A joint two-day blitz in South Australia revealed a raft of concerning safety issues and the exploitation of migrant workers, said the National Heavy Vehicle Regulator (NHVR).

The NHVR teamed with South Australia Police, the Australian Border Force (ABF) and SafeWork SA for Operation Vigilant at the Monteith Checking Stations with 32 NHVR Safety and Compliance Officers (SCOs) conducting 75 targeted intercepts. It was the first time the four agencies had worked together on a local operation.

NHVR Chief Operations Officer Paul Salvati said more than half of all heavy vehicles stopped on the Princes Highway were found to be non-compliant – with offences ranging from self-clearing defects to major violations.

“Unfortunately, there were 38 defect notices issued throughout the operation, three of which were classified as major, with the most prevalent offences being mechanical defects such as faulty brakes, and issues with steering and suspension, and wheels, tyres and hubs,” Salvati said.

“SCOs also issued one official warning and three in fringements, including for a s

serving as a clear reminder for drivers to ensure they aren’t driving tired.

To ensure drivers understood how to comply with their safety obligations, Salvati said SCOs provided education during 24 of the intercepts, guided by the NHVR’s inform, educate and enforce approach.

of safety and compliance related resources available to help with education, including guidelines, training videos and contacts for support.”

ABF officers from the Department of Home Affairs conducted checks relating to migrant worker exploitation, identifying “four individuals of concern”.

Pfeffer said the operation was important in monitoring the heavy vehicle industry’s compliance with the Work Health and Safety Act and indicates that the industry has more work to do.

We encourage industry to access the NHVR website, where we have a wide range

Among them were two unlawful non-citizens and two individuals suspected of breaching visa work conditions. As a result, one person was detained, while another was granted a bridging visa to facilitate their departure from the country.

It is a criminal offence to employ, refer or contract a non-citizen who doesn’t have the right to work in Australia.

SafeWork SA Director Compliance and Enforcement Brett

“Our inspectors issued 75 improvement notices relating to breaches of the WHS Act. These ranged from defective, poorly maintained or absent fire extinguishers and first aid kits to non-compliant vehicle maintenance and load restraint maintenance.

“A further five notices were issued in relation to carrying dangerous substances.”

SA Police Acting Inspector Tiffany Gray said South Australia Police will continue to have a coordinated approach to heavy vehicle regulation and welcome the support of partner agencies.

A two-day Hume Highway blitz by Victoria Police last month resulted in 450 offences detected, including 22 a lcohol and drug impaired drivers.

With two major checkpoints at Glenrowan Rest

A rea and Bentons Hill Rest Area, Operation Radihus was aimed at both light and heavy vehicles.

The operation comes after 17 lives were lost across East-

ern Region Division 4 last year — eight in Wangaratta and nine in Wodonga — and 169 people suffered serious injuries from motor vehicle collisions.

The multi-agency operation involved uniform, local and state Highway Patrol officers, local detectives, Dog Squad, and partner agencies including the National Heavy Vehicle Regulator (NHVR), Safe Transport Victoria, and

the Department of Transport and Planning.

Police conducted 4900 preliminary breath tests and 584 roadside drug tests, resulting in three drink driving and 19 drug driving offences.

There were also 17 drivers clocked travelling more than 25km/h over the legal speed limit.

The 450 offences detected during Operation Radihus included 118 heavy vehicle

offences. Of those caught out doing the wrong thing was a 64-year-old unlicensed truck driver from Craigieburn.

He was bound for Sydney but intercepted by police in Cobram.

The truck driver failed a preliminary oral fluid test.

Victoria Police alleges he admitted to officer that he had travelled via Cobram to avoid the police operation.

Police also located and

seized methamphetamine and valium.

The driver was charged for offences from an incident in January this year, including make threats to kill, and unlawful assault.

He was bailed to appear at Broadmeadows Magistrates Court at a later date.

He is also facing multiple heavy vehicle national law offences and a possible fouryear licence disqualification.

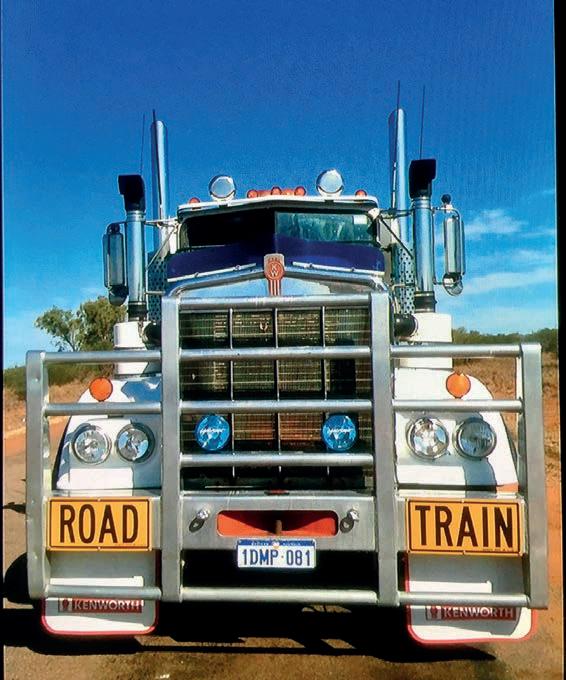

BRAKES, lights and reflectors are the major non-conformity issues for the industry, according to the results from the National Heavy Vehicle Regulator’s (NHVR) annual National Roadworthiness Survey (NRS).

During the 12-week long survey, 9082 vehicles and combinations were inspected nationally – an average of 103 heavy vehicles each day –making it the largest in-depth “health check” of its kind ever conducted, said the regulator.

Of those units inspected, 33 per cent had at least one non-conformity, which the NHVR report describes as a “small but significant” increase from 31 per cent in 2021.

The incidence of non-conformity remains well below 2016 levels, the NHVR added.

“The majority of non-conformities were given at most a minor defect notice (i.e. the continued use of the vehicle on road poses a safety risk, but the risk is not deemed as imminent or serious), the report said.

“The highest level of non-conformity was minor for 21 per cent of units, a slight increase from 19 per cent in 2021. There has been a slight increase in the incidence of highest level of non-conformity being a self-clearing defect (i.e. the use of vehicle on road does not pose a safety risk, but

a defect exists) from 6 per cent to 8 per cent.”

Overall, 75 per cent of units passed inspection (i.e. the highest level of non-conformity was a self-clearing defect or the unit had no defect). This remains stable from 75 per cent in 2021.

Non-conformity did not differ greatly between units inspected in their state of registration and those inspected interstate (33 per cent and 31 per cent, respectively).

Brakes were the most common non-conformity issue across metro and regional Australia with 14 per cent, the same total as 2021, followed by lights and reflectors on 10 per cent, up slightly from 9

per cent in the last NRS taken in 2021.

“The NHVR is still concerned that defects in brakes remains a top issue, and I would like to take this opportunity to remind operators and drivers of their responsibility to ensure their vehicles are properly maintained and daily vehicle checks are conducted,” said NHVR Chief Operating Officer Paul Salvati.

Structure and body, engine driveline and exhaust and steering and suspension, are also in the top 5 most common areas of non-conformity.

“The 2024 NRS was a monumental undertaking, and the important effort of our offi-

cers conducting these inspections has provided us with the most comprehensive data ever gathered on the mechanical health of heavy vehicles across the nation,” Salvati added.

Nationally, 75 per cent of units passed inspection, which was the same percentage as the 2021 survey, continuing the strong improvement over the 2016 benchmark survey of 55 per cent.

“Unfortunately, the number of units having multiple defects was slightly higher in comparison to the previous survey, up to 33 per cent in 2024 from 31 per cent in 2021,” Salvati added.

“However, the non-compli-

ance percentage remains well below the 2016 levels which is pleasing to see.”

Salvati said the sheer scale of the 2024 NRS has allowed the regulator to see where the NHVR and industry are making improvements in safety and where more attention is needed to focus regulatory efforts and future safety initiatives.

“We know that these inspections did result in a longer than normal intercept time [an average of 30 minutes], and I wanted to thank industry and drivers in particular for their patience and support while we undertook these crucial checks at the roadside.

“I know the impacts of this survey will enact positive results on the efficiency and productivity of the heavy vehicle industry, including safer roads for all road users.”

When Big Rigs first published the survey results on-

line, many readers were left wondering when the same ‘ruler’ was going to be run over the poor state of the roads, which has an adverse impact on safety and truck maintenance.

“When do they start the blitz on those responsible for the state of the roads,” asked Jeff Dawson.

