The leading innovator supplying cutting-edge integrity solutions. Together we can ensure sustainable decision-making. Our combination of advanced inspection systems and expert consultants delivers a comprehensive understanding of asset safety, lifetime, and performance.

Comprehensive Asset Integrity Management

www.rosen-group.com

C O NTENTS

WORLD PIPELINES | VOLUME 23 | NUMBER 5 | MAY 2023

03. Editor's comment

05. Pipeline news

Get up-to-date with current international pipeline stories.

KEYNOTE ARTICLES: SAFETY AND RISK MANAGEMENT

8. Consistent access management

Amit Pawar, VP of Consulting & Services, Xage Security, USA, charts a top pipeline operator’s journey to cyber harden and meet updated TSA security directives.

FIELD JOINT COATINGS

37. Exploring specialised robotic equipment

Kristopher Kemper, Technical Services Consultant, Association for Materials Protection and Performance (AMPP), USA.

42. Lasting connections

Paul McShane, Managing Director, CRC Evans, UK.

13. Never trust. Always verify.

Trevor Dearing, Director of Critical Infrastructure Solutions, Illumio, UK, advises how pipeline operators can stay ahead of mounting cyber threats.

Extreme

17. Connecting the dots

Jim Francis, Vice President – SMS Consulting, ENTRUST Solutions Group, USA.

22. A pipeline journey across the Danube River

Camila Sanchez Prado, Horizontal Drilling International (HDI), France.

27. A game-changing solution

Mario Moreno P.Eng., Seal for Life Industries, Canada.

31. Easing fugitive emissions

Ariel Avitan, Co-founder and CCO, Percepto, USA.

PIMS SOFTWARE

35. Digitise then automate

Vicki Knott, CEO and Co-Founder, CruxOCM, USA.

HOT TAPPING AND LINE STOPPING

47. Staying free-flowing

Darran Pledger, STATS Group, UK.

PIPELINE STEELS

53. An economically superior material

Girish Babu Nounchi and Jayaraj Padayachiyar Govindan, Wood Plc, and Shankar Mohan, Worley.

PIPELINE MACHINERY FOCUS

57. On the edge of innovation

Leonardo Gravina, General Manager, SICIM, Italy.

YOUNG PIPELINERS INTERVIEW

60. Recognising young achievement

Recipients of the 2023 John Tiratsoo Award for Young Achievement, Cassandra K. Moody and Sarah Newton.

