We are now better equipped than ever to help you to optimise your comminution and material handling operations for maximum performance, safety and efficiency.

Our industry leading expertise in crushing, screening, feeding, loading and wear protection allows us to bring you an unrivalled equipment line-up. We underpin this unique offering with our expert process knowledge, full range of digital tools, high quality OEM spare parts, consumables and life-cycle services.

Scan the QR code to discover why we are the industry’s partner in eco-efficient mineral processing.

6 WA Mining Expo set to return

8 Supporting Simandou

10 Modernising existing silo infrastructure

12 Understanding wind impacts on structures

14 Kilic is growing by the double

16 Sealing the transfer zone

20 Four decades and counting

22 Fastening for steely results

24 Legacy in Motion

40 The impact of moisture

42 Taking steps to stack

44 Weighing against the odds

46 Nurturing the leaders of tomorrow

48 Food for growth

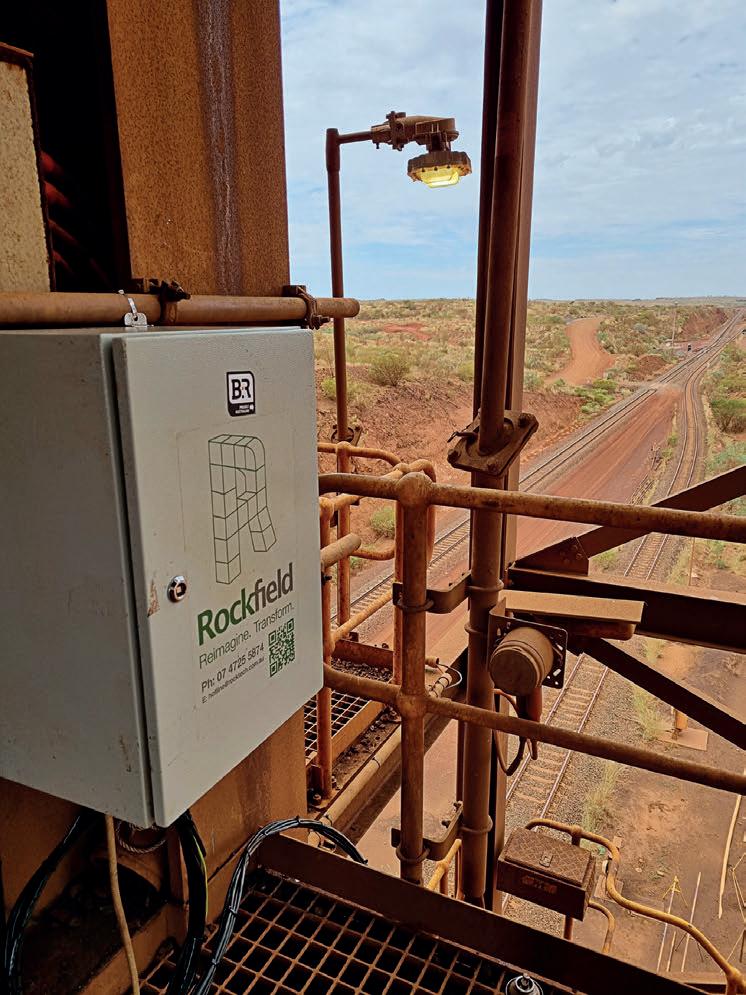

50 Revolutionary rail loading

52 Automate with friendly solutions

54 Flick the switch

56 TUNRA’s golden anniversary

58 ASBSH Member Profile: Sean Kinder

Stackers and reclaimers

26 Passing the bulk

28 Aurecon makes it stack up

30 Trusted and independent

32 Power e iciency through design

34 BULKtalk: Yard machines

38 Quaking without breaking

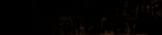

DHHI plans to deliver almost 30 machines to the Republic of Guinea for the massive Simandou iron ore project, and how the company can provide similar support for Australian miners.

For the full story, see page 8.

Published by:

379 Docklands Drive

Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chief Executive O icer

Christine Clancy

E: christine.clancy@primecreative.com.au

Editor William Arnott

E: william.arnott@primecreative.com.au

Assistant Editor

Joseph Misuraca

E: joseph.misuraca@primecreative.com.au

Business Development Manager

Rob O’Bryan

E: rob.obryan@primecreative.com.au

Client Success Manager

Janine Clements

E: janine.clements@primecreative.com.au

Head of Design

Blake Storey

Design

Laura Drinkwater

Subscriptions

T: 03 9690 8766

E: subscriptions@primecreative.com.au

www.bulkhandlingreview.com

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

The Australian bulk material handling sector features truly impressive feats of engineering and design, which power the sector to new heights.

Not only do these feats of engineering and design support the sector’s productivity, jobs and help deliver critical materials to Australia’s sector, they showcase all that is great about our industry and the people that work within it.

For me, there are two great examples that highlight all of this: stackers and reclaimers.

These are the unsung powerhouses of the Australian mining and materials handling sector. These towering machines are integral to the productivity of our mines, ports and heavy industries across Australia. While stackers systematically build up stockpiles of coal, iron ore, and other mined materials ensuring they are stored safely and e ciently

Reclaimers, in turn, retrieve these materials and feed them into processing plants or onto conveyor belts headed to ships bound for global markets. The seamless movement of millions of tonnes each year simply would not happen without them.

But beyond their basic functions in day-to-day operations, these machines embody the innovation that makes the Australian bulk handling sector shine. The modern versions of these machines are often technological wonders packed with advanced automation, real-time data systems and precision controls. Through this, they help reduce manual handling, improve safety and boost productivity, which is critical in our sector.

As Australia continues to move towards smarter and more sustainable mining and material handling as part of a cleaner, greener future, let’s celebrate the innovations that are taking us there.

These towering giants are the powerhouses of the country’s material handling sector.

INTRODUCING AN EASY WAY TO PROTECT YOUR WORKERS AS WELL AS PROTECT YOUR INVESTMENT INTO YOUR EQUIPMENT. THE CONVEYOR SAFETY SYSTEM™ IS AN EASY, COST EFFICIENT WAY TO GET PEACE OF MIND AND PROTECTION FOR CONVEYOR EQUIPMENT. BY BUNDLING OUR MODEL RS SAFETY STOP SWITCH WITH OUR MODEL TA BELT ALIGNMENT SWITCH, MODEL DB DAMAGED BELT DETECTOR WE HAVE YOUR WORKERS AND EQUIPMENT COVERED. COUPLE THAT WITH ADDING ONE OF OUR MOTION SWITCHES (MAG-NEAT-O™ OR MODEL CMS), YOU CAN FEEL CONFIDENT KNOWING THAT YOUR SYSTEM AND WORKERS ARE PROTECTED FOR A FRACTION OF THE COST OF DOWNTIME, REPAIRS AND REPLACEMENT EQUIPMENT.

WA Mining in 2025 will feature exhibitors such as Kinder Australia and conference contributions from the likes of Deloitte, Lifeline, Oracle, and more.

WHEN THE WA MINING CONFERENCE and Exhibition (WA Mining) returns to the Perth Convention and Exhibition Centre from October 8–9, it will once again drawing the state’s mining community together under one roof.

Following a sold-out event in 2024, this year’s edition is expanding in ambition and scale.

With many attendees expected, including mine owners and operators, the conference and exhibition are aiming to be the central stage for Western Australia’s most pressing miningconversations. ining reflects an industry in motion. Against a backdrop of shifting global demand, rapid technological advancement, and growing expectations around sustainability, the event is both a mirror and a catalyst for change.

Partnerships strengthen purpose

WA Mining enters a new chapter after Prime Creative Media announced the event s o cial partnership with the Association of Mining and Exploration

The collaboration reinforces the event’s relevance across the full mining ecosystem, from junior explorers to multinational operators. AMEC chief e ecutive o cer arren earce said in a statement that the timing of the event could not be more important, given the pace of change in Western Australia’s resources sector.

“With so much happening in WA resources at the moment, the event is a real opportunity for industry to come together to not only discuss the challenges ahead but celebrate the incredible work that is happening on the ground,” Pearce said.

