that includes nourishment, bypassing, and a backpassing arrangement, all coordinated with longshore sediment transport modelling.

At the centre is a 7.8 kilometre pipeline stretching from the Seaway to Surfers

Paradise. Booster pumps ranging from 760 to 1,300 horsepower push sand through this slurry pipeline during scheduled beach nourishment campaigns. The system is SCADAintegrated (Supervisory Control and Data Acquisition), enabling operators to remotely monitor and adjust operations.

“What we’re doing is accelerating natural recovery,” Moore said. “We monitor shoreline pro� les weekly and adjust our placement volumes using a beach volume index to meet resilience targets.”

These operations demonstrate how strategic investment in sand pumping infrastructure can reduce post-storm recovery times and build long-term erosion control capacity.

Shoreline management beyond emergency response

While the Gold Coast faces a constant longshore drift of approximately 550,000 cubic metres of sand annually, other councils deal with more dynamic local systems.

Sunshine Coast Council Principal Coastal Engineer Georgia Keeshan oversees a diverse suite of sand pumping infrastructure applications, including canal maintenance, estuary dredging operations, and open-coast beach nourishment. Her team uses a mix of permanent slurry pipeline installations and mobile dredging systems.

“Tropical Cyclone Alfred didn’t hit us as hard as the Gold Coast, but we saw substantial erosion, particularly around Maroochydore,” Keeshan said. “Bribie Island experienced another entrance breakthrough, which altered the tidal prism and changed sediment transport patterns throughout Pumicestone Passage.”

The council selects pumps and pipeline con� gurations based on placement site access, beach width, and

the proximity of approved sand sources.

“There’s no one-size-� ts-all,” Keeshan said. “The closer the sand source, the smaller the pump you need. But if the beach is narrow, high-volume pumps can create delivery challenges.”

Contractors are pre-approved under multi-year tenders. Booster pumps and dredge barges are mobilised on demand, and sand quality is tested for grain size, silt content, and ecological suitability. Community communication is also essential.

“We have long-term planning documents like the Coastal Hazard Adaptation Strategy and Shoreline Erosion Management Plan,” Keeshan said. “And every nourishment project using sand pumping infrastructure has a tailored comms strategy, including signage, social media, and targeted brie� ngs.”

Dredging operations, designed for delivery

Further south, in New South Wales, Lake Macquarie City Council has launched a permanent sand pumping infrastructure program to manage Swansea Channel. This narrow entrance is the only marine access point into Lake Macquarie, Australia’s largest coastal saltwater lake.

“Sand shoaling reduces safe navigation, increases pressure on marine rescue, and impacts local tourism,” said project manager Brent Wellham. “Although Cyclone Alfred didn’t directly a� ect us, this infrastructure is about longterm planning.”

The system includes a Beaver 30 cutter suction dredge, land-based booster pumps, and a high-density polyethylene pipeline that will transfer sand slurry from Naru Point to Nine Mile Beach. It replaces previous ad hoc dredging campaigns with a permanent, managed solution.

“The route will likely follow historic

alignments but will now be buried or protected,” Wellham said. “We’re under-boring the Paci� c Highway and negotiating easements to allow permanent placement.”

With a dredging capacity of 1,000 cubic metres per day, the system signi� cantly outperforms past e�orts. Environmental assessments are being managed by Transport for New South Wales and include water quality monitoring, seagrass mapping, and bed level surveys.

The funding structure includes ten million dollars from the Commonwealth’s Priority Community Infrastructure Program and six million dollars from the NSW Government. Once construction is complete, Transport for New South Wales will take over long-term operations and maintenance of the sand pumping infrastructure.

State-wide coordination through Transport for New South Wales Transport for New South Wales manages a portfolio of coastal resilience projects across the state, with a particular focus on navigational safety and infrastructure readiness.

“Our role in dredging focuses on safe access for commercial and recreational vessels,” a spokesperson said. “But sand pumping infrastructure also supports � ood mitigation, coastal protection, and sediment reuse.”

Transport for New South Wales delivers projects under the New South Wales Coastal Dredging Strategy and the Boating Infrastructure and Dredging Scheme, working with councils and other state agencies. It conducts hydrographic surveys, manages procurement, and ensures compliance with Marine Order 504 under Australian maritime law.

“All dredging vessels must meet national safety standards,” the spokesperson said. “Booster pump arrangements and slurry pipelines are adapted to the dredge capacity, and pipework is � oated at intervals using industry-standard buoyancy systems.”

SCADA integration is standard for all procured vessels, allowing remote

Dredging work on the Gold Coast. Image: City of Gold Coast

The Maroochy Beach Renourishment Program under way. Image: Sunshine Coast Council

operability via logic-controlled onboard systems. Monitoring includes water quality testing, avifauna assessments, and regular shoaling analysis.

Every dredging campaign is subject to a Review of Environmental Factors (REF). Transport for New South Wales coordinates with the NSW Environment Protection Authority (NSW EPA), Department of Climate Change, Energy, the Environment and Water (DCCEEW), Department of Primary Industries (DPI), and the community.

While sand for beach nourishment is often placed by local councils, Transport for New South Wales ensures that all sand pumping infrastructure is designed for reliability, compliance, and reuse.

Community expectations meet technical complexity

Despite the technical nature of modern sand pumping infrastructure, public understanding remains vital. Hydrodynamic models and sediment budgets may guide shoreline protection, but long-term success often hinges on whether the community supports visible works. Keeshan said community education continues to evolve.

“We’re trying to show how nourishment supports ecological and recreational values, not just engineering targets.”

To support that narrative, the Sunshine Coast Council has developed interpretive signage, animated videos, and live dashboards that help residents understand the scale and bene� ts of nourishment campaigns. Ecological safeguards include sourcing clean, lowsilt sand, minimising plume formation and avoiding areas with active seagrass beds. In the Pumicestone Passage, these strategies protect federally listed shorebird habitats and reduce dredging impact.

Gold Coast programs also include high-resolution shoreline cameras, LIDAR (Light Detection and Radar) scans and drone imagery to demonstrate performance in near real-time. These tools give ratepayers visual con� rmation that sand is being added, not lost.

“We aim for visibility and transparency,” Moore said. “People

don’t want to hear that sand is disappearing. They want to see that it’s coming back, and that it’s being placed intelligently.”

The City of Gold Coast uses a Christmas-tree pipe layout to distribute sand e� ciently across 200-metre beach cells.

“It reduces downtime and allows for faster delivery during critical recovery periods,” Moore said.

These kinds of technical adaptations help councils demonstrate the public value of sand pumping infrastructure as a long-term coastal asset. When ratepayers understand how and why beaches are being replenished, they are more likely to support ongoing investment and accept short-term inconvenience during operations.

Learning from each other

Each of the three featured councils underscored the importance of coordination and knowledge transfer, not just during disaster recovery, but as part of ongoing shoreline resilience planning.

Sunshine Coast works closely with Queensland’s Department of Transport and Main Roads to align harbour dredging and nourishment at Mooloolaba.

“We share not only equipment but lessons,” Keeshan said. “Sometimes that’s as simple as going to see each other’s work.”

Regular inter-agency site visits and shared contractors improve consistency across campaigns, particularly when working with mobile booster pumps and pipe systems.

Moore said that the Gold Coast partners with the Gold Coast Waterways Authority (GCWA) and contributes 25 per cent to the Tweed Sand Bypassing Scheme.

“That scheme has delivered more than 13 million cubic metres of sand since 2001,” he said. “Without it, our southern beaches would be in much worse condition.”

Data sharing with Surf Life Saving Queensland and Moreton Bay Regional Council ensures alignment on sand volumes, nourishment

timing, and hazard mitigation during joint campaigns.

Lake Macquarie’s upcoming handover to Transport for New South Wales re� ects a maturing model for shared sand pumping infrastructure operation.

“We’ll be monitoring pre- and post-dredge surveys, sediment movement and ecological health together,” Wellham said. “That level of coordination is critical.”

Across jurisdictions, there is a growing sense that collaborative sediment management is not just good policy. It is the only way to manage coastlines that don’t recognise local government boundaries.

Future readiness requires local insight The next decade is expected to see more councils integrating adaptive, site-speci� c infrastructure for beach nourishment and erosion control.

Keeshan said demand is growing for o� shore nourishment systems that reduce direct beach impact.

“We’re exploring campaigns that place sand in shallow o� shore areas, where wave action naturally returns it to the beach. It’s less intrusive for users and more ecologically sensitive.”

