APRIL / MAY / JUNE No. 2, Year 2

We ended the first half of 2024 with a significant number of activities completed after a great job by the entire Plastek de México team. This effort allowed us to maintain the good start of 2024 and extend it for two more quarters. Congratulations to all. During the month of June we had the BRCGS audit, of which we are waiting for the final result, although the auditor told us during the closing meeting that we were certified with a better grade than last year. This is the result of the hard daily work of all departments coordinated by the Quality Team. The clarification of the 5 minor findings has already been submitted to the auditor for consideration, so we are waiting for the final grade in the next few weeks.

This quarter was one of celebrations; we celebrated Children's Day, Mother's Day and Father's Day. On this occasion, during the Children's Day celebration, we coordinated with the administration of the Queretaro Industrial Park the participation of the park's fire truck and one of its ambulances. The children had a great time interacting with the firefighters and paramedics and riding in the units. They also enjoyed the presentations and tour of the facility. We thank DH for coordinating the event and the people who supported the activities.

The Plastek de México process team was mobilized to the Colgate Guatemala plant to provide technical support for the molding of toothbrush handles as part of the toothbrush project.

Colgate Guatemala expressed gratitude for the support received. This type of activity helps to reinforce the business relationship between the two companies and adds value to the business proposal offered by Plastek. During this quarter, we proceeded with the construction of our mold shop and initiated the training program for the personnel who will operate the equipment in the shop. The training is being conducted in two phases. The first phase is taking place at Plastek's Mold shop in Brazil, while the second phase will be held at the Brazil and Erie, Pennsylvania shops. We anticipate commencing shop floor operations by the last quarter of 2024.

For the first time, our President Dennis Prischak presented to all Plastek Group divisions and regions globally, discussing several topics with all Group employees.

The presentation covered a range of topics, including the Group's mission, vision, and values; its strategic growth plan for the next five years; and the pillars of growth. It also addressed frequently asked questions from employees, as submitted via digital media. This presentation is scheduled to take place on an annual basis. We remain on track to achieve positive results in 2024. The challenge is to maintain focus on daily activities and execute necessary corrective and follow-up actions to improve performance on a daily basis. As our president Dennis Prischak states, "Our customers have a variety of options, and we must provide them with reasons to choose us as their supplier on a daily basis."

ING. ALBERTO BORRAJO GENERAL MANAGER

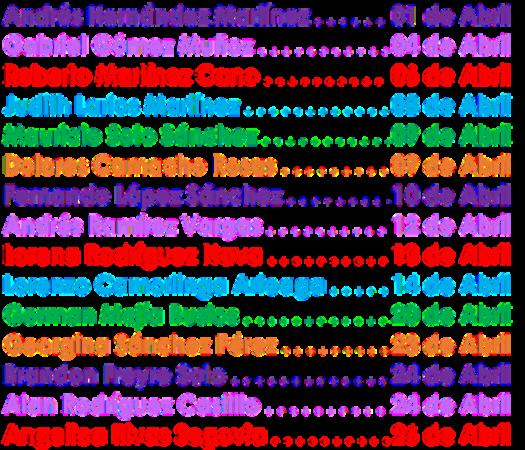

On April 25th and 26th, Plastek Mexico held a Children's Day celebration that was well-attended and greatly enjoyed by all employees. The event included a variety of activities designed to entertain the children while also providing them with insight into their parents' roles within the company.

Upon arrival, the children were greeted by Dr. Pedro Coto and Mr. Alberto Borrajo, General Manager. They were welcomed and provided with information about the company and the products manufactured by Plastek Mexico.

Yanet Nava, the SHE Manager, provided an overview of the importance of fire safety, while Dr. Pedro Coto offered a brief introduction to first aid. Furthermore, the children had the opportunity to interact with paramedics and firefighters, who provided them with a first-hand experience of fire trucks and ambulances.

The event proved an invaluable learning experience for the children, who gained insight into the crucial role of firefighters and paramedics. The children expressed interest in the tools and equipment used and how to act in specific situations.

The specialists were available to clarify any doubts the children may have had. In addition to gaining insight into the role of firefighters and paramedics, the children also had the opportunity to learn about the materials used to manufacture the parts at Plastek. The children were given a guided tour of the plant's facilities, accompanied by their parents, during which they learned about the manufacturing process. At the conclusion of the event, a small gathering was held where the children, visibly enthusiastic, shared their experiences with their parents.

By Estrella Becerril

In observance of Father's Day at PLASTEK, a special event was held to honor all the fathers in our company.

We extend an invitation to all fathers to visit our premises to receive a gift in recognition of their commitment and dedication as fathers.

We recognize that being a father is a significant responsibility, and we want to acknowledge the balance you maintain between your professional and personal lives.

