03. Guest comment

Kimberly-Joy Harris, Board Chair, Association for Materials Protection and Performance (AMPP).

05. Editor's comment

FIELD JOINT COATINGS

06. Coating colder

Dr. Jeffrey David Rogozinski, Sherwin-Williams Protective & Marine, USA.

LEAKS AND EMISSIONS

14. Significant strides in methane reduction

Daniel Kashmir, CEO and Co-Founder, Momentick.

HYDROGEN BLENDING AND INTEGRITY

19. The mixing pot

Nigel Curson, Executive Vice President of Technical Excellence, Penspen, and João Lemos Pinto, Head of Gas Engineering, REN Gasodutos, S.A.

MIDSTREAM DATA

23. Unlocking sea state insights Chris Moncrieff, Miros.

ILI AND INSPECTION

28. Validation of ILI performance using in-field data

Tom Oldfield, Service Manager – In-Field Verification, ROSEN Group.

CHEMICALS AND INTEGRITY

33. Fighting corrosion with chemical expertise

Catherine Rowley-Williams, OMMICA Ltd, Scotland.

COVER STORY

37. Integrity is integral

Christian Araiz y Lopez and Mark Kan, DENSO Group Germany.

PIPELINE COATINGS

43. Pioneering pipeline repairs

Gareth Urukalo, Technical Authority, and Ross McHardy, Chief Operating Officer, ICR Group, UK.

47. Simply solvent-free Martin Mehler, Teknos Germany.

ISOLATION AND INTERVENTION

53. Redefining pipeline intervention Garry Kidd, Managing Director, Wellube.

without an additional primer or equipment. SEALID® All-in-1 is wrapped just once and offers patented safety fulfilling ISO 21809-3 and EN 12068. sealid.com

Kimberly-Joy Harris Board Chair, Association for Materials Protection and Performance (AMPP)

The pipeline industry is indispensable in delivering the world’s energy resources efficiently and safely. As global demand grows and infrastructure ages, ensuring the safety and longevity of pipelines is more critical than ever. Industry standards are pivotal in addressing these challenges, offering a framework to ensure best practices are followed, risks are minimised, and the industry is prepared for future demands. This is where the Association for Materials Protection and Performance (AMPP) plays a vital role.

As Chair of AMPP’s Board of Directors, I oversee developments that impact our members and the broader pipeline industry. One of our proudest achievements has been providing our members with access to AMPP standards as part of their membership. These standards, created through the expertise of leading professionals in materials protection, corrosion prevention, and coatings, are the foundation for maintaining pipeline integrity.

Standards provide consistency, reliability, and safety throughout a pipeline’s lifecycle – from design and construction to maintenance and decommissioning. Pipelines operate under extreme conditions, including harsh weather, chemical exposure, and mechanical stress. Without proper guidelines, the risks of corrosion and failure increase significantly, leading to potential environmental disasters and economic losses.

AMPP has a long-standing history of developing and maintaining technical standards that promote safety and efficiency within the pipeline sector. Our pipeline-specific standards, such as SP0169, which outlines cathodic protection criteria, and SP0102, which focuses on inline inspection, are cornerstones in the industry. These standards result from years of collaboration between engineers, researchers, and industry experts who deeply understand the materials and challenges pipelines face.

This year, AMPP’s standards took on even greater importance with the release of our Guide 21569-2024, Guidance on Implementing Corrosion Control Methodologies to Align with New PHMSA Regulatory Procedures. In response to the US Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) revised pipeline safety regulations, this guide offers a detailed roadmap for operators to implement corrosion control requirements for onshore gas transmission, aligning with Part 2 of PHMSA’s Gas Mega Rule.

This guide complements our existing standards and provides operators with the tools they need to meet regulatory expectations and industry best practices, enhancing pipelines’ overall safety and integrity.

AMPP’s standards have always been pivotal in reinforcing pipeline integrity, particularly in corrosion prevention, and supporting safety protocols that benefit operators, regulators, and the public. For example, our emphasis on cathodic protection systems helps extend pipeline lifespans, improve operational efficiency, and prevent costly failures. With PHMSA’s recent guidance updates, it is clear that corrosion control and risk management strategies will remain top priorities for regulators.

In addition to standards, AMPP continues to provide training and certification programmes, ensuring that pipeline professionals have the skills to apply these standards effectively. These programmes ensure operators across the industry are equipped with the latest tools and knowledge to meet AMPP’s high standards for safety, integrity, and risk management.

At AMPP, we believe that by aligning with global regulatory bodies and fostering a culture of compliance and innovation, we can ensure the integrity and reliability of pipelines worldwide. We can meet today’s challenges and prepare for tomorrow’s needs through collaboration and adherence to the highest standards. Learn more at ampp.org

MANAGING EDITOR

James Little james.little@palladianpublications.com

ASSISTANT EDITOR

Isabel Stagg isabel.stagg@palladianpublications.com

EDITORIAL ASSISTANT

Alfred Hamer alfred.hamer@palladianpublications.com

SALES DIRECTOR

Rod Hardy rod.hardy@palladianpublications.com

SALES MANAGER

Chris Lethbridge chris.lethbridge@palladianpublications.com

SALES EXECUTIVE

Daniel Farr daniel.farr@palladianpublications.com

PRODUCTION DESIGNER

Amy Babington amy.babington@palladianpublications.com

HEAD OF EVENTS

Louise Cameron louise.cameron@palladianpublications.com

DIGITAL EVENTS COORDINATOR

Merili Jurivete merili.jurivete@palladianpublications.com

DIGITAL CONTENT COORDINATOR

Kristian Ilasko kristian.ilasko@palladianpublications.com

JUNIOR VIDEO ASSISTANT

Amélie Meury-Cashman amelie.meury-cashman@palladianpublications. com

DIGITAL ADMINISTRATOR

Nicole Harman-Smith nicole.harman-smith@palladianpublications.com

ADMINISTRATION MANAGER

Laura White laura.white@palladianpublications.com

Palladian Publications Ltd, 15 South Street, Farnham, Surrey, GU9 7QU, UK

Tel: +44 (0) 1252 718 999

Website: www.worldpipelines.com Email: enquiries@worldpipelines.com

Annual subscription £60 UK including postage/£75 overseas (postage airmail). Special two year discounted rate: £96 UK including postage/£120 overseas (postage airmail). Claims for non receipt of issues must be made within three months of publication of the issue or they will not be honoured without charge.

Applicable only to USA & Canada: World Pipelines (ISSN No: 1472-7390, USPS No: 020-988) is published monthly by Palladian Publications Ltd, GBR and distributed in the USA by Asendia USA, 701C Ashland Avenue, Folcroft, PA 19032. Periodicals postage paid at Philadelphia, PA & additional mailing offices. POSTMASTER: send address changes to World Pipelines, 701C Ashland Avenue, Folcroft, PA 19032

SENIOR EDITOR Elizabeth Corner elizabeth.corner@palladianpublications.com

The annual Integrity issue of World Pipelines tends, by its very nature, to look to the future of the pipeline sector. Keeping the world’s oil and gas pipelines safe, secure and operational for the decades ahead requires a host of moving parts, and in this special issue we look at innovative coating technologies, emissions reduction strategies, gathering midstream data, validating pipeline inspection data, the use of chemicals to fight corrosion, pipeline repairs, pipeline intervention works, and the safe transport of future fuels.

As the pipeline industry works to ensure the integrity of pipelines, both existing and new, governments around the globe are making choices about how to manage their pipeline assets, with varying degrees of ingenuity and foresight.

In the UK, the Forties Pipeline System, which links over 80 offshore oil and gas fields to the UK mainland, could potentially shut down by 2030 if plans to extend the windfall tax dampen investment. Ineos acquired the pipelines from bp in 2017 and had previously pledged £500 million to maintain operations into the 2040s. However, according to UK press, the government’s proposal to reduce North Sea capital and investment allowances could instead lead to the system’s early decommissioning. Andrew Gardner, Chief Executive of Ineos Forties Pipeline System, stated, “Back in 2017, we told our customers and workforce we’d operate [until] 2040 or beyond, because the amounts of hydrocarbons still left in the ground meant the oil and gas would keep flowing…But if Labour’s tax policy stops our customers offsetting their drilling and other investment costs against tax, then volumes will shrink – and we’re looking at 2030 - 2035 as a more likely end date.”