Moore pointed to scheduled upgrades for the Seaway back-pass system.

“We’re improving pump controls, reinforcing exposed pipeline segments, and adding redundancy to support faster responses.”

While the systems di� er, the trend is clear. Permanent, responsive, datainformed sand pumping infrastructure is no longer a luxury; it is a necessity. It is a requirement for shoreline resilience in a changing climate.

Georgia Keeshan o� ered a � nal insight from the frontlines of coastal engineering.

“Planning is everything,” she said. “Beach erosion only becomes a problem when it’s already a problem. If you don’t have the permits, the contractors, and the sand source assessments all ready, you can’t respond fast enough. And every coastline is di� erent. There’s no one-size-� ts-all system. You need the right pump, the right pipeline, and the right plan.”

Growing demand for scalable digital infrastructure is driving a shi toward more e cient cooling methods.

Australia’s data centre and cloud hosting sector is experiencing unprecedented growth, driven by digital transformation across every industry, the explosion of e-commerce, and the rise of arti� cial intelligence (AI) and machine learning. According to IBISWorld, the sector is forecast to grow at an annualised 9.7 per cent from 2025 to 2030, reaching $6.0 billion by 2030, outpacing many other sectors of the Australian economy. This expansion is underpinned by surging demand for secure, scalable, and energy-e� cient IT infrastructure, as both government and business accelerate their digital footprints.

This rapid growth presents a signi� cant challenge: how to cool ever-more powerful and densely packed server environments e� ciently and sustainably. Traditional air-cooling methods are reaching their limits, especially as rack power densities climb, sometimes exceeding 100 kilowatts (kW) in next-generation AI deployments such as NVIDIA’s GB200 NVL72 systems.

The industry, as identi� ed by IBISWorld, is increasingly turning to advanced liquid cooling technologies, which can improve cooling energy e� ciency by 20–50 per cent compared to air-cooled systems, depending on

the deployment type and rack density. This shift not only slashes operational costs but also helps data centres meet stringent environmental, social, and governance (ESG) and National Australian Built Environment Rating System (NABERS) sustainability targets, according to a 2025 IBISWorld report.

Why liquid cooling? Water and engineered � uids have a signi� cantly higher thermal capacity than air, enabling precise and e� cient heat removal directly at the source, whether it is the chip, rack, or coolant distribution unit. This translates to lower energy consumption, reduced water usage, and a smaller carbon footprint.

These bene� ts are directly aligned with the sector’s growing focus on sustainability, cost control, and regulatory compliance. For operators, this means a lower total cost of ownership, reduced downtime, and the � exibility to scale as digital workloads increase.

How Burkert can help

At Burkert, we are at the forefront of this transformation. Our precisionengineered �uid control systems, including proportional solenoid valves, �ow transmitters, and analytical sensors, deliver ultra-stable temperature control (often within ±0.1°C when integrated

with advanced CDU controls), robust water quality monitoring, and leak-free operation. These solutions are modular and scalable, integrating seamlessly into both new builds and existing facilities, and supporting a range of applications, from direct-to-chip to immersion cooling.

Burkert’s advanced � ow and valve technologies enable smart pump integration, demand-based cooling, and heat recovery features, which can deliver lower energy consumption and directly support operators’ ESG and sustainability goals. Our systems provide integrated leak detection, predictive maintenance, and remote monitoring, ensuring safe and 24/7 operation even in the most demanding Tier III/IV environments.

Additionally, our global support network, easy-to-replace modular components, and compatibility with both air- and liquid-cooled environments make us a reliable partner for data centre operators and OEMs.

As digital transformation accelerates and the demand for high-performance, sustainable data centre cooling grows, Burkert is ready to support the Australian market with proven, futureready solutions. By embracing liquid cooling, operators can ensure their facilities are prepared for the next wave of digital innovation, e� ciently, reliably, and sustainably.

For more information, visit www.burkert.com.au

Smart

Innovation in every degree

Smarter heating and cooling is reshaping expectations across commercial infrastructure and asset performance planning.

Australia’s commercial infrastructure is entering a new era. Facility owners, developers, and government clients want systems that not only meet operational demands but also anticipate them. Cost and compliance pressures are increasing, yet so are expectations for occupant comfort, e� ciency and responsiveness to weather changes. For LG, the answer lies in combining intelligent hardware with adaptive software.

At the heart of this shift is the new Multi V i system. It is LG’s most advanced variable refrigerant � ow (VRF) solution to date, placing arti� cial intelligence at the core of HVAC system performance. According to Virender Rana, Head of LG’s HVAC business in Australia, this represents more than an incremental update.

“HVAC will always remain in demand,” Virender said. “As buildings get more complex and energy use rises, we need smarter systems that respond to real-world conditions, not just static setpoints.”

Smarter control in complex climates

The Multi V i is LG’s most advanced variable refrigerant � ow (VRF) system to date. It brings together arti� cial intelligence, adaptive controls, and post-sales service improvements, all designed to optimise performance across Australia’s diverse conditions.

Virender said the system was designed around what he calls the “three I’s”: innovative, interactive, and intelligent.

“It adapts based on how many people are in a room, how humid it is, what the outdoor temperature is doing,” he explained. “The system is more than smart - it is intelligent. Indoor devices communicate with each other, while outdoor devices respond automatically. You’re not just turning on cooling and heating anymore. You’re making live decisions based on user needs and environmental data.”

That adaptability matters in a country where a single day can swing between sub-zero mornings and 40-degree highs. From Far North Queensland to urban

Melbourne, the Multi V i is engineered to handle these crucial conditions.

“Our outdoor units can operate in a wide temperature range from sub-zero to almost 50 degrees,” Virender said. “We’ve built the system to respond to those extremes.”

This responsiveness supports both comfort and e� ciency. Outdoor units shift from economy mode to rapid cooling based on detected humidity, while indoor systems prioritise occupant needs across a larger operational range.

“The capacity range is wide,” Virender added. “One unit can go up to 73 or 74 kilowatts. That saves space, simpli� es installation and reduces component count.”

While all new systems are trialled domestically in South Korea before international launch, feedback from Australian teams still in�uences future product development. Local standards, rebate programs and regulatory changes are forwarded to LG’s global R&D team.

“We don’t always get top priority straight away, but the message is clear,” Virender said. “We need Australiaspeci� c models, and we push for those constantly.”

Smarter service and lower disruption AI HVAC systems also o� er improvements in long-term servicing and maintenance. The Multi V i logs up to six months of performance data,

Virender Rana is the head of LG’s HVAC Business in Australia.

enabling fault diagnostics before a technician even arrives on site.

“If there’s a fault, a technician doesn’t have to guess,” Virender said. “They can look at the history and pinpoint what went wrong.”

This allows for more proactive servicing and reduces the risk of unplanned outages. Mobile access also eliminates the need for laptops or proprietary cables. According to Virender, technicians can download the required data or view operating conditions directly from their phones.

“This improves our troubleshooting and in-� eld engineering capability,” he said. “It also shortens service time and improves the customer experience.”

Sustainability, refrigerants and reality checks

Virender believes HVAC is a critical contributor to building sustainability, but

not the only one. While LG’s systems have helped commercial buildings achieve Green Star and NABERS ratings, HVAC alone cannot de� ne total performance.

“We can contribute, but sustainability depends on lighting, insulation and materials as well,” he said. “We are part of that picture, not the whole picture.”

LG is also addressing the shift to lower global warming potential (GWP) refrigerants. Current systems are transitioning from R-410A to R-32, with future moves toward R-290 being assessed. However, Virender pointed out that energy-e� cient and low-emission systems often come at a premium.

“If developers aren’t willing to pay the higher cost, the change will be slow,” he said. “We’re ready if the demand is there, but it has to be a holistic decision.”

Market education and training support

The uptake of next-generation HVAC solutions is increasing, but Australia still lags behind North America and Europe. Virender attributes this in part to cautious adoption cycles and commercial conservatism.

“A lot of change comes at a cost,” he said. “We follow what happens in the US and Europe but implement it at our own pace.”

To support industry readiness, LG runs regular training programs for contractors, pre-sales teams and post-sales technicians. These cover system control, energy optimisation and hands-on commissioning.

“We run training both in-house and at customer locations,” Virender said. “After launching the Multi V i, we scheduled sessions speci� cally to get partners up to speed.”

A future shaped by responsiveness

Looking ahead, Virender expects AI HVAC systems to become more deeply integrated with building management systems. He also pointed to the transition from gas heating to electric systems in Victoria and South Australia as a key driver of new demand.

