As we head into the first weeks of winter, it’s hard to believe we’re already halfway through 2025 – what a year it’s been.

Since our last issue, Australia has taken to the polls for the Federal Election and, once again, energy took centre stage. With the two major parties presenting vastly different directions for the industry, there were many questions about what Australia’s energy future would look like.

changes that lie ahead. In this issue, Energy Consumers Australia CEO, Brendan French, shares his thoughts on the role of proactive planning as Australia moves away from gas, and how the government can guide consumers through the process.

Chief

Art Director Alejandro Molano

National Media Executive Brett Thompson

Client Success Manager

Louisa Stocks

Head Office

Prime Creative Pty Ltd

379 Docklands Drive

Docklands VIC 3008 Australia P: (03) 9690 8766 enquiries@primecreative.com.au www.primecreativemedia.com.au

Now that the result is in, it seems the sector will forge ahead on its current path, with the Federal Government standing by its existing policies. But there’s still a long road ahead for Australia to reach net zero, so to kick off our June issue, we share some of the industry’s key recommendations.

While promises about energy policies dominated the headlines in the lead-up to the election, conversations about the workforce powering the transition continued behind the scenes. According to Powering Skills Organisation, building the workforce of tomorrow will require the industry to cultivate a culture of lifelong learning, and in this issue we shed some light on what that might look like.

We also showcase some of Hydro Tasmania’s initiatives to inspire the next generation, as the utility works to engage students and young people with hydropower careers, helping lay the groundwork to secure the passion and skills needed to power the state for decades to come.

Supporting a strong, skilled workforce to build Australia’s energy future is crucial. Equally important, though, is ensuring consumers can navigate the

As consumers transition to more sustainable solutions, we turn our attention to one group that has largely been left behind: apartment residents. While Australia has long been a leader in rooftop solar adoption, thousands of people living in multi-tenant properties have been unable to harness the power of the Australian sun. We explore the barriers they face and highlight some potential paths forward.

We are also proud to partner with Australian Energy Week 2025 (17–20 June) for Energy June, and we’re thrilled to share some insights from some of this year’s top exhibitors. The event will run from 18–19 June at the Melbourne Convention and Exhibition Centre, and we hope to see you there.

Speaking of events, we’re also looking forward to attending Australia Wind Energy 2025 on 17–18 July at the Melbourne Convention and Exhibition Centre. If you’re attending, you can visit us in the media centre – we’d love to say hello.

We hope you enjoy reading this June issue of Energy as much as we enjoyed putting it together. If there’s a story, project, topic or challenge you’d like to see us cover in a future edition, please get in touch.

Sarah MacNamara Editor

If you have a story idea, tip or feedback regarding Energy, I’d love to hear it. Drop me a line at sarah.macnamara@primecreative.com.au , and don’t forget to follow us on social media – find us on LinkedIn, X or Facebook.

22

52

• Charge your battery for free — directly from the grid*

• Get paid when you use your battery*

• Get paid more for your solar*

GloBird Energy’s ZEROHERO plan is designed to maximise the value of every battery you install. With features that boost your customers’ return on investment, ZEROHERO makes it easy to demonstrate the real benefits of buying a solar battery system.

Partner with GloBird Energy today — and focus on what you do best: selling and installing batteries. We’ll take care of the rest..

As the dust settles on the 2025 Federal Election, the energy sector has offered its thoughts on what the results mean for Australia.

The 2025 Federal Election placed Australia’s energy future firmly in the spotlight, with the major parties presenting two different paths to keeping lights on around the country.

Clean Energy Council (CEC) Chief Executive, Kane Thornton, described it as “a referendum on renewable energy”.

For the energy sector, the result

largely signals continuity. The Federal Government is expected to continue with the steps outlined in its existing Net Zero Plan and Powering Australia strategy, continuing towards the 82 per cent renewables by 2030 target. The most notable change is the addition of the $2.3 billion Cheaper Home Batteries Program, expected to roll out from 1 July 2025, reducing the cost of a typical installed battery by 30 per cent.

With the election now officially in the books, the industry has shared some of its key priorities for the upcoming term of government.

According to Thornton, the Australian people reconfirmed their strong support for wind and solar backed by batteries, pumped hydro and a small amount of gas.

“It’s now time to leave the politics behind and get on with the job of rolling out renewable energy to deliver affordable and reliable power for all Australians,” he said.

The CEC encouraged the Government to ensure new policies maximise investor certainty and deliver lower power prices and benefits to regional Australia, as well as reform to environment and planning laws and reform to the energy market to ensure clearer incentives for new investment, including for long duration energy storage.

Thornton also called for the need to continue working together to educate and engage the public on clean energy.

“We look forward to working with the Federal Government and the next Australian Parliament to ensure strong, stable and effective policy for the transition to clean energy,” he said.

Australian Energy Council Chief Executive, Louisa Kinnear, said the country is in the middle of an eradefining energy transformation that requires policy stability, continuity, and long-term reform that can endure beyond election cycles.

“We encourage all members of the 48th Parliament to commit to working to deliver the energy transition for the benefit of Australians,” she said.

Kinnear said the energy system of 2050 will be delivered by wind and solar, backed by hydro, storage and gas.

“There is sufficient understanding across the energy industry about the critical factors that will deliver the lowest-cost transition. Now we just need consistent, enduring and coordinated policy.”

The AEC’s key energy priorities for the Federal Government include focusing on affordability, harnessing consumer energy resources, backing the National Electricity Market (NEM) review, prioritising system security, and ensuring gas supply for electricity generation and retail.

“We look forward to working with the Federal Government and the next Australian Parliament in support of strong, stable and effective energy policy.”

Energy Efficiency Council

The Energy Efficiency Council (EEC) believes the election result sets the stage for a big ramp up in ambition on emissions goals, efficiency and electrification.

Chief Executive Officer (CEO), Luke Menzel, said there are still a number of policies on efficiency and electrification still sitting on the to-do list.

“With the nation’s trajectory to a high penetration renewable energy system now locked in, any additional cuts in carbon emissions will need to come from the demand side,” he said.

Menzel nominated the electrification of homes, manufacturers and food processors as low hanging fruit.

“We have the technology to pair efficiency and electrification to decarbonise vast swathes of the Australian economy, but we’re yet to see the serious policy and investments we need to get it done,” he said.

Among EEC recommendations for the government are upgrades to homes for health, comfort and efficiency, supporting business energy upgrades, setting national energy performance targets, strengthening the role of the demand side in the electricity market, aligning and modernizing retailer energy efficiency schemes and accelerating commercial builder efficiency.

Menzel said acting on these policies quickly will be critical to driving down energy bills and ramping up Australia’s emissions reduction effort.

“We’re looking forward to working with the Federal Government to get it done,” he said.

The Australian Energy Producers Chief Executive, Samantha McCulloch, said the decisive election result provided an opportunity for energy policy certainty and stability in the next term of Parliament.

“Australia and our region’s economic growth and energy security needs reliable and affordable gas supply, which requires continued investment in new gas exploration and development.”.

McCulloch said the Federal Government needs to prioritise implementing actions from the Future Gas Strategy and addressing the regulatory delays and uncertainty in the environmental approvals system.

The AEP’s election platform calls for the Federal Government to boost Australian gas supply to ease cost of living pressures, restore Australia’s global competitiveness for investment, deliver real emissions reductions with gas and carbon capture, utilisation and storage, and remain a reliable energy partner.

“We look forward to working with the Federal Government on advancing

the shared goal of boosting Australian gas supply to ensure reliable and affordable energy for Australian homes and businesses.”

The RE-Alliance said the Federal Election result is an invitation to get renewables done right in the regions.

RE-Alliance National Director, Andrew Bray, said, “We now need to redouble our efforts to ensure the shift to renewables is actively contributing to the strength and resilience of our regions.

“Let’s take the opportunity to work with our communities to ensure that renewable projects are done right.”

Mr Bray said polling consistently shows that people in the regions generally support the shift to renewable energy, so long as it’s done in a way that benefits communities and minimises impacts on nature.

“We look forward to working with regional MPs from all parties on practical solutions that ensure regional communities have the information and resources to participate in and benefit from the energy shift that is underway across the country.”

Rewiring Australia said the election result paves the way for meaningful commitments, such as the Cheaper Home Batteries Program, to be implemented.

Rewiring Australia Founder and Chief Scientist, Saul Griffith, said the program will drive down power bills. “Upfront costs are a big barrier to entry when it comes to home batteries, so knocking 30 per cent off the price of installation is a great step in the right direction,” he said.