In Germany, the government’s Federal Network Agency has approved its proposed “core network” of hydrogen pipelines, set to stretch across the country by 2032, with first hydrogen flow in 2025. An investment of €18.9 billion will create the largest hydrogen network in Europe, and solidifies Germany’s commitment to hydrogen production, consumption, storage and import.

In the US, the government is set to provide US$196 million in grants to repair and replace ageing natural gas pipelines across 20 states, as announced by the Department of Transportation’s Pipeline and Hazardous Materials Safety Administration in October. Funded through President Joe Biden’s Bipartisan Infrastructure Law, these grants will support 60 modernisation projects. This funding round targets the replacement of outdated, leak-prone pipelines that create safety risks, increase energy costs, and contribute to environmental damage.

With regards to new pipeline infrastructure in the US, executives from two major energy pipeline operators have stated that they do not plan to build new crude oil pipelines from the Permian shale field in West Texas, due to slow volume growth and challenges with new construction. At an energy conference in Houston in October, Enterprise Products Partners’ co-CEO Jim Teague said his company is not considering a new oil pipeline from West Texas, while Plains All American Pipeline’s CEO noted that companies are more likely to optimise current pipelines than build new ones.

The executives noted that Permian shale producers are unlikely to revisit the rapid growth that spurred pipeline construction in the last decade. The industry’s cautious approach here reflects the global challenges and evolving market dynamics that are reshaping not only US oil production but also the fundamental structure of how oil is transported and traded internationally.

The oil and gas pipeline industry is navigating a complex and evolving landscape where optimism is tempered by a recognition of the various challenges and changes that will reshape its future.

1. Preparing the surface of welded areas for coating applications involves blasting away rust and contaminants while creating a suitable profile for coating adhesion.

Dr. Jeffrey David Rogozinski, Sherwin-Williams Protective & Marine, USA, highlights the benefits of using low-application temperature fusion-bonded epoxy coatings.

The process of coating pipeline girth welds in the field has its share of familiar challenges – site access issues for personnel and equipment, variable weather conditions and the task of choosing the optimal materials for the job, for example.

Extreme cold temperatures make the process that much more challenging – not to mention inefficient, as pipes being coated must be heated and the application environment must be contained to block out the elements. That’s true whether using a liquid epoxy or a powdered fusion-bonded epoxy (FBE) coating. Liquid applications in cold conditions require pipe preheating, likely followed by a heated cure to ensure the material bonds to the substrate. Powdered applications also require preheating. However, the material cures nearly immediately to the appropriate hardness, allowing inspections and backfilling to take place sooner.

Powdered FBEs can also offer performance benefits compared to liquid epoxies. For example, field-applied FBEs offer better adhesion to pipe substrates and greater integrity with the mainline FBE coatings applied to pipes before they arrive at the installation site (Figure 2).

With powdered FBE girth weld coating applications typically being performed via automated methods, application consistency is also improved, as the potential for human error is nearly eliminated from the process.

The benefits of speed, performance and consistency afforded by automated powdered FBE applications prompted KEYMAY Industries to adopt this method years ago for a majority of the girth weld coating applications the company performs. However, the trusted supplier and service provider to the pipeline and civil construction industries had been experiencing inefficiencies with this method, particularly in extremely cold conditions.

Looking for an alternative, KEYMAY approached SherwinWilliams Protective & Marine wondering if it would be possible to apply powdered FBEs on girth welds at a lower temperature than what’s required for conventional FBEs. The resulting development of a low-application temperature (LAT) FBE formulation, known as PipeClad® 2000 LAT, has given KEYMAY a solution that requires 85°F less heat, leading to lower heating costs, reduced emissions and other benefits. Since adopting the LAT FBE solution, including additional duallayer formulations that minimise coating damage and moisture uptake, KEYMAY has used its automated equipment to coat more than 50 000 girth welds with LAT FBEs – and has done so with less than a 1% repair rate.

The process for coating girth welds begins the same – with surface preparation – whether applicators are using powdered or liquid coatings. Following confirmation of a sound pipe weld, applicators will wipe a solvent over the area and then use a blasting media to remove any residual rust and create a profile on the new weld (Figure 1). Cleaning and inspections follow.

For automated girth weld coating, operators will place an induction heat coil over the prepared weld to heat the area to the appropriate application temperature (Figure 3). Next, operators will remove the induction coil and either place an insulated clamshell over the area to retain heat or immediately attach an automated coating applicator over the weld area to spray the FBE powder.

The automated applicator unit rotates around the weld, spraying powdered FBE a calculated number of times to achieve the appropriate coating thickness (Figure 4). The powdered material melts instantaneously on the heated pipe, changing into a liquid that flows easily into the blasting profile and builds thickness before curing (Figure 5). As it cures, the coating creates a monolithic interface from the steel substrate to the outer surface, as well as to the adjacent coating materials applied to the pipe in the shop (Figure 6).

Due to the automated unit’s controlled application parameters, the monolithic barrier will have minimal to no voids in the coating that could lead to premature failure. The process and results are the same whether applying only the traditional green FBE powder, which provides anti-corrosion properties, or creating a dual-layer system comprising a base layer of green FBE powder and a topcoat of a red FBE powder designed for durability. Sprayed immediately after the green powder while the pipe is still hot, the red abrasion-resistant overcoat (ARO) resists the scratches and scrapes a pipe may encounter from handling to installation, including the rigours of horizontal directional drilling (HDD) and backfilling. The ARO layer also serves as a moisture barrier.

Following applications, operators will unclamp the automated coating unit and move it down the line where the next welds have already been prepared and heated.

“Our personnel prefer to use automated FBE applications whenever possible for pipeline girth weld projects due to the efficiency and consistency of applications,” noted Tara Chahl, Field Service Manager for KEYMAY.

Inspections close out the process, with applicators confirming the applied coating thickness via ultrasonic testing (Figure 7). Before backfilling, they’ll also run a holiday detector brush over the entire welded area – and the rest of the pipe – watching for any sparks that indicate a pinhole, void or insufficient coating thickness to be repaired.

Realising enhanced outcomes with LAT FBEs

Featuring novel and proprietary technology, LAT FBE powders melt and flow at significantly lower temperatures than other FBEs. Installers only need to heat welded pipe sections to

about 365°F (185°C) for LAT FBE applications compared to 450°F (232°C) or higher for conventional applications – a difference of 85°F or 47°C. This advantage significantly reduces energy costs for heating sections of joined pipe for coating applications. It also helps crews move faster, with less heating time required per weld.

Most importantly, the lower heat requirements for LAT FBEs compared to traditional FBEs mitigate three issues related to higher-temperature applications – the potential to damage coatings already applied to pipes, moisture challenges and pipe heat retention. Clamping an induction unit on the pipe and heating the metal to 450°F or higher runs the risk of burning and blistering the parent coating that was applied at the shop. Higher pipe temperatures in colder ambient conditions also introduce the potential for condensation to interfere with coating applications. Finally, pipes with thinner wall thicknesses can be hard to heat to high enough temperatures to consistently melt conventional powdered FBE coatings.

The automated application process for either LAT or conventional FBEs is faster than liquid applications, with an automated spray head applying a proper coating thickness in less than a minute. This speed enables additional cost savings, as less coating-related labour hours are required over the course of a pipeline project between the lower heating requirements and faster applications enabled by LAT FBEs.

Additionally, the cure time for powdered FBEs to reach the proper hardness value following application is near instantaneous. As soon as a powder application is done, installers can inspect the pipe and bury it if no repairs are needed. With liquid applications, installers must wait for the coating to fully cure. That could take a few hours or longer depending on ambient conditions and may require costly heat treating.

Application consistency is also enhanced when performing automated FBE applications compared to hand applying liquid epoxies. The automated spraying apparatus manages a number of variables, including the heat of the pipe, the dewpoint temperature, the material being used and the speed of the spray head to determine the precise number of rotations and powder volume needed to reach the appropriate final coating dry film thickness (DFT).

“When manually brushing and rolling liquid epoxies, more repairs are typically needed afterwards to correct high and low spots,” noted Chahl. “With automated powder applications, we’ve realised a less than 1% repair rate across tens of thousands of girth welds. In addition, applicators using automated equipment do not experience the mixing fatigue that is common when using liquid materials, further reducing the potential for error.”