“That means air-to-water heat pumps, hot water systems and chillers,” he said. “It’s not just about comfort anymore. It’s about compliance, energy ratings and electri� cation.”

LG is expanding into water-cooled VRF systems for high-rise buildings and is entering previously untapped markets with a broader range of solutions.

“We’ve come a long way from selling split systems,” Virender said. “Now we’re working across VRF, chillers, heat pumps and hot water. That means more opportunities, and more responsibility, to deliver what the market actually needs.”

For more information, visit lg.com/au

The LG factory in South Korea

LG technical manager and customer inspecting new technology

Future-ready with hose-diaphragm pumps

FELUWA has developed next-generation hose-diaphragm pumps while pursuing long-term sustainability and global market expansion.

For more than 50 years, FELUWA has specialised in designing and manufacturing hose-diaphragm pumps, a technology that has carved out a distinct niche in demanding pumping applications worldwide. The German company, which traces its origins back more than a century, has evolved through several industrial phases before establishing itself in the pump market. Today, FELUWA is recognised for engineering solutions that thrive where abrasive, solid-laden � uids need to be pumped at high pressure and over long distances.

In Australia, FELUWA is represented by Paolo Romagnoli, Managing Director of FELUWA’s Australian subsidiary, who explained how the company’s MULTISAFE® hose-diaphragm pumps di� er from other positive displacement designs.

“Traditional diaphragm pumps use a � at, circular diaphragm. We use a hose element that is softly actuated by hydraulic � uid, which brings major

bene� ts in wear characteristics and maintenance,” Romagnoli said.

This distinction allows FELUWA to deliver reliability in environments where centrifugal pumps or � at-diaphragm designs would struggle. The hose element isolates the pumped medium from the pump body, meaning only the hose and valves are exposed to the process � uid. As a result, exotic alloys are minimised, wear is reduced, and long service life is achievable, often measured in decades.

Australian installations

In Australia, hose-diaphragm pumps have been applied in several specialised niches. At Origin Energy’s Eraring Power Station in New South Wales, FELUWA pumps have been handling � y ash, an abrasive by-product of coal combustion, since 2006. These are among the largest FELUWA pumps operating in the country.

FELUWA has also supplied pumps to Glencore’s Murrin Murrin operation

in Western Australia, where they have been installed for more than 25 years.

“Those installations prove the longevity of our pumps,” Romagnoli said. “If they are maintained properly, a hose-diaphragm pump can operate e� ectively for 30 years or more.”

A new milestone is the Hemi Gold Project in Western Australia, where FELUWA will deliver pumps for Australia’s � rst autoclave gold processing facility. The pumps will feed solids-laden � uid at high pressure into autoclaves, representing a showcase application for hose-diaphragm technology in mining.

Where hose-diaphragm pumps �t best Romagnoli explained that the competitive advantage of hosediaphragm pumps in the mining and power industry lies in applications involving long-distance slurry pipelines or steep elevation changes.

“If you need to pump signi� cant distances and/or deal with large

elevation changes, you will need to stack multiple centrifugal pumps in series. With a hose-diaphragm pump, you can often achieve the duty with a single pump,” he said.

This is one reason why FELUWA has identi� ed strong opportunities outside Australia, particularly in India, where iron ore and coal slurry pipelines of hundreds of kilometres in length are being developed. By comparison, Australia’s rail infrastructure for ore transport makes such pipelines less viable.

In downstream processing, FELUWA pumps also serve industries such as chemicals, ceramics, pharmaceuticals, and waste sludge treatment such as Super Critical Water Oxidation (SCWO) or wet oxidation processes. In these applications, high-pressure atomisation or the ability to pump viscous, abrasive � uids provides a signi� cant advantage over alternatives.

Global expansion

China remains a major market for FELUWA, particularly in coal gasi� cation, but the company is also exploring new opportunities in Southeast Asia. Over the past 12 months, it has appointed agents in Vietnam and Malaysia to build local connections and open doors to growth industries. Vietnam is emerging as a processing hub, while Malaysia has a more established industrial base, and both markets could bene� t from hose-diaphragm pumps in upstream and downstream applications.

FELUWA also has long-running installations in Indonesia, where pumps have been operating successfully in gold mining for several years.

“Often the best sign of success is when you hear nothing from a customer,

because it means the pumps are quietly doing their job,” Romagnoli said.

Beyond Asia, one of FELUWA’s most signi� cant strategic moves has been the establishment of a US o� ce in 2023. North America represents about 18 per cent of the global pump market, compared with Germany’s 5 per cent and Australia’s less than 1 per cent. Many of FELUWA’s early US installations were speci� ed through European-designed plants. However, the new o� ce enables the company to serve customers directly and provide faster access to parts and service.

“Having a local presence enables us to build stronger relationships and to demonstrate the bene� ts of hosediaphragm pumps in the world’s second largest pump market,” Romagnoli said.

With Asia o� ering new industrial projects and the US accounting for a major share of the global pump market, FELUWA’s expansion strategy is designed to position the company where long-term opportunities are strongest.

Innovation and sustainability

Over the past two decades, FELUWA has steadily enhanced its MULTISAFE®

hose-diaphragm pumps with more advanced condition monitoring capabilities. Customers can now track valve performance, pump operation, and energy e�ciency in real time, either locally or remotely. This enables predictive maintenance, reducing downtime.

From a sustainability perspective, FELUWA highlights several advantages. Energy demand is lower than with multiple centrifugal pumps in series, and e� ciency levels of around 95 per cent are common. The hose-diaphragm design also reduces the need for exotic alloys, as only the hose and valves come into contact with the pumped � uid.

“The pumps are designed for a lifetime of 30 years or more,” Romagnoli said. “When customers maintain them correctly, they avoid the waste and disruption of full pump replacement. That long service life is an important sustainability contribution.”

Looking ahead

FELUWA is investing in the development of hose-diaphragm pumps capable of handling even higher temperatures. Current limits are around 180 °C, but mineral processing demands are emerging that require temperatures of 200 °C and above. Engineers in Australia and Europe are working to develop solutions at these levels.

“We’re in the early design phase, but if we can deliver hose-diaphragm pumps at those temperatures within next two years, it will change the industry,” Romagnoli said.

For FELUWA, the strategy is clear: maintain its strong positions in China and Germany, expand into Asia and the US, continue to re� ne the hose-diaphragm technology, and showcase the reliability of pumps already operating in some of the most demanding applications worldwide.

For more information, visit feluwa.com

Pumps on site at Glencore’s Murrin Murrin site

The cross-section of the MULTISAFE hose-diaphragm pump

Regent Pumps is investing in pump engineer development through training and apprenticeships to strengthen Australia’s pump industry workforce.

Australia’s pump industry faces a familiar challenge: an ageing workforce and a shortage of skilled engineers ready to step into senior roles. Engineers Australia has warned that demand for engineers is outstripping supply, with a national shortfall of more than 50,000 engineers across all sectors reported in 2023. Apprenticeships are also struggling to keep pace, with NCVER data showing that engineering trades account for less than � ve per cent of new apprenticeships nationally. For Regent Pumps, one of the sector’s most established suppliers, addressing this shortage means investing in the future by cultivating young talent.

Apprenticeships with purpose Conor McDonagh, Operations Manager at Regent Pumps, said the company has made a deliberate choice to prioritise apprenticeships, training, and mentoring.

“We are focused on pump engineer development, not just for Regent Pumps, but for the industry as a whole,” he said. “If we don’t create pathways for young people now, the skills gap will only widen in the years to come.”

Apprenticeships form a cornerstone of Regent Pumps’ strategy. McDonagh explained that the company has established partnerships with training organisations to ensure apprentices

receive both technical and practical experience.

“It’s not enough to hand someone a manual and expect them to learn on the job,” McDonagh said. “We combine structured training with hands-on work in real environments. That’s how you create con� dent, capable engineers.”

“We want our people to appreciate the role pumps play in critical infrastructure,” McDonagh said. “That perspective helps them see the impact of their work and the importance of doing it well.”

The value of mentorship and diversity

Mentorship plays an equally vital role.

Apprentices are paired with senior engineers, ensuring decades of knowledge are passed on. Elvin Khoo, Group Engineering Manager, brings over 20 years of core industry experience, interpreting technical illustrations and troubleshooting design/manufacturing challenges.

“We want to see young ones stepping up and owning the industry,” Khoo said. “It’s time they shine and show that they are the future leaders of the industry.”

Regent Pumps also recognised the importance of diversity.

