GLOBAL PLAYER STATS GROUP IS RAPIDLY EXPANDING ACROSS AUSTRALIA AND NEW ZEALAND

With innovation, safety and performance at our core, we’re proud to celebrate 10 years of partnerships and projects - and we’re just getting started

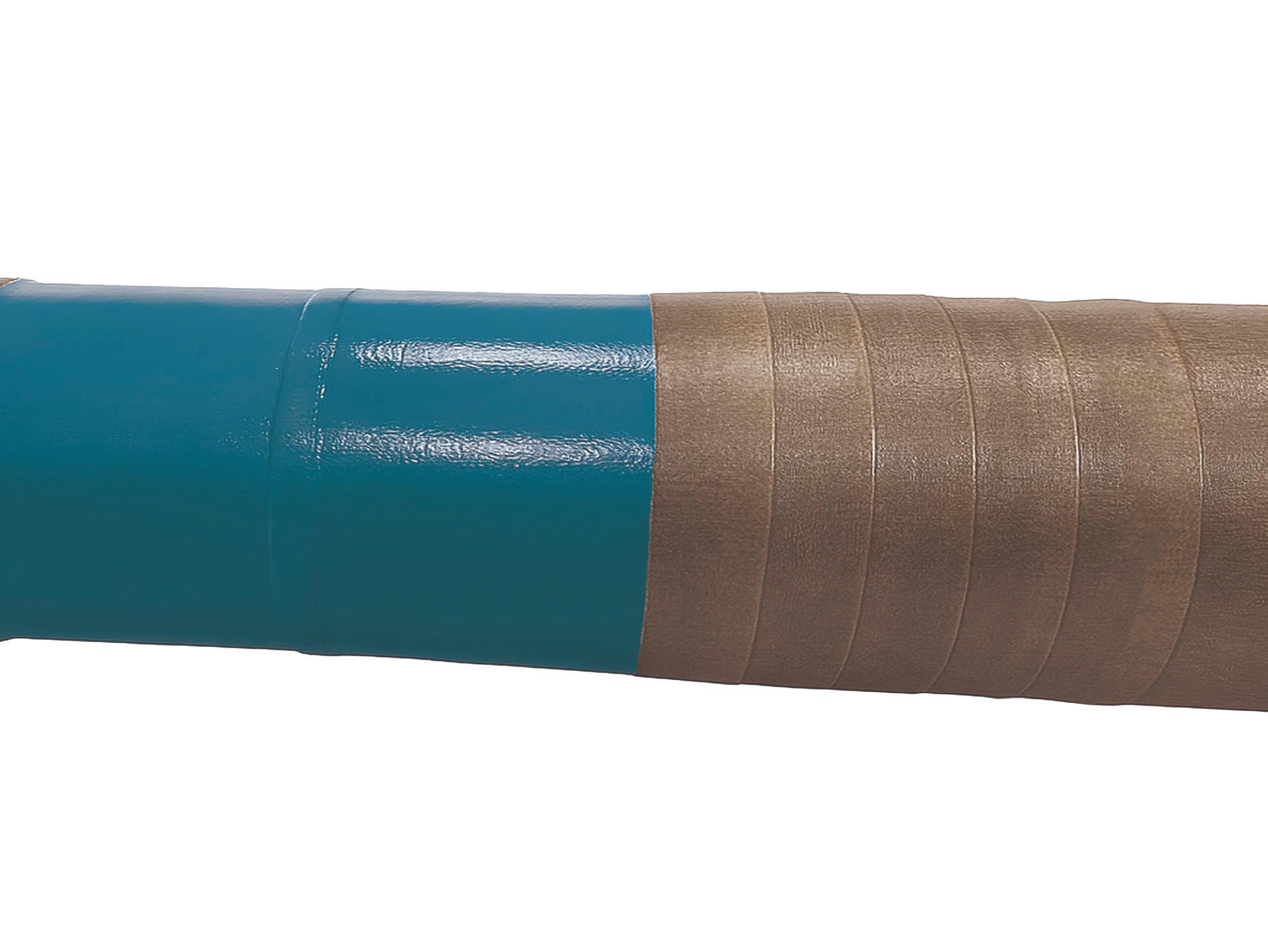

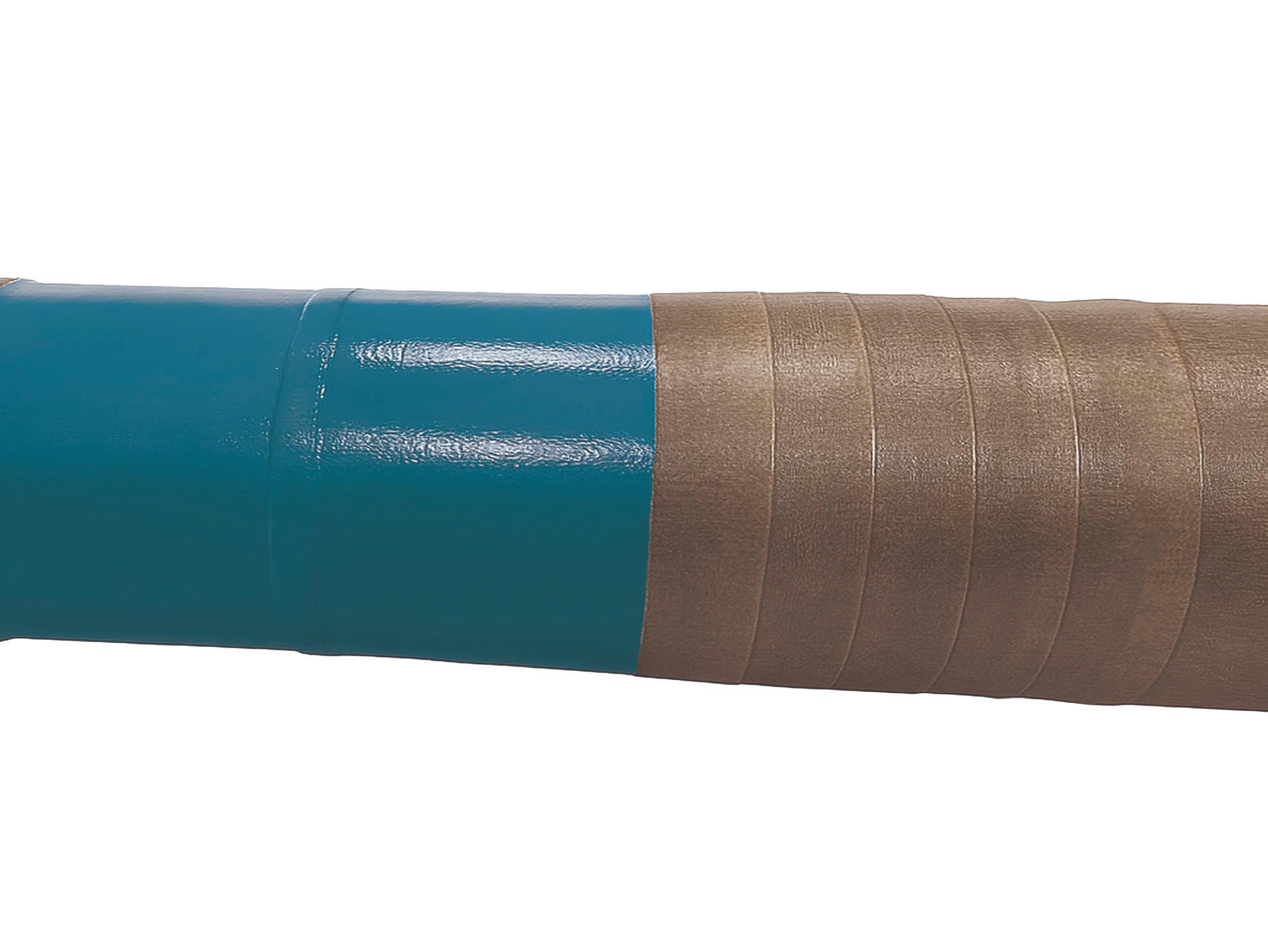

Protal 7700™ - Fully compliant with AS4822:2024 and CSA Z245.20 standards.

www.densoaustralia.com.au

Denso Bore-wrap™ - The most exhaustively tested ARO in Australia boasting the highest gouge resistance.

Visit Tesmec Australia at APGA event from 18 to 21 October 2025 in Brisbane. Ensuring depths up to 732 cm (24’) and widths up to 213 cm (7’), our trenchers improve safety, cut fuel consumption and emissions, and simplify site logistics, ultimately reducing costs and boosting productivity even in the hardest conditions. Contact us to optimise your next pipeline project.

Contact us: 1800 838 632 info.australia@tesmec.com

Chairman

John Murphy

CEO

Christine Clancy christine.clancy@primecreative.com.au

Managing Editor Eugene Duffy eugene.duffy@primecreative.com.au

Editor

Timothy Bond tim.bond@primecreative.com.au

Journalist Gerald Lynch gerald.lynch@primecreative.com.au

Business Development Manager Jake Niehus jacob.niehus@primecreative.com.au

Head of Design Blake Storey blake.storey@primecreative.com.au

Designer Apostolos Topatsis

Front Cover Image STATS Group

Copyright

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2021

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Printed by: The Precision Group

83-89 Freight Drive, Somerton VIC 3062

Ph: (03) 9490 1500

Maximise brand awareness by connecting with thousands of

The Australian Pipeliner brand comprises: six editions a year, a news website, a weekly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

16,500+ e-newsletter subscribers

20,000+ website views each month

13,700+ magazine subscribers

3,300+ social media followers

Contact our business development team to discuss how you can grow your business with The Australian Pipeliner. Call 0466 929 675 or email jacob.niehus@primecreative.com.au

Head Office

379 Docklands Drive, Docklands VIC 3008 Ph: (03) 9690 8766

Sydney Office Suite 11.01, Level 11, 201 Miller St, North Sydney NSW 2060

enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry.

The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Whether you’re testing open end pipe, systems terminating in long radius elbows, flange welds or isolating lines you can count on the GripTight Family of Test & Isolation Plugs from Curtiss-Wright to perform above expectations, test after test.

Installed countless times in a wide range of applications, their patented designs combined with hardened components and singlebody, uninterrupted seals make for field performance that’s second to none. When safety and reliability matter, make it GripTight!

• ID and OD solutions available

• Patented gripper designs for increased safety in high-pressure applications

• Eliminates welding end caps when testing pipe spools and piping systems

• Test flange-to-pipe welds without pressurizing entire systems

• Isolate & monitor upstream pressure and vapors during hot work

• Standard pressure ratings up to 15,000 PsiG (1034 BarG)

• ASME PCC-2 Type I, III & IV Testing Devices available

I am pleased to welcome you to the 2025 Convention and Exhibition edition of The Australian Pipeliner.

This year, I’m delighted to welcome many of you to the vibrant city of Brisbane – a hub of innovation, industry, and culture. Over the coming days, I encourage you to make the most of the engaging business sessions, network with peers, and take the opportunity to experience all that this dynamic city has to offer.

We have prepared an enriching and forward-looking program for this year’s Convention. Members of our industry will be sharing invaluable insights into emerging trends, evolving best practices, and future opportunities across the pipeline and gas sectors. Collaboration, creativity, and a shared pursuit of excellence continue to define our industry, and this event reflects that spirit.

Our Keynote Speaker, the legendary Wayne Bennett, brings a unique perspective on leadership, resilience, and high performance. His career in rugby league has inspired generations and offers powerful parallels to the challenges and opportunities we face as an industry. We are honoured to have him with us this year.

