INDUSTRY ON SHOW

The highly anticipated Contractor

Capability Showcase returns

SLIP, SLOP, SLAP

A road surface treatment has been described as the sunscreen of the roads sector

The highly anticipated Contractor

Capability Showcase returns

A road surface treatment has been described as the sunscreen of the roads sector

New technology is helping to improve the blending of road base and recycled products

VÖGELE SUPER 1700-3(i) / SUPER 1703-3(i)

VÖGELE SUPER 2000-3(i) / SUPER 2003-3(i)

The number one paver manufacturer on the global market presents innovative “Dash 3” pavers and screeds for Australia. Equipped with state-of-the-art Cummins engines available in either Tier 3 or Tier 4 Final / Euro Stage V emission standards, are the perfect choice for any application in the Universal (2.5m) and Highway (3.0m) paver classes. Thanks to the easy-tounderstand ErgoPlus 3 operating system which is common across all VÖGELE products both paver and screed operators can handle all VÖGELE pavers simply and safely. These machines are also available with vibrating screeds or high compaction tamping & vibrating screeds for those critical jobs. In combination with advanced optional features, such as VÖGELE EcoPlus, AutoSet Plus and Navitronic Plus 3D, these models are the stars of any road construction site.

www.wirtgen-group.com/australia

6 Embrace the evolution

Crusher Screen Sales & Hire is helping to introduce the next generation of technology for the blending of recycled products for road base production.

9 Time to protect Komobility is offering innovative material science technology that’s already proven to perform internationally.

12 Making what matters, possible Kennards hire is committed to delivering optimal and sustainable outcomes for projects of all sizes.

15 Partnership makes perfect Wirtgen machinery has connected multiple businesses, recently acquired and working in conjunction, leading to improved project outcomes.

18 Reaching new heights

A new component from Caterpillar increases performance, lowers total cost of ownership and improves drawbar durability, all in one.

22 Forging the future

Lintec & Linnhoff’s Concrete Batching Plants have made it big overseas. Now, the Australian market is getting its hands on them.

24 Honing in on bitumen tankers

Byford Equipment has a long held and celebrated foothold in the bitumen tanker market, as its customers can attest.

27 Connected through Geotab

We learn about the future of data and communication capture in Australia, and what this technology has in store for the transport sector.

30 A satisfied shire

With limited resources and funding, a small council has made a worthwhile investment for its transport data needs.

33 Your guide to industry

Roads & Infrastructure has proudly brought back the Contractor Capabilities Showcase for 2025.

49 Fit for purpose carbon reduction

SAMI Bitumen Technologies has been welcomed by the road industry as a positive force, focused on sustainability.

51 Seeing eye to eye

The Australian Flexible Pavement Association is proudly partnering with Converge.

55 Sustainable urban mobility

Sydney’s commitment to a greener future has been demonstrated through the use of innovative precast concrete solutions.

58 Roads & Infrastructure provides an update on some of the contracts and tenders recently awarded or put to market across the Australian infrastructure sector.

Learn about the latest equipment, treatments and initiatives from across the roads and transport sectors, in this edition of Roads & Infrastructure magazine.

100%

Premium,

10 integral easily accessible tie-down points make the transportation process safer and quicker

COST EFFECTIVE

500-hour Dig-End greasing intervals to reduce regular downtime

EASY TO SERVICE

Swing-out counterweight provides unrivalled and easy service access

THE INFRASTRUCTURE AND TRANSPORT project pipeline is heating up!

The past month or so has seen a major influx of funding announcements, as we near State and Federal elections, providing greater security and confidence for many infrastructure projects across the country.

This has given new life to projects, such as the controversial Melbourne Airport Rail, as well as further bolstering ongoing works to the Western Freeway, Tasman Highway and the Suburban Road Blitz in Melbourne, just to name a few.

However, for those who use regional and rural roads to access work, education and more, this funding may mean very little. There’s a lot more work required to increase the standard of roads around the country, not just for the major and eye-catching infrastructure projects.

That being said, there’s plenty of positives to focus on.

In order to better protect roads across the country, Komobility Roads has developed what its creators dub ‘sunscreen for roads’, a non-emulsion protective layer or additive that helps to protect road surfaces from some of the leading causes of road deterioration – ultraviolet rays and water.

To further assist in the delivery of infrastructure and transport projects, and to also make it easier to support Australian business, Roads & Infrastructure magazine has brought back the Contractor Capabilities Showcase for 2025.

Delivered in partnership with the Australian Flexible Pavement Association (AfPA) and sponsored by SAMI Bitumen Technologies, the showcase serves as a valuable resource for asset managers, road owners and governments to easily find contractors for specific sectors of road construction across Australia. If you’re looking for specialists in asphalt paving, soil stabilisation, spray sealing, all of the above and more, then this is the resource for you.

Also in this edition, we hear once again how the use of road data sensors and AI technology is making road maintenance a much easier, cheaper and more efficient process, particularly for councils facing funding and resource restrictions. Technologies like this are maximising the sector’s impact in maintaining essential transport corridors across Australia.

Get ready to discover this and so much more, in the April edition of Roads & Infrastructure magazine!

Happy reading!

Tom O’Keane

COO Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey

ART DIRECTOR Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Brad Marshall brad.marshall@primecreative.com.au

CLIENT SUCCESS MANAGER Isabella Fulford isabella.fulford@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COVER IMAGE

Crusher Screen Sales & Hire

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

CRUSHER SCREEN SALES & HIRE’S (CSSH) NEW IMS PM1200-20TB TRACK PUGMILL IS HELPING TO INTRODUCE THE NEXT GENERATION OF TECHNOLOGY FOR THE BLENDING OF RECYCLED PRODUCTS FOR ROAD BASE PRODUCTION. CSSH MANAGER JOHN ANDERSEN PROVIDES A PEEK BEHIND THE CURTAIN.

Crusher Screen Sales & Hire (CSSH) is a growing name within the quarry and earthmoving sectors.

As the IMS (Irish Manufacturers) distributors for Australia, CSSH has also caught the eye of many within the roads and transport sectors, with its portfolio of equipment and plant helping to make a difference in the very foundation of Australia’s’ transport network.

As CSSH Manager John Andersen explains, the company and its latest track pugmill have made a splash, thanks to high precision material processing.

“Both CSSH and IMS have worked together to create pugmills and blenders suitable for Australian conditions, as well as the changing requirements for blended material in the

quarry, construction and mining industry,” Andersen says.

He says CSSH’s products also help to maximise quality and accuracy for blends, making it easier to satisfy road construction requirements outlined for the development of road base.

“Some quarries have difficulty meeting road base standards without blending fines into the product,” he says. “There is also increased use in the industry of blending recycled products into virgin quarry products in order to reduce the amount of raw material being used, reduce the amount of waste being taken to landfill and reduce the amount of transport movements on the road.”

CSSH works closely with IMS to develop

pugmills and blenders, along with other plant, for the Australian market. A lot has changed since CSSH introduced the first IMS-PM105016TB Track Pugmill to the market back in 2014. Since then, the PM1050-16TB has been providing accurate blended material on major infrastructure projects Australia-wide, offering reliability and consistency.

The new PM1200-20TB is not a replacement for the PM1050-16TB. Rather, it’s an evolution that’s been achieved off the back of ten years’ experience in the blending industry, as well as changing requirements from market and industry.

“The new IMS PM1200-20TB track pugmill has two five-metre-long feed hoppers holding 10 cubic metres each, with separate hopper conveyors fitted with belt scales enabling the blending of two products with accuracy,” Andersen says.

“The pugmill has the option of one or two powder hoppers and the ability to add two liquids. This is fully automated with a PLC (Programmable Logic Controller) and recording system that can be operated with an iPad in a loader or site office.”

Andersen says the ability of the IMSPM1200-20TB pugmills to blend two raw materials with the option of adding two powders and liquids has made the unit a hit with the market.

Thanks to joint design and development between IMS and CSSH, the plant maintains simplicity without compromising on features. The same goes for the PLC control and

recording system developed and maintained in Australia, offering the ability to change the function of the unit, depending on client requirements.

The Australian designed PLC, with a full reporting program, shows the percentages of each product used, along with a supporting graph for each batch and will auto stop if the blend is not making the programmed percentages. It will also give daily totals of all the different products used for the day, aiding the management and ordering of materials.

Alongside the IMS PM1200-20TB pugmill, IMS and CSSH has released the new BP1200-48TB track blender.

Powered by a Cat C7 Generator, which can be connected to mains power, the blender has four five-metre-long feed hoppers all holding 12 cubic metres each, that can also operate in conjunction with the pugmills.