Rewiring Australia also said the continuation of the Federal Government’s policies will ensure the country remains on the path to achieving 82 per cent renewable energy by 2030.

“We are looking forward to working with the Federal Government to achieve its renewable goals,” Rewiring Australia CEO, Francis Vierboom, said.

“We also want to encourage the government to continue to accelerate electrification and bill savings for Australian households – including finance that works for low-income homes, a strategy for rental energy bills, and further incentives to drive down the upfront cost of electrification,” he said.

By Paul Cunningham, CSIRO

Just outside of Harvey in WA’s south-west, CSIRO has successfully completed its landmark Harvey 5 well drilling operation, marking a milestone for the future of carbon management.

CSIRO’s In-Situ Laboratory (ISL) became a hive of activity in March and April with the arrival of a large drilling rig and its associated support infrastructure.

Under the scrutiny of industrial, government and scientific observers from across Australia and around the globe, a CSIRO project team and drill rig, well construction and research partners successfully drilled more than 1000m below the surface, directly into and through a major fault zone.

But why?

Carbon capture and storage (CCS) is a carbon management method that injects carbon dioxide (CO2) deep underground in a dense phase under high pressure. Understanding the risks of CO2 leaking up to surface via a fault

is essential for industry and regulators to safely use CCS as a mainstream emissions reduction tool to help achieve upcoming net zero targets.

CSIRO’s energy research focuses on three major themes: accelerating the electricity transition; decarbonising the industry and transport sectors; and carbon management technologies, of which CCS is a part.

The Harvey 5 well drilling operation was a high-risk, high stakes, and high precision operation.

Fault zones often feature crushed, unstable material and rock formations with reduced strength, all of which can cause a drill rig to get stuck, resulting in an expensive failure.

CSIRO principal research engineer and ISL project lead, Dr Ludovic Ricard,

acknowledged that the program was “a little daunting”.

Harvey 5 is a CO2 injection well, and Harvey 6 – drilled in 2024 – is an adjacent monitoring well. Both wells cross the fault zone and are packed with various monitoring technologies.

The successful completion of Harvey 5 enables the next phase of fluid injection and monitoring programs in a major fault zone.

“Normally when planning projects, you avoid faults,” Dr Ricard said. “But we are trying to answer the question that everyone asks: how do faults behave in the CCS context?

“We are deliberately undertaking a worst-case scenario, drilling a well into a fault, and we plan to directly inject supercritical CO2 to see what happens.”

According to the International Energy Agency, CCS is one of a group of carbon-management technologies contributing to direct emissions reduction in key sectors and removing CO2 to balance unavoidable emissions.

As commercial-scale CCS projects increase, so does the interest in potential risks of CO2 reaching unmapped faults. However, field data can inform models and improve predictive forecasting of risks or impacts for regulators and project proponents.

That’s where the ISL comes in. It’s a collaboration between CSIRO and the Japanese Government’s Research Institute of Innovative Technology for the Earth (RITE), in conjunction with the Federal Department of Industry, Innovation and Science, and the WA Department of Energy, Mines, Industry Regulation and Safety.

With clearly stated emissions reduction goals, Japan is keenly interested in cutting-edge CCS research. The ISL provides contemporary, science-based evidence to inform cost-effective, safe and reliable CCS projects while providing a long-term field site for domestic and international education and training, capacity development and technology testing in the CCS environment.

Dr Ricard said the growth in CCS projects demands a deeper understanding of how CO2 interacts with these geological features.

“That’s why we are doing this,” he said. “There’s a lot of uncertainty which needs to be reduced to enable safe and cost-effective CCS projects.

“It’s not just about science. It’s also about education, economics and

community engagement because, in the end, community support is required, cost-effective monitoring systems would help with that, and the results and learnings need to be applicable to real-world commercial applications.”

CSIRO Energy Resources Program Research Director, Dr Damian Barrett, said the organisation has been at the forefront of CCS research and development over the past 25 years.

“Most CCS projects in Australia have sought CSIRO’s expertise at some stage,” Dr Barrett said.

“We have broad capabilities in the science that underpins carbon capture, utilisation and storage [CCUS] technology and a strong track record working on demonstration and operational projects.”

Through the ISL, international collaborations and research participation at Victoria’s CO2CRC Otway International Test Centre, CSIRO’s research experience and capabilities are wide-ranging. From large-scale demonstration projects to laboratory-scale experiments to dynamic modelling, the research is enabling substantial emissions reduction and provides a pathway for industry to adopt carbon management technologies at scale.

CSIRO has operated point-source CO2 capture pilot programs at power plants in Queensland, New South Wales and Victoria for more than a decade, generating valuable information on the technical, economic and environmental performance of leading absorptionbased technologies.

This work has also contributed to the development of an advanced capture technology, licensed overseas, with

international collaboration involving industrial partners from Norway, China, Japan and the US.

Another key research area for CSIRO is direct air capture (DAC), where CO2 is removed directly from the ambient air through chemical processes. This newer carbon management approach has emerging opportunities in Australia, Europe and the US.

CSIRO’s collaborative work to progress DAC includes Airthena, CarbonAssist and the Ambient CO2 Harvester.

Assessing the potential role of CO2 in a future low-emissions economy is also a central focus. In 2021, CSIRO published the CO2 Utilisation Roadmap, which explores the opportunities for Australia to support new industries and reduce carbon emissions with emerging CCUS technologies.

CO2 can be combined with other feedstocks such as hydrogen to make new low-emissions products and replace high-emissions materials like fossil fuels. This is a key component in CSIRO’s investigation into specific opportunities for CO2 utilisation in Western Australia and the Northern Territory as part of low-emissions CCUS hubs.

CSIRO published reports in 2024 to help inform the business case for a low-emissions hub at the proposed NT Middle Arm Sustainable Development Precinct near Darwin.

Additional work by CSIRO and the Global CCS Institute as part of the CCUS Hubs Study assessed the potential role of CCUS in decarbonising Western Australia’s industries.

These studies found CCUS hub models could deliver significant benefits as the technology can be implemented immediately, with potential to work across a range of emissions-intensive and hard to abate industries.

Back at the ISL, the site is being readied for the 2025–26 research program, in which fluids will be injected into and below the fault zone, generating a wealth of data about fluid movement and the performance of various monitoring technologies.

The keenly anticipated research results will be featured as part of discussions at the Greenhouse Gas Control Technologies Conference (GHGT-18), to be co-hosted by CSIRO in Perth on 26–29 October 2026 (ghgt.info).

For more information research, visit csiro.au/energy

From Brisbane to the rest of the world, NOJA Power is rewriting the rules of reliability.

s Australia continues to rewire its energy systems for a more sustainable future, the demand for safe, dependable switchgear across the medium-voltage network has never been greater.

Responding to the needs of Australia’s electricity sector is nothing new for Brisbane-based manufacturer NOJA Power. In fact, it’s business as usual.

The company’s latest innovation, the EcoLink, provides a practical solution for a longstanding industry challenge: delivering reliable recloser functionality on low network currents, particularly in regional and remote areas where reliability is a common concern.

The EcoLink is an innovative fuselink-mounted recloser designed to operate with as little as 0.15A of primary current. The fully self-powered uses supercapacitor technology, removing the need for batteries and reducing maintenance and environmental risk.

Designed as a direct replacement for traditional fuses, the EcoLink is easily retrofitted to most legacy fuse holders, making it a flexible solution for utilities looking to improve reliability on existing infrastructure.

What sets the EcoLink apart is its response time. The device is configured to interrupt faults in the same time as a conventional fuse, bringing a new level of reliability to even the most rural and remote distribution lines.

Importantly, the EcoLink places safety at the forefront of its design. A patented breaker interlock handle ensures the line current is interrupted with the internal vacuum interrupter before the device can be disconnected. This mechanism prevents external arcing, protecting equipment and operators.

As regional networks take on a larger share of the energy transition, the EcoLink is set to play a critical role in keeping infrastructure reliable and field crews safe, replacing legacy technologies that were not created for the modern energy system.

Designed and manufactured at NOJA Power’s Brisbane headquarters, the EcoLink stands as a prime example of Australian innovation solving energy challenges across the distribution network – all on local soil.

The focus on local manufacturing is central to the company’s ongoing success. While many companies can utilise overseas products or components, NOJA Power has made significant investments in its Brisbanebased production capacity.