FBE powder coatings also offer better adhesion and integrity with the mainline FBE coating compared to liquid epoxies. Pipes being welded in the field arrive with powdered FBE already applied to the majority of their surface, except for a 4 in. cutback on each end to enable welding to take place without blistering the applied coatings. This entire area is coated following girth welding. By using the same type of powdered FBE for the girth weld, a continuity of like coating materials exists, providing a strong bonding matrix that exceeds the tensile strength of the pipe. A liquid epoxy used on a girth

weld won’t have quite as strong of a cohesive bond with the mainline FBE.

Whether performed at low or high application temperatures in the field, powdered FBE girth weld applications offer a sustainability advantage over liquid epoxies in terms of waste produced. Any excess powder used during applications is vacuum collected during the process, keeping it out of the environment, while also enabling the material to be recycled for another project.

With liquid epoxy applications, waste adds up quickly. Each weld requires an applicator to don a protective painting suit, mix a new batch of coating material, use a container for that material and apply it with a brush and roller. For a 56 mile (90 km) pipeline project, KEYMAY calculated that waste to comprise roughly 600 bags of garbage filled with about 800 protective suits, 4200 coating kits, 8400 single-use paint brushes and 8400 short-nap rollers.

“Using powdered FBEs for girth welds is much more environmentally friendly than using liquid epoxies,” said Chahl. “That’s true not just in terms of waste, but also related to the solvents required to clean equipment used for liquid applications.”

When projects use LAT FBEs instead of traditional powders, environmental impacts are further reduced. For example, the lower-temperature requirement for coating girth welds reduces diesel fuel consumption and the associated emissions for each weld.

KEYMAY’s question about developing a LAT FBE kicked off a multi-year research and development project for SherwinWilliams Protective & Marine. Lab personnel manipulated paint molecules to enable powdered FBE material to melt at lower temperatures and then turned to lab and field testing to prove the performance.

KEYMAY participated in field trials, applying the new material and performing various tests to confirm the coating

adhered to pipe substrates as well as the conventional FBEs the company had been using. Certifications of the coating with key standards organisations followed, enabling KEYMAY to begin using the technology.

The first opportunity was for the 357 mile (575 km) Key Access Pipeline System (KAPS) that moves natural gas liquids (NGLs) and condensate through Alberta’s Industrial Heartland in northern Canada. KEYMAY successfully completed more than 35 000 girth weld coatings using the automated LAT FBE application process for the pipeline (Figure 8). That includes about 10% of the pipe length featuring dual-layer LAT FBE applications, as those sections required an ARO coating to mitigate any damage associated with their installation via HDD.

“Applications for the KAPS project took place during the cold winter months,” noted Chahl, “It was much more optimal to be able to heat the pipe to lower temperatures by using LAT FBEs. That was a game changer for us on this project.”

During the same time period, KEYMAY also performed LAT FBE applications on the Wolf Midstream NGL Pipeline Project in Conklin, Alberta. There, the company completed 15 000 girth weld coatings on 168 miles (270 km) of pipe using the new material.

“Powdered LAT FBE coatings work very well for long pipeline installations,” said Chahl. “Applicators are able to continue running and gunning the entire day, typically completing 1.5 - 2 miles [2.4 - 3.2 km] of pipe per day, depending on the pipe diameter and wall thickness, site access and environmental conditions. That pace means coating 10 - 12 joints per hour over a 10 hour shift.”

On the KAPS project, mainline crews working in the summer months were even reaching 140 automated girth weld coatings per shift at times. Surprisingly, wintertime obstacles associated with site access and weather conditions only brought that pace down to 100 - 120 coated welds per day.

For the Wolf project, which had a smaller crew, installers completed about 80 automated LAT FBE girth weld coatings per day. That pace was higher than the daily productivity expectations of 65 welds, proving that a smaller crew can maintain a healthy pace using the LAT FBE material. For comparison, crews applying liquid girth weld coatings on other sections of the pipeline were only hitting about 55 completions per day.

KEYMAY’s thought to consider a lower temperature for automated FBE applications has paid off, with more than 50 000 LAT FBE girth weld coating applications completed to date since 2020 with only 1% of applications requiring any sort of coating repair. Sherwin-Williams successfully answered the company’s needs with a solution that has not only streamlined the coating process for KEYMAY but also delivered notable cost savings and performance benefits over conventional methods. The PipeClad LAT FBE coatings have significantly lowered energy costs and minimised emissions, while also enabling faster project completions without compromising quality.

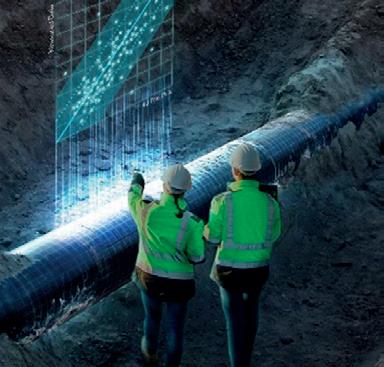

Daniel Kashmir, CEO and Co-Founder, Momentick, explores the key factors that complicate methane detection, its economic and environmental impacts, and the efforts needed to address this pressing issue.

In the oil and gas industry, midstream assets are significant sources of methane emissions, a potent greenhouse gas that contributes to climate change. Detecting and mitigating these emissions is essential for regulatory compliance and environmental protection.

Methane emissions present a significant challenge in the fight against climate change as detecting methane leaks is fraught with difficulties. This article explores the key factors that complicate methane detection, its economic and environmental impacts, and the efforts needed to address this pressing issue.

Methane detection is challenging for several reasons. Unlike CO 2 , methane is both colourless and odourless, making it difficult to identify without specialised equipment. Methane leaks can occur at multiple points along the oil and gas value chain, from extraction to storage, complicating detection efforts.

In the midstream sector, methane emissions can occur through leaks, venting, and equipment malfunctions. The vast and often remote nature of these assets makes it challenging to monitor and control emissions effectively. Traditional methods of methane detection, such as manual inspections and fixed-point sensors, are often labourintensive, costly, and limited in their ability to provide comprehensive coverage.

Many oil and gas infrastructures are situated in remote areas, making regular monitoring and leak detection difficult. Methane molecules are tiny and easily disperse, complicating detection in low concentrations or windy conditions. Existing detection technologies also have their drawbacks. For instance, other technologies only provide ongoing binary data or alerts, without the ability to quantify and make actionable insight for decision makers, making it difficult to quantify total methane emissions over time.

Undetected and unmonitored methane emissions cost the energy sector an estimated US$60 billion annually. Combined with the exposure to increasing regulatory taxation in the US and Europe, this price tag is further compounded. A 2018 study found a methane leakage rate of 2.3% from oil and gas operations. Capturing and selling this methane could increase natural gas producers’ revenues by an estimated US$188 million/y.

Pipeline leaks play a crucial role in this. According to the Environmental Defense Fund (EDF), only 7% of nearly 500 000 miles of oil and gas pipelines in the US are subject to leak inspections. They estimate that there are between 1.25 - 2.6 million tpy of methane being emitted from pipelines.

Undetected emissions pose a significant challenge due to the unknown quantities. In the US alone, with over 3 million miles of pipelines, less than 10% of gathering and transmission pipelines undergo regular leak inspections. This results in methane leaks estimated to be 60% higher than official EPA figures. Approximately 630 000 leaks in US natural gas distribution pipelines emit methane, leading to significant financial losses and global warming. The lack of accurate data hampers efforts by industry stakeholders, governments, international bodies, and financial institutions to address these emissions effectively.

In the US, a major pipeline gas leak is reported every 40 hours, three times a week. Studies estimate that leaks occur every 1.2 - 3.8 miles of pipeline, a conservative figure. With an extensive network of pipelines, transporting natural gas through infrastructure that averages 40 - 50 years old, monitoring and maintenance are critical. This issue is not confined to the US; natural gas pipelines around the world are very old and under maintained, exacerbating the problem. Satellites can play a crucial role in detecting emissions, especially along expansive and remote pipeline systems that are challenging to monitor in real time.