The endorsement from AMEC highlights WA Mining’s growing influence t also signals the event’s evolution from a showcase of products and services into a cornerstone of strategic dialogue for thestate’s economy. The two-day conference program has been curated around trends that matter to operators and policymakers. Delegates will hear from experts on advanced technology, decarbonisation, software and data, and

Practical discussions will explore how automation is rede ning safety, how emissions reduction targets can be achieved without compromising productivity, and how layered safety systems are improving workforceresilience.

Cybersecurity, economic policy, and mental health will also be addressed, with contributions from Deloitte Cyber, the Chamber of Minerals and Energy of WA, and Lifeline WA.

The calibre of the speaker line-up demonstrates the seriousness of the agenda. David Michael MLA, minister for Mines and Petroleum, will be joined by Oracle’s director of Customer Strategy, ichael imms ndustry apability Network’s national climate director, Dr Vanessa Rauland, and fatigue risk management expert, Dr Nicholas Mabbott, among others.

A timely platform for collaboration Mining in Western Australia has always been about more than extraction – it’s about building an economic and social foundation for the state and contributing to global supply chains n as the industry wrestles with decarbonisation, digitalisation, and workforce renewal, WA Mining arrives at a moment of both challenge and opportunity.

By bringing together policymakers, operators, suppliers, and service providers, the event helps ensure that ideas are not left on the conference stage but translated into practical actions across sites and o ces hether delegates are looking for insights into automation, strategies for emissions reduction, or solutions to strengthen workplace culture, WA Mining 2025 promises not only conversations but actionable pathways forward.

WA Mining will be held in Perth from 8-9 October. Register to attend WA Mining by visiting waminingexpo.com.au/getinvolved

family of primary belt cleaners deliver industry-leading performance in the most demanding and varied mining environments. QC1+™ Cleaners effectively discharge material from the belt while minimizing the carryback that can lead to conveyor system damage. Our patented Continuous Angle Radial Pressure blade-to-belt technology, our long-lasting application-specific urethane blades, and our rugged mainframes ensure superior cleaning power throughout the blade’s service life.

Easy to maintain and quick to service, these robust QC1+™ Cleaners protect belt components from premature wear and minimize fugitive material issues — keeping your operation running smoothly, safely and more productively.

ABHR learns how DHHI plans to deliver almost 30 machines to the Republic of Guinea for the massive Simandou iron ore project, and how the company can provide similar support for Australian miners.

THE SIMANDOU PROJECT

comprises three core elements – a mine, railway and port, as well as associated infrastructure. The Simandou mountain range, located in the southeast of the Republic of Guinea, is home to an exceptionally large deposit of high-grade iron ore, with an expected peak production of between 95 million and 100 million tonnes per year and estimated mine life of 26 years. Delivering this important project could position Guinea as the world’s thirdlargest exporter of iron ore and help meet growing global demand. However, DHHI Australia chief e ecutive o cer arald rosshammer said the project will be very challenging to deliver given the lack of existing infrastructure in place and the shear remoteness of the mine which requires approximately 670km of railway to transport the iron ore from the mine

to the Guinean coast and a new port southof Conakry.

“DHHI has done several projects like this one before,” Grosshammer said.

“We have the capability to work indi cultregionsandcandeliver machines manufactured to meet internationalstandards.”

DHHI is a global manufacturer, specialising in major bulk handling machines such as stackers, reclaimers, shiploaders, and car dumpers. Each year, the company produces around 600,000 tonnes of structural and mechanical equipment from its manufacturing facilities in China.

Thanks to its manufacturing capabilities, the company was selected to deliver 28 machines for the project, including seven car dumpers, 14 stacker/ reclaimers, and seven shiploaders.

As part of its scope of works, DHHI is required to design, fabricate, procure,

transport, construct, and commission each machine, using its own workforce to assist with the delivery and get the behemoth bulk handlers into position.

“Coordinating delivery of so many machinesisalreadyasigni cant undertaking. The challenges of the remote location and lack of local manpower to operate cranage and installation works was also something we needed to take into account.”

“DHHI has an in-house construction company that we are using to support the installation works. We have a big number of people on site to deliver the project. It’s a challenging task, but we’re con dentwecangetitdone

Several of the machines have alreadybeen delivered and installed, with more on the way soon through a staggered delivery schedule. The company is no stranger to delivering massive bulk material handling

machines to remote locations of the world. It has previously supported other projects in Guinea with stackers, reclaimers, shiploaders, and car dumpers. Grosshammer said DHHI has more than 60 years of history in building balanced machinery.

“We have provided balanced machines all around the world, from Brazil, to Europe, Malaysia, Africa, Australia, and more,” he said.

“This experience is how we developed the capability to adhere to local and international standards.

“DHHI is really good at working with clientsto ndthebestbene tsfora project. Clients often return to DHHI and work long-term with us to deliver their projects, because we can ensure that targets are met and can accommodate any changes.”

What sets DHHI apart as a partner of choice for major mining companies isitsscale.

DHHI’s immense production capabilitiesgrantitsigni cant purchasing power.

This, combined with its local expertise, allows it to sourcehighquality components at a scale few canmatch, ensuring that its machines

“We have provided balanced machines all around theworld, from Brazil, to Europe, Malaysia, Africa, Australia, andmore.”

arebothreliableandcost effective forcustomers.

This collaborative approach has been a major success for DHHI’s Australian mining projects.

Grosshammer said Australia has its own complexities when it comes to delivering balanced machines, which is why the company has established a permanento cewithanengineering and project execution presence in Perth.

“We have built the Australian team to support local project requirements,” he said. “We can combine the quality and scale manufacturing of our Chinese facilities with the technical expertise to optimise the delivery process and design for the Australian market.”

“We review the market, learn what the key requirements are for clients and what the key factors are in making a machine successful.

“Our team can provide full fabrication support, along with a

dedicated aftermarket team to support the full lifecycle of a machine.” hasseensigni cant growth in Australia, doubling its o ce space andincreasingthe size of its projectmanagement team to providegreater support fortherequirements of Australianprojects.

Moving forward, the company is committed to growing its Australian presence to provide clients the complete lifecycle service opportunities, particularly across the Pilbara region in Western Australia.

“As a result of our growth, we have been able to successfully win more work and execute projects that will bring more machines to the Australian market,”

Grosshammer said.

“We expect to continue growing andwill provide the Australian bulk handling industry with the best supportpossible.”

Kotzur Australia is upgrading silos for performance, e iciency and compliance without starting from scratch.

shift, technology advances, and e ciency e pectations rise grain storage operators must continually assess and adapt their facilities to remain competitive lthough many facilities have performed reliably for decades today s agricultural and bul handling operations face new realities as the demands of modern farming include faster harvest turnarounds higher throughput tighter compliance re uirements and increased pressure to improve labour e ciency ot ur chief technical o cer en ot ur said often the e isting core structures remain sound but the operational capabilities no longer matchthe pace of today s agricultural supply chain

lot of sites have opportunity within their e isting structural layouts for further throughput and e ciency gains ot ur said ather than starting from scratch we can upgrade the critical components to upgrade them in line with the client s strategic ob ectives ot ur s modernisation pro ects often focus on integrating automation systems upgrading handling e uipment and rethin ing site layouts to streamline wor flows hese upgrades can signi cantly improve e ciency without re uiring a complete rebuild amples include installing higher capacity buc et elevators and conveyors to accelerate grain movement recon guring grain flow paths to reduce bottlenec s during pea periods and introducing automated controls that minimise manual intervention while improving operationalconsistency e ve delivered pro ects where unloading times have been signi cantly reduced simply by rethin ing the layout and adding targeted e uipment ot ursaid

hese changes not only save time but also improve safety and reduce wear on machinery

hile the immediate focus may be on upgrading current operations ot ur stresses the importance of long term thin ing ven if e pansion isn t on the hori on planning for it from the outset can save signi cant time and comple itylater

master plan gives you the fle ibility to grow without having to undo previous wor ot ur said e always consider possible future needs whether it s additional silos further loading infrastructure or new handling e uipment and ensure there s enough physical footprint structural capacity and layout options to ma eitpossible

y incorporating master planning into modernisation pro ects the company ensures that today s upgrades won t limit tomorrow s opportunities allowing sites to adapt to changing mar et conditions and business growth he process begins with a thorough site assessment to understand the e isting infrastructure s strengths and limitations rom there ot ur ustralia develops an upgrade plan that integrates seamlessly with the current layout reducing downtime and minimisingdisruption

y avoiding the cost and delays of complete reconstruction modernisation pro ects can deliver a faster return on investment and e tend the life of e isting assets which in turn is helping operators remain competitive in a fast changingindustry

