It’s enough to make any sane person shudder.

It’s enough to make any sane person shudder.

Have you ever seen a car come into your shop — looked at its tyres — and thought ‘how have they gotten away with those for so long?’

The average motorist mightn’t want their tyres whittled down to the bone.

But every so often there’ll be someone quite content in letting their car tyres go balder than Peter Garrett.

Wheel and tyre maintenance is a crucial aspect of ensuring vehicle safety and performance.

It’s hard to ignore the importance of wheels/tyres to a vehicle — it’s how they get around.

Without them, cars would just be very small metal houses.

As the weather warms up, the demands on tyres increase, and the consequences of failure become more severe.

As mechanics, it’s essential that you’re equipped to diagnose and repair wheel and tyre issues efficiently and effectively.

To stay ahead of the curve, mechanics need to be aware of the latest best practices for wheel and tyre maintenance.

This includes utilising specialised equipment to detect subtle signs of wear and damage.

Ensure precise alignment and balancing to optimise tyre life and vehicle performance.

Finally, staying up-to-date with the latest repair methods and technologies to ensure safe and reliable fixes.

In this issue, we’ll be featuring expert insights and advice on wheel and tyre maintenance, including the latest trends and technologies in the field.

From tyre selection to wheel alignment, we’ve got you covered to help stay ahead of the curve.

As the seasons change and the weather warms up, it’s time to take action.

By refining our skills, updating our knowledge, and staying current with the latest best practices, we can ensure our workshops remain at the forefront of automotive repair. Let’s work together to provide the best possible service to our customers and drive the industry forward.

Harry Murtough – Editor

or 100 years, Penrite has been a staple in not only Australian oil, but one of the most recognisable brands nationwide. The family-owned operation that started from small beginnings has grown massively in the last century. In this edition, we look back at the history of Penrite as it celebrates its 100-year birthday.

Oct 21, 2025

Dec 3, 2025

18, 2026

CEO

Christine Clancy

Sales Director

Danny Hernandez

Editor Harry Murtough

harry.murtough@primecreative.com.au

Client Success

Arianna Lucini

arianna.lucini@primecreative.com.au

Art Director/Design

Daz Woolley

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website www.mechanics-mag.com.au

Background image

Iain Curry

Cover image

Penrite Oil

Copyright Australian Car Mechanic magazine is owned by Prime Creative Media and published by John Murphy. All material in Australian Car Mechanic magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronicor mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Australian Car Mechanic magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2025

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

19

24

Penrite Oil, one of Australia’s most trusted names in the automotive industry, is set to celebrate its 100th anniversary in 2026.

This milestone reflects a century of innovation, commitment to quality, and a family-driven legacy that has shaped the company into a respected leader in the automotive industry.

The story of Penrite begins with Les Mecoles, a young and ambitious entrepreneur who started his business journey while still a student at Melbourne High School in the 1920s. Les began by importing oils from overseas and acting as

an agent for established brands such as Shell, Autolene, Trogon Oils, and Rigolin.

His school notebooks were filled with sales figures and oil blend formulas, showcasing his early passion for business and technical knowledge.

On his sixteenth birthday, March 6, 1926, Les officially launched his own company.

Operating from his family home in St Kilda, Melbourne, he blended oils on his mother’s kitchen stove and delivered them using his father’s wheelbarrow.

Later, as his customer base grew, he relied on a courier service for deliveries.

Family stories recall that Les even sold his prized leather jacket to fund his first batch of oil.

Les was also deeply interested in photography, cars, and horse racing.

He often carried a camera or racing guide and even served as the photographer at his own wedding, leaving the reception early with his brother to test-drive a car.

These passions reflected his curiosity and entrepreneurial spirit, traits that would shape his business approach.

In the early years, Les operated a petrol service station on Hawthorn Road, Caulfield, selling oil and petrol from the curb side.

As the business grew, he purchased his first factory, allowing him to expand operations.

By 1932, he relocated the business to

625 Bridge Road, Richmond, Melbourne, acquiring the property for just £75 — a site now occupied by a McDonald’s restaurant. Over the following years, Les continued to grow the business, acquiring additional properties across Abbotsford and Richmond to import, distribute, and manufacture oil under the name L.H. Mecoles Oil Merchant.

In 1934, his brother Stan joined the company, helping further expansion.

Recognising the need for a distinct brand, Les initially sketched the name “Oil-Rite” on the back of an envelope.

However, when this name was already taken, Stan suggested “Pen-Rite,” combining “Pen” for Pennsylvania crude oil, regarded as the finest at the time,

with “Rite” to signify the right oil. In 1936, Les registered the name Penrite with the Commonwealth of Australia and became a member of the Pennsylvanian Grade Crude Oil Association, enabling him to import 100 per cent pure Pennsylvania crude oil for blending.

During the 1930s, Penrite experienced significant growth, moving to 71 Hoddle Street, Richmond, and expanding distribution to other Australian states.

By the time World War II began, Penrite offered not only oils and lubricants but also greases, automotive batteries, and workshop tools to meet growing customer demand. Records show that Penrite played an important role in supporting the Allied war effort, producing various products for both the European and Pacific campaigns.

Penrite Oil’s commitment to performance and innovation is reflected in its highperformance products and sponsorship of motorsport and community events, including the Penrite Racing Supercars team.

The plain green wartime Penrite tins marked a practical shift from Les’s usual marketing style, reflecting the needs of the time.

A January 1942 stocktake revealed that Penrite held £11,000 worth of stock, though the staff had been reduced to fewer than 10 people.

Throughout this challenging period, Les and Stan ran the operations, ensuring production for the Australian government.

After the war, Australia still faced extensive rationing, affecting manufacturing and daily life. By 1951, Penrite Oil had grown to become a Pty Limited company and was promoted as the ‘Specialist in lubricating oils and greases for every purpose’.

Les travelled frequently to Brisbane, Sydney, and Adelaide, expanding Penrite’s reach, and began hiring salespeople, dedicating effort to training them in the art of salesmanship.

One of his earliest recruits was Ron Walker, who would later become chairman of Fairfax Ltd, Lord Mayor of Melbourne, and head of Formula One.

In the late 1960s and early 1970s, the Abbotsford site was acquired by the Victorian government to make way for a new freeway, and Les brought a new facility at 3 Cross Street, Brunswick.

During this time, Les’s health began to decline after battling cancer twice.

With no children to inherit the business, he decided to sell.

He identified John Dymond, a young oil additives supplier and close associate, as a potential successor.

With support from John’s wife, Margaret, the Dymond’s negotiated the purchase, and Les helped finance the deal to ensure the company remained in capable hands. The sale was finalised in March 1979, and Les passed away shortly after, on August 23, 1979.

John Dymond, known as “JD”, started his career as an apprentice engineer at the Vauxhall motor factory in Luton, England.

He and Margaret migrated to Australia in the late 1950s, where John worked with British Petroleum on their long-life fuel additive program.

His work allowed him to travel across Australia and New Zealand, gaining insight into the local automotive market and identifying a need for oils designed specifically for Australian conditions. After leaving BP, John joined Lubrizol, a US-based additive company, developing oil and lubricant solutions tailored for Australia.

After purchasing Penrite, JD quickly identified a key gap in the Australian lubricants market: most oils were designed for North American or European conditions and were not optimal for Australian cars and climate. He focused on developing oils specifically engineered for local conditions and expanded Penrite’s

presence internationally, including New Zealand and Europe. In 1981, JD launched the Penrite HPR – High Performance Range, a line of multi-grade, full zinc oils featuring advanced “Extra Ten” technology. This innovative range became the first of its kind in Australia and quickly gained popularity, solidifying Penrite’s reputation as a leader in the high-performance oil market.

