Apply the E in ESG

Co-mans and co-packers are at a loss of how to contribute to ESG goals when their brand customers control product sustainability. Discover how to implememt environmental goals.

5 EBS Features Insights from Co-man/co-packers

6 A One-Stop-Shop Co-Manufacturer

10 CP Increases Line Efficiency With PreOwned Automated Line

14 Part 1: ESG Implementation for Co-mans and Co-packers

www.contractpackagingmag.com JULY/AUGUST 2023 THE OFFICIAL PUBLICATION OF THE CONTRACT PACKAGING ASSOCIATION

TM

YOUR CUSTOMERS DEPEND ON YOUR PRODUCTS. OUR CONVEYORS WON’T LET THEM DOWN.

WHEN

270.651.9166 WWW.SPANTECHCONVEYORS.COM

EDITORIAL

Melissa Griffen EDITOR mgriffen@pmmimediagroup.com

ART

Dave Bacho CREATIVE DIRECTOR

Jonathan Fleming ART DIRECTOR

AUDIENCE & TECHNOLOGY

Elizabeth Kachoris SENIOR DIRECTOR, DIGITAL AND DATA

Jen Krepelka DIRECTOR, WEBSITES & UX/UI

Lauren Sanz SENIOR DATA ANALYST

ADVERTISING

Lara Krieger PRODUCTION MANAGER • lkrieger@pmmimediagroup.com

Kelly Greeby SENIOR DIRECTOR, CLIENT SUCCESS & MEDIA OPERATIONS

PMMI MEDIA GROUP

David Newcorn PRESIDENT

Sharon Taylor DIRECTOR, MARKETING

Amber Miller SENIOR MARKETING MANAGER

Bea Greany BRAND OPERATIONS MANAGER

Janet Fabiano FINANCIAL SERVICES MANAGER

Lloyd Ferguson FOUNDING PARTNER

6

PMMI MEDIA GROUP 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 PHONE 312/222-1010, FAX 312/222-1310 • CIRCULATION FAX 312/222-1310

E-MAIL info@packworld.com • WEB www.packworld.com

PMMI The Association for Packaging and Processing Technologies 12930 Woodgate Dr., Suite 200, Herndon, VA 20170 PHONE 571/612-3200 • FAX 703/243-8556 • WEB www.pmmi.org

Contract Manufacturing + Packaging magazine is published for the Contract Packaging Association.

For information on association membership, contact Paige Jarvi, 571/287-6818, pjarvi@contractpackaging.org, or visit www.contractpackaging.org.

EDITORIAL CONTACT

Have a question or an idea for an article? Contact Melissa Griffen, Editor. CM+P Manufacturing + Packaging magazine prefers to receive press releases by e-mail. Send to mgriffen@pmmimediagroup.com.

PUBLICATIONS MAIL AGREEMENT NO. 40064408

Return undeliverable Canadian addresses to Express Messenger International, P.O. Box 25058, London Brc, Ontario, Canada N6C 6A8

6 A One-Stop-Shop Co-Manufacturer

Honeyville has a wide range of services to offer brand customers and has set initiatives for fair labor practices, promoting diversity and inclusion, to drive the company into the future.

14 Part 1: ESG Implementation for Co-mans and Co-packers

Yellow Emperor dives into actionable initiatives CM/CPs can engage in to meet personal ESG environmental sustainability goals and support those of their brand owner and consumer packaged goods (CPG) customers.

JULY/AUGUST 2023 CM+P 1 Contents TM DEPARTMENTS 2 Forefront 3 CPA President’s Letter 4 Brand Owner Insight 5 Industry News 10 JJM-R.A. Jones Case Study 12 Association News 18 New Products 20 Ad Index

VOLUME 19, ISSUE 2 JULY/AUGUST 2023

Engage in ESG Initiatives

MELISSA GRIFFEN, Editor

At the Contract Packaging Association’s (CPA) 2023 State of the Industry Report will soon be available for purchase and will be featured in the upcoming November/December issue of this magazine. Stay tuned for valuable insights on trends, economy, demographics and more.

In the meantime, Environment, Social and Governance (ESG) goals are a hot topic within the manufacturing industry and contract manufacturers and packagers (CM/CPs) must also do their part.

LEK Consulting Group and Oregon-

based co-manufacturer, Yellow Emperor dive into actionable initiatives CM/CPs can engage in to meet personal ESG environmental sustainability goals and support those of their customers. For initiatives you might consider applying, refer to page 14.

JJM Packaging , a New Jersey-based contract packager, found that new equipment can be used equipment, to align with environmental sustainability goals. The pre-owned automated line will be fixed up and brought to the JJM Packaging facility rather than adding to landfill waste. Read the details of the case study on page 10.

But sustainability extends to social and governance goals. Co-manufacturer, Honeyville has an open-book policy as well

as initiatives to ensure fair labor practices and promote diversity and inclusion. Read more on page 6.

I look forward to seeing many of you at CPA’s booth in the Association Partner Pavilion at PACK EXPO Las Vegas and around the event held in the Las Vegas Convention Center on Sept 11-13.

As always, please don’t hesitate to reach out to me with possible topics, news and case studies to cover within the magazine. CM+P mgriffen@pmmimediagroup.com

Forefront Convenient sample and dose packaging that appeals to the consumer. Perfect for on-the-go or simple daily use in a sustainable easy to use format. PA KAGING AT YOUR FINGERTIPS SA HETS - TOWELETTES - PA KETS WWW.AMERI ANFLEXPA K. OM (920) 430-1971

Welcome to CPA & Let us Embrace Sustainability for 2023

BY JERRY THOMPSON, President

Dear Members,

I hope you are enjoying your summer so far and that this letter finds you in good health and revved up with green energy. I am the new President on the Contract Packaging Association (CPA) board.

A little bit about me, especially for those who missed CPA’s ENGAGE event this last February, 2023. I have been a member of the CPA for 11 years. I started my own contract packaging business, Combined Technologies Inc. (CTI), in 2000, based in Bristol, Ind. with corporate offices in Libertyville, Ill. I am thrilled to see the increase in our membership in the last few years.

My aspiration during my term is for us to share a vision of building a sustainable future through our actions as individuals and as manufacturing companies. As a passionate advocate for sustainability, I believe that each step we take can make an impact on our planet and further the trends of change. Due to the immediate needs of our nation, we should strive to take as big of a step as we can within the packaging world.

I am excited about the growth of our group with added members and continued presence at all the trade shows around the country as well as abroad, such as at Interpack in Dusseldorf, Germany. I hope to see this growth continue.

I recall 20 years ago that sustainability was merely a buzz word and that “reduce, reuse and recycle” were words that many did not want to address. Now sustainability is a way of life to preserve our natural resources, protect biodiversity, and mitigate the negative impacts of humankind. It involves reengineering the way we produce and consume, integrating eco-friendly materials and practices into our daily routines, which comes down into our realm of manufacturing and packaging.