“All well and good that fees and charges continue to rise for operators, which are supposed to be funnelled back into the roads. These bureaucrats talk a big game, but the road toll proves otherwise.”

Ron Williams wondered how truckies could issue a defect notice for a poorly maintained or built highway.

“The only good roads are the freeways running between Sydney and Melbourne, and Sydney and Brisbane, and Melbourne to Adelaide, etc, because that’s where the most ratepayers and voters are,” he said.

GARY Mahon, a leading voice in Australia’s road freight industry, has expressed mixed reactions to the federal budget, highlighting both promising developments and missed opportunities for the sector.

The Queensland Trucking Association (QTA) CEO welcomed the boost to the Bruce Highway funding, but voiced disappointment at the end of the $20,000 small business instant asset writeoff on June 30.

Speaking to Big Rigs on the day Prime Minister Anthony Albanese formally announced May 3 as polling day, Mahon was also frustrated to see no specific money allocated towards training initiatives for drivers, particularly in support of apprenticeships, to address critical shortages.

On a more positive note, Mahon said the $70 million allocated to finalise the sealing of the Kennedy Development Road is a timely industry boost.

It gives operators another route into Far North Queensland when the Bruce and Gregory are “knocked out” due to weather events, as has happened recently.

“It adds quite a few hundred k’s but at least you can get in,” he said.

“The problem with that road is that 11.5 kilometres of that road [the Kennedy] are dirt so if there’s rain around it’s knackered as well.” Mahon is now calling for the sealing to be completed before the next wet season.

As for the $9 billion in funding to fix the Bruce – $7.2 from the Albanese government and $1.8 billion from the state – Mahon said he’s encouraged by the $300 million in early works announcements made last month.

Of that money, Mahon said $100 million has been allocated to designing how the first $1 billion will be spent, while the remaining $200 million will be spent in the next few

weeks on actual fixes. He said all the money is baked in, re gardless of who wins at the polls on May 3.

“There’s an expectation that a further $700 million [in works] will be underway be fore the year is out,” said Mahon, who is also a member of the Bruce Highway Advisory Council.

“Brent Mickelberg [the state Transport and Roads Minister] has been quite public in that he wants to make sure the $9 billion is spent over the next six years.

“That’s money in addition to what was already assigned to the Bruce.”

Mahon expects the first works to start between Gympie and Townsville and focus more on safety features, such as wide centreline marking,

overtaking lanes, intersection treatments, more rest areas, and the like.

North of Townsville, he said the QTA will be lobbying for more flood-proofing treatments.

“What we’re saying is that the first priority north of Townsville to Cairns has to be treatments that relate to all- weather reliability.”

Meanwhile, peak body Heavy Vehicle Industry Australia (HVIA) said the gov-

national competitiveness, the transition to net zero emissions, growing the future workforce, enhancing road freight productivity and optimising Australia’s road infrastructure.

While Treasurer Jim Chalmer’s fourth budget included a raft of high-level initiatives across energy, manufacturing, small business and road infrastructure, it stopped short of addressing HVIA’s specific concerns.

“The lack of targeted measures that directly address the issues faced by our sector is disappointing and indicates that both we and the federal government have a lot more work to do,” said HVIA CEO Todd Hacking.

ernment has to do a lot more to support Australia’s heavy vehicle manufacturing industry following the release of the budget.

In late February, HVIA distributed a detailed list of Federal Election Priorities to all 227 Federal MPs and Senators – the summary of which was published in the March 14 issue of Big Rigs It called for government assistance to address specific pressing issues such as inter-

“As such, we will continue to advocate for the needs of our industry at all levels in the lead-up to the federal election, calling for direct support as per the many practical and implementable actions listed in our election priorities.

Adam Ritzinger, HVIA’s Chief Technical Officer, said that while many budget announcements will assist industries adjacent to heavy vehicle manufacturing, he also laments the lack of direct ac-

tions revealed on last month’s budget night.

“The announcements bestaligned with HVIA’s priority areas were increases to the ‘Future Made in Australia’ package, including green metals, clean technology manufacturing and low-carbon liquid fuels, as well as the separate tax incentives for hydrogen production, the expansion of funding for the Clean Energy Finance Corporation and improvements in road infrastructure,” he said.

“What we desperately need though, and what HVIA has called for, is direct support for truck and trailer manufacturers, support for the private sector to deploy battery electric charging and hydrogen refuelling stations nationwide, incentives to offset the higher cost of purchasing low-emissions trucks and the expansion of high-productivity vehicle networks.

“Without that direct support, our industry will continue to face headwinds in its efforts to decarbonise, improve efficiency and provide the equipment necessary to keep the lifeblood of Australia’s economy and society pumping.”

Western Australia’s peak road freight body, the Western Roads Federation (WRF), was also less than impressed with how the industry fared

WA was left out in the cold.

Citing a report in The West Australian that day, he noted that the state received just 11 per cent of the infrastructure funds allocated to Victoria alone.

“In fact, WA, NT and SA combined barely received 25 per cent of what has been allocated to Victoria,” he said.

Dumesny said the state fared even worse with roading which he said decreased by nearly 33 per cent, while other jurisdictions all received significant spending spikes.

He was also disappointed to see that there was no identi-

‘HERE we go again’, was truckie Clynton Hawks’ first reaction to Peter Dutton’s budget reply announcement that the Coalition will halve the fuel excise for 12 months if they win on May 3.

Without a corresponding reduction in the road user charge (RUC), Hawks said Dutton’s proposal will repeat a disastrous similar move by Scott Morrison in 2022.

fied measure to address the

ern Australia, South Australia

“However, a billion dollars was allocated on a road blitz in marginal or vulnerable federal seats in the western suburbs of Melbourne.”

In its budget night summary, the Australian Trucking Association (ATA) also highlighted the personal tax cuts – down from 16 per cent to 15 per cent from July 1, 2026, and to 14 per cent from July 1 – and the ban on non-compete clauses for those earning less than $175,000. It also noted that ASIC will receive $3 million over four years to improve its ability to crack down on illegal phoenixing.

At present, operators can claim a fuel tax credit (FTC) of 20.1 cents per litre (cpl), being the difference between the 50.6 cpl fuel excise rate and the current RUC of 30.5 cpl.

When the fuel excise rate is lower than the RUC, they can’t claim any, and Hawks said that’s a recipe for disaster.

“We saw under the previous Morrison government that halving excise and removing the FTC for a period of six months did nothing other than raise fuel and freight prices and we saw many transport companies shut the doors,” Hawks said.

“They need to half the road user charge as well so we can continue to claim the fuel tax credit.”

The North Queensland

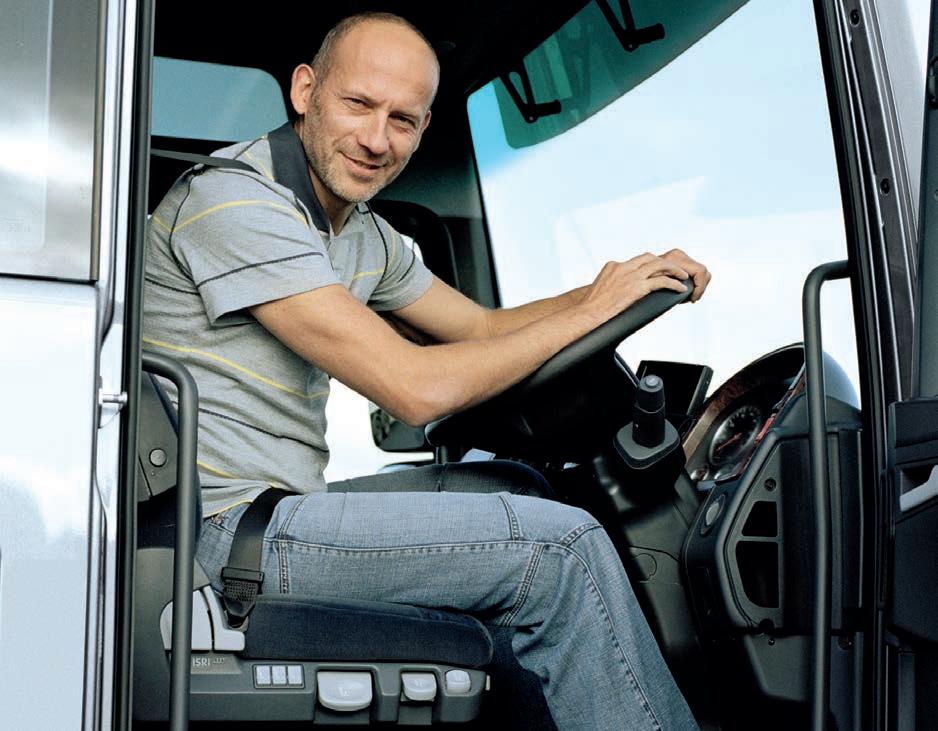

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164

Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

the state of the road network.