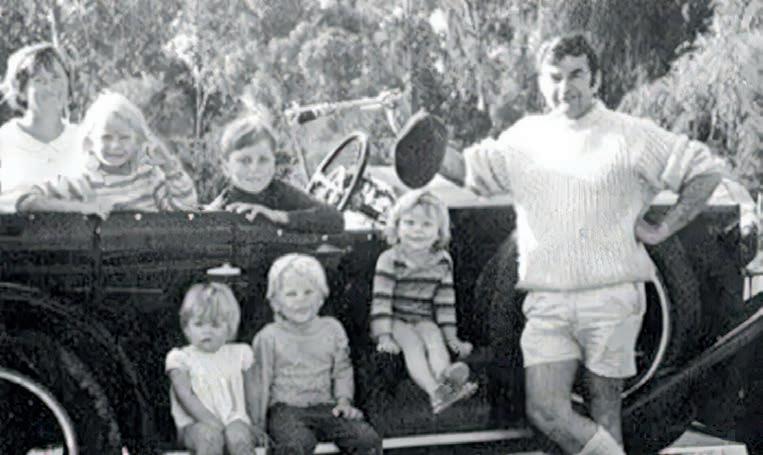

In the late 1980s, John launched his first major marketing campaign, showcasing classic, racing, and collectible cars belonging to his friends. The campaign emphasised the importance of using the best oil for valuable automobiles, connecting emotionally with car enthusiasts

and positioning Penrite as a trusted brand. By the mid to late 1990s, Penrite relocated its main blending plant to a purpose-built facility at 88 Lewis Road, Wantirna. The “Obsession with Oil” campaign connected customers with their cars, portraying vehicles as extensions of themselves and reinforcing the idea that Penrite offered superior protection and performance. This campaign, supported by television, radio, and retail promotions, resonated with a wide audience, from race car drivers to owners of rotary engines, V8s, and turbocharged cars.

Marsey’s milestone

Margaret Dymond, affectionately known as ‘Marsey’ or ‘Marg,’ has been a cornerstone of Penrite for over 45 years. Currently the owner of Penrite Oil and known for her warmth and dedication, she engages with young motorsport competitors, car enthusiasts, and local events, all while maintaining a low profile. Her commitment to family, Australian manufacturing, and the company’s values has been vital to

Penrite’s ongoing success. Today, Penrite continues under the leadership of Toby Dymond as CEO, with other family members, Nigel, Fleur, and Jon, holding significant roles. The company remains family-owned, proudly Australian-made, and committed to high-performance products suited to local conditions.

“I’m incredibly proud to be part of Penrite’s story as we approach 100 years,” Penrite Oil CEO Toby Dymond said.

“Our history is built on vision, hard work, and family values that continue to guide us today. I’m just as passionate about the future — ensuring Penrite remains at the forefront of innovation, supporting the automotive community, and delivering the high-performance products Australians can trust for the next century.”

Penrite also actively supports motorsport and community events, including sponsorship of the Penrite Racing V8 Supercars team, Naming rights sponsor of the National PRO MX Series, Penrite Racing Empire Kawasaki team (ProMX), the Penrite

Hattah Desert Race, and the National V8 Superboats. Penrite also sponsor some 250 brand ambassadors throughout Australia and New Zealand. These partnerships reflect Penrite’s ongoing commitment to performance, innovation, and engagement with Australia’s automotive and motorsport communities.

As Penrite approaches its centenary, the company has planned large-scale celebrations, activations, promotions, and exclusive experiences for its customers and partners.

Penrite’s journey from blending oil on a kitchen stove to a global leader in lubricants is a testament to innovation, dedication, and family values. The company’s centenary in 2026 will celebrate this rich history and the continuing legacy of providing high-quality, Australian-made products. With a focus on performance, innovation, and community, Penrite looks forward to another 100 years of success, honouring its roots while embracing the future of the automotive industry.

You’d be hard-pressed to find an Aussie motor sport that doesn’t have Penrite involved in one way or another.

Schaeffler Vehicle Lifetime Solutions strengthens its market leadership by expanding its powertrain solutions portfolio with Vitesco products

The integration of electronics and mechanics has become central to ensuring vehicle performance, efficiency, and compliance.

At the heart of this transformation are three components: sensors, actuators, and control units.

These systems form a complex but cohesive network that enables vehicles to operate more intelligently, cleanly, and efficiently. Sensors are the vigilant observers within a vehicle’s ecosystem. They constantly monitor parameters such as temperature, pressure, and emissions.

For instance, NOx sensors precisely and continuously measure the nitrogen concentration in exhaust gases — a critical function in reducing environmental impact and ensuring cleaner emissions.

Actuators are the doers.

Acting on the data provided by sensors, they execute physical actions to fine-tune vehicle systems.

Today’s advanced mechatronic actuators allow for extremely precise control over engine and drivetrain functions, optimising performance and reducing fuel consumption.

Control Units serve as the brain behind these operations.

They process the influx of sensor data and issue commands to actuators, ensuring real-time adjustments that keep the engine running smoothly and in compliance with ever-stricter emissions standards.

These intelligent units are fundamental to not only lowering emissions but also reducing operating costs and extending the lifespan of vehicle systems. Together, these components form the backbone of modern automotive design—an integrated network of sensing, decision-making, and action. And as automotive technology continues to evolve, so too must the aftermarket solutions that support it.

Recognising the importance of these advanced systems, Schaeffler’s Vehicle Lifetime Solutions (VLS) division has made a major strategic move by integrating Vitesco Technologies’ product portfolio.

This enhancement of Schaeffler’s offering in the independent aftermarket significantly strengthens its capabilities in providing cutting-edge emissions-related technologies, including high-precision NOx sensors, control units, and advanced mechatronic actuators.

“The integration of the Vitesco portfolio is a strategic and significant milestone for Schaeffler VLS,” Schaeffler Vehicle Lifestime Solutions Pacific Head Warren Barnett said.

“Sales channel partners and workshops will benefit from a stable supply chain, high-quality products, and comprehensive technical support across all powertrain types relevant for the Aftermarket. Further

expansion of range will follow in the coming years.”

Benefits of the integration for mechanics

• Stable supply chain: sales channel partners gain direct access to vital technologies in trusted original equipment (OE) quality.

• Technical support: Independent workshops benefit from expert assistance across a range of modern powertrain systems.

• High-quality products: Vitesco components are delivered with consistent reliability, backed by Schaeffler’s renowned service infrastructure. This strategic integration enables Schaeffler VLS to support the evolving needs of the Australian car parc, providing innovative solutions for sustainable mobility. It also opens up new market segments while accelerating the development of lowemission and highly efficient drive systems. By acquiring emissions-compliant diagnostic technologies like NOx sensors

and precision actuators, Schaeffler VLS is reinforcing its role as a key enabler of environmentally responsible vehicle repair and maintenance.

These components are crucial for ensuring CO2 reduction, enhancing drivetrain efficiency, and lowering long-term operating costs for vehicle owners.

As vehicles grow more complex with the integration of mechatronics, software, and connectivity, the challenges faced by independent aftermarket workshops increase.

Schaeffler VLS is addressing this headon through its REPXPERT workshop portal, offering extensive training and technical resources based on OE-level expertise.

This equips technicians with the knowledge and tools needed to stay ahead of rapid technological change.

At the same time, sales channel partners benefit from the ‘Schaeffler Vitesco’ co-branding strategy, allowing them to introduce previously exclusive OE technologies to the wider market.

This democratisation of access to top-tier automotive components is a game-changer for the aftermarket.

With this integration, Schaeffler continues its legacy as an innovation leader.

For more than 75 years, the Schaeffler Group has pioneered motion technologies across industries.

Now, with 120,000 employees in more than 250 locations worldwide, the company remains a global force in developing solutions for electric mobility, CO2 -efficient drives, chassis systems, and renewable energy — all aimed at making motion more intelligent, sustainable, and efficient.

In the modern vehicle, where the line between mechanical systems and digital intelligence is increasingly blurred, the trio of sensors, actuators, and control units are not just important — they are indispensable.

With the integration of Vitesco Technologies, Schaeffler’s VLS division is ensuring these essential components are accessible, reliable, and ready for the road ahead.

The PLB-802 handles everything from passenger vehicles to heavy-duty wheels with ease—fast, accurate, and built for high-volume workshops.

The PLB-503 delivers ultra-precise balancing with sonar diagnostics, a high-definition LCD screen, and lightning-fast performance — everything you need in one machine.

The PLB-402 offers reliable wheel balancing with minimal hassle — perfect for small to medium workshops that need efficiency at an affordable price.