“The IMS – BP1200-9TB is a track twin hopper blender with a mixer and the ability to add a small percentage of alternative materials for the likes of road base,” Andersen says.

The BP1200-914S twin feed hopper blender is on six jacking legs that a 2.5 metres wide drop deck can back under for transporting. The electric gear drive motors ensure constant flow, with variable speed

invertors and front of hopper adjustable flow gate that can be altered depending on product parameters.

The unit also comes with a remote stop and start, and feed hopper sensors can be fitted to stop and start the conveyors as well. Additionally, both feed hopper conveyors can be fitted with belt scales and PLC control and recording systems. The BP1200-914S can also operate with a IMS electric modular pugmill and radial stacker that offers four feed hoppers.

Andersen says innovation from both IMS and CSSH has resulted in a product range that’s interconnected and constantly

reviewable. He adds that he’s looking forward to the future growth of CSSH’s innovation across its product portfolio, and the growth of its standing in the Australian market.

“These machines also offer great serviceability, and the improved PLC control and recording system that can be monitored from an office and our service department increases both safety and ease of maintenance,” Andersen says.

“There are just some of the options developed and maintained in Australia, offering the ability to change the functions for whatever the industry throws at our customers.”

KOMOBILITY AIMS TO CHANGE THE SUSTAINABLE ROAD SOLUTION LANDSCAPE, LEANING AWAY FROM EMULSIONBASED SOLUTIONS, AND INSTEAD OFFERING INNOVATIVE MATERIAL SCIENCE TECHNOLOGY THAT’S ALREADY PROVEN INTERNATIONALLY.

According to the Bureau of Infrastructure and Transport Research Economics, federal, state, territory and local governments spend about $30 billion annually on the maintenance, upgrade and expansion of Australia’s 875,000-kilometre road network.

Despite less than half of these roads being sealed, repairs for asphalt surfaces still take up a great deal of available cost and time, across all levels of government.

Komobility, a sustainable solution provider for road maintenance, has recognised that current methods and treatments aren’t enough.

It’s why the company’s messaging focuses on the need to ‘sunscreen our roads’. So, what does sunscreen have to do with roads?

Danny Nadri, Managing Director –Komobility, believes that similar to our skin, roads should be protected against potential damage by the sun and UV (ultraviolet) rays, rather than waiting for an operation for treatment.

“When it comes to our skin, we don’t just wait for a skin cancer operation. We apply preventative methods, like sunscreen, to prevent that damage from happening in the first place,” he says.

“Traditional road builds are doomed to fail, it doesn’t matter how good you build it, because of the sun. UV rays go into the surface and can start to oxidise road layers, causing microscopic cracks. This can lead to water penetration, erosion and ultimately deterioration.”

Using innovative material science as its building block, Komobility has developed a variety of solutions, all of which are coldbased, that differ from current emulsioncentric remedies.

“Every single one of our products was designed primarily with sustainability in mind,” Nadri says. “Everything we do is cold, reducing the energy consumption and emitting of CO 2 (carbon dioxide)

emissions required to use our products.”

This cold application method is a key differentiator from traditional, hot asphaltbased road maintenance techniques.

Each of Komobility’s offerings also contain at least 70 per cent recycled material, including reclaimed asphalt, reducing the reliance on mining and extracting new raw materials.

Nadri says Komobility’s focus is on developing and delivering a genuine and impactful approach to sustainability in road maintenance.

“By maintaining the road through preventative maintenance, you can save significantly on resources and cost. Our product, KomoRoad, is a one-millimetre liquid that has two main features, the first being its ability to resist harmful UV rays and the second being water resistance,” he says.

“By resisting both of these factors, you’re effectively able to maintain the condition of the road over a longer period of time. This is particularly important in a country like Australia that has a lot of UV and considerable rainfall.”

Komobility’s KomoRoad, or the ‘Road Sunscreen method’, is a single component, black polymeric bitumen compound that acts as a seal and oxidisation preventor for asphalt surfaces. Suitable for roadways, airport runways, bridges, parks and more,

but by providing the technology and teaching the market how to use it and make it their own. We want to bring the best research and development in the world to Australia.”

With an extensive list of applications available internationally, Komobility has also had success breaking into the Australian market.

As an LGP (Local Government Procurement) Approved Contractor, Komobility has already applied products and received certifications from Transport for NSW, Sydney Airport and a variety of mining applications domestically, with more on the way.

The materials have been applied in 50 countries globally, for over 30 years. This includes proven applications in the US, including LAX Airport, as well as Canada, Latin America, Europe, Asia and South Africa.

The KomoRoad Rejuvenator has been found to still be active and performing on a variety of road surfaces, with

“BY MAINTAINING THE ROAD THROUGH PREVENTATIVE MAINTENANCE, YOU CAN SAVE SIGNIFICANTLY ON RESOURCES AND COST. OUR PRODUCT, KOMOROAD, IS A ONE-MILLIMETRE LIQUID THAT HAS TWO MAIN FEATURES, THE FIRST BEING ITS ABILITY TO RESIST HARMFUL UV RAYS AND THE SECOND BEING WATER RESISTANCE.”

this solution can prolong the service life of a surface by an estimated five to seven years.

On top of being resistant to chemicals, salts, acids and UV rays, Komobility’s KomoRoad is dry to touch in less than an hour of application, with the roadway also able to be opened to traffic in less than two hours, thanks to rapid curing.

“The key element is to take a holistic view on road maintenance and say, ‘why don’t we stop spending 10 billion dollars every year?’ Instead, we can do it the right way, straight off the bat,” Nadri says. Moving forward, Komobility aims to work with local Australian companies to manufacture and distribute the products, rather than doing it itself, allowing for customisation and local ownership of the solution. This customisation includes Komobility’s capability to provide each product in different colours for bus lanes, bicycles lanes and parking areas.

“We want to help, not by establishing our own manufacturing capacity in Australia,

some surfaces benefitting 10 years after application in South Africa, Korea and the US.

Each of these products and applications are backed by global patents, as well as the highest testing certification standards from global laboratories.

Nadri says Komobility sees significant potential in the large size of the Australian road maintenance market, and Komobility’s potential of becoming one of the leaders in sustainable road maintenance solutions.

He adds that the first step is advocating for a proactive, preventive maintenance strategy, rather than the reactive, repairfocused approach common in the industry.

“It’s extremely exciting, the prospect of introducing something that’s never existed before into a new market,” Nadri says. “What we’re really looking for is collaboration, so we can influence positive change across the sector.”

Visit komobilityroads.com.au for more information.

KENNARDS HIRE IS MUCH MORE THAN JUST AN EQUIPMENT HIRE PROVIDER; IT’S A CONSTRUCTION PARTNER COMMITTED TO DELIVERING OPTIMAL AND SUSTAINABLE OUTCOMES FOR PROJECTS OF ALL SIZES. NATHAN VENABLES, GENERAL MANAGER, FLEET, EXPLAINS HOW THE COMPANY MAKES THIS POSSIBLE.

Sustainability is the goal, and has been for some time, for the majority of organisations in the infrastructure sector.

While this notion isn’t new, more than ever before is being done across the construction industry, to turn the tide for what is one of the world’s largest carbon emitters on an industry-to-industry basis.

For many companies, a good step is reevaluating the equipment and machinery used on individual project sites where equipment hire plays a significant role.

By using, supporting and offering alternative sustainable solutions such as solar power, hybrid power units, water

recycling, and reusable and modular materials, Kennards Hire is helping to reduce the environmental impact of its own operations, as well as the projects it supports.

Nathan Venables, General Manager, Fleet - Kennards Hire says he’s seen a steep uptake and increase in demand for sustainable solutions, driven by company requirements, international obligations, and the environmental awareness of younger people entering the industry.

It’s just one of the many reasons why the company has invested financially and ethically in equipment and solutions that provide an alternative to

traditional options.

“We understand the environmental, economic, and operational considerations of our customers,” Venables says.

“It’s a space that’s continuing to evolve quickly. It’s an ongoing investment on our end and an area that we’ve explored by going overseas to make sure we’re sourcing the best equipment.”

In addition to its range of conventional equipment, such as earthmoving, landscaping, compaction and materials handling machinery, Kennards Hire also provides a bespoke range, developed for the modern needs of infrastructure and construction projects.

“We’ve got more equipment than you might realise – including modular and reusable building components, such as modular decking, made from recycled products that can aid access and safety on-site.”