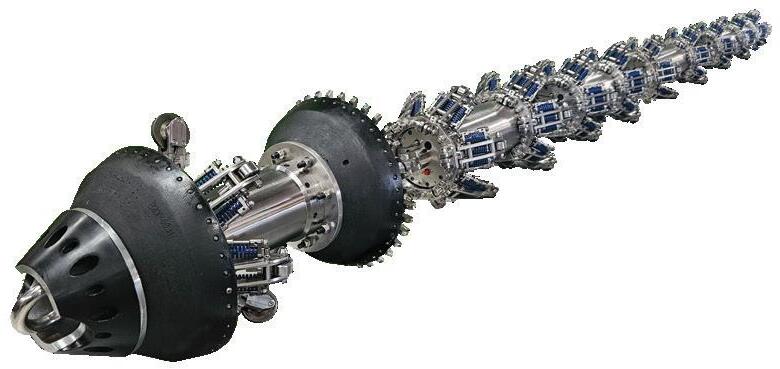

Unmatched accuracy in threat detection, characterization and sizing.

Now featuring Ultra Res MFL, the MDS™ Pro inline inspection system boasts increased sensor density, improving accuracy when detecting and sizing potential anomalies. Upgrade to Ultra Res and see what you’ve been missing.

A report by the EDF highlights the impact of monitoring frequency on emissions reduction: annual monitoring results in a 40% reduction, quarterly monitoring in a 60% reduction, and monthly monitoring in an 80% reduction. This report revealed a critical truth: more frequent detection of methane leaks significantly reduces emissions. Despite this knowledge, a recent 2024 report from the International Energy Agency (IEA) shows that natural gas emissions have steadily risen over the past decade.

Environmental impact of methane

Methane is a potent greenhouse gas, and the secondlargest contributor to climate change, with 60% of emissions stemming from human activities, particularly from the energy sector. In 2022, the global energy industry released 135 million t of methane.

One striking example is the recently detected methane super-emitters in Turkmenistan. Leaks from Turkmenistan’s two main fossil fuel fields caused more global warming in 2022 than the entire carbon emissions of the UK. Many other leaks worldwide remain undetected.

Governments and regulatory bodies worldwide are implementing stricter regulations to reduce methane emissions from the oil and gas sector. For instance, the United States Environmental Protection Agency (EPA) has set guidelines for detecting and repairing leaks, as well as reporting and mitigating emissions.

Moreover, reducing methane emissions can have economic benefits for oil and gas companies. Capturing

and utilising the leaked gas can improve overall efficiency and reduce waste, translating to cost savings and increased revenue. Additionally, demonstrating a commitment to environmental stewardship can enhance a company’s reputation and support its social licence to operate.

In the US, the Biden Administration has committed US$20 billion to reduce methane emissions. Announced at COP27, this plan includes 50 regulatory measures supported by significant new investments. The funding comes from the Bipartisan Infrastructure Law and the 2022 Inflation Reduction Act, which introduces a national methane emissions fee starting at US$900/t of methane in 2024, increasing to US$1500 in 2026.

The industry is also seeing increased collaboration between oil and gas companies, technology providers, and environmental organisations to tackle the issue of methane emissions. Initiatives such as the Oil and Gas Climate Initiative (OGCI) and the Methane Guiding Principles are bringing stakeholders together to share best practices, develop new technologies, and set ambitious targets for methane reduction.

The way forward: using satellites in methane monitoring

Effective detection of methane releases is crucial for implementing successful mitigation strategies. Achieving this challenging task sustainably and consistently requires integrating various approaches, including ground-based, airborne, and spaceborne detection and monitoring solutions. The latter leverages open-source satellite constellations, offering global coverage.

As satellites gain acceptance as a valid tool for detecting methane point-source emissions, their potential contribution to reducing global greenhouse gas emissions grows. Developing software solutions to process and utilise data from existing and future satellites is vital for the large-scale, continuous global detection and quantification of methane emissions. This step is essential for halting emissions.

Startups are at the forefront of innovations, empowering stakeholders to address methane emissions through evidence-based, data-driven decision-making. Their comprehensive emissions intelligence platforms enable scalable monitoring, reporting, and verification. By leveraging proprietary algorithms on satellite imagery, these platforms provide pinpoint monitoring for specific facilities and extensive area monitoring covering broad geographical regions or entire pipeline networks.

By enhancing detection capabilities and investing in advanced technologies, we can make significant strides in reducing methane emissions and mitigating their impact on climate change.

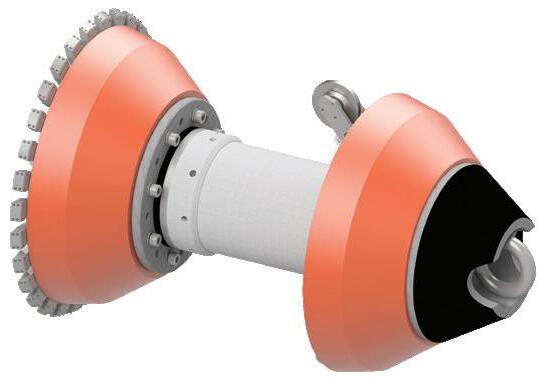

Nigel Curson, Executive Vice President of Technical Excellence, Penspen, and João Lemos Pinto, Head of Gas Engineering, REN Gasodutos, S.A., look at how advancements in direct injection technology may be the answer in scaling up hydrogen distribution for higher pressure environments.

lending natural gas with hydrogen is vital for meeting energy transition targets. Blending low-carbon hydrogen with other gases (primarily natural gas and biomethane) in pre-existing gas network infrastructure and appliances allows relatively direct access to a market for hydrogen from a wide range of geographic locations. It targets CO2 emissions associated with domestic and industrial consumption via existing connections. It reduces dependence on external energy sources whilst having a significant economic advantage of utilising predominately the same infrastructure and consumer equipment. This is evidenced by the fact that in the EU, 40% of households are connected to the gas network.1

Hydrogen can support decarbonisation, particularly in ‘hard to electrify’ sectors such as industrial heat. Hydrogen blending takes advantage of the many existing connections to the gas grid and creates a market for hydrogen with an export route for hydrogen producers and reduced production volume and investment risk. So, what’s the catch?

Until now, blending has only been trialled with medium-pressure, small-diameter public networks at relatively low volume flowrates for consumers, equivalent to a village. Indeed, UK blending trials have been part of the HyDeploy project, first occurring at Keele University on a private gas network, where 100 homes and 30 university buildings received the blended gas between November 2019 and March 2021. Several trials followed one near Winlaton near Gateshead in Northeast England, where 668 homes, a school, several small businesses, and a church were supplied with a 20% hydrogen blend. HyDeploy is now working with energyintensive industries to demonstrate 20% blends with glassmaking, ceramics manufacturing, and consumer products. Further afield, a 20% blend trial took place in Germany’s Erftstadt districts of Niederberg, Borr, and Friesheim, supplying 100 homes. At the end of 2023, the UK government announced it had decided to support blending up to 20% hydrogen by volume into the national gas distribution network.2

These first trials are significant and have proven hydrogen blending using a blending skid;3 however, scaling a skid concept up from medium-pressure distribution diameters to transmission diameters and high pressures (32 in. and 85 barg, respectively) would require significant investment with sizeable equipment and a potentially disruptive intervention.

Exploring blending technology

Enter Portugal. Compared with many European peers, Portugal is one of the leading countries in decarbonisation, with hydrogen planned to play a critical role. Portugal has set a goal for H2 to deliver 1.5 - 2% of Portugal’s final energy demand, with 10 - 15% provided by the existing natural gas network by 2030. REN Gasodutos, the incumbent gas transmission company in Portugal with Penspen, is assessing the challenges of blending hydrogen at multiple locations across the national network at the transmission level to facilitate this transition. REN Group is also evaluating blending across the distribution network of REN Portgás, a Distribution System Operator in the North of Portugal. Considerable economies can be obtained by injecting the hydrogen directly into the pipeline and using the pipeline itself as a mixer component. Transmission pipelines

are predominantly made of steel and operate at high stresses. Materials subject to these operating conditions can be sensitive to hydrogen, so to mitigate against this, there is a requirement to limit steel exposure to hydrogen/natural gas mixtures above predefined concentrations. Penspen and REN recognise that the challenges with using the pipeline as a mixer component are achieving adequate mixing within a reasonable number of diameters downstream from the injection point whilst not exposing the inside surface of the pipeline to unacceptable percentages of hydrogen. Additionally, designing a nozzle, or nozzles, that are practical from a manufacturing perspective, to allow inline inspection and which doesn’t introduce a structural weakness or have demanding construction or operational implications will be required to truly scale up blending.