Aussie mechanics understand the importance of having reliable, precise, and efficient equipment in their workshop.

When it comes to balancing wheels, whether for cars, trucks, or motorcycles, choosing the right machine can save you time, increase accuracy, and improve the overall customer experience.

Three new wheel balancers have been made available via Launch, catering for all kinds of workshop needs, great or small.

The PLB-802 is designed for both car and truck wheel balancing, making it a versatile choice for busy workshops that service a wide range of vehicles.

What sets this machine apart is its variable frequency technology, ensuring that it can handle everything from passenger car wheels to large truck tyres with ease.

The machine offers a high precision of 1g for cars and 10g for trucks, allowing for accurate results across various wheel sizes.

With an Italian software interface, the PLB-802 is intuitive and easy to operate, even for mechanics who might not be familiar with the latest technology.

The machine’s frequency converter-driven motor ensures smooth operation with low noise, making it a pleasant experience for both the technician and the customer.

The automatic input of two values and six o’clock laser indicator streamlines the process, while the intelligent dynamic switch adjusts automatically for different materials like ALU alloy.

Its high maximum wheel weight of 200kg and rim diameter capacity from 1” to 28”

make it capable of handling even the largest of wheels, including those found on heavyduty trucks.

The automatic balancing time of nine seconds for cars and 20 seconds for trucks keeps your workflow fast, while the standard lifting device reduces manual labour.

If you’re running a smaller shop or need a cost-effective option for lighter workloads, the PLB-402 is an excellent choice.

It balances wheels from 10” to 24” in diameter and can handle up to 65kg of wheel weight.

With an impressive 1g accuracy, this model ensures precise balancing, essential for passenger vehicles.

What sets the PLB-402 apart is its self-calibration feature, which ensures the machine maintains its accuracy over time without the need for complicated adjustments.

The machine’s high-stability computer and precision bearing-driven shaft also contribute to long-lasting performance with minimal wear and noise.

For those who require a quick and simple setup, the emergency stop button adds an extra layer of safety.

The full automatic dynamic/static balance check ensures that the machine works efficiently with minimal operator input.

Plus, the machine’s quiet operation (at ≤ 69dB) keeps the workshop environment pleasant, even during long hours.

For mechanics looking for cutting-edge technology, the PLB-503 is the ideal solution.

It boasts three non-contact sonars for tyre performance diagnosis and automatic width measurement, allowing for accurate readings without physical contact.

This model also comes with Italian software and has a high-definition 19” LCD monitor for clear, easy-to-read results.

One of the standout features of the PLB503 is its ability to automatically detect tyre conditions, with radial and lateral sonar measuring the surface of the tyre.

The LED illuminator makes operation easy, even in low-light environments, and the six o’clock weight placement mode with a laser indicator ensures you never miss a spot. The machine’s low-level noise motor and 140rpm rotation speed make balancing fast and efficient, with a balancing time of just seven seconds. This is especially beneficial for high-volume shops that need to keep things moving quickly.

Each of these machines offers something different depending on your workshop’s needs.

The PLB-802 is perfect for workshops that need to balance both light and heavy-duty wheels with speed and accuracy.

The PLB-402 provides a more affordable, user-friendly option for smaller operations, while the PLB-503 is ideal for those who want to leverage the latest in diagnostic and balancing technology.

Ultimately, investing in the right wheel balancer will enhance your service quality, improve efficiency, and keep your customers rolling smoothly down the road.

Head to launchtech.com.au or call 1300 369 788 to learn more about each model

Clutches:

LuK Clutches bring OE quality and engineering into the aftermarket for Asian automotive makes. Packaged with all necessary parts for a safe and efficient replacement, LuK clutches OE heritage they’re the perfect repair solution.

https://vehiclelifetimesolutions.schaeffler.com.au

isc Brakes Australia (DBA), a well-established name in braking technology and trusted for its high performance and reliability, has implemented a strategic expansion of its Street Series product line with the introduction of Brake Boosters.

This latest move reinforces DBA’s ongoing commitment to supporting the automotive aftermarket industry with reliable OE replacement parts tailored to the needs of trade customers.

While DBA has long been recognised for its advanced rotor and pad technologies across performance and 4x4 applications, the addition of Brake Boosters is a logical extension into the broader braking system, and more specifically into DBA’s Street Series range of hydraulic components, including calipers, brake hoses or brake cylinders.

As direct OE replacements, DBA’s Street Series Brake Boosters are engineered to match factory specifications for fit, function, and performance — ensuring a hassle-free install and dependable operation across a wide range of popular vehicle makes and models.

DBA’s expansion into Brake Boosters is less about reinventing the wheel and more about strengthening its offering to workshops, parts resellers, and trade professionals who rely on a one-stop solution for their braking needs.

With supply chains under constant pressure and the market demanding quicker access to quality replacement components, DBA’s addition to the hydraulic segment helps alleviate sourcing issues while reinforcing trust in an established local supplier.

“It’s about being where our customers need us,” DBA National Sales Manager Shane Jeffreys said.

“Workshops already turn to us for premium rotors and pads — they know what we stand for. Offering Brake Boosters allows us to provide even more value and convenience under the one brand.”

The new Street Series Brake Booster range is available now and stocked across DBA’s national distribution network, ensuring timely delivery and streamlined ordering for trade clients.

Each unit is backed by the same rigorous quality standards and aftersales support the industry has come to expect from DBA.

As the aftermarket continues to evolve, suppliers like DBA play a vital role in supporting workshops and resellers with reliable products that reduce downtime and improve customer satisfaction.

While this latest product may not carry the performance headlines of DBA’s Upgrade Dual-Diaphragm booster range, its arrival is nonetheless significant: another step in ensuring workshops have access to the right parts, right when they need them.

With this expansion, DBA reinforces its reputation not only as a performance leader, but also as a practical partner to the automotive workshop — offering parts that are proven, accessible, and trusted.

For more information on DBA products & vehicle application visit dba.com.au and follow DBA social channels to stay up to date

Exedy Australia, a trusted name in the automotive aftermarket, has expanded its offering with a new range of premium automotive brake drums now available to workshops and distributors nationwide.

Known for supplying high-quality driveline components, Exedy is now making it easier than ever for mechanics to source dependable braking solutions for a variety of popular passenger and light commercial vehicles.

These brake drums are engineered to deliver reliability, durability, and precise performance, ensuring consistent braking under all driving conditions.

Manufactured from high-grade cast iron and finished with advanced machining processes, they provide smooth operation, reduced noise, and an extended service life — all essential factors for maintaining customer satisfaction and vehicle safety.

The range covers many of Australia’s most common vehicles, from hard-working

utes to everyday commuter cars.

Applications include Toyota HiLux (295 mm and 254 mm variants), Holden Colorado, Isuzu D-Max, Ford Ranger, Mitsubishi Triton, Toyota Corolla, Hyundai Getz, Nissan Tiida, Suzuki Swift, and more.

This breadth of coverage means workshops can confidently service a wide range of makes and models without the hassle of multiple suppliers.

For mechanics, having access to quality brake drums through a single, reliable supplier offers multiple benefits.

It streamlines sourcing, reduces downtime, and ensures consistent product quality across different vehicle applications.

Exedy Australia’s established distribution network means these brake drums can be quickly and easily ordered, helping workshops get vehicles back on the road faster.

Brake drums remain a vital component

Exedy is making it as easy as possible for workshops to source high-quality braking components

for many vehicles on Australian roads, particularly in rear braking systems where longevity and stability are key.

Choosing the right brake drum can influence not only stopping performance but also driver comfort by minimising vibration and noise.

The addition of this range to Exedy Australia’s catalogue gives workshops confidence in offering their customers a dependable braking solution backed by a well-known and respected supplier.

With competitive availability, trusted quality, and broad fitment coverage, the new range of brake drums available from Exedy Australia is set to become a staple in workshops across the country.