Kennards Hire also has a variety of solar portable buildings and facilities, as well as water capture and recycling systems, all able to be supported by hybrid power units and battery-powered units.

This is on top of complementary services on offer, such as water supply, test tagging and certification, site cleaning, security services, as well as consumables and personal protective equipment (PPE). But sometimes, tier one, tier two and other construction contractors require more than just equipment services.

“Having a dedicated service segment – Kennards Hire Major Projects (KMP) –provides just that, for major infrastructure projects across Australia and New Zealand,” Venables says.

“We have our own project managers, a single point of contact for each of these sites. Our KMP managers will work one or two days on the project site, or in some cases even full-time, offering a single contact point, for whatever our customers need.

“They’re very familiar with the workings of the site, the scope of works and the forward works. That enables our project managers to suggest the most effective equipment available, even assisting with installation if needed. It’s all about taking away the pain and potential frustration

that could be faced on those jobs.”

The success and growth of this offering has opened the door for Kennards Hire to expand its site portfolio and capabilities, reflected by the company’s growing list of completed projects.

“We’re working on nearly all of the different types of major projects, whether it be roads, rail, tunnels or airports,” Venables says. “We’re also doing a lot in the renewables space, such as solar farms, wind farms, battery systems and more that are being built across the country.”

This includes projects such as the

Metro Tunnel in Melbourne, Western Sydney Airport, the Golden Plains wind farm and the Fitzroy River Bridge rebuild in Western Australia, just to name a few.

Strategic and sustained expansion has also seen the company advance beyond Australian shores since entering New Zealand in 2012.

“We’ve got 33 projects in New Zealand, which is just getting started in the solar farm space, so we’ve been engaged to support some of these including the Lauriston Solar Farm in Christchurch and Ta Rahul Solar Farm in Taupo,” Venables says.

He says that despite the growing success of Kennards Hire’s equipment and service solutions, the company continues to expand into new solutionfocused areas.

“There are many opportunities beyond just burning less diesel. Water for example is a big opportunity, which is why we’ve acquired the ability to capture and recycle water that would otherwise be runoff,” he says. “Waste is still a concern in the construction space, so we’re looking at ways that we might be able to work and partner with organisations to reduce the volume of waste and look at other ways that we can recycle and reuse these materials.”

Kennards Hire is also investigating the use of sustainable reporting, which can currently be collated upon request by the customer, offering users unprecedented access to equipment performance and outcomes.

Metrics like these can be used to satisfy contract requirements, as well as internal sustainability goals. Just one of many areas that Kennards Hire will look to further develop in the future.

“There’s still growth to come, both in terms of the number of locations we have in the country and New Zealand, as well as looking to invest in new products and increase service capability for our customers,” Venables says.

Kennards Hire’s commitment to innovation in sustainable equipment is not just about keeping pace with industry change – it’s about leading the way. By continuously investing in alternative solutions, expanding service capabilities, and partnering with customers to reduce environmental impact, the company is making sustainability an achievable reality for construction projects of all sizes.

Astec revolutionised the paving industry with the introduction of the Shuttle Buggy, and now the SB-3000 sets a new standard in material transfer vehicles. Effortless maintenance, unmatched performance, and four steering modes for ultimate agility to keep paving seamless. Experience groundbreaking innovation with the patented Ground Crew Control Station for the ultimate user experience and protection. The SB-3000 isn’t a machine, it’s a revolution in material transfer, built on Astec’s legacy of industry firsts.

AUSTEK ROADS AND CAPITAL ASPHALT – RECENTLY ACQUIRED MEMBERS OF MAAS GROUP HOLDINGS (MAAS GROUP) – HAVE LONG BEEN WIRTGEN GROUP CUSTOMERS, BENEFITTING FROM DECADES OF TECHNOLOGICAL INNOVATION AND IMPROVEMENT ACROSS THE COMPANY’S EXPANDING ROAD CONSTRUCTION MACHINERY PORTFOLIO.

Industry challenges have been no barrier for Austek Roads, an Australian owned and operated asphalt company that’s maintained a positive trajectory from its roots in Queensland.

With its services encompassing asphalt, spray sealing, as well as road preservation and rehabilitation, Austek has slowly but surely cemented its name among the leaders of road services in the region.

One of Austek’s major milestones has been its successful acquisition by Maas Group, an ASX-listed Australian industrial service and real estate business with diversified exposure across the property, civil, infrastructure and mining sectors.

Peter Ozoux, Austek Managing Director says both companies see eye-to-eye when it comes to values and vision.

“Both Maas Group and Austek Roads are proudly Australian owned and operated,”

he says. “As the CEO and Managing Director, Wes [Maas] has built and grown the company himself. That vision that he holds for the future is something that really identifies with us on a corporate level.

“For us, it really opens new doors in terms of capability. It’s only going to enable us to better deliver on our existing projects and services.”

Similar to Maas Group, Austek Roads was founded with just one bobcat and tipper truck. As such, an integral aspect to the growth of both companies has been significant investments being made in both plant and machinery.

Ozoux says Austek wouldn’t be in the position it’s in today if it weren’t for the assistance and support of the Wirtgen Group.

Beginning close to ten years ago, the relationship between the machinery and plant

manufacturer and Austek has grown stronger every year, and with each machinery purchase.

The first unit Austek acquired from Wirtgen Group was a VÖGELE paver. Ozoux says Austek now has more than 100 Wirtgen Group units across its machinery fleet, a testament to the company’s strong trust and belief in the globally renowned manufacturer.

“From our perspective, Wirtgen Group machinery is best in class,” he says. “We’ve virtually got at least one unit from across their entire machinery offering, including Wirtgen profilers, VÖGELE pavers, Hamm rollers, Kleemann crushers and Benninghoven asphalt plants.

“The technology and support that they’re able to provide has really stood out and continues to do so, to this day.”

Among the largest plant and equipment in Austek’s fleet is the ECO 3000 asphalt plant from BENNINGHOVEN. Able to cater for cold

Wirtgen can provide a full suite of machinery options, from rollers and pavers, to asphalt plants and profilers.

and hot recycling, while delivering quality asphalt production, the ECO 3000 has enabled Austek to achieve more sustainable outcomes for its clientele.

“By being able to produce and apply sustainable alternatives, we’ve been able to better align our principles and values with our customers, while delivering on what we’ve promised,” Ozoux says.

“That’s why we’re also looking into Wirtgen Group’s electric pavers and rollers, to see if we can further bolster our business from a sustainability standpoint.”

Capital Asphalt, a newly acquired business

“Having Capital Asphalt come onboard means we’ve got a greater combined capability, especially with the two asphalt plants in different locations,” says Ozoux. “It’s really going to broaden our horizons in terms of the scope and volume of works that we’ll be able to deliver.

“Especially with us having more than 200 employees across both businesses. We’re really looking forward to working in conjunction with Capital Asphalt moving forward.”

On top of providing “best in class” machinery, Wirtgen Group has also played an impactful role in broadening Austek Roads’

have helped the company and its operators to better understand how to optimise their Wirtgen Group machinery, while also opening their eyes to the technology and methods being used internationally.

“We try to do an annual refresher with our crews by having Wirtgen staff take them through our units and talk them through different applications and scenarios,” Ozoux says. “Since we’ve started that, from our supervisors, right down to our ground crews, I’ve definitely seen an improvement in terms of the mat laid and the quality of the project overall.”

Ozoux says parts and maintenance are also a “breeze”, with Wirtgen’s support facility situated only five kilometres from Austek Roads’ headquarters on the Gold Coast.

With an established network of sites around Queensland, strong backup service and equipment from Wirtgen, as well as its strong sense of partnership among its fellow subsidiaries within the Maas Group, Austek Roads is planning on continuing its path of “aggressive expansion.”

Ozoux says it’s this notion that really excites him moving forward.

“Maas Group is in such a great place, and with the opportunities that we’ve already had, I can see us only getting bigger and better,” he says.

“That’s why we’re attending events such as Bauma 2025 and contributing to projects such

SRE’s new fixed wing sprayer is available for delivery for the 2025/26 spray season. Fully compliant with all Australian regulations the sprayer meets all Austroads performance requirements for bitumen sprayers.

Through the years, Caterpillar has revolutionised the operation of motor graders with the introduction of joystick controls and a suite of advanced machine control and technology solutions, delivering enhanced operability and productivity.

Caterpillar Product Specialist, Darren Hodge says the new High-Performance Circle (HPC) option is yet another innovation from the globally renowned equipment manufacturer that’s sparked excitement from owners and operators around the world.