Aspec Engineering student engineers Drishti Patel and Jarred Richards discuss the impact of wind loads on key industrial structures, including conveyor galleries.

structures, understanding how wind loads interact and impact them can be the difference between successful operation and failure

ith a thorough understanding of the factors that influence wind loads engineers can develop e cient designs that can withstand these impacts

Factoring in wind load assumptions when designing ey infrastructure li e conveyor galleries is crucial

Wind loading is a critical considerationin structural design t directly influences elements of safety functionality and durability of buildings aninfrastructure hile it can be challenging to assess the impact on structures like conveyor galleries, due to their elongated design, susceptibility to outside influence the impact of dynamic effects the ability to ma e accurate load calculations is vital

hile there are many facets which should be considered when determining the validation of wind loads speci cally in relation to conveyor galleries, there are four areas of critical consideration Ensuring design wind speeds are determined in accordance with the relevant code, including AS/NZS

Aerodynamic drag and pressure coe cients and the calculation of wind loading on the structure

Validating the results via wind tunnel testing

• sing alternative techni ues for validation, including computational fluid dynamics is considered the primary design standard for the determination of wind loads on structures he determination of wind speed and design wind pressures for the structure encompasses several factors he nal design wind pressure on a structural element is determined via the following formula

here are multiple ey factors involved in the determination of the relevant design speed including the regional wind speed wind direction multiplier, local terrain and height, local shielding, climate change allowances and local topography

The terrain/height multiplier is calculated based non the height of the structure and terrain category from t can have a signi cant impact on the design wind speed with values ranging from to t should be noted that the climate change factor replaced the uncertainty factors when the standards were revised in he topographical factor is based on the surrounding topography such as hill shapes he shielding factor considers shield from ad acent structures

The wind direction multiplier is based on statistical probability of pea winds

to occur in each cardinal direction his allows for engineers to optimise designs based on a structure s orientations he wind directional factors are separated into four groups based on the governing weather patterns in each region he regions are as follows egion ominated by non synoptic winds e g thunderstorms • egion and ominated by e tra tropical synoptic winds e g large scale pressure systems egions and nfluenced by a mi of tropical synoptic and non synoptic winds ote includes tropical cyclones egions and ominated by tropical cyclones

For complex structures like conveyor galleries, it is challenging to accurately determine aerodynamic parameters such as the aerodynamic shape factor or drag coe cient n ppendi of methods are provided to determine aerodynamic shape factors for e posed structural members frames and lattice towers by utilising the drag coe cient of the structure or member he drag coe cient is a dimensionless quantity that is used to uantify the resistance of an ob ect in afluid he drag coe cient is

combinedwith additional factors such asthe aspect ratio correction factors and the shielding factor for multiple frames to determine the aerodynamic shape factor of simple shapes individual members and a series of multiple open frame structures such as truss style conveyor galleries

hile a member by member method can be effectively used to determine the wind force on a truss structure in accordance with applying it to conveyor galleries is more comple

hese structures often support additional e uipment e g wal ways conveyor idlers, conveyor belt, services, secondary structures etc which are common in bulk material handling assets hese attachments signi cantly increase the comple ity of accurately determining the aerodynamic properties of the structure

ue to the comple geometry of the e uipment e posed to wind can be substituted for e perimental and computational methods to assist engineers in determining the aerodynamic properties of structures

As a case study, wind loads on a singleopen conveyor gallery were assessed using the analytical methodsoutlined in ppendi of ind loads were calculated perpendicular to the gallery span and the results were converted into an equivalent drag coe cient based on the total bluff

area of the gallery total length total height allowing for direct comparison with values obtained from small scale wind tunnel tests

The analytical assessment yielded an e uivalent drag coe cient in the range of to for a gallery with a solidity ratio of around he drag coe cient for the conveying e uipment and tures was determined using engineering udgment and assumed drag values provided in AS

Wind tunnel testing has shown a range of values for different conveyor gallery geometries / constructions and can be invaluable in optimising wind loads compared with analytical methods pen truss galleries which consist of exposed structural members tend to have lower drag coe cient when compared to enclosed galleries especially if the structure is open on all sides and has lowsolidity

ypical drag coe cients values for conveyor galleries with low solidity and under range from to asmeasured through wind tunnel testing hese e perimentally determined values are generally lower than those obtained using analytical methods for galleries with similar designs and solidityratios

Enclosed galleries, which are clad in metal sheeting or other materials, present a more uniform wind pro le These structures typically have drag coe cients between and as measured by testing, depending on cross sectional shape aspect ratio and wind direction

omputational luid ynamics is the computational e uivalent of wind tunnel testing ts ey advantages include the ability to be conducted in house with greater e ciency and at a lower cost compared to traditional wind tunnel testing owever it is not recognised by as a prescribed method to determine aerodynamic parameters without additional wind tunnel testing is also limited to assessing models in steady state without dynamic effects considered in the simulation n conclusion there is no universal method in determining wind loads on comple structures and careful consideration must be given each time wind loads are assessed ind tunnel testing remains the most accurate and reliable method to determine wind loads, particularly for conveyor galleries and can lead to more e cient designs by reducing conservatism in wind load estimates n the absence in wind tunnel testing engineers should apply and interpret relevant standards such as – noting they are generally designed to provide conservative results to ensure structural safety

References

Holmes, J. D. (2001). Wind Loading of Structures (3rd ed.). CRC Press. Standards Australia. (2021). AS/NZS 1170.2:2021. Sydney: Standards Association of Australia.

A South Australian manufacturer has dramatically increased in size following a major expansion.

KILIC ENGINEERING HAD AN IDEAL problem – the company was growing so much that it needed more space.

The South Australian family business has been manufacturing bulk handling equipment for more than 50 years and had reached the point where an expansion or their manufacturing facilities was necessary.

Kilic Engineering general manager Craig Dennis said the company decided to make a parallel investment, growing its main factory and purchasing another premise to bolster its storage and production capabilities.

“The objective was to add that e tra space and use it more e ciently to improve on the material flow hetold ABHR

“We were getting cramped at the main factory, and by expanding we could nd ways to ma e our operation moree cient

“We have added 1750m2 of space, bringing the total size of the premises to 3500m2 , which now includes vegantrycranes

Ever since the expansion was completed in May, Kilic Engineering has been working to make the most of the space, relocating its equipment and changing its storage options.

With more room to move, the company now has space to research new developments on its existing productlines.

Dennis said the company spends up to $1.8 million a year on research and development to create products that offer better results to the customer.

“Our machines are becoming more automated, and we’re constantly looking at ways to improve both our products and our manufacturing operation including reduction of our energy footprint hesaid

“We’ve upgraded our welding equipment, have plans to use electric forklifts, and added a large solar array as part of the workshop expansion.

“On a sunny day, it can virtually power the entire facility

The extra manufacturing capacity has allowed Kilic Engineering to support a wide range of industries. While the company is well known in the agriculture sector, it also produces equipment for the scrap metal and defence industries.

Facilities are not the only thing Kilic Engineering is looking to grow. The next step for the company is growing the team itself. Dennis said Kilic Engineering has developed a thorough process for ensuring it nds the right t for the team

“We go through an interview process with everyone, whether they’re from a labour hire company or direct employment he said

“We want to make sure they are suitable for the business, as well as having the skills that are needed.

“Kilic Engineering is a family business, and the assessment processensures that the people we workwith have values that align withour own

Select customers have visited the new facilities and have provided positive feedback. Some have even encouraged Kilic Engineering to do more work with them after seeing the improvedprocesses.

Dennis said the team is pushing to immediately take advantage of the extra room by taking on more work to support the upcoming harvest.

“We’re looking to get the machines out and ready for the harvest and continuing to develop the business so wecan continue with this momentum he said

“Looking further ahead, Kilic Engineering is also considering a rental fleet service using our popular bun er stacker machines to help support ourcustomers

Martin Engineering’s president emeritus Todd Swinderman breaks down how to fix dusty conveyors.

transfer point, is dust escaping through gaps in the skirtboard?