“If the industry is going to re� ect the communities it serves, then we need to be open and proactive in recruiting and supporting diverse talent,” he said.

The company’s commitment to pump

engineer development aligns with a broader national need. Engineering skills are in short supply across Australia, with many sectors competing for the same pool of talent.

“Pumps don’t always get the spotlight, but they are vital to everything from water treatment to energy,” McDonagh said. “That’s why we need to make this industry an attractive and rewarding career choice.”

Looking ahead

Tim Yakup, National Sales Manager, is the driving force who is looking ahead. Regent Pumps plans to expand its training programs, including stronger links with schools and universities.

“We need to reach young people earlier,” Yakup said. “When students understand that pumps are at the heart of industries that matter, like water security, energy e� ciency, and manufacturing, they can see a meaningful career path.”

For Regent Pumps, the long-term goal is clear: create a pipeline of skilled, motivated engineers who will sustain the industry for decades to come.

“We’re not just training for today’s projects,” Yakup said. “We’re building the next generation of pump engineers who will solve tomorrow’s challenges.”

For more information, visit regentpumps.com.au

Image: Regent Pumps.

This style of pump is advantageous when pumping high temperature liquids that

have a tendency to vaporise. As the pump is submerged in the liquid the risk of cavitation is greatly reduced.

These pumps are useful when pumping dangerous chemicals as they eliminate the chance of leakage. They are also used as an alternative to surface mounted self-priming pumps. Regent Sump Pumps are available in a variety of construction materials giving them the ability to handle aggressive liquids.

Stay Ahead of the Curve

Predict. Prevent. Perform. Stop unplanned downtime before it starts! The Chesterton Connect™ System empowers you with real-time predictive maintenance, optimising equipment performance and keeping your operations running smoothly.

Anytime, Anywhere Monitoring – Access critical pump health data straight from your smartphone, tablet, or computer with our cutting-edge IIoT technology.

Easy Setup. Instant Insights. Maximum Efficiency. Choose from preconfigured solutions tailored to your needs and take control of your equipment’s future today.

Get Started Now!

chesterton.com

chestertoncustomseal.com.au

A smarter alternative to traditional packing

Chesterton’s injectable technology and AMPS™ system are redefining reliability with faster installation, reduced maintenance, and longer service life.

Traditional braided rings have long been the industry standard.

However, they can be timeconsuming, di� cult to install, and unforgiving when equipment isn’t perfect. Injectable packing changes the game.

This soft, � bre-based material, enriched with lubricants and � llers, is injected directly into the stu� ng box with a manual or pneumatic gun. The result? A custom-� t seal that conforms precisely to the stu� ng box and shaft—no cutting rings, no dismantling, no downtime.

Where injectable packing excels:

• Equipment that’s worn or out of round

• Pumps with shaft misalignment or eccentricity

• Applications where � ush water must be eliminated

The Automatic Mechanical Packing System (AMPS) is designed for safe packaging.

• Uniform compression across the packing’s life

This injectable packaging solution is changing the game for seals.

• Sites where safety demands hands-o� installation and fewer adjustments

Because it � ows into place, injectable packing dramatically reduces installation time and enables fast, clean repacks— even in hard-to-reach locations. Once in service, it forms a dense, uniform sealing mass that minimises leakage and avoids the wear caused by misaligned or over-compressed rings.

Consistency made simple with AMPS

Even the best packing needs the right gland load. Over time, wear and thermal cycling can cause materials to settle, resulting in leakage and requiring frequent manual adjustments. Enter Chesterton AMPS™ (Automatic Mechanical Packing System).

AMPS uses pneumatic actuators to maintain a constant load on the gland follower. This ensures:

• Automatic adjustment for material relaxation and wear

• Reduced risk of over-compression, protecting sleeves and extending packing longevity

With AMPS, operators gain reliability without the constant need for intervention—helping plants run leaner, safer, and longer.

Rede� ning Reliability in Modern Operations

For today’s reliability engineers and plant managers, the mandate is clear: reduce water consumption, improve safety, comply with tightening standards, and keep equipment online. Chesterton’s injectable packing and AMPS system are proven tools to deliver on all fronts.

• Less downtime through simpli� ed installation

• Lower maintenance burden with automatic adjustments

• Extended equipment life in even the toughest conditions

For more information, visit chesterton.com

Images: Chesterton

Every pump engineer has faced the same dilemma: when a unit needs repair, is it worth saving money with non-original components? On the surface, the cheaper path is tempting. Tight budgets and the urgency of keeping systems running can prompt decision-makers to seek substitutes. Yet this decision carries hidden risks.

Original Equipment Manufacturer (OEM) parts are not simply branded alternatives; they represent the original design intent, tested tolerances, and material choices that underpin pump reliability and performance.

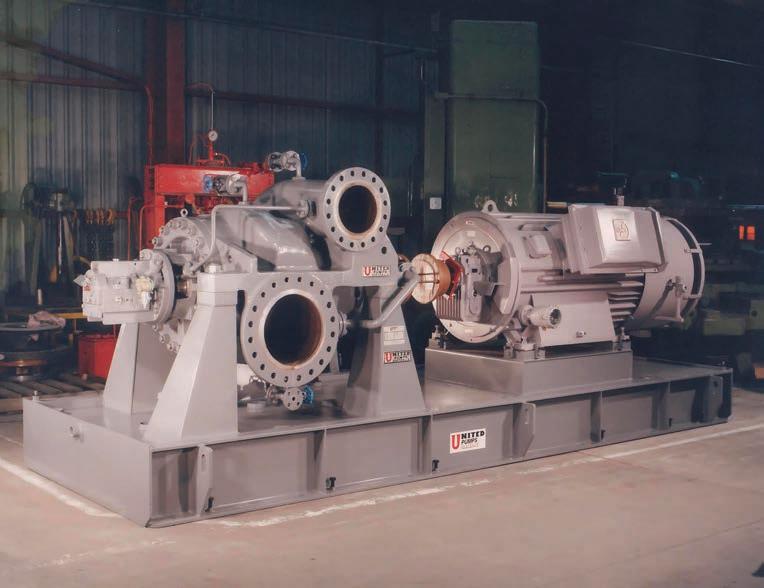

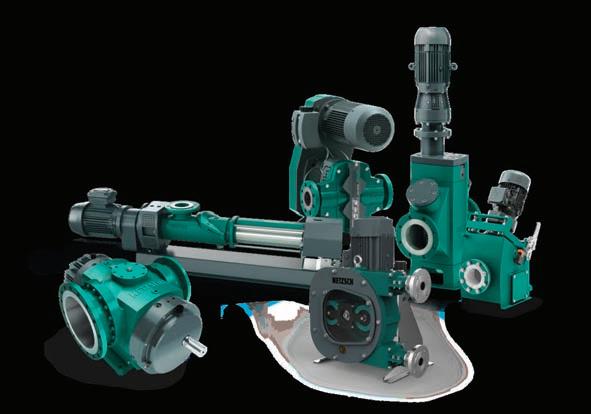

For over three decades, United Pumps has supported the Australian industry with parts and expertise derived from its rich engineering heritage.

Proven reliability in the � eld OEM parts are manufactured with knowledge accumulated across design iterations, operational data, and testing cycles. These parts are the result of engineering decisions that de� ne performance. For critical industries such as petrochemical and power generation, many original components were supplied with full certi� cation, inspection, and traceability. Those standards remain just as vital during maintenance as they were at commissioning.

This level of pedigree cannot be matched by copied or non-original parts, which often lack accountability, certi� cation, and the detailed understanding that comes with designing the pump in the � rst place.

United Pumps engineers, having designed, built, and maintained pumps for decades, bring this knowledge into every spare part they supply. That expertise is what ensures continuity of performance across generations of equipment.

Performance, e� ciency, and safety

The di� erence between OEM and copied parts is most visible in complex components such as impellers. An OEM impeller is drawn from a library of intellectual property and re� ned through hydraulic testing before release. A replacement impeller is made from the original mould, delivering near-identical performance. A copied impeller often relies on scans or reverse engineering, with no way to con� rm accuracy until it is in service.

This lack of precision can reduce e� ciency, shorten the pump’s service life, and increase safety concerns. Once non-original parts are introduced, OEMs cannot fully support the customer because the presence of unveri� ed components creates too many unknowns. The outcome is often higher running costs and reduced performance, undermining any initial savings. With United Pumps, operators retain access to the original technical knowledge and testing methods that remove these uncertainties and maintain con� dence in performance.