“Before we get into Caterpillar’s new HPC introduction, let’s look back at traditional Motor Grader design and past developments that led us to this new innovation,” Hodge says.

“As we know, Motor Graders spread and shape materials to a curvature and elevation design typically in road construction and maintenance. The drawbar, circle and moldboard (DCM) is the prime work tool to complete these works.”

The DCM has many linkages and moving parts to position it in a multitude of positions for precision grading.

The DCM can be lifted and lowered to control blade finish elevation. The blade can also slide left to right for greater reach, while also being able to be tilted fore and aft to assist the material rolling action, for easier spreading.

The main drawbar pivots within the main frame for greater reach in cutting ditches and side/high bank slopes. The circle can be rotated to maintain a desired blade angle of up to 360 degrees, but typically 0 to 50 degrees, depending on blade loads.

“In all, there are up to 10 linkages, ball joints, couplings, sliding surfaces and

gears to complete these operations, which all require wear tolerance maintenance, consuming expensive time, labour and parts to maintain,” Hodge says.

“A well-maintained DCM structure will ensure long life and durability of the components and ensure wear between parts is kept to a minimum, ensuring blade elevation position remains stable for accurate surface elevation finish.

“If left unmaintained the DCM can be

a costly assembly to repair, and reduced lifetime of components is expected.

Wear between linkages, slides and gears left unmaintained results in blade chatter, uncontrolled horizontal and vertical movement of the blade.”

Operators are expected to meet road construction design tolerances for curvature and elevation finish within five millimetres to 15 millimetres, error to specifications. With a worn DCM, the blade chatter can be actually greater

than 10 millimetres of blade movement, making it very difficult to meet design requirements efficiently.

“Fortunately, the Caterpillar Motor Grader DCM linkage design makes work a little easier to maintain this structure,” Hodge says.

“All these moving, sliding components can be easily adjusted to maintain a tight tolerance between moving surfaces and all the components include exclusive low-cost sacrificial wear strips, preventing costly parent metal wear out of the ball joints and sliding surface.”

Hodge adds that the traditional Cat design has been “the leader” in providing the lowest cost of operation for the DCM.

“Our G and H Series Motor Graders have shoes that carry the circle within the drawbar and allow for 360-degree rotation by a circle drive pinion and inner circle teeth,” he says.

“To maintain this structure once worn with movement between, circle gear shoes and drawbar assembly required extensive heavy labour under the DCM to

remove supporting shoes, maintain shim thickness and adjust thumb screws.

“This much-needed maintenance reduces wear between the horizontal drawbar and or circle surface. As well as between the circle and drawbar, to ensure smooth meshing of drive pinion and circle gears.”

Sacrificial wear strips are located between the circle shoes and inner drawbar, and between the horizontal rotating surface of the drawbar and circle, requiring periodical replacement when worn beyond reuse guidelines. With these repairs the grader could spend days in the workshop just to maintain this structure, resulting in a lot of downtime and costly labour and parts. With the introduction of the M Series grader, this structure was re-designed to significantly lower the time required

for adjustment and replacement of wear strips. Called the top-adjust, this drawbar was an exclusive design where the adjustment for wear between the circle and drawbar and replacement of wear strips could easily be maintained from the top of drawbar assembly, saving up to 70 per cent in time and labour costs.

“That’s set to get even better, with the introduction of Caterpillar’s new HPC,” Hodge says.

The HPC design improves machine performance, efficiency, and uptime through increased service intervals and longer life. Meeting grade elevation tolerance in road design efficiently is important to reduce rework on the job. With the HPC, operators have greater confidence in meeting grade elevation tolerance design due to reduced wear between circle and drawbar.

The HPC helps to eliminate hours of monthly planned maintenance for frequent inspection, wear strip replacement and circle shoe adjustments associated with conventional circles. The new design includes increased circle torque, performance, and improved durability advantages, providing a smooth, effortless rotation of blade, further assisting operators to meet road design elevation tolerance.

“With thousands of hours of testing before introduction, the proven design for Motor Graders can reduce service and labour time costs by up to 40 per cent when compared to the previous models,” Hodge says.

The design includes already proven

structures and components with the heavy-duty drive system, adopted from the Cat Excavator swing drive and grader worm drive from the Cat 14 Motor. A fully sealed bearing design replaces the open circle and drawbar, reducing maintenance touchpoints, removing exposure to abrasive materials during grading and increasing service intervals and machine uptime. A centrally located grease bank is easily reached to the lubricate circle ring and drive gear assembly.

A readily accessible cover can be removed for periodic wear inspection

customers using 3D Grade Technology, to reach fine elevation design tolerances in road construction. Although Grade technology can efficiently support the operator maintaining within 5-15 millimetres elevation design tolerance, as I mentioned previously, a traditional DCM design can have greater than 10 millimetres of horizontal blade movement if not maintained frequently,” Hodge says.

“It’s near impossible to achieve road design finish specifications accurately and efficiently with a worn DCM. As such,

“WITH THOUSANDS OF HOURS OF TESTING BEFORE INTRODUCTION, THE PROVEN DESIGN FOR MOTOR GRADERS CAN REDUCE SERVICE AND LABOUR TIME COSTS BY UP TO 40 PER CENT WHEN COMPARED TO THE PREVIOUS MODELS.”

of circle ring and once worn (likely after thousands of hours), the split ring can be rotated to get an extended replacement interval.

“We expect that within the grader’s first period of ownership, it’s unlikely the swing drive ring replacement will be required, as it is fully sealed, preventing abrasive soil materials in wearing out the components, compared to traditional designs.” Hodge says.

The traditional circle shoes and drawbar to circle adjustment and wear strip replacement are gone, a real winner from backbreaking labour experienced by mechanics.

“The HPC will be a winner with

the new low maintenance HPC design will be a delighter for owners, operators and maintenance personnel.

“3D Grade technology attachments can cost upwards of $100,000, a big investment for owners. But when used to complete road construction with automated controls to finish within tight design tolerances, the job is completed so much more efficiently and accurate saving thousands of dollars in fuel, labour and machine costs.

“The new HPC will enhance the use of Grade Technology saving the customer even more money.”

Make sure to contact a local Cat dealer to learn more.

Lintec & Linnhoff has a range of Concrete Batching Plants that have supported works on major projects in several countries.

LINTEC & LINNHOFF’S CONCRETE BATCHING PLANTS ARE WELL PLACED TO AID THE FUTURE OF AUSTRALIAN INFRASTRUCTURE.

Lintec & Linnhoff is at the forefront of providing solutions to Australia’s infrastructure needs, with concrete batching plants engineered to meet the rigorous demands of Australian road projects.

These plants deliver the efficiency and reliability needed to produce consistently high-quality concrete, even in the most challenging environments.

In January 2024, Lintec & Linnhoff signed a distributor agreement with construction equipment suppliers Tutt Bryant, to strengthen its commitment to the Australian market.

In its year of operations, Tutt Bryant has distributed Lintec & Linnhoff’s full range of asphalt mixing and concrete batching plants to meet Australia’s unique construction needs.

Alan Ong, General Sales Manager for

Lintec & Linnhoff, says the concrete batching plants are engineered for maximum efficiency, reliability, and adaptability.

“With modular designs, rapid deployment capabilities, and precision batching technology, our solutions help contractors reduce setup time, minimise downtime, and ensure consistent concrete quality. These are key factors in delivering successful infrastructure projects,” he says.

“Through our partnership with Tutt Bryant, we are making these highperformance solutions more accessible than ever to Australian contractors, reinforcing our commitment to supporting the nation’s infrastructure growth.”

REAL WORLD IMPACT

Lintec & Linnhoff’s Concrete Batching Plants have successfully delivered several projects across the globe.

These include the Malolos-Clark Railway Project in the Philippines, where two Lintec ECP60 Concrete Batching Plants were installed.

The plants supported work on a 16 kilometre section of railway which provided the first rail link to connect major

cities in the Central Luzon region with Clark International Airport (CRK).

In Madagascar, two Lintec ECP60 Concrete Batching Plants supported the redevelopment of the Toamasina Port Development Project, the largest commercial port in the country.

Other works include the Lintec UCP120 Concrete Batching Plant and Lintec Flake Ice Plant installed in Malaysia.

These were pivotal in producing highquality concrete for the landmark Merdeka 118, the tallest building in Southeast Asia, and the second tallest in the world.

The design of the Lintec UCP120 was specially customised to meet the space constraints of the downtown site, featuring modifications to enhance its efficiency.

Lintec & Linnhoff Concrete Batching Plants have supported works on other major projects in Sri Lanka, India, Kenya, Nigeria, Mali, Singapore Algeria, Saudi, UAE and Taiwan.