“I’ve just come back from a month on the Flinders High way and it’s atrocious.”

Hawks said currently a medium-sized transport company might be claiming $4200 for 20,000-litres of diesel on its quarterly business activity statement: “Take that way, that’s a bit of a loss.”

Queensland Trucking Association CEO Gary Mahon also warned that if the RUC isn’t halved under Dutton’s proposal, it will also cause freight prices to increase.

“Fuel pricing might dip a bit, but from the Morrison experience, it’s highly unlikely to dip to the same extent that the government has reduced the excise, so in effect our people are paying more and also not getting a

Association is heartened by Dutton’s speech night pledge to consult with industry first.

“Working with industry, we will ensure that heavy vehicle road users also benefit from this measure,” Dutton said. NatRoad, meanwhile, said the industry can’t afford another FTC hit.

“About 98 per cent are small businesses and average profit margins are just 2 per cent; they lack the bargaining power to simply pass on costs,” said CEO Warren Clark. He said that unless FTCs are protected, the benefits of lower excise will not flow on.

“Instead, many in the industry that keeps Australia’s shelves supplied could face financial ruin.”

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

BRISBANE NORTH

1/259 Cullen Av, Eagle Farm QLD 4009 Ph 1300 11 4774, email: seats@isrinb.com.au, www.isrinb.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106 Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

NEWCASTLE/HUNTER VALLEY

Ph 02 4932 0600,

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 email: sales@hvss.com.au www.isri.com.au

Award nominations open

Nominations are officially open for the Women in Industry Awards to be presented in Melbourne on June 19.

The categories include an Excellence in Transport prize which recognises an individual who has gone above and beyond to improve and positively impact the Australian transport industry.

To nominate someone you know who is driving change in the road freight industry, visit womeninindustry.com.au.

Nominations for all categories close on May 9.

Garbage truck cameras

Wollongong has given the green light to ramp up the use of high-tech cameras on its garbage trucks to spot potholes and issues that need fixing on its 1000km of roads.

The council undertook an initial 12-week trial of the technology, known as Intelligent Defect Management (IDM), to determine if damage to roads could be identified earlier, work prioritised and repaired in a timely manner.

The trial captured defect data via cameras installed in six Remondis waste collection trucks and a further four council vehicles. All the vehicles travel regular weekly routes and, together, cover around 90 per cent of council’s road network each fortnight. Since the implementation of the trial, more than 800 potholes have been identified and repaired.

Fines increased to $4633

Drivers of overlength vehicles who enter Galston Gorge will now face harsher penalties, including increased fines and demerit points.

The penalty for driving an overlength vehicle in Galston Gorge will skyrocket from a $2818 on the spot fine to $4633, and from six to 12 demerit points.

Transport for NSW (TfNSW) Deputy Secretary of Safety, Policy, Environment and Regulation Sally Webb said, “When a long vehicle gets stuck in Galston Gorge, the road is typically closed for about two hours which can cause major delays and can be difficult for response crews to rectify.” Since early 2020, TfNSW has detected and issued fines to over 800 overlength vehicles in Galston Gorge.

Haulage road reopened

The private Pilbara haulage road used by Mineral Resources (MinRes) to transport iron ore 150km from its Ken’s Bore mine to Port of Ashburton has reopened after a temporary closure.

There have been six reported truck accidents on the busy route since August, the latest last month when the rear two trailers of a 330-tonne triple road train rolled. The driver was uninjured.

Two days later, after receiving a notice from WorkSafe WA regarding “controls and risk-mitigation of the road train operations”, MinRes briefly paused haulage.

Operations kicked off again after “constructive discussions with WorkSafe WA”, the company told shareholders.

BY DANIELLE GULLACI

IT was a double celebration for livestock owner operator James Papworth, who recently walked away with the keys to his brand new Kenworth T659 – and a new fiancé. James, 28, proposed to his partner of several years, Laura Beer, at Twin City Truck Centre in Wodonga. He had a special note planted in the passenger door of the T659 that read: “Will you ‘Keep on Keepin on’ with me.” He then got down on one knee and asked Laura to marry him, to which she said, “Yes!”

As James explained, the note was in reference to the name they had given to the truck. “I had the proposal planned for a fair while, unbeknownst to her. There was only one other person there who knew about it and that was the lady who videoed it for us.

“Laura had no idea, so it was a big surprise. She never expected it at all.”

The go-getting young

truckie began his career in transport as a diesel mechanic. “I grew up working on a farm in Holbrook, New South Wales. Dad has his own local transport business and carts cattle. I left school and worked on the farm for a couple of years, then I did my trade,” James said. He then made the decision to move to the Northern Territory for two years to work and study. During his time

there, he built cattle yards, drove trucks and successfully completed his Certificate III in Agriculture.

After deciding to make truck driving his career, James got his MC licence in 2019 and joined Martins Stock Haulage as a driver.

“I moved to Scone and got the job with Martins – and didn’t look back. I was there for about four or five years. I started off transporting cattle for a couple of years and then went on to carting sheep. I was travelling right across the east coast – from the bottom of Victoria all the way up to Central Queensland,” he explained.

A nd it was during that time that James’ professionalism and dedication to the industry was formally recognised. In 2022, James was named Young Driver of the Year at the annual Livestock and Bulk Rural Carriers Association (LBRCA) conference.

He made the decision to go out on his own in July 2023, when he purchased his first

truck – also a Kenworth T659 and a B-double stock crate.

With that, his business Papworth Livestock was born.

“Laura and I were going to travel to America and the day before we paid for the trip, this opportunity came up to buy our first truck. We bought the truck and cancelled the trip,” James said.

While it hasn’t always been an easy ride for James, the purchase of his new T659 was an exciting milestone.

“My partner and I have been through a fair bit in the last 12 months and she’s always stuck by my side, so I wanted to do something really special for her,” said James.

“Laura says that we’ll never be able to sell this truck because it has a fair bit of sentimental value now.”

Laura works full time as a school teacher, along with assisting James with the business. “We live in Wagga and she works really hard. Along with being a school teacher, she does all the paperwork for the business and organises

a fair bit of that sort of stuff. Laura is the brains of the whole show,” added James. After picking up the new T659 on Saturday, March 29, James took it on its maiden run to the town of Junee, in the Riverina region of New South Wales.

“It’s very similar to the older T659 I had but I’ve dressed it up a bit better, with a nice paint job,” said James. “It’s a great truck to drive. I don’t think I’d change a single thing on it. Twin City Truck Centre were also fantastic to deal with – nothing was a drama.” James says about 70 per cent of his work involves carting sheep, while the remaining 30 per cent is cattle transport. “I enjoy working with livestock, particularly with sheep. I do a lot of paddock work, carting to meatworks.”

With the new truck now on the road, Big Rigs asked if a date had yet been set for the couple’s big day. “Not yet,” said James. “We’re taking it one step at a time!” he laughed.

TO celebrate the extraordinary milestone of 100 years in business, Wettenhalls has unveiled its centennial truck and trailer.

The story of Wettenhalls began in 1925, with a young man named Reginald Amezdroz. He was working as a cream tester and boiler attendant at Bulla Dairy in Colac, Victoria. With Bulla’s perishable goods needing to be transported to Melbourne each day, the company needed someone with a truck to do the job.

Reginald put up his hand, with his first load being 29 steel cans of cream – equating to around 1500 litres. With no refrigerated system to keep the load cool, it was instead done with the use of ice blocks!

After four years, Reginald entered into a business partnership with Roderick Menzies and they established a new company called Amezdroz & Menzies by 1931. Through the 1930s, the business continued to grow – expanding the fleet and extending its reach, eventually becoming a leading carrier in the western district. By 1947, the company grew to have a fleet of 10 trucks, and Reginald’s sons Ned (Frederick) and Bill joined the company. With its larger trucks, the

ber, groceries and hardware –in addition to dairy.

All the while, it continued to provide transport services to iconic Colac business, Bulla Dairy – a partnership that continues going strong to this day. It wasn’t until the 1960s that they purchased their first refrigerated van.

The first Kenworth prime mover joined Amezdroz & Menzies in 1967, allowing the company to deliver even larger loads.

The business experienced continued growth over the decades and purchased another carrier, Wettenhalls, in 1997.