To learn more about the available applications or to place an order, contact your local distributor or Exedy Australia: Email: sales@exedy.com.au or visit the website: exedy.com.au

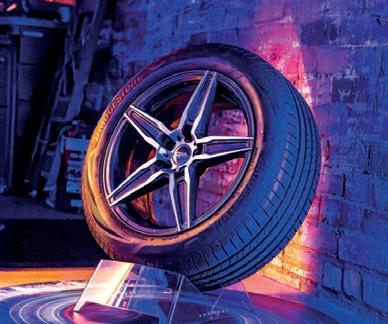

The launch of Bridgestone’s new flagship touring tyre, the Turanza 6, marks a pivotal shift in what defines a premium tyre in the Australian market.

As SUVs and new energy vehicles — such as hybrids — continue to dominate new vehicle sales, mechanics and tyre experts alike are seeing a shift in the needs of Aussie motorists.

“There’s an undeniable shift towards SUVs and larger vehicles in our market,” Bridgestone Australia & New Zealand Marketing General Manager David Honner said.

“The introduction of Turanza 6 is timely because it enhances our offering, providing tyres for vehicles that are quiet and comfortable in addition to having grip and braking performance for peace of mind on the roads.”

But safety, comfort, and performance are more essential than ever.

Benchmark testing of the Turanza 6 that was conducted at Tailem Bend’s skidpan highlighted the extent of the compromise against budget tyres: stopping up to 3.5 metres sooner in the wet and showing a 10 per cent improvement in wet lateral grip.

In dry slalom testing, the Turanza 6 was significantly quicker, highlighting the value of its advanced compound and construction.

Available in 75 sizes ranging from small passenger vehicles to large SUVs like the Volvo XC90 and Range Rover Sport, this new generation Turanza makes a compelling case for the premium choice at every fitment opportunity.

The Turanza 6 is the first tyre to showcase Bridgestone’s ENLITEN technology paired with its Bridgestone Commonality Modularity Architecture (BCMA), setting the tone for all future product development.

ENLITEN is Bridgestone’s design philosophy that balances safety and sustainability, while setting new standards in performance.

For Turanza 6 this includes considering the demands of both electrified and conventional vehicles alike.

Bridgestone Australia & New Zealand

Managing Director Heath Barclay said the release of the Turanza 6 marked ENLITEN’s introduction to Australia.

“This is technology that will underpin our future developments and products,” he said.

“The introduction of Turanza 6 also sees the expansion of our highly popular Turanza touring range into SUV sizes and allows us to provide a safe, reliable and durable solution in sizes previously not offered in our line up.

“Turanza 6 highlights how we continue to innovate and introduce products that meet the changing needs in our market –ensuring that we have an EV ready product for modern motorists and bringing ENLITEN technology to our core product ranges.”

It provides enhanced wet handling, lower rolling resistance, and a quieter, more comfortable ride — especially important for EVs where tyre noise becomes more noticeable.

Its compound durability and high torque tolerance make it EV-ready from day one.

Features like divergent shoulder blocks and double-sequence tread designs

improve water evacuation and minimise road noise. ENLITEN has already proven its worth in the harsh conditions of the Bridgestone World Solar Challenge, where almost every team ran ENLITENequipped tyres for maximum efficiency and durability — a true ‘mobile lab’ for real-world innovation.

Delivering on the Bridgestone E8 commitment

Beyond technical performance, the Turanza 6 represents Bridgestone’s global E8 Commitment — a set of guiding principles that align product development with broader social and environmental goals.

Specifically, the Turanza 6 delivers on energy, efficiency, and ease. For mechanics, that means offering a tyre

that not only improves fuel economy and driving comfort for their customers, but also supports sustainable practices through resource efficiency and reduced emissions in manufacturing.

Bridgestone’s integration of ENLITEN and BCMA technologies reduces production waste and simplifies product modularity, allowing for faster innovation without compromising quality.

As more Australian customers seek out EV-ready options and sustainable solutions, the Turanza 6 positions itself as the smart, future-facing choice — premium in every sense of the word, and purpose-built for the evolving road ahead.

Visit bridgestone.com.au for more information

Supporting automotive professionals with the range, pricing & trusted brands they rely on to get the job done.

2508_HL_ACM_210x150_Print.indd 1

or Clarke, life is all about passion — whether it’s on the racetrack, travelling with family, or guiding employers and members toward a stronger financial future. Outside of work, he’s a dedicated family man.

Weekends revolve around wife Clare and their two boys, Jenson (13) and Lachlan (11). Together, they’ve travelled widely, collecting memories from far-flung adventures. Sport is a big part of their lives too.

Most recently, the family returned from Malaysia after competing in two pickleball tournaments — proof that the Smith household thrives on challenge and friendly competition.

Then there’s the other love that’s been with Clarke since age 12: motorsport. Passed down from his father, it’s a passion that’s never faded.

He’s followed Formula 1 and the World Rally Championship for decades, and jumps into karting or track days whenever possible. “It’s an expensive passion,” he

laughs, “but I still love it as much as the day I started.”

At CareSuper, Clarke leads a national team — earning the nickname ‘Yoda’ among colleagues.

It’s not just for the dad jokes, but for the wisdom and guidance he shares.

Coaching and mentoring are his favourite parts of the role, with a clear mission: help his team become the best versions of themselves.

He knows that for many Australians, superannuation remains a mystery.

“The average Australian still has limited knowledge when it comes to super,” he says. “Everything my team does with our employer network is about giving staff access to financial literacy and education — and we do it really well.”

When pitching to new employers, Clarke keeps things straightforward.

“I avoid jargon so our audience can understand the super landscape and their obligations,” he explained.

His openness and honesty make it easy to build lasting relationships — perfectly aligned with CareSuper’s values of service, trust, and connection.

With around 2.5 million Australians set to retire in the next decade, Clarke is passionate about starting education early — even his own sons know the basics of super. “We should be talking about super in schools,” he said.

Whether racing or retirement planning, Clarke believes in starting early, focusing on detail, and playing the long game.

“I started investing at 15,” he said.

“You only retire once — make sure you’re ready to cross that finish line with confidence.”

Visit caresuper.com.au today.

For about 33 years, Prorepair has been a go-to for reliable auto repairs in the North Melbourne area.

Owner Steve Michaelides started the business with his brother, who retired about 10 years ago leaving co-ownership to Steve’s wife Menka.

“We started off on the mum and dad cars … we’ve also gone into the European market more so than what we had in the past,” Steve said.

“The everyday cars are our bread and butter, they’re the best kind of cars to deal with in my opinion.”

Throughout that time, Prorepair has built a reputation based on strong relationships, both with customers and suppliers.

An energised partnership

One of those relationships that has flourished is between Prorepair and Sealed Performance Batteries (SPB).

What drew me to SPB was the brand, its type of batteries and their customer service

Steve and his team have been exclusively using SPB batteries since 2019, and have been major fans of Energizer Automotive’s battery range specifically since 2023.

“What drew me to SPB was the brand, the batteries and their customer service,” Steve said.

“Whenever I need something, I get it immediately – they’re very helpful.

“Whether I speak to my account manager or the person who makes the deliveries; I get an equal amount of attention and responsiveness.”

Across its 25 years in the industry, SPB has proven itself a reliable supplier of energy storage solutions for mechanics across Australia like Steve. SPB sales representative Murray Bray said a strong relationship between SPB and its customers was crucial to success on both sides.

“It’s our lifeblood; it’s what we do,” he added.

“You can spend enormous amounts of time gathering more and more customers

“But if you don’t cultivate and maintain those relationships — all of that energy is lost. When you find someone with the philosophy that Steve and Menka have for their business, you do everything you

can to maintain and enhance it.”

Steve added there was an element of trust that batteries installed by his mechanics had a market-leading warranty and is backed by SPB’s national network that can support the customer no matter where they are in Australia.

“I’ve only ever had to change one Energizer battery since 2019,” he said.

“The come-back rate is great; the batteries rarely fault.

“When a customer comes in, I take it in good faith that SPB will honour the warranty of the battery I’m sending the customer off with. The customer trusts us, I trust the battery is backed and Murray trusts that I’ve done my due diligence in testing and installation.”

Teamwork like that between Steve and Murray aren’t uncommon, with SPB taking the same trustworthy approach to all its supplied workshops nationwide.