This opening letter serves as an invitation to connect with the CPA group and share your stories of sustainability, where we can work together towards a common goal and inspire positive change.

I believe it was Steve Jobs who said, “…ideas are worth nothing unless executed…” I look forward to meeting many of you in person if I have not yet already and hearing about your new ideas going into action!

I’d also like to express a warm welcome to our newest generalboard members, DeAnn Devenney, Director of Sales and Marketing for Maverick Packaging, Inc., and Dillon Vincent, Director of Quality Assurance, Crystal Packaging. We look forward to your

insights and contributions to CPA.

Feel free to find me at PACK EXPO Las Vegas 2023 at our CPA booth #C-1256 in the Association Partner Pavilion. Also of note, our very own Ron Puvak, Executive Director at CPA, will be participating in a panel to provide insights to emerging brands on how to navigate key growth stages. This will be in Pavilions 1-3 on Sunday September 10 from 11:15am to 11:45am (refer to page 5).

Thank you for your time, and I look forward to the opportunity to connect with you. Please reach out to me before the show as well at jthompson@ctipack.com. CM+P

Sincerely,

Jerry Thompson President, CPA

Jerry Thompson President, CPA

JULY/AUGUST 2023 CM+P 3 President’s Letter

CPA Board President Jerry Thompson, Jeff Graham, former CPA Board President Mark O'Malley, and CPA General Counsel Eric Greenberg at charity golf tournament.

Connectivity – Making the Data Support the Work

ROBBY MARTIN Sr. Packaging Engineer , Bush Brothers & Co.

In this column, we’ve looked at many aspects of good relationships between Brand Owners and co-man/ co-pack (CM/CP) providers. Most of these characteristics have been about how we interact, how we structure arrangements, etc. An area not often addressed, at least at the outset of a relationship, is the ability of CM/CPs to “connect” well to customers and their data and transactional systems. IT is not my area of expertise, so this discussion is about the practical aspects of good connections and will only touch on information security. In an ever increasingly competitive environment, I hope I can provide some thoughts that will help CM/CP companies consider where they stand competitively, and what they can do to enhance that position.

A major part of working with customers involves somewhat routine “blocking and tackling” activities like inventory levels of ingredients, packaging and finished goods. The ability of a CM/CP to provide up-todate, accurate data for raw, in-process, and ready to ship levels of production can be a crucial component for the execution of ongoing support. Moreover, the ability of a CM/CP to execute shipping of finished goods can be a valuable aspect of the relationship and a high value service to their customers. To do this well, CM/ CP providers require sufficient information systems and practices to make such interactions and services routine and relatively easy to achieve. Even if those systems cannot be made visible to the brand owner (BO), the ability of a CM/CP provider to quickly and routinely provide up to date and accurate information can

make or break how smooth and efficient the working process feels to the BO. Another factor affected by IT systems is the ability of a CM/CP to ship on behalf of the BO’s customers. A provider that can act as an extension in moving finished goods into the customer’s network, or directly to the BO’s customers can be a very valuable service that lowers complexity, cost, and the time component of order execution and delivery. In this world of Advance Ship Notices (ASN’s) and other electronic forms of Bill of Lading (BOL) and Packing Slip communication, the IT system of a CM/CP can truly be a gamechanger.

Some questions that CM/CPs can use to assess their ability to provide physical services and solid support in the information and communication space, are:

1. How long has it been since you updated, upgraded, or seriously considered the value your IT system provides or should provide to you AND your customers? If it has been some time, consider carving out space for a look into how newer technologies could open doors for you to improve your service.

2. Have you thought about making your systems a competitive point of differentiation? Are your systems set up to simply help run the business or can they also flex to meet the needs / wants of your customers? Contract manufacturing and packaging goes beyond the physical conversion of materials into finished goods.

3. Have you made a purposeful decision about the access you do or don’t grant to your customers to see into your data and information in a meaningful way?

4. Does your system provide visibility to on-hand ingredient and packaging inventory, including relevant expiration dates, version references, etc.? Real time inventory data, whether for raw

materials or finished goods, can help BOs know where you stand. That gets even more important when your customer discovers a new opportunity. Be ready to help them react to those, and you’ll be building a “preferred supplier” resume for sure!

5. Though we’re not addressing data and information security here, have you adequately addressed it, if at all? Your ability to ensure security will create confidence in your customers’ mind.

6. When it comes to shipping product, do you have what it takes to meet the requirements of shipping to today’s more detailed retailer channels? Can you ship only to your customers, or can you ship to your customers’ customers? What about Direct to Consumer shipping? Think ASN’s, electronic BOL’s, consumer information management, etc. It can be easy for such a list of questions to cause concern or worrisome thoughts. If this is your case, start with characteristics like honesty and transparency. Be up front with your self about where you stand, and where you are willing to go in this information, data and IT arena. Use the questions above to determine what additional VALUE you can bring to your customers. Once you’ve assessed your situation, be honest and transparent with your customers, or even with prospects, to make sure that you maintain a joint set of expectations that leads to addressing opportunities in a mutually beneficial way. You may find that opportunities in the “connectivity” space could lead to mutually beneficial outcomes for you and your customers. You might even find one or more customers who are willing to pay a little more for an increase in the service and value you provide to them. CM+P

4 CM+P JULY/AUGUST 2023 Brand Owner Insight

Emerging Brands Summit Features Insights from Co-man/co-packers

The Emerging Brands Summit (EBS) will take place on Sun, Sept. 10, just before the kickoff of PACK EXPO Las Vegas 2023 in the Las Vegas Convention Center on September 11-13.

EBS is designed to educate fast-growing emerging brands on how to scale their manufacturing operations. The event brings together expert advisors from seasoned brands, suppliers and contract services.

Among the panels and discussions providing valuable information and experience to these emerging brands is a panel discussion, “Navigating Key Growth Stages: Insights from Industry Co-Manufacturers and Co-Packagers,” led by:

Ron Puvak, executive director at Contract Packaging Association (CPA)

DeAnn DeVenney, director of sales and marketing at Maverick Packaging Inc., and new CPA board member

Dillon Vincent, director of quality assurance at Crystal Packaging Inc, and new CPA board member

Paul Shrater, president at Minimus Brands LLC

These experts will delve into the challenges commonly faced within the three growth stages all brands experience with the goal of helping new brands attending the EBS event understand the considerations crucial for sustained growth and operational excellence.

The three growth stages are:

1. The launch phase, which is completing the product and process development before using a contract service and

then finding one that is aligned with the brand’s vision.