These successful projects showcase Lintec & Linnhoff’s ability to deliver reliable, high-performance concrete batching solutions across diverse environments, capabilities that are available to support Australia’s infrastructure needs.

Lintec & Linnhoff offers a broad range of concrete batching plants designed for efficiency, reliability, and adaptability across various infrastructure projects.

A cost-effective, modular solution ideal for small to mid-sized construction projects, the ECP Batching Plant series is designed for fast installation with minimal foundation requirements, reducing setup costs and ensuring quick deployment.

Equipped with high-performance twinshaft mixers, it guarantees consistent concrete production with European-

manufactured components.

The Lintec MBQ MobiQuick Concrete Batching Plant is designed for projects that require flexibility, this mobile batching plant enables on-site production of fresh concrete.

It is ideal for short-term projects and frequent relocation, it minimises site preparation costs and maximises efficiency.

The PCP Portable Concrete Batching Plant series offers a skid-mounted design for rapid deployment, without the need for permanent foundations. It is ideal for infrastructure projects requiring high-volume concrete production with minimal downtime.

With output capacities of up to 250 cubic meters per hour, the UCP Ultra Concrete Batching Plant series ensures precise batching and superior concrete quality.

The high-capacity solution is suitable for large-scale infrastructure projects.

The future of Australia’s road infrastructure is undergoing a significant transformation, driven by large-scale

investments and strategic projects. These are aimed at enhancing connectivity, reducing congestion, and supporting economic growth.

Major developments like Sydney’s WestConnex and Melbourne’s North East Link and long-awaited Melbourne Airport Rail Link demonstrate Australia’s move in addressing critical transport challenges while preparing for future demand.

Lintec & Linnhoff says looking ahead, the outlook for road infrastructure in Australia remains promising, with continued government funding and private sector collaboration shaping the next phase of development.

As Australia’s cities expand and demands rise, the strategic integration of new road projects with public transport and emerging mobility solutions will be key to ensuring long-term efficiency and economic prosperity.

Ong says Australia’s ambitious infrastructure projects require concrete batching solutions that offer efficiency, mobility, and durability.

“Our advanced plants are designed to meet these challenges head-on, ensuring contractors have the right technology to deliver high-quality concrete consistently, even in the most demanding conditions,” he says.

Lintec & Linnhoff’s advanced concrete batching solutions aim to ensure Australian infrastructure projects meet the highest industry standards.

With the support of Tutt Bryant, these cutting-edge plants are now more accessible than ever to Australian contractors looking for efficient, reliable, and high-performance concrete production solutions.

RELIABLE TRANSPORT SOLUTIONS ARE ESSENTIAL TO KEEPING AUSTRALIA’S INFRASTRUCTURE RUNNING. FOR NEARLY 50 YEARS, BYFORD EQUIPMENT HAS BEEN AT THE FOREFRONT OF STAINLESS-STEEL TANKER INNOVATION, DELIVERING TRUSTED EQUIPMENT ACROSS VITAL INDUSTRIES.

Founded in 1976 as a milk transport tanker repair service, Byford Equipment has continuously evolved to meet industry demands.

After building its first new milk tanker in 1984, the company continued to innovate, introducing its first bitumen tanker in 2011.

In 2023, Byford Equipment expanded its bitumen tanker operations in EchucaMoama, further strengthening its presence while maintaining its expertise in stainless-steel transport.

Today, Byford’s portfolio extends beyond milk, food and bitumen, catering to the civil infrastructure industry with a range of specialised tankers, including water and liquid waste transport solutions.

Belinda Byford, General Manager for Byford Equipment, says strengthening the company’s capabilities in industryfocused tankers was a result of evolving market demands and a commitment to diversifying its expertise.

“The bitumen tanker industry offers unique opportunities, so we felt it was a suitable market to transition into,” she says.

“After starting out in the food industry almost 50 years ago, we felt it was natural to progress into other markets.”

Byford says the shift has allowed the business to leverage its expertise

Fulton Hogan’s 25 metre B-Double and 30 metre A-Double bitumen combination.

in custom manufacturing across multiple sectors.

“Our operations ensure we deliver high quality, specialised and durable tankers that meet the rigorous demands of the bitumen industry,” she says.

“Beyond bitumen, we’ve also expanded our offerings to include water tankers for roadworks, dust suppression, and emergency services, as well as liquid waste tankers essential for waste management and environmental operations.”

Byford Equipment’s water tankers are designed for efficient water delivery in civil construction, road maintenance, and large-scale projects. Meanwhile, liquid waste tankers are built to support the increasing demand for waste removal and environmental services.

“Over the years we have built working relationships with many customers enquiring after bitumen tankers, but also those requiring custom solutions for other civil applications,” says Byford.

“It was a natural step to build on that relationship with them in this next stage.”

Bitumen tankers require a specific set of engineering and design considerations, something Byford Equipment is well equipped to handle.

Built with premium stainless-steel and

advanced insulation, Byford’s bitumen tankers maintain optimal temperature control, reducing heat loss and maximising efficiency.

Recognising the challenges of operating in diverse Australian conditions, the tankers are built to withstand extreme

Fulton Hogan showcases its dedication to collaboration and customerdriven service.

By developing customised bitumen tankers that meet Fulton Hogan’s specific operational needs, Byford ensures reliability in road construction and maintenance, reinforcing its reputation as a trusted supplier of tailored transport solutions for Australia’s critical development projects.

“Most customers stipulate specific requirements for their orders, so the team is dedicated to providing innovative solutions that ensure the safety, efficiency and reliability of the bitumen tankers,” says Byford.

“As a business, we pride ourselves on our

the ones who are using them in rural and remote locations.

“We do this to build something that they are proud of and comfortable operating.”

In the design phase, the Byford Equipment team has incorporated feedback from experienced drivers to ensure an optimal experience.

“This is followed by the early build phase, during which we have the customers come to the facility to assess the tankers and tell us how they want the tanker changed to suit their operations,” says Byford.

“We pride ourselves on altering the equipment to suit the customer, no matter the customisation requirement.”

year in the business, Byford says many have taken time to reflect on the company’s origins.

“Byford first opened its doors repairing farm equipment, so we’re always reminding ourselves of where we came from. It’s an essential aspect of our business,” she says.

“We stand by our product, but we do acknowledge the excellence in our repair and support services.”

After the sale of a tanker, Byford Equipment’s service doesn’t end there. Instead, the company ensures that it can support customers for decades to come.

Matt Sullivan, Sales and Compliance Engineer for Byford Equipment, says Byford’s after-care is second to none.

“We’re very mindful that the transport industry is fast paced, so if our customers have a tanker off the road, it is not ideal,” he says.

“When our customers buy a new tanker, they’re expecting to use it in excess of 20 years, and we emphasise the fact that we can support them for a lifetime of use.”

Whether they’re an existing Byford customer or not, Sullivan says the team will do its best to provide a prompt solution.

“The tankers are a significant investment for our customers, so we want to keep them on the road and operating for as long as possible,” he says.

Looking ahead, Sullivan says the team is excited for the future of Byford Equipment and its continued evolution in delivering high-performance tankers for the transport and civil infrastructure sector.

“We are continuously exploring ways to diversify and expand our range,” he says.

For more information, visit: byfordequipment.com.au

Our cutting-edge Lintec CDP5001M mobile continuous asphalt mixing plant has been engineered for superior performance. The CDP asphalt mixing plant delivers top-quality asphalt quickly and directly at your job site. Say goodbye to transportation delays and hello to seamless, on-the- go operations. Elevate your projects with our innovative solutions and experience true mobility redefined. Your road to success starts here.

The CSM Containerised Asphalt Mixing Plant delivers efficiency, durability, and cost savings. Housed in 100% ISO-certified sea containers, it ensures low transport costs, quick setup, and minimal foundation needs. With precise batch mixing and advanced pollution control and it is also built for security and harsh conditions. The CSM range guarantees reliable, high-performance asphalt production for projects of any scale.

Our dedicated after-sales team located nationwide offers industryleading service for your asphalt mixing and concrete batching plants, ensuring maximum efficiency and reliability, and minimising downtime.

www.lintec-linnhoff.cominfo@lintec-linnhoff.com

DURING FLORIDA CONFERENCE GEOTAB CONNECT, ROADS AND INFRASTRUCTURE SAT DOWN WITH GEOTAB TO DISCUSS THE FUTURE OF DATA AND COMMUNICATIONS IN AUSTRALIA.