As the Wettenhalls’ name was better known nationally,

Wettenhalls employs close to 400 staff, operating a fleet of over 170 vehicles.

The newest of those trucks is the new milestone Kenworth T909, paired with a trailer covered with photos that show the company’s history.

“As part of our 100 year celebrations in 2025, Wettenhalls are excited to unveil our centennial truck and trailer – a tribute to a century of progress and a symbol of our ongoing commitment to excellence,” the company shared online.

“This stunning new addition to our fleet represents the perfect blend of heritage and modernity, showcasing cutting-edge technology while honouring the legacy

that has defined

over the years. From humble beginnings to becoming a leading name in transport and logistics, our journey has been driven by the passion and dedication of every team member, partner, and customer.

“As we reflect on this century of success, we also look ahead to the future.

“We remain committed to upholding the values that have defined us: integrity, reliability, and a forward-thinking approach to every challenge.”

EDITOR JAMES GRAHAM

ens up from here, we promise. I only wish I could also assure you of an easier ride after election day on May 3. Lots of people in higher places are trying to put a positive spin on the ‘spoils’ from the budget, but from where I sit, you’d need pretty big rose-tinted glasses. Yes, it looks like we’ll see definitive short-term improvements along the Bruce, finally.

But when you drill down into the road spending, most of it is directed into areas where Labor needs to lock up the electorates with motorists. There was nothing we didn’t already know about rest area spending, and zero for employers looking to take on trainees or apprentices.

For months now we’ve been kicking around the idea of a dedicated good news issue, celebrating all the positive stuff in the industry. May might be a good month to do it.

OUR online story last month about the National Transport Commission (NTC) releasing a new discussion paper that aims to “better support truckies health and to promote road safety”, sparked vigorous debate on our Facebook page.

Initiated at the request of Australia’s Infrastructure and Transport Ministers, the paper explores options for improving early detection and management of health conditions that impact the safety of drivers.

It also asked for truckies to have their say on the screening process. Below are just a few of the reactions we got from readers.

Something needs to change

Here’s the problem with truck drivers going to see a doctor. We can’t get an appointment because we don’t know when, or for how long, we will be home. Second, most of us will have a rough idea when we will be home but nothing is guaranteed so when I need to go see a doc I always ask for a Monday morning or late Friday afternoon appointment. Back in late October 2023, I hurt my knee climbing out of my truck and put it down to getting old. After a month of it not getting better, I booked an appointment with my doctor and the first available

appointment was two weeks away so I took it, told my boss I needed to be home and got in to see the doctor. Turns out I had torn the cartilage root off the bone and needed surgery, but to get that diagnosis it took over six weeks of getting scans and other appointments due to work schedules.

Come late December I get a call from the surgeon to say the first available appointment was next week, then he was on holiday until late January with surgery happening early February, no matter what appointment I took. The January appointment was a Tuesday morning so I booked it.

The doctor was appalled at me for taking so long to come see him and asked why I took so long. When I explained the situation he was again appalled at that situation. So, I think what we need as truck drivers is the ability to turn up at a hospital and ask to see a doctor whenever we need to, but have it so we have to prove we are truck drivers to stop everyone else abusing the service.

Niell Graham

Start investing where it counts

Here we go, another government grant funded program

that does absolutely nothing for drivers.

These associations that have so much power with govern ment bodies don’t give a f about drivers. But the government keeps throwing money at them with these useless programs.

Imagine what would hap pen if we took away all these BS grants and redirected that into roads and decent truck-only rest areas with fa cilities.

Leanne Dyer

It’s a very long list

The list is a looongg one… and this is only the things that came straight to my head.

1. If you want to improve the health of truck drivers, you need doctors that understand the lifestyle. You can’t even get a doctor to understand a bloody driver’s medical these days, let alone anything else. And make these doctors t hat understand the lifestyle accessible. I dunno, t hrowing random ideas around here and speaking out loud, maybe travelling buses that move around from truck stops, like the breast screen van?

from a highway, with shit, rubbish and God knows what strewn all around the place.

3. Safety at rest areas. How can someone sleep comfortably when they could be assaulted or have equipment tampered with?

2. Improve rest areas and facilities.

No one should have to sleep pulled off 5 metres

5. Truck stop kitchen facilities - the basics that every employee gets, a microwave, instant hot water, cold fresh water, etc.

6. Truck stop bathroom facilities - clean, tidy, showers a nd toilets. Go to Canada and America and see how they do it! Their truckstop facilities leave ours for dead!

4 Truck stops that actually have HEALTHY & A FFORDABLE meal options available 24/7! You mention cardiovascular disease and diabetes, but what options do most truck stops have? Deep fried foods sitting in a food warmer for hours on end or Maccas and KFC.

Amanda Herringe-Brown

US does it right I was reading up a while back about the US truck stops. Sure, they would be privately owned, but within the complexes they often have doctors, dental and other services, like hairdressers. How hard would it be to have a room set up at different truck stops here, where a s part of medical training, someone gets sent out to do walk-ins?

Shane Gibbs

BY JAMES GRAHAM

AN iconic second-generation container transport operator – legendary for treating drivers like part of the family – has quietly closed its doors after 66 years in business.

The announcement marks the end of an era for one of Tasmania’s longest-running family transport businesses.

Tim Norton, who has been at the helm of the company for decades, confirmed the April 11 closure during a recent interview with Big Rigs “I don’t need to, but I am going to retire,” Tim said,

reflecting on his difficult decision after 45 years in the transport industry.

The business, which began as FF&L Norton - named after Tim’s parents, Frederick Forrester, aka Bob, and Lorraine Norton - started from humble beginnings.

Tim recalled how his father, who started out driving buses, launched with a single Ford meat truck in 1959, making deliveries from their Moody Street home around the Burnie butcher shops before gradually expanding their services to Hobart and then onto the West Coast

Butcher shops. The business saw significant growth from the back of the first trailer Bob built himself.

“When one door shut, another opened and he’d walk straight into it,” Tim said.

When Australian National Line pulled out of Tasmania and Brambles arrived, Tim said that’s when the transport company “went bang”, building a reputation for reliability and quality service.

“We got to 10 trucks pretty quick and there were plenty of drivers around, good ones.”

At its peak, Norton Trans-

port operated a fleet of 15 trucks, though in recent years, the operation had scaled back to six vehicles, primarily handling container work.

“We have seen a lot of change,” Tim added.

Nortons had only two fulltime drivers toward the end –both had job offers for work within 24 hours of the news breaking – with three or four casuals on call, as work demanded.

“The full-timers told us they wouldn’t take those jobs until they knew we had closed the doors.”

Tim said he never thought about selling the company as a going concern.

His son Andrew and wife Judy worked alongside him for 25 and 32 years respectively, but the trio decided it was time for a clean break.

Andrew said it’s a good little business with good infrastructure, but he just can’t see a future in it with all the red tape and lack of loyalty.

Reflecting on the trucks he’d owned over the years, Tim counts 50 in all, 37 of those Scanias, some bought

off Laurie Kelly from Launceston.

Tim says he hasn’t thought about what he’ll do next. He’ll spend more time on restoring a 1977 single axle Scania, one of the company’s hardest-working and most reliable truck, back to mint condition. But mostly he’s looking forward to not having to come into the depot on the weekend just to set up for the next week.

“It just goes on and on, seven

INTERSTATE transport

giant SCT Logistics has announced the acquisition of the Burnie-based CRE Solutions Logistics.

Established in 2007, CRE offers daily trans-Bass Strait

services to and from the state.

In a media release revealing the news, SCT said the acquisition will better enhance operations through increased presence in the markets and networks currently occupied

in both Tasmania and across the rest of Australia.

“Additionally, it enables enhanced multi-modal revenue streams for the SCT Group,” the statement added.

SCT said the founder and current owner of CRE Solutions, Chris Anderson, has built a strong reputation for outstanding customer service, flexibility, and tailored logistics solutions.

“He believes that connecting the two family businesses, which have shared cultures, will be a benefit to all CRE employees.”

Anderson will stay on with SCT to oversee the trans-Bass

operations for “seamless stakeholder transition and continuity across service levels and business activities”.

SCT celebrated its 50th year of operation in 2024 and offers multi-modal transport and logistics solutions including rail and road linehaul, refrigerated transport, and bulk haulage rail solutions.

It was the first private rail operator in Australia to use the main interstate corridor between Melbourne and Perth.

It currently holds offices in every major capital city in the country, as well as regional locations in Queensland and NSW.