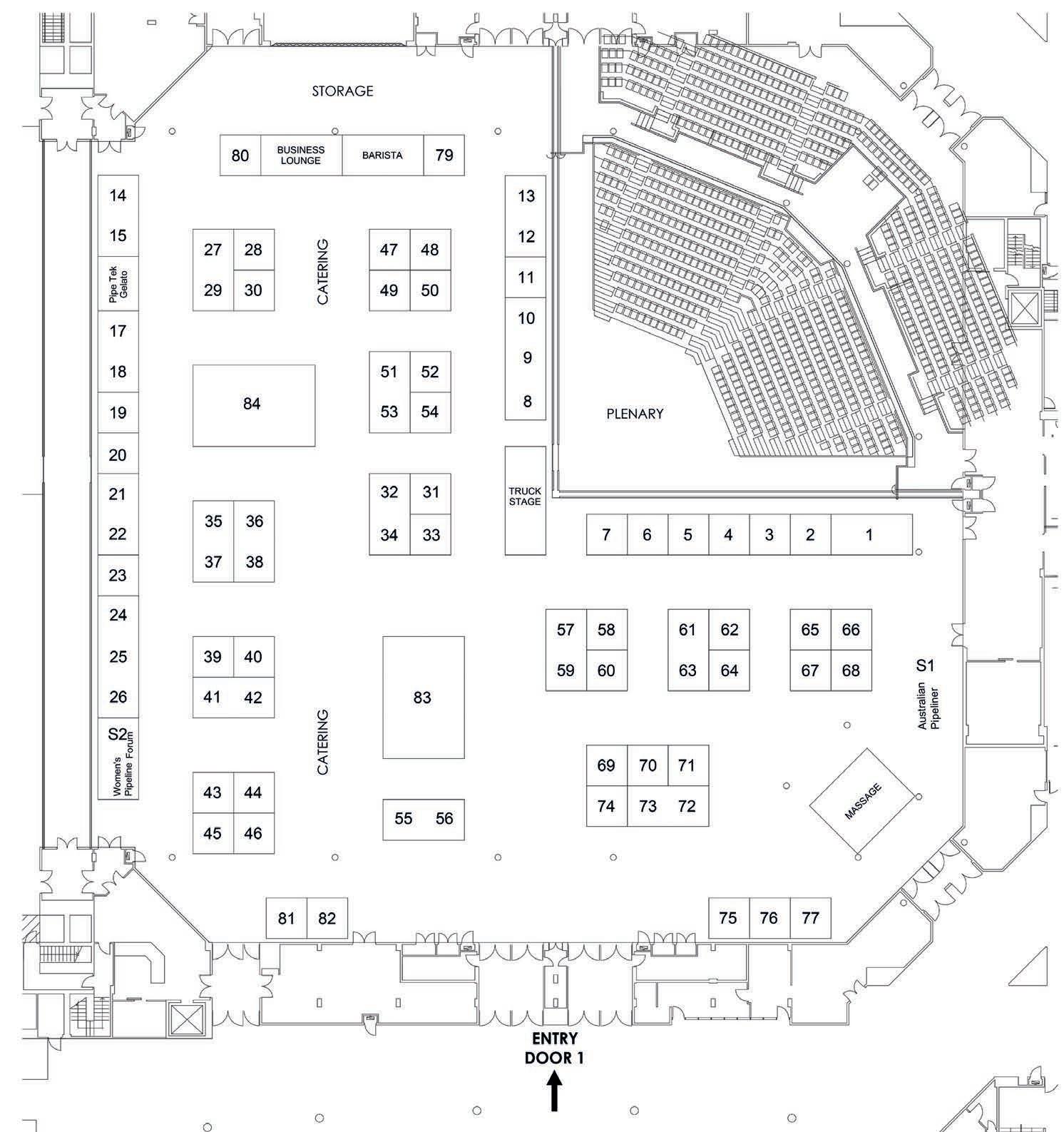

The fully subscribed Exhibition Hall is a testament to our collective efforts – providing a vital platform to share innovations, form partnerships, and build on our progress as a community.

This edition highlights many of our valued exhibitors, focusing on technologies and services from all across the pipeline industry. Beyond gas, many of our members are heavily involved in major water infrastructure projects, especially here in Queensland, which continue to grow in scale and importance and is another key area in this edition. Large-scale water pipelines including the 117km Fitzroy to Gladstone Pipeline, Stage 2 of the Haughton Pipeline Project and the Mount Morgan-Gracemere Pipeline have demonstrated the adaptability of our industry and the critical importance of infrastructure to Australia’s future.

I would like to thank the APGA Secretariat for their

APGA Secretariat

Registered Office:

2nd Floor, NFF House, 14-16 Brisbane Avenue, Barton, ACT 2600

(PO Box 5416, Kingston ACT 2604)

T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

ABN: 29 098 754 324

hard work in preparing this year’s Convention and Exhibition, and express sincere gratitude to our exhibitors, speakers, and presenters for their commitment, insight, and contributions. Congratulations also to this year’s award winners, recognised for their outstanding service and innovation. And finally, thank you to our members – your support, passion, and dedication are what drive the Association forward.

As APGA’s mission states: we exist to foster innovation and collaboration, deliver valued services, and represent our members’ collective interests. I trust your experience here in Brisbane delivers on that promise.

As this is my final message as President, I want to extend my sincere thanks to all of you. It has been a privilege to serve in this role. I leave immensely proud of what we have achieved together and confident in the strength, resilience, and innovation that will continue to shape our industry’s future.

Stay safe, and I look forward to seeing you here in Brisbane.

JOHN STUART-ROBERTSON APGA PRESIDENT

Chief Executive Officer

Steve Davies

Head of Corporate Services

Dhammith Abeysuriya

Head of Corporate Affairs

Paul Purcell

Head of Operations & Communications

Lawrence Shelton

Head of Engagement

Gayle Bower

Accounts & Membership Officer

Katy Spence

National Policy Manager

Catriona Rafael

Senior Policy Manager

Stephen Campbell

Technical Advisor

Craig Bonar

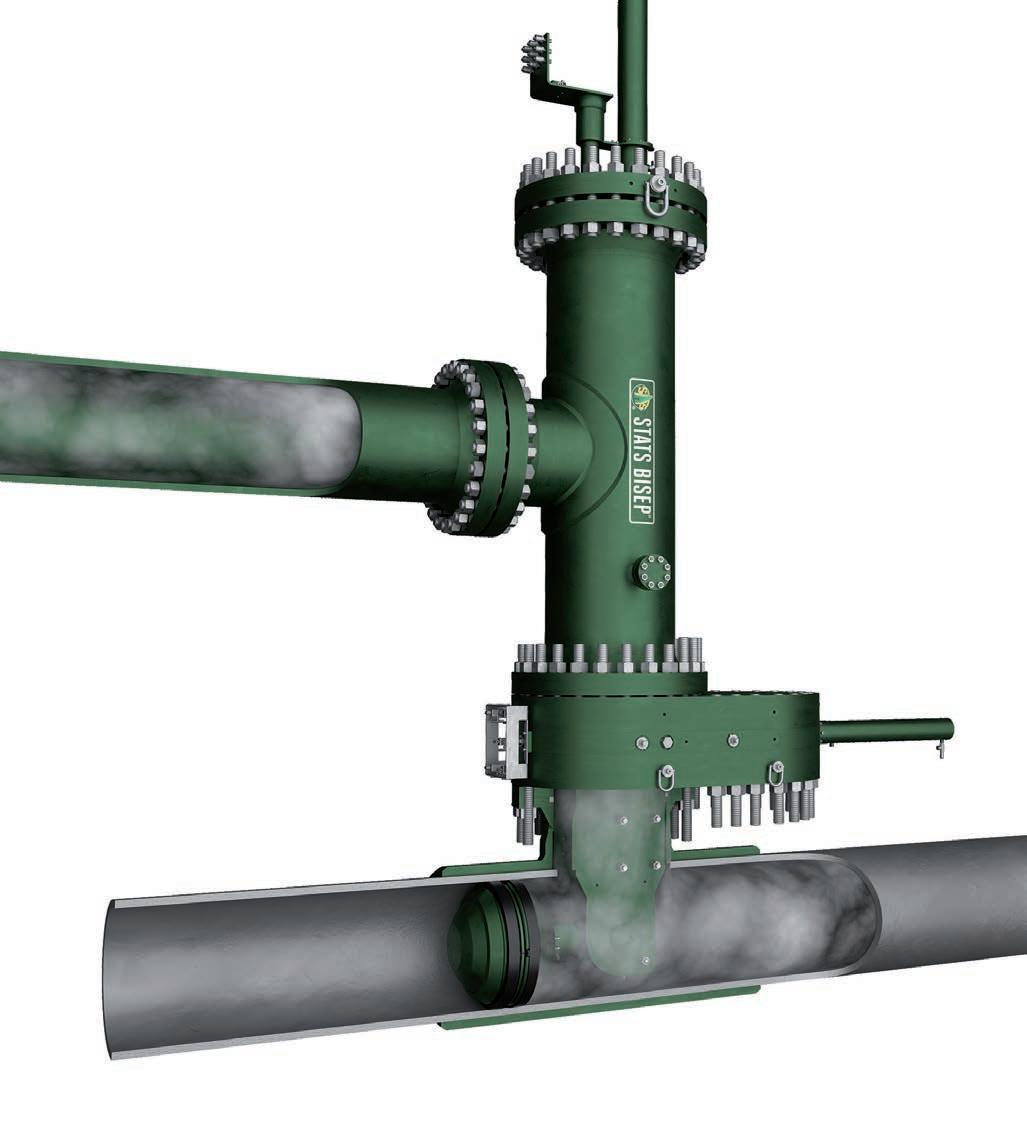

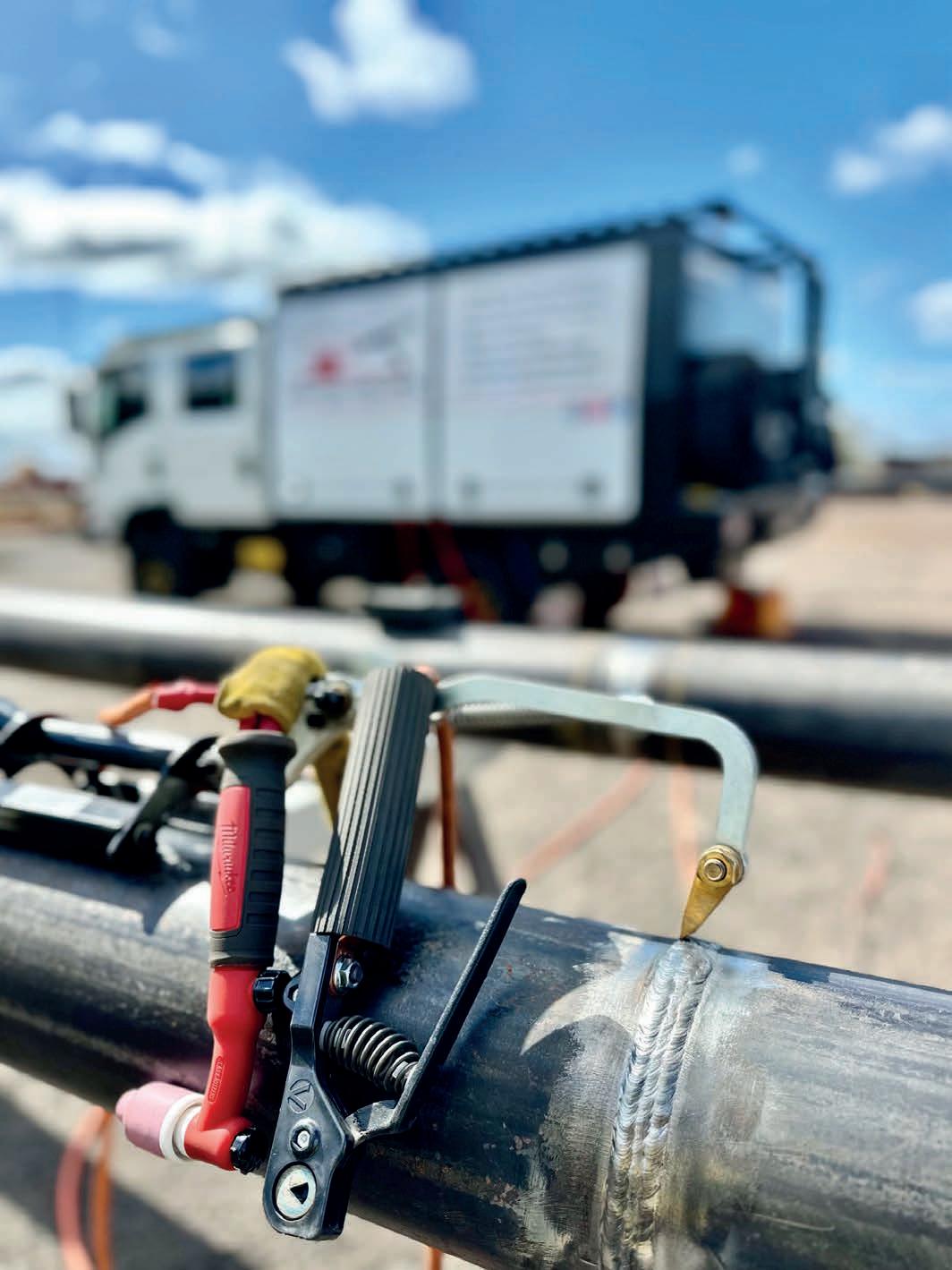

STATS Group expects revenues in the Asia Pacific region to more than double in the current year with demand from major oil and gas operators seeking high integrity inline isolation, hot tapping and line stopping technology.