Every father at PLASTEK is a vital member of his family and an indispensable asset to our organization. We would like to express our gratitude for their contributions and the positive impact they have on our organization and the work community. The gifts we have prepared are a modest expression of our appreciation, and we hope you will enjoy them. We would like to extend our best wishes to all fathers at PLASTEK on this Father's Day. We would like to express our gratitude for your invaluable contribution and for being a constant source of inspiration to all of us. We wish you all a wonderful day!

By Estrella Becerril

We recognize the significance of Mother's Day as a unique opportunity to acknowledge the exceptional commitment and affection demonstrated by mothers across the globe. We cordially invite all mothers to visit our establishment to receive a complimentary gift in appreciation of their invaluable contributions. The role of motherhood extends beyond the biological. It is an act of love, sacrifice, and guidance that shapes lives and strengthens families. We recognize the invaluable contribution mothers make to our lives and communities. From their capacity to heal with a hug to their ability to educate with patience and wisdom, every mother is an everyday hero. Their presence nurtures, protects, and encourages everyone to reach their full potential.

On this special day, we reflect on the importance of expressing our appreciation and love to the moms around us. Every smile they brighten, every tear they comfort, and every dream they make possible, deserves to be celebrated with gratitude and joy. To all moms at PLASTEK and beyond, Happy Mother's Day!

THIS IS A LETTER FROM A SON TO HIS PARENTS.

DearMomandDad,

I want to honor you today because I know how hard you've worked and how much you love me. You are the pillars of my life, guiding me with wisdom and tenderness. Your sacrifice and constant support have shaped and strengthened me. Through every challenge and joy, your presence is a beacon of hope and comfort. I am so grateful to have you as my first teachers, models of virtue and generosity. Today and always, I will celebrate your invaluable influence in my life. I love you so much and am eternally grateful forallyoudoforme!

By Nancy Reyes

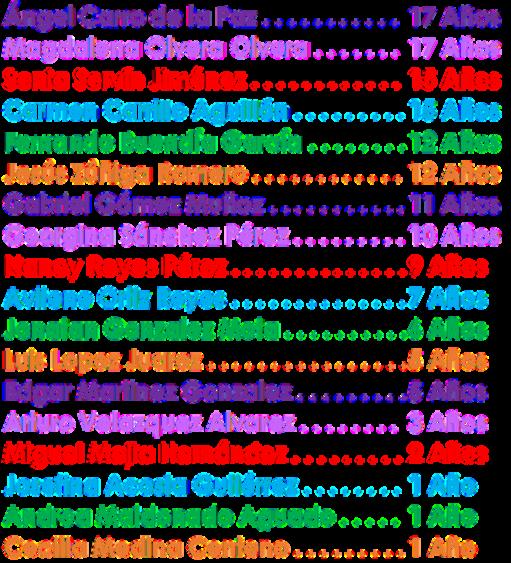

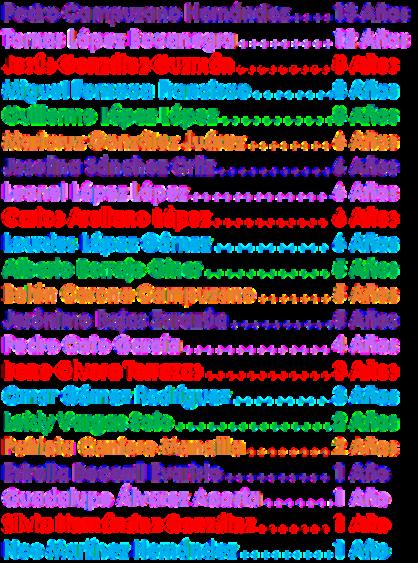

In a gesture that exemplifies the company's commitment to social responsibility, Plastek Mexico's employees have once again demonstrated their generosity by supporting the noble cause of Banco de Tapitas A.C. Through the collective effort and dedication to responsibly dispose of their plastic caps in the designated containers located in the canteens of plant 1 and plant 2, an impressive 38,600 kg of caps were collected.

This initial substantial delivery not only exemplifies Plastek Mexico's dedication to environmental stewardship through selective plastic collection but also illustrates the significant impact it has on the community.

The proceeds from the sale of the caps will be donated to a worthy cause: supporting children with cancer.

worthy cause: supporting children with cancer. This is a noble cause that provides vital support to those who need it most.

The Banco de Tapitas A.C. has distinguished itself through its relentless efforts in collecting plastic caps for the purpose of financing treatments and providing support for children and young people battling cancer.

The collection of bottle caps represents a tangible contribution to the advancement of hope and the enhancement of the quality of life for these courageous warriors. The success of this campaign would not have been possible without the active and enthusiastic participation of all Plastek Mexico employees. Their dedication to waste separation and environmental stewardship has enabled us to transform everyday actions into a meaningful contribution to our community.