BY JAMES GRAHAM

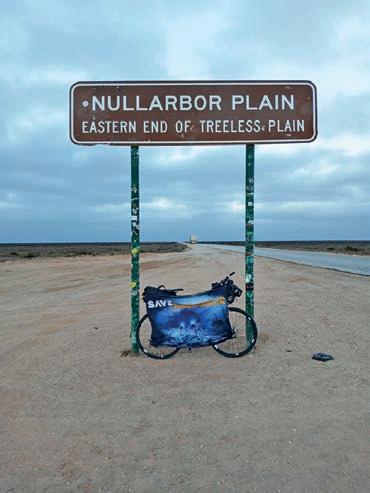

A cyclist in this year’s Indian Pacific Wheel Ride across ‘the paddock’ is calling for more collaboration with truckies to prevent further tragedy on the dangerous highway.

Kevin Paine, who’s riding by the name of Pizza Rider, reached out to Big Rigs from the road as he came through Ceduna, en route from Fremantle to Sydney in the unofficial 5500km annual event.

Paine has already crossed the Nullarbor in 2019, 2021, 2022 and 2023, and returned again last year, only to stop at Fraser Range when 62-year-old Chris Barker was killed after being stuck by road train about 190km west of the SA border.

When he returns home this year, Paine said he’s going set up a website to provide advice and information for the 100-plus who cycle across the desolate road each year and also wants input from truckies.

“I feel it’s best for the two communities to work togeth-

er, rather than be adversaries,” Paine said in an email to Big Rigs

“I’m reaching to you and others in the trucking community to have something that works well for all. Riders using hi-viz, mirrors, ultiple lights and UHF as

an example. Getting off the road when vehicles are going where you are (not a legal requirement, but absolutely recommended for the safety).”

Paine also said simple things, like a short toot of the horn or a flash of high beam at night to ensure the rider is aware of an approaching truck “would be great”.

“Riding at night is considerably safer due to lower traffic volumes and higher visibility,” he said.

Paine also said the lower temperatures, lack of sunburn, less wind, and the spectacular night sky are other reasons why night riding is popular among cyclists.

“Bicycles have been ridden across the paddock since Arthur Richardson in 1896,” he added.

“Each time I’ve crossed I’ve met riders heading in the opposite direction. There will a lways be riders on the Nullarbor. Long distance and touring cycling is a growing global trend.”

Paine said he’s hoping to start on the project in May.

Veteran interstate truckie

Robby ‘Roadtrain’ fears that it’s only a matter of time before there is another tragic accident on the Nullarbor involving a cyclist.

Robby was speaking out after witnessing first-hand the dangers for riders in the Indian Pacific Wheel Ride as he headed west on his weekly run to Perth.

He watched aghast as a road train was forced to come to a complete stop near the Nullarbor Roadhouse because there wasn’t enough space for it to safely pass the cyclist heading east and avoid the oncoming traffic.

“There’s just enough room for two trucks to pass –there’s no shoulder, but the cyclist didn’t bother to get off the road.” Robby said.

“He [the truckie] had to stop and let the other traffic go so he could go around her.

“This is becoming a weekly occurrence. They must wake up one day and decide they want to ride a push-bike across the Nullarbor, f##kn idiots.

“They shouldn’t be allowed on the Nullarbor. All they are is a travelling road block.

It’s way too dangerous.”

Robby said he can’t understand why cyclists aren’t allowed to ride on a motorway where there is plenty of room on the shoulder, but they can ride a cycle on this major freight route with next to no shoulder room.

“It’s only a matter of time before someone is killed and the poor old truckie is the one who’s going to get the blame for it.”

Truckie Damien Tsouris was so concerned for the cy clists’ safety he called the Ce duna police.

“One of the cyclists was on the fog line with no lights or high-vis in the dark. I nearly hit him as I didn’t know he was there.”

John Mulder also wrote on our Facebook page that the number of riders on the highway is “getting beyond a joke”.

“There used to be one or two you’d see a year, now it’s like six or seven each trip and they don’t wear hi-vis, but opt for the highly standout black - you struggle to see them.

law that a road train has to hit the brakes to slow for a pushbike, or veer onto the wrong side of the highway to avoid them

“It needs to be stopped before more are killed and innocent truck drivers pay the price of prison for driving down a highway trying to do their job.”

“It should be against the

THE driver of an oversize vehicle has heeded the warnings on a Sydney tunnel, a fter sensors detected that it was over-height.

On approach to the tunnel, the high-tech sensors triggered flashing lights and a warning on the message board reading ‘STOP’.

The sensors being trialled in Sydney scan trucks in real time and use connected warning signage to divert drivers of overheight vehicles from their routes before an incident.

Trucks taller than four metres are scanned as they pass

under the sensor, and their height and number plate information is then gathered and instantaneously displayed to drivers on the overhead Variable Message Sign ( VMS) to warn the driver.

If needed, the sensors can even initiate the tunnel closure process to prevent damage to the infrastructure –and the truck.

“After this our staff work to coordinate a safe turnaround,” said Transport for NSW (TfNSW). “This could require a tunnel closure in the opposite direction and a short-term lane closure.”

After this, TfNSW staff work to help restore traffic flow to normal.

Thankfully on this occasion the driver saw the warnings and was able to stop the truck in time.

TfNSW says this crackdown, combined with the work of the industry wide Overheight Truck Taskforce (launched in June 2023) has resulted in a dramatic drop in over height incidents in Sydney tunnels.

“In the first six months of the taskforce’s operation (July to December 2023) there was a 67 per cent de-

crease in total closure time minutes and a 32 per cent reduction in incidents, the lowest level in seven years,” said a TfNSW spokesperson.

“Over the same period, the Sydney Harbour Tunnel, the most disrupted route, saw an 80 per cent reduction in closure minutes and a 58 per cent reduction in incidents.”

The TfNSW spokesperson continued, “The reduction in incidents has continued across the network, with 57 recorded overheight incidents between March 2024 and February 2025, 44.1 per cent fewer than the previous

Mugridge, the widow of revered interstate truckie Neville ‘Slim’ Mugridge, is devastated by the news that her late husband’s roadside memorial on the Eyre Highway has been removed, feared stolen.

Slim was tragically killed, along with two other drivers, in a two-truck crash on the SA highway about 27km west of Yalata on April 4, 2024.

The memorial was made by Bruze Custom Trucks and erected at the accident site last July.

Delphine is thankful to the industry for offering a replacement, but is still shocked that the memorial inscribed with the words, ‘RIP Slim’ and ‘Legend in a Legend’ could disappear.

“Who would do something like that? It’s something so unique that nobody could say,

‘Look what I’ve got’. Everyone’s going to know now that it was stolen,” she said.

“A lot of people would slow down too because they knew there had been an accident there.”

Delphine drew some comfort from erecting a plaque for Slim at the White Hill Truck Drivers’ Memorial Wall in Murray Bridge on March 1, but said it’s too upsetting for her to visit the Eyre Highway site.

She said many truckies would pay their respects to Slim as they passed.

“A lot of the truck drivers thought that Nev was watching over them.”

Delphine said the shock news of the memorial’s disappearance – just a few days away from the anniversary of Slim’s passing – has only made her more determined to

lobby for nationwide changes to licensing pathways for international drivers.

Her online petition has already helped convince SA to lead the way, and she is drawing strength from the fact that signatories supporting her cause continue to climb –22,615 at the time of writing. She’s planning to relocate to her home state of Queensland soon, where she’s already made approaches to the state government for a meeting with the Minister for Transport and Main Roads Brent Mickelberg in the hope of broadening a lasting

for Slim.

NSW transport legend Kel Baxter pulls out all the stops to ensure the latest addition to his storied Berrigan fleet is one to cherish.

BY JAMES GRAHAM

POSING for celebratory pictures between two special Kenworths, Kel Baxter reflected proudly on his long association with Australia’s most popular heavy-duty badge.

On his left was his very first new Kenworth, a “rugged” 1997 T650 that’s still working hard today, earning its keep at Kelvin Baxter Transport’s Riverina yard, and on his right, a stunning T909, his 100th truck straight off the Bayswater assembly line.

Two trucks from very different eras, but both linked by their durability and dependability, traits that have also been the cornerstone of Kel’s success over four decades.

On the shoulders of the new trucks that followed ‘No. 1’, with wife Marilyn doing the books, family support and dedicated staff, Ken has built the Berrigan-based operation into a regional powerhouse dedicated to bulk agricultural commodity freight right across the east coast.