CBP006075

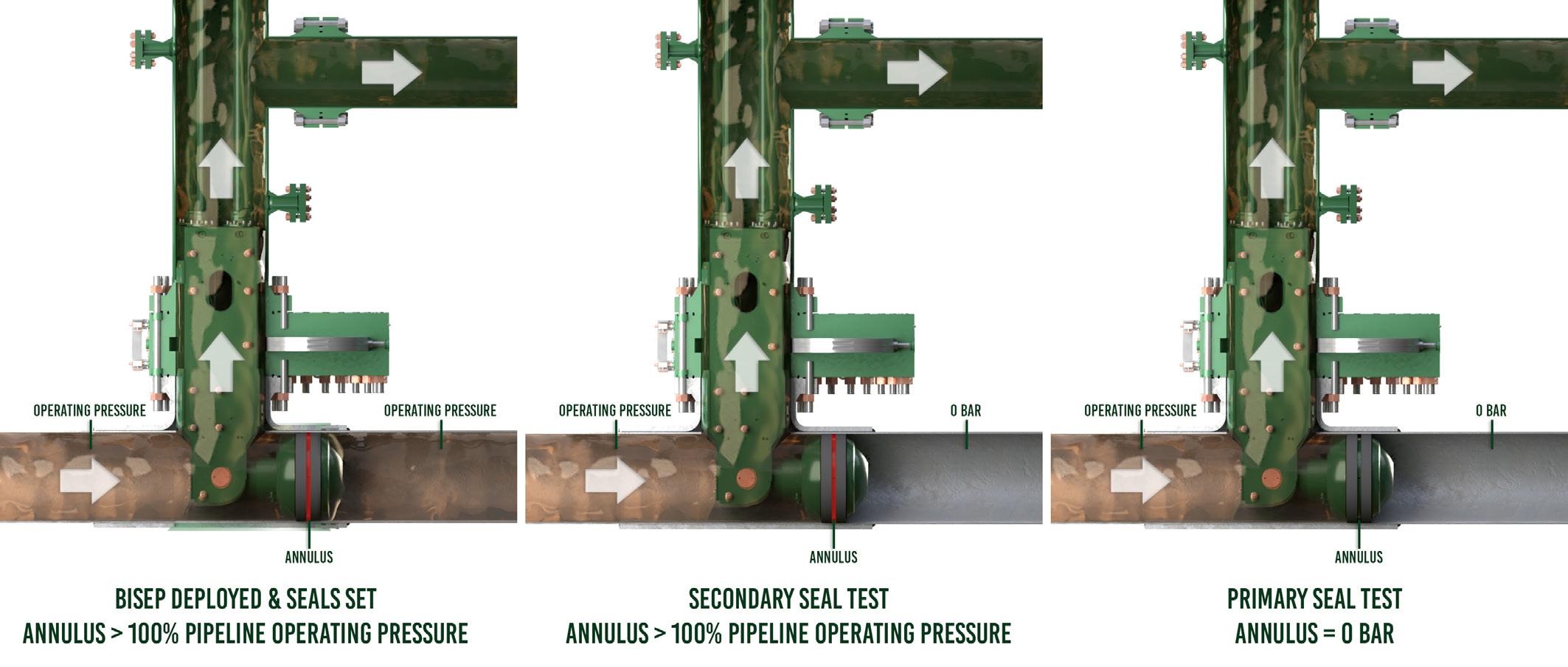

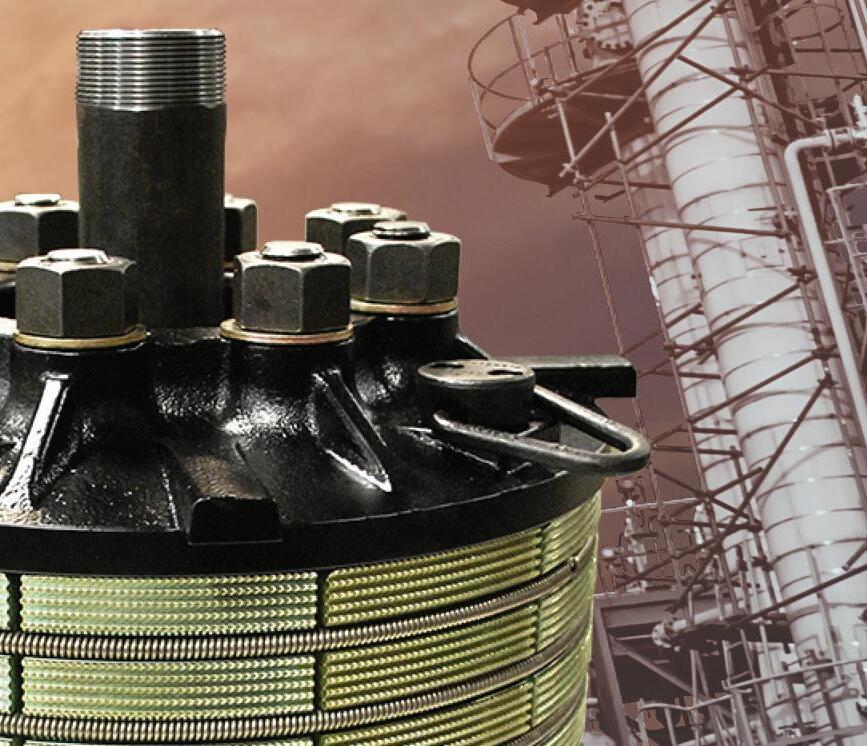

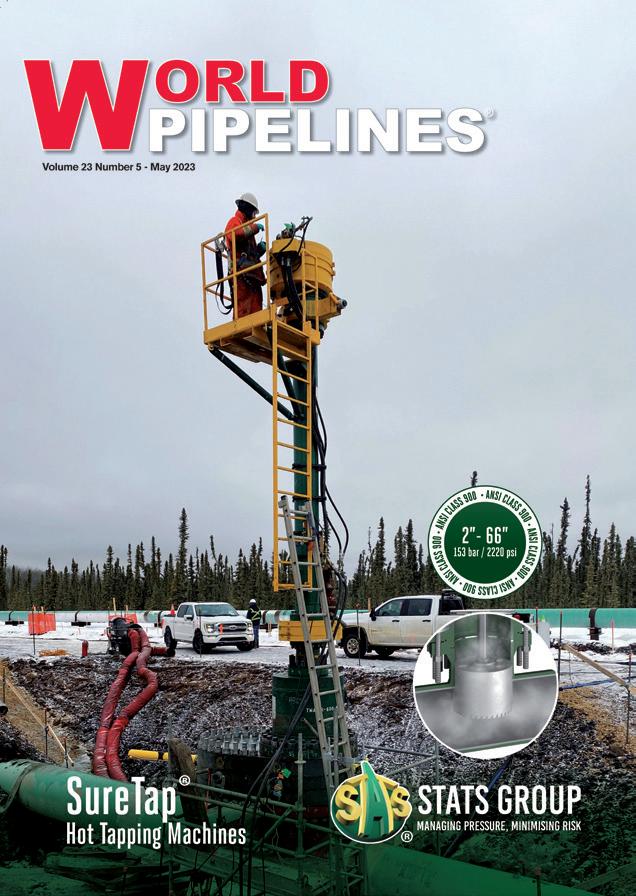

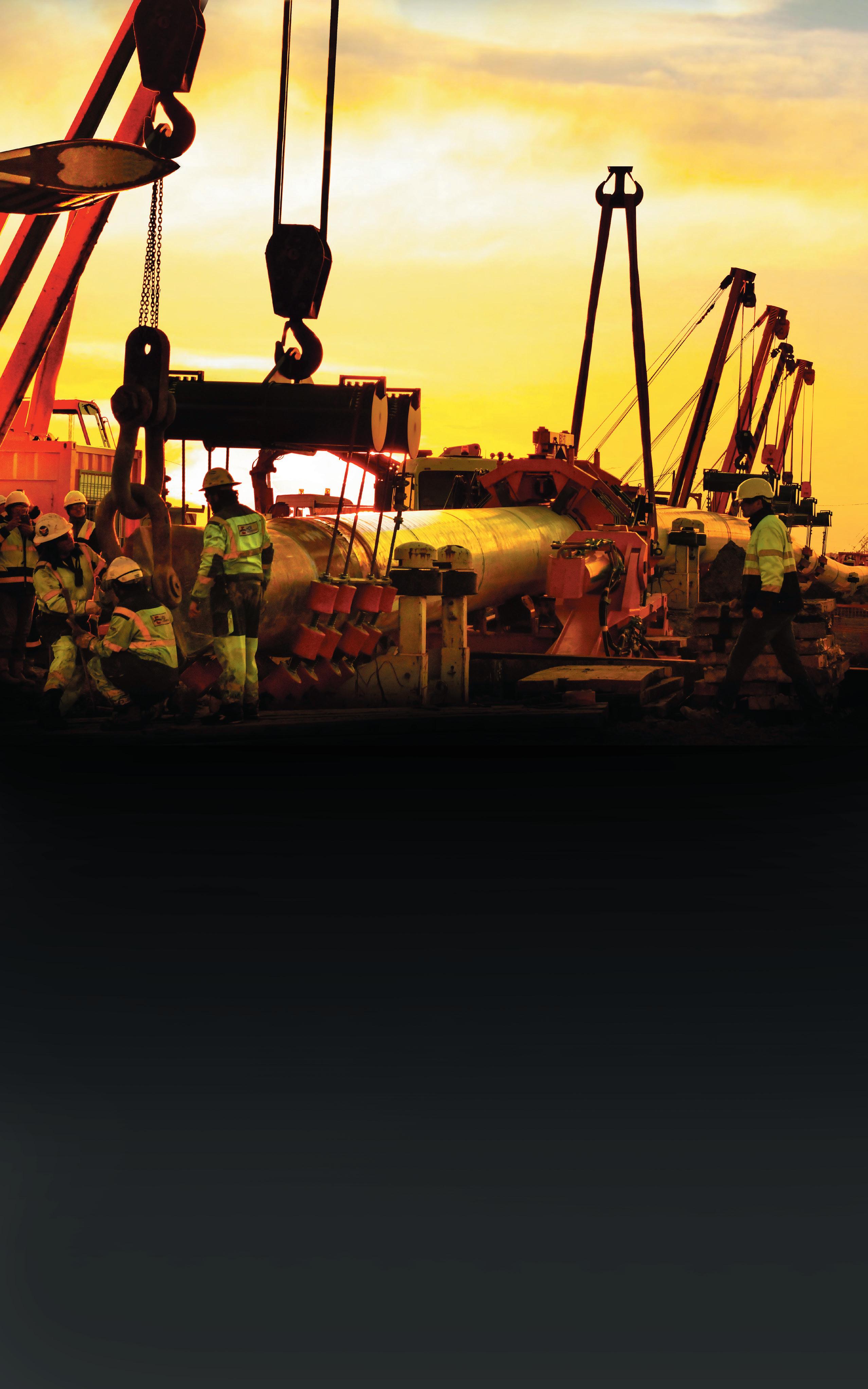

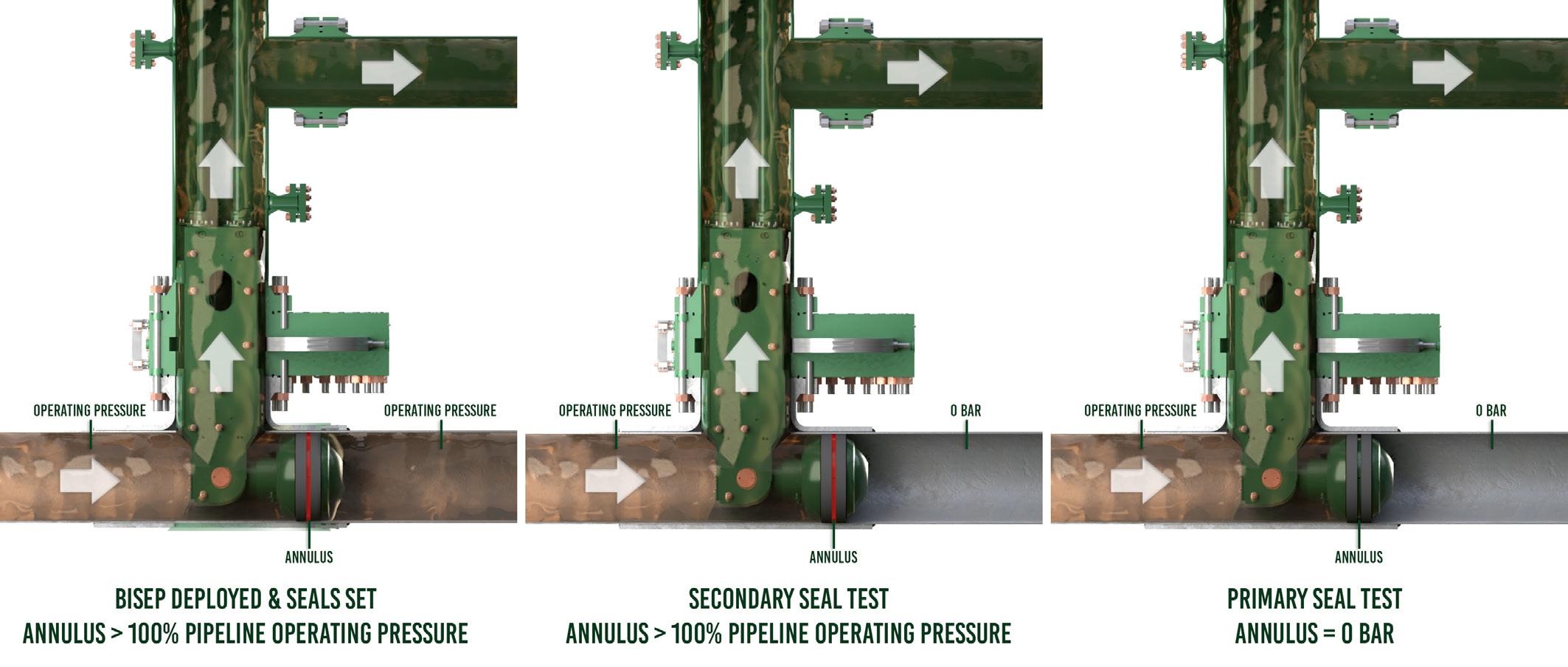

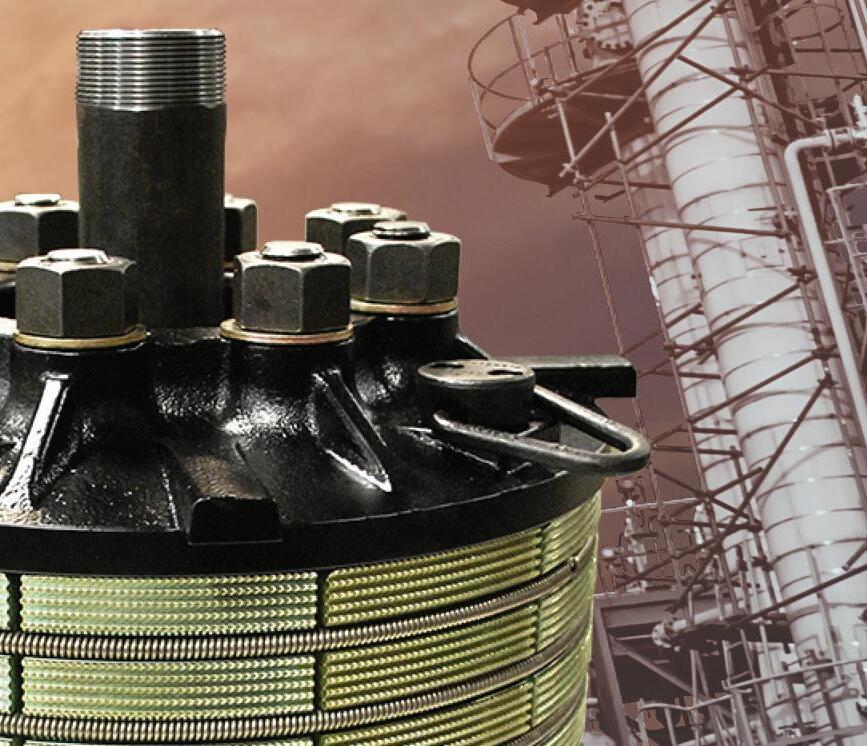

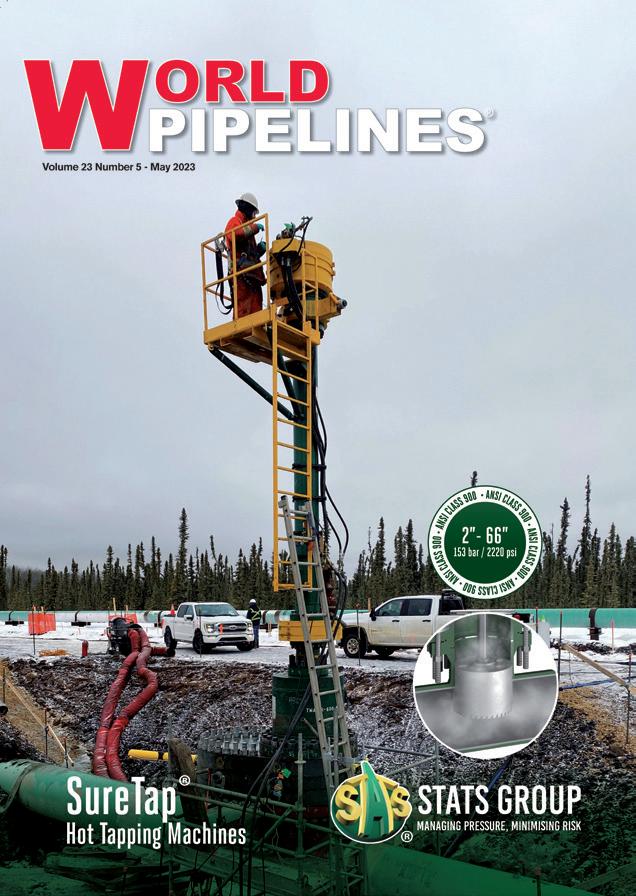

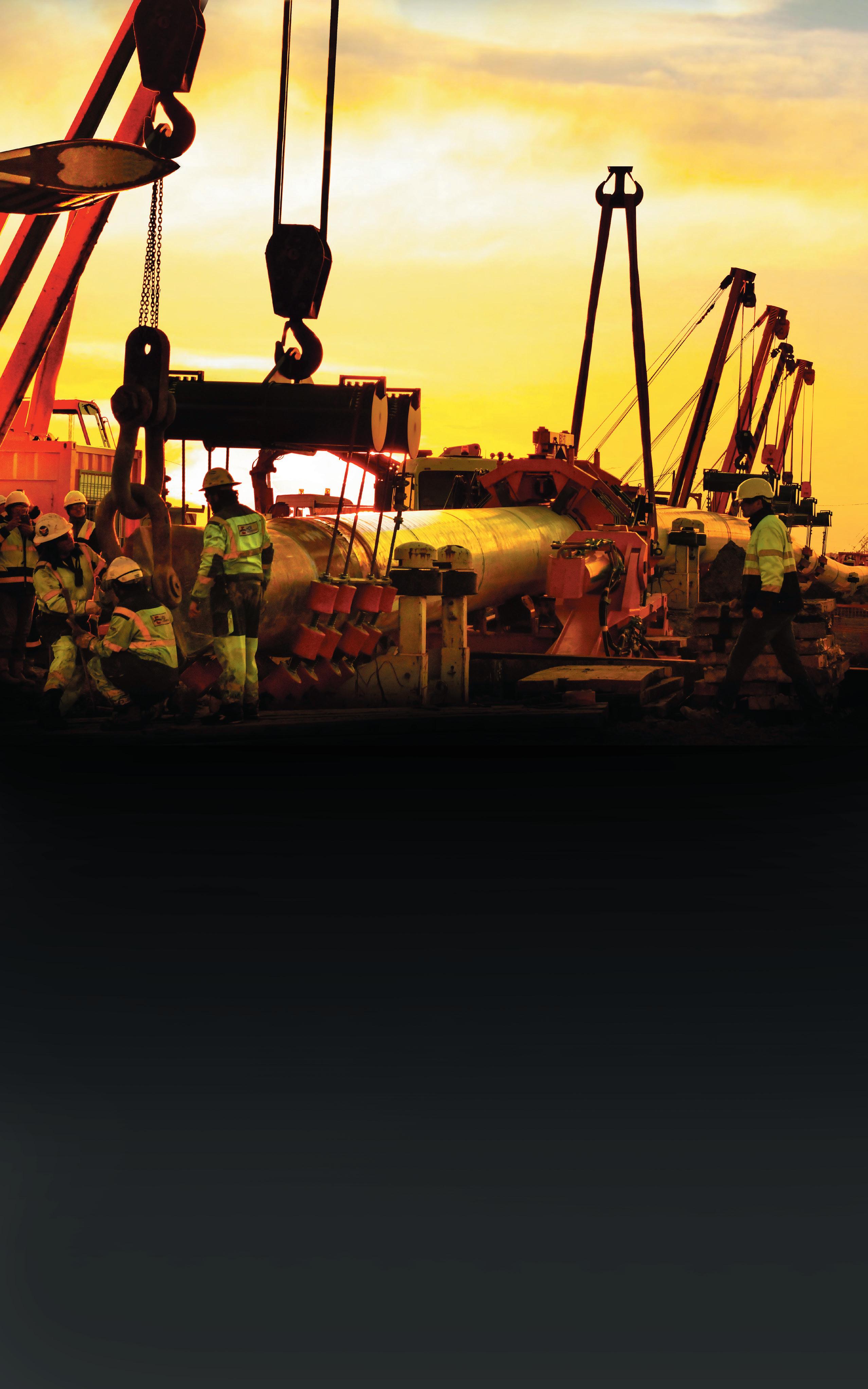

STATS SureTap® ST1530-90 hot tap machine providing access for STATS BISEP® double block and bleed line plugging tool. The 30 in. gas pipeline in Northern Alberta, Canada was operating at 69 bar. STATS hot tapping and plugging technology is suitable for onshore, topsides or subsea operations and fully compatible with industry-standard tapping equipment; including fittings, valves and completion plugs. www.statsgroup.com

ISSN 14727390 Member of ABC Audit Bureau of Circulations ON THIS MONTH'S COVER Reader enquiries [www.worldpipelines.com]

Copyright© Palladian Publications Ltd 2023. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. All views expressed in this journal are those of the respective contributors and are not necessarily the opinions of the publisher, neither do the publishers endorse any of the claims made in the articles or the advertisements. Printed in the UK.