Indeed, direct blending with simple 90˚ nozzles at the top and bottom of the pipeline has been studied before. University College London looked at injecting pure hydrogen using a single nozzle into a horizontal methane pipeline.4 They used Computational Fluid Dynamics (CFD) to understand the influence of blending and pipe geometry (diameter ratio, various 90° orientations) on mixing for a target of 4.8 - 20% volume fraction hydrogen blend. The results indicated that the low molecular mass of hydrogen reduces the penetration of hydrogen into the methane flow. Also, hydrogen’s buoyancy in natural gas (methane density is approximately eight times that of hydrogen) leads to stratification with high hydrogen concentrations on the upper pipe surface downstream of the branch.

Injection at the top leads to the hydrogen concentration remaining for up to eight pipe diameters from the injection point for volumetric dilutions less than 30%. Injection at the bottom promotes mixing within the pipeline and reduces wall concentration at the lower surface, compared to injection at the top.4 These studies showed that preventing the pipeline wall from being exposed to high concentrations of hydrogen when using a simple vertical nozzle at the top or bottom of the pipeline is unlikely to work.

The low molecular mass of hydrogen has two crucial effects on the injection process: the inertia of the injected gas stream is low, so penetration into the natural gas stream is limited, and the hydrogen buoyancy in natural gas tends to cause stratification. Both effects lead to higher hydrogen concentrations near the top section of the pipe.

With this in mind, Penspen and REN considered two further injection scenarios: three injection points equally placed circumferentially, one at 12 o’clock, one at 4 o’clock, and one at 8 o’clock, and a sparge pipe or injection quill located at 12 o’clock position. Several alternative experimental hydrogen blending configurations were tested, each evaluated using extensive analytical modelling using Computational Fluid Dynamics (CFD).

A natural gas pipeline with an inner diameter of 32 in. was modelled with three circumferentially arranged hydrogen nozzles, each 2 in. in diameter. The nozzles were placed three diameters downstream of the inlet, and the resulting flow field was analysed for a further pipe length of 8.44 pipe diameters. A single geometry was employed to model four blending

conditions with different, ideally mixed fractions. Two natural gas flowrates were tested with four typical hydrogen injection rates. The flow was modelled as a compressible gas mixture with a large eddy simulation (LES) approach to turbulence. With pressure in the natural gas pipeline at 83.5 barg, the computation was run for 10 sec. after allowing 25 sec. for the flow field to develop into a quasi-steady state.

Another model used a gas pipeline with an inner diameter of 32 in. but included a 2 in. cylindrical quill inserted at the top. The quill sparges hydrogen through several nozzles placed in the lower half of the sparge pipe.

The advantage of the injection quill is that it can be removed to inspect the quill itself. Inspection of the quill is necessary because injection quills, like thermowell, will shed vortices in a steady flow. This assists with mixing but also produces vibration, which can lead to fatigue damage. Several manufacturers have already produced retractable injection quills for chemical injection.

In the CFD model, the injection quill was set up with the same conditions as the three hydrogen nozzles, with one geometry employed to model flow conditions – a compressible gas mixture with a large eddy simulation approach to turbulence. The nozzle flows were modelled assuming that the flowrate is constant at all the nozzle exits, regardless of position.

In the case of three equally spaced nozzles, the top nozzle induced a stronger toroidal vortex due to buoyancy forces opposing gravity and the natural gas flow path. The resulting

viscous dissipation caused a region of much lower velocity, like a flow blockage, in which the less dense gas component may infiltrate, remaining relatively stagnant. If the dynamic forces of the flowing natural gas are insufficient (low velocity), flow reversal may occur, and hydrogen may be carried upstream. All jets must rapidly enter the free stream to reduce the risk of a high percentage of hydrogen contacting the pipe wall. If buoyancy forces are not sufficiently strong relative to the natural gas dynamic pressure, the natural gas may effectively 'blow' the unmixed hydrogen jet onto the wall. If the hydrogen jet is blown onto the wall, it will likely remain close to the pipe surface, particularly for top injection where buoyancy opposes gravity, promoting this attachment.

These cases are also associated with flow reversal and a high probability of elevated hydrogen levels stratifying and being dragged downstream along the walls. The walls close to all nozzles are continuously exposed to the highest levels of hydrogen. The effect is more pronounced on the top nozzle, where the effects of buoyancy tend to push the flow outwards, creating a more pronounced spherical cap than is otherwise seen in the bottom injection.

Results for the sparge pipe, or injection quill, indicate that the arrangement of nozzles along the length of the quill minimises the concentration difference and achieves a more homogeneous mixture through an increased hydrogen-methane interface area. The geometry of the quill and pipe, as well as the buoyant jets, causes

a counter-rotating vortex pair at the top of the geometry, which causes a strong recirculation that aids mixing. Elevated vorticity levels are generated at all the nozzle planes, further aiding mixing. The lower injection points allow the buoyant gas to rise slower and mix adequately before reaching the upper wall. The lower jets and strong buoyancy forces avoid contact with the lower pipe wall. The highest hydrogen volume fractions are detected at the top wall in close downstream proximity to the injection location. Multiple, separate, lower jets maximise the usable space available for mixing.

Higher levels of hydrogen (>10%) are detected at the quill wall near the nozzle exit. However, the quill can be manufactured with material tolerant to hydrogen. The buoyant hydrogen’s vertical rise rate is further reduced through a symmetrical vortex pair, which aids mixing and ensures hydrogen is recirculated downwards, thus decreasing the hydrogen levels at the upper wall. Rapid mixing of the hydrogen phase to a level lower than ~3% is achieved within two diameters from the injection point. The hydrogen volume fraction at the walls for all cases, eight diameters downstream, is predicted to be under ~3%.

n N E W O n - g a u g e h e l p e x p l a i n s m e n u i t e m s a t t h

o f a b u t t o n

n N E W We a t h e r p r o o f , d u s t p r o o f , a n d w a t e r- r e s i s

I P 6 5 - r a t e d e n cl o s u r e

n N E W E r g o n o m i c d e s i g n w i t h d u r a b l e r u b b e r i z e

n S h o c k - a b s o r b i n g p r o t e c t i v e r u b b e r h o l s t e r f o r

i m p a c t r e s i s t a n c e

n Tw o y e a r w a r r a n t y o n g a u g e b o d y A N D p r o b e

n C

Kits...

Is quill technology the key to unlocking our hydrogen future?

For the range of flow conditions tested, a nozzle at the top, bottom, or three around the circumference exposes the inside surface of the pipe to high-volume fractions of hydrogen, which, in some cases, was as high as 50%.

For the same flow conditions, a vertically inserted injection quill, extending to most of the inside diameter of the pipe, with nozzles placed towards the bottom half, can very effectively mix hydrogen and natural gas within a few diameters and prevent the pipeline wall from meeting high concentrations of hydrogen.

The results of this study show that the use of a vertically inserted injection quill is highly advantageous to all high-pressure large-diameter transmission networks considering blending and perhaps provides a solution that will enable further development of large-scale hydrogen transmission.

1. European Union Agency for the Cooperation of Energy Regulators.

2. Hydrogen Blending into GB Gas Distribution Networks: Government Response to Consultation Summary of responses received and government response to the consultation on hydrogen blending into GB gas distribution networks December 2023.

3. https://hydeploy.co.uk

4. EAMES, I et al., Injection of gaseous hydrogen into a natural gas pipeline, International Journal of Hydrogen Energy, https://doi.org/10.1016/j.ijhydene.2022.05.300

Successful offshore operations, particularly in oil and gas pipelay activities, heavily depend on understanding sea state conditions, emphasises Chris Moncrieff, Miros, drawing on a Northern Lights pipelay project.

Operating in some of the world’s most challenging environments is routine for the offshore energy industry. Successful offshore operations, particularly in oil and gas pipelay activities, heavily depend on understanding sea state conditions. Real-time, accurate sea state information is crucial for ensuring the safety, efficiency, and costeffectiveness of these operations.

Sea state – defined by factors such as wave height, period, and direction, as well as surface current and wind conditions – directly affects the design, deployment, and maintenance of offshore infrastructure, vessels, and equipment. For pipelay operations, precise sea state data is especially critical, as the stability of the vessel and the pipeline must be carefully managed to avoid costly disruptions or damage.