Visit sealedperformance.com.au to learn more

This year celebrates a century of NAPA — 100 years of expertise, innovation, and service that has made it the trusted provider of automotive products and solutions in the USA.

While NAPA’s journey in Australia is just six years old, its foundations run deep.

Heritage brands that became NAPA — like COVs, founded 96 years ago, and Ashdown-Ingram with over 55 years, have long been part of the fabric of Australia’s automotive industry.

Many of the company’s team members have dedicated decades to this business, bringing invaluable industry knowledge that sets NAPA apart.

Their expertise, paired with NAPA’s global strength, is what makes it a trusted name in automotive aftermarket parts and solutions.

NAPA is all about being Globally Local — leveraging the scale, capability, and heritage of the world’s largest automotive aftermarket parts provider while delivering the local expertise, brands, range, and service that Australians rely on.

NAPA Australia comes from a proud heritage of automotive electrical

and air conditioning expertise.

Over the years, it has expanded its range, deepened its knowledge, and refined its specialist capabilities to deliver a truly comprehensive aftermarket solution.

Whether you’re sourcing parts for air conditioning, electrical, braking, clutch & driveline, engine cooling, servicing and consumables, steering and suspension, tools, or workshop equipment – NAPA’s deep industry expertise ensures you get the right part, first time, every time.

But its support doesn’t end with parts. NAPA delivers innovative business solutions that drive real efficiency — offering inventory management, automatic stock replenishment, eCommerce, and digital systems to help its customers save time and reduce costs.

NAPA’s automotive passion extends beyond the workshop and onto the track.

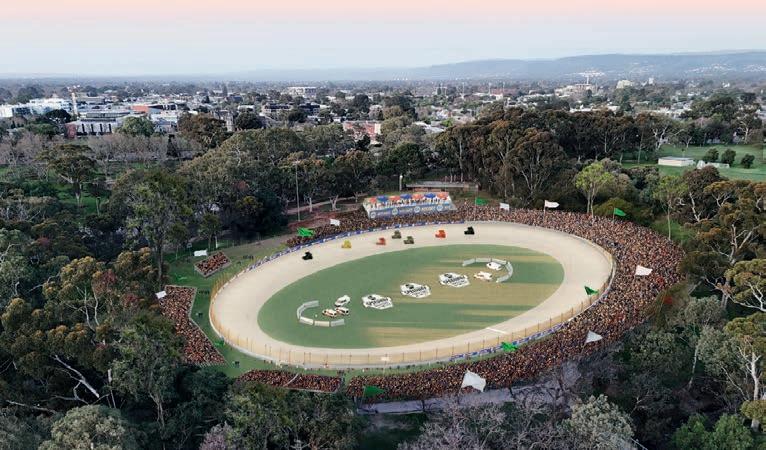

As naming rights sponsor of the NAPA Speedway – Sprint Car in the City, returning to Adelaide this November, NAPA proudly supports the future of Grassroots Motorsport.

It has long been a driving force in

motorsport, with major sponsorships dating back to 1977, supporting the National 500 in the NASCAR Cup Series.

Nearly 50 years later, the NAPA brand remains a dominant presence in global racing, backing stars like Chase Elliott (NASCAR), Brad Sweet (World of Outlaws Sprintcars), Ron Capps (NHRA Drag Racing), and teams in the British Touring Car and Truck Racing Championships.

The NAPA Sprintcar Invitational returns in 2025 after a thrilling debut last year that saw packed crowds witness Sprintcars tearing through Adelaide’s city centre.

This year, the event expands to a threenight schedule, held from Wednesday November 26 to Friday November 28, as part of the bp Adelaide Grand Final.

Featuring a 40-car field, fierce competition, and a boosted $110,000 prize pool, fans can expect more action than ever before on the 342-metre temporary NAPA Speedway.

As if that weren’t enough, Lenny Kravitz and Jet will headline Saturday night’s entertainment, leading into an explosive Sunday finale featuring none other than AC/DC, closing the Supercars season with a bang.

“The success of the NAPA Speedway

was incredible in 2024, and it is exciting to increase the Sprintcar action to include Wednesday evening at the bp Adelaide Grand Final,” South Australian Motor Sport Board CEO Mark Warren said.

Located within the Adelaide street circuit precinct, the event will once again bring 950-horsepower Sprintcars into the heart of the Supercars season, delivering heat races, qualifiers, and feature events across the three days.

The 2024 debut was a standout success, earning NAPA Speedway the ‘Innovation/Promotion/Event of the Year’ at the Australian Speedway Awards.

“It’s fantastic to confirm the return of the NAPA Speedway at the bp Adelaide Grand Final this year,” NAPA Marketing Executive General Manager Mitch Wiley said.

“The inaugural event last year was nothing short of outstanding.

“To see Sprintcars in the heart of Adelaide was an incredible spectacle, and the 2025 edition promises to deliver so much more.

“NAPA is proud to have played a part in bringing it to life and we all look forward to seeing another huge event in the Adelaide Parklands as part of one of Australia’s great sporting events.”

Giving back:

$100,000 for 100 years NAPA believes in supporting the communities where its employees live and work.

That’s why it’s proudly partnered with Starlight Children’s Foundation for more than 15 years. Starlight understands that every child deserves a happy childhood, but for seriously ill kids, hospital stays and treatments can be overwhelming.

Through play, creativity, and social connection, Starlight brings joy and positivity to families during their toughest times.

To mark 100 years of NAPA, it’s donating $100,000 to Starlight, continuing its commitment to improving the lives of seriously ill children and young people.

Because happiness matters.

The NAPA Sprintcar Invitational will be returning in November.

For a century, NAPA has been the trusted name in automotive parts and solutions, delivering expertise, scale, and service wherever it’s needed. In Australia, its national network ensures that no matter where you are, you have access to the parts, knowledge, and support to keep your business ahead of the curve.

NAPA is more than parts - NAPA powers your performance.

It makes its business to drive yours. Visit napaparts.com.au to learn more

FEATURES

Compatible

In an era where access to vehicle repair and diagnostic information is increasingly complex, the Victorian Automotive Chamber of Commerce (VACC) Technical Library has emerged as one of the most significant repositories of automotive knowledge in Australia.

It is widely regarded as the largest and most comprehensive collection of its kind in the Southern Hemisphere, providing workshops with the information they need to repair, maintain, and service vehicles spanning more than a century of automotive development.

For today’s workshops, technical information is both critical and increasingly difficult to access. Essential service manuals and diagnostic procedures can only be accessed behind subscriptionbased portals, while aftermarket databases are not always complete. Imported vehicles, whether Japanese grey imports, American trucks, or emerging Chinese models, frequently arrive with little to no local technical documentation.

This leaves independent workshops at risk of being unable to service the diverse Australian vehicle fleet.

The VACC Technical Library was

established to address this challenge. What began as a growing reference collection in the post-war period has developed into a strategically managed archive designed to support the evolving needs of the automotive service sector.

Today, the library contains more than 40,000 volumes of workshop manuals, covering passenger vehicles, motorcycles, heavy vehicles, agricultural machinery, and more.

Located at VACC’s offices in North Melbourne, the library houses shelves stretching floor to ceiling with manuals and technical guides representing virtually every make and model ever sold in Australia.

European luxury brands, Japanese imports, American classics, Korean massmarket vehicles, and new entries from China are all represented.

Beyond conventional engine and transmission manuals, the library includes comprehensive coverage of electrical systems, body repair, advanced driver assistance systems (ADAS), hybrid and electric vehicle platforms, and emerging technologies.

The library is not static.

It continues to expand weekly with

new acquisitions and carefully curated additions. Each new vehicle type entering the Australian market is reviewed by VACC’s Technical team, which then prioritises acquisition of relevant manuals.

Relationships with international publishers, including exclusive arrangements with Haynes and access to Haynes Pro digital resources, ensure coverage of both legacy and emerging models.

For workshops, the value of the library lies in its immediate application to daily business. When a service advisor or technician encounters a complex or unusual problem, VACC’s Technical advisory team draws upon the library to locate the exact information required.

In many cases, a single enquiry begins with a search of a digital database but is completed by retrieving detailed diagrams or procedures from the physical collection. This dual approach allows workshops to solve problems faster, clear repair bays sooner, and provide reliable service to customers.