In addition to growth in Australia, the company is also investing in assets and increasing local personnel numbers to support an uptick in opportunities in New Zealand, Malaysia, Indonesia, Vietnam and China.

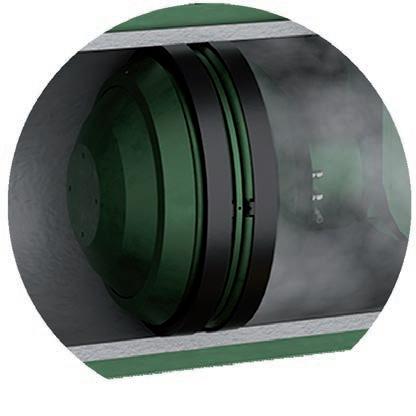

STATS patented double block and bleed isolation tools offer a comprehensive and efficient solution for the repair and maintenance of critical hydrocarbon pipelines.

The ability to perform operations without shutting down the pipeline, providing dual leak-tight seals for enhanced safety and realtime seal monitoring capabilities, position these technologies as valuable assets in the industry.

STATS Group’s patented branch installed self-energised plug (BISEP®) technology represents a significant advancement in line stopping. Developed over two decades ago to address specific client challenges, the BISEP provides a true double block and bleed isolation through a single full-bore hot tap.

Its hydraulically actuated dual elastomer seals surpass the limitations of conventional lip seal technologies, delivering a proven, leaktight, and fail-safe isolation, verified through a multi-stage testing process once deployed into the pipeline.

STATS BISEP is fully certified by DNV to verify that the design criteria satisfies the requirements for pipeline isolation plugs to provide dual seal and isolation in accordance

with offshore standards, DNV-OS-F101 (submarine pipeline systems) and recommended practices, DNV-RP-F113 (subsea pipeline repair), and in compliance with code ASME BPVC Section VIII, Division 2.

Earlier this year, STATS Group was engaged by a leading gas network operator in Western Australia to support the decommissioning

and removal of key infrastructure from the historic East Perth Power Station site, helping pave the way for future redevelopment.

STATS safely and successfully executed multiple hot taps and BISEP line stop isolations on four-inch, six-inch, and ten-inch pipelines using STATS-supplied standard split tees and spherical tees, including operations that maintained live gas flow via integrated temporary and separate permanent bypass arrangements.

The project was delivered within a suburban residential area, requiring careful planning and execution to minimise disruption and ensure the highest safety standards throughout.

“We supplied all fittings and services, with our local team completing full function testing prior to mobilisation from our operational facility in Perth,” STATS Business Development Manager Sam McKinnon said.

“We are very proud of the STATS site team and all project partners for the safe and collaborative delivery of this complex scope”.

A leading natural gas transmission and distribution company in New Zealand recently purchased two eight-inch #600 BISEP line stop tools along with a range of STATS dual seal slab valves, split tee fittings, and other specialist ancillary equipment.

STATS Group APAC Regional Manager Gareth Campbell said reaching this milestone and seeing STATS equipment located in the facility was a proud moment.

stop equipment means repairs can be completed without disrupting production, with fewer onsite operations and enhanced safety,” he said.

Zealand, STATS delivered theoretical and practical hands-on training for selected technicians at STATS global training facility. In addition to the BISEPs and Slab Valves, test fixtures were also supplied which can be used for pre mobilisation and routine training campaigns, providing the client with the ability to continuously develop technician competence.

Challenging subsea platform tie-in

STATS recently achieved another major milestone for the company, successfully

completing a complex subsea platform tie-in for a leading Chinese energy company.

STATS deployed its SureTap® subsea hot tapping machine and BISEP line stopping technology at two locations in the East China

“The BISEP is the only line stop technology

STATS completed its first-ever hot tap and BISEP isolation project in Indonesia for an oil and natural gas corporation, executing 12 precision operations across three challenging locations in a single campaign. The scope included six 16-inch high pressure hot taps to deploy BISEP isolations and six 16-inch hot taps for a new bypass flow, enabling a seamless pipeline re-route without disrupting production.

The project provided an efficient, commercially significant solution for the client, allowing them to divert their pipeline away from privately owned land. Despite complex rigging requirements and demanding site conditions, STATS’ team demonstrated the resilience of their equipment and the depth of their expertise, completing the work efficiently and safely.

outstanding collaboration with third parties and

“This landmark achievement for STATS has not only proven the capability of our technology in Indonesia but also sets a new benchmark for high integrity, leak-tight pipeline intervention and isolation projects in the region,” Campbell said.

With major projects successfully delivered in Australia, New Zealand, Malaysia, Indonesia, Vietnam and China, STATS is cementing its position as a trusted partner for high-integrity pipeline intervention and isolation solutions across Asia Pacific.

Supported by patented technologies such as the BISEP and Tecno Plug, full DNV certification, and an expanding local footprint, business in the Asia Pacific region is set to boom. With planned further investment and rising demand from leading operators for leak-tight, high-integrity isolation solutions, STATS is also preparing to grow its workforce to support continued expansion.

APGA Head of Communications and Operations Lawrence Shelton discusses how collective investment in the convention strengthens the pipeline industry.

We are now standing on the cusp of an event that not only celebrates technical excellence – but delivers long-lasting value to the entire industry.

What makes the APGA Convention so impactful isn’t just the quality of the technical content or the number of delegates in attendance. It’s the fact that the entire event is the result of collective investment of time, expertise, insight, and trust. Year after year, individuals and organisations across the pipeline sector contribute to the Convention not simply for recognition, but because they believe in the value of shared progress.

The Convention as a product of industry investment

Every abstract submitted, every speaker prepared, every question asked from the audience – they’re all examples of members choosing to give back to the industry. In doing so, they help build a Convention program that reflects the true priorities of our sector.

But this investment goes far deeper than technical papers. It includes organisations granting their staff time to attend, present, and participate. It includes committee members and reviewers who volunteer their expertise to shape the program. It includes sponsors and exhibitors who ensure the event remains viable and vibrant. It even includes delegates who show up with curiosity and openness – ready to learn, ready to challenge, and ready to grow.

This is not a passive audience. This is a

committed professional community that understands that the value of the Convention lies not only in what is shared, but in what is created when we come together.

When the industry shows up, value multiplies

There is a multiplier effect that occurs when the right people are in the room.

For early-career professionals, the Convention provides an accelerated learning environment, with exposure to a full spectrum of industry expertise. For technical leaders, it’s a chance to road-test ideas, gain validation, and source inspiration. For decision-makers, it’s a rare opportunity to hear firsthand how technologies, regulations, and priorities are evolving across the value chain.

This depth and diversity only happens when the industry shows up – not just physically, but with the intention to contribute.

Importantly, this kind of shared environment creates more than just intellectual benefit. It builds a stronger, more resilient sector – one where people are more likely to collaborate across organisational boundaries, where good practice spreads faster, and where new ideas are treated with rigour, not resistance.

Sharing the load, reaping the reward

The simple truth is this: the more we all invest in the Convention, the more we all benefit from it.

An organisation that sends a speaker also sharpens its story. A company that encourages a young professional to attend also accelerates their development. A delegate who shares insights from a panel session back at the office spreads knowledge more widely. A question asked during Q&A can shape the direction of future research.

The return on investment from this kind of industry engagement is exponential – not just for the individual, but for the sector as a whole.

As we prepare to gather in Brisbane this October, we do so with the knowledge that the APGA Convention is more than a fixture in the calendar. It’s a strategic opportunity to advance our thinking, align our efforts, and affirm our shared commitment to excellence.

The program is strong. The conversations will be rich. But the real value will come from how we carry this momentum forward – how we continue to invest in one another, in the industry, and in the idea that collaboration makes us all stronger.

If you’re attending the Convention this year, thank you. Your presence is part of what makes this community work. And if you’re contributing – through a presentation, a panel, or a paper – know that your voice is not only heard. It’s valued.

Together, we’re not just building a great event. We’re building a better industry.

Elevate your asset integrity with unmatched data accuracy and unparalleled expertise

Our unique synergy of advanced inspection systems, cutting-edge analytics and human expertise allows us to transform data into knowledge. Knowledge enables smarter decision-making and delivers a comprehensive understanding of asset safety, lifetime, and performance.

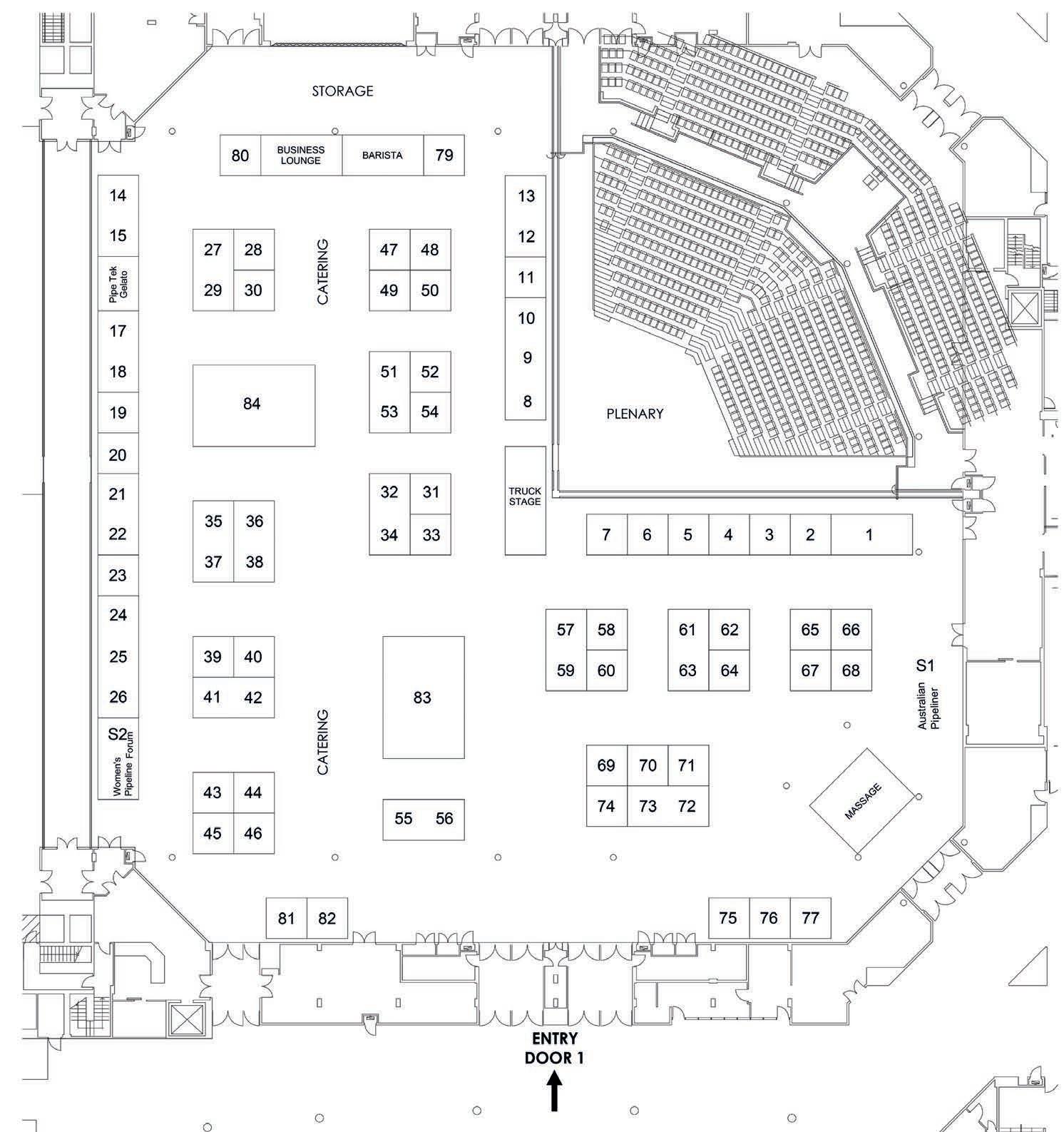

CONVENTION

FRIDAY – 17 OCTOBER 2025 Time Session

8:00 am–5:00 pm 2025 WLDP Alumni Leadership Summit (Invite Only) APGA

SATURDAY – 18 OCTOBER 2025

8:30 am–11:00 am 2025 WLDP Alumni Leadership Summit (Invite Only) APGA

11:15 am–5:00 pm Vermeer Golf Classic

SUNDAY – 19 OCTOBER 2025 Time Session

11:00 am–2:30 pm Sunday Get Together CNC Project Management

4:00 pm–6:00 pm Women in Pipelines Function APA Group, Jemena

6:00 pm–7:30 pm Exhibition Opening

7:30 pm–11:00 pm Opening Dinner

Turbines, Tremco Pipeline Equipment

Partners, Vacuworx, Bao Steel, Jemena, Baker Hughes 11:00 pm–12:00 am Happy Hour

MONDAY – 20 OCTOBER 2025

8:00 am–9:00 am Arrival and Registration

9:00 am–9:05 am Convention Opening John Stuart-Robertson APGA

9:05 am–9:15 am Official Welcome to Country Jahmarley Dawson A proud Gomeroy Man

9:15 am–9:25 am State of the Industry Steve Davies APGA

9:25 am–9:55 am Minister's Address Hon Dale Last | Minister for Natural Resources and Mines