From humble beginnings with two secondhand Kenworths in 1990, the company now boasts up to 55 trucks on the road on any one day, operating in some of the highest

p available today.

on the road with loyal truck ie Stuart Adams behind the wheel, running in a 36.5-metre, AB-triple configuration, owered by a Cummins X15

Queensland, NSW, Victoria and South Australia,” Kel said.

“I’ve taken trucks to Western Australia in the past when it’s very dry over here. We tend to follow where the grain is and that’s where the truck will go, with the others.”

Kel isn’t known for the ‘bling’ in his trucks, but admits he went all out to make the celebrated T909 a standout, leaving no stone unturned in a six-month build-up to handover day, right down to the commemorative ‘KBT 100’ rego plate.

“We decorated it up a bit more than I usually do, and I think we came up with what I think looks pretty smart,”

replaced with a big flat alloy bumper by BT Bull bars in Wagga Wagga, the fuel tanks were wrapped in stainless steel by RC Metalcraft in North Albury and the interior was customised throughout from maroon to blue.

PACCAR Australia was also able to mark the occasion with commemorative ‘Celebrating the 100th Kenworth’ plaques, inside and outside the cab, and a similar message embroidered on the seat.

“It was a privilege to be part of this 100th Kenworth handover event,” added Michael Long, Director Sales and Marketing, PACCAR Australia.

“Not only because Kel is an

done by Dean Laws Signs and the customised lights on the steps and tanks deftly handled by DMG Truck Electrics in North Albury.

“There’s a host of people involved once a new Kenworth comes out of the factory before they actually get on the road,” Ken said.

Twin City Truck Centre in Wodonga, which hosted March’s commemorative handover event, also played a crucial role in all the pre-delivery customisation.

Salesman Aaron Berkinshaw had the honour of coordinating the 100th truck but Kel a lso paid tribute to his recently retired predecessor Darren

icholl who had helped secure the 99 Kenworths that came

“Their attention to the details is very good. There is quite a bit involved in building a truck –there’s that many options. I’ve got a pretty good idea now what works amd what doesn’t – round tanks versus square tanks, for example.

“We do a fair bit of rural work and we don’t want the too lower clearance trucks.

“They [Twin City] know what we want and they do a good job, and they back it up with good service and spare parts availability.

“I think that’s one thing about the Kenworth product that’s so popular, particularly in regional areas where we do a lot of our work.”

Kel, who was recognised as a ‘Kenworth Legend’ in 2019,

WITH OVER 30 YEARS OF EXPERIENCE SUPPLYING TO THE HEAVY TRUCK AND BUS BULLBAR AND BUMPER BAR INDUSTRIES.

ACM can recommend a bumper or bullbar to suit your specific requirements. With a huge range on offer, we can match a product to your vehicle that will not only perform to the highest level but is backed by quality materials and manufacturing processes in the industry.

has tried other brands over the years – his first was a TK Bedford – but nothing comes close to the Kenworth’s durability and dependability in some of the toughest terrains.

“The strength of the cab stands alone,” Kel said.

“You can get similar running gear; engines, suspension and other things, but they don’t stand up to rural work as well.

“We do a lot of harvest work and are on and off farms a lot and are accustomed to that.

“If a load of gypsum or lime needs to go down the back paddock, then we know that’s where we can take it. The trucks will put up with that sort of treatment.”

Inside the cab, the driver comforts are also a long way from what the 1997 Kenworth boasted – a state-of-the-art

Custom Air air-conditioning system, microwave, TV, ample storage and standup fridge, just a few of the standout features.

“This is not the first truck

that we’ve fitted those accessories to, but we make it as comfortable as we can.

“We have drivers employed over a wide area of the grain belt, so drivers can get home on weekends, but our drivers do spend time away on the season work, which provides variation, plus good earning opportunities.”

Kel prides himself on the driver training program at Kelvin Baxter Transport and the strong core of long-term truckies on the roster.

“They work hard and they get paid well. I’ve got a lot of respect for my drivers.”

Kel concedes that is a shortage of skilled drivers across the industry.

One of the main causes, he feels, is that it’s not regarded by many newcomers as a career option.

With more of the national fleet now road trains and A B-triples, Kel would also like to see the MC licence split

into two tiers: one for those driving B-doubles, and another for those behind the wheel of a road train, B-triple or AB-triple.

“Most people can back a B-double, but plenty of them can’t back an A-double. There’s a lot more training involved there.

“You’re also going up significantly in gross weight yet there is no difference in the licence needed at the moment.”

A former chair of the Australian Trucking Association’s (ATA) Industry Technical Council (ITC) and now life member, Kel has been at the forefront of lobbying for higher productivity vehicles on Australian roads for many years.

In 2009 he donated his own equipment to run the first legal BAB Quad on NSW roads and at a similar ATA demo day at Dubbo in 2010. He has been instrumental in achieving better access for road trains in the R iverina, and beyond.

productivity vehicles that has taken place in the last couple of years.

“Supply chain costs in this country are as high as anywhere else in the world because of our distances, and we make use of the fact we can run longer vehicles.

“It doesn’t matter whether you’re running by the tonne or pallet, the higher productivity vehicles do it at a lower cost.”

Kel admits it hasn’t always been easy to get those in charge of the road and bridge network to see the benefits for the freight industry, and in turn, the end consumer. Although there have been significant breakthroughs in recent years, many as a direct result of Kel’s advocacy, he says the permit process is still tangled up in far too much red tape.

Kel said bridge access is another bugbear and could be managed a lot better. He’d like to see more jurisdictions adopt the approach of Transport for NSW which has recently allowed PBS vehicles access over the Sheahan Bridge at Gundagai.

“That alone has opened up the Hume Highway for high productivity vehicles and is a great example to use on other bridges on other highways.”

Kel, meanwhile, seems as busy as ever, wearing multiple hats.

When Big Rigs checks in, he’s in Dubbo for an ITC meeting, and as a committee member of the Livestock, Bulk and Rural Carriers Association of NSW, also knee deep in helping to organise this month’s National Rural Carriers Convention

n Canberra. On the businessport has also been gradually rowing over the last five years:ers, and we’ve stepped up to meet their needs.”

Now 73, Kel concedes, however, that he is slowly delegating a bit more of the workload to members of the team.

He feels fortunate to have his two sons Glen and Noel heading up the 35,000-acre crop farming side of the operation that started in 1970 with a relatively modest 1700 acres, and their respective wives, Fiona and Amy, heavily involved in the transport side of the large family business.

Fiona leads the compliance team, while Amy plays a key role in the management of the many subcontractors.

“I get a fair bit of advice from them on trucking, and I give them a fair bit of advice on farming as well – makes for some good discussions.”

No one wants to ever have to call on their services, but when they do, it’s reassuring to see this big Scania V8 arriving to save the day.

BY DAVID VILE

FOR Canberra based towtruck operator Trai Hildeb rand, putting ‘Thor’, his Scania heavy wrecker unit on display at the Cooma Motorfest late last year gave him both the chance to both show off his impressive rig and enjoy a rare day off.

Trai works for Aplus Towing and has been behind the wheel of the big Swede which has been kitted out with an Ekebol underlift recovery unit and a swag of associated gear since it was put into service in early 2023.

“It’s one of those things; no one really wants to see us, that’s why the truck shows are good as you can get out and see people when they are not broken down or have had an accident - you can have a chat to them and it’s not the worst day of their life,” Trai said.

With the Snowy 2.0 Hydro project in full swing, and a lot of extra vehicle movements in the region, Troi and the Sca nia have tackled a variety of towing and recovery jobs in the rugged terrain of the New South Wales Snowy Mountains.

and Thor ready to roll at short notice.

“A-Plus is the recovery provider for Future Generation (who are managing the Snowy 2.0 Project) which keeps us on our toes,” Trai said.

Along the Snowy Mountains Highway there has been a few incidents so we have a very high presence in this area - we can run down here every day and its convenient to Canberra - we are virtually local to it.”

Given the variable alpine weather and the winding mountain roads throughout the area, the call for help to retrieve a stuck vehicle can come at any time, with Trai

“One of the biggest jobs we did was 12 trucks which got stuck at a place called Powerline Hill in the snow, we ended up being out there for 16 hours.

The weather can vary so much too - a couple of years ago I was doing recoveries in the snow in November with lots of trucks sliding off the road or getting stuck for traction,” he explained.

Getting the big Scania on the road was a two-year process with the truck being built and then fitted out with the recovery unit.

The back end is packed with every sort of tool required in-

cluding around 150 metres of chain, ladders, power tools, a bus lift, snow chains and blocks.