42

57

31

PAGE 42

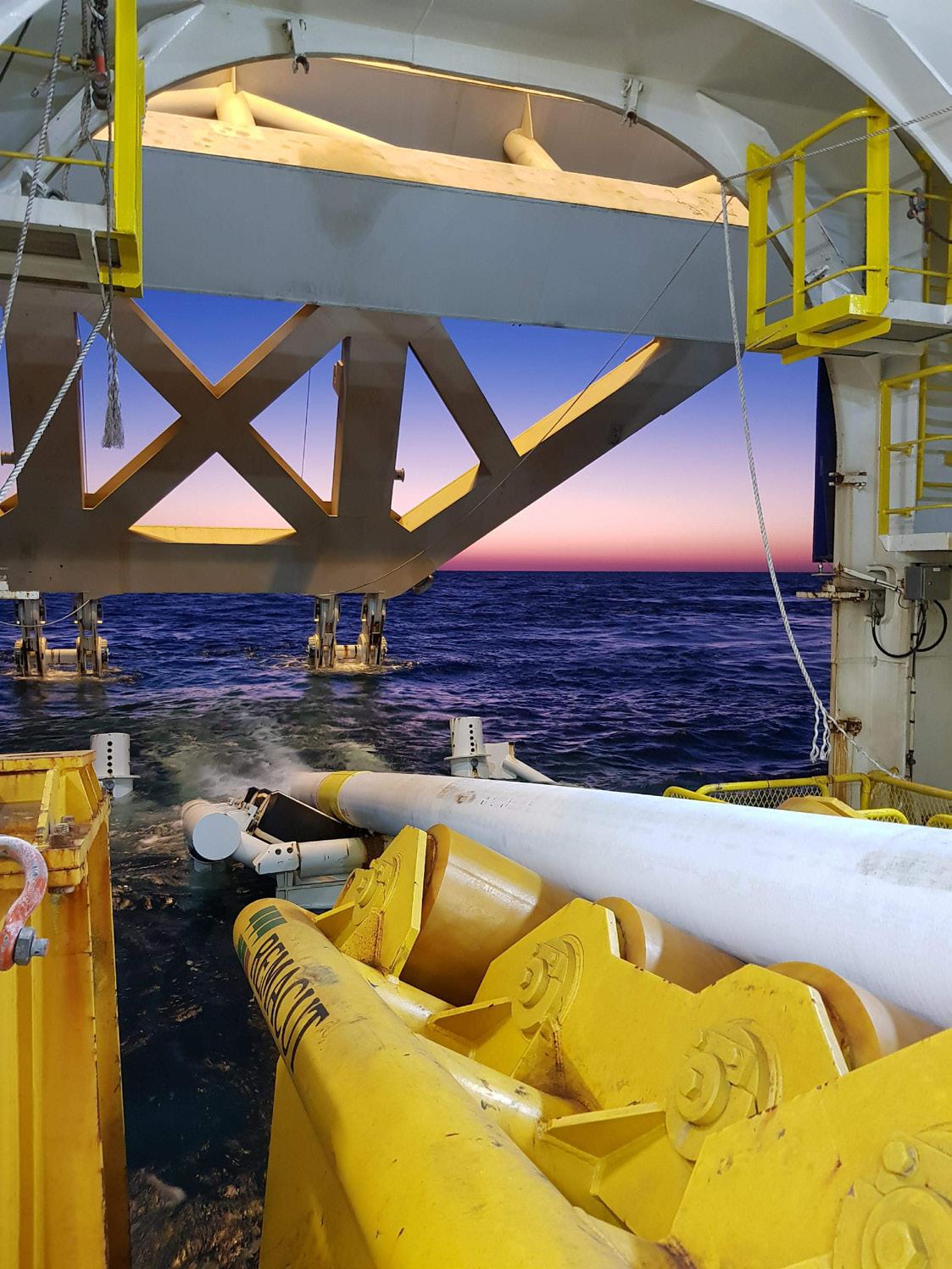

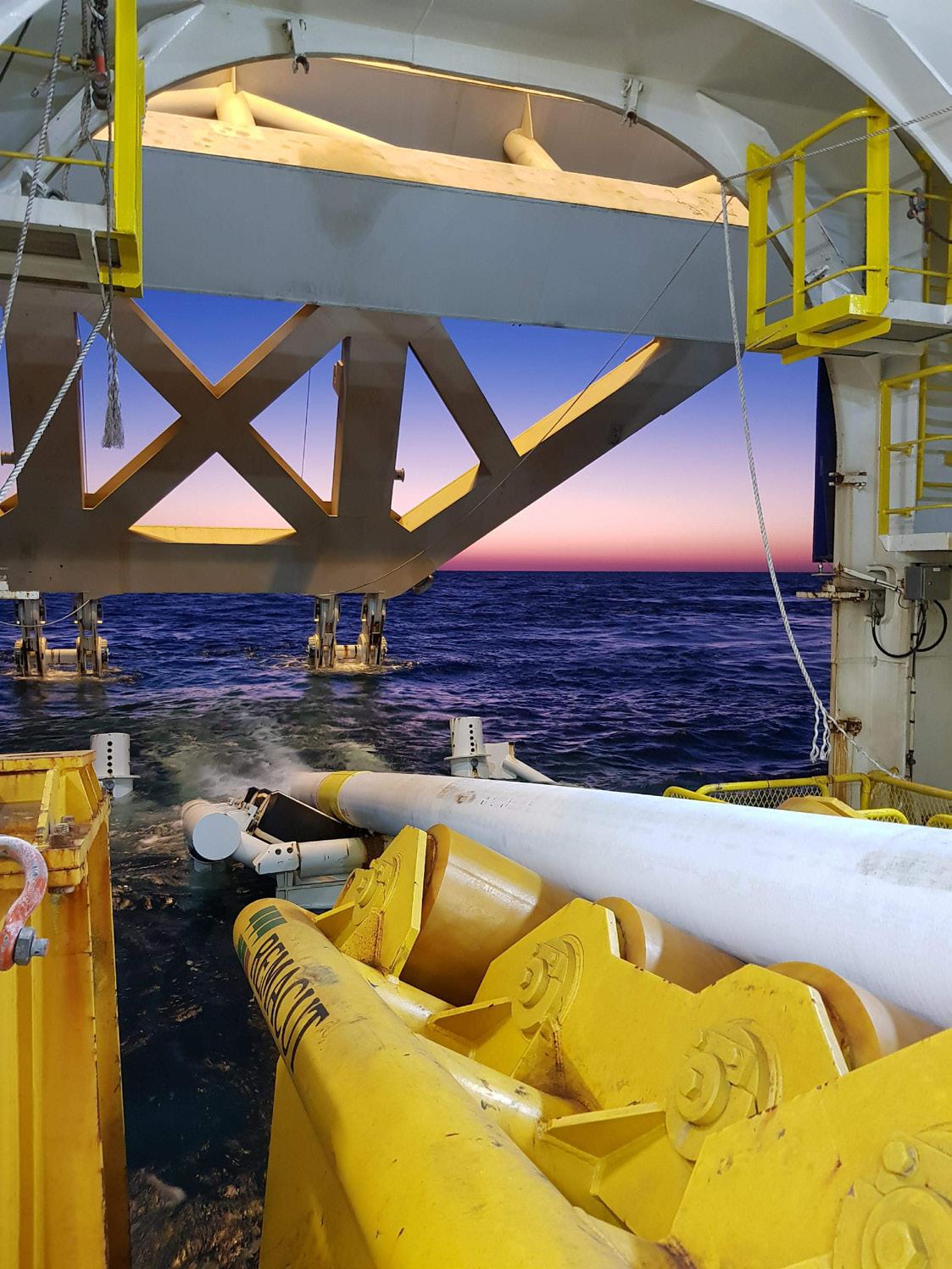

I the world of field joint coating, CRC Evans’ team has an enormously successful track record and has The company’s full turnkey service capability helps to ensure the optimised delivery times that customers trust. The engagement begins early at the materials selection and delivery stages, with the support of state-of-theart equipment, specialist personnel and purpose-built anti-corrosion and insulation materials to field joints, for onshore and offshore pipelines, CRC Evans is now leading the way in developing new procedures and practices and Enhancing efficiency through automation As market-leader the offshore application of field joint (J-Lay) and horizontal (S-lay/multi-jointing) techniques, where increasing expectations for quality, reliability, and of technologies and methodologies. The growing emphasis As field joint coating workscopes become more technically challenging, with larger diameter pipe and deeper water, companies must adapt, says Paul McShane, Managing Director, CRC Evans, UK. Figure 1. Spoolbase Bintan, Indonesia. 42 43

pipeline operators and cybersecurity leaders across the world. The incident forced the company to halt operations across its more than 5500 mile pipeline Gulf Coast to the New York Metro area. The six-day cost in downtime caused fuel shortages and price increases. action from the US government. New guidelines from The White House, the Cybersecurity and Infrastructure Security Agency (CISA), and the Department of Homeland pushing critical industries towards the adoption of zero trust cybersecurity approaches. Specifically, the TSA’s latest version of its Pipeline Security directive doubles down on infrastructure systems. This presents range of challenges for pipeline operators with distributed mix of legacy and To address these security and compliance challenges, one of the top pipeline operators in North America turned to Xage, cybersecurity company helping critical infrastructure The major pipeline operator has thousands of miles of pipelines transporting natural gas, gasoline, crude oil, carbon dioxide, and more. Fabric delivers zero trust security to cyber-physical systems with proactive, easy to implement approach that treats stream as its own independent ‘perimeter’. This allows for granular access policy enforcement and prevents breaches before they happen. Zero trust can be delivered as an overlay making possible to implement seamlessly in complex OT environments. trust approach in OT, this pipeline operator was able to quickly reach compliance with access control, credential management, and multi-factor authentication (MFA) or remodelling their existing technology ecosystem, which critical for operators with mix of legacy and modern infrastructure. With the Xage Fabric, the operator’s strategy sites and 5000+ OT assets. The operator also increased productivity for its 500+ users with simplified experience outline of the steps this operator took to become one of the first companies to receive TSA-approval and adopt zero trust cybersecurity model all without disrupting the Assess and evaluate As first crucial step, was important to assess and vulnerabilities and gaps against any federal security guidelines. The operator had plethora of varying systems, protocols, Amit Pawar, VP of Consulting & Services, Xage Security, USA, charts a top pipeline operator’s journey to cyber harden and meet updated TSA security directives. 9 8

PAGE 8

EDITOR’S COMMENT

CONTACT INFORMATION

MANAGING EDITOR

James Little james.little@palladianpublications.com

EDITORIAL ASSISTANT

Sara Simper sara.simper@palladianpublications.com

SALES DIRECTOR

Rod Hardy rod.hardy@palladianpublications.com

SALES MANAGER

Chris Lethbridge chris.lethbridge@palladianpublications.com

SALES EXECUTIVE

Daniel Farr daniel.farr@palladianpublications.com

PRODUCTION MANAGER

Calli Fabian calli.fabian@palladianpublications.com

EVENTS MANAGER

Louise Cameron louise.cameron@palladianpublications.com

DIGITAL EVENTS COORDINATOR

Stirling Viljoen stirling.viljoen@palladianpublications.com

DIGITAL CONTENT ASSISTANT

Merili Jurivete merili.jurivete@palladianpublications.com

DIGITAL ADMINISTRATOR

Leah Jones leah.jones@palladianpublications.com

ADMINISTRATION MANAGER

Laura White laura.white@palladianpublications.com

Palladian Publications Ltd, 15 South Street, Farnham, Surrey, GU9 7QU, UK

Tel: +44 (0) 1252 718 999

Website: www.worldpipelines.com

Email: enquiries@worldpipelines.com

Annual subscription £60 UK including postage/£75 overseas (postage airmail). Special two year discounted rate: £96 UK including postage/£120 overseas (postage airmail). Claims for non receipt of issues must be made within three months of publication of the issue or they will not be honoured without charge.

Applicable only to USA & Canada:

World Pipelines (ISSN No: 1472-7390, USPS No: 020-988) is published monthly by Palladian Publications Ltd, GBR and distributed in the USA by Asendia USA, 17B S Middlesex Ave, Monroe NJ 08831. Periodicals postage paid New Brunswick, NJ and additional mailing offices. POSTMASTER: send address changes to World Pipelines, 701C Ashland Ave, Folcroft PA 19032

warm welcome to the May edition of World Pipelines, which includes a special section on pipelines in extreme environments. Since 2015, we have published an annual focus on ‘extreme’ pipelines, and even hosted online conferences on the topic, such is the breadth of interest in pipeline activity in challenging places. Pipeline design, construction and operation for extreme environments is so interesting because it showcases the industry at its best and most cutting edge; difficult conditions push the sector to adapt and innovate. In covering extreme topics, we’ve seen that the necessity of working in extreme or risk-filled environments affects the pipeline industry in different ways.

Safety is the primary concern, and all endeavours should work towards addressing risk and reducing incidents of harm. We have featured articles on working in dangerous weather conditions, handling hazardous chemicals, constructing pipelines on unsafe terrain or at great depths, navigating the possibility of physical risk, facing local unrest, and more. In any of these environments, or any worksite that is out of the ordinary, appropriate modifications to safety protocols and training are essential.

From a financial perspective, working in challenging places can be rewarding for pipeline personnel: risky jobs command higher wages (although, it must be stated, not in all cases) with compensation generally rising to offset the potential danger or discomfort experienced.