2. Scaling up through strategies that allow for smoother transition to larger volumes of production, while also keeping in mind product consistency and quality as well as cost-efficiency.

3. Expanding distribution with an understanding of the challenges and opportunities attached to each channel, which involves finding the right partners who will support market requirements and regulatory compliance.

Co-man and co-packer experts will provide practical insights and actionable strategies based on their experiences, both successes and failures and difficult roads that fall somewhere in between.

Industry News For details on these and more stories, visit contract packaging at www.packworld.com

CM+P

A One-Stop-Shop Co-Manufacturer

A wide range of services as well as an emphasis of employee engagement drive the Utah-based co-manufacturer, Honeyville, into the future.

BY MELISSA GRIFFEN, Editor

Not located in the Mid-west where most of the industry operates, Honeyville has needed to differentiate itself to retain value as a partner to brands and consumer packaged goods (CPG) companies. Honeyville’s history in food and beverage allows the company to provide a wide range of services within and without contract manufacturing. The co-man has also invested resources into workforce to increase employee engagement.

A history of innovation and entrepreneurial drive

The company was founded in Honeyville, Utah as a milling and processing plant for specialty grains in 1951 by Lowell Sherratt, Sr. When Lowell Sr. died, his son, Lowell Jr., was bent on driving Honeyville into the 21st century. The company began buying and reselling bulk ingredients and by the mid 1990s, had built three more facilities and invested in its first blending operation, primarily for bulk.

By the late 90s, blending operations had extended to small pack for CPG customers and the contract manufacturing side of the business was born. Honeyville’s co-man business has become a growth engine for the company and mainly operates out of its Ogden, Utah facility.

“Lowell Jr. could look at a line and he could say we can do this better. Or he was willing to take his money which was invested in the company and figure it out,” says Johnny Ferry, vice president of business development, who started as a production line worker at the company in 2000 and married into the Sherratt family.

Since Lowell Jr.’s passing in 2018, the company is owned by various family members, with industry professionals brought on, such as David Brown, the CEO since September 2022. This transition

allows Honeyville to grow in new ways, while striving to keep its innovative drive.

Considering Honeyville’s history with dry ingredients, it’s no surprise that it serves the breakfast, baked goods and cold and hot drinks industries, but it also delves into dry blends for dinner meals, soups and side dishes. Honeyville also works in e-commerce, direct-to-consumer and emerging brands.

Co-man services the company provides include, dry ingredient mixing, blending and packing, custom grain milling, heat treatment to ensure sterilized dry ingredients, material sourcing, outsourced supply chain for logistics, fulfillment and supply planning, in-house research and development services, including formulation and nutritional analysis.

Co-man as an innovation partner

Searching for innovative solutions widens the CM/CP’s range of abilities, which can open the door to further contracts that require abilities the company didn’t realize it could possess. Ferry shares two projects that increased Honeyville’s applications.

The first he found at a trade show. A few soccer moms made a healthyier, tastier granola dish served as oatmeal-in-acup out of their garage. Though a newer concept to industry, Lowell Jr. gave Ferry the green light to line up tables and nail down the process and ratios.

Through Honeyville’s blending capabilities, the process was decreased to four drops — oats, powders, berries, and one other variable component. Success on that line resulted in a second line and a high-speed third line.

The second project involved a large brand wanting to put a mix in a rigid, traditional 502 canister with metal endseam paperboard. Due to effects from

Honeyville, Inc.

Headquarters: Ogden, Utah

Locations: Honeyville, Utah; Chandler, Arizona; Rancho Cucamonga, California

Employees: 400+

Main industries served: CPG brands, supermarket/grocery, club stores and foodservice.

Types of products handled: Dry ingredient mixes (blending and packaging); product categories include drink mixes, side dishes, baking mixes, breakfast, dessert and ingredients. Packaging services offered: Bagin-box, pouch/stand-up pouch, microwavable cups (paperboard, plastic and/or fiber – traditional or biodegradable/compostable), bulk bag-in-box, totes/supersack, 50lbs bags and rigid container.

Certifications: SQF certification at each plant; Global Food Safety Initiative (GFSI) certified; peanut free, non-GMO verified, Organic, Kosher, Halal, Vegan and Gluten Free (GF).

the COVID-19 pandemic, costs of those materials had gone up exponentially, taking the project off the table. Ferry offered another packaging solution.

Keeping in mind that the customer wanted a durable container, the Honeyville team connected with their cup format supplier to create a giant-sized

6 CM+P JULY/AUGUST 2023

Profile

Packager

David Brown, CEO of Honeyville (left) & Johnny Ferry, vice president of business development at Honeyville (right).

version to fit three pounds of product. This cut the cost of manufacturing by more than half and improved shelf space utilization and recyclability.

“It was a simple plate change to go from a small little round to a bigger container. The customer loved it. It resurrected the five million pound a year project,” says Ferry.

The new machine has been running since June for three customers with more on the way. What normally would have been a two-year process was compressed to six months and the product will be on the shelves fall 2023.

Focusing on a diversity of supply

Offering variety of services can make a valuable partner. Ferry lists diversity of machinery — to run different pack formats as customers branch out to reach consumers — and diversity of supply, becoming a one-stop-shop. Honeyville manages different pack formats through a good engineering team and ensuring enough space for machinery.

On diversity of supply, Honeyville’s history of milling and blending operations means the company has a direct-to-farmer connection, and it both uses the products it mills internally and sells them to local bakeries. Honeyville also keeps many suppliers for access to ingredients.

The Ogden facility has five blenders, including ribbon blenders,

Honeyville Sl i ll . i lit , vy d y i i wi asy rati . ll l ds i , ccu lator lers. B N , C f r , U www.simplexfiller.com • 640-A A k R , N , CA 94558 707-265-6801 • FAX: 707-265-6868 F y w f r v r 5 y r . L b g w w h F r. l u w 7 S x V- 0 i i i li i , i- li i l lli . i i i , i l i

Honeyville’s Ogden Utah facility.

Honeyville’s cupping line.

paddle blenders and gravity blenders with inclusion capability, that hold up to 5000 pounds per batch. When customers bring a product to Honeyville that they want commercialized, Honeyville’s R&D team will suggest the order of blending and blending times in steps that includes metal detection, sifting, micro lab testing and other testing capabilities.

R&D services and testing are free for brands and retailers looking to formulate or modify recipes. Testing capabilities include sensory, pH levels and viscosity. Honeyville has partners for further testing.

Honeyville plans to invest in 3PL services by warehousing stock product for customers and shipping directly to retailers and some consumers and brand customers. Being a partner involves both timely responsiveness to customer demands and questions and transparency through communication when challenges and delays occur.

The co-man also improve its transparency and efficiency by moving paper records to the Redzone system to better track ingredients and overall quality, regulatory compliance, operations and food safety.