In the oil and gas industry, accurate sea state data in real-time is vital, not only for the safe operation of offshore rigs and vessels, but also for the precise laying of pipelines and cables. Pipelay operations require accurate and reliable information to plan effectively and to minimise risks such as pipeline buckling or misalignment during installation. Real-time sea state measurements allow operators to monitor conditions closely, plan work during optimal weather windows, and minimise downtime caused by adverse conditions.

Exact ocean data helps reduce operational risks, as it allows teams to avoid weather-related delays and to schedule maintenance and repairs during favourable conditions. Beyond improving operational efficiency, reducing unnecessary trips offshore also minimises the environmental impact of offshore activities, contributing to lower carbon emissions.

Dry-mounted wave radars have become a valuable tool for improving the efficiency and safety of maritime operations, particularly those involving pipelay activities. These radars, installed above the waterline, are shielded

from harsh marine conditions, leading to low maintenance costs and longer lifespans. By providing accurate, real-time measurements of wave height, period, and direction, drymounted radars enhance decision-making and navigation, allowing for more efficient fuel use and reduced operational costs. Their versatility also makes them suitable for deployment across various platforms, including ships, offshore rigs, and coastal installations.

One leading technology in this space is the Miros WaveSystem, which exemplifies the state-of-the-art in real-time sea state monitoring. The system includes the automatically calibrated Miros Wavex, a virtual sensor that uses data from standard marine X-band radars for directional wave and current measurements, and the DNV alpha-factor approved and motion-compensated RangeFinder, a highfrequency microwave radar that provides sea level and draft measurements. Both are IoT-enabled and designed to be standalone devices with embedded processing and browserbased user interface, eliminating the need for complex integration or external processing systems.

When paired with Miros Cloud, this system provides all stakeholders in offshore operations – such as pipelayers, diving technicians, control room and vessel operators – a secure overarching view of sea conditions. This facilitates better planning, decision-making, and coordination during complex offshore operations.

In addition, Miros also offers Forecast, a new app that integrates real-time ocean data with sea condition forecasts, empowering marine teams to navigate unforeseeable environments with greater certainty. Forecast equips users with real-time ocean data and forecasted conditions seamlessly integrated into a dynamic dashboard. By providing up-to-the-minute views of sea conditions alongside forecasted data, with up to 10 days in time-series visualisations, the app allows marine operations teams, to confidently navigate unpredictable seas and execute their operations with reduced risk and enhanced efficiency.

The value of real-time sea state data is especially evident in pipelay operations, which have typically been critical for transporting hydrocarbons from offshore production sites to onshore facilities but will soon take on new importance for the deployment of carbon capture and storage (CCS). Precision in such operations is crucial as errors can lead to environmental hazards, increased risks, and compromised pipeline integrity. Leveraging advanced pipelay technology alongside real-time data, operators can significantly enhance both the efficiency and safety of these activities, reducing costs and bolstering the sustainability of oil and gas operations.

A notable example is Miros’ contribution to the successful laying of a 109 km pipeline for the pioneering Northern Lights CO 2 transport and storage project. By equipping project vessels with a cloud-enabled WaveSystem and an additional RangeFinder wave radar, Miros delivered accurate, real-time sea state data, ensuring safe and efficient pipelay operations for this groundbreaking initiative.

Northern Lights, Norway’s first CO 2 storage licence on the Norwegian Continental Shelf, is part of the wider ‘Langskip’ (Longship) CCS project, spearheaded by major energy companies and instrumental in helping Norway – and Europe – achieve decarbonisation targets.

Precision is paramount in pipelay operations. With WaveSystem, the Northern Lights project successfully deployed critical infrastructure safely and accurately, despite fluctuating wave and weather conditions. Real-time ocean data kept vessels accurately on course, ensuring the project proceeded without delays.

Miros’ WaveSystem facilitated safe and dependable offshore operations by providing real-time sea state data via the Miros Cloud platform (miros.app). This seamless and secure data sharing enabled project vessels to confidently navigate the offshore environment and complete the pipelay mission on schedule.

The WaveSystem technology empowered the project team to respond confidently to sudden changes in offshore conditions by delivering reliable, up-to-the-minute sea state measurements around the clock. With easy installation and automatic calibration, the system made critical data quickly accessible and securely shareable, ensuring optimal situational awareness for the entire project team.

Enhancing offshore safety with real-time insights

Safety is another key benefit of real-time ocean data. Offshore operations depend on accurate and reliable

weather information to protect personnel and assets. Inaccurate weather forecasts, particularly those that might underestimate wave heights, can put offshore teams at risk. Even a small period of exposure to severe conditions can have critical implications for safety. By combining reliable real-time measurements with traditional weather forecasts, offshore operators can ensure that they have the most accurate information available, allowing them to better evaluate and make safer, more informed decisions.

A mere three to four hours of additional operational time saved over the course of a year could be enough to justify the investment in a wave radar system. When combined with the use of weather forecasts, the technology yields significant benefits in terms of operational efficiency, cost savings, and safety.

ahead – predict the unpredictable to improve

The true value lies not only in the sensors themselves but much more in the data they provide. Actionable insights are key to improving operations and safety while reducing downtime.

By focusing on the continuous improvement of user interfaces and developing new applications, companies can ensure that the data collected from sensors is effectively used to optimise operations. Therefore, real-time and historical sea state data should be accessible from any device at any time, whether locally or through the cloud,

making it easier for operators to plan and adapt to changing conditions.

Knowledge of what sea conditions to expect, and what happens at the current offshore location, is a huge advantage and a significant safety measure. However, one challenge with waves is their stochastic nature, meaning they are inherently random and variable. While wave conditions can be analysed, predicting the exact characteristics of unseen waves is nearly impossible. This makes real-time sea state data particularly important, as offshore operations often rely on timely insights to make split-second decisions.

Wave prediction can be broken down into two broad categories: statistical and deterministic. Statistical prediction uses up-to-date information to forecast likely wave conditions over a range of time frames, from minutes to days. However, this method primarily provides general trends and does not predict individual waves.

Deterministic prediction uses advanced analytics and artificial intelligence (AI) to track specific waves in real time.

This approach offers specific insights into the behaviour of waves, providing personnel with advanced warnings of large waves that could affect operations. While deterministic wave prediction is still an emerging technology, there is growing demand for it, especially from key offshore players. Companies like Miros are intensely investing in these advancements, leveraging their decades-long expertise in accurate sea state measurement to bring this demanding next-generation technology to market.

The future of the oil and gas industry hinges on more precise and localised sea state measurements. Traditional methods, which often rely on distant forecasts or outdated data collection techniques, lead to discrepancies that compromise the safety and efficiency of offshore operations. Despite advancements in technology, these conventional practices still dominate much of the industry.

However, forward-thinking companies are adopting cutting-edge technologies that are transforming how sea state data is measured and applied. By obtaining real-time data directly from the operational site, these innovative methods ensure more accurate, relevant, and actionable measurements. Advanced radar systems and integrated sensor networks are pushing the boundaries, providing detailed insights into wave conditions and enhancing both safety and efficiency across offshore operations.

These technological advancements are poised to reshape the offshore energy sector, making it more resilient and capable. As the industry evolves, real-time ocean data and predictive analytics will become central to improving operational efficiency and sustainability. These technologies enable better decisionmaking, reduce downtime, and enhance safety, boosting economic returns while promoting a more environmentally responsible offshore energy industry.

Real-time sea state insights unlock significant efficiencies for offshore energy operations, be they oil and gas or CCS. As the industry moves towards more sustainable maritime practices and strives to meet net-zero goals, Miros is proud to provide reliable real-time ocean condition measurements as well as prediction technology that help drive these efforts forward, as we have done for the past 40 years. Our long-standing partnerships across the energy sector reflect our deep expertise in delivering accurate and actionable ocean insights that optimise efficiency while minimising environmental impact.