The 2023–24 financial year (FY24) saw the company secure an additional

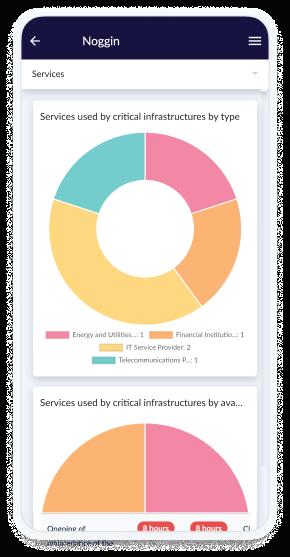

Threats to Australia’s critical infrastructure are on the rise, and policymakers have responded with legislation like the Security of Critical Infrastructure Act (SoCI) to keep assets safe and the country secure. To comply, critical infrastructure entities can turn to Noggin’s integrated resilience software, to help prepare for and respond to business disruptions and critical events.

The Noggin platform seamlessly combines 10 solutions into one, easy-touse system, with solutions for: operational and third-party risk management, business continuity, crisis & emergency management, operational resilience, and safety & security operations.

Learn why Australian critical infrastructure entities choose Noggin to strengthen their resilience against business threats: www.noggin.io

Field service teams are the lifeblood of a resilient energy network, but what happens when logistics can’t keep up? Droppoint has a solution.

In the race to modernise Australia’s energy infrastructure, much of the attention has focused on big ticket items such as grid upgrades, renewable integration and the sector’s digital transformation.

But there’s a quieter, less assuming challenge threatening to hold the industry back, and it’s hiding in warehouses and depots around the country – literally.

Inventory visibility is proving to be one of the most pervasive issues facing the sector – and it’s a challenge that leading field services provider Droppoint is actively working to solve.

Indeed, a 2024 survey from leading field services provider Droppoint found that 46 per cent of respondents in the utility sector experience challenges related to limited real time visibility into current inventory levels.

Utility respondents specified inventory visibility as a top challenge for them, more so than other industries, with almost half regularly losing time collecting parts of waiting at home for deliveries.

At first glance, this may seem like a small operational detail. But the inability to accurately track and manage critical parts and materials is causing avoidable delays, increasing costs and undermining service reliability as the industry is ramping up the energy transition.

Droppoint CEO, Jason Flanagan, said a lack of adequate operational visibility presents significant business risks and inefficiencies.

“Without clear insight into inventory status and movement, organisations are prone to challenges such as redundant stock holdings, unnecessary procurement, stagnant inventory, poor stock rotation and lost productivity

due to time spent searching for items.” With decarbonisation targets looming large and a growing pipeline of transmission infrastructure to be delivered, the stakes are higher than ever. Inventory gaps are no longer just an inconvenience – they’re an obstacle the sector can’t afford to ignore.

The rising cost of poor visibility Managing spare parts has been critical to energy operations for as long as they have existed, but it’s the scale and complexity of today’s energy network that’s changed.

With the renewable rollout now in full force, businesses are working across vast geographies with a growing diversity of assets.

Field service crews are responding to more sites more often, and in more dynamic conditions. Whether it’s planned maintenance, emergency repairs or rapid upgrades, they need the right parts, and they need them fast.

Without clear visibility, however, the entire operation slows. Missing or misplaced parts trigger a domino effect of rescheduling, increased overtime, additional freight costs and blown out project timelines. And that’s just the most obvious impact.

In response to uncertainty, some businesses overstock “just in case”, tying up capital in inventory that might never be used. Others rely on emergency deliveries, or have workers travel long distances to retrieve missing parts, wasting time, budget and energy.

Then there are the less tangible impacts: extended outages, missed service level agreement metrics, delayed deadlines, frustrated customers, and potentially even reputation damage.

In a sector tasked with powering the nation, even the smallest inventory management issues can have major consequences.

Poor inventory visibility also adds a constant layer of friction for field technicians, who work hard behind‑the scenes to keep the industry running smoothly.

Instead of focusing on critical tasks such as installation, maintenance and repairs, technicians can spend valuable time chasing parts – calling depots, driving between warehouses or improvising on site without the right materials.

Inventory visibility is a top challenge for utilities, but efficient logistics is crucial to delivering the energy transition. Image: surachetkhamsuk/stock.adobe.com

stretched thin by labour shortages, dealing with the consequences of poor inventory visibility wastes hours they don’t have.

As the energy transition accelerates and demand on these essential crews increases, smart, efficient logistics will be crucial to supporting field technicians.

Traditional inventory models based around static warehouses and rigid stock allocations are struggling to keep pace with the demands of today’s energy sector. A new approach is needed to guide the industry through Australia’s transition and into the future energy system. This means:

• real time visibility across all locations, from central warehouses to field vehicles

• smart forecasting tools that position parts where they’ll be needed most

• seamless logistics that deliver to technicians quickly and reliably, no matter their location.

These solutions will form the foundations of a responsive,

ready to lead Australia through its energy transformation.

As Australia and New Zealand’s leading field services inventory management software provider, Droppoint is helping businesses bridge the inventory visibility gap in the Australian energy industry.

The company’s approach is simple: get the right part, to the right place at the right time – every time.

Rather than relying solely on a traditional warehouse model, Droppoint combines digital material tracking, distributed logistics and a network of 24–7 pick up and drop off (PUDO) locations.

As a managed service provider, Droppoint partners with best in class carrier partners and storage providers to create custom logistics solutions to field service teams in the energy industry. With Droppoint, parts can be delivered close to homes, work sites or one of the 500 conveniently located

the need for technicians to return to a central depot or travel between sites.

The whole system is coordinated with the support of the Material Orchestration System (MOS), Droppoint’s purpose built logistics software. MOS brings transport, inventory and location management together to provide a single source of truth.

It allows managers and technicians to manage workflows at every stage of the part lifecycle. From the movement of materials to their use in repairs, MOS provides end to end inventory visibility, right down to the serial number.

“The energy sector faces the dual challenge of ensuring operational uptime while managing inventory efficiently,” Flanagan said.

“Droppoint excels where enterprise resource planning systems (ERPs) often fall short, delivering effective last mile visibility for inventory tracking from its source – depot or vendor – to the point of use.”

Built by field service professionals for field service professionals, MOS is designed to keep technicians working, not waiting.

It represents absolute visibility, marking a shift toward more proactive field operations in the energy sector.

Droppoint equips field service teams in the energy sector with the real time visibility and reliable logistics they need to keep Australia switched on.

For more information, visit droppoint.com.au or chat with the team at booth B6 at Australian Energy Week, from 18–19 June at the Melbourne Convention and Exhibition Centre.

As the energy landscape transforms, one of Australia’s most established equipment specialists is bringing its expertise to the sector.

For more than 80 years, Tutt Bryant has been synonymous with reliability, capability and scale in Australia’s industrial landscape.

With a national footprint across equipment hire, heavy lifting and parts and services, as well as its longstanding relationships with global original equipment manufacturers (OEMs), the company has supported many of Australia’s major construction and infrastructure projects. Now Tutt Bryant is entering a new chapter.

Through the launch of Tutt Bryant Power and its Go Green initiative, the company is now turning its attention to the energy sector, bringing its decades of experience to focus on the future of low and zero emissions technology.

Tutt Bryant National Business Manager – Sustainable Products and Innovation, Chris Leahy, said the expansion represents a natural evolution of the company’s existing experience and capabilities.

“Tutt Bryant is committed to promoting sustainability and decarbonisation in our area of influence,” he said.

decarbonisation journey, the Go Green initiative seeks to increase the sustainable products, services and solutions available to the market.

“We recognise that through our three operating divisions, we’re able to reach a broad spectrum of customers who currently have limited options to lower their carbon emissions,” Leahy said.

The company is committed to developing home-grown solutions tailored to Australian conditions by utilising its in-house capabilities, collaborating with local enterprises and tapping into its vast network of global OEM partners and suppliers.

“The Tutt Bryant Go Green initiative is a whole-of-organisation approach to leverage the expertise from all parts of the group to deliver practical, sustainable and cost-effective solutions,” Leahy said.

This is being realised in part through Tutt Bryant Power’s low and zero carbon equipment solutions, which are centred by three key product offerings:

Battery energy storage systems

From a mobile charging system

The SANY SPL210 BESS is engineered for simultaneous charging and discharging and is easily transportable.

suitable for industrial use, Tutt Bryant offers battery energy storage systems (BESS) suitable for machines and sites of all sizes.

The company offers a range of AJ Power diesel generators to suit a variety of applications, with options ranging from 10 kilovolt-amperes (kVa) all the way to three megavolt-amperes (MVA) – all powered by leading engines renowned for durability and low fuel consumption.