Digitalization drives higher employee engagement and learning

The Redzone system, which is accessible to employees on tab-

lets, is also a means for Honeyville to meet environment, social and governance (ESG) goals through:

1. Access to the system: Operators can check equipment to ensure they’re within specifications and achieving production goals.

2. Communication: Operators communicate with other employees about setbacks and delays or other factors that impact production.

3. Suggestions and feedback: Redzone allows employees at all levels to use a suggestion feature. Many suggestions have come from frontline workers on how to improve efficiency in packaging and raw material handling. “We want to drive that culture throughout the organization. It’s not just quality and safety, but it’s also about efficiency, and how we can achieve the best possible results,” says Brown.

4. Employee development: Redzone is used as a learning and retention tool for employees. Through a learning module, employees will have the opportunity to control their own destiny through further education and skill development, says Brown.

Besides using Redzone, Honeyville is currently working with its HR team to create a professional development program and other educational opportunities. Three sessions have been identified to bring in professional trainers on accountability, interviewing and engaging in hard conversations with fellow employees. To assist the trainings, all Honeyville employees complete a personality

Honeyville NEW XCP SERIES CONTINUOUS MOTION CASE PACKER go.brentonengineering.com/cmp_XCP 320.852.7705 | Brenton@ProMachBuilt.com BOOTH: C-3822

Incoming

Changeover Repeatability Consistent, repeatable changeover including easy access to all critical areas of operation.

Seamless Product Loading

products are contained at the case transfer point to reduce product jams.

Medium to High Speed Solution Runs wrap around cases and trays up to 70 cases per minute utilizing continuous motion.

Ergonomic Blank Load System Conveyor fed case blank loading system accepts flat stacks of blanks for easy loading.

test that lays out individual’s decisionmaking ability and motivators, such as sustainability and compliance. The test helps individuals better understand how to approach fellow employees about hard discussions, as well as of their own weaknesses, to improve collaboration.

Honeyville strives to be a learning organization, encouraging employees to step out of their comfort zones and develop new skills that can lead them to management positions, whether they be with Honeyville or another company.

Honeyville also operates on an open book management system since 2021, which details the company’s financials. Weekly meetings include representation from each department, reporting on their impact to the bottom line, from custodian to CEO.

“Each of our [department] financial statements are being shared with the line workers, which allows a more detailed conversation and training because each person knows the impact that they have financially on the bottom line,” says Ferry.

Employees also participate in Honeyville’s bonus incentive program, which takes savings, earnings or profits and puts them in a pool for frontline workers, which Ferry says has changed the culture.

Finding value in CPA membership

Honeyville joined CPA in November 2021 thanks to CEO, David Brown, who saw value from the very first CPA meeting in getting to know the market and competitors, talking with competitors to gain a better understanding of industries worth investing in, meeting fellow CM/CPs who have experienced similar challenges and are willing to share insights and even a phone call with their maintenance personnel for an equipment issue and opportunities to connect with potential customers.

“This is what we needed,” says Brown. “Right now we’re working with one of our competitors. We don’t do anything peanut here at this facility, so one of the

people we met at CPA, that business is going to them.”

Brown looks forward to further opportunities to benefit from CPA, discuss best practices and learn from his fellow members. “In my old association, I could

call somebody and say, ‘I’m thinking about this in best practices,’ and we’re willing to share. There’s things to be gained. That’s going to benefit the entire industry,” he says. CM+P

Honeyville JULY/AUGUST 2023 CM+P 9

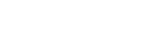

CP Increases Line Efficiency With Pre-Owned Automated Line

Remanufacturing machinery gives contract packagers a chance to customize equipment to their needs while reducing material waste and keeping costs in check.

BY Melissa Griffen, Editor, CM+P magazine

When it comes to automation, what’s old is sometimes new again. Take the case of JJM Packaging, a New Jerseybased contract packager (CP) for powderbased food and supplement products.

To meet growing demands, the company, which provides services from formulation and raw material sourcing to blending and consumer ready packaging, sought to improve its line efficiency with increased capacity and capability through automation.

Whether it be robots, collaborative robots, or an entire automated line, JJM was in search of a machine that could handle both powders and particulates. The automation solution also needed to be able to gravimetrically check-weigh every pouch at up to 800 pouches per minute.

Considering the success JJM already had with a fully automated R.A Jones Pouch King PCU-2000 machine line installed at its Totowa, N.J. facility, the CP decided to purchase another. Joseph Apuzzo, founder of JJM Packaging, stumbled across a company selling a pre-owned Pouch King machine and a Criterion 2000 cartoner that had never been installed by the original buyer after purchasing them in 2014. They were still in good condition despite missing some components.

“When a machine is stationary and it’s not going to run, it becomes a spare parts bin for other machines,” says Kevin Webster, sales account manager for the food marketing segment at R.A. Jones. “So, it wasn’t complete or operational, but overall, it was in good shape.”

After weighing his options and consid-

ering the necessary customizations to fit JJM’s needs, Apuzzo bought the used line and had it sent directly to R.A. Jones for modification.

Working with an OEM to customize the machine

The Pouch King employs circuit heating technology, supports a range of materials such as polyethylene, poly-paper or cellophane, and provides feeding systems for both individual and multi-component blends, to improve filling and accuracy control over products. The line is originally designed from packages of eight, 10 and 12 counts in a dual stack configuration.

For JJM’s machine, R.A. Jones replaced the missing human-machine-interface (HMI) system, designed as an interactive, touch screen platform to set up feeder combinations and facilitate safer, quicker

changeovers between product types. Further modifications to fulfill JJM’s needs included a line reconfiguration to accommodate a new pouch transfer system and floor space requirements.

Another adaptation to the Pouch King stemmed from the pouch size change. Originally, JJM had been working with a 2.625-inch pouch but had transitioned to a 4-inch pouch. To accommodate the size change, R.A Jones had to change the pitch of the machine and rework several assembly elements, such as installing new wheels throughout to fit the new pouch width.

R.A Jones also re-equipped the machine with specific feeders to account for the customer’s multi-component blend product, which is comprised of different powder and particulate ingredients.

Case Study 10 CM+P JULY/AUGUST 2023

Workers at the JJM Packaging company on the production line at the Totowa, NJ facility.

Taking customization to the next level

The most demanding change was the integration of individual pouch-weighing capabilities, which required a second line reconfiguration to a Z-shape. Individual pouch-weighing is crucial to JJM’s customers in order to provide accurate serving size details on the label of each dietary and health-based supplement.