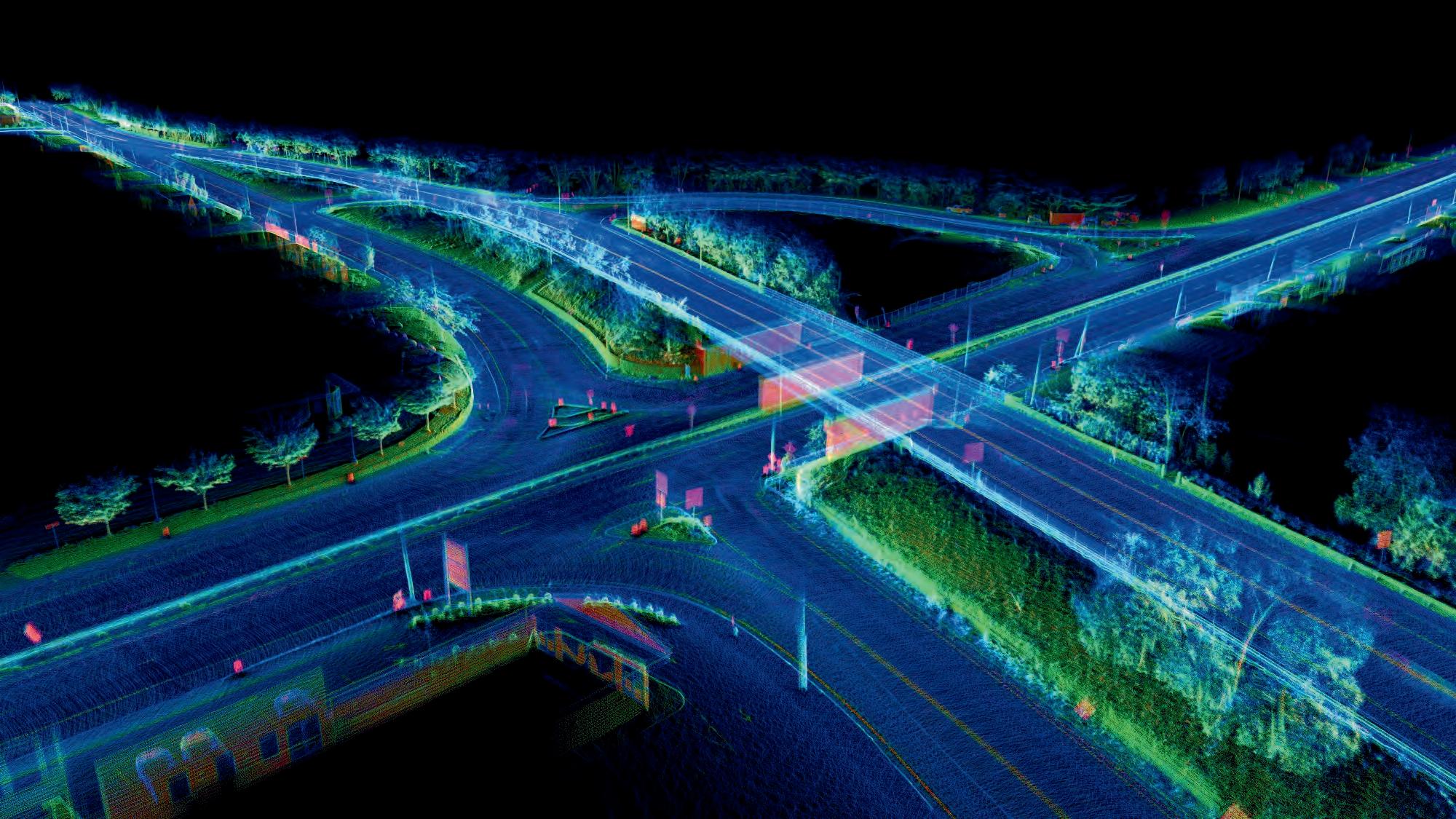

Vehicle-to-infrastructure (V2I) communication transfers information between cars, trucks and buses and traffic signals, lane markings and other smart road infrastructure through a wireless connection.

Geotab Connect, an annual event hosted in Florida by connected transportation solutions providers Geotab returned from 25 to 27 February 2025, drawing telematics and fleet management professionals from around the world.

For more than 20 years, Geotab has invested in ground-breaking data research and innovation to enable partners and customers to transform their fleets and operations. This is on top of providing telematics, vehicle and asset tracking solutions to over 55,000 customers in 160 countries, including Australia.

Connecting to over 4.7 million vehicles and processing more than 80 billion data points a day, Geotab aids its customers in increasing productivity and achieving their sustainability goals.

Over three days, Geotab Connect united industry leaders to explore the future of data-driven mobility, from AI-powered telematics, to innovations designed to make roads safer and fleets more efficient.

The event was also a platform for major announcements, with Geotab outlining its vision for the evolving transport and logistics sector.

Speaking to Roads and Infrastructure , Chris Martin, Senior Manager, Solutions Engineering APAC for Geotab, says just like many other industries, fleets within the roads and infrastructure sector must be utilised as efficiently as possible.

“Often, these are field service fleets which send multiple types of vehicles to construction sites,” he says.

“Whether they are service vehicles transporting people or tools to a job, or

machinery working on the road, all of these vehicles face common challenges.”

These challenges include downtime on machines and significant fuel consumption, both of which translate to increased costs.

“If a machine cannot complete its task, it leads to more traffic control, extended project timelines, and missed deadlines,” he says.

“Fleet management and telematics systems play a critical role in these industries by tracking vehicle activity, identifying potential issues, and ensuring that information reaches the right systems.”

One of those telematics systems is vehicle-to-infrastructure (V2I) communication, a two-way exchange of information between cars, lorries and

buses and traffic signals, lane markings and other smart road infrastructure

Martin says a key factor in advancing V2I communication is ensuring vehicles are connected and generating data to support these systems.

“Traffic management, government planning, and insights into congestion and vehicle types on roads are all crucial from a regional perspective,” says Martin.

One example in Australia is the heavy trucking industry, where connected vehicles provide data to regulatory bodies through programs like Transport Certification Australia (TCA).

Martin says these programs help operators gain better road access by connecting their vehicles, ultimately benefiting both the industry and road managers.

“Operators get improved access, while road authorities gain valuable data to plan budgets, monitor road usage, and prioritise spending,” he says.

“This could mean upgrading a particular bridge or investing in specific road segments, improving productivity for operators and delivering more effective infrastructure planning.”

In addition to productivity being a driving force in the industry, safety is a major priority, and one that businesses are always looking to improve in their operations.

According to the Australian Road Safety Foundation, despite being less populated areas, rural and remote roads accounted for almost two thirds of the 2023 road toll.

Martin says connected vehicle technology has already been in place in rural and remote areas of Australia,

where safety on roads is a priority for the Federal Government.

This technology is not just about vehicle incidents, but also for individual staff members working on isolated environments.

“Someone could arrive at a site and experience a fall or another emergency, and the ability to send an alert is crucial,” says Martin.

“At a commercial fleet level, this technology has been in use for a long time, particularly in industries like mining and oil and gas, where many workers operate in remote areas, sometimes alone.

“The safety benefits are well established for these areas, one example being the use of satellite backhaul. Notifications can be sent when an incident occurs, whether it is a rollover, an impact, or a lone worker pressing a duress button.”

Martin says connected vehicle technology has a huge role in improving safety for remote workers on rural roads, and while it is already in use, advancements in satellite connectivity will make it even more reliable and cost effective.

Another challenge often faced by rural areas across the country is connectivity.

Martin says in populated areas, coverage

connectivity in remote areas.”

Currently, commercial fleet vehicles make up a small portion of the vehicles on the road. Martin says the more that can be connected the better. At the forefront of this, is Geotab with its Altitude platform.

“As more Original Equipment Manufacturers (OEMs) produce vehicles with built-in connectivity, that will help drive adoption,” he says.

“Regulatory frameworks also need to be in place to integrate this data into broader systems.”

Altitude by Geotab provides reliable and contextualised mobility insights for public and commercial sector decision-makers to gain a complete understanding of movements across road networks.

This enables customers to achieve improved planning capabilities as well as better financial outcomes, without the challenge of finding trustworthy and usable data sets.

With 4.7 million vehicles connected and reporting daily, Geotab has an unprecedented dataset to analyse vehicle movements and identify patterns, which Martin says makes Geotab a leader in the connectivity space.