The system is designed for efficiency.

Advisors can access and retrieve information within minutes, often locating

manuals or bulletins unavailable through manufacturer or aftermarket channels.

Historical depth also provides unique advantages: when vehicles age out of digital manufacturer support, the hardcopy resources maintained by VACC remain accessible, ensuring older vehicles can still be repaired with accuracy.

The VACC Technical Library is not only about preserving the past but also about preparing workshops for the future. Recent

acquisition priorities include detailed documentation on hybrid and electric vehicle platforms, battery systems, and charging infrastructure. With the rollout of ADAS technologies, calibration procedures and advanced diagnostics have also become central to the collection.

Alongside this focus on new technologies, VACC continues to invest in digitisation projects, ensuring key historical manuals are converted to searchable formats while preserving physical originals. Integration between digital databases and the physical

collection ensures members benefit from a complete technical ecosystem, unmatched by any single-source provider.

For VACC members, access to the Technical Library provides a significant commercial edge. Workshops can accept work on a broader range of vehicles, including grey imports and rare models, knowing reliable support is available.

The ability to quickly diagnose and repair vehicles increases efficiency, reduces downtime, and improves customer satisfaction.

As the automotive industry becomes more fragmented and complex, the VACC Technical Library stands as an irreplaceable asset. By maintaining the most extensive archive of automotive technical information in Australia and combining it with expert support, VACC ensures that independent workshops remain competitive, capable, and ready to meet both the challenges of today and the technologies of tomorrow.

WorldSkills Australia has today announced the 39 rising stars who have been named in its national training squad — the first step toward selection for Team Australia, which will compete at the 48th WorldSkills Competition held in Shanghai, China, September 22-27, 2026.

The squad includes high-performing apprentices, trainees and young professionals from every state and territory, who excelled at the recent WorldSkills Australia National Championships in Brisbane, earning medals across 60 different skill categories, including Automobile Technology, Autobody Repair and Heavy Vehicle Technology.

“The talent on display at the National Championships was nothing short of extraordinary — a true reflection of the world-class skills that exist right here in

Australia, WorldSkills Australia CEO Trevor Schwenke said.

“These young people have proven themselves among the best in the country and now have the opportunity to show the world just how strong and competitive Australian skills excellence is.

“Behind every squad member is a dedicated trainer, mentor, and a VET system

that equips young people with real-world skills and career pathways. WorldSkills is more than a competition — it’s a platform to showcase potential, elevate ambition, and celebrate the skilled professionals shaping Australia’s future.

“We’re incredibly proud to support this next generation as they take their first step toward the world stage.”

Over the coming months, squad members will undertake an intensive training program. Those selected for the final team will represent Australia on the global stage in September 2026, competing against more than 1,400 peers from over 60 countries in the world’s largest skills excellence event.

The announcement coincides with the launch of National Skills Week, an initiative that champions vocational education and highlights the critical role of skills-based careers in shaping Australia’s future workforce and economy.

The training squad was officially launched at a special event at Parliament House in Canberra on September 1, where they met with Prime Minister Anthony Albanese who took photos with the squad and congratulated them on their achievements.

Following the Prime Minister meet and greet an official launch of the squad was held inside Parliament house and was attended by Minister for Skills and Training, the Hon Andrew Giles MP, Patron for WorldSkills Australia, former MP Brendan O’Connor, MPs, TAFE directors and other dignitaries.

“I congratulate every member of the national training squad, who’ve already proven their success following their participation at the WorldSkills National Championships in Brisbane and are now looking to the global stage,” Mr Giles said.

“These rising stars represent just a snapshot of the incredible skill and dedication that is shown by apprentices, trainees and students right across Australia – and showcasing to other Australians the endless possibilities that come from pursuing vocational education and training.”

In the lead up to the event, the team attended a four-day team development camp to strengthen team bonds, train in high performance and resilience, and prepare for the honour and challenge of representing Australia on the world stage.

The Australian Government proudly supports the WorldSkills program, which plays a vital role in encouraging young Australians to pursue skills-based careers.

With ongoing skills shortages across multiple sectors, events like the National Championships help to promote trades and training pathways as valuable, future-focused career options.

First held in 1950, the WorldSkills International Competition aims to raise the profile of vocational skills worldwide, engaging young people, parents, educators and employers in the value of trades and technical education.

In the automotive industry, standing still isn’t an option.

Technology changes, customer expectations change, and the skills you need to run a successful business change, too.

That’s why I’m excited to share with Australian Car Mechanic readers that MTA ACT is officially back in action.

By bringing MTA ACT into the MTA NSW Group, the ACT’s automotive businesses will now have the backing of a 100+ strong team with a proven track record in advocacy and industry leadership.

This relaunch is designed to give ACT businesses the same level of support, training, and advocacy that thousands of NSW operators already rely on.

Whether it’s fighting for fair regulations, influencing training standards, or pushing for investment in industry infrastructure, MTA ACT will have the muscle to get things done.

Even if you’re not based in the ACT, this relaunch strengthens the industry’s overall voice.

Canberra plays a big role in shaping policy, and having a strong MTA presence there means better representation for the trade nationwide.

The ACT is also big when it comes to influence. Many policy ideas are tested there before being rolled out nationally.

That makes it the perfect place to push for rules that actually work for the trade, not against it.

By building stronger networks and better resources in the ACT, we’re building strength for the entire sector.

Our industry is in the midst of a skills shakeup. EVs, hybrids, and advanced diagnostics all demand new knowledge.

Through My Trade Start and MTA NSW Training, MTA ACT members will now have access to the same high-quality apprenticeships and upskilling pathways that thousands of NSW technicians already use.

It’s about future-proofing the workforce so we’re ready for whatever comes down the road.

When you’re running a workshop, every hour counts. MTA ACT will be offering

hands-on workplace support to keep businesses running smoothly, including advice on industrial relations, help with compliance, and solutions for the everyday problems that can slow you down. The aim is simple: keep you focused on fi xing cars and serving customers, not drowning in red tape.

Being part of a membership organisation ensures every voice counts. When workshops, dealers, and technicians come together under one banner, the whole sector gets stronger. It means governments listen harder, training standards are lifted, and industry problems are solved faster.

For smaller automotive businesses especially, collective representation levels the playing field. Instead of tackling challenges in isolation, members gain the benefits of shared resources, expert advice, and a united voice pushing for better outcomes. The bigger and more connected the network, the more influence we all have.

It means your voice is being heard when new laws or standards are being set. It means ensuring your apprentices are learning the right skills for the future. That someone’s got your back when you hit a tricky IR issue.

That’s exactly what MTA ACT, and the wider MTA NSW Group, is here for. So whether you’re in Canberra, Queanbeyan, Newcastle or Tweed Heads, the message is the same: we’re stronger when we work together.

Your super partner in the motor trades Across the motor trade. Around Australia. For every workshop, team and business. We’re your Australian fund who cares about you, your business, and employees. Supporting you every super step of the way.

Scan the QR code to learn more

YCO has been instrumental in outfitting the GEN3 Mustangs and Camaros with the latest in performance filtration.

RYCO has announced a newly extended partnership, expanding on its commitment to motorsport with the naming rights of the RYCO Enduro Cup and perpetual trophy for the Supercars Championship through to the 2027 season.

The RYCO Enduro Cup is a significant part of the Supercars Championship and has a unique history in the sport.

The RYCO Enduro Cup recognises the team and drivers that show endurance,

persistence and consistency in getting the job done with the highest point scores over the two endurance race weekends of the AirTouch 500 at The Bend, and the Repco Bathurst 1000.

RYCO’s development of Supercars GEN3 Filtration Program was specifically designed to provide increased engine longevity, performance and endurance, culminating in lifting the engine rebuild frequency from 4500km to over 8000km.

Along with the RYCO Enduro Cup being the ultimate endurance achievement for all

Supercars competitors, it was a no brainer and an honour for RYCO to be associated with.

RYCO is enthusiastic about drivers everywhere being able to benefit from the technologies developed for Supercars, and the extensive Ryco SynTec® range and growing Ryco NanoCel® range, available now, are reflective of this.