The line reconfiguration involved three 90-degree turns to carry the pouches from the knife cutter to the individual check weigher. From there, the pouches are grouped in packs of seven before being dropped into the Criterion bucket conveyor. However, since the Criterion cartoner was an existing machine, the bucket conveyor did not match the height of the Pouch King. Usually these levels align, which allows for a horizontal transfer system. Instead, R.A Jones needed to design an incline bucket conveyor, carrying the pouches on an upward trajectory into the cartoner.

“In order to weigh each package, you have to individualize them then you have to get them back together,” says Apuzzo. “So, a lot of the automation rework was how to get them separated first, weigh

them and then put them back together in counts of seven.”

JJM became aware of this customer demand late in the reconfiguration process, which resulted in the production line becoming bigger than planned. It also meant a longer rebuild time frame than normal because of supply chain shortages. The line is expected to be fully operational at the JJM facility in the summer of 2023.

Reducing material waste and growing a strong CP-OEM bond

Buying from the used market made sense in this case because it also fell in line with JJM’s sustainability efforts. Refurbishing a used machine extends its usage for years, thus reducing the amount of material waste being discarded to a landfill. This also reduces the amount of virgin material needed to create a new machine.

The Pouch King line is not the only machine that JJM has reused. In fact, the first Pouch King that JJM owned was also reconfigured by R.A. Jones to meet its needs, and the company plans to continue purchasing from the used market in the future.

“We’re turning used machinery into new machinery, outfitting things with servos, but using the frames that are there,” says Apuzzo. “We don’t run the same product for 15 years. Flexibility and our ability to make a new machine quickly that fits to a new package type that we have to handle, that’s the key to the CP business.”

Apuzzo emphasized that this project would not have been near the success without the strong relationship the contract packager has with R.A. Jones. Though he understood that adjusting the machine to fit JJM’s application would be a difficult project, Apuzzo felt confident that it would be achievable thanks to his relationship with Webster, his account manager at R.A. Jones.

“The biggest thing with projects like this is you need to have a relationship with the OEM,” says Apuzzo. “Either you personally or your team must be really involved in the project. Our maintenance team is pretty robust and making the changes to the line mid-project or knowing that if the line comes in, and we have to make some changes, we can do that in house [is] a huge lifesaver with the project.”

Case Study JULY/AUGUST 2023 CM+P 11

CM+P

JJM Packaging’s pre-owned R.A Jones cartoner, the Criterion 2000, stationed at the R.A Jones Covington, KY facility where the line is undergoing reconfigurations.

JOURNEY to ZERO

CONTRACT Manufacturing + Packaging magazine is the official publication of the CPA, The Association for Contract Packagers and Manufacturers. The association provides business development support, industry education, networking opportunities, and industry intelligence for contract packagers and contract manufacturers.

This section of the magazine is dedicated to sharing how CPA members can leverage their membership to propel their business and empower operations. For more information on becoming a CPA member and to gain access to industry expertise, best practices, and support, visit: contractpackaging.org

CPA Election Results, Success from Partnerships

Networking and partnerships

CPA expanded their interaction with CPGs through a joint event in June with Chicagoland Food & Beverage Network, which represents the second-largest food and beverage industry market in the nation. CPA formed a partnership with Chicagoland Food & Beverage Network last summer and has been working to provide mutually beneficial opportunities for both associations. The event entitled, “Leveraging Co-Packers for Innovative Supply Chain Solutions,” was held on June 8th at the Frain Industries, Inc. headquarters in Carol Stream, Ill, and included a co-pack/co-man state of the industry report, a panel discussion and Q&A featuring CPG decisionmakers, co-manufacturing leadership and industry analysts, a facility tour and networking.

On May 18th, CPA sponsored a golf tournament put on by the Chicagoland Food & Beverage Network and Bigger Table–a 501(c)3 nonprofit organization bringing together the food & beverage industry to address hunger, unemployment, and inclusive economic development in Chicagoland. The foursome included CPA Board President Jerry Thompson, Jeff Graham, former CPA Board President Mark O’Malley, and CPA General Counsel Eric Greenberg.

CPA also furthered their relationship with CHPA, Consumer Health Products Association, by securing participation in the CHPA 2023 Regulatory, Scientific & Quality Conference. This conference takes place September 18-20, 2023, in Bethesda, Md. and brings together leaders from industry, regulatory authorities, and academia across the consumer healthcare landscape to focus on the self-care space. This is the first CHPA event they have participated in and gives CPA the chance to talk to self-care product developers about co-packaging and co-manufacturing services offered by its members. CPA hopes to expand awareness of its “Request for Quote” tool to help more consumer healthcare brands find member companies that can help bring their product to market.

CPA election results

The CPA board held elections for two General and two Associate Board Member positions following the February ENGAGE event. After votes were tabulated, CPA had two new General Board Members, DeAnn Devenney, director of sales and marketing for Maverick Packaging, Inc., and Dillon Vincent, director of quality assurance at Crystal Packaging. Two Associate Board Members were re-elected to another term – Gregory Frazier, director of sales for Frazier & Son and Dan Altman, vice president of sales and marketing at Delkor Systems, Inc.

The full board met onsite in June at the Wyndham Bonnet Creek in Orlando, Fla,

12 CM+P JULY/AUGUST 2023 Association News

home to the 2024 ENGAGE event, The Contract Packaging and Manufacturing Experience. The group came together to plan how to make the next show even more successful than the record-breaking 2023 event.

Coming soon–PELV and the state of the industry report

At the close of the summer, CPA’s biennial State of the Industry Report will be released. The association looks forward to sharing its findings from the preeminent guide to trends and statistics regarding the contract packaging and manufacturing industry since 2008. The guide can be ordered at www.contractpackagingreport. com and CPA members always receive a discount on the report and complimentary executive summary.

CPA looks forward to a busy fall, exhibiting again at PACK EXPO Las Vegas, September 11-13, in the Association Partner Pavilion. This year, they will also participate in four separate speaking engagements at the show. This includes their debut as part of the PACK EXPO First Time Attendee Lounge. CPA will be presenting “Bringing Your Products to Market Using Contract Packagers & Manufacturers” in the lounge to help brands learn how to find help at the show through its members. Additionally, the association will return to exhibit at Natural Products Expo East in Philadelphia, Pa.

Panel discussion at the “Leveraging Co-Packers for Innovative Supply Chain Solutions” event.

CPA Board President Jerry Thompson, Jeff Graham, former CPA Board President Mark O’Malley, and CPA General Counsel Eric Greenberg at charity golf tournament.

New general board member, DeAnn Devenney,Director of Sales and Marketing for Maverick Packaging, Inc.

New general board member Dillon Vincent, Director of Quality Assurance, Crystal Packaging. Don’t miss out on the 2024 ENGAGE event in Orlando, Fla.

JULY/AUGUST 2023 CM+P 13 spee-dee.com | 877.375.2121 QUICKLY. SAFELY. CLEANLY.