Tutt Bryant also offers customisable and scalable hybrid power systems such as the LiFePO4D, which enables customers to automatically switch between photovoltaic (PV) self-consumption, battery supply and diesel power.

Beyond power equipment, Tutt Bryant offers a range of other solutions under its Go Green initiative to support the energy industry, from ranging from electric cranes and plant equipment to initial energy monitoring, load profiling and turnkey project solutions.

Its services are backed by a national network of trained technicians, a significant parts inventory and the resources needed to keep projects running smoothly.

With a legacy built on innovation and capability, Tutt Bryant is now delivering the same strengths to the energy sector, laying the groundwork for a cleaner, greener energy future.

For more information, visit tuttbryantpower.com.au

Whether you’re powering remote equipment or integrating renewables for your project, Tutt Bryant Power Products & Services delivers high-performance diesel, electric, or hybrid energy solutions.

OUR PRODUCT RANGE:

• Battery Energy Storage Systems (BESS) by Sany and Infinity Cube

• Renewable & Hybrid Energy Systems (LiFePO4D)

• AJ Power Stage V Diesel Generators with a 94% reduction in HC and NOx, with a 97% reduction in PM

Engineered for reliability. Built for Australia.

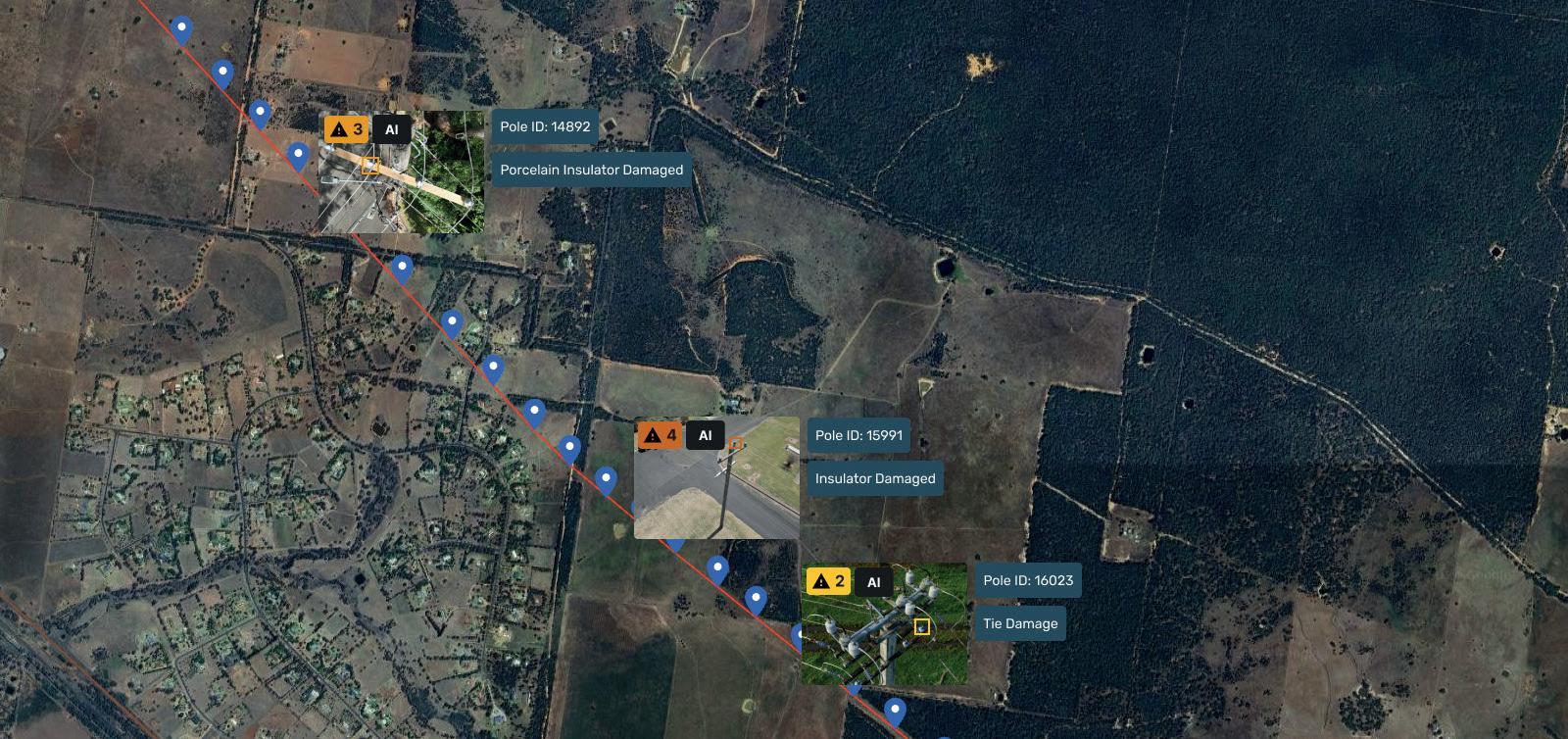

Smarter asset inspections are helping utilities inspect their assets with greater speed, accuracy and safety.

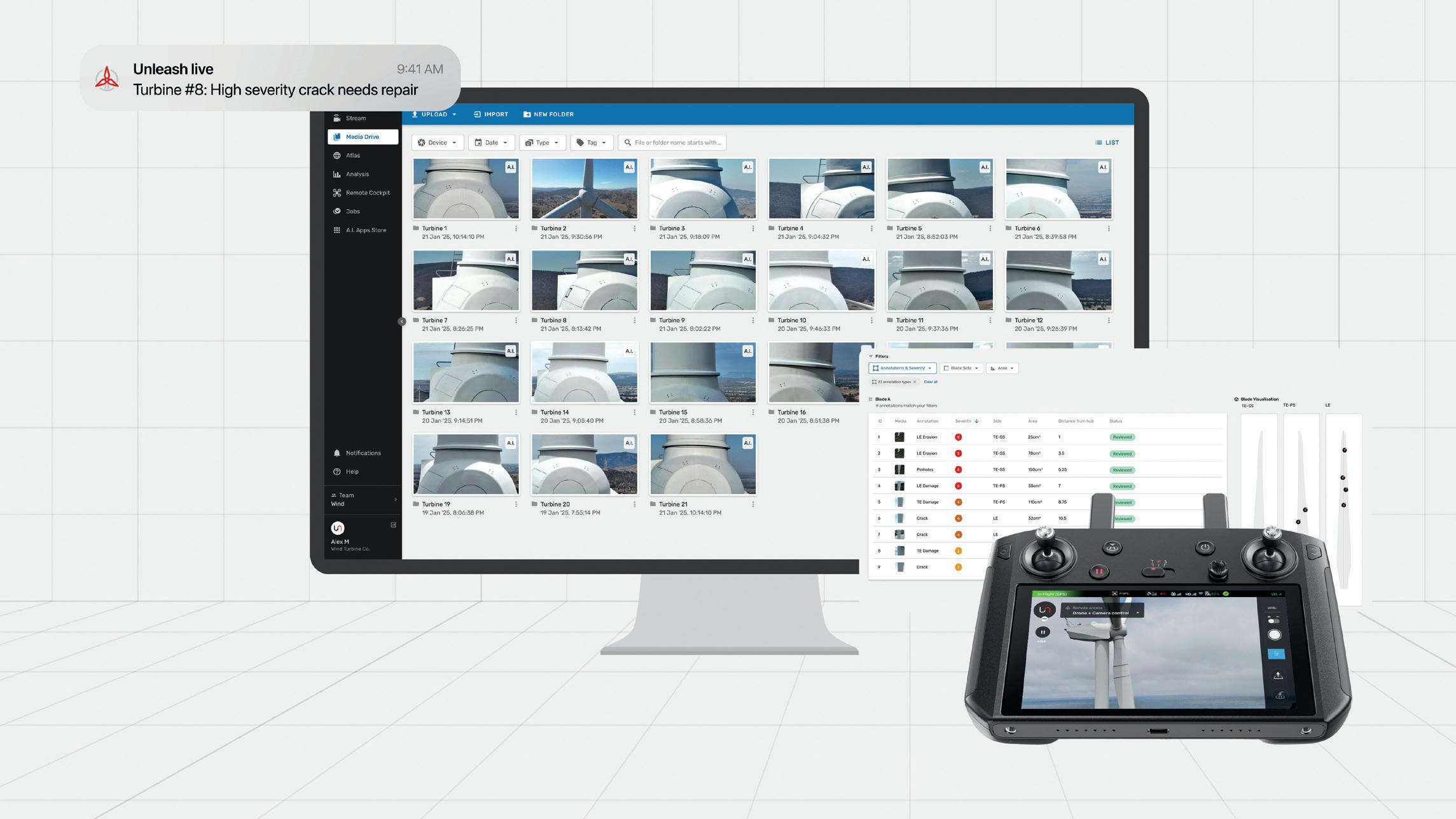

Images: Unleash live

The energy sector is working hard to meet the dual pressures of climate resilience and operational efficiency, and one company is leading the charge in critical infrastructure inspection.