“WE ARE FORTUNATE TO HAVE ACCESS TO SUCH A RICH SOURCE OF INFORMATION AND TO BE ABLE TO USE AI, WHICH PLAYS A KEY ROLE IN THIS. IT IS NOT JUST ABOUT HAVING THE DATA BUT BEING ABLE TO ANALYSE IT AND UNCOVER PATTERNS.”

is generally good, however much of the road network extends into regions with little to no connectivity. From a road and infrastructure perspective, real-time connectivity is important, but it is not always essential.

“Data can still be collected and transmitted once a vehicle returns to coverage. As long as the information reaches the right systems, it remains valuable for planning,” he says.

“For real-time applications, satellite connectivity is an option. New low Earth orbit satellite constellations, such as Starlink, are making this technology more accessible.

“Mobile carriers are also moving towards satellite-based cellular coverage. While it is not fully available yet, it is on the horizon, which will significantly improve

“It is exciting to see how Geotab can leverage its vast data set to provide insights into how road networks are used,” he says.

“We are fortunate to have access to such a rich source of information and to be able to use AI which plays a key role in this. It is not just about having the data but being able to analyse it and uncover patterns.”

Martin says identifying trends in road usage, vehicle movements, and conditions, such as the impact of time of day or weather on certain events, is “incredibly powerful.”

“If we can train models to recognise what a collision looks like and the conditions leading up to it, that has huge potential for improving safety and efficiency,” he says.

WITH LIMITED RESOURCES AND FUNDING, A SMALL COUNCIL IN WESTERN AUSTRALIA ENGAGED CIVILTECH SOLUTIONS FOR ITS CYVL PLATFORM, REALISING A WORTHWHILE INVESTMENT FOR ITS TRANSPORT DATA NEEDS.

Six months ago, the Shire of Broomehill Tambellup, a regional council in Western Australia, started using the services of national civil engineering provider Civiltech Solutions.

Civiltech Solutions deliver innovative and high-quality civil engineering and project delivery services across a range of industries, including local government.

Servicing a range of local government areas (LGAs) like the Shire of Broomehill Tambellup, Civiltech delivers infrastructure knowledge through its road data sensor and platform created by Cyvl.

The Cyvl platform is used to derive roadway information, such as location and condition rating of pavements, signs, kerbing, footpaths signs and line marking.

A single data capture provides many information outputs that can empower local governments to make better decisions about local roads. This includes long-term financial analysis and valuations, upon which specific maintenance activity needs to occur, all of which can be achieved with the one data set.

Leigh Carnall, Founder and Chief Executive Officer, Civiltech Solutions says the partnership with the shire has been an optimal chance to assess the data requirements of small councils.

“There are specific requirements needed by small and regional councils, and in Broomehill Tambellup’s case, there were knowledge gaps that the team were keen to fill,” he says. “We wanted to make sure the data we gave them was fit for

use in its entirety, so if the team needed a particular question answered, we could extract that and give them the exact outputs to make them more effective at their job.”

Carnall says he hopes councils Australia-wide will regularly use Civiltech Solutions data to gain information on their roadways.

“If we can have councils running a network sweep using our sensor every year, they will be able to use the data to accurately assess what planning or strategies need to be changed in the LGA to best meet the long-term needs of the community,” says Carnall.

“We need to be doing things right to extend the life of community infrastructure, as opposed to running an asset into the ground, then reconstructing.”

In early meetings with the shire, Carnall sat down with Karen Callaghan, Chief Executive Officer for Shire of Broomehill Tambellup to understand the shire’s primary objectives.

“Over the course of four days, our

sensors collected data across the entire road network in the LGA,” says Carnall.

“In our discussions we deciphered what they wanted from the data. This included what audits were coming up and

which images they would need to supply to councillors.”

Callaghan says the council decided to partner with Civiltech to improve its cost savings.

“We are a very small shire, which means we have very limited resources and funding, so when we came across this opportunity, we jumped on it,” she says.

Having the data automatically in the system has allowed Callaghan and her small team to better prioritise and address their core duties.

“Before we worked with Civiltech, all data collection was done manually and didn’t include tracking footpaths and signage,” she says.

“We would have our work supervisor go out and survey the roads himself. Being able to put this data into our asset management systems alleviates a lot of the work that we need to do within the office, while also increasing the lifespan of those assets.”

During the course of the partnership, the shire has received data on pavements, signs, lines on roads and more.

The data is accessible through a web interface and is easily shared through a link, something Peter Vlahov, Works Manager, Shire of Broomehill Tambellup says is a great feature.

“The way the AI translates the data into photos and plain English is very helpful, you don’t have to be a scientist or

engineer to understand it,” says Vlahov.

“The few times I have had queries, the Civiltech Solutions team has been able to instantly help in bringing up a piece of data, making the whole process very convenient and accessible.”

Vlahov says the data has primarily been used for long-term maintenance planning, funding applications and to monitor road deterioration, subject to abnormal loadings.

“Being able to capture all of the data accurately in real time is brilliant and way ahead of any other AI data collection software out there,” says Vlahov.

The data is primarily displayed in photos rather than other forms of graphical data.

Vlahov says the imagery is appreciated when presenting council with funding applications.

“We have used the data to apply for road repairs, road reconstruction, road improvement projects and more,” says Vlahov.

“BEING ABLE TO CAPTURE ALL OF THE DATA ACCURATELY IN REAL TIME IS BRILLIANT AND WAY AHEAD OF ANY OTHER AI DATA COLLECTION SOFTWARE OUT THERE.”

The data can be used to derive the location and condition rating of pavements, signs, kerbing, footpaths signs and line marking.

“Having the imagery to be able to justify why we need the funding for the roads, footpaths, signage and verges has been monumental.

“Not to mention we are able to source the data within the space of a few hours rather than a week.”

In the six months the pair have been working together, Callaghan says the data has exceeded all expectations.

“Without a doubt we would recommend it to as many shires in the area as possible, and I have already mentioned it to a few of my Chief Executive Officer counterparts,” says Callaghan. “We have noticed the accuracy of the data is incomparable with anything we would’ve done ourselves. It is so worthwhile and done so efficiently.”

For more information, visit https:// www.civiltechsolutions.com.au/

Roads & Infrastructure, inpartnershipwiththeAustralianFlexible PavementAssociation(AfPA)hasproudlybroughtbacktheContractor CapabilitiesShowcasefor2025,sponsoredbySAMIBitumenTechnologies. B eyondthispageliesavaluableresourceforassetmanagers,roadowners, governmentsandmore,toeasilyfindcontractorsforprojects ofanysizeandscale.

NOW IT’S TIME FOR YOU TO DISCOVER WHAT THIS YEAR’S CONTRACTOR CAPABILITIES SHOWCASE HAS TO OFFER!

SUMMARY

SAMI Bitumen Technologies, established in 1978, has been a pioneer in the Australian roads industry, meeting the market demand for advanced bitumen technology. We pride ourselves on being a reliable company, consistently supplying the full range of high-quality bituminous products for the construction of critical infrastructure such as highways, bridges, runways, and local roads. Our commitment to sustainability is ingrained in our operations, as we continually strive to develop environmentally friendly solutions that contribute to the long-term durability of Australia’s road network.

OUR VALUES

Innovation is at the heart of SAMI’s success story. Over the years, we have invested heavily in research and development, pushing the boundaries of bitumen technology to provide cutting-edge solutions to our customers. Our forward-thinking approach enables us to adapt to the ever-evolving needs of the road industry, delivering innovative products that enhance the safety and efficiency of road construction and maintenance.

At SAMI, we firmly believe in the intrinsic link between quality and reliability. Our products undergo rigorous testing and adhere to the highest industry standards, ensuring that they meet and exceed our customers’ expectations. As a result, SAMI Bitumen Technologies has earned a reputation as a trusted and dependable supplier in the Australian market, building strong and enduring relationships with our valued clients.

As we move forward, sustainability remains a core focus for SAMI. We are dedicated to reducing our environmental footprint and promoting eco-friendly practices throughout our supply chain. By prioritising sustainable sourcing, production, and distribution methods, we contribute to the preservation of natural resources and the reduction of our industry’s environmental impact.

SAMI Bitumen Technologies stands as a beacon of innovation, sustainability, quality, reliability, and resilience in the Australian roads industry. With an unwavering commitment to excellence, we continue to lead the way in providing advanced bitumen solutions that strengthen the infrastructure backbone of Australia while ensuring a greener and more sustainable future for generations to come.