A pipeline operator needs up-to-date risk analysis intelligence in order to ascertain the current risk to personnel, since this advice can often change in a heartbeat. AKE International’s Global Intake platform contains detailed country profiles updated in real-time, and offers emailed intelligence containing risk advisories, daily updates and analytical briefings. Look out for AKE’s upcoming article (July 2023 issue), which will offer expert analysis on the current spate of pipeline incidents in Colombia.

Work in extreme environments can also have an impact on the health, safety and livelihood of the communities situated near pipeline routes. These communities need spokespeople and I’m always cheering for those who seek to make the relationship between pipeline company and community more harmonious. One such trailblazer is Kaella-Marie Earle, who I have admired ever since I interviewed her a few years ago, when she won the John Tiratsoo Award for Young Achievement, awarded by Young Pipeliners International. In her current role as Engineer-inTraining and Construction Project Manager at Enbridge Gas, she works on the management and execution of major pipeline, integrity and storage enhancement projects, and serves as the ViceChair of the Indigenous Advisory Committee. Her commitment to truth and reconciliation with Indigenous peoples, and her drive for reconciliation and inclusion going forwards, is impressive.

Environmentally, extreme environments are often places where pipeline companies are most at risk of ‘losing their social license to operate’. The secure backing of insurers and financial institutions, along with strong evidence-based mandates for the work in the first place, help make these pipeline projects a success for everyone.

Finally, politics can never be taken out of the equation: the political decisions of the few affect the many. The issues of energy independence, national security and climate change often intersect with policy about where to extract natural resources, and how those resources should get to market. The viability of working in an extreme environment can often be determined by the pressure of political imperatives, rather than simple market forces.

Whatever forces shape the outlook for pipeline projects in these testing environments, let’s make sure that we forever prioritise safety and wellbeing for optimum project success. Dig in to the Extreme section at p.17, and let the capable contributors to this special section assume the risk on your behalf.

SENIOR EDITOR Elizabeth Corner elizabeth.corner@palladianpublications.com

The welding and coating experts you can trust

Ensure the efficient, on-time delivery of your onshore and offshore projects with CRC Evans’ market-leading welding and coating services, technologies and integrated solutions, and extensive fleet of pipeline equipment

americas Europe Middle East Africa Asia Pacific crcevans.com enquiries@crce.com @crcevansglobal CONNECT WITH CRC EVANS

WORLD NEWS

TC Energy: Keystone oil spill was caused by a fatigue crack

Canada’s TC Energy said a 14 000 bbls oil spill from its Keystone pipeline in rural Kansas in December was primarily due to a progressive fatigue crack, which originated during the construction of the pipeline (Reuters reports).

The Calgary-based company released the findings after receiving an independent third-party root cause failure analysis (RCFA), as required by regulators.

Keystone’s spill into a Kansas creek was the biggest US oil spill in nine years and prompted a 21 day shutdown of a portion of the 622 000 bpd pipeline, which ships crude from Alberta to US refineries.

TC said it has recovered 98% of the spilled product from the pipeline and cleaned up 90% of the Mill Creek shoreline.

“We are unwavering in our commitment to fully remediate the site and are taking action on the recommendations from the RCFA,” said Richard Prior, President of Liquids Pipelines at TC Energy in a statement.

The company said it is now investigating other sites along

Keystone with similar characteristics, performing extra inspections on 300 miles (482 km) of the pipeline, and reviewing design guidelines, construction and operations.

TC said the RCFA report found the fatigue crack came from a girth weld connecting a manufactured elbow fitting to the section of pipe constructed across Mill Creek. The girth weld was completed at a fabrication factory and met applicable standards.

During construction, the pipe segment came under ‘bending stresses’ that initiated a crack in the girth weld and also led to a deformation in the elbow fitting and a wrinkle in the adjacent piping, TC said. The design of the weld transition made the pipe in that location more susceptible to bending.

“This resulted in the initiation of a circumferential crack in the weld, which led to failure through operations after over a decade,” TC said.

The company said the RCFA findings are consistent with its own investigation released in February.

‘State actor’ is “absolute main scenario” in Nord Stream blasts

A state actor’s involvement in the damage of the Nord Stream pipelines last year is the “absolute main scenario”, though confirming identity will prove difficult, the Swedish prosecutor investigating the attack said on 6 April.

In September 2022, several unexplained underwater explosions ruptured the Nord Stream 1 and newly-built Nord Stream 2 pipelines that link Russia and Germany across the Baltic Sea. The blasts occurred in the economic zones of Sweden and Denmark, and both countries say the explosions were deliberate, but have yet to determine who was responsible.

The blast in the Swedish zone occurred at a depth of 80 m, which the Swedish prosecutor said made it complicated to investigate.

“We believe it will be rather difficult to determine who did this,” prosecutor Mats Ljungqvist told Reuters in a phone interview. “The people who did this have probably been aware that they would leave clues behind and probably took care so that the evidence would not point in one direction, but in several directions,” he added. “That makes it difficult to clearly

Cano Limon-Covenas pipeline attacked again

The suspension of pumping operations at Colombia’s Cano Limon-Covenas oil pipeline will be prolonged after a new bombing attack damaged its infrastructure in the country’s Arauca province, oil transportation company Cenit said.

The attack, the ninth this year, took place on Thursday 20 April in the Saravena municipality, prompting the company to activate its emergency contingency plan to control the subsequent oil spill and mitigate pollution, said Cenit, a subsidiary of Colombia’s majority state-owned oil company Ecopetrol.

“The company calls on the nearby community to refrain from approaching the site of the incident, until the evaluation, repair and clean-up operation that is in place is completed,” Cenit said in a statement. Colombia’s military is working to

point to one actor.”

The investigation continues.

Ljungqvist said investigators had been able to determine what type of explosive had been used and that it ruled out “a very large number of actors”, but declined to name the explosive, citing the ongoing nature of the investigation.

While no conclusion has been drawn, there have been a number of theories as to who blew up the pipelines and how. Germany has confirmed its investigators raided a ship in January that may have been used to transport the explosives used to blow up the pipelines. German media reported the boat could have been used by a small Ukrainian or pro-Ukrainian group.

Ljungqvist said it could not be completely ruled out that an independent group, as opposed to a state actor, was behind the attack, but that it was unlikely.

“There are certain companies that have certain special missions that mean they could, in theory, carry this out,” he said. “We don’t rule out anything, but that it is a state actor who is directly or at least indirectly behind this is of course our absolute main scenario, given all the circumstances.”

secure the area, Cenit added.

Pumping along the pipeline has been suspended since 14 April due to other attacks, a Cenit spokesperson said, adding that the restarting of operations will depend on the military’s ability to secure the area where the attacks took place while repairs continue.

Cenit did not attribute the attack to any particular group, but guerrillas of the National Liberation Army (ELN) and FARC dissidents who reject a 2016 peace deal with the government operate in the area, according to the military.

The Cano Limon-Covenas pipeline, which can transport up to 210 000 bpd of oil and runs along Colombia’s northern border with Venezuela, was attacked 13 times in 2022, leading to fires and contamination of the surrounding area.

MAY 2023 / World Pipelines 5

CONTRACT NEWS

Fugro wins contract for extensive offshore surveys in UAE

Transocean: harsh environment contract award

8 - 11 May 2023

Pipeline Technology Conference (ptc) Berlin, Germany

www.pipeline-conference.com

9 - 11 May 2023

Canada Gas & LNG Exhibition and Conference

Vancouver, Canada www.canadagaslng.com

30 May - 1 June 2023

AIEN International Energy Summit Miami, USA www.aien.org/forms/meeting/Microsite/IES2023

13 -15 June 2023

Global Energy Show 2023 Calgary, Canada www.globalenergyshow.com

8 - 10 August 2023

Rio Pipeline 2023

Rio de Janeiro, Brazil www.riopipeline.com.br

5 - 8 September 2023

Gastech 2023 Singapore www.gastechevent.com

5 - 8 September 2023

SPE Offshore Europe 2023

Aberdeen, Scotland www.offshore-europe.co.uk

21 - 22 September 2023

Subsea Pipeline Technology Congress (SPT 2023)

London, UK www.sptcongress.com

2 - 5 October 2023

ADIPEC 2023

Abu Dhabi, UAE www.adipec.com

Fugro has been awarded a contract for site characterisation services in support of one of the largest long-term field development programmes in the United Arab Emirates (UAE).

Commencing April 2023, Fugro will perform a series of offshore surveys including geophysical, geotechnical and ROV inspections supported by advanced engineering and geoconsulting studies to help inform the FEED. The project consists of approximately 600 km pipeline route assessment with 800 crossings, 49 jacket surveys and island offshore surveys.

Near real-time insights into the ground conditions will be available using Fugro’s remote data management solutions, delivered via Fugro’s digital platform.

Perma-Pipe announces contract awards

Perma-Pipe International Holdings, Inc. has announced it has been awarded two contracts with a combined value in excess of US$8 million. The first is to provide insulated piping for a thermal distribution system on the campus of Fanshawe College in London, Ontario, Canada. The contract is to supply Perma-Pipe’s XTRU-THERM® thermally insulated piping system.

In addition, Perma-Pipe International Holdings, Inc. announced its subsidiary, Perma-Pipe Middle East LLC, has been awarded contracts by China Petroleum & Chemical Corporation (Sinopec) for the provision of thermally insulated pipe and field joints for a project in Uganda.

This project will feed the East African crude oil pipeline (EACOP) transporting oil to the coast in Tanzania. The project will utilise Perma-Pipe’s XTRU-THERM insulation system, a spray-applied polyurethane foam jacketed with a high-density polyethylene casing. The projects will begin execution in Perma-Pipe’s new facility in Abu Dhabi, UAE in 3Q23.

Saleh Sagr, Senior Vice President for Perma-Pipe’s MENA region commented, “I am glad to announce that this important project has been assigned to Perma-Pipe. We have recently announced the opening of the new plant in Abu Dhabi and obtaining this award is an excellent start.”

Transocean Ltd. has announced contract fixtures for two of its harsh environment semisubmersibles.

Transocean Endurance was awarded a multi-well plug and abandonment contract in Australia with an independent operator. The estimated 240 day contract is expected to commence in January 2024 and contribute approximately US$91 million in backlog, excluding fees for mobilisation.

In Norway, Wintershall DEA exercised a one-well option on Transocean Norge The well is expected to commence in May 2023 ahead of the existing firm term for 60 days and contribute approximately US$22 million in backlog.

ON OUR WEBSITE

• Borusan Mannesmann finalises acquisition of Berg Pipe

• Iraq asks Turkey to restart northern oil exports

• Corinth Pipeworks awarded contract for the N05-A pipeline

• DNV grows energy testing capability in the Netherlands

• US warns companies over Russian oil price cap

• Growth expected in AUV and ROV market

Follow us on LinkedIn to read more about the articles linkedin.com/showcase/worldpipelines

EVENTS DIARY 6 World Pipelines / MAY 2023

PROTECTIVE OUTERWRAPS

HEAT SHRINKABLE SLEEVES

SOIL-TO-AIR INTERFACE

INTERNAL

DENSO™ are leaders in corrosion prevention and sealing technology. With 140 years’ service to industry, our mainline and field joint coating solutions offer reliable and cost effective protection for buried pipelines worldwide.

United Kingdom, UAE & India

USA & Canada

Australia & New Zealand

Republic of South Africa

FOR CORROSION PREVENTION

www.denso.net

www.densona.com

www.densoaustralia.com.au

www.denso.co.za

LIQUID EPOXY COATINGS

PETROLATUM TAPE WRAP SYSTEMS

BUTYL TAPE WRAP SYSTEMS

PIPE LININGS

BITUMEN TAPE WRAP SYSTEMS

A MEMBER OF WINN & COALES INTERNATIONAL

VISCO-ELASTIC COATINGS

he Colonial Pipeline attack was a wake-up call for pipeline operators and cybersecurity leaders across the world. The incident forced the company to halt operations across its more than 5500 mile pipeline responsible for transporting gasoline and other fuels from the Gulf Coast to the New York Metro area. The six day cost in downtime caused fuel shortages and price increases.

Since then, increased cyber threats have spurred action from the US government. New guidelines from The White House, the Cybersecurity and Infrastructure Security Agency (CISA), and the Department of Homeland Security’s Transportation Security Administration (TSA) are pushing critical industries towards the adoption of zero trust cybersecurity approaches. Specifically, the TSA’s latest version of its Pipeline Security directive doubles down on strict access control and credential management for critical infrastructure systems. This presents a range of challenges for pipeline operators with a distributed mix of legacy and modern equipment.

To address these security and compliance challenges, one of the top pipeline operators in North America turned to Xage, a cybersecurity company helping critical infrastructure organisations adopt zero trust.