As energy providers seek smarter, faster ways to monitor their assets, Unleash live has become a force in real-time video analytics and drone automation, and has been named a finalist in the 2025 Australian Financial Review’s AFR AI Awards in the productivity and efficiency category.

Energy sat down with Unleash live Group Chief Executive Officer, Hanno Blankenstein, in the lead up to Australian Energy Week (17–20 June) to learn how artificial intelligence (AI) and automation are redefining infrastructure management, from powerlines and transmission towers to wind turbines and solar farms.

management processes using machine learning, cameras and drone automation.

towers, substations and other assets with greater speed and accuracy and, importantly, without putting crews at risk. The results speak for themselves: lower inspection costs, faster fault detection, reduced downtime and improved safety. We do this across a range of sectors within energy, including fault detection on large solar farms, wind turbine blade condition assessment and industrial machinery.

Essentially, we can automate and speed up any manual visual inspection process that takes up precious time.

How is Unleash live’s platform helping the energy sector?

The challenges faced by utilities have not changed. Safety, reliability and efficiency continue to drive the agenda, with many investing in drone technology.

That’s where we come in.

Simply put, we automate the data collection and analysis for asset

Our platform connects virtually any camera to real-time, machine-learning AI apps that produce insights such as condition assessments. For utilities, that ranges from fast, automated image capture via drones, to computer vision machine learning models that improve fault detection on widely dispersed, costly-to-maintain assets, and enterprise resource planning (ERP) reporting of the network condition. It means utilities can inspect thousands of poles, wires,

What can we expect in your new video case study at Australian Energy Week?

We’re excited to showcase a case study featuring one of Australia’s largest utilities, serving more than three million customers in bushfire-prone regions. This client has completely transformed its inspection process using autonomous drones and our Autofly technology. Previously reliant on helicopters, this utility now conducts faster, quieter and more precise inspections using drones,

cutting costs and dramatically reducing bushfire risk.

We’re screening the full video at our booth and discussing how other networks can adopt this scalable model.

Can you tell us about Autofly and how it fits into your technology stack?

Autofly is at the heart of the productivity gains realised by customers such as Endeavour Energy and many other utilities worldwide. As a connected ground control station (GCS) application, Autofly supercharges pilots by providing efficiency capabilities that aren’t available in standard GCSs, such as DJI’s Flighthub2. These include one-click capture of pre-defined assets for fast, repeatable and structured data collection; zero latency live streaming to any browser for real-time remote collaboration; and real-time synchronisation of media assets.

This is enabled through a purposebuilt cloud-based media management tool, specifically designed to integrate with our machine learning applications and your ERP systems to analyse and generate insights from the assets inspected.

We have flown millions of assets many thousands of automated flight kilometres, achieving benefits such as three times the number of fault detections, an 80 per cent reduction in CO2, and a 78 per cent reduction in time using automation and

reporting when compared to manual drone flights.

Can you tell us more about the use of AI?

Unleash specialises in a branch of AI known as computer vision. We’re focused on the end-to-end pipeline, from capturing the images and video right through to analysing and reporting the data. This means we work with very specific datasets. Unlike broader large language model fields such as ChatGPT that use publicly available material as training data, we accelerate our customers’ capture of high-quality imagery in a structured and automated manner, which results in high performance machine learning models specific to our customers’ datasets.

We know there can be concerns about security and privacy when using third-party AI tools, so I’d like to highlight here that Unleash offers the option for our customers to wholly own their models.

I might be biased, but if you ask me, Unleash is the ultimate digital pipeline for delivering vision-based data insights – and it’s deployable across an unlimited number of use cases. Our customers find this pretty powerful.

What makes Unleash live stand out in the energy tech space?

For the Australian market, quite a lot. Our headquarters are in Barangaroo, Sydney, and since 2016 we’ve worked with

many of the industry’s leading players. This has given us a wealth of expertise addressing local cybersecurity, critical infrastructure, and SOCI-related matters. We understand the regulatory environment and can add a degree of ‘local insight’ to our offering.

I’d also like to reiterate that although Unleash is a software company, our key focus is using data analytics to drive productivity and efficiency gains in operational workflows.

What are you looking forward to most about Australian Energy Week this year?

We’re looking forward to meeting energy leaders, field teams, and asset managers at the show to hear about the challenges they’re facing in asset management.

You’ll be able to visit us at booth A2 to view the full case study, see the latest DJI M4 drone, and talk with our team, including Hamid Fardoost, our ANZ CEO, and Richard Braithwaite, our Field Solutions Specialist.

We’re proud of our impact in delivering real productivity gains and safer infrastructure.

The future is predictive, and we’re helping the energy sector get there.

For more information, visit unleashlive.com/utilities, or chat with the team at booth A2 at Australian Energy Week from 18–19 June at the Melbourne Convention and Exhibition Centre.

As Australia’s regulatory landscape evolves and maintaining compliance is becoming increasingly complex, Brave Energy is helping businesses stay ahead with smarter, more responsive solutions.

Many energy businesses operate under an assumption that compliance must be built into their core business systems – designed into platforms like billing, CRM and metering from the outset.

While this approach may seem logical, it can become limiting for Australian energy market participants, particularly those working with international software providers. The fact these systems are often developed for larger overseas markets means Australian regulations are unlikely to be considered in the base design.

The cost of getting it wrong and falling foul of regulators is high, and it’s a key reason leading software provider Brave Energy is committed to helping the sector stay in compliance.

Recent breaches in Australia have resulted in record-setting fines, a trend that is expected to continue as more regulatory changes impact all areas of the country’s energy market.

Both the Australian Energy Regulator (AER) and the Essential Services Commission (ESC) in Victoria have broad enforcement powers.

Beyond monetary penalties, they can revoke or suspend licences, make legally binding agreements to remedy breaches and subject companies to court action and injunctions. They may also publicly report compliance breaches on public registers or through media releases, leading to potential reputational damage.

However, the AER and the ESC also play key roles in shaping the future of energy policy, aiming to create stronger consumer protections and compliance frameworks.

With 20 years of experience in the Australian energy market, Brave Energy is familiar with the dynamic and ever-evolving nature of the industry. The company said it has noticed a

significant shift in regulatory strategy in recent years, from reactive enforcement to proactive oversight. This includes an increased focus on using data analytics and risk profiling, and targeted strategies to address the areas of greatest regulatory risk, like life support registrations, hardship, disconnections and billing accuracy.

The company said it is seeing a trend of retailers being encouraged to self-report breaches, which is reflected in annual reporting on areas such as wrongful disconnections, embedded networks and life support protections.

Strengthened consumer protections are also shaping the regulatory landscape. Brave Energy pointed to the ESC’s Payment Difficulty Framework and Life Support Registration Guidelines as examples of the greater regulatory emphasis on customer protections.

Transparency is another tool being used more frequently to drive

compliance, according to Brave Energy. Regulators are publishing comparative performance reports covering billing errors, complaint rates and disconnections on retailers, alongside public registers of breaches, naming non-compliant companies and detailing the actions taken against them.

Collaboration is increasing, too. Regulatory bodies like the Australian Competition and Consumer Commission (ACCC) and the Australian Energy Market Commission (AEMC) are engaging with consumer advocacy groups, retailers and metering companies.

The goal is to co-design rules that are fit for purpose and enforceable, especially as the market navigates the integration of distributed energy resources (DER), smart meters and digital platforms.

With all of this in mind, the dilemma facing energy market participants is how to minimise the cost and complexity of compliance without compromising the ability to choose the best fit systems for their operations.

If businesses weren’t limited to software with compliance pre-built, how would their IT strategies change? Could they choose from a broader range of systems without being locked into rigid regulatory frameworks?

If those questions were asked of Brave Energy, it would say the solution is decoupling compliance from core business systems. Rather than built-in compliance, the company advocates for centralised compliance.

Brave Energy believes this approach ensures consistent rule application, eliminating the risk of different systems interpreting rules in different ways.

But what does this look like in practice?