Visible dust emissions (typically de ned as m from conveyors draws the attention of workers, neighbours, and inspectors. Often, the use of respirators is viewed as an acceptable workaround.

owever studies have shown that respirators can reduce productivity by as much as 19 per cent, and prolonged use can signi cantly impact cognitive and sensory abilities hese decreases in productivity alone can ustify improvements to conveyor dust containment to lower emissions.

Dust emissions originate from air turbulence in the loading zone from the belt s movement and tons of material impacting the belt. One of the most effective and economical solutions is to examine the skirtboard, seal the environment and control the airflow

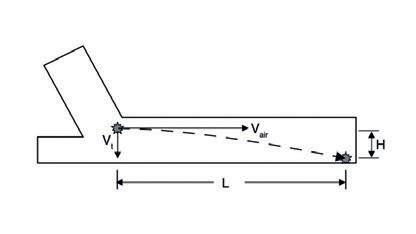

he s irtboard enclosure is essentially a settling chamber he basic concept is that a dust particle will settle out of a laminar air stream based on the speed of the air flow air and the terminal velocity t of the dust particle.

here are many rules of thumb along with traditional and industry-based practices for skirtboard sizing and dust curtain placement to contain the dust in the skirtboard enclosure. Most of these practices are without proof of performance other than hat s the way we ve always done it.”

urrent practice for conveyor skirtboard enclosures is to design for Vair m s by increasing the height of the enclosure wo common rules of thumb for the enclosure length are two times belt width or m for every m s in belt speed. It is interesting to note that if H is increased the distance that the average dust particle must travel also increases detailed design study of air flow and

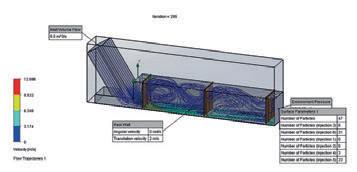

particulate settling was performed using flow simulation software

standard conveyor was established as the baseline for the study. he standard conveyor is a mm wide belt with a 35° trough angle, traveling at m s generic material was used to produce the baseline data, with a bul density of g m and a nominal mm minus particle si e distribution with a degree surcharge he discharge chute was si ed based on a material volume e ual to or less than per cent of the chute cross section A drop height of 3m, an open area of m an average particle si e of mm and bul flow of mtph were used to calculate the induced air volume everal variables were investigated to simplify the analysis he complete conveyor with discharge and receiving belts was modelled and, while there were signi cant regions of recirculation in the upper discharge section the air flow in the chute was reasonably consistent. he chute was simpli ed with the air volume and dust particles in ected into the last two metres of the chute. he combination of variables studied are given in able oth e ternal and internal analyses were conducted, with complete moving discharge and receiving conveyors

PARAMETERS

he bul material surface was set to absorb particles and the walls set to reflect particles he effectiveness of the enclosure variations was determined by counting the number of each size particles that escaped the end of the enclosure compared to the numberinjected.

he results of the e ternal analysis indicated that escaped dust particles increased in speed, as the air current is affected by traveling around the belt and the discharge pulley.

his phenomenon is nown as the agnus effect and emphasises the need for effective belt cleaning as close to the discharge as possible. A space of 1mm between the bottom of the skirtboard and the belt was used to simulateleakage.

everal e perienced maintenance technicians were surveyed and their preferred curtain arrangements modelled. In addition, multiple curtain designs and placement schemes were studied, including staggered slit curved angled with and without slits, with holes and nocurtains everal unconventional skirtboard enclosures were modelled to create recirculation in the enclosure and improve dust settling

Belt speed (m/s) 2.0 2.0 to 8.0

Belt width 1200 600, 1200 & 1800

Bulk material solid density kg/m3 1500 750, 1500 & 3000

Air flow (m3/s)

0.5

0.25, 0.5 & 0.75

Curtain placements 1 @ exit 1 to 6 Curtains, at various spacings

Curtain clearance (mm)50 0 to 150 above load

Skirtboard height (mm)300 300, 600 & 900

Skirtboard length (mm)2400 2400, 3600 and 4800

Wall roughness (mm) 1 0 to 100

Chute to skirtboard Standard inline Mitred, full width & 90°

Tail box length: 600 mm300 high

300, 600 & 900 high

Dust particle diametre (µm) All configurations modeled with 100, 50, 40, 25, 10 and 1µm dust particles

Table 1. Variables used in the particle study

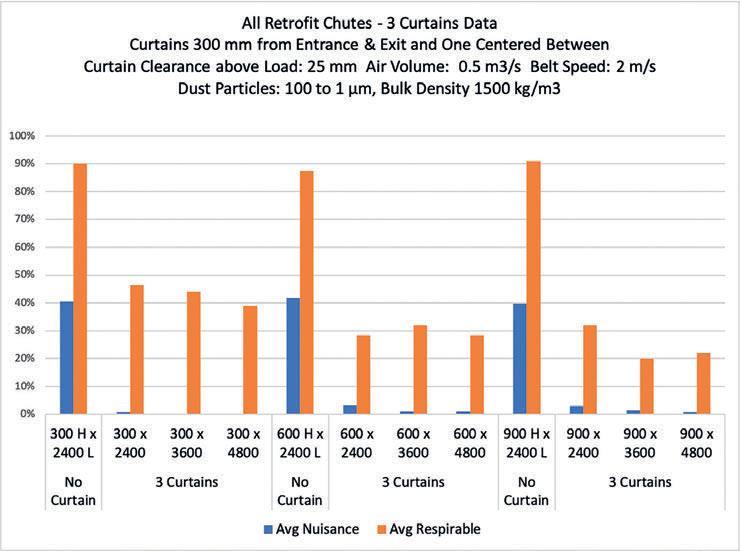

he optimum design for the standardconveyor was determined to be a conventional enclosure with a height of mm a length of m and three dust curtains placed in de ned locations

Worn exit curtains were also modelled and as the spacing above the load increased, the dust settling performance deteriorated he use of a single curtain right at the e it proved problematic in all cases, acting to speed up the e it air flow even further when close to the belt and re-entraining dust in the exiting air stream, while being ineffective in creating recirculation within the enclosure.

When the curtain placed at the exit was worn too much, it was as if there was no curtain at all. A curtain placed right at the exit and adjusted close to theload creates another fugitive materialproblem, sometimes called the popcorn effect where the curtain causes spillage by noc ing material off thebelt.

olid density had little effect on the settling of nuisance dust particles from to m n every case per cent of the and m particles settled almost immediately. As the bulk density increased, there was a moderate reduction in respirable dust emissions.

he unction between the discharge chute and the skirtboards was found to be an important design detail for creating recirculation. Making the width of the discharge chute narrower than the width of the skirtboard helps to fold the air flow going into the rst curtain and that encourages distribution of the air flow toward the top of the enclosure, rather than along the surface of the material. he retro t and mitered unctions were signi cantly more effective than a simple butt connection and mm height he tail bo had little effect on dust emissions

Pack your cement, building material or chemical products into valve bags at up to 1000 s/h with our new-gen INTEGRA.

out of the skirtboards’ exit end. In most con gurations the height of the tail bo was set at mm he tail bo length was set at mm to match the typical mm idler spacing used in the load zone by most conveyor manufacturers and engineers

Length of skirtboard

It was found that for most situations a mm long s irtboard produced the best results. Increasing the length to mm and height to mm had some marginal effect but may not be worth the e tra investment

Height of skirtboard

n enclosure height beyond mm for the standard conveyor with a single e it curtain did reduce nuisance emissions but tended to increase respirable dust discharge, because the average settling path was greater with the higher enclosure.

ir o

s would be e pected the average air velocity through the s irtboards was directly proportional to the induced air flow and cross sectional area verage velocities in the skirtboards due to induced air ranged from to m s elt speed has a minor effect on the average velocities he ma imum air velocities were almost always found where the air flows under the skirtboard curtains.

hese high air speeds ept the respirable dust suspended, so reducing induced air into the chute is also important in improving performance

Curtains

he best results were obtained with three or more curtains he design of the slits in the curtains is important to allow air to pass through allowing the airflow paths to ll the entire chamber and not ust flow at high speeds under the curtains t was found that the individual flaps should be about mm wide with slits at least 5mm wide and the curtains extending the full width of the enclosure.

Preferred embodiments

he best value for the cost of the s irtboard enclosure and its effectiveness is udged as s irtboards mm high and mm long and three full width slit curtains using either the retro t or mitred discharge chute-to-skirtboard connection.