The major pipeline operator has thousands of miles of pipelines transporting natural gas, gasoline, crude oil, carbon dioxide, and more.

In contrast to perimeter-based security models, the Xage Fabric delivers zero trust security to cyber-physical systems with a proactive, easy to implement approach that treats

the identity of each machine, application, user, and data stream as its own independent ‘perimeter’. This allows for granular access policy enforcement and prevents breaches before they happen. Zero trust can be delivered as an overlay on top of the existing systems and network architectures, making it possible to implement seamlessly in complex OT environments.

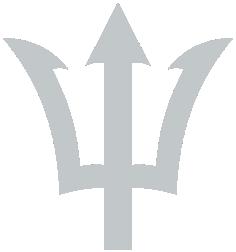

Despite the perceived challenges of adopting a zero trust approach in OT, this pipeline operator was able to quickly reach compliance with access control, credential management, and multi-factor authentication (MFA) requirements. They were able to do so without replacing or remodelling their existing technology ecosystem, which is critical for operators with a mix of legacy and modern infrastructure. With the Xage Fabric, the operator’s strategy accelerated the pipeline’s zero trust rollout across 700+ sites and 5000+ OT assets. The operator also increased productivity for its 500+ users with a simplified experience and single sign-on for all OT assets. The following is an outline of the steps this operator took to become one of the first companies to receive TSA-approval and adopt a zero trust cybersecurity model – all without disrupting the services that communities rely on every day.

Assess and evaluate

As a first crucial step, it was important to assess and evaluate the operator’s current systems and networks for vulnerabilities and gaps against any federal security guidelines. The operator had a plethora of varying systems, protocols,

8

9

Amit Pawar, VP of Consulting & Services, Xage Security, USA, charts a top pipeline operator’s journey to cyber harden and meet updated TSA security directives.

and control interfaces. These systems were composed of new devices with robust security controls along with older legacy devices that had little to no security capabilities. Some examples include: programmable logic controllers (PLCs), remote terminal units (RTUs), human machine interfaces (HMIs), meters, and sensors.

This created a major roadblock for their productivity and displayed inadequate protection. Specifically, it resulted in inconsistent access management across their 5000+ OT systems. There was heavy reliance on shared static device passwords and group accounts across these varying systems and assets – posing a gaping vulnerability to breaches.

What’s more, the operator was unable to enforce granular policies within their Purdue model architecture, a key framework used to protect OT technologies from malware and other attacks. The operator’s existing devices were zonebased so they were unable to restrict access to individual assets based on employees’ identities. In turn, malicious files could be accidentally uploaded into the OT environment by the operator’s 1000+ employees. At this stage, enabling access to any new employees required firewall policy changes that could take days to weeks to implement, harming productivity. Providing access to OT devices via protocols like virtual network computing (VNC) and remote desktop protocol (RDP) through firewall rules, at the lowest levels of their Purdue model implementation, increased security risks unnecessarily.

Another task at hand was to update multi-factor authentication (MFA) tactics to meet specific TSA requirements. If an attacker retrieves a password, an MFA request usually prevents them from getting any further. However, the Uber hack by the Lap$sus group showed that even MFA can be vulnerable under the right circumstances. Deemed ‘MFA fatigue attacks’, this strategy targets security professionals by sending multiple MFA requests to a secondary device, usually in the middle of the night, in hopes they inadvertently approve access. After passing the single MFA layer, hackers typically launch malware and attempt to make their way deeper into the company’s systems to find valuable assets. In the case of an oil and gas pipeline, that could give hackers access to systems that run these critical assets to wreak havoc.

Develop a roadmap to mitigate gaps; and begin implementation to meet TSA guidelines

Following the assessment, we outlined suggested technologies and strategies based on gaps, then developed a roadmap and implementation plan to meet compliance requirements. In this case, the operator needed a solution for a zero trust identity verification and access policy enforcement for all their employees and OT assets that could be implemented into their systems with ease. The final implementation plan and roadmap were then sent to the TSA for review, which was quickly approved by the agency.

To solve their access management problems, we implemented a scalable and consistent access control approach across multi-vendor OT systems and synchronised with Active Directory for single sign-on. Another benefit

was eliminating static and shared passwords across systems. To ensure continuous, active operation at all locations, we enabled a distributed architecture with decentralised policy enforcement. This provides access management even when remote sites do not have connectivity to the central site. Lastly, it was crucial to ensure no single point of security failure via multi-node architecture, so security services continue uninterrupted, even if an attacker succeeds in a partial compromise.

To address concerns with current MFA strategies, Xage provides a multi-layer MFA tool that puts up a series of gates, so that if an attacker makes their way into the first level, they won’t be able to get to the organisation’s more critical technology. In the case of this pipeline operator, implementation of multi-layer MFA helps them mitigate any potential attacks from compromised file uploads via scanning and blocking malicious files. We made sure that the operator could verify and control all connections and interactions between users, devices and apps, whether they come from inside or outside the network perimeter.

We also recognise that cybersecurity tasks can be taxing on personnel and staff, particularly when the operator had disjointed systems at the start. So, we looked to increase their productivity, costs, and cyber harding without the expense, disruption and lengthy timescales of replacing their existing systems. We helped their personnel productivity by establishing a consistent approach to access management with single sign-on for all OT assets. We also improved their access visibility by beginning to log interactions between users and devices, thus helping to establish reliable audit trails for investigating security incidents. An added financial bonus: we lowered application maintenance costs by integrating their applications and processes with the Xage Fabric.

Support and ongoing assessment programming

Overall, the operator successfully improved their security posture with the Xage Fabric rollout while meeting TSA security requirements. We are continuously covering ongoing maintenance and improvements for the pipeline operator and ensuring they’re receiving necessary operational support.

Looking to the future, this operator plans to scale secure remote access to all their sites to enable technicians, including authorised third-party technical experts, to work remotely. With critical infrastructure in need of stronger protection from threats, all operations across oil and gas will benefit from independent expertise to accelerate their shift to proactive cyber-defence strategies and meet security requirements.

Federal regulations aside, undergoing the necessary shift from a reactive to proactive zero trust security strategy is a critical step towards a more secure future for energy infrastructure. This pipeline operator proved that despite how distributed and complex OT environments may be, meeting TSA security requirements quickly and without disruption is possible. We hope their success will inspire greater adoption of zero trust security strategies and help curb the effects of a growing threat landscape.

10 World Pipelines / MAY 2023

YOUR TRUSTED HDD PARTNER FOR ALMOST 40 YEARS 2313 boulevard de la Défense, 92000 Nanterre France +33 (0)1 57 60 93 21 contact@hdi.fr www.hdi.fr HORIZONTAL DRILLING INTERNATIONAL TRENCHLESS INSTALLATION OF PIPELINES UNDER NATURAL OR ARTIFICIAL OBSTACLES

25 years gone in a FLASH!

Thanks for the continued support of our much-valued staff, clients and suppliers.

Propipe will continue to supply Pipeline Pigs, Pipeline Plugs and Trident Pig Tracking Equipment to the same high standards that we have maintained since 1998. www.piggingsmarter.com

TrevorDearing,DirectorofCriticalInfrastructure Solutions,Illumio,UK,adviseshowpipelineoperatorscanstay aheadofmountingcyberthreats.

he energy sector finds itself operating against a turbulent backdrop of soaring electricity demands, price spikes and an unrelenting climate crisis. Such pressures are forcing rapid digitalisation in the sector and combined with socioeconomic challenges, have exposed the industry to severe cyberattacks.

Criminal groups increasingly deploy disruptive attacks such as ransomware against the sector, risking serious consequences like blackouts and fuel shortages. Highprofile incidents such as the Colonial Pipeline attack have shown how damaging such attacks can be.

Building up to a cyber crisis

Today’s heightened level of cyber risk has been years in the making, with a confluence of different factors creating a perfect storm. Skyrocketing demand is one primary issue. ExxonMobil estimates that global energy demand increased by 15% from 2021 to 2022, driven by developing nations

13

and international growth in industrialisation. The spike in demand and an unstable geopolitical climate has also seen soaring prices, with wholesale gas increasing by more than 400% in 12 months.

The rise in demand has increased pressure to modernise ageing architecture for generating and delivering energy, with many operators turning to automation to increase efficiency. These trends have been exacerbated further by the global push for environmental energy production, such as the EU’s proposed changes around hydrogen and the construction of Europe’s first clean hydrogen, beginning in December 2022.

However, as digitalisation continues, the energy sector is trapped in a difficult balancing act between operability and security. With operations reliant on large physical assets such as refineries and pipelines, building and transforming infrastructure is a slow process. The sheer scale means that even minor updates can be daunting with so many systems involved.

How threat actors exploit complex and ageing infrastructure

While there is an unavoidable need to update infrastructure, further digitalisation will also increase cyber risk exposure. As data processing and grids become more intrinsically interlinked, the potential for a major IT-side failure impacting energy delivery increases. Remotely located smart systems are more difficult to secure with traditional network-based security.

This results in an increasingly complex combination of traditional IT systems, operational technology (OT), and connected Internet of Things (IoT) infrastructure. Effectively monitoring and protecting this mixture of disparate systems against cyber threats presents a steep challenge, as different elements are rarely designed to work together.

The outcome is organisations struggling with expansive, convoluted IT environments that present a large attack surface for cyberattacks. The complexity means that ageing infrastructure elements are often overlooked, presenting easy attack paths for threat actors. In October 2022, for example, Tata Power suffered a breach due to a discontinued web server that was still integrated with other systems. The ransomware gang known as Hive claimed responsibility for the attack and followed up the initial ransomware infection by leaking stolen confidential data when Tata apparently refused ransom demands.

The notorious Colonial Pipeline ransomware incident was also the work of the criminal gang DarkSide, apparently acting independently despite allegations of state-backing. The same group appears to be behind a more recent attack this year on German oil and gas storage company, Oiltanking, and its sister company Mabanaft.

Alongside opportunistic criminal gangs, we have seen an increase in the weaponisation of energy in global, physical, and cyber conflicts. As critical national infrastructure (CNI), the energy sector has been targeted in geopolitical conflicts for some time, with the infamous Stuxnet attack of 2010 being one of the earliest high-profile examples. More recently, major attacks on Ukraine’s power grid in 2015 and 2016 during the earlier conflict with Russia resulted in widespread blackouts.

Why are pipeline providers being targeted?

Pipeline infrastructure is an attractive target for both independent criminal gangs and state-backed threat groups because it is particularly vulnerable to cyber tactics like ransomware. These attacks are centred around causing as much disruption to the target as possible by locking down critical systems and encrypting essential data.

For criminal gangs, the aim is to force the victim into meeting their ransom demand. These groups know that pipeline operators will be under intense pressure to pay up as every minute of downtime will rack up more costs. The prospect of fuel shortages and other widespread consequences gives the attacker even more leverage against the industry. The encryption is also increasingly coupled with data exfiltration, with attackers stealing large volumes of data and threatening to leak it unless their payments are met. This ‘double extortion’ technique has become a mainstay for ensuring a profit, evident in the Colonial Pipeline breach, the recent Tata Power incident, and many others.

Meanwhile, nation-state-level actors will generally seek to weaken opposing nations and send a message. Such attacks are an appealing alternative to physical sabotage or traditional military strikes, as cyber activity has a high level of deniability. While these adversaries will seek to extort payments from their victims, the disruption itself is often the primary goal.

The impact of a serious attack

Whatever the perpetrator’s motivation, the result of a successful attack on pipeline infrastructure can have serious impacts that ripple across entire industries and economies. The Colonial Pipeline system, for example, is responsible for moving roughly 45% of all fuel consumed on the East Coast of the US. While the ransomware locked down payment systems rather than the pumping infrastructure itself, it still meant that pumping operations ground to a halt. Despite Colonial Pipeline opting to meet the US$5 million ransom in the hopes of a swift resolution, the disruption lasted for nearly a week.

The resulting fuel supply shortage caused widespread issues across the country. Multiple airports reliant on the pipeline implemented urgent schedule changes to compensate. Panic buying set in across several states as the shutdown dragged on, with filling stations from South Carolina to Washington DC seeing most of their stations entirely run out.

The same group’s recent attacks on German storage and trading firms Oiltanking and Mabanaft saw an immediate impact on inland supply, with terminals operating at limited capacity. The attack again appears to have hit payment systems and impacted a large swath of the fuel distribution infrastructure.

Rubbing salt into the wound, many of these incidents also saw large volumes of corporate data stolen and often publicly leaked online. More than 100 GB of data was stolen from Colonial Pipeline before the encryption was triggered, although the Darkside group appeared to have refrained

14 World Pipelines / MAY 2023

from leaking it when the ransom was met. Just over a week after the Tata Power breach, the perpetrators began leaking large volumes of data ranging from employees’ personal information to engineering specs and financial records.