Long-term cost considerations

While non-original components may o� er a short-term saving, they frequently shorten maintenance cycles, increase running costs, and diminish e� ciency. United Pumps has centrifugal units in the � eld that have operated for more than 30 years without

overhaul when maintained with genuine parts. The assurance of long-term reliability outweighs the upfront cost of OEM spares.

That reliability is tied not only to the parts themselves but also to the expertise of United Pumps. The company has decades of experience in engineering, manufacturing, and supporting centrifugal pumps across industries, including petrochemical, power generation, and water infrastructure.

Its engineers maintain the original drawings, patterns, and test data for legacy brands, including United Centrifugal Pumps, Sterling, Harland, Johnston, Indeng, Aturia, Finder, and Marelli. This heritage knowledge ensures that every spare part is produced to the exact speci�cation of the original design.

United Pumps also invests in modern testing facilities and technical programs, allowing it to support customers with both current-generation equipment and pumps that have been in the � eld for decades. That continuity of design, service, and support means operators gain not only a replacement part but also the assurance that comes from working with the original manufacturer. In industries where downtime is costly and reliability is non-negotiable, this skill set is what makes OEM partners indispensable.

For more information, visit unitedpumps.com.au

These parts guarantee reliability.

Power Pumps with Confidence.

Precise and protective pump power

Flexible engineered solutions meet end-user productivity, ensuring reliable performance in hazardous and safe environments.

In today’s manufacturing and processing environments, it is vital that electro-mechanical equipment used in OEM machines, such as pumps, are not only designed to high standards, but are also compliant where hazardous environments are present, such as Oil & Gas, Chemical Plants. They must also operate reliably in heavy-duty sectors such as Marine and Mining where IP ratings and mechanical sealing is vital. Hazardous environments are created where dust is generated, gases may escape, or solvents could evaporate, and where serious issues or harm could occur if the correct mechanical/ electrical products are not selected.

Mining and marine applications also require careful consideration to ensure that the product selected can withstand heavy-duty operational loads, as well as harsh environmental conditions common in Industrial applications, such as pumping.

Considering the above, it is vital to align with a supplier who understands these risks and has a product range that suits both hazardous and heavyduty applications.

WEG is a well-known global manufacturer of electromechanical equipment, now o� ering the range of WG20 helical gearboxes to complement its industry-leading range of industrial (safe area) and hazardous area electric motors.

From this expanded portfolio of rotating machines, WEG can provide both standard and hazardous area geared motor packages designed for speci� c industrial pumping applications where operational performance and safety are top priorities.

The WG20 gearbox range consists of inline (C), parallel shaft (F), helical bevel (K), and helical worm (S), with the C series being the most common reducer used in pumping applications. With

its male shaft, foot/� ange mounting options, and industry-standard mounting dimensions, the C series can be easily integrated into most common pump con� gurations – both new and existing.

With a modern design focusing on e� ciency and reliable operation, the WG20 range is available in both hygienic smooth die cast housing up to 600Nm, and a robust MONOBLOC cast iron housing for the 800Nm to 18,000Nm range, each member of the WG20 family can be con� gured as an integral geared motor, an IEC geared motor, or a standalone gear unit with an IEC dry face input.

With the needs of the end user in mind, WEG Australia has con� gured its local gearbox stock to cater for the use of IEC motors and the reduced downtime bene� ts that this provides. Not only does the IEC input provide the opportunity for WEG to utilise its own extensive range of B5 motors, but it also allows the end-user to access a motor from the wider market when an urgent replacement is needed and maintaining productivity is paramount.

WEG’s range of IEC motors include the venerable W21 in both aluminium and cast iron frames, the W22 Industrial with its cast iron construction and IP66 enclosure, W21 and W22 Hazardous area options for both Flameproof (ExdB) and Increased Safety (ExeC, Extc, Extb, Exeb), and the often copied W22 Mining that continues to set the standard for heavy-duty industrial motors with Class H Insulation, IP66 rating and taconite sealing as standard on frame sizes 160 and above.

With a stock range of ten di� erent electric motor types catering for industrial, hazardous and heavy-duty applications, WEG is perfectly placed to o� er a complete geared motor package that not only conforms to relevant safety standards but also provides the end-user with operational peace of mind and product lifecycle � exibility.

Peter Vila never set out to become a pump salesman, or, for that matter, the managing director of SEEPEX Australia, which now also includes responsibilities as the Ingersoll Rand Precision Technologies Brand Leader for ANZ. His career began in the 1970s as a � tter and turner, with hands-on experience across the oil and gas sectors. It wasn’t until service clients started placing orders based on his technical advice, without the help of sales reps, that he realised where the real value lay: trust. That principle would guide his approach for decades to come.

By 1999, Vila had been approached to lead East Coast operations for the Australian distributor of SEEPEX progressive cavity pumps.

“They had the West Coast sewn up,” he said. “But to become the national distributor, they needed a footprint here.”

Vila built that from scratch, and when SEEPEX parted ways with the distributor in 2012, they invited him to launch their Australian subsidiary.

The new business started small, but Vila already had a vision: deliver locally assembled, custom-engineered progressive cavity pumps. That strategy proved pivotal. By 2017, the team had begun manufacturing in Tuggerah, and business accelerated. In 2019, they

moved into a 2000 square metre facility and outgrew it within three years.

In 2021, SEEPEX joined Ingersoll Rand, bringing Vila’s team into one of the world’s largest industrial portfolios. The acquisition opened new doors.

Strategic integration, new opportunities

For Vila, the Ingersoll Rand acquisition was less about change and more about scale.

“SEEPEX was still a family-owned company,” he said. “As the company grew, the owner sought integration into a group that could preserve the culture while supporting long-term success.”

Cultural compatibility was central to the deal, with SEEPEX retaining its leadership, processes, and innovation priorities.

“From the beginning, we explored opportunities with other Ingersoll Rand brands,” Vila said. “By stepping back and carefully assessing the landscape, we identi� ed where our combined o� ering brings the greatest value to our customers. This allows us to deliver the right solution at the right time.”

This approach better connects SEEPEX with relevant Ingersoll Rand businesses and channel partners. The outcome is a more deliberate integration process, driven by customer needs and

requirements.

“We’re identifying where SEEPEX progressive cavity pumps can � t together with other technologies within broader project scopes, whether that’s alternative pumps, macerators, mixers or other rotating equipment,” Vila said.

SEEPEX has long provided proven pumping solutions. Today, customers bene� t from an even wider choice. Guided by pump experts with deep, wide-ranging knowledge, they can select equipment perfectly suited to their applications. Whether handling abrasive slurries, hygienic food products, or high-pressure transfer duties, customers rely on a single trusted partner and the assurance of optimal performance and lifecycle value.

Building local from global parts SEEPEX operates three identical manufacturing plants in Germany, the

Images: SEEPEX, Ingersoll Rand

Peter Vila is the Managing Director of SEEPEX Australia.

SEEPEX food pumps hygienically dose shear-sensitive ingredients such as chocolate with exact precision.

United States and China. Each was commissioned with the same tools, quality systems and process � ows, ensuring that parts from any plant meet German standards. Australian orders draw from all three.

“Assembly happens here in Tuggerah,” Vila said. “We cover all of Australia, New Zealand and the Paci� c Islands. For regional sites, we work closely with trained distributors, often acting as the local service experts.”

The approach strikes a balance between global e�ciency and local agility.

“Some customers still assume we’re shipping � nished product from Europe,” Vila said. “That changed when we began local assembly. We’re now able to ship products much faster. ”

SEEPEX progressive cavity pumps are custom-built for every order.

“There’s no box in, box out,” he said. “We qualify each enquiry and build to the speci� cations of each client.”

That level of engineering detail provides clients with � exibility in industries where � ow precision, solids handling, and downtime management are critical.

Water and wastewater remain the company’s largest sector globally, but in Australia, mining is a close second.

“Oil and gas and food processing follow close behind,” Vila added. “We also serve general industry, but water and mining drive the bulk of our growth.”

Smart pumps for tough sites

Digital capability is a growing focus, supported by both SEEPEX and Ingersoll Rand. The team o�ers live pump monitoring for performance diagnostics and predictive maintenance. It is especially useful when trialling new installations or troubleshooting process failures.

“If a pump is failing in a way the customer doesn’t understand, we o� er a live-monitored unit to capture what’s happening,” Vila said. “Or if they’re hesitant to trial something new, we can install a monitored demo unit so everyone’s con� dent in what it’s doing.”