“There is another heavy recovery unit at Goulburn but if it’s away the next truck is either Sydney or Wagga - we are on our own a fair bit, so we have set it up to do everything from a small job up to a B -double or B-triple,” said Trai.

Originally white in colour, the Scania has had approximately 44 metres of vinyl wrap applied by Capital Signs in Canberra to give it its distinct appearance in the A-Plus colours.

With the 16.3-litre V8 punching out 620 horses and 3000nM of torque, the Scania is not short of get-up and go and Trai reckons it is a good bit of kit to drive as he explained, “The V8 has so much torque and the hub reduction on the back helps a helluva lot.

“She will scoot up the hills but obviously in this region a good retarder is a big thing - it will hold back 100 tonne B-doubles going down hills.

“It has a great stopping capacity without having to jump on the brakes.”

The recovery unit has 108

tonne capacity and the most I have moved is 92 tonnes from Mt Selwyn, so it was around 118 tonne all up and it did really well - I haven’t had anything on it that it hasn’t been able to do yet.”

Needless to say, the back end of the truck is where all the work happens with the Ekebol recovery unit proving its worth out in the field.

“It’s all Australian made and built by Ekebol on the Sunshine Coast. They have been building this type of body for 20 years and have kept updating it as they go along and their after sales support has been great.

“The Scania is a really good platform for this type of unita company in Sydney has been taking measurements and so forth off this one as they are looking at making an exact copy of this type of unit.”

Since hitting the road, the Scania had clocked up around 90,000 kilometres and around 2500 operating hours.

Generally, Trai works within 450km of the Canberra base, but has made trips to Brisbane, Newcastle, Melbourne and the NSW South Coast, working with other operators as the need arises.

“We have friends in different companies such as Wagga Towing and GRS Towing, so we spread the work, just getting it done for the customer is the biggest thing.

“Our distances on jobs can vary - I have done over 3000 k’s this week, but you could go to a job 5 k’s from the depot and be there for 12 hours,” he said.

Originally working as a plumber, Trai made the switch to trucks and joined Aplus six years ago.

“I climbed the rope; I had

my MC licence and had been driving B-doubles here and there and started out with Aplus on a supertilt.

“The company bought a Freightliner with an underlift from Queanbeyan which been in the local area for 20 odd years and I took it on.

“They always planned to buy this as there was a couple of year wait for it and we hit the ground running with it - it was built how we wanted, a lot of things added and changed for the ease of use.”

The Cooma Motorfest was one of many Thor has had a presence at in recent times, with Trai taking in shows at Bathurst, Bredbo and Casino along with other events such as the Goulburn Convoy for Kids.

But with towing and accident recovery being an on-call 4/7 type of operation, Trai was ready to fire up the big V8 and head off on the next assignment.

“It’s just a matter of waiting for the phone to ring - the next recovery job could be locally, Sydney, Melbourne or anywhere.

We have a very important role to play in the industry.”

After over 20 years in office roles, this go-getting outback truckie now feels more at home on the Strzelecki Track or the Tanami than sitting behind a desk.

BY DANIELLE GULLACI

SINCE making the switch into the trucking field four years ago, 42-year-old Nat Smith says she has only one regret – that she didn’t do it sooner.

Based in Adelaide, her work takes her to all corners of Australia. “I go everywhere, any capital city, any dirt road and any mine site,” she said. Nat works for Energy Logistix Transport, running double and triple road trains out of the company’s Largs North depot.

Her start in trucking came four years ago. As she explained, “I was a keyboard warrior for about 20 years until my kids grew up. Once they finished school, I decided I wanted to do what I want to do!

“I’ve always loved being on the road and have always been an outdoors person. Even when I was in those office roles, whenever I needed to take a step back mentally, I would go back to an old job I had of driving lunch vans.

“That’s when I decided to look at other avenues where I could get out on the road –and stay out on the road. It’s all grown from there and now trucking has become an addiction!”

Nat had worked in various office roles including consumer finance and customer service. As she explained, “Those jobs weren’t ever a career for me, whereas this is.

“My kids are 20 and 22 now and they both live out of home and are doing their bit in life. I would have loved to have started this 20 years ago, but then I probably wouldn’t have had the life I’ve had with my children.”

Nat’s first role in the industry was with Remote Transport Australia (RTA). Four years ago, she started there doing yard work, before she even had her truck licence. “It was through friends that I was blessed to have that opportunity at RTA. I was washing trucks, loading trailers, learning to back trailers into bays, snapping combinations together. Then once I got my truck licence three years ago, I began driving for them, doing local work,” she explained.

“I’d go out to Port Pirie or load freight around Adelaide, and it progressed from there. Eventually I was heading out to the mines. That job at RTA gave me the opportunity to understand where to place things on trailers, how to restrain things, how to take care of the equipment.

“I was so new to the industry. And I still am compared to other drivers.

“There’s a big gap I think – a lot of people don’t understand that being a truck driver is not just sitting behind a steering wheel. You need to know how to maintain your trailers too.”

From there, Nat went on to work at Bonetti Transport and Hire. “I loved this company but the work was very city-based. I wanted to get back into the dirt work. They understood that was my end game. Now I keep adding more and more trailers.”

Nat started with ELX in October 2023 and says she’s loving every minute. Often the work sees her on the road for numerous weeks at a time, pulling anything from double road trains to AB triples, and carrying general freight.

“The longest I’ve been away in the truck is five weeks. I love those long trips. I’m privileged enough that my kids

ALL GROWN FROM THERE AND NOW TRUCKING HAS BECOME AN ADDICTION!”

time on the Strzelecki Track. “It’s our gateway coming into Queensland.” She’s also tackled the Great Central Road and the Tanami up to the Tanami Gold Mine. “But there’s still much more of the Tanami up north I haven’t done yet. I also haven’t done the Birdsville Developmental Road but would love to do it.”

Nat got her MC licence in January 2024, while working with ELX. “I had wanted to upgrade to my MC, but I wanted to make sure I was competent with my HC before I started adding trailers. I had a really good support team at ELX and they gave me that opportunity to upgrade my licence. I’m slowly adding more trailers as I go.

“ELX has been fantastic with the career progression I wanted. They’ve put a massive amount of trust in me by handing over the keys to this equipment. I’m forever grateful and blessed to have been given that opportunity.”

have grown up so I can make that commitment and spend that time out on the road,” said Nat.

“You always try and be home for the events you need to be at and work is really good like that. If I need to take annual leave, they make it happen. It’s a two-way street. They know the commitment we put in and the effort. We give our all to the job and they give their all to us.”

In terms of the freight she transports, Nat explained, “I could carry anything from drill rods, to chemicals, iso tanks of nitrogen, motor components that go into a beam pump, to the massive beam pumps themselves. Whatever our client requests is what we’ll carry. Sometimes loading the trailers is like playing Tetris.”

Starting in Adelaide, Nat

travels wherever is needed to service ELX’s clients, which are based Australia-wide.

“From that point, I could be on the road for however long it needs to be. This job I just did went from Adelaide to Perth, then to a mine site past Newman, back to Perth and now back to Adelaide,” explained Nat.

“The majority of our clients are in the oil and gas field. There’s no client too big or small. If anything needs to be done, I’ll do it.”

Nat was recently handed the keys to a 2020 Kenworth C509 named ‘Odin’. “I love it, it’s so nice to drive and very comfortable. To have to live in the truck as we do, we are incredibly blessed with the space. I’ve got two fridges, a microwave, TV, sound bar – it’s got all the creature comforts you would want in

Asked what she loves most about the work, Nat responded, “It’s the remoteness and the scope of work I do. I do enjoy my solitude and my quiet time, being away from noise and city life. There’s also the people you get to meet, and seeing some of the machinery that gets moved around.

“Some of the landscapes younificent too. In the Kimberleyarts Well on the way to Alice Springs, there’s this stretch oftains with flat tops on them, there’s the cloud formations coming into Darwin where it can look like Armageddon, the epic sunrises in Moomba,ple road train on. The photos

With over 150,000 parts across 30 product groups, SAMPA delivers one of the most comprehensive selections of commercial vehicle components in the industry. Our extensive range includes suspension systems, drivetrain components, fifth wheel assemblies, air springs, landing gears, and much more – all engineered to meet the highest industry standards for durability and reliability.

If you're looking to take your fleet to the next level, we invite you to visit us at the Brisbane Truck Show where you’ll have the opportunity to explore our full range of products. Come see first-hand how SAMPA can support your business with durable, high-quality parts.