We encourage all employees to continue supporting this initiative by depositing their bottle caps in the designated containers at our facilities. Every bottle cap is important, and every contribution makes a difference in the fight against childhood cancer. Let us continue to set an example of solidarity and community commitment. By working together, we can make a meaningful impact in the lives of many children and young people who need our support.

By Estrella Becerril

state of the company and reviews the strategic plan. Dennis discusses the strategic plan, which is designed to drive the company's growth and profitability over the next five years.

He emphasizes the importance of transparency, customer focus, sustainability, dfcd

Over the past few months, we have shared an invitation for Plastek employees to ask questions of our CEO, Dennis J. Prischak.

During June and part of July, we received the annual report in which Dennis J. Prischak answered each question.

In his video address, Dennis Prischak, President and CEO of Plastek, discusses the dddfdf

innovation, and profitability in the company's business model.

He also highlights the company's mission, vision, values, and strategic goals, emphasizing the need to maintain a sustainable and customer-focused approach for long-term success.

By Estrella Becerril

In recent months, we have conducted a series of key outreach sessions as part of our annual training plan at Plastek. These sessions addressed essential topics such as NOM-006, NOM-030 and NOM-026, ensuring compliance and safety in our labor practices. Training was also offered on the safe handling of substances, electrical installations, pest control, sdssdsdsd

noise control and ergonomics, ensuring a healthy and efficient work environment. In addition, topics such as knowledge of the collective bargaining agreement and effective conflict management were addressed. These sessions not only provided essential information, but also offered practical strategies to apply in our day-today work.

We would like to extend an invitation to all employees to actively participate in our upcoming outreach. Your participation is critical to strengthening our collective knowledge and ensuring that Plastek remains a safe and productive workplace. Together, we can continue to improve and successfully achieve our goals.

By Estrella Becerril

We are pleased to announce that Luis Fernando Juárez Maya has been recognized for successfully completing his Technical Superior University Degree (TSU) in Refrigeration and Air Conditioning. This accomplishment is a testament to his dedication, effort, and commitment to professional and personal development.

Luis Fernando has demonstrated an exceptional ability to balance his work and academic responsibilities, excelling in both areas. His success not only reflects his tenacity and skills, but also inspires his peers to pursue their own educational and professional goals.

On behalf of the entire Plastek team, we would like to congratulate Luis Fernando on this important milestone in his career. We are confident that his knowledge and experience will be a valuable asset to our team and will contribute significantly to our goals.

Congratulations, Luis Fernando, and we wish you continued success!

By Estrella Becerril

To enhance the professional development of our warehouse team, a specialized forklift course was recently conducted. The course enabled participants to enhance their operational abilities while also developing their potential as future instructors. The curriculum covered best practices for safe and efficient forklift operation, as well as preventive maintenance techniques. Additionally, the course equipped the warehouse team with pedagogical tools to facilitate effective and confident training of new team members. The training program included both practical and theoretical components, ensuring a comprehensive understanding of the technical and safety aspects.

This comprehensive approach ensures that our employees not only demonstrate proficiency in operating forklifts, but also possess the ability to effectively transfer this knowledge to others.

We are confident that these new instructors will bring valuable expertise to our team and look forward to seeing the benefits of this course reflected in our daily operations.

By Estrella Becerril

The essential fire brigade and first aid courses were recently conducted. In addition to current members of the fire brigade, personnel from various departments also participated in these courses. This initiative enabled employees to gain valuable knowledge that they can apply in both their professional and personal lives. The fire brigade courses were designed to impart knowledge and skills related to fire prevention and management.

and the implementation of safe evacuation procedures.

These skills are essential to maintaining a safe working environment at Plastek.

They help to minimise the risk of incidents and ensure an effective response in the event of an emergency. Furthermore, the first aid course provided training in the immediate care of injuries and medical emergencies.

Participants were instructed in the proper use of fire extinguishers, the identification of potential hazards, sdsd

Participants received instruction in cardiopulmonary resuscitation (CPR) techniques, wound management, fracture care, and other crucial lifesaving procedures.

First aid training is an invaluable skill that can make a critical difference in both work and home situations.

The importance of these courses cannot be underestimated. At Plastek, we are committed to the safety and well-being of our employees.

Fire and first aid training not only prepares our employees to handle emergencies in the workplace, but also provides them with skills they can apply in their daily lives. This knowledge is essential to creating a safer and more prepared environment, benefiting both our company and the community at large.

We thank all participants for their enthusiasm and commitment to these courses. Their dedication to safety and continuous learning strengthens Plastek and promotes a safer work environment for everyone. We will continue to promote these trainings to ensure that all our employees are well prepared for any eventuality.