Such incidents are far from one-offs, and each successful attack and payment encourages further attacks. The GridEx VI exercise, jointly run by NERC and E-ISAC from April 2022, shows that future cyberattacks could cause widespread power outages.

Focusing on limiting cyber threat disruption

The widespread threat posed by cyberattacks on pipeline operators has not gone unnoticed. The Colonial Pipeline attack served as a particular eye-opener on the risk to the pipeline industry and the impact on supply. The incident has prompted a sea change in the industry, including several security directives from the TSA in quick succession with heightened requirements for pipeline operators.

The new TSA directives require pipeline operators to focus on maintaining services while under attack. To meet requirements, operators will need to implement a planned approach to protecting their pipeline networks. These requirements include mapping the interdependencies between the OT and IT systems, segmenting the IT and OT systems and mitigating vulnerabilities. Operators should look towards newer technologies, such as zero trust segmentation, that can help meet multiple requirements while also driving immediate resilience gains.

Segmentation is the process of dividing the network environment into separate sections, making it more difficult for intruders and automated malware alike to travel through the network and reach critical data and systems. Zero trust segmentation technology is a more advanced form, coupling the segmentation approach with the zero trust principle of ‘never trust, always verify’. This means users cannot move across segments without meeting verification demands such as multifactor authentication (MFA).

The zero trust approach means the authentication requirements will fit the asset’s criticality and the risk involved, enabling legitimate users to pass through smoothly while blocking unauthorised intruders. Zero trust segmentation is particularly effective against disruptive and fast-moving attacks like ransomware, as well as halting or delaying high-level threat actors seeking to infiltrate deeper into the network.

Steps for increasing cyber resilience

Globally, there is an increasing need to secure our energy delivery systems and infrastructure. But with many pipeline operations comprising sprawling expanses of IT, OT and IoT systems, it can be challenging to know where to begin to strengthen cyber resilience.

Operators can cut through much of the complexity by following an established cybersecurity framework. This will make it easier to identify priorities and divide the seemingly impossible task into manageable stages. The NIST Cybersecurity framework is one of the most widely

respected and relied-upon examples. It divides improving security resilience into five key steps:

Identify

Determine what assets are most in need of protection and prioritise activity accordingly. This requires extensive auditing to accurately map assets across IT, IoT and OT systems.

Protect

Implement a plan to protect vulnerable areas and replace or compensate for ageing software or assets like OT that run on different systems. Limiting connectivity and communication through technology like zero trust segmentation is valuable here.

Detect

Ensure capabilities are in place to detect and mitigate threats already within the network. A combination of tools such as network detection and response (NDR) and user and entity behaviour analytics (UEBA) will help to provide an early warning of abnormal activity.

Respond

The ability to move quickly to contain active threats and mitigate their impact. A combination of automated and manual approaches through security operation centre (SOC) and security orchestration automation and response (SOAR) is necessary. Segmentation can prevent fast-acting threats such as ransomware from spreading through the network.

Restore

Finally, being prepared to restore any damaged systems as quickly as possible. This also includes processes to learn from attacks and fine-tune processes, technology, and response playbooks to improve resilience against future incidents.

Moving to a more proactive mindset

Implementing the right technologies and processes will improve cyber resilience, enabling even the most expansive and unwieldy pipeline infrastructure to be more tightly managed and defended against incoming threats. Measures such as EDR and zero trust segmentation will also help to shift the organisation to a more focused, proactive approach to security. The emphasis is on protecting the assets rather than the network as a whole.

This also leads to a mindset known as ‘assume breach’ – accepting that some form of cyber intrusion is inevitable and focusing instead on limiting the damage. Even if outer network defences are breached, technology like zero trust segmentation can prevent the attack from reaching critical areas, minimising the chance of a significant disruptive incident.

With such a vast attack surface and so many threat actors targeting the sector, pipeline operators will inevitably be breached at some point. But by being prepared to contain attacks, organisations will have the best chance of preventing a breach from spiralling into a major crisis leading to pumping shutdowns and fuel shortages.

16 World Pipelines / MAY 2023

The Best Liquid Epoxy Solutions For Pipelines SCAN ME SCAN ME The Toughest HDD Coating on the Market HBE - The Best Performing Field Joint Coating ®

The welding and coating experts you can trust

Ensure the efficient, on-time delivery of your onshore and offshore projects with CRC Evans’ market-leading welding and coating services, technologies and integrated solutions, and extensive fleet of pipeline equipment

americas Europe Middle East Africa Asia Pacific crcevans.com enquiries@crce.com @crcevansglobal CONNECT WITH CRC EVANS

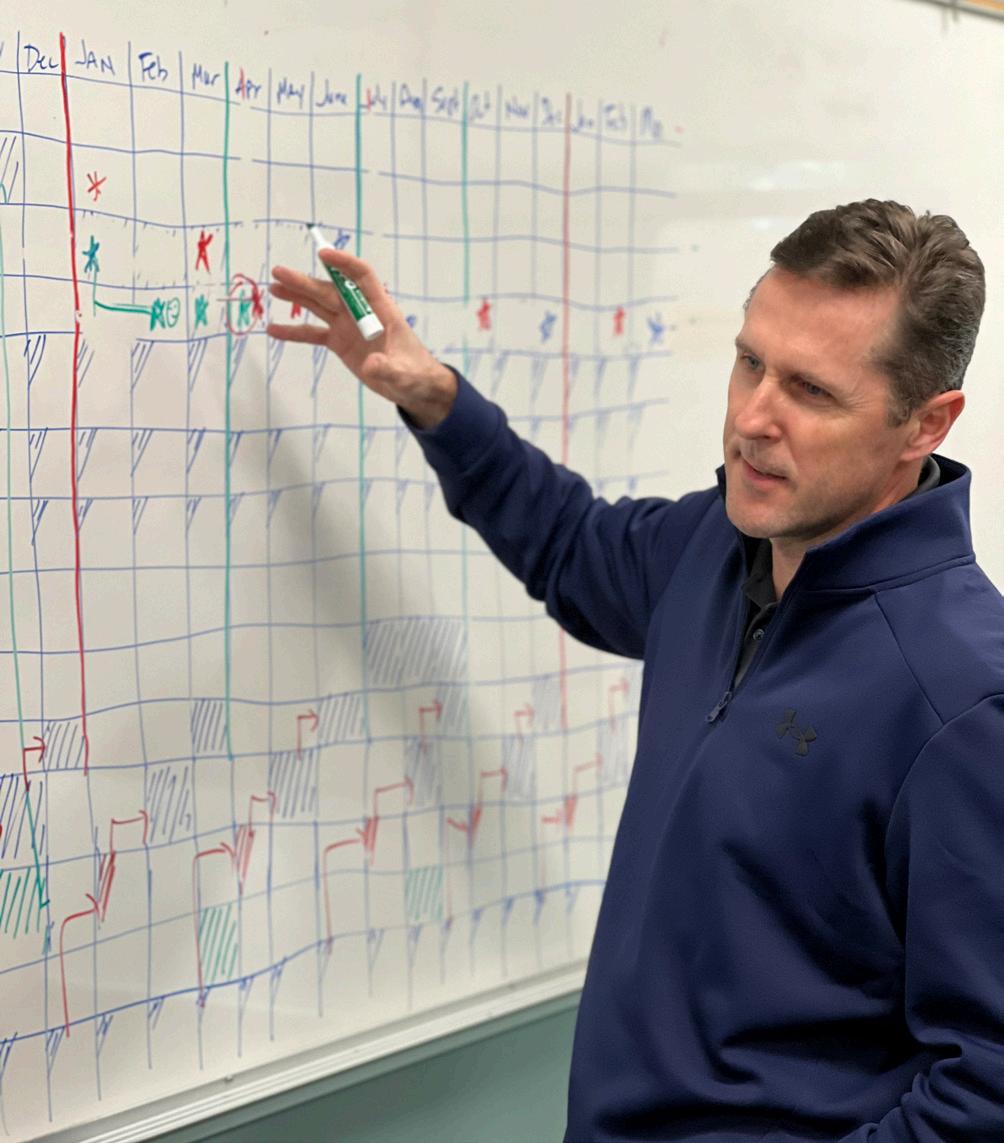

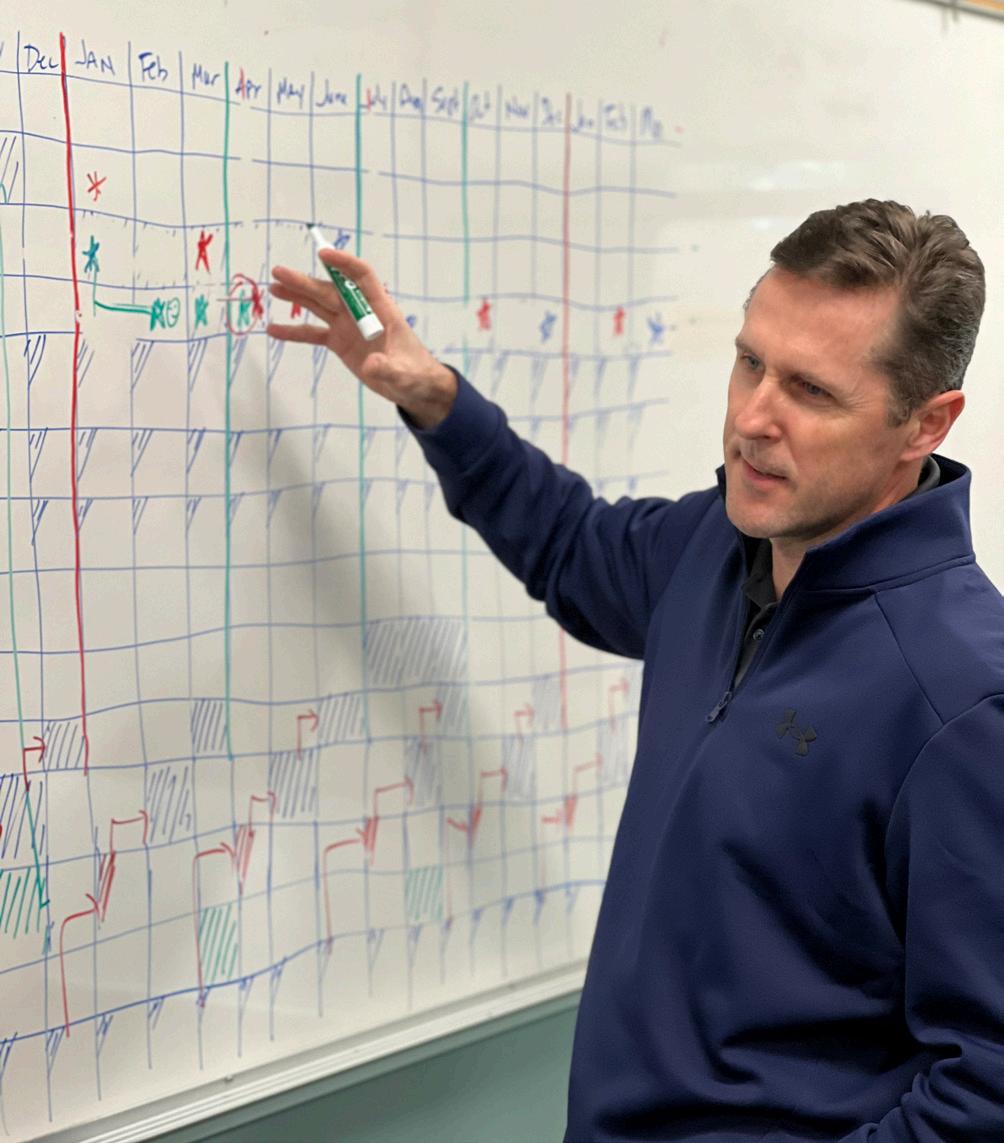

ENTRUST Solutions Group’s safety management systems reduce risk before an incident occurs, says Jim Francis, Vice President – SMS Consulting, ENTRUST Solutions Group, USA.

earning to identify, analyse, and mitigate potential hazards in the workplace drives us to take a deeper look into our safety management systems (SMS). ENTRUST Solutions Group (EN), a leading national engineering, consulting, and compliance services firm, has experts experienced in the development, implementation, and improvement of a SMS.

A SMS is a comprehensive, systematic and deliberate approach to managing the safety of the workforce, assets, and the public. It is focused on proactively identifying and reducing risk. Employees and stakeholders are empowered to raise concerns and act to mitigate risks, while continuously improving processes, procedures, performance, and culture.

EN has resources in place to help clients address specific challenges and areas of risk that surface when exercising the SMS. EN’s data solutions, integrity management, and engineering and design teams can guide businesses in addressing risks in their workplace and support solutions to mitigate risk.

In 2015, The American Petroleum Institute (API) provided the framework for SMS in the ‘Recommended Practice 1173’. The team at EN uses key elements from API RP 1173 and other SMS and quality management system (QMS) standards to work together to drive engagement and accountability in the workplace.