9:55 am–10:35 am APGA Awards Presentation 2025 John Stuart-Robertson APGA

10:35 am–11:05 am Morning Tea

11:05 am–11:45 am Leaders Panel Steve Davies, Erik Cornelissen, Craig de Laine, Liza Maimone APGA, Rosen Group, AGIG, FYFE

11:45 am–12:15 pm Keynote Speaker Wayne Bennett

12:15

1:15 pm–1:35 pm Global Learning for Local Application - International Best Practice Klaas van Alphen, Tom Jackson RSC, GPA

1:35 pm–1:55 pm FFCRC Projects (Combined) and GIRA, (GIRA - A New Standard in Gas Industry Research) Doug Proud GIRA

1:55 pm–2:15 pm EPRG Research Update Marion Erdelen-Peppler EPRG

2:15 pm–2:35 pm Addressing Design Challenges in Storage Pipeline Systems

2:35 pm–2:55 pm Supporting Electricity Networks - Distributed Gas Backup and Inertia

2:55 pm–3:15 pm Future Fuels Pipelines –Why a Digital Engineering Approach is Required

3:15 pm–3:45 pm Afternoon Tea Enscope

3:45 pm–4:05 pm Constructing The Kurri Kurri Lateral Pipeline. A Truly Unique Infrastructure Project that Includes a Gas Transmission and Large Storage Pipeline

4:05 pm–4:25 pm Atlas East: Improving CSG Facility Design, Construction and Commissioning Sequencing

4:25 pm–4:45 pm Reducing the Pressure on Redevelopments: Delivery of Urban Gas Infrastructure to Enable High Density Development in Perth’s CBD

4:45 pm–5:05 pm Atlas to Reedy Creek Pipeline

CONVENTION PROGRAM

5:05 pm–5:10 pm Convention Close for Day 1

7:00 pm–11:00 pm Fancy Dress Dinner Tremco Pipeline Equipment, Solar Turbines

11:00 pm–12:00 am Happy Hour

TUESDAY – 21 OCTOBER 2025

Time Session Speaker

8:00 am–9:00 am Arrival and Registration

8:30 am–9:00 am APGA Annual General Meeting

9:00 am–9:05 am Convention Opening

9:05 am–9:25 am Safeguarding Sustainability: APA's Path to Process Safety Excellence

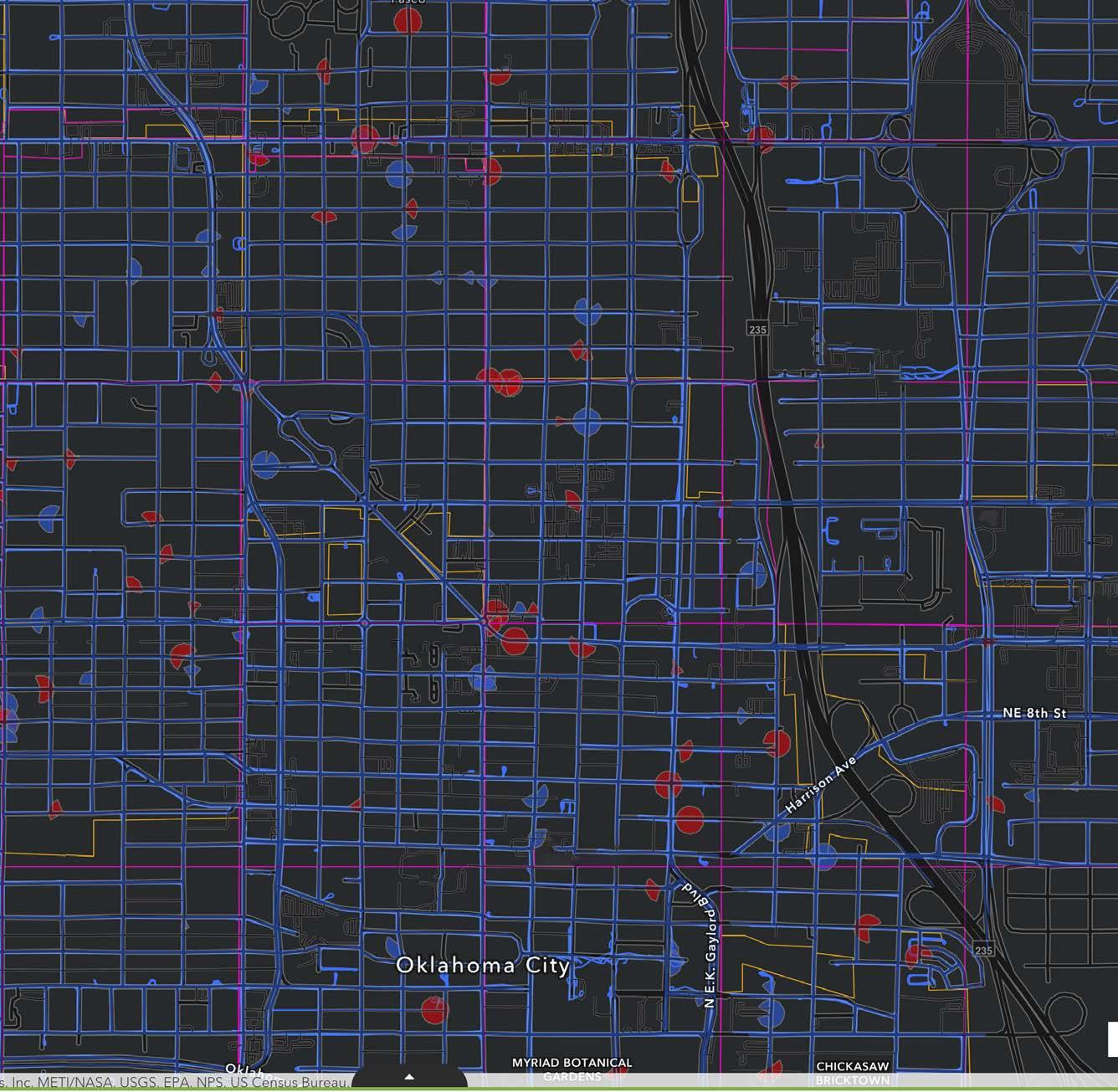

9:25 am–9:45 am Transforming Utility Planning: BYDA’s GIS-Based Digital Portal

Sponsor/organisation

Allyson Woodford, Tim Wall APA Group

Mell Greenall BYDA

9:45 am–10:05 am Psychological Safety Nada Wentzel Jonah Group

10:05 am–10:35 am Panel – Psychological Safety

10:35 am–11:05 am Morning Tea

11:05 am–11:25 am Final Report: DEI in the Pipeline Sector-Voices & Recommendations

Carol Bond

RMIT University

11:25 am–11:45 am Navigating Ambiguity: Lessons From Our Journey Towards a Zero Gas Future in the ACT Carina Nixon, Phil Colvin GPA Engineering

11:45 am–12:05 pm How The Renewable Roll Out Will Impact Future Pipeline Projects Marcus Baker CNC Project Management

12:05 pm–12:25 pm The Comfort Zone: Advocating for a Safe Pipeline Industry for All with APGA's Newest Code of Practice

12:25 pm–12:55 pm Panel - YPF - Next-Gen Pipeliners: Building Careers from the Ground Up

12:55 pm–1:55 pm Lunch

Elizabeth Wheeler

APGA Women in Pipeline Forum

Gretyl Lunn, Charlotte Lyndon, Mark Hutchinson, Steph Johnson, Nathan Crouch APA Group, UEA, GPA, PFP, Inductabend

1:55 pm–2:15 pm Pioneering Renewable Gas in NZthe First Biogas Upgrading Project Tim Lepper First Gas Limited

2:15 pm–2:35 pm Australia's Hydrogen Horizon: Navigating Challenges and Unlocking Opportunities in Pipeline Infrastructure?”

2:35 pm–2:55 pm Repurposing an Existing Onshore Natural Gas Pipeline for CO2 Service: Key Safety Considerations

2:55 pm–3:15 pm Driving the Renewable Gas Sector Forward with Policy

3:15 pm–3:45 pm Afternoon Tea

Jason Amiri Fyfe

David Johnson APA Group

Suzie Jakobovits, Phillipa Minton Jemena

3:45 pm–4:05 pm Changing the Definition of Unpiggable: A Case Study with APA Group on the Inspection of an “Unpiggable” Critical Natural Gas Pipeline and Avoiding Shutdown by Launching via Hot Tap - An Australian First

Herman Quakkelsteijn, Robert Nearhos Intero Integrity, Services Australia

4:05 pm–4:25 pm Advancements in In-line Inspection of Gas Pipelines Under Challenging Conditions Kelly Verhagen Pacific Gas & Electric

4:25 pm–4:45 pm 2024 Queensland Gas Pipeline Rupture Raj Jeyarajah, Marshall HolmesJemena, Resources Safety & Health Queensland

4:45 pm–5:05 pm Closed Vent Compression Systems Roxy Mounter Tremco Pipeline Equipment

5:05 pm–5:10 pm Convention Close for Day 2

7:00 pm–7:30 pm APGA Pre-Dinner Reception APA Group

7:30 pm–11:00 pm APGA Gala Dinner Austrack Equipment, Tremco Pipeline Equipment, Bao Steel, McConnell Dowell Constructors, Fyfe, Denso Australia

11:00 pm–12:00 am Happy Hour CNC Project Management

Unbonded, robust connections for LNG, LH2, Ammonia and more.

In Pipe Tek’s 10th year in business, The Australian Pipeliner spoke with co-founders Myles Brannelly and Taddam Farrant about their shared passion for pipelines, a leap of faith and the challenges of establishing the company as a leading turnkey pipeline contractor.

How do you define ‘pipeline people’? The answer to that question is no doubt entirely objective; however, two people that embody the ideology are Pipe Tek cofounders, and current managing director and coo, Myles Brannelly and Taddam Farrant.

Pipelines are in their blood. Brannelly grew up around the industry through his family’s business Tank Calibrators, established in 1953, which he eventually took over in 2000.

Farrant got his start in pipelines labouring with AJ Lucas, filling sandbags and throwing skids. He went on to work on some of the country’s major pipeline and energy projects, including the Eastern Goldfields Pipeline, the Curtis Island QCLNG, and extensive work in the Cooper Basin on behalf of Santos.

The two men eventually met on a pipeline testing and pigging project in 2014 when Brannelly was working for himself and Farrant for a construction company.

Pipeline passion

They quickly bonded and identified a shared passion for pipelines. It didn’t take long before the pair identified a gap in the market when it came to testing and commissioning.

Backed by their years of cumulative

experience, they established a plan to fill that space and haven’t looked back since. And now, in the blink of an eye, they are celebrating 10 years since they backed themselves, went out on their own and established Pipe Tek.

“It might be a cliché, but it really does feel like yesterday that we decided we were going to go for it,” said Brannelly.

“Time does fly when you’re having fun, but there have been some tough and challenging times along the way and it hasn’t been easy.”

Farrant said the early days of the business were tough. Pipe Tek was coming in and disrupting the way things had been

done for – in some cases – decades.

“Being the new kid on the block was challenging in a lot of ways,” he said.

“While we have always been passionate about the industry, there are a lot of organisations that just default to doing what they’ve always done. Trying to change the way people think and promoting a more efficient way of testing, cleaning, and commissioning has been a challenge.

“We’ve been able to cut through and overcome this legacy mindset. But it wouldn’t have been possible without the support of key industry people along the way.”

The early days of Pipe Tek were ‘no frills’. Initially based out of Brannelly’s family home in Brisbane, where Farrant was also living at the time.

They scrounged together enough to purchase a ute, trailer and some gear to get going and split responsibilities for running the business between the two of them. Anyone that has crossed paths with the two men knows they are unconventional, and the concept for the business was no different.