Design Recommendations

Discharge chute width across s irtboards mm width betweenskirtboards.

Skirtboard outside width based on horizontal dimension of free belt edge for sealing and belt wander edge allowance mm per side irtboard height mm nlet to s irtboards air volume flow m s

• Length of skirtboards for material loading turbulence mm whenre uired

Length of skirtboards for dust settlement mm plus e tra allowance for loading turbulence ifnecessary.

Skirtboard dust curtains: ntrance st curtain mm past end of extra allowance for material turbulence and distributing air flow nd middle curtain centered between entrance and exit curtains.

• it rd curtain mm from end of skirtboards.

urtain clearance above the bul material mm preferred mm ma

• urtain flaps mm wide strips separated by slots mm

Conclusion

hile some improvement is seen with increased skirtboard height and length, it is doubtful that it can be economically usti ed on the reduction of respirable dust alone return on investment for control of nuisance dust for new and retro t designs can be based on reducing cleaning labor increased e uipment life and or elimination of dust collection f the improvements reduce the time weighted average of respirable dust emissions to the point where engineering or administrative controls could be less stringent then a nancial case could alsobe made based on improvements in labor productivity

Kinder Australia’s chief executive o icer Charles Pratt reflects on the company’s history and future as it celebrates its 40th anniversary.

FOUNDED IN 1985 BY Neil and Christine Kinder, Kinder Australia has transformed from a supplier of off the shelf conveyor component products into a provider of customised engineered solutions.

t the core of inder s success is its people he company aims to foster a culture of continuous improvement and innovation encompassing engineering product development customer service and technical support

n addition the company invites its customers to underta e in house training programs where they can gain practical nowledge that helps improve safety optimise e uipment performance and extend equipment lifespan.

inder ustralia chief e ecutive o cer harles ratt said building strong long term relationships with its customers through these methods has been a driver of inder s success

ne of our rst customers heetham Salt Ltd in South Australia, remains with us to this day ratt said hat spea s to the value we aim toprovide

ith years of e perience we have a responsibility to help shape the future of the bul materials handling sector ey to maintaining these relationships is the company s eld application specialists and business development managers his team wor s closely with bul materials handling companies around the country assessing the issues they face and nding the right solution for each ob inder can then relay the common pain points the industry is facing which ratt said is vital etting in front of customers is important t s what has created the trust our customers have in inder he said rying to innovate for the sa e of innovation has no value ou need to ndout what problems customers are facing and wor with them to ma e things better

A philosophy of innovation

n an industry where e uipment is pushed to the limit uality must never be compromised ratt said

This belief is at the heart of inder s engineering philosophy very

product from heavy duty pulleys idlers to conveyor covers is built for endurance and reliability in the toughestenvironments owever ratt believes there is enormous scope to continue innovating conveyor systems here s such a big gap in how technology has been implemented in conveyors compared with other sectors li e the automotive industry he said f you compare the suspension in a car to the suspension at a conveyor transfer point it s a star difference art of it is because you re not feeling how the belt is getting smashed with roc s going down a chute here s a lac of appreciation for what the conveyor goes through inder s technology is based on solving real world issues that the bul materials handling industries are facing ften these issues occur at a transfer point where material causes belt damage misalignments, spillage, or dust.

roducts li e the hield ynama impact idler and ure belt support system were designed to address these

issues hese solutions enable customers to reduce downtime improve safety and boost e ciency in their operations

e don t ust supply parts e engineer outcomes ratt said

A new chapter

s industries have evolved so has inder s vision arlier this year a consortium led by ttalis apital including the ictorian usiness rowth und successfully ac uired inder ustralia

he move mar ed the ne t phase for the company building on its legacy and positioning it for long term growth

inder is e ploring strategic e pansions including bolt on maintenance services consumables and service partnerships that will allow it to offer more holistic support across the full lifecycle of its solutions

hese efforts aim to enhance the customer e perience and strengthen inder s role as a long term value driven partner of choice

Kinder also plans to expand into Western Australia and Queensland, with o ces showrooms and warehouse distribution located around thecountry s inder moves into its fth decade of operation, Pratt said its mission is to set the benchmar for safety sustainability and innovation in bul materials handling

“Our future is about more than products ratt said t s about building

deeper partnerships, expanding our global reach and continuing to innovate in ways that matter.

e re investing in the people technologies and ideas that will shape the ne t years

“Our goal is to remain the benchmar for safety sustainability andengineering performance in bul materials handling globally

Flexco’s hands-on training and fastening technology is helping underground coal mining operations across New South Wales improve safety, reduce downtime and boost maintenance e iciency.

Sebastian Olguin said the company’s approach to training is designed to be hands-on and highly relevant to the real-world conditions that the maintenance teams face underground.

“By working directly at the mine site, we ensure our products are installed correctly and safely,” he told ABHR

Flexco is a manufacturer of belt conveyor products including belt fasteners, scrapers, and maintenance products. Its products play a vital role on operational productivity and safety in bulk material handling applications.

le co offers customisable training programs, including in-class sessions at their training facilities, on site, and online. These programs are designed to support safe and effective product use

As part of the on-site training program, crews can raise concerns, provide feedback, and collectively work towards best practice.

“A recent training session in southern New South Wales on the XP Fastening System highlighted the

impact of this approach. The team there said the training was well structured, informative and tailored to their needs. They appreciated the balance between theory and hands-on learning, with the practical sessions receiving outstanding feedback,” Olguin said.

With the introduction of a custombuilt training trailer, the company has brought its expertise directly to remote and hard-to-reach sites.

“Our custom training trailer has completely transformed how we deliver practical education,” Olguin said. “It’s a fully mobile training hub equipped with installation gear, allowing us to replicate real-world conditions at the customer’sdoorstep.”

This has been especially valuable for mine sites located several hours from Flexco’s newly built training facilityinSydney.

“In regions like northwest and midwest New South Wales, we can now bring high-quality, hands-on training directly to them, no matter the location,” he said.

The trailer ensures consistent skill development across all crews, while reinforcing site speci c safety and e ciency practices

The Flexco® XP™ Staple Belt Fastening System combines an enhanced applicator tool with the longest wearing staple fastener and hinge pin on the market to produce a superior belt splice for tough mining environments.

The fastener plays a major role in underground coal mining due its strength and durability in tough mining environments he nished splice features a smooth low pro le that enhances compatibility with belt cleaners and other conveyor components, signi cantly e tending wear life

Installation is also made easier and safer with an ergonomically designed tool that pulls towards the operator, rather than the traditional sideways motion.

“This greatly reduces operator fatigue and improves control, especially in con ned and constricted underground environments,” Olguin said.

“The XP staple fastening system’s cold-rolled steel construction delivers enhanced strength and wear resistance.

“The larger loop area accommodates a bigger diameter hinge pin, which reduces fatigue across the splice.”

Another standout feature of the tool is its built-in reset mechanism. If a misdrive occurs, crews can skip over it without starting from scratch—saving time and ensuring greater accuracy.

“The tool also includes a safety interlock that prevents it from compressing the fastener unless it’s properly aligned. That protects both the tool and the bed from potential damage.”

The XP bed itself features segmented, replaceable H-plate holes, allowing operators to replace only worn sections, reducing long-term maintenance costs.

“We’ve also seen excellent durability from our applicator tools in the eld lguin said

“Very few XP tools have come back for repair, which speaks volumes about the strength and build quality under continuous use in challengingenvironments.”

he fastening system s bene ts were recently validated during a 14-week trial at an underground coal operation. The results were clear – and game-changing.

“After completing the trial, the site fully converted to the XP system across its operations. The extended splice life meant fewer clip changeouts, and crews had more time to focus on other critical maintenance tasks,” Olguin said.

Crews also praised the system’s reliability and the reduced need for unplanned downtime.

“When your fastening system performs longer and more consistently, the productivity bene ts are immediate And in this industry, strong results get noticed quickly,” Olguin said.

Since the successful trial, other coal mines have trialled the staple fastening system, experienced similar results, and have now made the switch to XP.

With durability and uptime being essential in underground coal operations, every aspect of the XP system is engineered for performance.

“The larger loop area reduces stress concentrations and increases fle ibility at the splice,” Olguin said. “The coldrolled steel construction offers improved resistance to wear and fatigue. Even the robust design of the fastener helps protect staple legs from damage, extending the overall lifespan.”