RYCO Sales & Marketing General Manager Tony Sullivan commented on RYCO’s excitement regarding the extended partnership.

“RYCO is steadfast in supporting the leading motorsport code in Australia & New Zealand, and we couldn’t be more excited to continue our relationship and development within the Supercars Championship,” he said.

“The RYCO Enduro Cup is a new chapter for us and further solidifies our commitment to continuing our partnership with Supercars, teams and drivers alike.

“We look forward to lights out for the commencement of the RYCO Enduro Cup at The Bend, and continuing our development and implementation of the Supercar proven technology into our everyday performance range.”

Visit rycofilters.com.au for more information on RYCO products and components

The automotive industry is constantly evolving. New technologies reshape how vehicles are built, diagnosed, and repaired. Regulations and compliance requirements tighten each year.

Customers expect not just mechanical

expertise, but also digital literacy, sustainability awareness, and professional standards.

In this environment, no professional or business can thrive in isolation.

That is where the Institute of Automotive Mechanical Engineers (IAME) continues to play a vital role.

For over 80 years, IAME has been more than an association—it has been a trusted voice, a professional community, and a support system for thousands of automotive technicians, apprentices, educators, and businesses across Australia.

For current members, the question isn’t simply ‘why join?’ but rather ‘why stay?’.

Continuing your membership means investing in your own future and strengthening the wider industry.

The value of networking is not just in swapping business cards or adding contacts on LinkedIn.

In the automotive sector, genuine connections often spark the biggest opportunities — whether that’s finding a supplier who understands your challenges, connecting with a peer who has already solved the problem you’re facing, or discovering a new business partnership.

IAME makes these connections possible.

From technical forums and branch events to online platforms such as member-only Facebook groups, members can openly discuss issues, share solutions, and collaborate.

In an industry where technology moves quickly, this community support is priceless.

As one long-time member put it, “The best advice I’ve ever received didn’t come from a textbook, it came from a conversation with another IAME member at an event.”

The pace of change in the automotive world is relentless.

Electric vehicles, hybrid systems,

Just like being a great mechanic for your customers, having association support behind you is just as important.

When governments and regulators set new standards, someone must ensure the perspective of automotive professionals is heard.

advanced driver assistance technologies, digital diagnostics, cybersecurity — these are no longer ‘future issues’, they are here today. Without access to accurate and timely information, professionals risk falling behind.

IAME ensures members stay ahead by delivering:

• Technical bulletins that break down complex systems into practical knowledge.

• Industry journals and publications that cover trends, innovations, and best practice.

• Legislative updates so members understand compliance requirements before they become pitfalls.

• Educational resources designed for technicians and business owners alike. Having the right information at the right time doesn’t just prevent costly mistakes—it creates confidence when serving customers and training staff.

IAME plays this role by sitting on advisory boards, technical panels, and government committees.

This advocacy work means that your challenges — whether around training frameworks, emissions standards, licensing requirements, or workplace legislation — are represented at the highest levels.

Membership gives weight to this advocacy.

The stronger the membership base, the stronger the collective voice.

By continuing your membership, you are helping to shape the policies that govern the industry’s future.

The days of ‘once qualified, always qualified’ are long gone.

To remain relevant technicians must constantly refresh their skills and learn new ones. IAME provides a wide spectrum of development opportunities:

• Workshops and seminars on emerging technologies, from EV servicing to ADAS calibration.

• Industry conferences that bring together global and local experts.

• Accredited training to ensure professional qualifications remain current.

Professional development is not only about technical ability.

Increasingly, IAME also supports members with training in compliance, business management, and customer service — skills that are critical for running a successful modern workshop.

Membership of a respected industry body sends a clear signal: you are serious about your craft.

For businesses, it reassures customers.

For employees, it demonstrates professionalism and pride.

IAME takes recognition seriously.

Certificates of membership, loyalty awards (25-year and 50-year milestones), and professional grading systems all ensure members receive the acknowledgment they deserve.

Displaying these in your workshop or office is not simply decoration —

it is a statement of credibility and trustworthiness.

Practical benefits are another reason to continue membership. IAME members gain access to:

• Discounted products and services, from workshop equipment to publications.

• Exclusive tools, including signage, safety resources, and compliance materials.

• The Online Print Shop, which allows members to quickly order and track branded workshop stationery and signage—saving time and ensuring professionalism.

• Industry events and trade nights, giving members affordable access to knowledge and networking.

These savings often outweigh the cost of membership itself, turning it into an investment rather than an expense.

Beyond the direct benefits, IAME membership is about contributing to the reputation of the automotive industry.

By uniting under one professional banner, members help raise standards, showcase excellence, and promote the sector as a highly skilled, essential industry.

Through initiatives, recognition programs, and public campaigns, IAME actively promotes the work of its members and the value of the trade.

In a time when young people are considering their career options, this visibility is critical to attracting the next generation of automotive professionals.

Perhaps the most overlooked benefit of membership is the sense of community it brings.

The automotive industry can be

challenging — long hours, rapid change, and constant pressure from customers and regulators.

Having a network of peers to share those challenges, celebrate wins, and offer advice creates resilience.

IAME fosters this sense of belonging. It’s not just about “what you get,” but about knowing that you are part of something bigger than yourself: a

professional community committed to growth, integrity, and the future of the industry.

The automotive industry is on the cusp of transformation unlike any it has seen before. Electrification, automation, sustainability targets, and globalisation are reshaping every aspect of the trade.

Those who remain isolated risk being left behind.

By continuing your membership with IAME, you are not only securing resources and benefits for yourself — you are strengthening the very fabric of the industry.

You are helping to ensure that the voices of automotive professionals are heard, that skills and standards remain world-class,

future of

is full of changes — make sure you stay up to date.

and that the industry is recognised for the critical role it plays in Australia’s economy and society.

At the end of the day, membership is not about ticking a box. It’s about pride. Pride in your profession, your business, your community, and your future.

Because together, we are stronger.

For more information, visit: iame.com.au

The third Noosa Concours proved a sun-kissed extravaganza of high value vehicles and thousands of car enthusiasts

WORDS AND IMAGES: IAIN CURRY

Whatever you think of Australia’s mega wealthy, they’re easier to relate to when they have impeccable taste in cars, as opposed to simply spanking their millions on garish clothes, facelifts or at casino tables.

When you see them driving a classic Lamborghini Miura, Ferrari 288 GTO, Mercedes-Benz 300SL or the latest supercar exotica, it’s easy to think: “Yep, if I had the money, that’s how I’d spend it too.”

Noosa’s Concours d’Elegance is a car show with its fair share of well-heeled entrants, as you’d expect from something in the mould of America’s flagship Pebble Beach Concours.

But fair play to them.

They make it accessible to everyone, as witnessed by some 20,000 spectators turning out for this third edition in 2025, all able to enjoy the cars up close without spending a dollar.

Noosa in winter is a pretty magic place, and the sun gods turned out to ensure the 50 entered cars were bathed in golden rays.

Hastings Street, the town’s main shopping and dining strip, was closed for the cars’ arrival, with thousands of onlookers jostling for position, phones in hand to record proceedings.

The proper oldies come through first, with a French 1905 Eugène Brillié 20/24HP pouring out quite the smokescreen, as

you’d accept from a 120-year-old. It’s the world’s sole surviving example of its type, and deservedly won Best Preservation Award for being maintained in near original form.

Some pre-war Mercedes-Benzes, a 1935 BMW 315/1 Roadster, 1937 Wanderer W25K Sports Roadster (the first car designed by Ferdinand Porsche) and impossibly elegant 1935 Bugatti Type 57 Atalante next rolled under the pandanas and palm-lined street.

The post-war Brits were next, reminding of the incredibly varied output the Motherland managed once peace had broken out. A 1950 Jaguar XK120; aluminium-body 1950 Land Rover Series 1 80”; 1953 Bristol 403 and 1957 Rolls Royce Silver Cloud I all showed the Best of British.