“When you think of the changes to the natural gas and liquids pipeline industry over the last 20 years, we’ve already developed programmes that have improved safety and compliance,” said Jim Francis, EN’s Vice President of SMS consulting.

17

“Numerous regulations and the evolution of technology add a complexity and increased demand to continue to drive SMS to be better,” he added.

Building a SMS requires continuous focus over a long period of time. “Implementing SMS is a marathon, not a sprint,” said Francis, “and it takes dedication, persistence, and fortitude to be engrained in your culture and business operations.” Often, a measurable reduction of risk requires multiple cycles of analysis before it is known if the mitigations are effective. A SMS adds a layer of control to an evolving environment. EN ensures that SMS is inclusive of all programmes in the workplace by complementing and creating an opportunity to improve safety processes.

Risk management

“Risk management is at the heart of a SMS,” said Francis. “It establishes the need for education, drives goal setting and creates the basis for continuous improvement.”

Along with all of the factors in a SMS, risk management must be routine and intentional. This allows all of the compliance requirements and activities to be measured, establishes the criteria for the management system, and, because of audits, measures whether the work is completed as required. Addressing and analysing risks are to be completed throughout the year and on purpose. Risk management first starts with a defined set of procedures that describes how the processes will be executed. The procedures break down each process into different components: risk collection, decision-making, risk assessment, and mitigation planning.

According to Francis, the owner of the risk management process should meet at least annually with stakeholders to have a facilitated discussion about the operational risks relevant to their group.

“The fourth quarter of the year is a great time to reflect on the performance and experiences of the previous months. By

discussing new or changing risks, you can develop a plan for the upcoming year,” Francis said.

Once a plan has been made for the year, including goals and objectives, the team can start conducting deep-dive risk assessments on individual risks. These are facilitated sessions that thoroughly review a risk, the associated operational controls, and create a defined improvement plan as an outcome. A risk management process must be flexible to allow for urgent and emerging issues. Most risks are identified during the facilitated and routine execution of the SMS. Evaluating the effectiveness of controls allows for additional or changing risks that may occur.

At its best, Francis shared, a SMS reduces risk before an incident occurs. By creating structure and establishing intentional engagement activities, risk discussion ensures that the voices of all stakeholder groups are incorporated into a risk management programme. The outcome of the process creates clear operational focus for the upcoming year, setting safety improvement priorities for the enterprise.

The SMS risk management process bridges the gap between detailed asset-based integrity processes and the high-level enterprise risk management process. Identifying risks for SMS allows an examination of all aspects within a company. The mitigation of these risks provides a closer look at the controls that are in place and to determine if it is effective at preventing risks from occurring.

Operational controls

In SMS, operational controls are designed to minimise the likelihood of a hazard leading to a safety incident. These controls also help minimise the consequence when an incident occurs.

Francis shared, “The further you go up on the hierarchy of controls, the solution is more effective at preventing the risk from occurring. Higher level controls should be outcomes of the engineering processes and integrity management programmes.”

Operational controls can be found in two forms: preventive and responsive. A preventive control is intended to keep a hazard from causing an incident to occur, such as locating a service line to prevent excavation damage. A responsive control is intended to minimise the consequence if the incident does occur, such as having an excess flow valve installed on the service line, which shuts off the gas before something more catastrophic can occur.

Understanding the relationship between operational controls can be challenging due to industry regulations. SMS is at its best when a company is facilitating intentional and routine risk assessments. This can include reviewing operational controls and its effectiveness before an incident occurs.

Francis said, “EN thinks well beyond the compliance requirements when assessing our operational controls. Controls should be specific and evidence should be available to prove compliance.”

Using statistical analysis and sampling tools, EN provides clients with confidence in the results of the process control checks. By leveraging tools such as a bow-tie analysis or process hazard analysis, companies can visually see the relationships. These analyses involve facilitating small teams in identifying and documenting which operational control is intended to prevent or minimise a hazard.

18 World Pipelines / MAY 2023

Figure 1. Risk management is the engine that drives the SMS process.

FOREFRONT INNOVATION SERIES

A new, virtual, technical series from AMPP!

Forefront Innovation Series is a new and innovative web-based series from AMPP. Filled with the latest insights and technical developments, Forefront brings together subject matter experts from a wide variety of industries and professional backgrounds to discuss hot-button materials protection and performance related technical topics. Utilizing best practices, case studies, and lessons learned, these engaging sessions will shed light on challenges faced by different industries. Top 5 reasons to attend:

• Gain insights to the New & Emerging Technologies

• Participate in Open Discussions about Future Innovations and Theories

• Engage with Subject Matter Experts to get your questions answered

• Network with peers & discuss hot-button materials protection and performance related technical topics

• Earn up to 6 Professional Development Hours per series

View our Calendar for Upcoming Events!

Visit www.ampp.org/events/forefront-innovation-series

Francis said, “Creating a visual map to see the relationship between the hazards, controls, risks, and outcomes is an important outcome in a risk assessment. This approach is very effective when implementing new regulations. Evaluating your controls through a risk assessment allows you to see the gaps as you plan for implementing new requirements, particularly thinking beyond just updating your compliance procedures.”

Documented controls are a foundation to compliance and continuous improvement. Without structure or procedures in place, it is difficult to identify the effectiveness of a risk assessment.

“One of the more rewarding aspects of mapping your controls is that it often reveals to individuals who own parts of a process how what they do affects the work of others,” Francis said.

Whether it be changes to controls, such as procedures and training, or changes that directly affect the pipeline system, there are decisions made every day that have an impact on the safety of a pipeline system and the stakeholders that operate it.

Safety assurance

The EN team works together with clients to ensure the SMS is driving the level of performance expected by providing improved safety and a reduction of risk. Safety assurance makes sure that SMS is having a positive impact on a company’s safety culture. Putting a structure in place is key to allowing the measurement of progress and effectiveness of a SMS against an established baseline.

Francis said, “It is important to not only show how you are complying with the SMS requirements, but also demonstrate that you are reducing risk.”

Auditing is one of the most effective ways to measure risk. Internal audit processes create a continuous improvement plan and supports compliance with the requirements. Leveraging an external resource to perform these audits can provide added value to a company’s SMS by recommending practices that an internal audit team may not be privy.

Francis said, “Going beyond compliance is important. It is good to get an outsider’s perspective to assess the quality of the process.”

Measuring the effectiveness of risk management is one of the primary goals of a SMS. A risk management programme should provide metrics that quantify the change in risk over time. These measurements reflect the quality of the process, stakeholder engagement, and leadership commitment to risk management.

Programme level metrics provide continuous measurements of high-risk processes, such as emergency response times or excavation damage rates. The performance of stakeholders can be measured by engagement metrics. These metrics illustrate participation in continuous improvement events or SMS leadership meetings.

Measuring risk at an individual level shows progress of the mitigation efforts over time and evaluates if the mitigations were effective. Particularly early in the implementation of an SMS when the risk register is more volatile and more stakeholders are getting engaged, improvement can be shown even if the aggregate risk score increases. “Your goal is to quickly be able to communicate to your leaders whether there are additional actions that need to be taken to address any emergent issues,” Francis said.

Establishing key performance indicators (KPIs) is also a way to demonstrate how an SMS is reducing risk and improving safety. There are multiple elements to how KPIs are leveraged within a SMS.

SMS programme metrics illustrate progress. These results, which include implementation progress and audit results, are

Figure 2. Annual cycle of an SMS should drive decision-making, prioritisation, resource planning, and review in a routine and intentional way.

20 World Pipelines / MAY 2023

Figure 3. Author, Jim Francis, facilitating a workshop on safety management systems.

typically reported on an annual basis. Risk management metrics demonstrate the change in risk from the baseline assessment and previous results. This includes changes in risks associated with specific areas where mitigation activities were completed.

Engagement metrics measure the level engagement in the SMS from various stakeholders, such as employees identifying risks or corrective actions. Pipeline safety programme metrics are continuous metrics associated with high-risk processes, including excavation damage rate, emergency response times, and integrity assessments. These programme-level metrics are actively tracked and monitored through the year as part of an SMS.

“At EN, we help our clients develop their SMS metrics and scorecards,” Francis said. “We’ve worked with our clients to develop systems, metrics, dashboards, and reports that allow them to see the effectiveness of their SMS.”

Conclusion

Creating an infrastructure of support within your company allows teams to quickly gather the information needed to review the effectiveness of a SMS. Francis shared, “A SMS management review should be structured around the input requirements, making it easy to demonstrate compliance and provide a good visual of the programme’s strengths.”

Implementing a governance process that is executed throughout the year will allow management to perform on-going analysis. Management is also responsible for communicating plans and outcomes of the SMS to stakeholders. By doing so, stakeholders know that they have a voice in the SMS.

According to API RP 1173, leadership ensures that routine processes are in place to foster continuous improvement. Continuous improvement methods should be leveraged on a daily, weekly, monthly basis to drive change both intentionally and routinely. Engagement in continuous improvement creates active stakeholders who solve their own problems, which drives further engagement and influences a positive culture.

Francis explained when applying continuous improvement to risk mitigation activities, “You want the people who own and exercise the process to help improve it. When this occurs, you get the type of engagement that’s needed to drive your company’s safety culture.”

Ensuring that continuous improvement methods are fully implemented and effective is driven by accountability.

“By having effective, continuous improvement processes and expecting your teams to use them in their daily work activities, risk management becomes routine,” Francis said.

Building a quality SMS adds a layer of control to an already complex environment. EN works together with clients to ensure the SMS process is efficient in its execution and continuous growth.

“EN helps clients develop procedures to all aspects of a SMS. We help connect the dots to all of your existing procedures, operational control documents, and elements of your management system,” Francis said.

PosiTector ® Inspection

All Gauges Feature...

n NEW Larger 2.8” impact resistant color touchscreen with redesigned keypad for quick menu navigation

n NEW On-gauge help explains menu items at the touch of a button

n NEW Weatherproof, dustproof, and water-resistant —IP65-rated enclosure

n NEW Ergonomic design with durable rubberized grip

n Shock-absorbing protective rubber holster for added impact resistance

n Two year warranty on gauge body AND probe

n Conforms to national and international standards including ISO and ASTM

n NEW Auto rotating display with Flip Lock

n NEW Screen Capture—save 100 screen images for record keeping and review

Customized Inspection

Kits... Build your own kit from a selection of gauge bodies and probes to suit your needs.

Backwards Compatibility!

The PosiTector gauge accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), gloss (GLS), and ultrasonic wall thickness (UTG) probes manufactured since 2012.

Introducing the next generation PosiTector gauge body for all your inspection needs.

DeFelsko Corporation l Ogdensburg, New York USA Tel: +1-315-393-4450 l Email: techsale@defelsko.com

22

orizontal Drilling International (HDI), a major international player in horizontal directional drilling (HDD) for the energy market, has completed the works to replace the crude oil import pipelines between stations C1 - C2 and C3 - C4, including the crossing of the Danube River and the Borcea branch, by trenchless method, for CONPET SA, in Romania.

The crossing site was in Fetesti, about 150 km east of Bucharest. This place is well known by Romanian geologists and is used as a site for learning for future geologists, since it has almost all the types of soil that can be found in Romania (rocky and sandy ground).

The project was carried out jointly by the CIS GAZ S.A, Romania, as the leader of the association, and HDI. The contract was concluded on 30 August 2021 for the design and execution of the works, with a deadline for the completion on 15 August 2023. The execution of the works started on 10 May 2022 and was completed four months ahead of schedule.

The scope of work included the pipe supply; the welding of six steel pipelines (1250 m of 8 in., 20 in. and 28 in., and 1460 m of 8 in., 20 in. and 28 in.); six horizontal directional drillings; trench works; and welding from drilling entry and exit of each 20 in. and 28 in. pipe to the stations; backfilling; and site reinstatement.

“Reliability of energy transport infrastructure is of paramount importance, not only with regards to security of supply but also from an environmental perspective. The completion of this project, using environmentally friendly

23

Camila Sanchez Prado, Horizontal Drilling International (HDI), France, outlines a crude oil pipelines replacement project under the Danube River.

techniques, reinforces the security of supply in Romania while reducing the potential environmental hazard.

“We are proud of our contribution to the successful delivery of this landmark project”, said Atef Khemiri, HDI’s Managing Director.

The original undercrossing of the Danube and the Borcea arm with crude oil transport pipelines was carried out in two stages, in 1968 and 1978 respectively. At this time, the pipelines were covered with concrete and sunk to the bottom of the river, without any protection.

Given the age of the pipelines, to ensure optimal conditions for crude oil transport and to avoid the risk of damage with severe environmental consequences, modernisation and restoration works have been implemented.

For the Minister of Energy, Virgil Popescu, it is an extraordinarily important project as it ensures the transportation of crude oil from the Black Sea to the interior (to refineries) and it was an important project from an environmental point of view.