“There was no ‘real’ business plan written down,” said Farrant.

“It was just two mates trying to change the world. We had a conversation around what was missing and what we thought we could bring [to the industry], which was a turnkey solution.

“Rather than going out to different vendors, we wanted to put a company on the market that gave clients a one-stop-shop for integrity and maintenance.”

Brannelly echoed the same sentiment.

“We always talk about Pipe Tek being a family and it’s easy to see why that mindset is embedded and part of the company’s DNA,” he said.

“The fact Taddam (Farrant) was living with my young family at the time meant we were all in, living and breathing the business.”

After the first few years in operation, Pipe Tek grew and resources naturally expanded. The company invested in more plant and equipment, technology and moved out of Brannelly’s family home, setting up a lay down yard near Brisbane airport.

In 2019, they wanted to align themselves with industry leaders, and identified an opportunity to secure a partnership which they believed would give them a point of difference, and take Pipe Tek to the next level.

“Enduro Pipelines Services reputation really does precede them,” said Brannelly.

“The company is recognised and respected around the world for manufacturing and designing the world’s most technologically advanced pipeline cleaning and inspection equipment. It didn’t have a presence in Australia or anywhere else in the world, so we decided to reach out and see if we could do business.”

But Enduro – based in Oklahoma, US –was a tough nut to crack.

“As an established pipeline integrity product manufacturer with a focus on quality, Enduro is particular about who they partnered with,” said Farrant.

“We sent emails and didn’t get a response. We knew they were going to be exhibiting at a

pipeline inspection show in Houston, US, so Myles [Brannelly] and I took a leap of faith and flew there.”

Without any indication Enduro would be open to a partnership, Brannelly and Farrant booked flights for the 14,000km journey from Brisbane to Houston.

On the first day of the event they introduced themselves to Enduro’s CEO Dwayne O. Laymon.

“We said: ‘We want to promote it. We think it’s the best. And we want to keep Pipe Tek associated with quality, so Enduro was the only fit for us,” said Farrant.

Laymon was receptive to the pitch and over the course of the next couple of days, an exclusive partnership was negotiated, making Pipe Tek one of a handful of companies to represent Enduro products outside of the US.

Brannelly said the partnership with Enduro has been everything they expected and more.

“In the more than six years since that initial meeting we have been welcomed into the Enduro family with open arms,” said Brannelly.

“Dwayne (Laymon) and his team have offered unwavering support, advice and direction.”

In addition to a full suite of pipeline products, like pig tracking and analysis tools, Pipe Tek stocks an extensive range of Enduro cleaning pigs, in a range of diameters, at the company’s headquarters in Brisbane. These can be supplied to asset owners running their own integrity and maintenance crews, or Pipe Tek can utilise the equipment itself and be contracted to complete cleaning, inspection and testing works.

Despite the economic challenges facing most of the country and world during the pandemic, Pipe Tek was able to continue to grow during this period. In addition to working on major gas pipeline projects, the company diversified into other markets including water, carbon capture and storage, hydrogen and more recently resources.

Over the past 10 years Pipe Tek has contributed to more than 100 pipeline projects, working directly or indirectly for companies like Chevron, Ventia, Downer, Ampol, BHP, Origin, Viva, APA, Jemena and dozens more.

To capitalise on opportunities in mining and resources Pipe Tek has established a footprint in WA, giving it the capabilities to service all of the country.

“We predict there will be a lot of work for Pipe Tek in the region servicing the gas and LNG sector, as well as demand from the resources and mining sector,” said Brannelly.

He said the company’s strategy will be to continue positioning itself as more than a contractor.

“Mining environments are some of the most challenging; remote locations, harsh conditions and tight schedules are the norm. What sets Pipe Tek apart is our ability to deliver highly specialised services with flexibility and efficiency.

“We’re not just a contractor; we’re a partner that works closely with clients to tailor solutions to their infrastructure and operational needs.”

For Brannelly and Farrant, who both admit they wear their hearts on their sleeves, Pipe Tek’s journey so far has been a personal one.

“We’re proud of the journey so far – from a small start-up to a trusted name in pipeline integrity,” said Farrant.

“It’s been built on the back of strong relationships, quality work and a team that genuinely cares about what we do. We’re excited about what the future holds for the business and the challenges that lay ahead.”

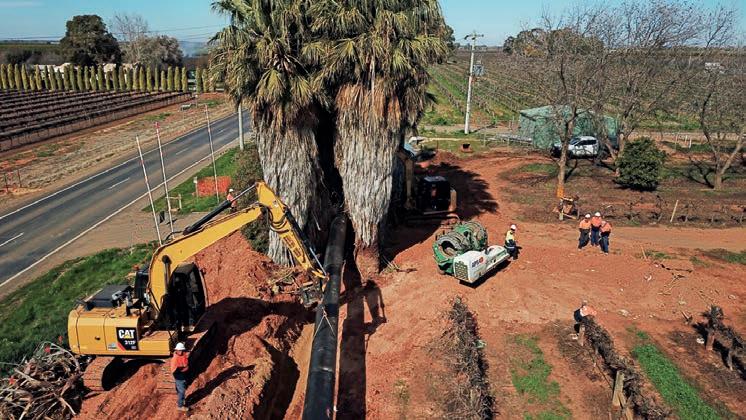

The Australian Pipeliner sat down with Tesmec to learn how the company’s trenching machines are improving infrastructure projects around the world.

Whether it’s coping with difficult terrain, tight timelines, limited manpower, or rising environmental expectations, pipeline professionals face a growing set of challenges on every job site.

At the 2025 APGA Convention and Exhibition in Brisbane, Tesmec Australia will be on hand to showcase how it is helping Australian customers meet these challenges head-on, with trenching solutions built entirely around their needs.

When the ground gets tough, Tesmec Australia trenchers get going. For pipeline contractors needing to cut through everything from solid monolithic rock to soft, sandy soils, Tesmec Australia provides a robust lineup of chainsaw trenchers that offer precise, reliable performance in any condition. With trenching depths ranging from 91cm–732cm and widths from 15cm–213cm, Tesmec Australia machines are engineered to match project specifications exactly delivering the right cut. This precision ensures better downstream performance in pipe laying and backfilling, reducing rework, material waste, and unexpected delays.

Tesmec Australia understands that every project is unique, and that responsiveness matters. That’s why the company has committed to a strong local presence in Australia, with a dedicated office in Sydney and a highly experienced local team ready to support customers nationwide. By combining global innovation with local expertise, Tesmec Australia delivers solutions that are not only technically advanced but tailored to the specific conditions and requirements of the Australian market. From faster service response to immediate spare parts availability, customers benefit from real-time support and seamless project continuity.

Contractors today are looking for ways to reduce overhead, streamline operations, and make better use of limited resources. Tesmec Australia trenchers are designed to do exactly that. A single Tesmec machine can replace multiple conventional machines, accelerating trenching operations while minimising personnel, equipment, and fuel use.

For long-distance pipelines, this means shorter construction timelines, fewer disruptions, and a leaner, safer, more agile worksite, an essential advantage in today’s competitive market. Material handling presents an opportunity for efficiency gains in trenching operations.

Tesmec Australia trenchers turn spoil into an opportunity: excavated material is immediately suitable for on-site reuse, whether as bedding, padding, or backfill, without additional processing. This reduces the need for haulage, cuts fuel usage, and contributes to a lower carbon footprint. At a time when sustainability is no longer optional, Tesmec’s approach supports both environmental goals and bottom-line performance.

Job sites today demand visibility, traceability, and real-time data. Tesmec Australia delivers with integrated digital technologies that include GPS-guided trenching, georeferenced data logging, realtime remote monitoring, and automated reporting. These features allow project managers to track progress, ensure quality, and make informed decisions.

With Tesmec Australia, customers get more than just a machine, they gain a strategic tool for smarter project execution.

Pipeline projects often run around the clock and in harsh environments. Tesmec Australia trenchers are built to keep up, with rugged components, improved digging teeth, and simplified maintenance access for faster servicing and less downtime. Designed for double-shift operation, these machines are trusted by contractors worldwide for their long-term durability and return on investment.

From remote deserts to urban corridors, Tesmec Australia trenchers help Australian pipeline professionals meet the demands of modern construction with strength, precision, and intelligence. At APGA 2025, visitors will see firsthand how Tesmec Australia is transforming trenching into a strategic advantage, solving real-world challenges with innovative, customer-centric solutions.

In a market where results matter more than ever, Tesmec Australia is proud to stand beside its clients as a trusted partner in their success.

•Hot Tapping

•Line Isolation & Bypass

•Pipe Cutting

•Commissioning

•Decommissioning

•Equipment Maintenance

•Training

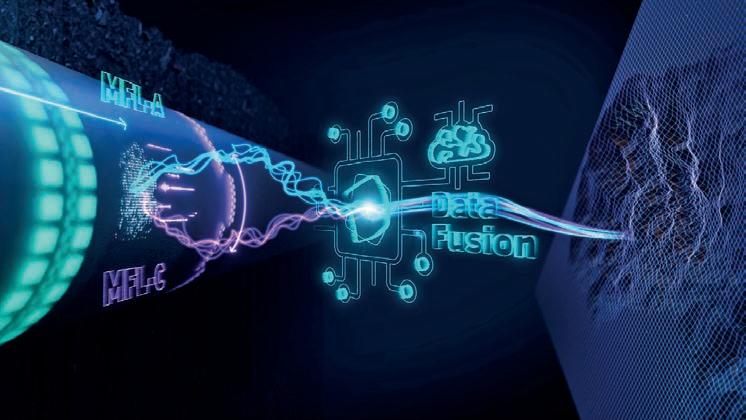

MDS Pro’s SMFL and LFM uncover every pipeline threat in one run.

MDS™ Pro is a cutting-edge in-line inspection (ILI) tool that combines multiple advanced sensors to provide a comprehensive survey of pipelines in a single inspection run.

By collecting six data streams at once (geometry, ID/OD discrimination, low-field MFL, high-field axial MFL, SpirALL® MFL, and mapping), MDS Pro provides pipeline operators with a complete integrity assessment while eliminating the need for multiple individual tools.

This one-run approach reduces inspection times and costs. MDS Pro’s SpirALL Magnetic Flux Leakage (SMFL) and Low-Field Magnetic Flux Leakage (LFM) technologies deliver unique benefits: SMFL enhances detection of axial (longitudinal) defects, and LFM reveals ‘hidden’ material issues like hard spots.

Traditional MFL tools magnetise the pipe axially, which best finds general metal loss and circumferential anomalies. SMFL, by contrast, induces a spiral magnetic field in the pipe wall. As a result, axial anomalies trigger a clear signal in the SMFL data.

The advantage of this is that SMFL detects axially oriented defects that axial MFL can struggle with. Examples include seam weld flaws (lack of fusion, hook cracks), selective seam weld corrosion (SSWC), or narrow axial metal loss features that run along the pipe

axis. In an axial field these sorts of flaws might produce weak indications, since the magnetic field is parallel to the anomaly. The spiral field, however, cuts across them, creating a signal in the data. In essence, SMFL closes the detection gap for longitudinal seams and cracks. SMFL can reliably flag long-seam corrosion or crack-like anomalies that would be under-called by traditional MFL. This makes SMFL a key technology for assessing seam weld integrity – helping find seam cracklike or SSWC anomalies early, before they grow towards an increased threat to pipeline integrity. Additionally, by comparing SMFL and axial MFL signals together, analysts can distinguish defect geometry. If SMFL sees a strong indication but MFL doesn’t, it’s likely an axial planar flaw rather than corrosion. Using the combined datasets together thus improves the characterisation accuracy and helps in avoiding false calls.

“SMFL on MDS Pro revealed seam-weld anomalies that would have been missed with a conventional axial MFL tool,” said senior MDS Pro analyst Kevin Tyler, referring to seam crack indications that axial MFL alone did not highlight. “Combining SMFL and axial MFL in one run gave us confidence no seam threat slipped through.”

This feedback underlines SMFL’s value in pipeline operations: it provides a dedicated lens

In turn, this extends pipeline life by enabling proactive repairs on seams and axial flaws.

Low-field MFL is an innovative technology included in MDS Pro system that magnetises the pipe at a lower field level than standard high-field MFL. High-field MFL saturates the steel, mainly revealing metal loss. LFM, by keeping the pipe below saturation, maintains the magnetic response sensitivity to the magnetic permeability. Permeability shifts occur due to material properties or increased levels of the pipe steel.