Compliance as a service (CaaS) is an emerging best practice solution in heavily regulated industries such as energy. These models, Brave Energy said, are all about modularising, centralising and automating compliance logic, so it can be reused across systems.

Indeed, Brave Energy’s CaaS operates as a centralised engine of microservices that manages compliance requirements on behalf of other systems, such as billing, CRM, metering and customer portals.

Rather than embedding rules in each system, Brave Energy’s CaaS module: • maintains the latest regulatory rules, whether related to general market

like best offer messaging, life support registration or customer data right compliance

• applies configurable business logic with rules based on specific requirements, such as a customer’s eligibility for disconnection

• uses smart automation for key compliance processes such as customer consent logging, life support registration checks and disconnection warning periods

• enables the addition of validation rules to ensure data integrity, preventing non-compliant actions such as disconnecting customers in hardship without proper review

• logs and audits all decisions, with reporting dashboards providing real-time visibility into risks such as bill correction timelines or missed life support registrations.

Regulation in the energy market is expensive. However, the cost of getting it wrong is significantly more expensive. A key benefit of CaaS systems is that they are less expensive to maintain; instead of adjusting every downstream system when rules are changed, only the central module needs to be updated. They’re also faster and easier to implement, with streamlined API integrations.

Importantly, CaaS models enable businesses to be more responsive. Whether it’s a new billing rule from the ESC or updated life support protections from the AER, regulation changes are

compliant with every new rule change.

Founded 20 years ago by two Australian energy industry experts, Brave Energy helps businesses in the sector meet compliance challenges head on.

As a proudly Australian company, Brave Energy possesses extensive expertise in the local energy landscape, honed over its decades serving the industry. All of the company’s solutions meet Australian energy industry regulations and compliance requirements.

Brave Energy combines deep industry knowledge and a passion for software development to provide intuitive and reliable software that accurately captures and automates data, allowing energy market participants to rapidly adjust to regulatory changes and streamline market interactions.

Trusted by some of the country’s largest energy players, Brave Energy allows energy businesses to automate complex regulatory processes, reduce risk and stay ahead of the constantly evolving market.

For more information, visit braveenergy.com.au or chat with the team at booth D2 at Australian Energy Week from 18–19 June at the Melbourne Convention and Exhibition Centre.

Achieve regulatory compliance with Brave’s SaaS centralised platform, which abstracts compliance away from your other business systems, ensuring faster set-up via APIs, a faster, centralised response to regulatory change, and a lower operational cost structure.

Wind energy is set to play a significant role in Australia’s clean energy transition, but it takes more than a breeze to keep the turbines spinning.

Wind is one of Australia’s fastest growing renewable energy sources, with the Australian Energy Market Operator (AEMO) finding it accounted for 42 per cent of new capacity registered in 2023–24.

But delivering clean wind energy isn’t just about installing turbines. It requires community support, sustainable operations and keeping downtime to a minimum.

Svendborg Brakes, a Regal Rexnord brand, is helping operators rise to the challenge.

“The material is designed to meet strict global environmental standards,” Sinclair said. “It is also corrosion resistant and produces less dust than traditional friction materials.

“Not only does this minimise contamination to the local environment; it also reduces health risks for maintenance personnel.”

Once operational, regular maintenance is critical to keeping turbines delivering clean energy, but accessing the brakes themselves – a typical wind turbine has up to eight brakes, each weighing between 60–200kg – represents a major hurdle.

Regular maintenance is critical to the delivery of wind energy to Australia’s grid. Image: kelvn/stock.adobe.com

To streamline the process, Svendborg Brakes lifting and installation tool allows brakes to be safely lowered to the floor, serviced and then reinstalled, all without heavy manual lifting. In addition to improving safety, Sinclair said the tool can reduce service time by up to 50 per cent, bringing them back online as soon as possible.

Resurfacing yaw brake discs is another common maintenance task, one that previously required disassembling the nacelle or using cranes. However, Svendborg Brakes’ disc resurfacing tool removes this need entirely.

At Genus, we’re not just building power and communications infrastructure; we’re shaping Australia’s future. From transmission lines and substations to communications solutions and renewable energy, we design, construct, and maintain the systems that keep the country moving forward.

We’ve become one of Australia’s fastest-growing infrastructure companies, winning landmark projects and setting new industry standards.

Our difference? A challenger mindset, hands-on approach, and commitment to our people. That’s The Genus Way, and it’s driving our mission to be Australia’s contractor of choice.

In a nation sculpted by vast distances vulnerable to nature’s fury, reliable telecommunications are more than a convenience – they’re a lifeline.

When bushfires paint the sky crimson, floods engulf communities, or cyclones unleash their wrath, the ability to communicate is paramount. It’s the thread that connects emergency responders, families, and communities, a vital artery in the face of adversity.

Decon Corporation understands this fundamental truth, and the company has poured its expertise into a self sufficient solution designed to fortify Australia’s telecommunications resilience: the Smart Power Cell.

Imagine an unfaltering telecommunications network, even when the main power grid fails. This is the promise delivered by the Smart Power Cell.

The transportable, off grid power solution is a revolution in resilience.

It combines a suite of renewable energy technologies, including high efficiency solar panels and optional wind turbine, with a long lasting sodium metal chloride battery.

During daylight hours, the solar panels harness the sun’s energy, powering critical telecommunications infrastructure. As night falls, the sodium metal chloride battery seamlessly takes over, ensuring uninterrupted operation, charged throughout the day by the solar array.

But the Smart Power Cell goes beyond renewable sources.

Recognising the unpredictable nature of disasters, it incorporates a backup diesel generator – a failsafe capable of supporting a site for an impressive four to six weeks without refuelling.

This self sufficiency is vital in remote and disaster stricken areas, where resupply may be delayed or impossible.

Crucially, the Smart Power Cell eliminates the need to send personnel into potentially hazardous and unpredictable scenarios for refuelling, prioritising the safety of human lives. It allows for the continued operation

of mobile towers, data centres, and communication hubs, meaning vital information can still be sent, and received, for prolonged periods.

Decon Corporation’s commitment to reliability extends beyond deployment. The company proactively monitors every Smart Power Cell 24/7, ensuring optimal performance and rapid response to any potential issues

This constant vigilance guarantees that Australia’s telecommunications infrastructure remains protected, even in the most challenging conditions.

The Smart Power Cell is designed for rapid deployment, its modular nature allowing for quick installation in remote and disaster stricken areas. This adaptability is crucial in restoring communication swiftly, minimising the impact of disruptions.

The system’s advanced controls stabilise power flow, protecting sensitive telecommunications equipment from damaging voltage fluctuations and surges, extending operational time during prolonged outages. This extended operational time provides a crucial

window for emergency services, and for communities to get vital information.

Decon Corporation understands the unique needs of Australia, especially the remote communities who often bear the brunt of natural disasters.

The company’s Smart Power Cell is designed to provide the reliability needed to keep these communities connected, and to provide energy independence and reliability.

Decon Corporation is committed to ensuring that all Australians remain connected, regardless of the challenges they face. The Smart Power Cell is evidence of the company’s dedication to building resilient and dependable telecommunications infrastructure.

Decon Corporation is also committed to Australian manufacturing and the creation of Australian jobs and is proud to be manufacturing the Smart Power Cell locally with the Australian‑made certification, building sovereign capability.

For more information, visit deconcorp.com.au

From education programs to apprenticeships and a graduate program, Hydro Tasmania is building the workforce it needs to power the state into the future.

On a crisp autumn day at Strathgordon in the south-west of Tasmania, a group of young people are walking across the top of Edgar Dam, one of the walls that holds back Australia’s largest water storage.

It rains more than half the year here, but today the sun is shining for the second day of the Edgar Dam Work Exposure Program, a collaboration between Hydro Tasmania and Workskills Tasmania that aims to introduce young people to careers in the hydropower industry.

It’s a career path many in the group haven’t considered before, including 18-year-old Sophie Sproule, who said the program had sparked her interest in a future as a maintenance assistant.

“It’s opened my mind a lot because you don’t realise how many jobs there actually are within the one industry,”

she said. “I would like to try out a maintenance assistant role. I think there are lots of different opportunities within that.”

to tour a power station, participate in speed careering and shadow staff members at the Edgar Dam Upgrade works.

the Tarraleah hydropower scheme and pumped hydro at Lake Cethana underway, the program is just one of the ways Hydro Tasmania is working to ensure it has the workforce it needs to help meet future energy demand.

Hydro Tasmania Project Manager Oliver Giudici said the workshop focuses on introducing participants to different roles within the business.