FILL NUTRACEUTICAL POWDERS INTO RIGID CONTAINERS OF MANY SIZES, SHAPES & MATERIALS WITH OUR COMPACT ROTARY FILLER.

PACK EXPO Booth: C-4809

Part 1: ESG Implementation for Co-mans and Co-packers

Brands determine the sustainability of a product and its manufacturing, but contract manufacturers still have ample opportunities to go green. Oregon-based Yellow Emperor points the way.

BY Melissa Griffen, Editor

Environment, social, and governance (ESG) goals are increasingly demanded by government and expected by consumers. According to the Manufacturers Alliance for Productivity and Innovation (MAPI) trends report ‘Interesting Sustainability: ESG and Smart Manufacturing Trends,’ “ESG is a set of frameworks used to assess the impact of a company’s sustainable and ethical practices on its financial performance and operations.”

The ESG categories are used to measure and report a company’s progress and include areas often overlooked, such as inequality, climate risk, quality, safety, diversity, and ethics, when uptime and other pressing matters demand more attention. The MAPI report says research also links high ESG ratings with higher profitability, higher dividend yield and decreased business risks, less volatility and higher valuations.

Considering these benefits, ESG goals can therefore be “useful financial indicators of company performance and of a sound investment … [as] higher scores reflect better management of risks and opportunities by companies,” according to the report.

But in many ways contract manufacturers and packagers (CM/CPs) often have little

input as the sustainability of the materials, ingredients, and processes used in their facilities are most often controlled by their brand and consumer packaged goods (CPG) customers. But that doesn’t mean they are without options.

3 ways contract manufacturers and packagers can be environmentally conscious

LEK Consulting , a consulting firm that helps manufacturers and packagers, including CM/CPs, breaks down into three categories the efforts contract services can make to reach environmental goals:

1. Equipment with the flexibility to run virgin or sustainable substrates.

2. Internal ESG initiatives.

3. Providing a suite of sustainable support services to brand owner customers. Sustainable substrates , particularly those that include recycled content, historically couldn’t be run on the same equipment as virgin materials, or if they did, the speed of the line needed to decrease significantly. This impacted the rate of production, making sustainable sub-

strates seem like more effort and money than was feasible for most CM/CPs. But, as LEK Consulting partner and managing director, Amanda Winters points out, now “there’s more innovative equipment out there where you could run sustainable substrates on similar equipment.”

Purchasing equipment that can run substrates with recycled content, bio-based resins, and other eco-friendly alternatives is a difficult decision for a CM/CP to make and one that very often won’t be made until brand owner customers provide an ultimatum. However, deciding to purchase such flexible equipment can also be one of the biggest efforts a CM/CP can make to help its customers meet their sustainability goals, according to Thilo Henkes, partner and global packaging practice lead at LEK Consulting.

Internal sustainability initiatives are easier to commit to as they have no correlation with customers. Internal initiatives can include efforts to reduce landfill waste, increase recycling, or reduce carbon emissions. Many CM/CPs

14 CM+P JULY/AUGUST 2023

Sustainability

Yellow Emperor’s new Eugene facility, set up for increased efforts in sustainability.

LEK Consulting, a consulting firm that helps manufacturers and packagers, including CM/CPs, implement environmental goals.

are actively striving to accomplish goals like reducing energy consumption, reducing water consumption within production and sourcing energy from renewable options.

“These are the activity set that manufacturers, agnostic of packaging, can deploy as a means of meeting internal ESG goals, without necessarily needing to do anything that’s tied to the behavior of their upstream customers, like equipment purchases mentioned before,” says Jon Moss, partner at LEK Consulting.

Sustainable support services are services CM/CPs can offer their brand owner customers and can involve things like support for more sustainable design of packaging and formulation. Though CM/CPs don’t have a direct effect on the packaging or product, they can provide suggestions for a more sustainably sound packaging solution and product formulation. KDC/One is an example of a co-manufacturer who provided such services to smaller brand owners in the beauty packaging space. Another area of support is freight optimization. This entails efficiency in shipping full truckloads and improving secondary packaging architecture, particularly for non-cube-based products, for more efficient space usage. This is especially applicable in direct-to-consumer packaging in terms of shipping the products in primary packaging versus placing the product inside a larger box with void fill.

“Optimizing the freight reduces spend, but also the amount of

protective packaging material, and as a consequence, the amount of fuel that’s used in transport,” says Jeff Cloetingh, managing director and partner at LEK Consulting.

Environmental co-man goals in the works

Yellow Emperor, a Eugene, Ore.-based liquid supplement contract manufacturer, has made sustainability a goal and provides insight into how CM/CPs can do their part.

Yellow Emperor’s efforts over the years have led to certifications such as GMP-certified plant and Certified Organic Processor for organic supplement private label manufacturing. The CM undergoes audits and inspections by state and federal regulatory agencies regularly. The certifications aren’t the ultimate point, however.

“You don’t have to have a certification to be a sustainable business. You can do things that encourage sustainability without needing a third party,” says Sarah Vito, director of business development at Yellow Emperor.

Vito explains that third parties can bring many benefits to a company, such as in showing clientele that the CM/CP has been vetted, but they are not necessary to becoming a green business. Sometimes, third parties can even come with a lot of administrative overhead, requiring time and funds that a CM/CP may not be willing to spend. According to Vito, to be sustainable a company

Let’s talk about your project today!

•Robotic

•Integrated

Sustainability

Palletizers

Bagging

Lines

•Collaborative Robots

just needs to choose an area in which to make effort and start.

In fact, Yellow Emperor has made a commitment with The Climate Collaborative , a natural products industry nonprofit that is working towards unifying the industry around certain sustainability commitments without the use of certifications.

Yellow Emperor’s general environmental goals are to recycle, compost, use 100% post-consumer recycled paper, green energy and public or bicycle transportation to commute, encourage working from home, and buy packaging that can be recycled, packaging that has recycled content, organic ingredients and to buy local.

What this looks like for Yellow Emperor is 50% recycled content in boxes and 30% post-consumer recycled content in bottles. Vito’s own personal mission is to find ways to reduce secondhand or one-time use plastics, such as pallet wrap,

straps, and shrink sleeves.

“I have made headway on a post-consumer recycled pallet wrap, which we’re going to be testing soon. If we can reduce the use of fresh virgin plastic, I feel like that’s somewhat of a win. My goal is to find some kind of biodegradable, compostable nonpetroleum-based pallet wrap,” says Vito.

How can a contract manufacturer or packager start?

CM/CPs can also become an innovation partner for brand and consumer packaged goods (CPG) customers, providing the design and formulation services mentioned above by LEK Consulting. Brands are looking for CM/CP innovation and growth partners, who meet with the brands’ marketing and consumer insights teams and offer services to improve product and process innovation.