SEEPEX pump monitoring enables pumps to operate as intelligent devices. Sensors collect real-time data, which is analysed in the cloud to identify potential wear, blockages, or drops in performance before they become issues.

The system provides clear, actionable insights and access to operating data, allowing users to optimise pump performance and maintenance.

But SEEPEX’s digital approach extends beyond data. A standout feature of its progressive cavity pumps is the ability to make � ne-tuned adjustments in situ, while the pump is running.

“You can re-clamp the rotor and stator using just a spanner,” Vila said. “That renews performance without downtime, labour costs or parts replacement.”

He said that while conventional PCPs degrade as the stator wears, SEEPEX’s design allows the user to recalibrate the system multiple times.

“We guarantee at least double the life compared to our standard pumps, and that’s just our benchmark. Some clients get four or � ve times the service life.”

This e� ciency feeds directly into customers’ ESG goals.

“Less energy, less waste, fewer spare parts: it all contributes to lower environmental and operational costs,” Vila said.

What comes next

While the SEEPEX team continues to consolidate its leadership in progressive cavity pumps, macerators, and pump systems, the future lies in broader integration. The company has already begun working with select Ingersoll Rand brands.

For asset managers and procurement leads, that means one thing: more value, closer to home.

“There are global brands with great reputations, but long lead times. We’ve demonstrated that when assembling locally, there can be many bene� ts to this process compared to importing � nished products. Once the market sees what our internal team already knows and embraces, we will see rapidly accelerating momentum.”

For more information, visit seepex.com

SEEPEX BNM progressive cavity pump – large standard pump with Easy Maintenance solutions for quick, cost-e ective service and high availability.

WA Mining, formally the WA Mining Conference and Exhibition, is returning to Perth on 8–9 October 2025, transforming the Perth Convention and Exhibition Centre into an epicentre for the state’s mining industry.

This two-day event brings together mining companies, technology innovators, service providers, and government representatives for targeted networking, product showcases, and conference sessions.

With a carefully curated paid conference program alongside a dynamic exhibition � oor, WA Mining is where engineers, technical managers, and procurement teams come to explore industry advancements, sustainable practices, and future trends.

For Perth-based Dynapumps, the event presents an ideal platform to showcase how engineered pump solutions can enhance performance, reliability, and e� ciency in WA’s demanding conditions.

Billy Prinsloo, Business Development Manager - ERA 3 Solutions at Dynapumps, said the exhibition is about far more than products.

“We are using WA Mining to explain what we call ERA Three, which stands for Engineered solutions, Reliability, and Aftermarket support,” Prinsloo said.

“The expo gives us a chance to show end users how we are evolving into a solutions-based partner, not just a supplier of pumps.”

A showcase of engineered partnerships

Dynapumps has a long history in Australia’s mining sector, with pump systems deployed across iron ore, gold, nickel and lithium sites.

The company partners with international and domestic brands, such as Hydra-Cell, Grundfos, and Southern Cross, to tailor solutions to each mine’s speci� c needs rather than supply onesize-� ts-all systems.

“We look at the data sheets, engage with the site engineers, and provide a pump system that will last in those conditions,” Prinsloo said. “If the original design no longer � ts reality, we engineer a solution to extend mean time between failure and reduce costs.”

Local presence, faster solutions

Industry events like WA Mining play a vital role in bringing together suppliers and operators from across Western Australia into one central hub.

For local companies, showing up is an important signal of commitment to the state’s mining sector and an opportunity to connect directly with end users. With

long lead times for critical parts, often stretching 14 to 16 weeks, WA operators are increasingly looking for suppliers who can provide solutions quickly and reliably.

“Many clients now prefer to source locally wherever possible. We hold stock for particular customers we partner with, which cuts lead times and ensures continuity of supply,” Prinsloo said.

For companies like Dynapumps, being visible at WA Mining means demonstrating not only technical expertise but also readiness to support the state’s industry in real time.

The event attracts talent, ideas and decision-makers from across WA, making it a place where local presence, long-term partnerships and responsive solutions can come together.

Sustainability in focus

Sustainability is a recurring theme at WA Mining, re� ecting the pressure on miners to lower emissions, conserve water and deploy more e� cient technologies.

Dynapumps’ approach to energy e� ciency and total cost of ownership ties directly into this conversation, with onsite audits, � re system upgrades and predictive maintenance programs all designed to improve performance while reducing lifecycle costs.

The containerised versions of the pumps ensure easy transport and a small base of operations.

Prinsloo said many clients now see long-term value as more important than lowest upfront price.

“We do not see it as just selling a pump. We look at the total cost of ownership. A slightly higher upfront investment often saves money through reduced maintenance, lower downtime and better energy e� ciency,” he said.

This is particularly relevant to WA Mining because the event attracts operators and engineers from across the state who are under constant pressure to manage costs, improve e� ciency and plan for the long term.

By demonstrating how engineered solutions reduce downtime and energy use, Dynapumps can show visiting decision-makers how sustainability and reliability go hand in hand.

Supporting this approach is Dynapumps’ integrated capability at its Perth head o� ce, where in-house fabrication, electrical design and testing facilities allow the company to deliver complete pump packages. Systems are fabricated, engineered and tested at up to 350 kilowatts before dispatch,

providing upfront assurance that reduces installation risk and rework, particularly at remote WA sites.

For attendees of WA Mining, this local capability illustrates how WA-based suppliers can provide end-to-end solutions that keep projects on track and resilient against the challenges of distance and supply chains.

Dynapumps’ debut and future focus WA Mining has quickly become a cornerstone of the state’s mining calendar, attracting thousands of attendees and providing access to leading technology, industry insights, and strategic networking opportunities.

While Dynapumps has previously exhibited at mining events in Queensland and oil and gas shows in WA, this marks its � rst participation at WA Mining. Prinsloo said this decision re� ects a commitment to deeper engagement with Western Australia’s mining sector.

“Our main purpose is to show WA miners that we are here, that we are a solutions partner, and that we are

Tailings management is a major concern for mining companies.

aligned with some of the world’s best pump brands,” he said. “This event gives us a platform to meet more end users and demonstrate the value of working with us.”

The stand will also highlight the company’s quality and safety credentials, including ISO certi� cations in quality management, environment and occupational health and safety, as well as its adoption of Toyota’s TSSC continuous improvement program. By showcasing these strengths alongside its engineering partnerships, Dynapumps aims to reinforce its position as a long-term partner for WA Mining.

For the wider industry, the expo is the ideal venue to explore how suppliers and technology providers are adapting to the evolving challenges of mining.

For Prinsloo, it represents the opportunity to demonstrate how an engineering-led, solutions-driven approach to pump systems can deliver measurable improvements in uptime, reliability, e� ciency, and sustainability.

“Every mine has its own problems, and our role is to engineer the right solution for those speci� c conditions,” Prinsloo said. “The expo is the perfect place to show how we can deliver that.”

Get tickets at waminingexpo.com.au/ attend

The vast state of Western Australia can be harsh for mining equipment.

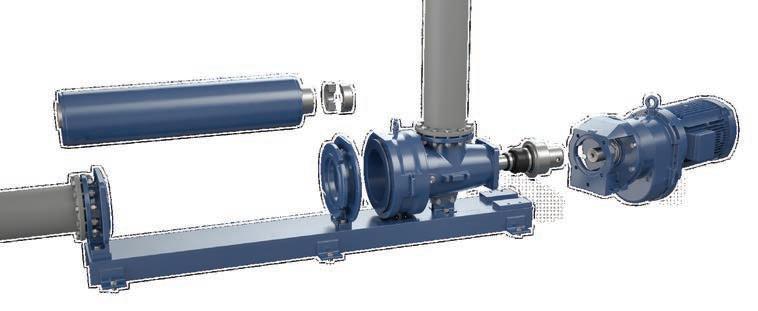

Supporting mining with ROTO

Progressive cavity technology is helping meet e ciency and reliability demands in Australian mining.

The mining industry in Australia demands pumping solutions that can withstand abrasive � uids, extreme pressures, and continuous operation. Among the technologies that have proven reliable in these conditions are progressive cavity (PC) pumps. For ROTO Pumps, this area has become a key focus, with the company building a strong reputation for supporting mining clients worldwide.

ROTO Pumps has long recognised that Australian mining operations require more than just robust equipment. The company has invested in developing tailored solutions that prioritise ease of maintenance, energy e� ciency, and overall lifecycle cost reduction. By providing pumps that can handle slurry, tailings, and other challenging applications, ROTO has positioned itself as a partner to the mining sector rather than just an equipment supplier.