“It’s not every day you get an upclose look at an infrastructure project of this size, or the chance to explore a power station,” Giudici said.

“This program is designed to provide young people with insights into a range of trades and professional roles and give them the confidence to try something new.”

The obstacles to entering the renewable energy sector emerge early in life.

With entrance to many energyrelated university degrees requiring prerequisite subjects for maths and science, Hydro Tasmania said an important part of the solution is ensuring students have options when applying to university.

The utility took a critical step in encouraging science, technology, engineering and mathematics (STEM) studies with the 2017 launch of its education program Generation Hydro.

Generation Hydro runs free activities for primary and secondary school students, including school visits, power station tours and hands-on interactive tasks that get young people excited about STEM.

The program is focused on increasing awareness of STEM industries facing skills shortages and encouraging students to study STEM throughout school and into their careers.

Hydro Tasmania is also taking steps to tap into an important talent pool that has historically been left out of STEM industries – women.

One of Generation Hydro’s activities is Girls in Power, a workshop series that aims to engage young women in grades nine and 10 in fun and inspiring STEM activities and experiences.

Girls make up only one quarter of year 12 enrolments in information technology, physics and engineering subjects, according to the Federal Government’s STEM Equity Monitor.

Hydro Tasmania Manager of Engagement Programs Sarah Metcalf said the Girls in Power program aims to introduce young women to the possibility of a career in STEM.

“Women are still underrepresented in STEM industries, including the renewable energy sector. We want to encourage more young women to take up STEM subjects in years 11 and 12 and

consider careers in our industry when they graduate,” she said.

“We need young women to feel they belong and can achieve great things in our sector. One way we can do this is to introduce them to STEM subjects from a young age and encourage them to follow these pathways at university.”

Attracting and retaining staff

Hydro Tasmania runs an annual graduate program to help university students get their foot in the door, with each participant guaranteed a job at the end of their two- or threeyear program.

Participants are exposed to different areas of the business through six-month rotations before settling into one.

The program offers a wide range of career options for graduates, with positions in civil, electrical and mechanical engineering, business, information technology, commercial, environmental science, legal and accounting.

Hydro Tasmania Executive General Manager of People and Corporate Affairs, Ruth Groom, said the program was the first step for many graduates in a long and rewarding career.

“Our graduate culture is collaborative and hands-on and the program gives graduates the chance to learn about the possibilities that await them with a career at Hydro Tasmania,” Groom said.

“Many of our senior leaders started their rewarding careers in the graduate program.”

Mechanical Engineer Zali Steiner recently completed the graduate program, and she said it gave her the opportunity to explore different areas of the sector and the diverse roles engineers play.

“From strategy and risk to handson maintenance, I gained valuable problem-solving skills while working with cutting-edge and historic machinery that powers communities across the state,” Steiner said.

“The best part has been the variety of work, incredible locations, and collaborating with passionate, skilled people every day.”

Graduate Environmental Analyst Annalise Ball said the graduate program had a great balance of field and office work, and provided access to expert mentors and professional development opportunities.

“Two years in, I feel confident and ready to step into a permanent role with hands-on experience and a diverse skill set,” Ball said.

Hydro Tasmania said its power stations couldn’t run without its maintenance assistants and mechanical and electrical fitters, and there are exciting career pathways for people who take on these positions.

In addition to the utility’s graduate program, Hydro Tasmania offers maintenance assistance traineeships and apprenticeships for mechanical and electrical fitters.

On King Island and Flinders Island, which are not connected to a mainland electricity supply, the apprenticeship program extends to diesel mechanics and lineworkers.

During a four-year apprenticeship, apprentices work side-by-side with experienced tradespeople across Tasmania on routine maintenance and large-scale projects at power stations.

The utility also covers the cost of each apprentice’s TAFE course and tuition fees.

Hydro Tasmania supports its tradespeople to develop their career with the utility and many people who started as an apprentice have gone on

to become power station operators

Production Supervisor Jeramy Whitehouse-Summers started his career with Hydro Tasmania as a lineworker and electrical apprentice before working his way up to power station operator and then to his current role, where he manages a team of 13 employees on King Island.

“Hydro Tasmania has really supported and encouraged me throughout my career,” Whitehouse-Summers said.

“When I started my linesworker apprenticeship with Hydro Tasmania, I never expected I’d one day be working as a production supervisor and managing a team.

“I’ve grown up on King Island and have a great sense of community pride,” he said.

“Supplying power to the community is a great passion of mine, as it is for the rest of the team.”

For more information on careers and pathways with Hydro Tasmania, visit hydro.com.au/education/ secondary/career-pathway-options

Pacific Energy is helping to shape Australia’s future energy system with its stand-alone power systems, designed and manufactured right here in Australia.

In Australia’s vast and often remote landscapes, stand-alone power systems (SAPS) have been a beacon, offering a safe and reliable off-grid alternative to the country’s vast fringeof-grid network.

Pacific Energy is playing a major role in developing and deploying SAPS nationwide. The company’s Managing Director Renewables, Daniel Jackson, said these systems are more than just a remote power solution.

“SAPS will play a critical role in Australia’s future energy mix,” he said.

While SAPS uptake has typically been driven by the need for greater power supply reliability, Jackson said the key drivers are evolving as the renewable transition continues.

“More clients see the CO2 reductions that can be made by the large quantities of fossil fuels that SAPS can displace,” he said.

Indeed, replacing a diesel generator with one of Pacific Energy’s SAPS can lead to a 70 per cent reduction in CO2 emissions.

The benefits have been proven by early adopters, Jackson said, like Western Australia’s power utilities, who have been rolling out SAPS in bushfire prone areas at the end of long, isolated spurs to great effect.

Now, the versatility of SAPS is extending beyond remote utility applications. Pacific Energy is seeing a trend of miners and private industry replacing traditional mobile generators with smaller scale, rapidly deployable SAPS.

“This is because these self-contained units can be quickly deployed virtually anywhere, providing assurances against fuel insecurity and price fluctuations and helping clients to reduce their Scope 1 emissions,” he said.

This also extends to the National Electricity Market (NEM), with Pacific Energy seeing east coast providers do the same.

Jackson believes WA’s continuing large-scale adoption of SAPS provides east coast operators with the confidence to continue pursuing the

technology, seeing that it can meet their cost-saving and reliability objectives.

Staying ahead in the rapidly evolving energy sector means keeping innovation at the centre of all operations. “At Pacific Energy, innovation is central to our product development,” Jackson said. “It’s how we continue to stay ahead of the curve.”

SAPS engineers and technicians at Pacific Energy have an ongoing review program for new technologies that emerge in the space, which helps the company determine if and how they could be integrated into its platforms to enhance reliability, functionality and efficacy for end users.

“We also make significant investments into research and development as an organisation, with a particular focus on SAPS development,” Jackson said. This approach has led to the development of the Pacific Energy Centre of Expertise, which is dedicated to exploring new technologies and

innovating processes that the company can adopt across its product and services offering.

One key outcome has been a range of rapidly deployable SAPS the company is rolling out for mining and commercial clients, the smallest of which can be installed and providing power within 60 minutes.

Pacific Energy has been continually refining its SAPS platform over the past six years as it works to deliver more than 300 units for Western Power’s Stand-alone Power Systems Program.

“These improvements mean our SAPS can cater to a wide array of customers, load profiles and functional requirements with very few changes to the design,” Jackson said.

“We have some of the most experienced SAPS experts in the country on our team, from engineering and design through to construction, installation and operations.”

The company’s SAPS are manufactured by a specialised team of locals in a purpose-built Perth workshop. “Our specialised facility is one of the largest of its kind in the world,” Jackson said. “It’s kitted out with advanced manufacturing technologies, meaning we can produce units to a consistently high standard, quickly and at scale.”

Pacific Energy is committed to local manufacturing, which Jackson said not only ensures high-quality, cost-effective production but also supports job security.

“Our Perth facility means we can play a central role in strengthening and diversifying local skills and building up a strong foundational workforce for Australia’s energy and manufacturing sectors,” Jackson said.

Pacific Energy secured a $2.4 million grant from the WA Government’s Investment Attraction Fund in 2023, aimed at creating local jobs and securing new investment opportunities that strengthen the state’s economy.

“The grant, plus our own dollar-fordollar investment, has enabled us to advance the capacity and output of our SAPS by improving automation, safety and production efficiencies,” Jackson said.

Keeping up with the demand for SAPS requires Pacific Energy to turn over high-quality units quickly and at scale. The company relies on a large workforce of skilled professionals, but the capabilities required are in high demand across the sector.