LFM excels at spotting variations in material or increased level of stress in the pipe, in addition to metal loss. For instance, hard spots – localised hardened areas from manufacturing or welding – show up as distinctive LFM signals. They often don’t have metal loss, so depending on the morphology of the hard spot, signals in axial MFL might be ignored.

detection of fatigue-prone seam defects, SMFL

Conversely, the altered microstructure causes a permeability change that’s detectable in LFM data. Hard spots matter because they can be brittle and crack under stress. With LFM, operators can find these hard spots and treat or remove them before they become crack initiation sites. LFM also highlights zones of cold work or strain, for example, the workhardening at a dent’s shoulders. This means MDS Pro can help rank dents, extending beyond just dent depth, considering signal responses in all six MDS Pro technologies –something geometry tools alone cannot do. In short, LFM acts as a ‘detector’ for metallurgical and stress anomalies, mapping locations where the steel itself is unusual. LFM can also indicate areas of heightened stress. This allows MDS Pro to be used to identify circumferential stress corrosion cracking (CSCC) and help prioritise uncharacteristic girth welds.

In mid-2024, T.D. Williamson (TDW) conducted an MDS Pro inspection on a gas pipeline that was over 50 years old. The LFM response prompted an excavation, and the hard spot – which standard MFL had not highlighted strongly – was confirmed and removed. In multiple other cases, LFM helps pinpoint critical dents, sometime very shallow, that have associated gouging; these dents are proactively repaired and the threat to pipeline integrity mitigated. These cases show LFM’s unique contribution: finding the unseen threats (material embrittlement, residual stress, or even material differences in the steel) that other ILI methods miss. For operators

MDS Pro provides pipeline operators with a complete integrity assessment.

preparing pipelines for new challenges, LFM’s ability to identify hard spots and other material issues provides invaluable insight.

By integrating SMFL and LFM with conventional sensors on one platform, MDS Pro offers the most comprehensive picture in a single inspection. The synergy between datasets yields several benefits:

• Full coverage of defect types: Axial MFL finds general corrosion; SMFL finds axial/ seam anomalies; LFM finds hard spots and stress zones. Together, virtually all structural threats are detectable.

• Better characterisation: Data fusion means an anomaly can be cross compared across multiple ILI technologies. For instance, a dent with metal loss will appear in geometry, MFL, SMFL, and LFM data – giving a multi-dimensional understanding of its severity.

• Operational efficiency: One tool run replaces what previously might require three separate runs (geometry, high-field MFL, and a seam tool). This saves time and reduces costs and the risk of disruptions.

“Our Australian operators manage vast, remote pipelines and can’t afford multiple inspection runs,” TDW APAC Regional Manager of Pipeline Integrity Matt Runchey

said. “MDS Pro’s ability to catch every threat in one go is a game-changer. We’re excited to bring this technology to solve pipeline challenges here, helping customers boost safety and efficiency.”

By combining multiple innovative technologies in a single survey run, MDS Pro detects and accurately identifies every critical anomaly, ensuring nothing is missed. For operators navigating aging infrastructure and rising integrity demands, MDS Pro delivers fewer surprises, greater certainty, and stronger operational confidence. One run is all it takes to uncover hidden threats, confirm pipeline integrity, and empower smarter, faster decisions.

minimise environmental impact.

For over 60 years, Vinidex has delivered trusted pipe systems and solutions. From large-bore pipelines for water and gas to custom-fabricated products, we engineer durable, high-performance solutions that endure tough conditions and minimise environmental impact.

To find out more about our industrial solutions come visit the Vinidex team at stand 44.

To find out more about our industrial solutions come visit the Vinidex team at stand 44.

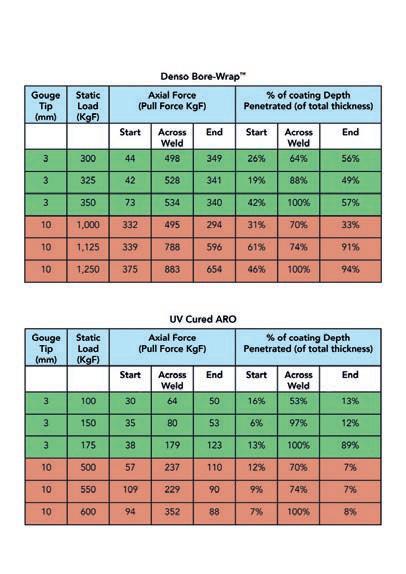

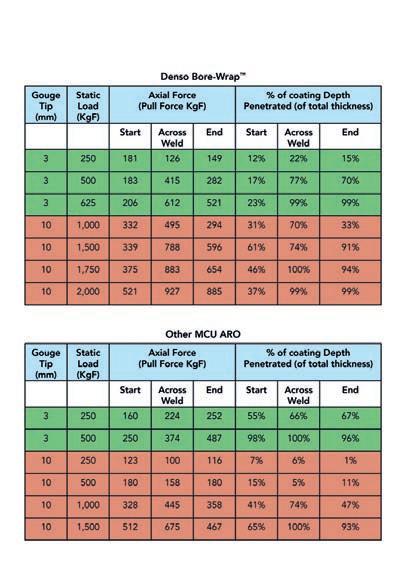

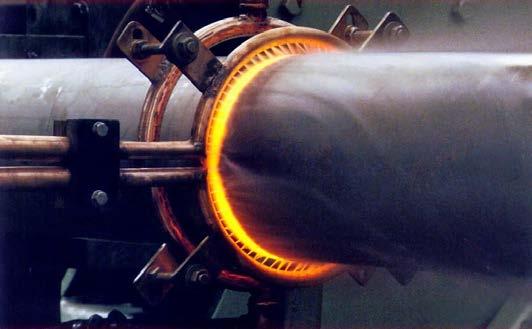

Denso Bore-Wrap’s impressive HDD performance has been confirmed through rigorous independent testing.

As technology continues to evolve, so too does the expectation for protective coatings that can withstand the extreme demands of horizontal directional drilling (HDD).

The team at Denso Australia believes that these expectations must be met with evidence – not assumptions.

Since launching Bore-Wrap, Denso Australia has committed itself to an extensive program of internal research and development and independent thirdparty testing.

Its most recent collaboration with the National Facility for Pipeline Coating Assessment (NFPCA) at Deakin University provided valuable, unbiased insights into the product’s performance across a range of fieldrelevant conditions.

The testing assessed gouge resistance and adhesion strength using international standards including CSA Z245.20, NACE TM0215, and ASTM D4541. Two separate gouge test setups were used to reflect realworld HDD risks.

Gouge Test 1 tested with a simulated weld margin to represent side-impact strain and

Gouge Test 2 tested without a weld margin to assess overall material integrity in standard

In both scenarios, Bore-Wrap demonstrated exceptional resilience.

In the weld margin configuration, it resisted gouging forces up to 1250kgF before disbondment – more than double the load required to compromise other tested systems. This is a critical result, as field joint weld zones are particularly susceptible to mechanical damage during pull-through.

Beyond its mechanical performance, BoreWrap also offers several practical and longterm advantages for trenchless pipeline installations.

It is fully non-shielding, ensuring compatibility with cathodic protection systems.

The wrap is supplied in convenient, easy-toapply packaging and can be installed in multiple layers if required. Its field-friendly formulation allows for application in a wide range of environmental conditions, whether on-site or off-site.

Bore-Wrap’s patented fibre architecture ensures that during HDD installations, its flexural strength is greater than that of the underlying parent coating system such as FBE, 3LPE and 3LPP parent coatings.

This is due to its high fibre content which provides enhanced durability under HDD stress, unlike more brittle UV-cured ARO systems.

Adding to this, Bore-wrap’s overlaps are smooth thus allowing for an easier installation uninhibited by larger overlaps which can cause additional stress on coatings and equipment.

From lab validation to in-field success (such as with recent applications in Bolivar, South Australia), Denso’s approach has been consistent and clear: test, refine, verify, and protect.

Denso Australia is committed to

As a long-time Host Sponsor, the Tremco Pipeline Equipment team knows a thing of two about surviving – and thriving – at the Australian pipeline industry’s most prestigious event.

The APGA Convention and Exhibition is the ultimate mix of high-vis expertise, technical deep dives, and good oldfashioned industry banter.

Whether you’re a first-timer still figuring out the difference between a pig and a pig launcher, or a seasoned attendee with a wellworn Gala Night tux, here are Tremco Pipeline Equipment’s essential dos and don’ts to help you make the most of Brisbane this October.

Do: Pack your business cards –and your best handshake

QR codes are great, but a physical card with your name on it is harder to forget (and makes a handy coaster at the bar). You’ll meet everyone from gas policy buffs to field operation veterans. Make connections, swap cards, and remember: nothing says “I’m serious about networking” like a firm handshake and a question that shows you’re interested in learning more.

Don’t: Skip the business sessions

The social events are legendary but the daytime business sessions are where the real gems are shared. The technical papers and policy discussions are one of the best ways to stay up to date with the latest in operations, research and regulation – from gas policy debates to real-world lessons from recent projects.

If you miss the 9am sessions, don’t worry. Someone will happily inform you at lunch that they were “the best ones yet”.

One not to miss: the ZEVAC team will be presenting on closed vent compression systems. They will cover best practices for managing pipeline emissions during pigging, maintenance, and repair operations, plus how ZEVAC’s portable compression equipment is helping operators reduce venting

and stay ahead of regulatory and environmental expectations.

Do: Go all-in on Fancy Dress Night

APGA’s themed costume parties are the stuff of industry legend. If you’re not dressed up, you’ll stand out – and not in a good way. Bonus tip: don’t underestimate Brisbane’s humidity and choose breathable fabrics.

The hotel aircon may be icy, but step outside and that full-body nylon jumpsuit won’t seem like such a good idea.

Don’t: Be the one who talks shop at the Gala Dinner

There’s a time for compressor specs, and there’s a time for cutting shapes on the dance floor. Know the difference. If you try to discuss hydrotest procedures over dessert, someone will gently guide you toward the bar – for everyone’s sake. Key business relationships are forged at APGA’s social events, but not because you’ve cornered someone into a 30-minute sales pitch.

Do: Visit stands 8, 9 and 10 to tap into international expertise

With David Henry from Girard Industries, Guz Garza Jr from CRC Evans, and a representative from ZEVAC, you’ve got a global brains trust at your disposal.

Whether it’s how to progressively pig your pipeline, avoid venting during maintenance, or align your welding system in the middle of nowhere – chances are, our global

experts have solved it. Use your time at the stand to dive deep into technical solutions with people who live and breathe this stuff.

The Tremco Pipeline Equipment team will be on hand throughout the exhibition to demonstrate equipment, discuss product solutions, and catch up with customers and industry peers.

Don’t: Underestimate the massage booth

Yes, it’s real. Yes, it’s free. And yes, after a day on the exhibition floor (or night on the dance floor), it will change your life.

Brought to you by Tremco Pipeline Equipment because we care about your lower back almost as much as your pipeline integrity. Remember: prevention is better than a cure. We’re basically offering free physio.

Do: Pace yourself at the social events

APGA’s iconic social events bring fun and connection to the convention experience, and

Tremco Pipeline Equipment is proud to cosponsor the Exhibition Opening, Fancy Dress Dinner and the Gala Dinner.

But be warned: four nights of back-to-back social events require pacing. You don’t want to peak too early – and you definitely don’t want to try to keep up with someone from WA at the bar. You will lose. They’ve trained for this.

Don’t: Forget to follow up post-convention

You’ll have dozens of great chats – in sessions, at the booth, over satay skewers. Don’t let those leads and learnings fade away after you return to your desk. Follow it up on LinkedIn or email, and lock in the next step. The real value is what happens after the event.

Visit Tremco Pipeline Equipment and its global supplier brains trust at Stands 8, 9 & 10 – and don’t miss ZEVAC presenting on Closed Vent Compression.

For more information, contact TPE on sales@tremcopipeline.com.au

Whether navigating iron-hard rock, undulating terrain, or tight project deadlines, Australia’s pipeline contractors increasingly rely on one name: Vermeer.

In the high-stakes world of pipeline construction, the ability to move earth with surgical precision isn’t just a matter of efficiency, it’s essential to project success.

With a robust line-up of track trenchers engineered for performance and durability, Vermeer has quietly become the muscle behind many of the nation’s most critical pipeline projects.

From the compact yet capable T555III to its flagship T1255III, the range offers tailored solutions for every phase of trenching, no matter the complexity of the geology or the scale of the task.

Pipeline installation in Australia often means working in remote, rugged, and sometimes unforgiving environments. Vermeer’s trenchers, particularly the T755III, T1055III, and T1255III are designed with this reality in mind.