“Our pumps are known for their performance in critical and demanding applications,” a ROTO Pumps spokesperson said. “We focus on designing systems that minimise downtime and provide reliability under the harshest conditions.”

Designed for demanding environments

PC pumps are particularly well-suited for applications where consistent � ow and minimal pulsation are crucial. ROTO’s designs incorporate features such as wear-resistant materials, modular components, and high-pressure capability. These qualities enable them to deliver performance even when handling abrasive or chemically aggressive � uids.

The company’s global experience enables it to translate lessons learned from large-scale mining projects overseas into value for Australian clients. At the same time, ROTO is committed to ensuring that local operators bene� t from access to technical expertise and support services within Australia.

A track record in mining

ROTO Pumps has highlighted its success in servicing some of the world’s largest mining and explosives sites. These projects demonstrate not only the versatility of PC technology but also the company’s ability to adapt systems to site-speci� c requirements.

“Every mine site has unique conditions and expectations,” a ROTO Pumps representative explained. “Our engineering teams collaborate closely with operators to deliver solutions that meet performance targets while reducing overall operating cost.”

This approach has earned ROTO recognition within the industry, particularly for its focus on customised and technically advanced helical rotor pumps. Mining clients have commended the company for its willingness to adapt designs to unique requirements, ensuring that each installation aligns with site-speci� c operational goals.

Local implications for Australia

In Australia, where reliability and safety are paramount, the ability to deploy proven technology that can operate with minimal downtime o� ers clear bene� ts. By reducing unplanned maintenance and extending the life of pumping assets, operators can improve production e� ciency while meeting sustainability targets.

ROTO Pumps’ Australian footprint ensures that technical assistance, spare parts, and service expertise are available locally. This reduces delays in responding to operational challenges and gives mining operators con� dence that their critical pumping systems are supported.

The company’s ability to combine global expertise with local service means it is well-positioned to support the future of Australia’s mining sector. As demand for e� cient, sustainable, and resilient pumping grows, ROTO’s PC technology will continue to play a central role.

For more information, visit rotopumps.com.au

Images: ROTO Pumps

PC pumps are designed for the most challenging and harsh environments.

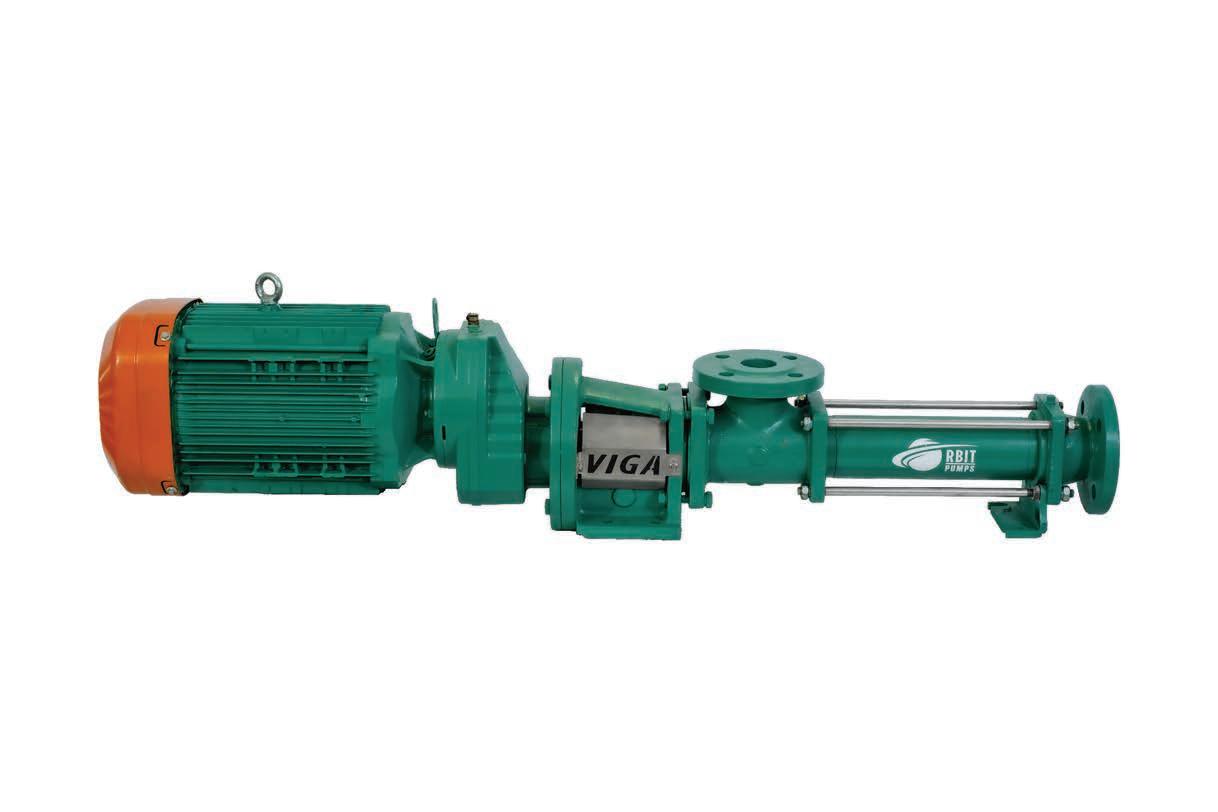

Performance where it counts

Progressive cavity pumps are evolving rapidly, but reliability and maintainability remain the metrics that ma er most on-site.