Yellow Emperor has become a partner and advocate for sustainable manufac-

turing in situations where a material is expensive or hard to acquire or is an herb that is threatened in some way.

“Most folks are really appreciative of the heads up, because everybody wants to make sure that they have a steady supply chain,” says Vito.

Yellow Emperor also categorizes its suppliers into tiers to serve as an internal benchmark to determine how sustainable its sourcing is. Platinum vendors have a strong sustainability focus and are likely

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Sustainability 98 34 108 116 102 2 1 101 1 17 51 61 103 104 20 107 12 33 32 99 36 26 41 42 0842 27 56 26 16 52 14 28 LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING. info@heatandcontrol.com | heatandcontrol.com

you bring your best products to market.

Results.

Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers. Sep. 11-13, 2023 Booth C-1623, Central Hall Las Vegas Convention Center Las Vegas, NV USA

Helping

Delivering

With

L Sarah Vito, director of business development at Yellow Emperor.

in Oregon or the pacific Northwest, gold vendors have somewhat of an eye on sustainability and are likely located in the Midwest and continental West, and silver vendors have no sustainability goals and are likely located on the East Coast.

CM/CPs can also drive operation sustainability by buying used machinery and used office furniture, refurbishing computers to avoid contributing to e-waste, and recycling electronics if possible. Vito also suggests CM/CPs seek out local opportunities for upcycling materials such as plastic. Even smaller efforts can make a difference. CM/CPs can use reusable printer cartridges, install auto faucets in bathrooms, and motion-sensor light switches. Yellow Emperor is also looking into using more solar energy.

Ultimately though, it comes back to customers, Henkes suggests CM/CPs aim to understand how they can help customers meet their ESG goals. “That may give the co-man or co-packer some ideas as to what should be their first, second and third initiatives,” he says. Henkes also suggests understanding, from a competitive standpoint, what other CM/CPs are doing to meet ESG goals.

‘It’s not as hard as it seems’: benefits of being more sustainable

The most obvious benefit, according to Vito, is in the workforce. The company saw an increase in job candidates who specifically

applied to Yellow Emperor positions thanks to the company’s sustainability focus. Vito explains that having a workforce whose values line up with the company’s makes some of Yellow Emperor’s goals easier to implement. Vito also says Yellow Emperor finalized contracts with a number of new customers within the last 18 months who made it a point to discuss the contract manufacturer’s sustainability goals.

Yellow Emperor’s new facility is large enough for receiving, warehousing and production to be in one location, whereas the old facility couldn’t. This reduces truck emissions and travel costs. The new facility also allows the space to implement lean manufacturing and increase time efficiencies. This further eliminated needless running of machines.

Over time, monetary benefits accrue from green efforts as small as using more sustainable light bulbs. They may cost more upfront, but use less energy and are changed less often.

“It’s little steps, then you turn and you’re like ‘Oh wow, we’ve really come a long way and it was just little things that we did along the way and none of it really hurt. And some of it actually saved us money,’” says Vito. “You don’t have to upturn everything, it can be a gradual, slow progression. So just start somewhere and do the next best thing you can do. If you’re buying office supplies, just buy 100% post-consumer recycled paper. It’s not as hard and as daunting as it seems.” CM+P

Sustainability 61 8 16

AUTOMATIC BOTTLE FILLING MACHINES

Specialty Equipment has a full line of bottle filling and capping machines ideal for the lubricants, oils, chemicals, cleaning and personal care/ beauty industries. Up to 14 filling heads; fills up to 100 2oz to 2.5 gallon bottles or 5-gallon F-style jugs a minute; servo-driven, inline, rotary filling; both flowmeter and piston-based fillers available. For more information, contact us at specialtyequipment.com

Benefits

» Quick Product Changeover

» Runs 24/7 Without an Operator

» Accurate, Fast, Flexible and Silent

» Clean In-place Functionality

» Increase Production & Maximize Uptime

» Add Savings to Your Bottom Line

Types of Bottles We Fill

Innovative Blister Cu er

The free-standing module unit integrates with new and old blister machines to provide different blister cards without expensive tooling or long costly changeovers

The unit provides toolless changeover and precision cutting and tracks the blister with an optic sensor to ensure cross cuts are in the proper location AZCO Corp. www.azcocorp.com

Temp-sensitive Label Applicator

The Compact labeler applies thermochromic vaccine vial monitor (VVM) labels that change color when exposed to out-of-tolerance temperatures to help ensure product efficacy

The VVM applicator handles vials, bottles, and other container formats at speeds up to 600 ppm with fast changeover

We also provide installation, parts and field service.

Learn more by calling 833-467-3432 www.specialtyequipment.com

Weiler Labeling Systems https://www.weilerls.com/

18 CM+P JULY/AUGUST 2023 New Products

built better...

BUILT TO FILL. BUILT FOR LIFE. Just

Compact Pump for Food & Bev

The Certa Compact Pump is a more flexible and simplified design to save on assembly time and cost for an integrator during installation

High suction capability and Certa’s sinusoidal rotor reduce shear and power consumption for the handling of viscous products such as chocolate, soft fruit, and sauces

Watson-Marlow Fluid Technology Solutions www.wmfts.com

In-line screw capper

These desiccants are designed to protect the functionality of medical devices, including clinical and home-use in-vitro diagnostic platforms

Drop-in desiccant packets offer durability, moisture protection and breathability while taking up little space inside the primary packaging Sanner GmbH https://www.sanner-group.com/

JULY/AUGUST 2023 CM+P 19 New Products 844-293-2814 Draper Z Incline Conveyor NEW Contact Us for Details CONVEYOR EQUIPMENT IN 6 - 8 WEEKS • Made at fixed angles of 30, 45, and 60 degrees

Reduced footprint

Eliminate changeover adjustments

Accessibility layout for operator and fork truck traffic Visit Us at PACK EXPO Las Vegas Booth C-2214

•

•

•

Contract Packaging is a supplement to Packaging World® (ISSN # 1073-7367, a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Packaging World® is published monthly by PMMI with its publishing office, PMMI Media Group, located at 401 N. Michigan Avenue, Suite 300, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodicals postage paid at Chicago, IL, and additional mailing offices. Copyright 2018 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.packworld.com/subscribe. Paid subscription rates per year are $200 in the U.S., $285 Canada and Mexico by surface mail; $475 Europe, $715 Far East and Australia by air mail. Single copy price in U.S. is $20. To subscribe or manage your subscription to Packaging World, visit Packworld. com/subscribe. Free digital edition available to qualified individuals outside the United States. POSTMASTER; Send address changes to Packaging World®, 401 N. Michigan Avenue, Suite 300, Chicago, IL 60611-3789. PRINTED IN USA by Quad Graphics. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@packworld.com. Mailing List: We make a portion of our mailing list available to reputable firms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address.