Speed of acquisition

3X quicker than traditional tools

Precise, remote, non-contact technology

Access to entire network regardless of ground conditions

Reduced human risk with autonomous data collection

Locating buried pipeline and characterizing their movements using innovative magnetic technology, UAVs and advanced analytical techniques

Precise geolocation of pipeline centerline +/- 1 ft (30cm) within 90% confidence level

High density centreline points: precise geospatial location every 2 inches (5 cm)

Acquisition rate of 1.2 miles (2km) per day on average

Curvature changes detection greater than 1/400D on the first inspection

Ability to inspect pipelines up to 50 feet (15 meters) under water

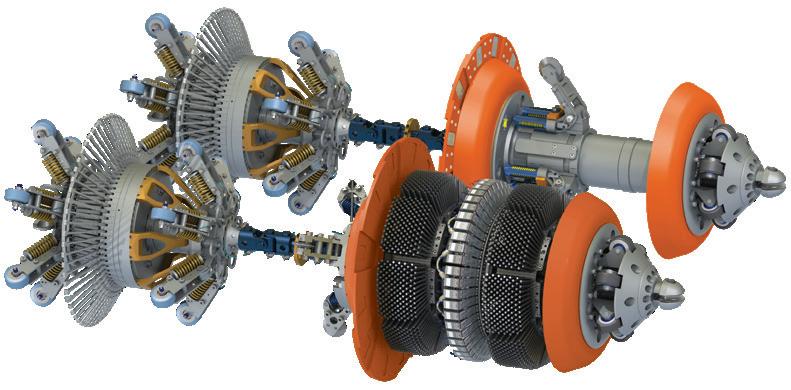

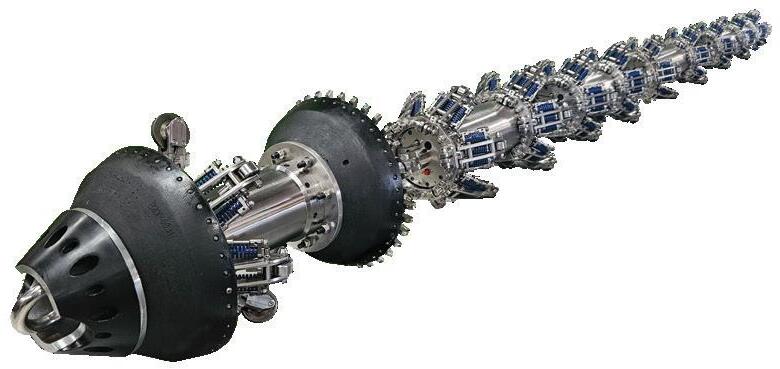

Tom Oldfield, Service Manager –In-Field Verification, ROSEN Group, discusses validating the performance of ILI systems to ensure that the data collected in-field can demonstrate that the system specification has or has not been met.

alidation of inline inspection (ILI) system performance in accordance with API 1163 is a critical task to ensure that, on a run-by-run basis, ILI systems have likely performed within their

specifications (level 1 and 2) or can be used to understand case-specific, as-run performance (level 3) of an ILI system. Without understanding the system performance per run, it may not be conservative to use the stated ILI specification in subsequent integrity decision-making in case the ILI sizing falls outside the stated specification.

ILI systems are rigorously tested across a vast array of variables in the lab, in pull tests, and under real-world operational conditions to build up a basis of a specification. These specifications define the statistical probability of finding features of a certain dimension and classification to set a realistic expectation of the types of features that can be found and the certainty at which they can be sized.

To validate the performance of the ILI system, we need to ensure that the data collected in-field can demonstrate that the system specification has or has not been met. This typically goes beyond the data collection requirements needed for integrity decision-making, as the morphology of the features and the accuracy of the in-field inspection technique have a critical impact on the applicability of the ILI system specification.

External metal loss is the most common form of damage to cross-country pipelines worldwide, and the industry

has a wealth of knowledge on both mechanical and semiautomated data capture with the likes of pit gauges and laser scanning. Laser scans provide high-accuracy, high-resolution data that enable signal-to-signal comparison of the ILI system vs in-field measurements. This signal-to-signal comparison is critical for a detailed understanding of system performance, as it can help to disseminate interacting features, breaking it down to the individual feature classification within clusters, which is fundamental to the physics driving the inspection quality.

A feature type typically mis-sized by ILI systems is the pinhole classification, which is less than 1 wall thickness (WT) in both circumferential and axial directions. This feature type is generally omitted from ILI specifications (except for the highest resolution systems) as features below this size reach the limits of the tool’s sensitivity and capability to size accurately within its specification. If there is an area of significantly more aggressive localised corrosion within an area of general corrosion, understanding the dimensions of the pinhole within the cluster is critical in confirming that the system has or has not met the specification. Conventional methods of boxing the feature and identifying the peak depth with a pit gauge, while sufficient for conservative integrity assessments, do not paint a clear enough picture for ILI system validation.

Internal corrosion has the potential to provide highly detailed feature information when using a dual-axis encoded phased-array ultrasonic testing (PAUT) mapping system with an accuracy potentially an order of magnitude higher than an MFL system. When correctly processed, this data enables us to see the internal surface of a pipeline in operation with significant detail. However, this is a slower, more expensive technique requiring higher-skilled personnel to deliver the work. The general trend still leans towards manual UT, which, in theory, when applied by a competent person, can identify the deepest point and general area of corrosion and be applied to conservative integrity assessments, but again this does not provide sufficient detail to validate the ILI system performance. Encoded PAUT is the preferred method for ILI validation data capture due to the digital fingerprint of the feature that is created and can be interrogated. A better understanding of ILI system behaviour within its specification not only enables a fair representation of ILI performance but also enables an integrity management strategy to cope with the specific needs of the pipeline in question, particularly when aggressive corrosion morphology is present.

Geometric defects can be measured in field with the same level of accuracy as corrosion when using a laser system. However, there is the additional complexity of variations in pressures and elastic rebound from removal of the indenters. This is an area where validation of the absolute performance of the system is complex and there is currently no real agreed industry methodology for validation of these types of features.

WeldFit.com/ReCAP

WeldFit’s ReCAP® Emissions Recovery System with patent-pending XR Technology is the safe alternative to venting or flaring during common pipeline operations. ReCAP delivers the industry standard in cross compression speeds with Straight-LineTM predictability that ensures projects remain on schedule. And by keeping your gas in the pipeline, it reduces GHG emissions by nearly 100%. ReCAP is the solution that puts today’s challenging goals in reach. ®Trademark

Cracking is perhaps the most complex form of defect found in pipelines from both an inspection and integrity management perspective.

Validating ILI system performance for cracking has two significant considerations: 1) How is the accuracy of the in-field measurement factored into the validation and 2) Does the in-field measurement demonstrate compliance of the ILI system to its specification?

The first factor is a complex one; determination of the accuracy of an in-field measurement is a significant challenge due to the human element still prevalent in a large number of the methods used for depth sizing crack-like anomalies. In conventional NDT, applying a large tolerance compensates for the measurement uncertainty, resulting in a conservative outcome. In ILI system validation, features are deemed to be acceptable if the measurement is within the combined tolerance of the ILI and in-field result, in the manner described in API 1163. Therefore, the greater the uncertainty in the in-field tolerance, the more likely it is that a feature will be accepted as meeting the specification, but in reality, creates a higher uncertainty in the performance of the ILI data set. However, assuming in-field data is absolute creates an unfair representation of ILI system performance. For this reason, technicians taking these measurements should be capable of achieving a high level of consistent accuracy, using the most transparent technologies to reduce the uncertainty in the ILI results.

The second factor mirrors the challenges seen in metal loss validations: is the captured data capable of determining whether or not the ILI system has met its specification?

It is possible for some in-field technologies to collect high-quality encoded data, which can provide sufficient evidence to support the ILI validation process. This is subject to the feature morphology being investigated, the particular setup of the in-field technology, and the experience of the operator in the purpose of ILI validation.

A good example of this can be from an issue reported by ILI on an ERW seam weld. The in-field solution is to use axially encoded high-resolution Total Focus Method (TFM) ultrasonic inspection data collected by a competent person with a known tolerance of 0.8 mm at 80% confidence from blind trials of the NDT system. With this system in place, various factors like the inclination to the pipe surface can be assessed to identify hook flaws, the intermittent nature of the features can be correctly quantified at the detection threshold, and the combined tolerance from API 1163 is small enough to have a high confidence in the resulting ILI depth sizing.

An example of poor data collection for ILI validation could be manual or spot PAUT measurements of unknown quality of an SCC colony to determine the deepest point, length and width (which again is acceptable from an integrity perspective), but ultimately does not provide sufficient evidence to demonstrate that the ILI system has met its specification.