CONPET is the operator of the National Petroleum Transport System by pipelines in Romania and operates a pipeline network with a length of over 3800 km throughout the country. This contract is one of the biggest ever signed by the company, with a total value of €26.5 million.

The current project scope included 1250 m and 1460 m long HDD crossings with pipelines of the following diameters: 8 in., 20 in. and 28 in. A maxi drilling rig of 400 t capacity was mobilised and successfully executed the crossings.

Two crossings of 1250 m were completed within a month (July 2022); the four others (one 1250 m and three 1460 m) were completed in about two months (September and October 2022). Subsequently, the rest of the pipeline could be installed by open cut and connected to the existing network.

The overall scope of work, from design to commissioning, has been mastered by the project team.

“A good team spirit quickly emerged between the joint venture stakeholders and its subcontractors, everyone was there for the same purpose and always with the intention of helping each other when possible”, said Alcyme Rambaud, HDI Project Manager.

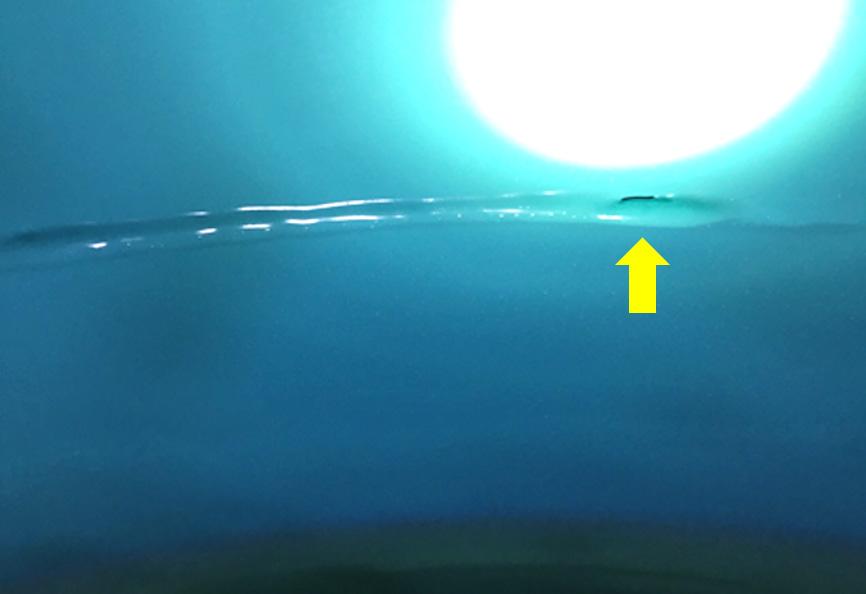

The Danube River is undercrossed by 10 pipelines, on a perpendicular corridor on the minor riverbed.

It was not the first time HDI has performed HDD works under the Danube: the company performed two crossings for fibre optic cables in a northern section in the 1990s, with a much smaller diameter and smaller length.

The successful execution of the most recent project was made possible thanks to the excellence of the detailed design, which finds its roots in reliable subsoil characterisation.

In addition to geotechnical boreholes, the interpretation of the data collected during the geophysical investigation (electrical and seismic) allowed a better understanding of the ground conditions along the drilling routes and subsequent design adjustments in order to mitigate the risks.

Ground investigations revealed a major rock formation on the second quarter of the Danube crossing, which was the called the ‘rock mountain’ by the project team during project operations.

With those investigations HDI was able to redesign the drilling by adding a second horizontal tangent to stay above the rocky area and then go down again to pass under the river.

“In a global context marked by climate change, global warming, but also by intense institutional concerns in the field of climate change, the realisation of this project will contribute to the security of energy supply in Romania, in terms of reducing pollution risks. We are happy that we managed to successfully complete a large-scale project using the most modern technologies available internationally”, said Hora

Sebastian

ţiu

C ălug ăr, Cis GAZ General Manager.

Figure 2. The Handover ceremony took place on 3 April 2023 in Festite, in the presence of The Minister of Energy, Virgil Popescu, the Secretary of State George Niculescu, the representatives of Conpet top management, the General Director of CIS Gaz, Horaţiu Sebastian Călugăr, the General Director of Horizontal Drilling International (HDI), Atef Khemiri, as well as local officials from Ialomiţa and Constanța counties.

24 World Pipelines / MAY 2023

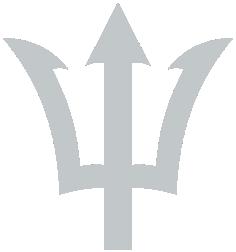

Figure 1. The works started on 10 May 2022 and were completed four months ahead of schedule.

The Best Liquid Epoxy Solutions For Pipelines

Combining industry-leading abrasion resistance with unmatched flexibility, our range of epoxy solutions are built tough, easy to apply and designed to last. Whether its HDD or field joint coatings, we’ve got the solution.

The Toughest HDD Coating on the Market

HBE - The Best Performing Field Joint Coating

SCAN ME SCAN ME

Mario Moreno

P.Eng.,

Seal for

Life Industries,

Canada, discusses revolutionising pipeline field joint coating with high flexibility epoxy coatings.

orrosion prevention for underground structures is essential to ensure their long-term integrity and reliability. A combination of a durable coating and cathodic protection (CP) is necessary for effective corrosion prevention. When focusing on field joint coatings, there are many advantages and disadvantages of the different coating technologies available. We take a look at what those are and introduce a new epoxy formulation that promises extraordinary corrosion protection properties and flexibility.

Background

For optimal corrosion prevention in underground structures, a robust coating combined with CP is the recommended approach. The protection cost comprises both the coating and the CP system.

Since its introduction in 1960, single-layer FBE has demonstrated remarkable effectiveness as a pipeline coating. It currently enjoys widespread use as the preferred pipeline coating in North America and has a strong following worldwide. Its exceptional performance characteristics, as well as its track record of success in underground and undersea applications, make it an ideal choice for line pipe, fittings, and bends.

However, for field joint coatings there are several reasons why liquid epoxies are often preferred over FBE to treat the joints between pipes.

Ease of application

Liquid epoxy is easier to apply than powder FBE epoxy, especially in field conditions. The liquid form allows for easier mixing and application, making it more convenient and efficient for use onsite.

Faster cure time

Liquid epoxy has a faster cure time than powder FBE epoxy. This means that the coating can be applied

27

Figure1.After applicationwithCanusaHBEFLXthepipeline isinstalled.

and cured more quickly, reducing the overall downtime for the pipeline.

Better adhesion

Liquid epoxy has better adhesion properties than powder FBE epoxy, particularly in wet or humid conditions. This makes it more effective in protecting the pipeline against corrosion and other forms of damage.

More sustainable

Liquid epoxy installation requires no force curing or external energy compared to FBE. Plus the material has minimum waste during application.

In order to ensure the long-term integrity and reliability of a pipeline, it is important for the field joint coating to

possess mechanical properties similar to those of the main line coating. This approach helps to promote corrosion protection, compatibility, uniformity, and reduces the risk of delamination, stress concentrations, and potential cracking or damage due to thermal expansion.

Generally, liquid epoxy coatings used for field joint coating applications must undergo a series of qualification tests before they can be considered for pipeline use. These tests are specified in the standard CSA Z 245.20 (plant applied coatings) and CSA Z 245.30 (field applied coatings). The main difference between the two standards lies in the flexibility value, which is the performance limit between the two. A liquid epoxy that meets the required flexibility level will also satisfy the other parameters.

In the realm of pipeline engineering, flexibility plays a crucial role in the performance of joint coatings, especially for pipelines that undergo thermal expansion, ground movement, and other environmental stresses. The ability of a coating to flex and move with the pipeline, without experiencing cracking or fracturing, is of paramount importance. Ideally, both the mainline and field joint coatings should exhibit similar behaviour and movement patterns.

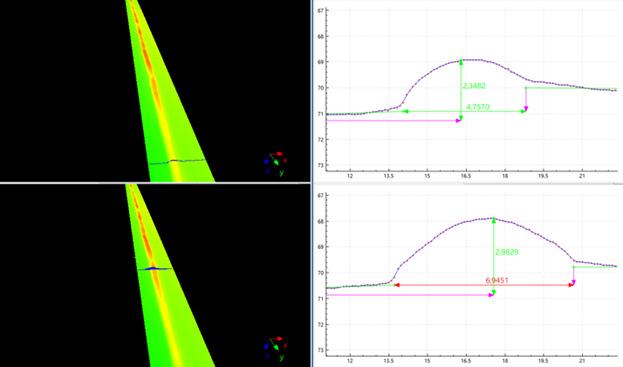

For instance, let’s consider the flexibility requirements outlined by CSA Z245.20 (plant applied coatings) and CSA Z245.30 (field applied coatings). While the former specifies a flexibility limit of 3°/PD, the latter mandates a more stringent limit of 0.75°/PD for an 18 in. OD pipe (Figure 2).

In the context of field joint coatings, flexibility requirements differ from those of mainline coatings during installation. This trade-off exists to enable better performing epoxy coating systems, as adhesion and cathodic disbondment properties also significantly impact the coating’s long-term performance. The engineering decision is justified, provided no alternatives that offer comparable performance alongside flexibility are available.

To achieve enhanced flexibility, alternative modifiers have been introduced in the market. One such alternative resin is a polyurethane-epoxy hybrid, which improves the epoxy matrix’s flexibility through the addition of polyurethane functionality. However, this solution’s drawback is that the material’s temperature performance is affected, leading to a compromise in performance characteristics such as cathodic disbondment test results and temperature resistance.

Canusa, a division of Seal for Life Industries, conducted a benchmarking exercise to compare the performance of epoxy field joint coatings, which highlighted a significant performance gap between the epoxy-polyurethane hybrid technology and traditional epoxy field joint coatings.

In the search to meet the requirements for effective corrosion control and mechanical properties, the development of the next generation of field joint coatings is crucial. CANUSA CPS Division of Seal for Life Industries has created a new epoxy formulation that delivers exceptional flexibility and corrosion protection. Known as HBE FLX, this coating system is based on epoxy polymer modified with core-shell rubber nanoparticles. These nanoparticles improve the tensile properties, fracture toughness, and glass transition temperature of the epoxy resin. Core-shell FJC epoxy formulation is patent-pending technology.

Core-shell rubber nanoparticles are a type of nanocomposite material that consists of an elastic rubber core surrounded by a shell made of another material, such as polymers, metals,

Thickness CSA 245.20 System 1A CSA 245.30 System FC1 24 hr cathodic disbondment at 65˚C < 6.5 mm < 6.5 mm 28 d cathodic disbondment at 20°C < 8.5 mm < 8.5 mm 28 d cathodic disbondment at max rated service temp < 20 mm (95˚C) < 10 mm (95˚C) Flexibility (-30˚C) 2.0˚/PD 0.75˚/PD Flexibility (23˚C) 3.0˚/PD N/A 1.5 J impact resistance No holiday -30˚C No holiday -30˚C Adhesion to steel substrate N/A Rate 1 Adhesion to existing coating N/A Rate 2 Adhesion to steel after hot water immersion (95˚C, 28 d) Rate 1 - 3 Rate 1 Adhesion to existing coating after hot water immersion (75˚C, 28 d) Rate 1 - 3 Rate 2

Table 1. OEM FBE vs field applied liquid epoxy qualification requirements

28 World Pipelines / MAY 2023

Figure 2. Bending radius example 18 in. OD pipe.

WeldFit.com/ReCap

ReCAPTM Emissions Recovery System with patent-pending XR Technology—the safe alternative to venting or flaring during common pipeline operations. ReCAP delivers the new industry standard in depressurization and methane recovery speeds with Straight-LineTM predictability that assures projects remain on schedule. And by keeping your gas in the pipeline, it reduces GHG emissions by nearly 100%. ReCAP is the solution that puts today’s challenging ESG goals in reach. TM Trademark of WeldFit Corporation in the United States and other countries. © Copyright 2023 All rights reserved by WeldFit Corporation Trusted Solutions Partner FAST. PROVEN. PREDICTABLE. ELIMINATE

EMISSIONS

Introducing

VOLUNTARY

ceramics, or other types of nanoparticles. This technology offers a promising approach to enhance the mechanical properties of coatings while maintaining their corrosion resistance.

The performance characteristics of the novel product HBE FLX in addition to being highly flexible are:

• Excellent adhesion to well-cleaned steel.

• Good chemical resistance.

• Low oxygen permeability.

• Non-shielding – works with CP.

• No reported cases of stress-corrosion cracking (SCC) of pipe coated with FBE (6).

• The coating remains bonded to the extent that it separates the pipeline steel from an SCC chemical environment.

• It allows the passage of current in case of bond failure.

• Resistance to biological attack.

• Tough.

• Excellent penetration resistance.

• Good impact resistance.

• Good abrasion resistance.