Jackson said Pacific Energy is passionate about contributing to the essential pipeline of skilled talent required to transition Australia to a clean energy future. The company has developed an apprenticeship program that offers fabrication, mechanical and electrical apprenticeships that expose

apprentices to many aspects of the business before participants become qualified tradespeople.

“We’re also developing an educationto-employment program that is building relationships with schools and fostering a pipeline of interest in the manufacturing and energy-generation sectors,” Jackson said.

The program is already providing on-the-job training for participating students while they’re still attending school. It also offers internal progression opportunities to junior and unskilled employees, supporting them with maths tutoring that prepares them for apprenticeship applications and further career development.

Jackson said there is potential demand for thousands of SAPS across the country as the tech continues to evolve, costs reduce and clients see more success stories.

“At the current rate of interest, private industry could supersede the deployment of utility SAPS in terms of volume and opportunity,” he said.

“Whether it’s replacing diesel generators in remote locations, powering construction and road crew applications, or even supplying power to festivals and events, SAPS have great potential across the NEM.

“And there are plenty of learnings that we can apply to accelerate the rollout.”

WA’s SAPS rollout has set a strong example for the rest of country as it begins to follow suit, and as demand grows across the NEM, Pacific Energy is ready to support both utilities and private industry alike with its proven, locally manufactured SAPS.

For more information, visit pacificenergy.com.au

Renewables may power the grid, but people are powering the transition. Supporting the workforce will be key to Australia achieving its net zero goals.

When it comes to change, there is perhaps no other industry going through it quite like the energy sector.

The core technologies that underpin the industry have been undergoing a significant transition over the last 20 years. Legacy generation and storage technologies, which have evolved steadily for decades, have been challenged by the rise of renewables and the broader electrification revolution.

While large-scale, centralised fossil fuel generation used to be the norm, a range of renewable technologies now contribute to Australia’s energy supply – from utility-scale wind and solar to pumped hydro, biogas and hydrogen.

At the other end of the spectrum, small-scale commercial and domestic solar installations also play a role in the energy mix, and micro-grid systems are becoming increasingly popular through the use of home batteries.

The sector is being further diversified by the electrification of the automotive industry, the rise of home and industrial automation, and a growing need for digital skills related

to the Internet of Things (IoT) and the interconnected systems on which these technologies rely.

The changes to the sector have also affected the workforce.

Powering Skills Organisation (PSO) – one of 10 jobs and skills councils established by the Federal Government – has been tasked with managing this as the transition continues. The organisation oversees the training for apprentices entering the energy sector and is responsible for managing the expansion of the workforce as the industry continues to evolve.

With so much change happening, PSO CEO, Anthea Middleton, understands as well as anyone that there’s a lot of work to be done.

“After all, if business is booming, we need workforce power to deliver it. And that is where the real struggle comes in,” she said.

“The sector is battling not only the volume of work from these projects and changes, but also the conundrum of how to provide the workforce with the skills and knowledge to install, maintain and repair these technologies in an informed and, most importantly, safe manner.”

PSO believes that for Australia’s energy transition to be successful, it is not just the technologies the sector works with that need to transform, but also the sector’s cultural approach to learning.

“By embedding lifelong learning into the cultural ethos of the energy sector, its employers and workers, we can successfully meet the future needs of the Australian industry and the public,” Middleton said.

The energy sector is evolving rapidly. When industry first turned its focus to the sector’s growing workforce needs a decade ago, the idea of net zero didn’t form even part of the discussion.

By 2022, however, the Federal Government had legislated the Climate Change Bill, committing to emissions reduction targets of a 43 per cent reduction of 2005 levels by 2030 and net zero by 2050.

If you ask PSO, the enduring workforce shortages in the Australian energy industry put these ambitions in jeopardy.

Jobs and Skills Australia currently estimates that expanding production

of renewable energy beyond our own domestic requirement would see Australia onshoring green manufacturing and would require an additional 42,500 electricians by 2030, with almost 100,000 additional electricians by 2050.

PSO estimates that Australia needs to grow the volume of new energy apprentices by 40 per cent above current levels to meet demand. In August, the organisation will release its ‘2025 Energy Sector Workforce Plan’, a blueprint to respond to the industry’s workforce, skills and training needs.

Middleton believes the report will help guide governments in making decisions about the energy sector, and the workforce and skills it requires.

“The transition to net zero and the corresponding technological advancement will impact every aspect of the workforce,” she said.

“The skill requirements of the energy workforce are already broadening, with indications that current specialisations like commissioning, data analytics, cybersecurity, system integration and even ozone-friendly refrigerants will become core skills into the future.”

Middleton said the same about soft skills.

“They’ll help workers liaise with increasingly savvy customers who are keen to embrace automation, real-time energy forecasting, grid integration and other consumer energy systems,” she said.

According to the Australian Computer Society’s ‘Technology Impacts on the Australian Workforce’ study, automation presents a relatively low risk for job loss or reduction in the energy sector.

However, the impact of technology and role augmentation is more significant.

PSO said this highlights the importance of ensuring the energy workforce is adaptable and allows workers to continually develop their skills and knowledge, formally and informally. But this reality poses its own unique challenge.

How can a workforce trained in traditional energy systems and training products that have remained relatively unchanged for 20 years pivot to a future defined by automation, IoT, artificial intelligence and sustainability?

The answer is not in singular retraining initiatives, according to PSO, but a cultural shift within the industry towards continuous, lifelong learning.

Though it is not a new principle, PSO said lifelong learning is something the energy sector is yet to truly embed within its broader industry culture. Staying ahead of technological trends and changes in the field and building on existing knowledge will be the key to ensuring workers are suitably skilled for the future, the organisation said.

PSO argues the solution is not shorter, more condensed training, but rather the quality delivery of

From apprenticeships to advanced tech skills, training is the key to a future-ready energy workforce.

foundational skills and ongoing learning and professional development to keep pace with change. This should also include embedding processes for peer-to-peer knowledge sharing and mentoring in the workplace.

Middleton said when lifelong learning is truly supported by the energy sector, and not seen as a burden, workers become more agile and adaptive.

“They will drive the adoption of new technologies, innovation and increased productivity through smarter practices and a more intelligent, tech supported approach,” she said.

By embedding lifelong learning within the industry’s DNA, PSO believes there’s opportunity to empower and engage workers in the change taking place around them, making a positive impact on attraction and retention to the sector.

Although some of the key skills, knowledge and culture will inevitably be dispersed throughout the industry by more experienced members of the workforce, the bulk of formal training will continue to sit within the vocational education and training (VET) system.

The issue, PSO said, is that the enduring labour shortages and the associated increased workload on the existing workforce can result in training being perceived as unnecessary – and even as a burden – by the industry and workers themselves.

In addition, the VET system is battling labour shortages of its own, with the volume of workers having largely plateaued since roughly 1986, despite significant increases in enrolment and initiatives like fee-free TAFE. PSO said this has led to critical training gaps in pre-apprenticeship, apprenticeship and post-trade levels.

While the organisation agrees non-accredited and original equipment manufacturer training has a role to play, it argues a strong, quality-focused, effective VET sector remains vital.

But how can the sector achieve a culture of lifelong learning and impart the skills required for Australia’s energy future if the VET sector doesn’t have the capacity to train the workforce?

“In short, we can’t address one and not the other,” Middleton said. “The two are inextricably linked.

“When we talk about embedding lifelong learning in the energy sector, that must also include imparting knowledge, encouraging skilled workers to contribute to the training of the next generation – whether it be as a formal educator, or informally within the workplace.”

PSO is undertaking a number of projects to help get this up and running, including updating training packages, looking at the cultural changes required in certain locations and determining which skillsets are required for different qualifications. The organisation said embedding lifelong

learning and building the workforce Australia’s energy sector needs is not a task for a single entity or organisation.

“Government, industry, workers, the training sector and PSO all have a strong role to play,” Middleton said.

According to PSO, collaboration and the sharing of knowledge and resources will foster the right conditions for success. The organisation said each party will need to carefully consider the available opportunities to contribute to a new learning culture, commit to developing inter-relationships and collaborate to secure the skilled energy workforce Australia needs.

The energy industry is at a pivotal moment, with technological advancement and the transition to net zero redefining every aspect of the sector. To meet the challenges ahead, PSO feels Australia must build a workforce that is not only skilled but perpetually learning.

Embedding lifelong learning is not optional, the organisation said, but essential. It is the key to ensuring a successful, inclusive and sustainable energy transition. And it is how the organisation sees the future vision of Australians powering the nation to achieve net zero is upheld.