America and Europe provided most of the show metal, but Australia was strikingly represented with a lesser-spotted 1960 TR Ausca, a roadster whose design was inspired by the gorgeous Maserati A6GCS/53 Spyder sportscars of the mid1950s. With racing number on bonnet and flanks, it was a standout piece of Aussie motoring history.

Shaken, not stirred

The wows continued with a James Bond-like 1964 Aston Martin DB5, rotary-powered tiny 1967 Mazda Cosmo, ’68 Fiat Dino Spider and duo of C2 Chevy Corvettes.

But then the unmistakable rumble of an Italian V12.

There is really nothing like Lamborghini’s Countach, and it’s at its purest in non-

winged, wedge-like LP400 guise.

At Noosa, a 1976 Australian-delivered version prowled the glitter strip, it one of only 22 delivered in right-hand drive.

And, proving that Life Really Isn’t Fair, the same owner paraded his 1970 Lamborghini Miura P400S – one of just six delivered new to Australia.

Clearly, here’s a bloke who knows the right way to spend his money.

Newer delights included a 1988 Ferrari Testarossa, 1991 Honda NSX, 2005 Porsche Carrera GT, 2006 Ford GT and 2016 Pagani Huayra. The latter alone will set you back many, many millions.

Numerous Noosa locals asked me what was the most valuable car on show.

That’s easy, I replied, pointing them in

the direction of the Sunoco-liveried 1973 Porsche 917/30 Can-Am Spyder.

This turbocharged flat-12 legend is one of history’s most powerful race cars, with up to 1600 horsepower realised in its ultimate trim. One of just six made, should one ever come up at auction you’d be looking a well into eight figures.

While this track-only race legend sadly couldn’t clear its lungs in the parade, spectators did enjoy a 917/30 engine start up and a few gentle blips of the throttle. While it screaming at 8000rpm would have been nice, it probably would’ve exploded a few ear drums and restaurant windows.

The 50 show cars all angle parked along Hastings Street, with handy signs in front detailing their vitals.

Even better, visitors could have an audio guided tour, explaining the cars via narrated insights sent to their mobile devices. For the more personal touch, white-coated officials were stationed in front of each car, ready to share details and specifications about their assigned vehicle.

Best in Show was, like the previous year, snared by local mining magnate and politician Clive Palmer.

His 1935 Bugatti Type 57 Atalante, recently bought at auction for many millions, took top honours, and deservedly so.

Only ten of these Grand Raid two-seaters were built, with just three featuring the Atalante coachwork seen on this car.

Other class winners included the 1935

A free event means anyone and everyone can get up close to the cars, including the next generation of car enthusiasts.

BMW 315/1 and 1970 Lamborghini Miura, while the Spirit of Noosa award went to one of the few true Australian vehicles on show: a boxy 1988 Giocattolo Group B with midmounted Holden 5.0L V8 engine.

These distinctive coupes began life as Alfa Romeo Sprints, then were heavily modified just down the road from Noosa in Caloundra, with just 15 built in total before the company shut up shop in 1989.

With muscled arches and oh-so-80s side strakes (like the Ferrari Testarossa), it looked every inch from the decade of big hair and neon.

While serious-looking be-hatted judges with clipboards in hand were considering their decisions, so were “Next Gen” Judges, where local children get to make their verdict on the car that most makes them go “wow”.

Little wonder they were blown away by something more modern, choosing the carbon fibre Pagani Huayra with its spectacular gullwing doors.

The 730hp AMG twin-turbo V12 on show also played a part in making this 1-of-100 Huayras the people’s choice too.

And credit to the owner, who added another few kilometres on to the hypercar’s clock, as it’s only travelled

180km since new…or roughly 20km per year.

The good people of Noosa were out in force, some casually rolling in off the beach in boardies or bikinis.

They contrasted with the impeccably dressed contingent, and there were ample VIP experiences in which they could indulge.

A Champagne masterclass, vintage wine tasting, degustation dinners, gourmet canapés, Fashion on Concours, and a sunset cruise on Noosa River. Make no mistake, there was plenty of money in town.

The well-heeled could also plan their next car purchase, with latest models on show from Bentley, Lamborghini, Maserati, Range Rover and Porsche. A few too many gins with lunch and who knows what you’ll end up buying?

For those in the know, the best way to enjoy Noosa Concours is in the late afternoon when most spectators have gone home but the cars remain.

With the sun setting and golden light peeking through the buildings, now’s the time to snare a table at a roadside café and order refreshments.

Then, sit back and watch literally millions of dollars’ worth of some of history’s finest automobiles fire up their engines and cruise up the street before turning and coming right back again.

That 120 year-old veteran Eugène Brillié continued its glorious pollution as it chuffed away on its skinny tyres, before the V12 Italians blipped their way past with perhaps the most appreciated way to gulp petrol.

And kudos to the Mercedes-Benz SL300 driver who made a swift exit with those gullwing doors open to best show off the red leather interior and grinning occupants.

Lovely.

In no time at all, the award-winning Noosa Concours has made a significant mark on both the Australian and international luxury car and lifestyle event calendar.

You may need deep pockets to afford a car significant and immaculate enough to be in the top 50, but the fact Noosa’s open to any and everybody to enjoy these cars for free remains the most impressive and important part of this glittery event.

Continued appreciation for such special cars – all of which reside in Australia – is vitally important.

And for our industry, the maintenance, repair, restoration and renovation of such vehicles is one of the most interesting and rewarding specialist areas open to mechanics.

A Lamborghini Countach engine out job? That’s never going to be a boring day.

Kelpro’s new range of Shocks & Struts are designed to meet or exceed OEM specifications, ensuring that every component delivers like-for-like quality with enhanced performance, a perfect fit, and smooth installation for any make or model.

hen it comes to keeping vehicles running smoothly, oils and lubricants are just the beginning. They reduce friction, protect engine internals, and support day-to-day performance — but what about the systems keeping everything at operating temperature?

For Aussie mechanics, particularly those working on hard-driven vehicles in tough conditions, a healthy cooling system is just as critical as engine oil.

Overheating remains one of the most common — and costly — causes of engine failure. Without proper diagnostics, cleaning, and sealing, even the best-maintained engines are at risk.

That’s why cooling system maintenance tools like Irontite Cooling System Sealer, Tee-Kay Head Check Combustion Leak Detector, and Irontite Thoro-Flush are becoming essentials in well-equipped workshops.

Let’s take a closer look at how each one helps keep cooling systems reliable and efficient.

Available in 150ml and 375ml sizes, Irontite’s Cooling System Sealer offers a practical, workshop-grade fi x for leaks in radiators, heater cores, head gaskets, and more.

It’s designed to seal on contact with air or combustion gases — no breakdown, no clogs. Unlike some quick-fi x solutions that use vegetable fibres or soluble oils, Irontite uses synthetic fibres that form a lasting seal without risking blockage in narrow coolant passages.

It’s safe for all common metals — cast iron, copper, bronze, aluminium — and won’t degrade rubber hoses, water pump seals, or liners.

Modern engines, especially in Australian conditions, run hotter and are pushed harder. Irontite gives mechanics peace of mind by not just patching a leak — but helping restore the system’s integrity long term.

Some problems can’t be seen — until it’s too late. Cracked heads, blown gaskets, or porous blocks often start small but cause major dramas like coolant loss, poor starts, and overheating.

The Tee-Kay Head Check Combustion Leak Detector is built to catch these issues before they escalate.

It tests for the presence of CO2 in the air pocket above the coolant, turning the test

Irontite has your back when it comes to both flushing and leak protection.

fluid yellow (in petrol engines) or green (in diesels).

The result? A clear yes-or-no answer without pulling the engine apart.

It’s a smart, simple way to verify postrepair work, check for lingering faults, or confirm suspicions during a service. Compatible with petrol, diesel, and LPG engines — and supported with spares — it’s a tool that earns its keep in busy Aussie workshops.

Leaks aren’t the only enemy of cooling systems.

Over time, sludge, grease, scale, and rust reduce coolant flow and heat dissipation — slowly sabotaging an engine’s reliability.

Irontite Thoro-Flush (455ml) tackles this head-on.

It’s an industrial-strength system

The Tee-Kay Head Check is ideal for tasks like post-repair verification, routine diagnostics, or pre-tune-up checks.