These features contribute to fewer breakdowns, lower maintenance costs and higher production availability – delivering real-world value to miningoperations.

Olguin said Flexco positions itself as a long-term partner to mine operators.

“We’ve always believed our role doesn’t end once the product is delivered,” Olguin said.

“We’re here to support our customers every step of the way – from the initial setup and training to ongoing technical support throughout the life of the mine. When you work with Flexco, you’re not just getting a product – you’re gaining a team committed to your success.”

Motion’s Nick Kerwin and Stephen Forbes reflect on the legacy, leadership and loyalty behind two of Australia’s most respected industrial names.

TWO OF MOTION’S

legacy businesses, CBC and Hardy Spicer, celebrated milestone anniversaries in 2024: 70 years and 75 years respectively.

For Motion, these anniversaries are more than a celebration – they represent the foundation of Motion’s ongoing commitment to local expertise, customer partnerships, and technical innovation.

Founded in Sydney in 1954 by J.J. Martin-Weber, CBC established itself through a customer rst strategy

“Martin-Weber worked harder than anyone else otion sia aci c executive general manager Nick Kerwin said. “When CBC teams visited remote mine sites or sugar mills, they’d arrive on the wee end ensuring they were rst through the door on Monday morning. That mentality became embedded in ourDNA.”

ne de ning early move was s aggressive acquisition of bearing stock from a British company, outmanoeuvring a major competitor and accelerating CBC’s expansion. From a single Sydney outlet, CBC grew to a network of over 120 branches nationwide, becoming one of Australia’s largest distributors of bearings and power transmission products.

“Our competitors today have 25 to 30 branches,” Kerwin said. was ve times that si e nd it wasn’t just stock on shelves – we

invested heavily in technical people andengineering e pertise offering customers full solutions to improve uptime and performance.”

Hardy Spicer’s journey, meanwhile, stretches even further back. Originating in Birmingham, England during the First World War and expanding into Australia by 1949, Hardy Spicer began as a manufacturer of complete driveline components, serving the burgeoning agricultural and automotive sectors. Initially part of the Repco group, Hardy Spicer’s Australian branch built a strong reputation for manufacturing quality andreliability.

“Drive shafts and hydraulics are fundamental to so many industries – mining, rail, agriculture, waste management, and even ski lifts,” Motion sia aci c e ecutive general manager Stephen Forbes said. “If it moves, Hardy Spicer can support it.”

Through the decades, Hardy Spicer evolved from pure manufacturing into a broader service-driven business, incorporating hydraulic hose solutions alongside its core driveline expertise. Strategic acquisitions in the 1970s and 80s helped build the hydraulic side of the business, while ongoing investment expanded its branch network nationally.

“People sometimes ask why we offer both drive shafts and hydraulic

said. “Those capabilities came through strategic acquisitions – and over time, they became central to our value proposition.”

Hardy Spicer was acquired by the Inenco group (and later by CBC’s parent company) in 2002, setting the stage for its eventual integration into Motion. Today, Hardy Spicer operates 14 branches nationally, supporting customers with local service centres capable of building, repairing, and customising drive shafts and hydraulic solutions.

“Each service centre is a front door to our capabilities,” Forbes said. “They’re e uipped to offer technical advice assemble products, and deliver rapid support across the industries we serve.”

These capabilities have allowed Hardy Spicer to build deep relationships across Australia’s heavy industries, supporting not just everyday operations but critical infrastructure projects and specialised emerging sectors. From renewable energy projects to recycling operations and heavy vehicle electri cation ardy Spicer continues to evolve alongside the industries it services.

Motion’s acquisition of CBC and Hardy Spicer did not signal the end of their brand stories – rather, it marked a new phase of growth. Both brands continue to operate within the company, bringing together decades of technical knowledge with Motion’s capital strength, expanded national footprint, and shared systems.

he cultural t was strong from the start,” Kerwin said. “The Martin-Weber family, who ran CBC, had a long-standing relationship with Motion in the US. They knew Motion would support their legacy, their employees, and their customers for generations to come.”

Forbes echoes this sentiment, noting that the integration has brought tangible bene ts across the business

“Motion gives us the ability to scale, to access capital, and to invest in better

systems and safety standards,” he said. “It also helps us innovate – whether that’s through upgrading our hydraulic testing equipment or investing in technologies suited to industries like wind energy and recycling.”

While the Motion brand will become more visible across branches over time the values that de ned and Hardy Spicer remain unchanged. Local knowledge, technical expertise, and a genuine commitment to helping customers succeed continue to drive the business.

“We’re seeing it in action already,” Forbes said. “New opportunities are opening up across emerging sectors. Whether it’s advanced hydraulic solutions for solar panel installations or custom driveline engineering for heavy electric vehicles, our legacy brands are powering the future.”

As Motion moves forward, it is doing so with a clear view to preserving and enhancing the strengths that made

CBC and Hardy Spicer trusted names in the rst place

“While our long-term intention is tobring all of our offerings under the oneMotion brand – we will

ensure the legacy of all our brands endures,” Forbessaid. “What matters is that theservice, the expertise, the reliability – that remains. And it’s gettingstronger.”

With strong local partnerships, new product innovations and the addition of Eurosilo technology to its portfolio, AUMUND is setting its sights on an even bigger role in the nation’s resource and infrastructure sectors.

FOR MORE THAN 50 YEARS, the AUMUND Group has had a strong presence in Australia, with over 150 installations across mining, steel, cement, fertiliser and other heavy industries. Many of these equipment installations are with repeat and internationally renowned customers and have stood the test of time to offer reliable material handling solutions.

The German-headquartered engineering company has built its reputation on adapting global technologies to Australia’s unique bulk handling conditions, a strategy that continues to underpin its success.

AUMUND Group Australia country manager Dan Birkett said that the company’s formula for longevity in this market comes down to local partnerships, customised engineering, and a strong after-sales network.

“The local partnership gives us support and engineering around the Australian standards, which are unique in the global market,” Birkett said. e re not here to offer something that suits the global everywhere. It’s more tailor-made for the Australianmarket.”

This localisation extends to manufacturing fle ibility

AUMUND can build equipment in Asia or Europe, but also in Australia to suit customer preferences, a valuable option given the strong “Australian made” sentiment in local procurement.

With the AUMUND group partners, we are able to ensure full compliance with local and national standards.

SCHADE’s partnership with WDT Engineers is a prime example of how local alliances have bolstered its market position. WDT, based in Brisbane and Mackay, has worked with AUMUND subsidiary SCHADE for 25 years, delivering robust stockyard solutions.

Likewise, Ammermann based in NSW, have been with the group for many years as a partner agent, Ammermann are very strong with the AUMUND range of products with close customer alliances across all Australia.

Both Ammermann and WDT are able to hold stock at their facilities and supply service technicians for AUMUND groupequipment.

“It’s that mutual support and the deep understanding that WDT have of the industry,” Birkett said. “They’re here in the time zone for quick response, that could be repairs, maintenance, or getting an engineer on site within 24 hours.”

The partnership’s ability to provide fabrication, local contracting and immediate customer support means AUMUND can compete on more than just technology, it can match the responsiveness of a purely domesticsupplier.

SAMSON Materials Handling, another AUMUND brand, is recognised for its mobile ship loaders and Eco Hopper dust-control systems. These solutions are particularly suited to Australia’s multiuser and seasonal ports, where berth space must be reallocated quickly.

“Mobility is key,” Birkett said. “The ability to remove equipment from the uay to free up the berth for different operations is critical.”

Environmental compliance is equally central to SAMSON’s designs. The Eco opper uses advanced air ltration rather than water mist, preventing valuable product loss.

“We can return any product collected on the lters bac to the process stream Birkett said. “Your yield is high, and your product isn’t being blown away or dampened down.”

The AUMUND, SCHADE and SAMSON brands are known for their reliability in process-critical applications, from feeding cement kilns to unloading silos at mining operations.

This durability is supported by a century of experience within AUMUND, and nearly 250 years of combined expertise across the Group’s subsidiaries.

“Understanding failure modes is very, very critical,” Birkett said.

The company’s preventative maintenance tool, PREMAS 4.0, is a digital monitoring system, that tracks real time and historical data to allow monitoring and analysis allowing customers to address issues before they lead to costly downtime.