Heavy-duty undercarriages, SmartTEC electronics, and powerful Caterpillar engines give operators the confidence to cut through limestone, basalt, and even granite with minimal downtime.

Vermeer’s trenchers, particularly the T755III, T1055III (pictured), and T1255III are purpose built for Australian terrain.

Advanced features like auto-tilt tracks, elevated cabs, and adjustable conveyor systems ensure that productivity isn’t sacrificed in difficult terrain. These aren’t just machines, they’re purpose-built platforms designed to adapt to real-world jobsite demands.

For pipeline contractors, precision is as important as power. A trench that’s even a few degrees off alignment can translate into costly adjustments and delays.

Vermeer’s track trenchers offer laser-guided accuracy paired with high tractive force like the T1055III’s 415 horsepower engine, coupled with a track-driven system that holds grade and alignment even on long hauls.

Models like the T655III and T955III also feature sectionalised booms and SmartTEC control systems, allowing contractors to tailor the depth and width of cuts without changing equipment making them ideal for projects that require multiple trench profiles.

One of the reasons Vermeer trenchers have found a home in Australia’s pipeline sector is their focus on up-time.

With up to 600 horsepower, machines like the T1255III are built not just to work hard, but to keep working for thousands of hours.

Extended care packages offered by Vermeer Australia up to five years or 5000 hours mean these machines can be operated with confidence, even in remote locations far from service centres.

In a competitive industry where time and accuracy are everything, Vermeer’s trenchers give pipeline contractors a strategic edge.

The trenchers’ ability to cut through the toughest material while maintaining line and grade translates directly into faster installs, fewer reworks, and reduced environmental impact due to cleaner trenching paths.

As Australia continues to expand its energy and water infrastructure, Vermeer’s trenchers are likely to become even more essential.

With a strong local support presence, rugged machine design, and operatorfocused technology, Vermeer isn’t just making trenchers – they’re shaping the future of pipeline construction.

Michels in Motion: Between March 2023 and February 2025, Michels completed 3 record-breaking HDDs in New South Wales. The 2,250-metre HDDs included elevation changes of 590 metres.

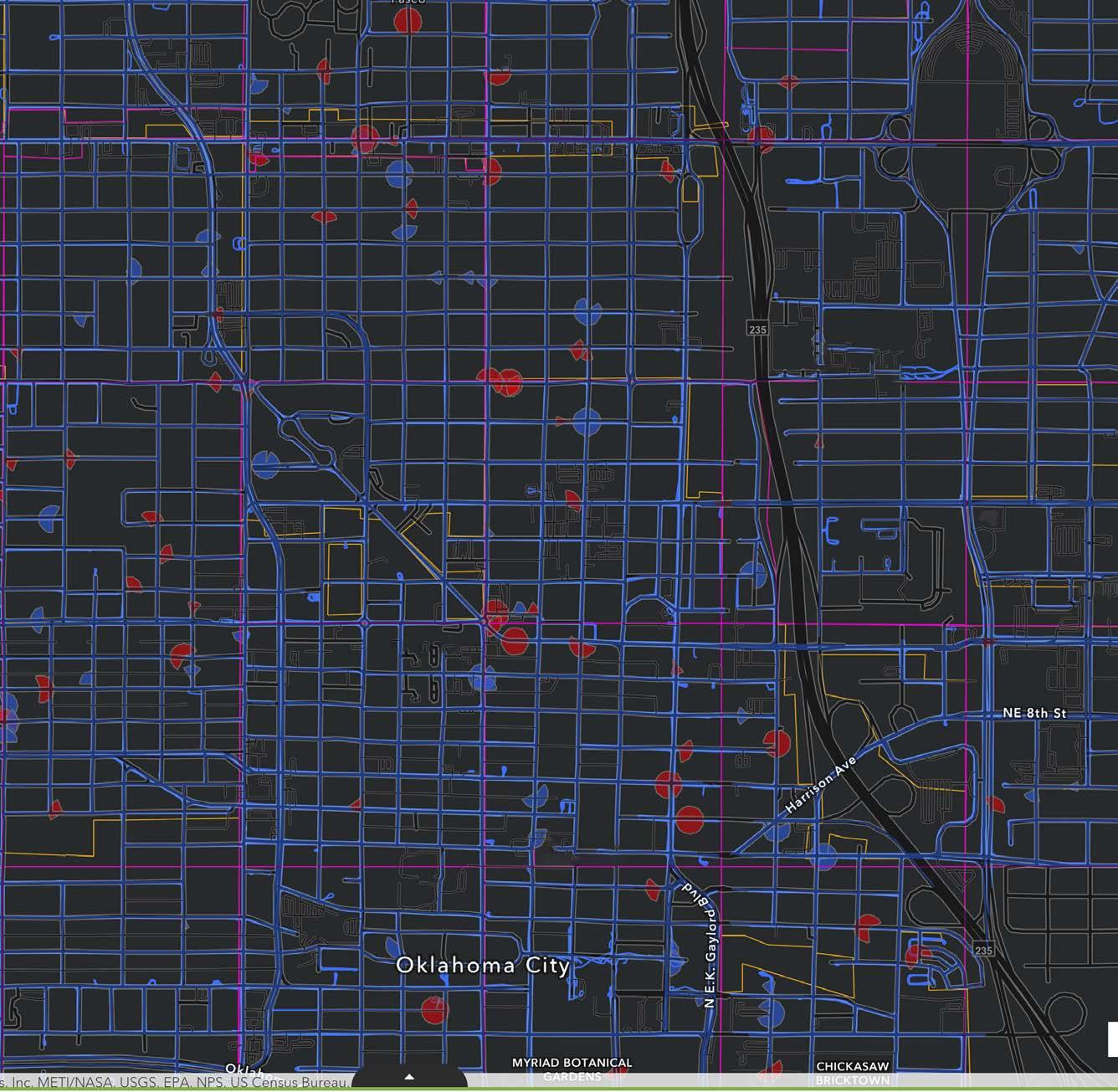

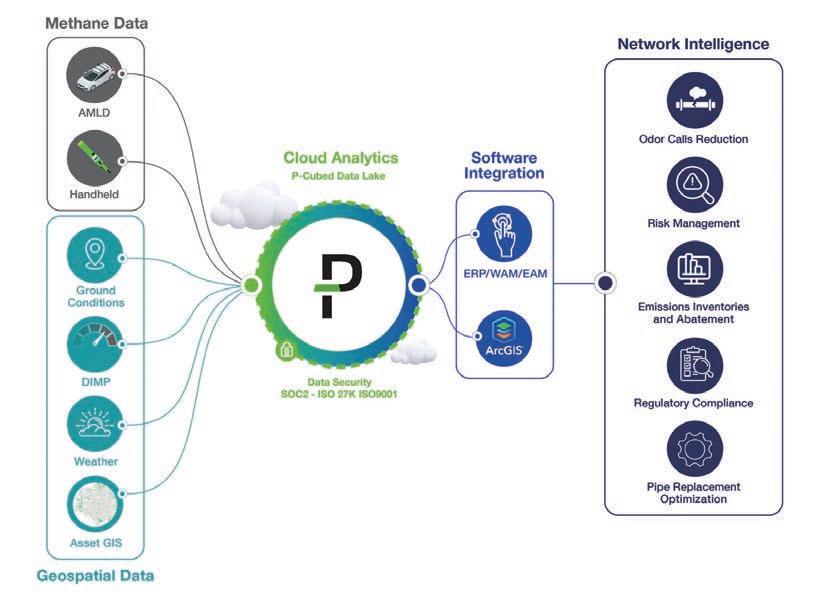

For oil and gas operators, cutting emissions and improving efficiency go hand in hand. The challenge is finding ways to detect and fix leaks faster without wasting time or resources. A growing body of best practices is emerging, supported by advanced methane detecting technologies that offer more accurate data and operational insights.

But how can operators use this new technology to reduce emissions and increase efficiency? Below is a step-by-step guide outlining how operators can streamline leak detection and repair (LDAR) strategies to reduce wasted gas and improve operational performance.

Step 1:

One of the most significant sources of inefficiency in emissions management is uncertainty. Operators sometimes spend hours chasing leaks that are either misattributed or too vaguely located to act on quickly.

High-resolution data can eliminate this guesswork by mapping emissions plumes down to within a couple of meters and tying them to specific pieces of equipment. With this level of precision, crews can be dispatched directly to the source of the leak, reducing travel time, improving safety, and cutting operating costs.

Step 2: Quantify to prioritise

Not all leaks are equally important. Small leaks may not demand immediate action, while large leaks can have outsized impacts on emissions intensity and lost product. This is where quantification – the ability to measure the actual size of a leak – becomes essential.

By knowing how large each emission source is, operators can make data-driven decisions: fixing the biggest leaks first, reducing emissions more effectively, and allocating maintenance resources where they matter most.

Operators should seek out technology that has peer-reviewed studies that demonstrate that the technology can provide quantification accuracy with low uncertainty, ensuring that decisions are based on reliable data.

Step 3: Distinguish fugitive from process emissions

Another key to efficiency is understanding what kind of emissions are being detected. Are they fugitive leaks (unintended losses) or part of normal process operations? Some technologies, including aerial LiDAR paired with repeat surveys (reflights), can distinguish between persistent and intermittent emissions. This distinction helps operators understand whether emissions are likely tied to equipment faults or expected process activity.

With this context, maintenance teams can prioritise leak repairs over process emissions that may require different strategies. Additionally, having clear and updated imagery of the site and emission plumes as a part of your data can help you understand where a leak may be coming from and how to address it.

Leak detection shouldn’t just be about reacting to problems. The most effective emissions management strategies use data to anticipate and prevent future issues. Consistent, high-quality data allows operators to:

• Develop baselines and inventories – Track progress over time and support compliance with reporting frameworks such as OGMP 2.0 and Australia’s National Greenhouse and Energy Reporting scheme.

• Benchmark methane intensity – Measure emissions relative to production volumes across assets and identify opportunities for improvement.

• Spot trends across assets – Identify recurring issues at the equipment, facility, or regional level and act proactively.

• Support transparent reporting – Provide regulators, investors, and the public with defensible data to demonstrate accountability.

Smarter emissions management doesn’t just reduce environmental impact and increase safety; it can also improve operational efficiency and reduce wasted product. By combining accurate leak detection, quantification, and contextual data, operators can move from reactive fixes to proactive strategies that prevent leaks before they occur.

Companies like Bridger Photonics are helping operators worldwide implement these approaches with advanced methane detection technology and industryleading data.

If you’re attending the APGA Conference, visit Bridger Photonics at booth 45 to learn how it’s already working with operators to make leak detection and repair safer, faster, and more efficient.

SUPPORTING PIPELINE OWNERS AND OPERATORS THROUGH EVERY STEP OF THE PIGGING PROCESS

Trusted by industry leaders, FB Pigging specialises in pigging and testing services from the planning stage, right through to project delivery and beyond. We act as an extension of your team, providing a complete suite of services from advanced pig tracking to inspection and testing.

The very latest SafeVac Lifting Systems SV400i makes its debut at the APGA Convention and Exhibition.

As the annual APGA Convention and Exhibition approaches, Austrack Equipment is furiously putting the final touches to its very latest SafeVac Lifting Systems vacuum lifter. This will be the third model the company has released since the first public showing of the SV400 at the Perth convention in October 2023.

When Austrack embarked on its journey almost five years ago to design and build what was to become its most ambitious excavator attachment, it had no idea where that path would lead. It developed into a circuitous and sometimes complicated journey involving design, fabrication, testing, redesign and more testing of the SafeVac Lifting Systems SV400.

Once all the necessary standards were met,

the mechanical components were installed, and the sophisticated electronic control system had been integrated, Austrack knew that it had created something exceptional.

The company was so confident, in fact, that an IP patent for the machine was lodged on completion in mid-2023. This leg of the journey culminated in June this year, when Austrack received notification of the patent approval for a number of design elements of the SV400 model.

Another milestone came this year with official Australian Made certification, allowing all SafeVacs to sport the trusted kangaroo logo. For Austrack, the certification confers high levels of recognition and trust in the marketplace.

The SV400 vacuum lifter was released in 2023 just before Austrack’ first ever participation in the APGA Convention and Exhibition held that year in Perth. Two years on and the SV400 is approaching 100,000 safe lifts.

Then, the following year in Adelaide, Austrack unveiled its second model: the SV200, a smaller unit on a wheeled Hitachi ZX170 excavator. This combination is intended to service vacuum lifting activities on gas gathering works in places like the Surat Basin in Queensland, and has been steadily gaining admirers among contractors and gas producers there.