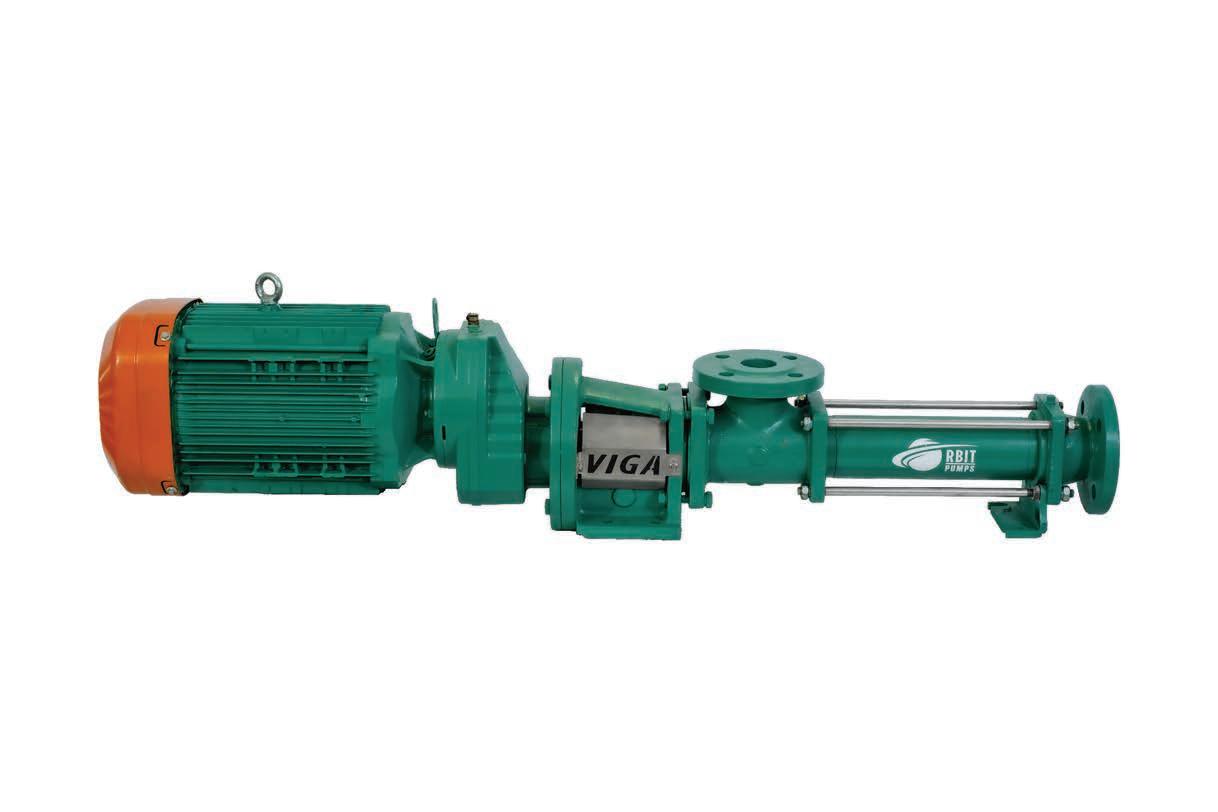

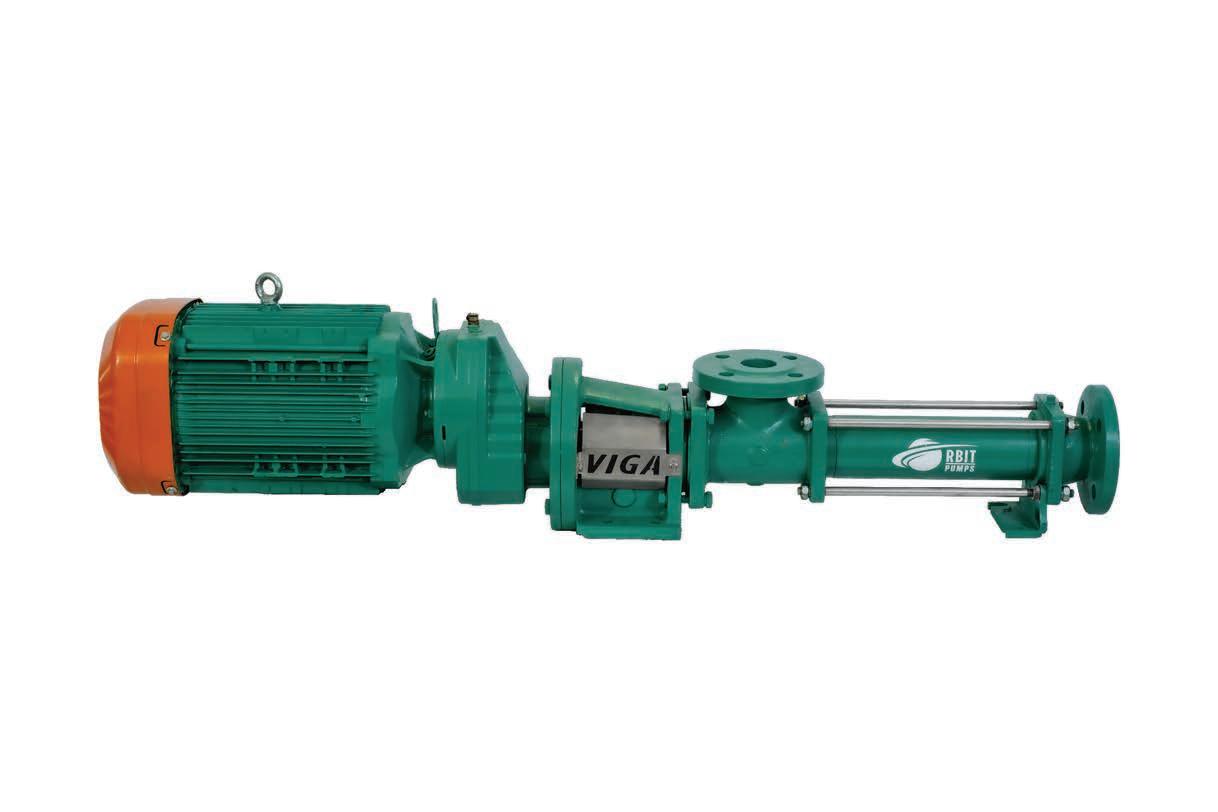

In Australia’s heavy industries, pump system failure is more than an inconvenience. It’s a risk to uptime, safety, and cost control. For engineers working in remote or space-constrained environments, selecting the right system means weighing performance against energy demand, footprint, and serviceability. That’s where the new Orbit VIGA range, now supported nationally by Southern Pumping, is gaining traction.

Southern Pumping’s role goes beyond distribution. The team is integrating these systems across high-demand sites, where operational reliability is just as important as technical performance. Their focus is clear: to make the VIGA pump system’s e� ciency work in the real world.

Engineering e� ciency without compromise

Designed by Franklin Electric’s Orbit Pumps, the VIGA series brings a new approach to progressive cavity pump performance. The extended pitch rotor increases � ow per revolution by up to 60 per cent. At the same time, lower starting torque allows smaller motors and reduced power draw, making it ideal for sites with limited electrical capacity.

Key features include sealed universal couplings for leak prevention, preassembled rotating assemblies for rapid changeouts, and a compact footprint suitable for skid systems and tight plant rooms. These are not just spec-sheet improvements. They’re engineered responses to typical constraints faced by maintenance and design teams.

“VIGA is compact, tough, and designed for real-world conditions,” Southern Pumping Managing Director Michael Wallace said. “Its low power requirement and quick-swap rotating assemblies mean it’s not just easier to run, it’s easier to keep running.”

With applications in mining, wastewater, and industrial processing, the pump is already proving its worth on sites that demand uptime and easy maintenance.

Matching performance to site conditions

Southern Pumping doesn’t just ship pumps: they specify and support them in the � eld. Every installation begins with a site-level assessment that considers � uid properties, power availability, and spatial constraints. That feeds directly into system selection, commissioning, and lifecycle planning.

“We’re not just supplying pumps,” Wallace said. “We’re integrating them into live environments, commissioning them in real time, and staying connected to those systems across their lifecycle.”

That long-term view shapes the company’s � eld service model. With Orbit components kept in stock and teams distributed across Australia, Southern Pumping can deliver fast diagnostics and replacements where national wholesalers often fall short.

Wallace noted that VIGA’s compact design has helped mining clients avoid costly infrastructure upgrades.

“We’ve seen customers avoid full panel

upgrades or switchboard changes simply by using VIGA’s lower kW rating,” he said.

Rethinking service as infrastructure

Rising power costs and reduced tolerance for downtime are changing how pump systems are evaluated. For Wallace, the measure of success isn’t innovation alone: it’s performance under pressure, over time.

Southern Pumping continues to invest in people, stock, and processes that support not just the pump but the whole pumping outcome.

“We don’t walk away once a pump is installed. We stay engaged, we stock what’s needed, and we understand the operating environment. That’s what turns a good pump into a great system, and that’s what keeps our clients running when it matters most.”

For more information, visit southernpumping.com.au

Orbit pumps are known to be sturdy and produce more output with less power.

The all new Orbit Viga

Powering e�ciency at Yarra Yarra

Yarra Yarra Golf Club was able to reduce its energy costs thanks to Franklin Electric’s High E ciency System motor package.

As one of Melbourne’s prestigious sandbelt courses, Yarra Yarra Golf Club is known for

from Bore Down Drilling to further enhance the system’s performance. The recommendation was to upgrade to the

projections, potential ROI modelling and a full quotation outlining installation timeframes and expected outcomes.

But the bene� ts didn’t stop there. The club also invested in remote access and bore level monitoring tools. These upgrades provided the grounds team with unprecedented oversight of their water infrastructure, enabling better scheduling, system alerts, and longterm planning.

These capabilities support more than just e� ciency; they improve reliability. By identifying issues early and responding to conditions in real time, the club can avoid unexpected outages or overuse.

Scaling success across the course

Encouraged by the performance of the � rst installation, Yarra Yarra Golf Club expanded the project. Two additional bores were upgraded with the HES package, each contributing to a broader strategy of energy and water optimisation.

Together, these upgrades now deliver approximately $17,000 in annual energy savings. That � gure is particularly signi� cant in the context of sport and recreation budgets, where capital improvement funding is often competitive and closely scrutinised.

For Yarra Yarra, those savings represent a reinvestment opportunity, whether in maintenance, turf care, or broader sustainability initiatives.

Collaboration from ground to green

The project’s success hinged on strong collaboration across stakeholders. Bore Down Drilling brought site knowledge, drilling expertise and long-term client relationships. Franklin Electric contributed the high-performance technology and technical support. Yarra Yarra Golf Club’s board and ground sta� provided strategic input and on-theground feedback.

This kind of partnership model is increasingly vital in infrastructureheavy sectors, such as golf, agriculture, and municipal water. As energy markets shift and expectations around sustainability grow, pump systems are no longer viewed in isolation. They’re part of a broader operational ecosystem.

A model for e� cient irrigation Golf courses across Australia face similar pressures, including ageing infrastructure, climate variability, and tightening energy budgets. The Yarra Yarra case study showcases what’s possible when site-speci� c knowledge and energy-saving technology are combined.

The High E� ciency System motor didn’t just meet performance targets. It exceeded expectations, provided data visibility and paid itself o� faster than traditional systems. Importantly, it also supported Yarra Yarra Golf Club’s commitment to maintaining world-class playing conditions while advancing its operational sustainability.