Large after-sales and spare parts warehouses in Asia, along with technical support from global and local teams, ensure parts and expertise are on hand.

“If that piece of equipment goes down, your process stops,” Birkett said. “By employing AUMUND technology, we can help prevent that.”

In June 2025, AUMUND integrated ESI Eurosilo into its portfolio, an acquisition that e pands its ability to offer complete material handling systems.

Eurosilo technology provides largescale storage solutions for industries including energy, agriculture and food, opening doors to sectors where AUMUND has been less active in recent decades.

“It’s an additional string to our bow,” Birkett said.

“We can bring in various facets of our bulk material handling technology and provide process-critical solutions as part of a bigger scope.”

•Smooth, low profile splice with increased tensile strength

Applicator

•A larger and more durable loop area for longer splice life

•Applicator tools that skip over misdrives without starting over

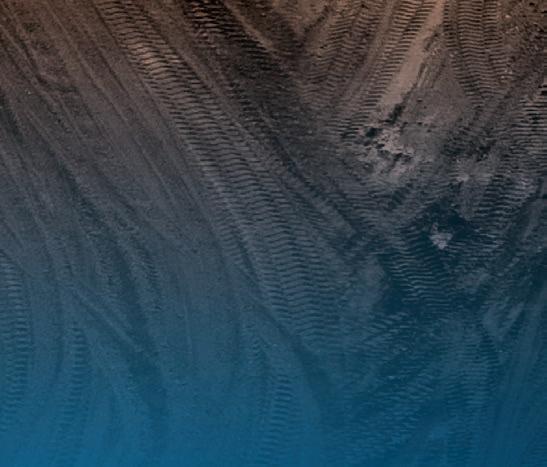

While stackers and reclaimers can endure harsh environmental conditions for decades, they still need maintenance work and replacements, and this is where Aurecon can help.

are paramount to Australia’s bulk material handling operations. Whether in the Pilbara iron ore supply chain or on the east coast’s coal terminals, these towering machines form the link between mine, port,andship. But while their size and productivity are often what catch the eye, the real challenge lies in sustaining them safely and reliably across decades of service. For Aurecon, supporting clients to navigate this challenge is high on its priority list.

“The company’s role spans the full life cycle of these machines –

“We’ve got a long history of working with our clients and their assets, which involves stacker and reclaimer machines on both the east and west coast. A lot of the work we do is across the full life cycle of a stacker or reclaimer, so we understand how risks and investment decisions have evolved over time.”

According to Brooks, fatigue remains one of the most signi cant ris s foroperators.

“Particularly with these machines, metal fatigue is a key risk with

analysis, we’ve been able to help clients focus inspections on the critical areas that matter.”

Many of these areas, Brooks said, can be di cult to access from general walkways and platforms, meaning cracks or other fatigue damage can go unnoticed without targeted inspection regimes. Aurecon’s work often involves validating analysis models through onsite instrumentation.

“There’s one thing to understand the theoretical side of what a code might prescribe,” he said. “But there’s another piece in actually understanding how these machines operate in service, which can

Alongside fatigue, corrosion –particularly in coastal environments –remains a major challenge.

“Corrosion, in conjunction with fatigue, is a key area of risk for these machines,” Brooks said.

“There’s no prescribed method in design codes to fully understand the implications of condition with fatigue, so it is a big consideration.”

While stackers and reclaimers are often grouped together, Aurecon draws a clear line between the operational stresses each type of machine faces.

“Typically, we see reclaimers as a lot more arduous in the work they do,” Brooks said. “They generate far more cyclic loading driven by digging effects whereas a stac er is not sub ect to such loading. That means stackers are generally less susceptible to fatigue compared to reclaimers.”

Still, both machine types demand careful planning when it comes to maintenance and remediation.

Aurecon frequently assists clients with scoping and executing remediation works during shutdowns and outages –balancing the reality of limited downtime against the scale of repairs required.

“It would be a luxury if you could take these machines down for long periods to remediate them,” Brooks said.

“But production is key. Tonnes mean dollars, so the challenge is keeping them operational while also ensuring their long-term integrity.”

Beyond inspection and remediation, Aurecon is also guiding clients through the challenge of ageing assets.

Many machines are reaching or exceeding their theoretical design life, forcing operators to decide whether to invest in life extension or pursue replacement.

“The landscape has shifted. Whereas production was once the number one driver, capital is now almost the leading factor,” Brooks said.

ome machines re uire signi cant remediation to extend their life safely. It’s a balancing act between capital, production, and safety.

“It’s not just about the machines themselves. On top of condition, compliance, reliability and obsolescence issues it is also how each machine ts into the wider ecosystem of operations. Making a decision solely with blinkers on about a particular machine may not be the right decision for the business.”

For Aurecon, a long-term view is key to guiding clients from inception right through to those end-of-life strategies.

“We are heavily involved across the full spectrum of a machine’s life cycle,” Brooks said. “That means getting involved early to help inform clients about the operational risks, inspection tactics and regimes, through to helping them maintain and make complex decisions about whether to extend or replace them. Having that understanding across the spectrum adds value at every stage.”

Since 1985, Kinder Australia has been at the forefront of conveyor solutions, delivering trusted, innovative products that improve e ciency, safety and productivity in bulk materials handling.

We support our customers with:

• High-performance products that evolve with industry needs

• Expert advice and genuine customer care every step of the way

• Reliable outcomes that support long-term site success

As we mark 40 years of progress, we continue to engineer smarter, safer and more sustainable solutions for every site we serve.

Discover what Kinder can do for your operation.

Structural Integrity Engineering has celebrated 25 years of supporting thousands of projects in the mining and material handling sectors.

Structural Integrity Engineering’s (SIE) mission has remained the same: providing independent specialist expertise in structural engineering with its talented team.

“Our role is to ensure that our engineering and our auditing aligns with the middle word in our company’s name being integrity,” Structural Integrity Engineering managing director Doug Hawkes told ABHR.

“That’s both an engineering outcome but also a cultural outcome thatwevalue.

“We value the ability to convey our messages to our clients in a frank manner because we value integrityandindependence.

“That’s both structurally, and also morally, because at the end of the day, there are people who rely on our work to be correct, and their lives depend on it.”

Fundamental to SIE’s operations is its experienced team of engineers who specialise in the mining, ports, bulk handling and heavy sectors.

aw es leads a uali ed team that has specialist skillsets including deep standards knowledge, design, risk assessments nite element analysis

3D modelling and reality modelling and years of industry experience across the bulk handling, mining, ports and heavy industrial sectors. This range of skills has also be used in applications involving bulk materials handling machines.

The team also maintains a strong connection with the industries they work in through leadership roles. Hawkes has been part of several Australian Standards committees, including the ME-043 Committee for AS4324.1, where he has been the drafting leader for the last two revisions, as well as BD-001, for AS4100 and AS/NZS 5131.

There is a sense of responsibility that the SIE team carries with it when conducting structural design, assessments and inspections in these sectors. The machines are often subject to immense capital expenditure by SIE’s clients, and, in circumstances where things can go wrong, it can be costly andhazardous.

Therefore, SIE has team members with a depth of knowledge in structural mechanics, Australian design standards, and the skillset to utilise the latest technology in their work.

The result is an economical and e cient design and assessment process. In sectors that can scarcely afford downtime and shutdowns s e ciency means engineering solutions can be designed with the client’s constraints in mind.

“We train our people to have a depth of knowledge,” Hawkes said.

“This is not only in the engineering sphere, but it is also important to understand what clients in our sectors expect. Our industries have very little downtime or the ability to shut things down for extended periods of time.

“The way we engineer solutions for our clients has to consider the client’s constraints and the engineeringconstraints.

“The value of experience sets us apart. We always have young engineers who are able to perform some services, and they have the oversight of our senior and heavily experienced engineers. The depth of knowledge that our team has is a key advantage.”

Since it was established, the company has honed its s ills speci cally in some of Australia’s biggest sectors and completed thousands of projects. When it comes to stackers and reclaimers, SIE has supported projects from concept to decommissioning and everything inbetween.