The striking innovation in this design is the natural void in the excavator dipper arm has

been cleverly engineered to function as a vacuum chamber which eliminates the need for a conventional spreader bar. This delivers weight-saving benefits that translate into increased lifting capacity. The integration is so seamless it is hard to see where the excavator ends and the SafeVac unit begins.

Austrack set the tone for the 2024 APGA Convention when it transported a fully operational SV200 unit onto the exhibition floor to give attendees an up close and personal look at the machine.

The SV200 has all of the control systems and safety smarts of the SV400 but is capable of ground speeds of up to 35km per hour, giving it the speed and flexibility to handle lighter HDPE pipes quickly, efficiently and safely. It is equally at home with concrete culverts and steel plates as it is with HDPE, and indeed anything its vacuum seal can latch onto.

Returning to the present, Austrack will once again return to the APGA Convention

in 2025 in a big way, this time armed with its brand-new model the SV400i.

The new unit is possibly the company’s most innovative to date, combining the very best elements of its predecessors.

As with the SV200, the dipper arm has been converted to provide a vacuum chamber which in single shoe mode dispenses with the requirement for using a spreader bar. This frees up more than a tonne of lifting end weight, resulting in the excavator being able to safely lift weights not previously possible. The intelligent design delivers an immediate efficiency payoff.

“We have been working hard on the development of the SV400i for the best part of twelve months, and I am happy to confirm we will have a unit on display at the show,” Austrack Operations Manager and SafeVac Project Leader Dylan Gamble said.

“We are very excited by the prospect of showing off our very latest model in our hometown and giving everyone at the show the opportunity to see the unit at close quarters.

“The development of the dipper arm as a vacuum chamber in the SV200 opened up the possibility of using that technology with larger tracked units, allowing us to take advantage of the lifting benefits that this design change produced.”

Gamble said the new unit will be impossible to miss at the convention.

“This time we have fitted the unit to a Komatsu PC360LC. A 36-tonne excavator with an emerald green dipper arm will definitely stand out,” he said.

“We are really pleased with our newest model and the best news is that all the safety benefits of the original SV400 are retained in the SV400i.

“The approach at Austrack is to constantly look for new and better ways to do things –and our vaclift project has very much followed that philosophy.

“Come and visit Austrack at the show and witness the very latest in pipe vacuum lift design.”

Heath Pipeline Services is backing the industry with gas leak detection equipment and surveys.

For as long as there have been natural gas pipelines, operators have battled leaks.

And for more than fifty years, Heath Pipeline Services has been on the frontlines of this fight.

While there’s no silver bullet to prevent gas leaks entirely, prevention is the name of the game. But not all leak detection solutions are created equal.

Operating across Australia, New Zealand, and Papua New Guinea, Heath Pipeline Services has established itself as a distributor of choice for the supply, service, training, and rental of a comprehensive suite of gas leak detection equipment.

In particular, GMI gas detectors, including the GS700H hydrogen-capable portable unit, Heath USA laser detection, including the RMLD-CS handheld and AMLD vehiclebased systems, Addglobe high flow methane sampling units, Konica Minolta QOGI thermal cameras, Opgal EyeCGas range of QOGI thermal cameras, Sealweld sealants and valve servicing equipment, and more.

Put simply, the company has a broad range of tools that allow it to take on an equally broad range of pipeline challenges.

In addition to equipment supply and servicing, Heath Pipeline Services specialises in conducting fugitive emissions detection and gas leak surveys, as well as

onsite valve maintenance training. Heath Pipeline Services’ field service consultants have access to the full range of its detection equipment, allowing them to provide clients with the most comprehensive, flexible, and cost-effective option for gas leak and fugitive emission surveys.

The team combines advanced detection tools – ranging from TDLAS lasers and optical gas imaging cameras to high-flow direct samplers – to produce bottom up, component level leak surveys.

Heath Pipeline Services General Manager Chris Reddy put it best: “With our help, pipeline operators can catch all their small leaks before they become big ones.

“Our detailed surveys capture parts per million-level component leaks under realworld conditions, allowing technicians to keep it all in the pipe.”

Reporting and regulatory compliance is another major focus of Heath Pipeline Services’ approach.

“We’re helping clients develop long-term and cost-efficient Oil and Gas Methane Partnership 2.0-compliant sampling programs,” Reddy said.

“The thoroughness of our surveys allows clients to share operational expenditure across

production, maintenance, and sustainability departments, with all departments’ regulatory requirements met with a single survey.

“The resulting data can be entered directly into a client’s existing maintenance and reporting system daily, eliminating the need for extra leak management software.”

“Pipeline network surveys utilising vehicle mounted lasers also help to reduce transportation risks, as they can result in less kilometres per person travelled than that of a beyond visual line of sight drone support crew,” he said.

“Our surveys predominately involve low speed driving on linear assets, with minimal vehicle interactions, and no aviation risks or associated Civil Aviation Safety Authority requirements.”

Heath Pipeline Services will exhibit at the upcoming APGA Convention, and the Heath team are eager to make some new connections.

“Drop in to our stand to meet our visiting Konica Minolta specialist, Atsushi Yamada,” he said.

“We’re excited to teach the industry more about our capabilities and discuss how we can best assist with their pipeline projects.”

From routine valve leaks to complex high-pressure repairs, TEAM Inc. keeps your operations online and compliant.

24/7 rapid response

World’s largest inventory of clamps & enclosures

LDAR programs that cut emissions, protect safety, and meet regulations

TEAM UK – Your Reliability Partner. Leak sealed. Risk reduced. Reliability restored.

Meet us as APGA in Brisbane, QLD, October 18 - 21st

Fleet Helicopters is helping pipeline operators at every stage of a project’s life.

As the pipeline industry pushes for the development of new sources of natural gas, and the infrastructure needed to move it, logistical challenges are appearing.

The vastness of Australia is one major stressor in this space, complicating matters such as easement mapping and the transportation of crew and equipment.

Fortunately for the pipeline industry, Fleet Helicopters is bridging this gap.

As Fleet Helicopters CEO Mike Watson put it: “We’ve got a helicopter for everything.”

In the early stages of a project’s life, asset owners are leveraging Fleet Helicopters’ aerial capabilities to conduct easement identifications and flora and fauna surveys with speed that terrestrial surveying simply cannot match.

When it comes to cargo, Fleet Helicopters can transport equipment up to 1.5 tonnes, enabling the fast and efficient placement of equipment into otherwise inaccessible sites. The same goes for moving people, which cuts out lengthy commutes through often harsh environments.

These capabilities are helping gas asset

owners bring projects online faster, with less overhead costs, greater employee safety, and no fuss.

And once pipeline infrastructure is constructed, the Fleet Helicopters’ role evolves. Measuring pipeline emissions was once a numbers game – an equation factoring in the length of the pipe, its intricacies, and a presumed rate of leakage. Leak inspections were onerous, requiring the deployment of ground crews to scan hundreds of kilometres of pipeline, potentially exposing them to harmful gases.

But Fleet Helicopters brings a vastly different approach, replacing ambiguity with precise, actionable information.

Utilising the Boreal GasFinderAB laser system on board its helicopters, the company is able to scan pipeline infrastructure on an enormous scale to detect gas leaks.

“Our aerial leak detection surveys are much more economical and efficient than traditional ground inspections,” Watson told The Australian Pipeliner

“We can do 1000km in a day, not 14km.

We also don’t have all those huge ongoing labour, accommodation, and vehicle expenses, or any issues with land access.

“The system uses an infrared laser that’s tuned to the frequency of light absorbed by methane. It’s very accurate and very sensitive, measuring down to 0.5 parts per million.

“And by measuring at the aircraft, it’s physically reading the gas rather than trying to sense it at a distance.”

This data is reported clearly and in a timely manner to asset owners. When a leak is detected, this critical information can be reported directly from the helicopter, allowing stakeholders to take immediate action.

All of this comes at a crucial time as Australia seeks to strengthen energy security through expanded gas infrastructure. But delivering new pipeline networks demands more than capital; it demands know‑how, agility and dependable logistics.

Fleet Helicopters provides exactly that: a fusion of aviation expertise, innovation and operational flexibility that answers the industry’s needs at every phase.

18 - 21 October

Your commitment and generosity are the driving force behind the APGA Convention & Exhibition. We deeply appreciate your involvement and continued support, which help make this event possible and successful year after year.

Whether it’s natural gas, LNG, LPG or hydrogen, Elaflex has a broad scope in the fluid transfer sector that few other companies can match.

Even if you don’t know the name Elaflex, chances are you’ve seen its products in action.

“Go to a petrol station anywhere in Australia and you will be holding the Elaflex ZVA nozzle in your hand while fuelling your vehicle,” Elaflex Pacific Sales Manager Mario Iglic told The Australian Pipeliner.

But Elaflex’s reach extends far beyond everyday nozzles. Over its century‑long evolution, the company has developed into a global powerhouse in fluid transfer and handling, playing a critical role in large‑scale LNG, gas, nuclear and hydrogen infrastructure. Through strategic growth and acquisitions, it now supplies an extensive product suite to the pipeline industry, spanning specialised pipes, expansion joints, penetration seals, and much more.

When it comes to LNG, Elaflex backs the industry with Brugg Flexwell Offshore Pipe. This eight inch, double walled pipe enables the dynamic transfer of cold fluid between offshore rigs and floating LNG facilities.

Thanks to its flexible construction, the pipe is easily deployed and can be reeled back in once transfer is completed. This eliminates the need for fixed pipeline infrastructure, reducing cost, manpower and time.

Fluid is transported through the inner pipe, and the annulus between the outer and the inner pipe is vacuum insulated. This means that the transfer of environmental heat to the fluid is reduced, similar to a thermos flask.

It is also an important safety consideration that the fluid is contained in two pipes. In the unlikely scenario that leakage occurs in the inner pipe, the outer containment pipe

prevents spillage into the environment.

Flexwell Safety Pipe is another key offering from Elaflex. This flexible, double walled pipe system is designed for the underground transport of flammable, water hazardous fluids. It can be used as a suction or positive pressure supply pipe, and thanks to its unique construction, can be permanently monitored by means of leak detectors that are also supplied by Elaflex and SGB Leak Detection, part of the Elaflex Group.

Flexwell Safety Pipe can be laid directly into the trench in one piece either overground in a trace or inside of buildings. The unique corrugated pipe design ensures excellent flexibility, allowing it to be bent through tight radii. The intelligent design also allows the pipe to be cut to required length on site, or laid endlessly depending on a project’s requirements.

Expansion joints are another pillar of Elaflex’s offering. These components ensure safe and stable connections between pipelines and infrastructure, such as treatment plants or power facilities, by absorbing axial movement that could otherwise cause damage. Elaflex

stocks expansion joints up to three metres in length, with larger sizes available through its partner company Ditec.

Ditec’s approach to manufacturing is rigorous and precise. Its expansion joints aren’t produced en masse from a production line but are each handmade, allowing the company to alter its standard models to suit custom orders and deliver premium quality.

“Ditec is one of the very few manufactures in the world that can make expansion joints for round, rectangular, oval, or other designs, for high pressure applications up to DN5000,” Iglic said.

“Ditec has supplied expansion joints to water and energy projects all over the world –even in nuclear facilities, and that’s a very difficult certification to get.”

It’s precisely this marriage of artisanal craftsmanship, rigorous engineering and far‑reaching global capability that has cemented Elaflex’s place in the pipeline industry.

In Iglic’s words: “You can be sure that when you’re going to Elaflex, you’re dealing with high quality and reliable equipment.”

With its rapid rise in less than a decade, Pro Pipe Services has positioned itself as an indispensable force in Australia’s transmission and distribution pipeline landscape.

Operating nationwide, and even reaching Papua New Guinea, Pro Pipe Services has earned its place through mastery of hot tapping, line isolation, and cutting-edge pipeline interventions that keep critical infrastructure flowing without a hitch.

At the heart of Pro Pipe’s offering are its hot tapping and line isolation services across gas, oil, water, slurry, biogas, and just about anything else that goes into a pipe. These capabilities span from smaller distribution pipelines, all the way up to high-pressure Class 600 pipelines, and pipelines in sizes up to 42-inches. These capabilities give Pro Pipe a significant scope within Australia’s infrastructure sector.

Pro Pipe Director and Owner Joe Buttigieg told The Australian Pipeliner about a few of the more memorable jobs.

“In 2023 we were engaged by one of Australia’s major pipeline operators to remove two 34-inch Class 600 LOCK-O-RING plugs, installed over 46 years ago on the Moomba to Wilton pipeline,” he said.