12 PERSPECTIVES AW JULY 2022

OEM’s Pneumatic vs. Servo Test Demonstrates Specific Savings Matt Reynolds, Packaging World

D

ave Brownson, engineering manager at Forpak, was the first engineer hired onto the food stacking equipment OEM when it opened its doors more than 30 years ago. With three decades under his belt as an engineer with the company, Brownson remembers the days when pneumatics were the only actuator game in town for Forpak machinery applications. He also recalls the first introduction of linear servo in the place of incumbent pneumatic technology about six or seven years ago. “I was looking for a IP69K solution for a project that we had, so I went to my vendors and they came up with [linear drive system supplier] LinMot,” he says. “I was introduced to them, and we’ve never looked back.” More recently, Brownson set his sights on building an all-electric, pneumatic actuator-free stacker. But it was a matter of waiting for the right size and shape of linear motion tech to be ready, as nothing existed on the market that could fit his application. “I had kept on pushing Peter [Zafiro of LinMot] to make a smaller and smaller motor, and he asked me, ‘How many would you buy?’” Brownson recalls. “I answered, ‘Well, how many can you make?’ Because if I can make an all-electric stacker, it would really make efficiencies go up.” Brownson finally saw the LinMot prototype that would do the job at a recent PACK EXPO. Forpak is now developing a machine that is 100% electric with no pneumatic technology. The plan is to exhibit the new machine at PACK EXPO International, to be held Oct. 23-26, 2022 in Chicago. It bears mentioning that pneumatics aren’t going anywhere, and they are firmly ensconced in the controls and automation tool kit. And some operations require pneumatics for safety reasons—in explosive environments for instance—so switching out pneumatic for electric isn’t always possible. Still, Brownson sought an all-electric model because he says LinMot linear servo motors save energy and are highly efficient for his specific set of applications and customer base. Plus, they allow for a lower total cost of ownership thanks to their comparatively few wear items, and that results in less downtime—especially unexpected downtime. In his experience, these factors bring real-world, longterm savings that are attractive to Forpak’s CPG and brand-owner customers.

2207_Perspectives.indd 12

But so far, that’s just been Brownson’s anecdotal experience— one man’s opinion. To test the efficiency and power savings, Zafiro enlisted Brownson, along with Joel Geisel and Adam Shank, both from Hamilton Automation, a LinMot manufacturer representative, and JB Korte of Van Meter Inc., a LinMot distributor. The OEM, automation supplier, and distributors together devised a test of Forpak’s machine using pneumatic actuators compared to all-electic actuators. The idea was to establish actual power consumption and energy savings data. What follows are the results of this test.

Equipment tested

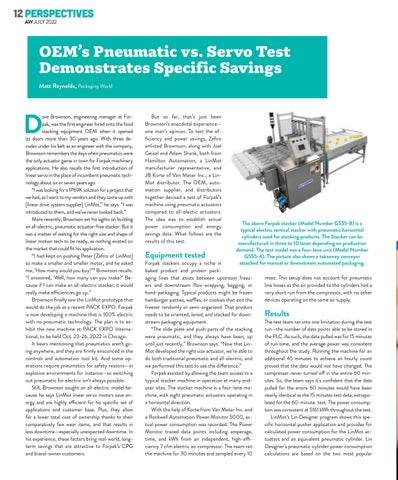

The above Forpak stacker (Model Number GSS5-8) is a typical electric vertical stacker with pneumatic horizontal cylinders used for stacking products. The Stacker can be manufactured in three to 10 lanes depending on production demand. The test model was a four-lane unit (Model Number GSS5-4). The picture also shows a takeaway conveyor attached for manual or downstream automated packaging.

Forpak stackers occupy a niche in baked product and protein packaging lines that exists between upstream freezers and downstream flow-wrapping, bagging, or hand-packaging. Typical products might be frozen hamburger patties, waffles, or cookies that exit the freezer randomly or semi-organized. That product needs to be oriented, laned, and stacked for downstream packaging equipment. “The slide plate and push parts of the stacking were pneumatic, and they always have been, up until just recently,” Brownson says. “Now that LinMot developed the right size actuator, we’re able to do both traditional pneumatic and all-electric, and we performed this test to see the difference.” Forpak assisted by allowing the team access to a typical stacker machine in operation at many enduser sites. The stacker machine is a four-lane machine, with eight pneumatic actuators operating in a horizontal direction. With the help of Korte from Van Meter Inc. and a Rockwell Automation Power Monitor 5000, actual power consumption was recorded. The Power Monitor traced data points including amperage, time, and kWh from an independent, high-efficiency 7 cfm electric air compressor. The team ran the machine for 30 minutes and sampled every 10

msec. This setup does not account for pneumatic line losses as the air provided to the cylinders had a very short run from the compressor, with no other devices operating on the same air supply.

Results

The test team ran into one limitation during the test run—the number of data points able to be stored in the PLC. As such, the data pulled was for 15 minutes of run time, and the average power was consistent throughout the study. Running the machine for an additional 45 minutes to achieve an hourly count proved that the data would not have changed. The compressor never turned off in the entire 60 minutes. So, the team says it’s confident that the data pulled for the entire 60 minutes would have been nearly identical as the 15 minutes test data, extrapolated for the 60-minute test. The power consumption was consistent at 5161 kWh throughout the test. LinMot’s Lin Designer program shows this specific horizontal pusher application and provides for calculated power consumption for the LinMot actuators and an equivalent pneumatic cylinder. Lin Designer’s pneumatic cylinder power consumption calculations are based on the two most popular

6/29/22 1:56 PM