This again is important as ILI systems have limitations for the minimum length of the feature, length of the peak depth, threshold length, how the subsurface inclination may affect the sizing ILI system, and it is important that these factors are considered when validating ILI system performance.

There are many available NDT technologies to size cracks in pipelines, but from a validation perspective, the use of a technique that can be interrogated to understand the morphology and size with a high level of accuracy is preferential. The Total Focus Method (TFM) Ultrasonic is one that shows potential to fill this criteria, but has operating limitations that mean it is not a silver bullet to solve all problems.

Hopefully, it is clear how important the role of the field verification technician is as part of this process. The data collected has to be of the highest quality, taken in what can be very challenging conditions. The data has to be traceable and reliable but also needs to demonstrate whether the feature meets the ILI specification or not. Once the raw data is processed and the report of the feature dimensions is written, the subtle complexity of how the feature really looks can be simplified to three numbers: length, width, and depth.

When the expectation of an ILI validation technician is compared to the role of a conventional NDT inspector, where only the peak depths, lengths, and widths are requested as part of an inspection report, it is clear that there is a potential gap in the knowledge expected from the people delivering this work.

The practical application of API 1163 has recently been given a boost with the release of the supplementary guidance from PRCI (PR-719-223803-R01), which has provided more clarity on how to implement the standard. However, the fundamental collection of data and the understanding of the purpose of an ILI verification still lack the clear guidance required. Through better collaboration between ILI vendors, operators and their NDT contractors, a better understanding of the ILI validation task should lead to data that better represents ILI performance and the integrity threats to the pipeline.

Without high-quality in-field verification data, it is difficult to assess the performance of an ILI system. This can potentially lead to non-conservative integrity decisions if the ILI tool is not performing within its specification or if the morphology of the particular features is more severe than the tool is capable of seeing.

ILI verification is a challenging task, but there is a much better chance of a successful inspection with a clear understanding of what the data is being used for and the importance of quality within this process. With this knowledge, it is possible to create a clear work scope to allow NDT companies to develop procedures that are suitable for the purpose of ILI validation data collection and not only immediate integrity decision-making.

With a wealth of experience in in-field verification and ILI, ROSEN can help establish clear in-field work scopes to ensure the highest-quality data collected in the field is relevant to the verification task and maximises the value of the excavations on their pipeline networks.

ipeline corrosion is the most common of the many issues and challenges pipeline operators face – and may often be disastrous. Industries and communities are heavily reliant on the integrity and condition of pipeline assets. Corrosion is something that operators have to contend with, but too often, corrosion is left untreated, spiralling into a more consequential issue than necessary.

When ignored or handled poorly, the long-lasting damage of corrosion will compromise the integrity and lifespan of pipeline assets. This is especially true – and will be increasingly visible – as energy demands evolve and infrastructure changes. New pipelines continue to be developed and expanded upon in new regions, including high-consequence areas (HCAs) and in deeper reservoirs where temperatures and pressures increase. This places even greater significance on the integrity of assets in complex situations and environments.

The result, when mismanaged, is expensive and poses a risk to assets, projects, the environment, local communities, and workforces. If a reactive (instead of proactive) approach is taken in corrosion management, it is likely to result in wasting significant resources, materials, and productive time.

The oil and gas industry has taken great strides in several aspects of pipeline inspection and integrity (such as updated pipeline technologies and infrastructure); however, the impact of corrosion remains. The Association for Materials Protection and Performance (AMPP) reported that the impact of corrosion costs upwards of US$1.372 billion annually.

Corrosion in pipeline assets can be split into internal and external corrosion. The US Pipeline and Hazardous Materials Safety Administration (PHMSA) believes that internal corrosion is responsible for approximately 60% of all pipeline incidents caused by corrosion in transmission and gathering pipelines.

To understand how to mitigate the serious risks of corrosion, it’s critical to recognise the causes of corrosion.

Unfortunately for oil and gas operators, internal and external corrosion occurs naturally in pipelines exposed to the elements. In addition, several chemical components in the materials carried by pipelines may lead to corrosive reactions. These include oxygen, water, moisture, acid chloride, and common bacteria and microorganisms.

One of the main types is sour corrosion. This is caused by hydrogen sulfide (H2S) that may occur in crude oil and natural gas. Sour corrosion degrades assets, creating rust within metal infrastructures such as steel-based pipelines. Naturally occurring corrosion may be exacerbated by a lack of proper maintenance and neglect.

Whether natural or due to neglect, the result of corrosion is often the same: the loss of critical properties and structural strength, risking the pipelines breaking down or at worst, rupturing. Thankfully, several methods exist to combat and minimise the effects of corrosion.

Corrosion in pipelines that transport H2S-containing materials is an area that operators have sought to address because of its relevance in the upstream and midstream markets. With sulfide naturally appearing in oil throughout its journey along a pipeline, operators must consider the causes and appropriate prevention strategies to avoid economic loss and operational risk.

Understanding the risks, including those that occur naturally and those that are avoidable, is crucial to maximising the asset’s performance and lifespan. Recognising the potential causes of degradation and corrosion will help identify the appropriate

solutions when required further down the line. Through dedicated inspection and access to the latest technologies, solutions, and treatment chemicals, operators can manage a pipeline to ward off the effects of corrosion.

The development and implementation of proven corrosion management strategies will help secure asset longevity alongside other benefits, including optimising performance and full compliance with the latest regulatory standards for health, safety, and the environment, while helping to avoid costs for long-term maintenance issues.

Comprehensive corrosion control measures, along with regular maintenance and inspection, will help reduce the impact of internal corrosion. Through dedicated and thorough maintenance, operators can significantly increase the pipeline lifespan.

Chemical treatment is a standard industry approach to minimise corrosion. These chemicals include corrosion inhibitors (that prevent corrosion) and biocides (that prevent microbially induced corrosion). Tetrakis (hydroxymethyl) phosphonium sulfate (THPS) is a commonly used biocide; a safe and effective liquid component that targets and controls the growth of harmful bacteria and microorganisms.

Introduced into the midstream market to support pipeline inspection and integrity, THPS has since been proven effective in targeting microbial growth and the specific bacteria that lead to hydrogen sulfide formation and souring.

Since its introduction to the industry, operators who use biocides such as THPS have experienced prolonged waiting times to receive results on its effectiveness. Monitoring the biocide’s progress is critical to understanding the necessary volume to inject into various pipeline sections. This lack of oversight has posed challenges as excessive biocide use can elevate corrosion risks and associated chemical expenses, while insufficient dosages may lead to microbial-induced corrosion (MIC), thereby diminishing the pipeline’s lifespan.

Alongside the solutions, it is critical to have assurance they are being utilised correctly. For the chemicals to effectively protect the system, they must reach all areas of the pipeline. To ensure this is happening at the required dosage requires timely and accurate testing of chemical residuals.

The effectiveness of various chemical choices is crucial, but they are not a one-size-fits-all solution; the chemicals used must match the specific conditions of the pipeline. And that is where expertise is essential.

Analysis of chemical residuals is one of many components in the complex management of pipeline integrity. Scottish chemical expert company OMMICA is the frontline solution for chemical analysis in the midstream market.

Manufacturing, developing, and distributing a series of innovative, portable chemical analysis testing kits, the team behind OMMICA utilises over 20 years of expertise to support its international clientele. These testing kits were developed to redefine chemical analysis of methanol, monoethylene glycol (MEG), and THPS levels in oil, condensate, and water.

OMMICA prides itself on the ability to deliver rapid results (under one hour) without sacrificing accuracy, which stems from the controlled way the assay is run. This methodology ensures operators have all the information they need to manage risks and optimise their resources effortlessly.

As the contamination of crude oil (caused by the necessary upstream use of production chemicals, as well as issues like corrosion) costs operators millions of dollars in penalties, fines, and halts to production, OMMICA has developed solutions to help stop this from happening. Through portable, fast, and accessible testing kits, OMMICA helps save time and money, ensure environmental compliance, and prevents unnecessary crude discounting to customers in over 25 countries that have adopted the OMMICA method.

Recognising this bottleneck, the industry has embraced portable testing methods. This shift has transformed monitoring processes, enabled swift responses, and enhanced operational efficiency.

OMMICA uses its kits and its teams’ guidance to aid this shift and support production chemists, securing results in the process.

Since entering the market just over two years ago, OMMICA’s THPS test kits have supported pipeline operators across Europe, the US, Oceania, and the Middle East.