Show Dates: 15-18 May 2025

Show Location:

The Brisbane Convention & Exhibition Centre, Brisbane, QLD, Australia Booth No.: No. 314

After over 50 years in the game, this veteran transport operator has called time on his trucking career – selling the successful Sunshine Coast business he started 25 years ago.

BY DANIELLE GULLACI

PETER Carter was just 17 years old when he got his truck licence and began driv ing at his father’s sawmill, hauling timber and logs, from behind the wheel of an In ternational, powered by a V8 petrol engine.

A lot has changed since then, with Peter continuing to roll with the times, through the highs and the lows. He spoke with Big Rigs about making the difficult decision to walk away from the industry he’s been part of for his entire working life.

“I’ll be 70 this year, that’s why I reckon it’s time to give it up,” he told Big Rigs. “The industry is in a fair bit of hurt right now and there’s a lot that transport operators are having to go through.”

One particular issue he not ed was the difficulty operators are having with finding good truck drivers. “People just can’t get drivers. That’s been an issue for a couple of years now. I had a number of driv ers who were with me for 20 years or more. We had good drivers who stayed with us. Now there are a lot of young people who just don’t want to work. It’s hard to get people in. So many want to get their truck licence and go straight into a B-double. They don’t realise you need to work your way up to that.”

Based on the Sunshine Coast, Peter spoke of how he came to establish Peter Carter Transport in 2000, a successful transport operation with a fleet of 38 prime movers, 74 trailers and 16 rigids – operating from three depots (Coolum Beach on the Sunshine Coast, Rocklea and Townsville).

During the 1970s, he worked by his father’s side for six or seven years, until he closed the sawmill. “Then I went carting for Bells Transport for four years. I got out of that and went back into sawmills for another 16-17 years,” he explained.

Peter had been running his own sawmill; harvesting, and carting timber and logs with his small fleet of trucks.

“That was until 2000. The Greens had been pushing to stop logging in various forestry areas around the state, so the Queensland government shut down my sawmill due to the Regional Forest Agreements.”

At that moment, Peter had to choose which of two career paths he wanted to take. “I had to decide if I wanted to keep sawmilling or move into trucks.”

Peter chose the latter, keeping two of his trucks to form Peter Carter Transport.

“When we started up, we were doing recycled cardboard into Brisbane; and recycled glass, bricks and alcohol out of Bris-

bane,” he explained.

A family business through and through, Peter credits his wife Kate for helping to get the business to where it was.

“Behind every good man is a good woman, and my wife has been there since we started this business. We wouldn’t have gotten to where we are today without her, and my son Trent and his wife Kaicee,” said Peter. “When we started this business, Trent came back from Broome in WA, where he was driving trucks. He came into this business and we continued to build it from there.”

In the early days of Peter Carter Transport, growth was slow and steady, with the fleet

growing to four or five trucks by 2004. That was when an opportunity came up to acquire Morgans Suncoast Freighters, bringing another nine trucks into the mix. Along with tripling the size of the fleet, this move also saw the business expanding into general freight.

Asked about his biggest career highlight, Peter nominated the move to the purpose built Coolum Beach facility eight years ago. “It was a huge decision to make that move and make such a big investment in the space. We were previously based at a 3000 square metre facility at Kunda Park and went into a 10,400 square metre space at Coolum

SOMETIMES WHEN THINGS LIKE THAT HAPPEN, YOU WONDER HOW TO GET PAST IT, BUT YOU’VE GOT TO KEEP ON GOING.”

PETER

CARTER

Beach. From there we ran the transport operation and a separate cardboard baling business. The day we moved was a really big highlight for me.”

However it certainly hasn’t always been smooth sailing.

“We have had our run of ups and downs. Our Rocklea site was flooded in 2011, then we had a fire at the cardboard baling facilities at Coolum Beach in 2018 and another flood at Rocklea in 2022,” said Peter, admitting those moments were tough to get through. “Sometimes when things like that happen, you wonder how to get past it, but you’ve got to keep on going.”

And that’s exactly what he did, continuing to grow the business into the respected player it is today.

With Peter and Kate both ready for the next chapter of their lives, their business was sold to Blacks Transport Group, with the acquisition announced in early March.

“It was a difficult decision and took a lot of consideration but we knew it was time. Our staff were our biggest concern

when we sold. We wanted to make sure that our staff were looked after, as well as our customers – and Blacks Transport were happy to do that, taking on all our staff,” explained Peter.

Like Peter’s business, Blacks Transport Group is also family owned and operated. It was started in 1995 with a single truck and has been built up to a fleet of over 150 trucks and trailers, predominantly servicing south-east Queensland, the Burnett/Wide Bay Region and North Queensland.

As part of the transition, Peter Carter Transport has now been rebranded as Carters Transport Qld, operating as a division of Blacks Transport Group.

Peter revealed his decision to sell to Blacks also came down to timing. “We didn’t actually have the business on the market but were looking to retire and Blacks Transport Group was looking to expand.”

He added that it was great to know his staff and customers would be looked after by another family owned and operated business.

Blacks Transport Group has depots in Brisbane, Sunshine Coast, Maryborough, Bundaberg and Rockhampton. The acquisition of Peter Carter Transport will add a company-owned depot to Townsville; along with an additional depot on the Sunshine Coast.

Managing Director at Blacks Transport Group, Bruce Black, told Big Rigs, “The acquisition will give us depots right along the east coast of Queensland, with our agent depots located across the rest of the state.” Asked about the attraction to Peter Carter Transport, Bruce commented, “We were looking to expand our business further. The Carters business has a lot of the correct freight profiles, that complement the freight profiles we already had, so we believed it would be a good blend.

“It will allow us to further improve our services and provide additional services daily.”

With the acquisition, Blacks Transport Group now has a fleet of around 125 trucks. While all transport operations will now fall under Blacks Transport Group, Peter has retained his cardboard baling business that operates from the same site at the main Coolum Beach depot. “I have someone managing that for me. A man has to retire but he can’t have nothing to do,” laughed Peter. Looking ahead, now that he has more time on his hands, Peter is looking forward to doing some travelling. “Kate and I are going to get in our motorhome and travel around Australia. We’d also like to take a few overseas trips too,” he said. “I’ve got to keep the wife happy!”

When the Fuso Canter first hit Australian shores, it delivered on a promise: a safe and practical work truck you could rely on to get the job done. And get jobs done it did. Since 1971, Aussies have been turning to an ever-evolving range of Fuso Canters for all kinds of jobs – cabs to carry crews and pantechs to help with moves, trays for loading and tippers for disposing. The work carries on with our new-look Canter.

An updated design combines brighter LED headlights, sleek exterior styling and an enhanced 8” multimedia touch screen with the DNA of Australia’s hardest-working light-duty truck. Add in class-leading payload across most models, advanced active safety systems* and impressive 30,000km service intervals, and you have everything that you need to get the job done.

off-road

FG

For

This reluctant recent addition to the Wall of Fame says he stands on the shoulders of all those who worked for, and with him.

BY AINSLEIGH BILATO

WHEN Kevin Englefield received news of his nomi nation for the National Road Transport Museum’s Shell Rimula Wall of Fame, his initial reaction was reluc tance.

“When I got the letter to say I’d been accepted into the Wall of Fame, I actual ly took three days to decide I was going to accept that,” Kevin says. He did not see himself as a figure worthy of such rec ognition. To Kevin, he was simply a man who had done his job.

Having grown up in the transport industry, Kevin had himself admired so many of the names on the Wall of Fame, respecting their accomplishments and aspiring to reach even a fraction of their success.

To find himself placed among them was a challenge for Kevin to fully come to terms with. It was only after some persuasion from those around Kevin - family, friends and colleagues who knew the extent of his contributions - that he accepted the honour.

Kevin felt that he owed it to all the people who had helped him throughout his career, recognising that his success was not his alone but a product of the sacrifices of those who worked for and with him.

“When I stepped up to receive that award, I wasn’t receiving it for me,” says Kevin. “I received it for us.”

Long before leaving school, Kevin had a clear vision for his future. He knew he wanted to be a truck driver and own a successful transport business.

This decision, shaped by his parents, John and Joy Englefield, who started their transport business in 1972, marked the beginning of a long and dedicated career in

the transport industry. In the mid-1970s, Kevin and his brother Michael joined the family business, responsible for loading the trucks for their parents.

By 1979, an 18-year-old Kevin took over the long-distance driving for the business, carting wine grapes, citrus and various other farming goods and equipment.

In 1999, Kevin transitioned from interstate driving to a management position within the business, working closely with his father to oversee its day-to-day operations. At the time, the business was running up to 25 subcontractor owner drivers.