Ad Index TM COMPANY/WEBSITE PAGE COMPANY/WEBSITE PAGE AMERICAN FLEXPACK INC 2 www.americanflexpack.com BRENTON 8 www.brentonengineering.com CHEMBLEND OF AMERICA LLC 20 www.chemblend.net COLUMBIA/OKURA 15 www.columbiaokura.com DO-IT CORPORATION 17 www.companywebsite.com DOMINO AMJET INC. 12 www.domino-na.com ECONOCORP, INC. 5 www.econocorp.com HEAT AND CONTROL, INC. 16 www.heatandcontrol.com NERCON CONVEYOR SYSTEMS 19 www.nerconconveyors.com PMMI, THE ASSOCIATION FOR PACKAGING AND PROCESSING TECHNOLOGIES IBC www.pmmi.org PROSYS FILL LLC. 9 www.prosysfill.com SIMPLEX FILLER 7 www. simplexfiller.com SPAN TECH LLC IFC www.spantechconveyors.com SPECIALTY EQUIPMENT 18 www.specialtyequipment.com SPEE-DEE PACKAGING MACHINERY 13 www.spee-dee.com TEXWRAP PACKAGING SYSTEMS OBC www.texwrap.com

Everything you need to move projects forward and prepare for the future.

Step onto the PACK EXPO Las Vegas show floor and immerse yourself in the largest display of innovative packaging and processing machinery and materials on the continent.

Discover Solutions Up Close

2,000 exhibi tors 40+ vertical markets 100+ free show floor sessions Endless networking opportunities expectinnovation REGISTER NOW at packexpolasvegas.com

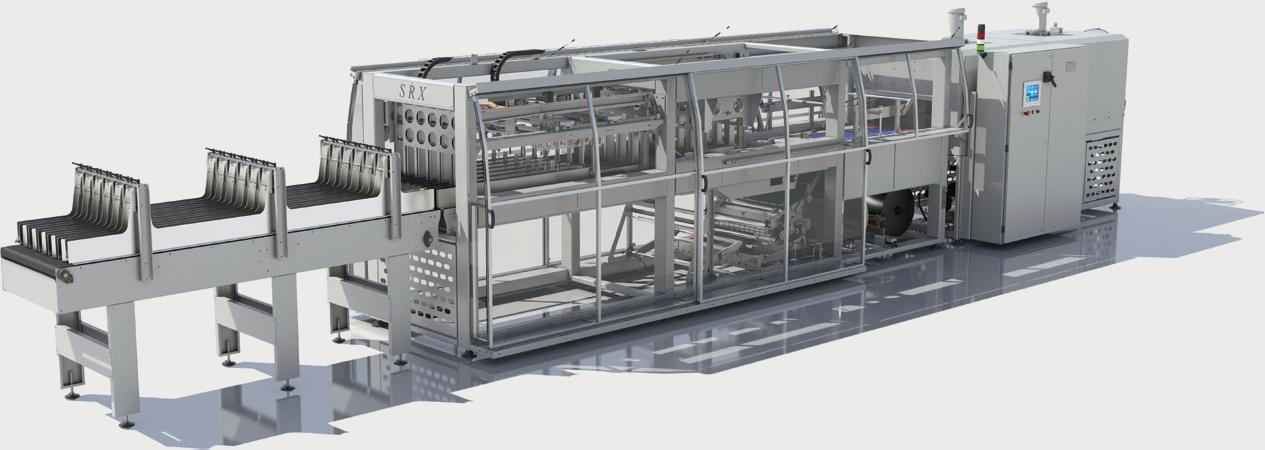

From Small-Scale Projects to High-Volume Packaging

Contract Packaging Solutions Uniquely Suited to Meet Your Demands

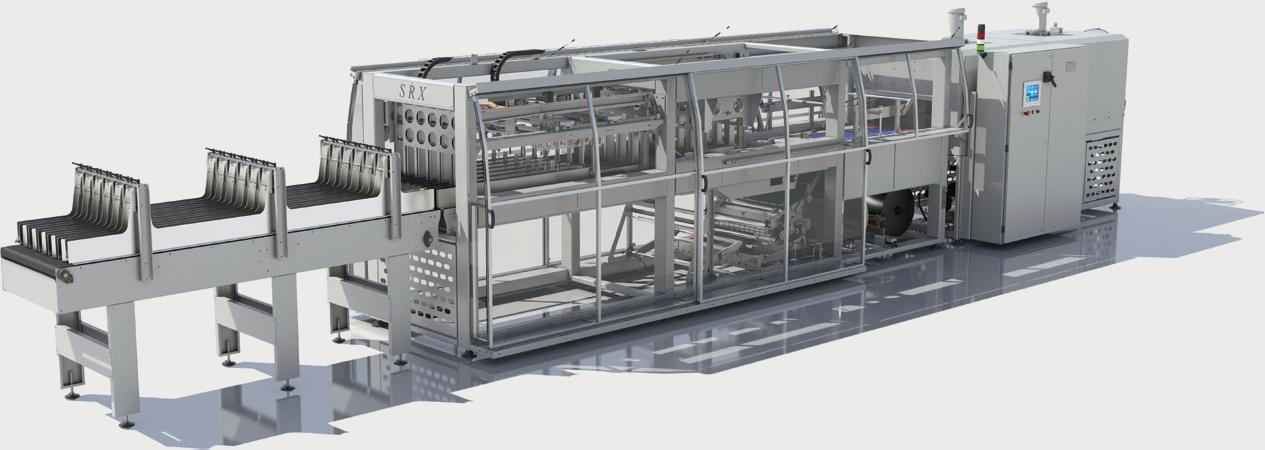

Kayat SRX Series Shrink Bundler

Bundle pre-formed trays on the SRX-CTF or loose packaged food and beverage products on the new SRX-CUF. Both machines accommodate clear or print registered shrink film and speeds of up to 60 cycles per minute.

Continuous Motion Side Sealers –Most Demanded!

High throughput speeds with patented Motion Trim Technology™. Accommodates randomly fed or spaced product and separates them into reliable, consistent packages using the absolute minimum amount of film.

Multipack products in an upright position including bottles, canisters, aerosols, or jars directly from a filler.

In-Line Wrappers

Designed for shrink bundling products that can stand by themselves, this machine provides options for shrink bundling product on corrugated pads, in trays, or loose.

PERFORMANCE, PACKAGED

CSS Series

Tekkra

Texwrap@ProMachBuilt com (6 6) www.Texwrap.com Visit us at Booth C-3625

BVS Series Box Motion Vertical Wrappers

Find out more: Proud member of the NEW!

Jerry Thompson President, CPA

Jerry Thompson President, CPA