As an independent expert, SIE has worked with clients across the lifecycle of their machine. From the early stages, can complete the speci cation for new machines, undertake tender assessments and perform their specialty - design audit services. For fabrication, SIE can provide advice and carry out inspections to determine if fabrication is being completed according to AustralianStandards. Within the operational scope, SIE has carried out machine condition inspections and risk assessments, as well as upgrade feasibility and detailed assessments, life extension and decommissioning assessments, and incident investigations. The Australian-based consultancy has also supported customers with their operations through assessments for the replacement of machines and the impacts on existinginfrastructure. Hawkes told ABHR that a ey difference is wor s for the owners of the machinery rather than the machinery manufacturers.

This means the client can have peace of mind that they are receiving an honest perspective in the advice received with the owner’s interests in mind.

“We’re not aligned with the machine suppliers; we respect their role but we work for the owners. We always have the owner’s interests as the primary consideration and that allows us to provide frank and fearless advice,”hesaid.

“Our clients respect our trusted advisory services, and we can advise them on solutions that achieve their desired outcomes.”

Over the years, SIE has managed to maintain a trusted reputation for its ability to deliver independent advice its customersrelyupon.

“Our purpose is in our name to deliver structural integrity through engineering and that means we’re all about safety,” Hawkes said.

“It is a responsibility that we take veryseriously.”

Global engineering specialist Koch Solutions is delivering all-electric, sustainable material handling solutions, from stackers to reclaimers, designed for decades of reliable service.

a machine, every structural, mechanical, electrical, and automation component must work in harmony. Even small changes can trigger a ripple effect across the design.

For example, replacing a ladder with stairs and a platform adds weight, which may require upgrading the hydraulic lu ng cylinders his in turn demands larger pumps, electric motors, and switchrooms with each modi cation compounding the machine’s size, weight, and cost.

With mining companies seeking both cost e ciency and reduced carbon footprints, design optimisation is critical.

Original equipment manufacturer (OEM) head of sales Luke Bennett told ABHR that, without careful oversight, incremental changes can spiral.

“As an OEM, we know where to draw the line so we can deliver a machine that meets the project’s requirements safely, delivers the tonnes needed, and stays within budget. A machine that might start at 1500 tonnes can end up signi cantly overweight adding millions to the cost of the machine and the clients required infrastructure.”

From collaborative design to advanced automation, Bennett said OEM partnerships are delivering measurable gains in productivity, safety, andsustainability.

Koch Solutions’ stackers and reclaimers are typically designed for a minimum 25year service life. Over that time, mining technology, operational needs, and environmental, social, and governance (ESG) priorities can shift dramatically. Close OEM collaboration ensures clients can upgrade equipment for improved throughput energy e ciency and safety echnology changes priorities emerge, and automation becomes more advanced,” Bennett said.

“We partner with specialist suppliers around the world to integrate the latest solutions into existing assets.”

Pre-study phases involve working with clients to determine the optimal machine si e con guration and e ciency strategy whether that means a single high-capacity unit or multiple

Solutions can increase utilisation rates from around 70 per cent to 80 per cent and beyond translating into signi cant performance upside as well as cost and energy savings.

Productivity gains through smarter design

example where a new machine seemed underpowered he culprit was the bucket tooth design, which increased cuttingresistance.

By using computer-aided simulations to redesign the tooth, Koch Solutions reduced friction and boosted performance without increasing motor size.

“We can now apply that design across other machines and sites,” Bennett said. “It’s a great example of the iterative process that only an OEM with both design and servicing capabilities candeliver.”

his approach nown as total lifecycle asset management, focuses on baselining current performance and continuously improving, whether that means extending wear life, reducing manual intervention, or implementing safer inspection methods.

Building smarter, connected systems

Automation and digital integration are making supply chains more intelligent.

Koch Solutions’ machines connect mine stockpiles with export logistics, and newtechnologies enable precise ore tracking from pit to ship.

re uest a speci c grade and moisture content from a stockpile quadrant, andthe machine will automatically reclaim exactly what they need,” Bennettsaid.

operatewithout on-board operators, apart from shiploaders, which are transitioning towards semi-automation.

just a machine, but the knowledge, partnerships, and experience that ensure it delivers value for decades.”

TUNRA Bulk Solids develops custom solutions to suit the individual needs of our clients.

Services:

Flow Properties and Materials Testing

Dust (environmental) Testing

Wear Testing (Impact, Abrasion and Erosion)

Conveyor Belt, Idler Roll and Pulley Testing

Discrete Element Method (DEM) Modelling

DEM Calibration Testing

Materials Handling Consultancy and Contracted Research

Bin and Stockpile Design

Pneumatic and Hydraulic Conveying

Computational and Scale Modelling

Site Visits

Professional Development Courses

2025 Professional Development Opportunities:

Storage, Feeding, Transfer and Belt Conveying Course: 11-13 November (Perth) 2026 Professional Development Opportunities: Storage, Feeding, Transfer and Belt Conveying Course: 19-21 May (Brisbane)

STEVE DAVIS

Steve Davis discusses Australia’s bulk handling sector, highlighting the advancements the industry has made and the organisations that are providing local innovations and expertise.

Steve has worked in bulk handling for 30 years, for both resource companies and professional engineering firms, in Australia, South Africa, the Middle East and Canada. His experience encompasses such commodities as iron ore, coal, potash, phosphates, petcoke, sulphur, sands andgrain.

Bulk material handling expert Steve Davis dives deep into stackers, reclaimers, and the yard machinery critical for mining operations around the world.

As with all rail mounted machines, AS4324.1 applies.

Other stacking methods that are commonly used include the overhead tripper conveyor. An overhead support structure is needed so these are common is storage sheds s with a ed boom stacker these can only provide a continuous cone stockpile.

Some stackers have bypass facilities to allow through feed, especially if there are two stackers on the same yard conveyor, or if there is a requirement to bypass the stacker for direct loading to a ship. Stackers are available with capacities well in excess of 10,000tph.

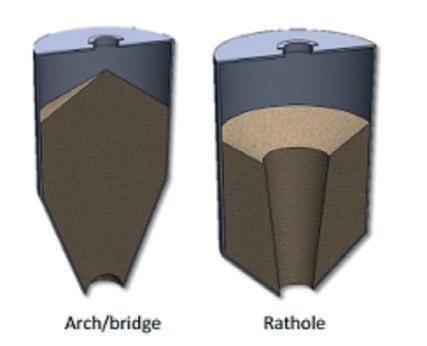

Many types of reclaimer are available ifferent reclaimers wor better with speci c stoc piles and material management methods. Stockpiles can be considered as long term storage such as a buffer for a coal

power plant, simple turn over where no mixing or turn over order matters, batching stoc piles to feed a speci c ship or train, or more complex stockpiles where some mixing is required during stacking and reclaiming to even out the variability of the material. Reclaimers are generally operated under automated control with no need to provide an operator cabin.

If mixing of the reclaim stream is required to obtain a relatively homogenous bulk, the selection of machines and stockpile arrangement should be de ned as early as possible Blending, that is the proportional blending of two or more materials, requires as many discrete stockpiles and reclaimers as there are blend materials. Blending is rarely used in the minerals industry, yet the term is frequently used when mixing is required. Both mixing

and blending require that the material is stacked correctly to enable reclaim to be controlled to match.

Reclaimers are installed on stockpiles to recover bulk materials. Where the material reclaim rate is relatively constant, such as power plant feed, the reclaimer capacity needs to be only marginally more than the required rate. Bulk materials are often reclaimed from stockpiles to batch transport systems. Ships, trains and trucks are batch systems, and reclaimers must be sized well above average capacities to cover this. Loading to ships will not be continuous due to hatch changes, berthing, and other delays and the reclaimer (and shiploader) will likely have a rated capacity near twice the average loading rate. Trains and trucks will likely require a surge bin immediately prior to load out.

The boom bucket reclaimer is the most fle ible machine for stoc pile operation and offers the highest continuous reclaim rates. More than 10,000tph is possible with these machines. The average or aggregate reclaim rate is determined by many otherfactors, and a 10,000tph reclaimermay only achieve less than 5000tph average due to the method of reclaim, the size of the stockpile reclaim rate. Boom bucket reclaimers can reclaim stockpiles with 50 metre or more base width and can recover material from anywhere along the length of a linear stockpile.

here is a difference between long travel, or trench, reclaim and slew reclaim. Most bucketwheel reclaimers are installed for slew reclaim. Specialist advice should be obtained if looking at long travel reclaim.

Boom bucket wheel reclaimers are designed for slew or trench reclaim and, although they can be used for either method are not as effective in the alternate mode.