Our innovative high-performance products

• SAMIfalt I-Brid: Advanced hybrid-modified bitumen that excels in extreme conditions. Developed with RMIT University, this versatile asphalt binder incorporates innovative polymers for exceptional resistance to deformation and cracking, perfect for demanding Australian roads. It offers excellent workability and compactability, simplifying paving and compaction. Its self-crosslinking abilities ensure durability, surpassing traditional PMB products. With high cohesive strength, it resists crack initiation and propagation in various asphalt mixtures, making it ideal for heavily trafficked areas. The selected polymers also provide resistance to fuel and hydrocarbons, making it suitable for regions prone to leaks. Additionally, it offers exceptional moisture damage resistance for stability in wet environments.

• SAMIBioPrime: SAMIBioPrime is a petroleum solvent-free cationic bitumen emulsion that contains vegetable-derived oil from renewable sources. It quickly penetrates stabilised, bound, or unbound granular compacted base courses, eliminating the need for a curing period and allowing for same-day application of the next layer. This enhances project productivity. SAMIBioPrime is nearly carbon-neutral, reducing the carbon footprint of pavement construction. It is also safe to use, posing no explosion hazards or risks associated with VOCs. It can be used beneath various bituminous layers without causing softening, unlike conventional cutback primers.

• SAMIGreen: Eco-conscious Polymer Modified Binder and emulsion range designed to reduce the carbon footprint of the road industry. By partially substituting petroleum bitumen with a blend of biogenic renewable resources, SAMIGreen minimises reliance on fossil fuel-derived sources, leading to a significant reduction in carbon emissions. This advanced PMB meets rigorous specifications while offering a carbon footprint that is more than 60 per cent lower than conventional correspondent. By integrating renewable and eco-friendly resources, SAMIGreen contributes to the conservation of nonrenewable resources and supports the industry’s goal of achieving a net-zero carbon footprint.

Bitumen Technologies

2,3-5GibbonRoad

WinstonHills,NSW2153

P:(02)96240101

W:www.sami.com.au

Key personnel: SebastienChatard GeneralManager schatard@sami.com.au

• SAMIFloat: Versatile and environmentally friendly high-float emulsion designed for surfacing roads. Its gel-like structure, created with special polymers and additives, enhances binder adhesion and minimises early aggregate loss. Unlike traditional methods, SAMIFloat eliminates the need for petroleum cutters to soften binders before spraying and precoating aggregates. It offers a more sustainable solution by requiring lower heating during application. SAMIFloat is a unique cationic high-float emulsion, avoiding logistical issues associated with anionic emulsions. It provides reliable and adaptable spray-sealing binder options with superior performance and durability for various pavement treatments.

• Velofalt: Innovative hybrid polymer modified binder designed for race tracks, offering exceptional performance. Its superior cohesion and adhesion properties provide an unparalleled grip for car tyres, ensuring enhanced safety and confidence for drivers during sharp turns, braking, and accelerating zones. Velofalt effectively prevents aggregate loss, maintaining track integrity. With excellent rutting and fatigue resistance, Velofalt is highly reliable under high-frequency loads, making it an ideal choice for demanding race track conditions.

• Crumbflex: Innovative hybrid polymer-modified binder that prioritises sustainability in pavement construction. By incorporating crumb rubber from end-of-life tires, this binder reduces its carbon footprint by approximately 10 per cent, replacing the need for virgin bitumen. SAMIfalt CRUMBflex adheres to the engineering properties of conventional PMB binders and ensures equivalent performance. Carefully blended additives and polymers guarantee compatibility and excellent storage stability. This eco-friendly binder represents a significant step towards greener infrastructure development, utilising waste materials to create a more sustainable and resilient future for the pavement construction industry.

EVER SINCE ITS RELEASE OF THE SAMIGREEN RANGE, THE PRODUCT AND SAMI BITUMEN TECHNOLOGIES AS A COMPANY, HAS BEEN WELCOMED BY THE ROAD INDUSTRY AS A POSITIVE FORCE FOCUSED ON SUSTAINABILITY.

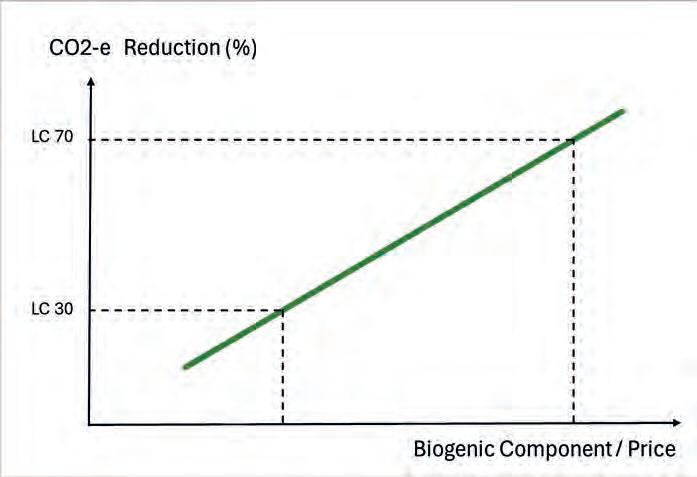

Two years ago, SAMI introduced its bio binder range as part of the road industry’s efforts to meet environmental targets. SAMIGreen is an elastomeric polymer modified binder (PMB) with a bio component that can achieve over 60 per cent carbon footprint reduction.

It’s available in both the Austroads elastomeric modified binder range and the crumb rubber modified binder range. However, not all projects are designed with the budget to incorporate high carbon reduction solutions. Some lowbudget projects have a requirement for cost-effective options that still contribute to carbon reduction. As Hamidreza Sahebzamani, PHD, MIEAUST, R&D and Technical Support Manager – SAMI Bitumen Technologies explains.

“To address this need, we’ve developed alternatives to the SAMIGreen range. Continuous research and development at our central laboratory in Sydney have led to the creation of products tailored to meet customer-specified sustainability requirements,” he says.

For example, SAMIGreen A15E LC70 (Deep Green) and SAMIGreen A15E LC30 (Light Green) achieve carbon footprint reductions of 70 per cent and 30 per cent respectively, compared to the standard A15E, without compromising its technical performance. The availability of these products now allows all projects, regardless of budget constraints, to incorporate carbon reduction measures.

This customisation is a feature across the entire SAMIGreen product line, which includes all elastomeric modified binders suitable for a wide range of asphalt and sprayed sealing applications, such as A10E, A15E, A20E, S25E, S20E, S15E, S15R, and A18R.

“An officially verified Environmental Product Declaration (EPD) is also available for this range, providing transparency

and validation of sustainability claims,” Sahebzamani says.

SAMI is committed to ensuring that the new bio-based materials integrated into traditional bituminous materials comply with all safety requirements. Occupational Health and Safety (OHS) measures are rigorously upheld, with comprehensive Safety Data Sheets provided for each product.

The SAMIGreen CRUMBflex represents a significant advancement in sustainable construction materials. It offers a range of hybrid-modified biogenic binders suitable for various asphalt and sprayed seal applications. These binders can be tailored to any elastomeric modified grade, addressing diverse project needs. Depending on the specific grade selected, SAMIGreen CRUMBflex products can achieve a carbon footprint (Global Warming Potential) that is over 60 per cent lower than traditional counterparts, while still meeting national technical specifications.

This innovative binder incorporates

biogenic carbon sink material and crumb rubber sourced from local end-of-life tyres, thereby promoting a lower environmental impact and supporting the circular economy by utilising waste materials. Importantly, SAMIGreen CRUMBflex remains safe for crews, just like conventional polymermodified binders.

“The technical performance of the SAMIGreen range has been thoroughly evaluated over several years. The binders conform to Austroads specifications, and all performance metrics for asphalts made with SAMIGreen have demonstrated high performance levels,” Sahebzamani says.

“Since its introduction in 2023, several successful trials have been conducted, and the acceptance of this binder continues to grow.”

The SAMIGreen range can be tailored to achieve desired carbon footprint reductions, making it a versatile and eco-friendly choice for modern paving projects and for those who care about the future.

Take your fleet operations to the next level with Geotab, the industry leader in telematics. Our advanced solution combines real-time vehicle data, powerful analytics and intuitive dashboards, empowering you to make smarter, faster decisions that keep your fleet on the road.

DEPARTURE

9:10 AM

Visit www.geotab.com/au/ to learn how our telematics solutions can

THE AUSTRALIAN FLEXIBLE PAVEMENT ASSOCIATION IS PROUDLY PARTNERING WITH CONVERGE, IDENTIFYING THE EVENT AS AN IDEAL WAY TO PROMOTE ITS INNOVATION AND EXPERTISE TO THE CONSTRUCTION AND MUNICIPAL WORKS SECTORS.