In today's business environment, it is imperative that we provide our employees with the necessary training to ensure the continued success and sustainability of our organization. Training allows us to maintain our competitive advantage by ensuring that our employees acquire the new skills and knowledge required to work more efficiently and effectively.

Sonia Guadalupe Servín is currently undergoing metrology training in preparation for a role as a metrologist in the Tool Shop, following 15 years of valuable contribution to Plastek.

By Alfonso Alba

We are pleased to announce that Benjamin Martinez, Roberto Martinez, and Diego Lopez have joined the Plastek team as our newest collaborators. Benjamin is undergoing training with Leandro Seabra and Fabiano Davanso in the programming and operation of 5-axis machines. Roberto is acquiring expertise in the operation and handling of 5-axis machines under the guidance of Leandro Seabra. Diego is enhancing his proficiency in programming and post-processing for 5-axis machines. This specialized training is essential for those looking to gain expertise in programming and machining management. The Plastek Mexico team extends its gratitude to Plastek Brazil for providing this invaluable training opportunity and for their collaboration on this pivotal project, namely the design and manufacture of plastic injection molds.

The precision and efficiency with which new machines are started up not only ensures the quality of the final product, but also makes the difference between a smooth start-up and possible complications.

Recently, in a toothbrush production plant (Colgate) in Guatemala, there was an experience that stood out for its success and efficiency: the collaboration of the Process Control team of Plastek Group Mexico.

By Nancy Reyes

From the very beginning of the project, the Process Control team was closely involved to ensure that the toothbrush molding machine would start up smoothly and meet the expected quality and efficiency standards. The visit of the team, consisting of Fernando Buendía, Felipe Torres and Vicente Galicia, was crucial.

They provided real-time technical support during the installation and setup of the machine, as well as hands-on training for local personnel. This ensured a smooth start-up and enabled the team to face future challenges autonomously. The experience in Guatemala demonstrated operational efficiency, collaboration and professionalism that exceeded expectations and ensured the success of the project.

By Estrella Becerril

During the month of June, on June 19 and 20, we received a visit from the BRCGS Standard Auditor to our facilities. This event marked an important milestone in our ongoing commitment to quality and safety in our processes.

We would like to congratulate all the employees who prepared and supported us with their dedication and efforts to improve their work areas. Their hard work and cooperation was evident during the audit and reflects the high level of commitment and professionalism that characterizes our team.

While we await the official results, we want to highlight and celebrate the active participation of each and every one of you. Your contribution is fundamental to maintaining and improving our standards and ensuring that we meet the requirements of the standard.

We deeply appreciate the collective effort and proactive attitude demonstrated during these crucial days. Regardless of the final outcome, which we hope will be positive, it is important to recognize and appreciate everyone's work. Let us continue to work together to maintain and improve our quality and safety standards.

By Estrella Becerril

We would like to congratulate all the participants for their dedication and hard work. Your commitment to quality and excellence was impressive.

Guadalupe Sánchez Velázquez

Margarita Duarte Hernández

Ricardo Robles López

Leticia Moya Hernández

Norma Acosta Olvera

Remember, you have already earned 5 points just for participating, and you will continue to earn points until you complete your final evaluation. This program is not only an opportunity to be recognized, but also to continually improve our skills and contributions to the company.

Do not hesitate to ask for assistance from your manager or the program sponsors: Ruben Avendaño, Scarleth Rabling, Cynthia Tellez and Enrique Lopez. They will be happy to assist you with the registration process and any questions you may have.

Thank you all for your hard work and dedication. Together we will continue to raise the bar in everything we do, so congratulations to all of you and let's keep striving for excellence!

By Yanet Nava

In 2024, Planta 1 completed a major renovation to significantly improve the security and functionality of its facilities. The project began in February with the construction of a new guard house in the parking lot, which was completed and inaugurated on May 2. This booth has improved access control for both employees and visitors, enhancing the overall security of the site.

At the same time, a perimeter fence was installed to further enhance security and provide an additional barrier against unauthorized access.

A critical part of the renovation was the complete resurfacing of the maneuvering yard, which was completed in June.

This resurfacing not only improved safety conditions for forklifts, but also reduced the risk of contamination of stored and transported products, contributing to a cleaner and safer environment.

In addition, a new eightspace parking lot for suppliers and contractors was built on Jurica Street.

This has facilitated workflow by eliminating congestion in the main parking lot, improving operational efficiency.

The facility is in the final stages of construction of a maneuvering yard gate, which is scheduled for completion in midJuly.

This gate will complement the security measures already in place and provide even more stringent and efficient access control.

These renovations have not only enhanced the safety of the work environment at Planta 1, but have also significantly improved its image and functionality.

These efforts reflect a continued commitment to excellence, safety and protection of both facilities and finished products, ensuring a safe and efficient working environment for all involved.